International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Shaurya Godha1

1Teoler High School, Jaipur, Rajasthan, India

Abstract - This paper presents a comprehensive analysis of aerodynamic drag effects on fuel efficiency for popular vehicles on Indian roads through Computational Fluid Dynamics (CFD) simulations. Three widely-used vehiclesHyundai Creta, Maruti WagonR, and Swift Dzire - were analyzed to determine drag coefficients and their impact on fuel consumption at typical Indian driving speeds. The study reveals that at common urban speeds of 40-60 km/h, aerodynamicimprovementsyieldminimalfuelefficiencygains of only 0.3-0.4 L/100km between the most and least aerodynamic vehicles. Given the predominance of low-speed driving conditions, frequent idling in traffic, and mechanical losses in Indian driving scenarios, the paper concludes that focusing on vehicle weight reduction, transmission efficiency, and engine optimization provides significantly better returns on fuel economy than aerodynamic refinements. This finding challengestheconventionalemphasisonaerodynamicdesign fortheIndianautomotivemarketandsuggestsareorientation of engineering priorities toward mechanical efficiency improvements.

Key Words: Aerodynamics, Fuel Efficiency, CFD Analysis, Indian Roads, Drag Coefficient, VehicleDesign, Fuel Economy

TheIndianautomotivemarketpresentsuniquechallenges forvehicledesignoptimization.Withincreasingfuelprices andenvironmentalconcerns,manufacturersareexploring various strategies to improve fuel efficiency. While aerodynamicdesignhasbeenaprimaryfocusindeveloped markets with high-speed highway networks, the applicabilityofsuchstrategiesintheIndiancontextrequires criticalexamination.

Indian road conditions are characterized by dense urban traffic, frequent stops, lower average speeds, and mixed traffic patterns. The National Highway Authority of India reports that average speeds on Indian highways rarely exceed 80 km/h, with urban speeds typically ranging between20-40km/hduringpeakhours.Thisstarkcontrast to Western driving conditions, where highway speeds of 100-130 km/h are common, raises questions about the prioritization of aerodynamic optimization for the Indian market.

Thisstudyaimsto:

- Quantify the impact of aerodynamic drag on fuel consumptionforpopularIndianvehicles

- Analyze the relationship between vehicle speed and aerodynamiclossesinIndiandrivingconditions

-Compareaerodynamicimprovementswithalternative fuel-savingstrategies

- Provide evidence-based recommendations for vehicle designprioritiesintheIndiancontext

1.2

Theanalysisfocusesonthreerepresentativevehiclesfrom different segments: Hyundai Creta (compact SUV), Maruti WagonR (hatchback), and Swift Dzire (sedan). CFD simulationswereconductedtodeterminedragcoefficients, followed by calculations of power requirements and fuel consumption impacts at various speeds typical of Indian roads.

Extensive research has been conducted on vehicle aerodynamics and fuel efficiency globally. Hucho (2013) establishedthataerodynamicdragincreaseswiththesquare ofvelocity,makingitthedominantresistanceforceathigh speeds. However, Sovran and Blaser (2003) noted that at speeds below 50 km/h, rolling resistance and mechanical lossesconstituteover60%oftotalvehicleresistance.

Studies specific to Indian driving conditions reveal unique patterns.BandivadekarandGunter(2008)foundthatIndian vehiclesspendapproximately35%oftheiroperationaltime idling in traffic, contributing to 15-20% of total fuel consumption.Thisidlingcomponentremainsunaffectedby aerodynamic improvements. Similarly, Guttikunda and Mohan (2014) reported that stop-and-go traffic in Indian citiesresultsinfuelconsumptionpatternswhereacceleration lossesdominate,accountingforupto40%ofurbanfueluse.

International research on low-speed driving efficiency supportsthesefindings.Mocketal.(2012)demonstratedthat weightreductionof100kgtypicallysaves0.3-0.5L/100km

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

acrossall speed ranges, while aerodynamic improvements show negligible benefits below 60 km/h. Engine efficiency improvementsthroughtechnologieslikestart-stopsystems, direct injection, and variable valve timing have shown consistent10-15%fuelsavingsregardlessofdrivingspeed (Johnson,2014).

The Indian Ministry of Road Transport reports average speeds of 30-35 km/h in major cities and 60-70 km/h on highways. At these speeds, aerodynamic drag contributes only15-25%tototalfuelconsumption,comparedto50-60% at speeds above 100 km/h common in developed nations (SIAM,2019).

3.1 CFD Analysis

ComputationalFluidDynamicssimulationswereperformed using ANSYS Fluent to determine drag coefficients for the threevehicles.Thek-εturbulencemodelwasemployedwith standardwallfunctions.Meshindependencestudiesensured grid-independentsolutionswithelementsrangingfrom8-12 millioncells.

3.2 Drag Force Calculations

Dragforcewascalculatedusingthestandardequation:

Fd=0.5×ρ×v²×Cd×A

Where:

-Fd=Dragforce(N)

-ρ=Airdensity(1.225kg/m³)

-v=Vehiclevelocity(m/s)

-Cd=Dragcoefficient

-A=Frontalarea(m²)

3.3 Power and Fuel Consumption Analysis

PowerrequiredtoovercomedragwascalculatedasP=Fd× v.Fuel consumptionimpactwasestimatedassuming25% thermalefficiencyforpetrolenginesandanenergydensity of32MJ/Lforpetrol.

