International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

1Post graduate student, Dept. of Civil Engineering UVCE college (University) Bangalore, Karnataka, India.

2Assistant Professor Department of Civil Engineering Presidency University, Bengaluru.

3Associate Professor, Dept. of Civil Engineering, UVCE college Bangalore, Karnataka, India.

Abstract - This study investigates the performance optimization of Piled Raft Foundations (CPRF) using threedimensionalnumericalsimulationsinPLAXIS3D.Theaimis to understand the effects of varying raft thickness, pile diameter, and pile length on total and differential settlement behavior, which are critical for the design of efficient and stable foundation systems in complex soil conditions.Thesubstructurewasmodeledwithdetailedsoil stratification and appropriate constitutive model. Structuralloadswerederivedfrompriorstructuralanalysis and applied to the foundation model. The numerical simulations captured soil-structure interaction through interfaceelementsandenabledacomprehensiveevaluation of load transfer mechanisms, settlement behavior, and foundation stiffness. The results reveal that increasing raft thickness from 0.5 m to 0.75 m consistently reduces total settlement by 5.67% to 7.28%, while also significantly minimizing differential settlement by up to 38.54%, especially for smaller pile diameters. Additionally, increasing pile diameter from 0.35 m to 0.50 m and pile length from 10 m to 14 m yielded improvements in differential settlement up to 11.59% and 10.99%, respectively. Among the three parameters studied, raft thickness showed the most pronounced impact on overall foundation performance. The findings underscore the importance of optimizing raft stiffness and pile configurationsforimprovedstructuralsafety,serviceability, and cost-effectiveness. This research offers practical design insights for implementing CPRF systems in seismic and settlement-sensitive environments through an integrated geotechnical-structuralapproach.

Key Words: Piled Raft, PLAXIS 3D, Settlement, Differential settlement, Raft Thickness (Rt), Pile length (Lp), Pilediameter(Pd), Foundation Optimization.

1. INTRODUCTION

Piledraftfoundationsare compositesystemscombininga raft and piles to support heavy structures, especially in challenging soil conditions. In such systems, both the raft and piles contribute to load sharing, improving bearing capacity and reducing total and differential settlements. The effectiveness of load distribution depends on the relativestiffnessofthesoil,raft,andpiles.

Compared to fully piled foundations, piled rafts offer a cost-effectivesolutionbystrategicallyusingfewerpilesto control settlement without compromising safety. This makes them particularly useful for high-rise and offshore structures.Combinedpiledraftsystems(CPRS),withrigid pile-to-raft connections, further enhance performance under vertical and lateral loads, including seismic conditions.

Depending on geometry, piled rafts are categorized as small or large, each with different design priorities bearing safety in small systems and settlement reduction inlargeones.Thepiledraftapproachintegratesstructural and geotechnical design, offering an optimized balance betweenperformanceandeconomy.

Supporting this concept, Bhaduri et al. (2020) [2] highlighted that CPRF systems exhibit superior seismic performance in liquefiable soils, with shear resistance improvements of up to 70% compared to traditional pile groups. Dang Dinh Chung Nguyen et al. (2014) [3] conducted parametric studies using PLAXIS 3D and demonstrated that optimized pile arrangements significantly reduce total and differential settlements and bending moments in large piled rafts. Similarly, Rabiei et al. (2015) [7] utilized ELPLA software and showed that a non-uniform pile layout concentrated under maximum loading zones improves settlement control while enhancingeconomicefficiency.

A three-dimensional numerical analysis was conducted using PLAXIS 3D to investigate the performance of a pileraft foundation system under various loading conditions. The substructure model incorporated detailed soil stratification, with material properties defined using the Mohr-Coulomb model for soil and Hoek-Brown model for rock to simulate realistic nonlinear soil behaviour. The properties used in the analysis are given in Table 1. The foundationloadswereobtainedfromadetailedstructural analysis of the superstructure, incorporating seismic effects as part of the load assessment to ensure realistic loadtransferfromthesuperstructuretothesubstructure. Thepileandraftelementsweremodeledwithappropriate geometric and material specifications and is given in the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Table 2. Interface elements were introduced at critical contact zones to accurately capture the soil–structure interaction,includingslipandsheartransfermechanisms. Subsurface soil data was obtained through a detailed geotechnical investigation aimed at determining soil stratification and relevant engineering properties. Based on the findings, a representative soil profile was developed,incorporatinglayersofclayeysand,weathered rock,andsoftrock.Theseparameterswereusedtomodel thegroundconditionsaccuratelyforfoundationanalysis.

