International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

1 , Abhishek Mishra2 , Sachin kumar singh3

r1Student,DeptOfCivilEngineering,IetLucknowIndia

2 AssistantProfessor,DeptOfCivilEngineering,IetLucknowIndia

3AssistantProfessor,DeptOfCivilEngineering,IetLucknowIndia

Abstract -The integrityandserviceabilityofstructural systems are increasingly threatened by aging, environmental exposure, and insufficient maintenance practices. Conventional inspection techniques, while widely used, are labor-intensive, time-consuming, and oftenreactiveratherthanproactive.Thisstudyproposes apredictivemaintenanceframeworkusingMobileNetV2 (MobileNetV2) to automate the detection and forecasting of structural surface defects. A customlabeled image dataset comprising various damage types Intact Crack Spalling Corrosion, is utilized to train the MobileNetV2 model. The model not only achieves high accuracy in multi-class damage classification but also demonstrates potential in recognizing early patterns of deterioration through sequential image analysis. Performance evaluation indicates superior detection precision compared to traditional deep learning models such as Faster RMobileNetV2 and YOLOv5, with reduced computational requirements. The findings suggest that the proposed MobileNetV2-basedapproachcansignificantlyenhance structural health monitoring by facilitating timely interventions and extending the lifespan of infrastructure. This study contributes toward the advancement of AI-driven predictive maintenance systems and their application in real-world civil engineeringcontexts.

Key Words: Predictive Maintenance, MobileNetV2, Structural Health Monitoring, Deep Learning, Damage Classification, Infrastructure, Civil Engineering

The increasing complexity and aging of global infrastructure necessitate innovative approaches to ensure safety, longevity, and cost-effective maintenance. Conventional inspection and maintenance practices, such as manual visual inspections or non-destructive testing methods, are inherently reactive, prone to human error, labor-

Impact Factor value: 8.315

intensive, and unable to scale effectively for large structures or networks. With the growing interest in smart infrastructure, there is a compelling need for predictive and automated systems that can assess structuralhealthwithminimalhumanintervention.

Recent advancements in Artificial Intelligence (AI), especiallyinDeepLearning,haverevolutionizedmany engineering domains. MobileNetV2 (MobileNetV2), a class of deep learning models particularly effective in image processing tasks, offer a promising pathway toward real-time and scalable Structural Health Monitoring (SHM). By leveraging historical image data and learning visual patterns associated with degradation, MobileNetV2 enable early detection of defectsandclassificationoftheirseveritylevels.Unlike traditional models that focus purely on object detection, MobileNetV2 excel at classification tasks where nuanced differences in visual features (such as crackdepthorspallingextent)arecritical.

In this research, we present a MobileNetV2-based predictive maintenance system designed to identify and classify surface defects in civil structures. Our approach utilizes a custom image dataset, carefully annotatedandrestructuredfromYOLOv5formatintoa MobileNetV2-compatible structure. The images representaspectrumofdamageseverity:intact,crack, spalling, and corrosion. Our results demonstrate that the proposed model not only achieves high classification accuracy but also holds the potential to identify deterioration trends when extended with sequentiallearningmethods.

This study emphasizes the potential of AI-driven systems in transforming infrastructure maintenance strategies from reactive to predictive, enabling civil engineers and city planners to make informed decisions for extending the service life of critical assets

Recent advancements in deep learning have significantly impacted the domain of SHM. Techniques such as YOLOv5, Faster R-MobileNetV2, and Mask RMobileNetV2 have demonstrated high efficacy in detecting defects like cracks and spalling in concrete and masonry structures. However, these models are largely detection-focused and less suited for classification tasks or predictive insights based on progressivedamagestates.

MobileNetV2, on the other hand, offer a simplified architecture optimized for classification tasks. Prior studies have shown MobileNetV2 to be effective for binary and multi-class classification of cracks, dust, discoloration,andothersurfacedefects.

The predictive framework is centered around a MobileNetV2 designed for multi-class classification of structural surface defects. The MobileNetV2's architecture was chosen for its balance between performance and computational efficiency, making it viable for deployment in edge devices or embedded SHMsystems.