4. RESULTS

4.1 Drag Coefficient Analysis

Table - 1: VehicleSpecifications

TheSwiftDziredemonstratedthelowestdragcoefficientat 0.33,whiletheWagonRshowedthehighestat0.40.However, theeffectivedragarea(Cd×A)revealsminimaldifferences betweenvehicles.

Table - 2: Dragatdifferentspeeds Vehicle

4.2 Speed-Dependent Drag Analysis

Table - 3: PowerRequirementstoOvercomeDrag(kW)

Vehicle

At typical urban speeds of 40 km/h, the power difference betweenthemostandleastaerodynamicvehiclesismerely 0.18kW.Evenat60km/h,representativeofIndianhighway conditions,thedifferenceisonly0.59kW.

4.3 Fuel Consumption Impact

Table - 4: FuelConsumptionDuetoAerodynamicDrag (L/100km) Vehicle

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

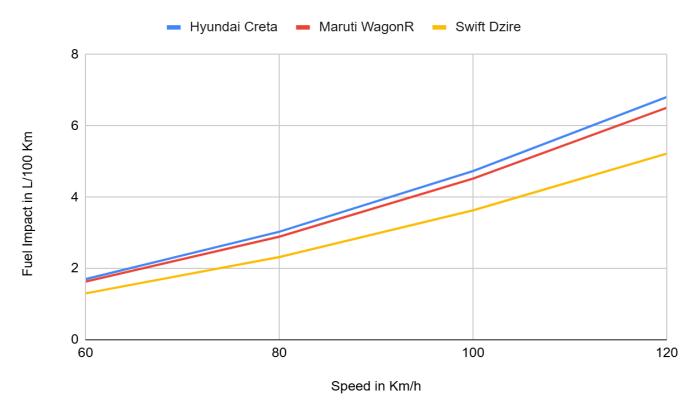

The data reveals that at 60 km/h, the fuel consumption difference between the best and worst aerodynamic performersisonly0.40L/100km.Thisrepresentslessthan 5%oftypicalurbanfuelconsumptionof8-10L/100kmfor thesevehicles.Youcanseehowthisimpactconvergestoa negligibleamountinChart1

Chart -1:FuelimpactinL/100Km

4.4 Comparative Analysis with Other Efficiency Measures

Whencomparedtootherfuel-savingstrategiesapplicableto Indianconditions:

-Weightreduction:A10%weightreduction(approximately 100-150kg)cansave0.5-0.7L/100kmacrossallspeeds

- Engine efficiency: Modern fuel injection systems can improveefficiencyby10-15%,saving0.8-1.5L/100km

- Transmission optimization: CVT or dual-clutch transmissions offer 5-8% improvement, saving 0.4-0.8 L/100km

- Start-stop systems: Can save 0.5-1.0 L/100km in urban conditions

Theseimprovementsshowconsistentbenefitsregardlessof driving speed, unlike aerodynamic improvements which becomenegligibleatlowspeeds.

5. CONCLUSIONS

This CFD-based analysis of popular Indian vehicles demonstratesthataerodynamicdesignimprovementsoffer limitedfuelefficiencybenefitsundertypicalIndiandriving conditions.Keyfindingsinclude:

1. At common urban speeds (40-60 km/h), aerodynamic dragaccountsforlessthan20%oftotalfuelconsumption, withdifferencesbetweenvehiclesunder0.4L/100km.

2. The exponential relationship between speed and drag powermeansaerodynamicbenefitsareminimalatthelow speedscharacteristicofIndianroads.

3. Alternative strategies such as weight reduction, engine optimization, and transmission improvements offer more consistent and significant fuel savings across all driving conditions.

4. For the Indian market, engineering resources would be better allocated to mechanical efficiency improvements ratherthanextensiveaerodynamicoptimization.

The study suggests a paradigm shift in vehicle design priorities for emerging markets like India, where driving conditions differ significantly from those in developed nations. Manufacturers should focus on holistic efficiency improvementsthataddresstheactualusagepatternsrather thanpursuingaerodynamicrefinementsthatyieldminimal real-worldbenefits.

[1] Hucho, W.H., "Aerodynamics of Road Vehicles," SAE International,5thEdition,2013.

[2] Sovran, G. and Blaser, D., "Quantifying the Potential ImpactsofRegenerativeBrakingonaVehicle'sTractiveFuelConsumption,"SAETechnicalPaper2003-01-2303, 2003.

[3] Bandivadekar, A. and Gunter, L., "Fuel Economy Standards for Light-Duty Vehicles in India," InternationalCouncilonCleanTransportation,2008.

[4] Guttikunda, S.K. and Mohan, D., "Re-fueling Road TransportforBetterAirQualityinIndia,"EnergyPolicy, Vol.68,pp.556-571,2014.

[5] Mock,P.,German,J.,Bandivadekar,A.,andRiemersma,I., "DiscrepanciesbetweenType-ApprovalandReal-World FuelConsumption,"ICCTWhitePaper,2012.

[6] Johnson, T.V., "Vehicular Emissions in Review," SAE InternationalJournalofEngines,Vol.7,No.3,pp.12071227,2014.

[7] Society of Indian Automobile Manufacturers (SIAM), "Indian Automobile Industry Statistical Report 201819,"2019.

[8] National Highway Authority of India, "Traffic Speed Study Report," Ministry of Road Transport and Highways,2020.