This modeling approach enabled the evaluation of settlement profiles, stress distributions, and load-sharing behavior within the foundation system. By simulating multiple design scenarios, the analysis facilitated the optimization of pile-raft configurations for enhanced structuralperformance.

Table 1: Soilandrockparametersusedintheanalysis.

3.1. INFLUENCE OF CPRF ON OVERALL SETTLEMENT

3.1.1.For a given pile length and diameter varying raft thickness i. Pd=0.35m

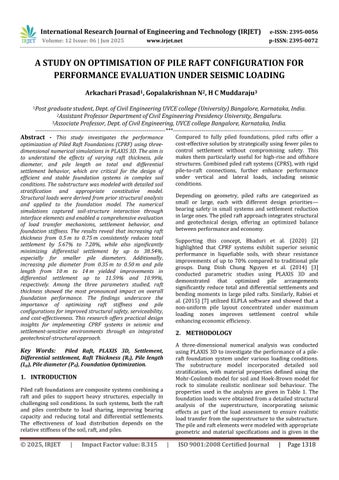

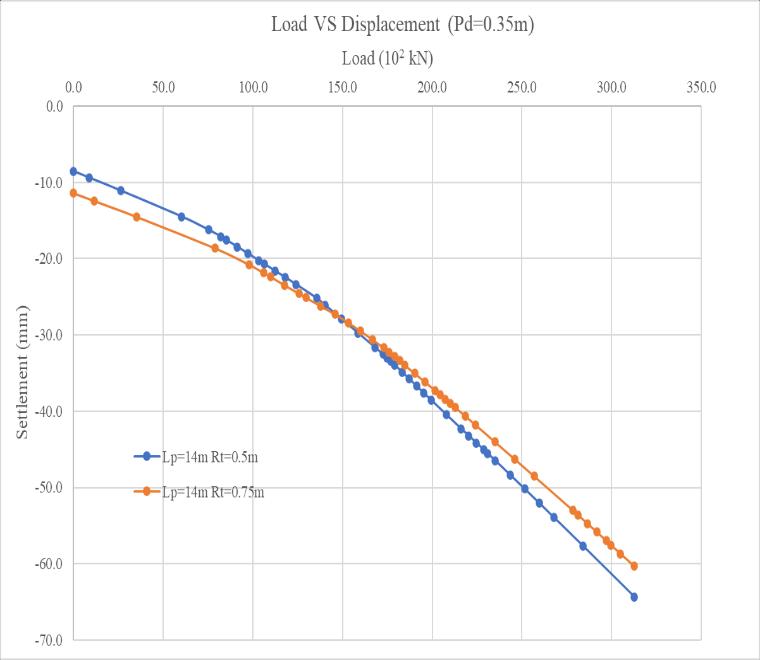

TheFig1,Fig2andFig3illustratestheloadvs.settlement behavior for a foundation system with constant pile diameter (Pd=0.35m) and pile length (Lp=10m,12m,14m), whilevaryingraftthickness(Rt)between0.5mand0.75m.

Fig 1: LoadvsDisplacementforDifferentRaftThicknesses (Pd =0.35 mLp =10m)

Table 2: Materialproperties

Fromthecurves(Fig1),itisevidentthatincreasingtheraft thickness has a positive influence in decreasing the settlement atall load levelshowever it is not pronounced. The maximum settlement observed for Rt=0.5m is 72.64 mm,whereasforRt=0.75m,itisreducedto68.52mm.This translates to a 5.67% reduction in settlement, which, indicatesaclearimprovementinperformance.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