3.1Dataset Description

Thedatasetincludesatotalof 3757 training images and 3623 validation images, categorized into four classes:

Intact

Crack

Spalling

Corrosion

These images were originally collected and labeled in YOLOv5 format and later transformed into a flat classificationformatsuitableforMobileNetV2training. Preprocessingstepsincluded:

Imageresizingto 224x224 pixels

Normalizationofpixelvalues

Data augmentation via horizontal/vertical flipping, rotations, zooming, and brightness variations to mitigate class imbalance and improvegeneralization.

2395-0056 p-ISSN: 2395-0072

3.2MobileNetV2 Architecture Overview

Thearchitectureconsistsofthefollowingkey components:

1. InputLayer:Accepts224x224x3RGBimages.

2. Convolutional Layers: Five convolutional layerswithincreasingfilterdepths(32,64,128, 128, 256) and kernel size of 3x3, each followedbyReLUactivationtointroducenonlinearity.

3. Stride and dilation are used instead of pooling tomaintainspatialresolutionefficiently.

4. Global Average Pooling: Reduces spatial dimensionsbeforeclassification.

5. FullyConnectedLayer:Finaldenselayerwith dropoutandsoftmaxactivation.

6. DropoutLayer:Setat0.3toregularizethefinal denselayer.

7. OutputLayer:Asoftmaxactivationlayerwith fourneuronsrepresenting:Intact,Crack, Spalling,andCorrosion.

Loss Function: Categorical Cross-Entropy

Optimizer: Adam

Batch Size:32

Epochs: 20

Learning Rate:Adaptive,withearly stoppingandcheckpointingbasedon validationloss.

The MobileNetV2 progressively extracts hierarchical features through convolution operations. In earlier layers,itcaptureslow-levelfeaturessuchasedgesand textures; in deeper layers, it learns class-specific features like crack morphology or spall distribution. These features are then aggregated and interpreted in the dense layers to output a probability distribution across the four damage classes. The model's internal representationsallowittogeneralizewell across new, unseen images, enabling accurate classification even undervaryinglightingorsurfaceconditions.

4.1 Model

and Performance

The model was trained for 20 epochs. Validation accuracypeakedat89.75%withaminimumvalidation loss of 0.1653. Training accuracy reached 88.65% by the19thepoch.

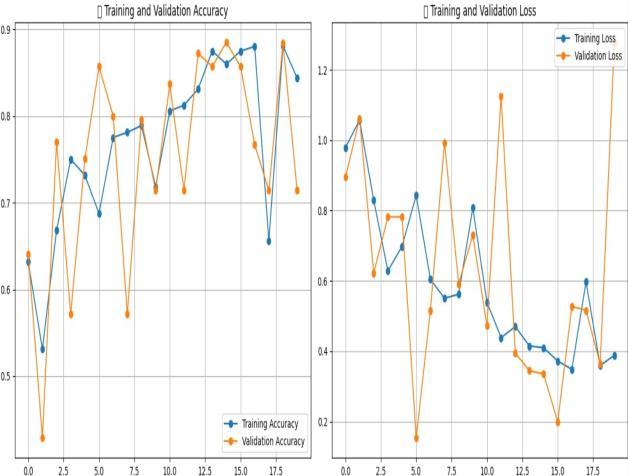

4.2 Training and Validation Accuracy and Loss of MobileNetV2 Model

Thisplotshowshowtheclassificationaccuracyofthe MobileNetV2modelevolvesovertrainingepochsfor boththetrainingandvalidationdatasets.

The blue line represents training accuracy.

The orange line represents validation accuracy.

Themodelstartswithmoderateaccuracy,andover successive epochs, both training and validation accuracies improve, with fluctuations observed particularly in validation accuracy. The final accuracy stabilizes around 90%, indicating that the model learns discriminative features for structuraldamageclassificationeffectively.

Fig-1:TrainingandValidationAccuracyandLossof MobileNetV2Model

1.1.2. Right Plot – Training and Validation Loss

Thisplotrepresentsthecategoricalcross-entropy loss,whichthemodeltriestominimize.

The blue line indicatestrainingloss.

The orange line indicatesvalidationloss.

Initially, both training and validation losses are high, with sharp fluctuations in the early epochs especially for validation. However, as training progresses, both losses gradually decrease, and validation loss stabilizes, which confirms that the modelislearningandnotoverfittingseverely.

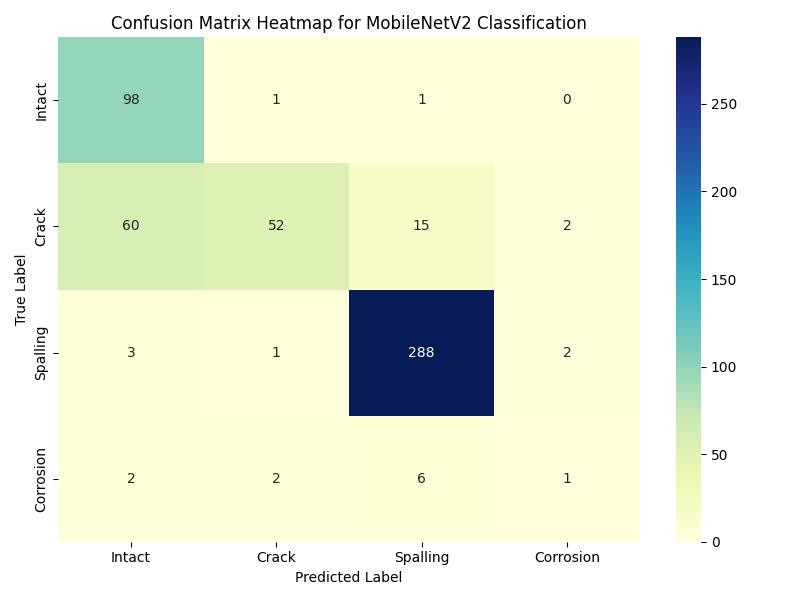

The MobileNetV2 model was evaluated using a separate test dataset comprising 534 labeled images. The final model achieved a test accuracy of 88.95% and a test loss of 0.379, demonstrating its robust generalization ability. The classification report highlights per-class precision, recall, F1-score, and support, reflecting the model’s capability across diverse structural defect categories.PerformancemetricsaresummarizedinTable 1.

Table-1 classification matrix

The model performs exceptionally well in detecting “Intact” and “Spalling” categories, indicating its strength in distinguishing visually clear or well-represented classes. However, performance in the “Crack” and especially“Corrosion”classisrelativelylowdueto class imbalance, limited sample size, and visual similarities with other categories. These observations suggest future improvements may include class balancing, feature refinement,andaugmentationtechniques

To visualize the classification performance across all classes, a confusion matrix heatmap was generated. It highlights that the model performs well in identifying “Spalling” and “Intact” categories. However, misclassifications are evident in the “Crack” and “Corrosion” classes, likely due to class imbalance and feature overlap. This visualization aids in understanding the prediction behavior of the MobileNetV2 model and Impact Factor value: 8.315 ISO 9001:2008 Certified Journal Page147

revealsareasforfurtheroptimization,suchasadvanced dataaugmentationandclassrebalancing.

4.4 Analysis

TheMobileNetV2showedstrongperformanceforthe "intact" and "spalling" classes. Minor and corrosion classes were less accurately predicted due to class imbalance and visual similarity between categories. The confusion between "minor" and "moderate" damage may be mitigated in future studies by incorporating temporal data or additional image enhancements.

This study demonstrates the effectiveness of a MobileNetV2-based deep learning framework for the classification of structural surface defects. By leveraging a custom-labeled dataset and applying a lightweightyetrobustconvolutionalarchitecture,the model achieved a test accuracy of 88.95%, showing excellent capability in identifying “Intact” and “Spalling” surfaces. These results validate the feasibility of MobileNetV2 for use in real-time Structural Health Monitoring (SHM) applications, especially in resource-constrained environments such as embedded systems or drone-based inspections. Furthermore, the integration of this approach into infrastructure maintenance protocols can significantly reduce inspection time, enhance safety, and support cost-efficient asset management. AsAIcontinuestoevolve,suchsystemsholdpromise in becoming a standard component of smart civil infrastructure.