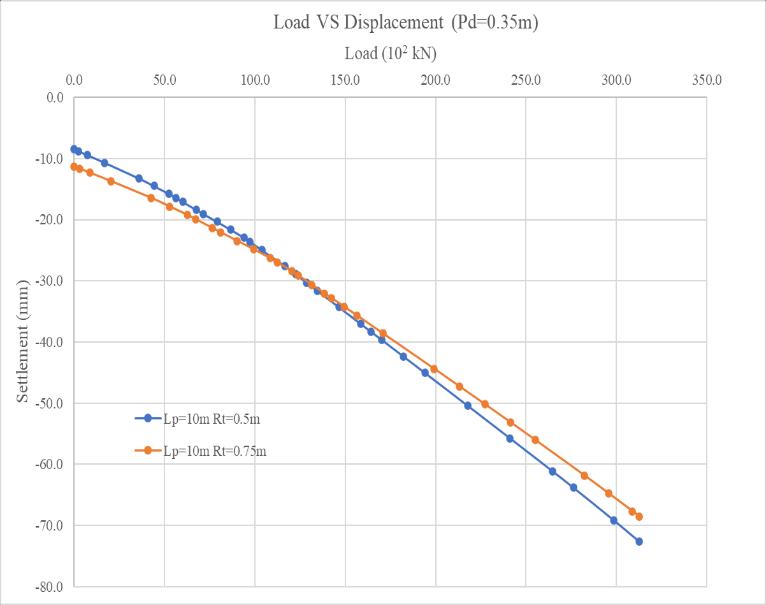

2: LoadvsDisplacementforDifferentRaftThicknesses

(Pd =0.35 mLp =12m)

Fromtheplotteddata(Fig2),itisclearthatincreasingthe raft thickness reduces settlement across the full range of applied loads. Specifically, the maximum settlement for Rt=0.5m is 68.78mm, while for Rt=0.75m, it reduces to 64.75mm.Thisindicatesa 5.85%reductioninsettlement, which highlights the beneficial impact of increasing raft thickness.

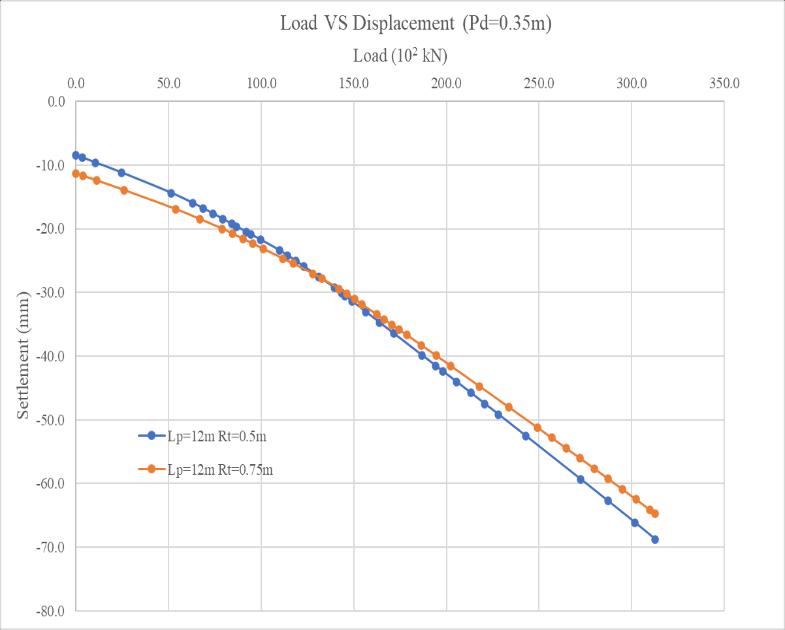

Fig 3: LoadvsDisplacementforDifferentRaftThicknesses (Pd =0.35 mLp =14m)

From the plot (Fig 3), it is evident that increasing the raft thickness leads to reduced settlement. The maximum observed settlement for Rt=0.5m is 64.32mm, while for Rt=0.75m, the settlement decreases to 60.33mm. This yields a 6.21% reduction in settlement, indicating that a thicker raft contributes to improved foundation performance.