2395-0056

p-ISSN: 2395-0072

While the MobileNetV2 model demonstrated high classification accuracy, there are several avenues to furtherimproveandextendthisresearch:

Class Balancing: The model showed reduced performance for underrepresented classes like "Corrosion." Future studies should address this by increasing the volume of samples through advanced data augmentation or synthetic data generationusingGANs.

Temporal Learning: Incorporating time-series image data could allow the model to detect and forecast progressive deterioration trends, enhancingitspredictivecapabilities.

Explainability and Interpretability:Integration of model interpretability tools like Grad-CAM or SHAP can offer insights into what regions of the image influenced classification, making the systemmoretransparenttoengineers.

Deployment on Edge Devices: Due to its compact architecture, MobileNetV2 can be optimized further for real-time deployment on edge devices such as Raspberry Pi or Nvidia Jetsonplatformsforfielduse.

Multi-Modal Sensing Integration: Combining visual inspection with non-destructive testing (NDT) methods such as ultrasonic or infrared thermographycouldyieldamorecomprehensive defectassessmentsystem.

3D Structure and Drone Integration:Extending themodeltoprocessLiDARorphotogrammetrybased3Dsurfacedata,capturedviadrones,could support full-scale inspection of bridges, facades, ortowers.

These directions will help transform the current classification system into a comprehensive, scalable, and fullyautonomousstructuralmonitoringsolution.

[1] Mayank Mishra1 · Tanmoy Barman1 · G. V. Ramana2 “Artifcial intelligence-based visual inspection system for structural health monitoringofculturalheritage”

[2] “Deep learning-based post-earthquake structural damage level recognition” Xiaoying Zhuanga, d,∗ iD, Than V. Trana , H. NguyenXuanb,TimonRabczuk

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

[3] Tan,M.,&Le,Q.V.(2019).EfficientNet:Rethinking model scaling for convolutional neural networks. Proceedingsofthe36thInternationalConferenceon MachineLearning,6105–6114.

[4] Bochkovskiy, A., Wang, C.-Y., & Liao, H.-Y. M. (2020). YOLOv4: Optimal speed and accuracy of objectdetection. arXivpreprint arXiv:2004.10934.

[5] Redmon, J., Divvala, S., Girshick, R., & Farhadi, A. (2016). You only look once: Unified, real-time objectdetection. ProceedingsoftheIEEEConference on Computer Vision and Pattern Recognition, 779–788.

[6] Jocher,G.,Chaurasia,A.,Qiu,J.,&Stoken,A.(2020). YOLOv5byUltralytics. GitHubrepository

[7] Ultralytics. (2024). YOLOv10 models. GitHub repository

[8] Kim, B., Cho, S., & Sim, S.-H. (2019). Vision-based automated crack detection for concrete structures using a deep learning algorithm. Automation in Construction,104,129–139.

[9] Dorafshan, S., Thomas, R. J., & Maguire, M. (2018). Comparisonofdeepconvolutionalneuralnetworks andedgedetectorsforimage-basedcrackdetection in concrete. Construction and Building Materials, 186,1031–1045.

[10] Zou Z, Zhao P, Zhao X (2021) Automatic segmentation, inpainting, and classifcation of defective patterns on ancient architecture using multiple deep learning algorithms. Struct Control HealthMonit28(7):e2742

[11] Trier ØD, Cowley DC, Waldeland AU (2019) Using deep neural networks on airborne laser scanning data: results from a case study of semi-automatic mapping of archaeological topography on arran, scotland.ArchaeolProspect26(2):165–175

[12] MishraM,BhatiaAS,MaityD(2020)Predictingthe compressive strength of unreinforced brick masonry using machine learning techniques validated on a case study of a museum through nondestructive testing. J Civil Struct Health Monit 10(3):389–403

[13] Mondal TG, Jahanshahi MR, R-TW, Zheng YW (2020) Deep learning-based multi-class damage detection for autonomous post-disaster reconnaissance. Struct Control Health Monit 27(4):e2507

Impact Factor value: 8.315