ii. Pd=0.45m

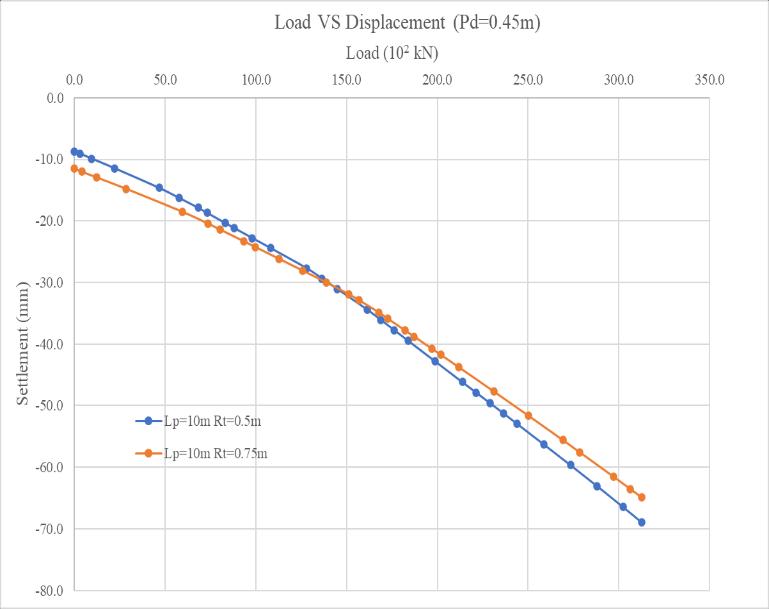

TheFig4,Fig5,andFig6illustratestheloadvs.settlement behavior for a foundation system with constant pile diameter (Pd=0.45m) and pile length (Lp=10m,12m,14m), whilevaryingraftthickness(Rt)between0.5mand0.75m.

Fig 4: LoadvsDisplacementforDifferentRaftThicknesses (Pd =0.45 mLp =10m)

Fromthecurves(Fig4),itisevidentthatincreasingtheraft thickness results in a noticeable decrease in settlement at all load levels. The maximum settlement observed for Rt=0.5m is 68.93mm, whereas for Rt=0.75m, it is reduced to 64.92mm. This translates to a 5.82% reduction in settlement, which, indicates a clear improvement in performance.

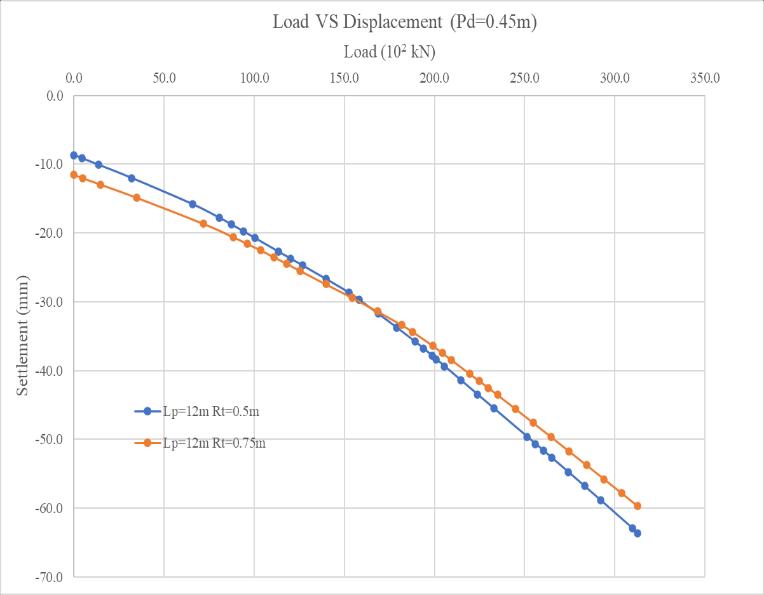

Fig 5: LoadvsDisplacementforDifferentRaftThicknesses (Pd =0.45 mLp =12m)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

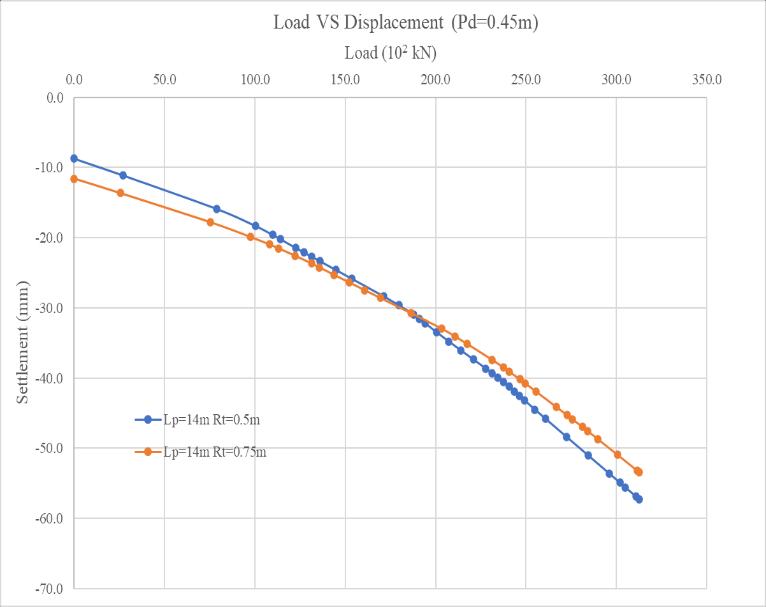

6: LoadvsDisplacementforDifferentRaftThicknesses (Pd =0.45 mLp =14m)

Fromtheplotteddata(Fig5),itisclearthatincreasingthe raft thickness reduces settlement across the full range of applied loads. Specifically, the maximum settlement for Rt=0.5m is 63.64mm, while for Rt=0.75m, it reduces to 59.72mm. This indicates a 6.16% reduction in settlement, which highlights the beneficial impact of increasing raft thickness.

From the plot (Fig 6), it is evident that increasing the raft thickness leads to reduced settlement. The maximum observed settlement for Rt=0.5m is 57.34mm, while for Rt=0.75m, the settlement decreases to 53.46mm. This yields a 6.76% reduction in settlement, indicating that a thicker raft contributes to improved foundation performance.

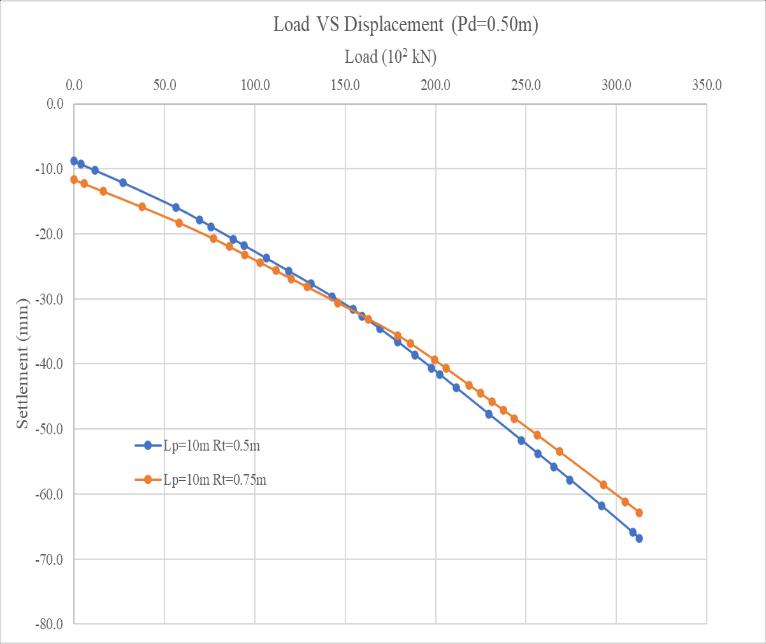

iii. Pd=0.50m

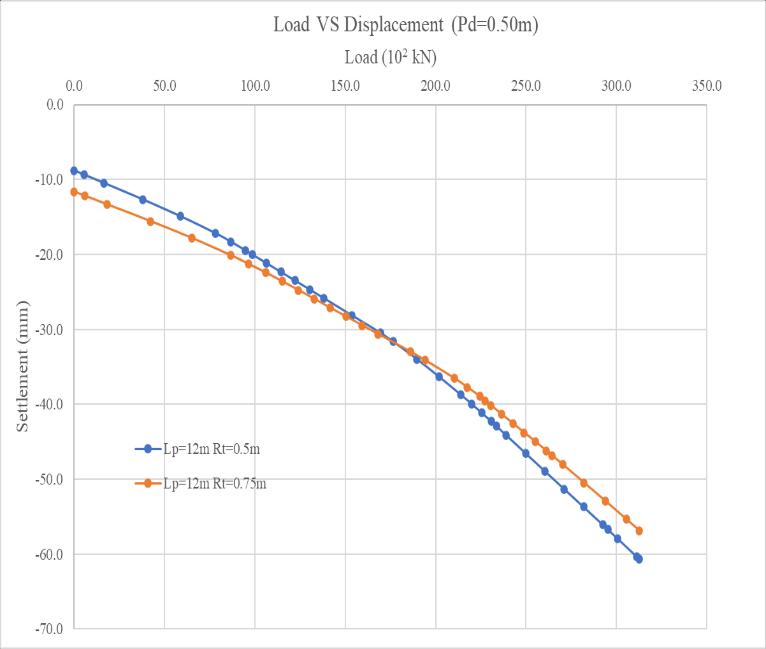

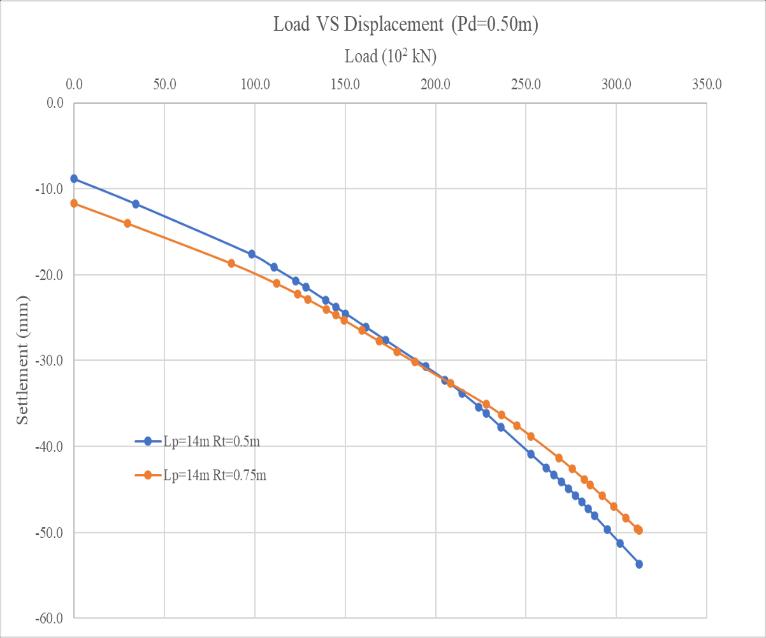

TheFig7,Fig8andFig9illustratestheloadvs.settlement behavior for a foundation system with constant pile diameter (Pd=0.45m) and pile length (Lp=10m,12m,14m), whilevaryingraftthickness(Rt)between0.5mand0.75m.

Fromthecurves(Fig7),itisevidentthatincreasingtheraft thickness results in a noticeable decrease in settlement at all load levels. The maximum settlement observed for Rt=0.5m is 66.81mm, whereas for Rt=0.75m, it is reduced to 62.87mm. This translates to a 5.90% reduction in settlement, which, indicates a clear improvement in performance.

7: LoadvsDisplacementforDifferentRaftThicknesses (Pd =0.50 mLp =10m)

Fig 8: LoadvsDisplacementforDifferentRaftThicknesses (Pd =0.50 mLp =12m)

Fromtheplotteddata(Fig8),itisclearthatincreasingthe raft thickness reduces settlement across the full range of applied loads. Specifically, the maximum settlement for Rt=0.5m is 60.66mm, while for Rt=0.75m, it reduces to 56.89mm. This indicates a 6.21% reduction in settlement, which highlights the beneficial impact of increasing raft thickness.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Fig 9: LoadvsDisplacementforDifferentRaftThicknesses (Pd =0.50 mLp =14m)

From the plot (Fig 9), it is evident that increasing the raft thickness leads to reduced settlement. The maximum observed settlement for Rt=0.5m is 53.69mm, while for Rt=0.75m, the settlement decreases to 49.78mm. This yields a 7.28% reduction in settlement, indicating that a thicker raft contributes to improved foundation performance.

Theanalysisoftheload-settlementbehavioracrossvarious configurationsofpiledraftfoundationsclearlyrevealsthat increasingthe raft thickness from 0.5 m to 0.75 mleadsto consistentandmeasurable reductionsin settlement forall combinations of pile diameter (Pd = 0.35 m, 0.45 m, 0.50 m) and pile length (10 m, 12 m, and 14 m). The observed reduction in maximum settlement ranges between 5.67% and 7.28%, indicating that a thicker raft significantlyenhancestheload-distributioncapacityofthe system. Across all applied load levels, settlements were uniformly lower for thicker rafts, regardless of the pile geometry, demonstrating a clear performance benefit. Furthermore,theinfluenceofraftthicknessbecomesmore pronounced with increasing pile diameter and length, suggesting an interaction effect between raft and pile stiffness. The improved behavior can be attributed to the increased stiffness of the thicker raft, which allows it to distributeloadsmoreevenlyoveralargerareaandengage more effectively with the surrounding soil. This reduces stressconcentrationsandlocalizedsettlements,whilealso enabling the raft to carry a greater portion of the load before transferring it to the piles. As a result, the overall foundation system experiences reduced settlement and

improved structural integrity. These findings affirm that increasing raft thickness enhances the performance of piled raft foundations by promoting better interaction among the raft, piles, and soil, and should therefore be considered a beneficial design strategy in geotechnical engineeringpractice.

i. For a given pile diameter & raft thickness, varying pile length

Fig 10: InfluenceofPileLengthandPilediameteron DifferentialSettlement(Rt=0.5m)

Thebargraph(Fig.10)foraconstantraftthicknessof0.5m illustrates the influence of increasing pile length on differential settlement across different pile diameter. At a pile diameter of 0.35m, settlement reduced by 2.07% and 3.97% for pile length of 12m and 14m, respectively. At 0.45m,reductionsof2.91%and6.88%wererecorded.The highestimprovementoccurredat0.5mpilediameter,with reductionsof3.52%and10.99%,respectively.

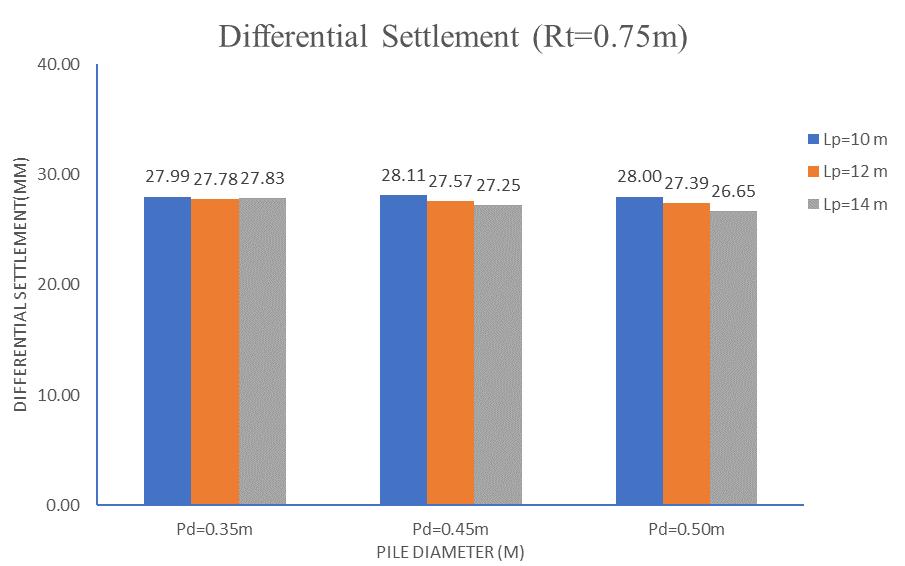

The bar graph (Fig 11) for a constant raft thickness of 0.75m illustrates the effect of increasing pile length on differential settlement across various pile diameters. A marginalreductionindifferentialsettlementisobservedas the pile length increases from 10m to 12m and then to 14m. At a pile diameter of 0.35m, the differential settlement decreased by 0.77% and 0.55% for pile length of 12m and 14m, respectively. For a 0.45m pile diameter, thereductionswere1.94%and3.07%,whilefor0.5mpile diameterareductionof2.18%and4.81%wasobserved.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

3.4.

The comparative analysis of bar graphs (Fig. 10 and Fig. 11) highlights that differential settlement in piled raft foundations is significantly influenced by three primary parameters: raft thickness, pile diameter, and pile length. Among these, increasing the raft thickness from 0.5 m to 0.75 m emergesas the mosteffective strategy, resultingin the highest percentage reductions in differential settlement up to 38.54%, particularly for configurations with smaller pile diameters and shorter pile lengths. This substantial improvement is attributed to the increased stiffness of the thicker raft, which enhances its ability to distribute loads more uniformly and control settlement variations across the foundation. The influence of pile diameter is relatively less pronounced but still beneficial; for example, at a pile length of 14 m, increasing the diameterfrom0.35 mto0.50 myieldsareductionofupto 11.59% in differential settlement, reflecting an improvement in load-bearing capacity and a reduction in stressconcentrationsontheraft.Meanwhile,theimpactof pile length shows moderate effectiveness, with reductions in differential settlement reachingupto10.99%forlarger diameters, indicating improved end-bearing and skin friction contributions. Overall, the findings suggest that while all three parameters positively affect the control of differential settlement, raft thickness plays the most dominant role, followed by pile diameter and pile length. These insights are essential for optimizing the design of piled raft foundations, particularly in challenging geotechnical conditions where controlling differential

settlement is critical for structural performance and longtermstability.

This study presents a detailed investigation into the performanceofpiledraftfoundations(CPRF)usingthreedimensional numerical simulations in PLAXIS 3D, with emphasis on optimizing raft thickness, pile diameter, and pilelengthundervariousloadingconditions.The primary objective was to understand the influence of these parameters on total and differential settlement, thereby aidinginthedesignofanefficientandcost-effectivepiled raftfoundationsystem.

The results demonstrate that raft thickness plays a dominant role in controlling both overall and differential settlements. Increasing the raft thickness from 0.5 m to 0.75 m resulted in a consistent reduction in maximum settlement across all pile configurations, with improvements ranging from 5.67% to 7.28%. This enhancement is attributed to the increased flexural stiffness of the raft, which allows for more uniform stress distribution and greater load-sharing capacity with the piles.

Similarly, differential settlement showed a marked decrease with increased raft thickness, reaching a maximum reduction of 38.54% for smaller pile diameters and shorter lengths. This demonstrates the raft’s increased ability to span non-uniform soil support and redistribute stresses more evenly. This effect was especiallysignificantincaseswherepileswereshortorof smaller diameter, highlighting the raft's compensating role.

The study also analyzed the effects of pile diameter and pile length. An increase in pile diameter from 0.35 m to 0.50 m led to differential settlement reductions of up to 11.59%, owing to the higher axial stiffness and loadcarrying capacity of the piles. Increasing pile length from 10 m to 14 m showed a moderate improvement, with differential settlement reductions reaching 10.99%, primarily due to enhanced end-bearing resistance and increasedshaftfriction.

An important observation from the results is that the combined optimization of all three parameters i.e raft thickness, pile diameter, and pile length, yields the most favorable outcomes in minimizing settlements. However, the influence hierarchy among the parameters is evident: raft thickness has the most significant effect, followed by pilediameter,andthenpilelength.

The outcomes of this study provide valuable insights into thedesignofpiledraftsystems,particularlyinseismicand settlement-sensitivezones. Bystrategicallyenhancingraft

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

stiffness and appropriately selecting pile dimensions, engineerscanachieveefficientloaddistribution,improved structural performance, and economic savings in foundation design. The methodology and results also emphasize the importance of integrated soil-structure interaction modeling in capturing realistic foundation behavior.

[1] Anup Sinha and A. M. Hanna, P.Eng. F.ASCE “3D Numerical Model for Piled Raft Foundation” © 2016 American Society of Civil Engineers DOI: http://dx.doi.org/10.1061/(ASCE)GM.19435622.0000674

[2] AniruddhaBhaduri,VansitteeDilliRaoandDeepankar Choudhury “The Behaviour of Pile Group and Combined Piled-Raft Foundation in Liquefiable Soil under Seismic Conditions.” Geotechnical Engineering Journal of the SEAGS & AGSSEA Vol. 51 No. 2 June 2020ISSN0046-5828

[3] Dang Dinh Chung Nguyen, Dong-Soo Kim, Seong-Bae Jo “Parametric study for optimal design of large piled raft foundations on sand” Elsevier Ltd. All rights reserved. http://dx.doi.org/10.1016/j.compgeo.2013.07.014

[4] Duaa Al-Jeznawi, Ismacahyadi Bagus Mohamed Jais*, Bushra S. Albusoda, and Norazlan Khalid “The slendernessratioeffectontheresponseofclosed-end pipe piles in liquefied and non-liquefied soil layers under coupled static-seismic loading” Journal of the Mechanical Behavior of Materials 2022; 31:83–89 https://doi.org/10.1515/jmbm-2022-0009

[5] IS 2911-1-2 (2010), “Design and Construction of pile foundations”,BureauofIndianStandards,NewDelhi.

[6] Joseph E. Bowles, “Foundation Analysis and Design”, Fifth Edition, McGraw Hill Education (India) Edition 2012.

[7] MeisamRabiei,AsskarJanalizadeh,Choobbasti“Piled Raft Design Strategies for High Rise Buildings” Geotech Geol Eng DOI:https://link.springer.com/article/10.1007/s1070 6-015-9929-x

[8] Ningombam Thoiba Singh. “Baleshwar Singh Settlement Profile and Pile Load Distribution Under Vertical Load of Piled Raft Foundation in Clay” Geotech Geol Eng https://doi.org/10.1007/s10706020-01359-6

[9] Rajib Modak, Baleshwar Singh “Time-dependent performance of large piled raft in clayey soil”. 0029-

8018/© 2024 Elsevier Ltd. https://doi.org/10.1016/j.oceaneng.2024.117839

[10] ShivanandMali BaleshwarSingh “Behavior oflarge piled raft foundation ondifferent soil profiles fordifferent loadings anddifferent pile raft configurations.” © Springer Nature Switzerland AG 2019https://doi.org/10.1007/s41062-018-0193-9