International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Pooja Gupta1 , Ajeet Kumar2

1 M.Tech Student MED Sagar Institute of Technology & Management Barabanki UP India

2 Assistant Professor MED Sagar Institute of Technology & Management Barabanki UP India

Abstract - Thisdissertationaimstoinvestigateandcompare the mechanical properties of 3D printed Acrylonitrile Butadiene Styrene (ABS) and Polyethylene Terephthalate Glycol (PETG) specimens widely used in medical, automotive andconsumer industries.The studyexplores thefundamental principles of FDM technique of 3D Printing, its process parameters, and their impact on the mechanical characteristics of ABS and PETg materials. The research investigates the effects of key 3D Printing parameters such as layer thickness, infill density and print speed on tensile and flexural strength. Additionally, the dissertation evaluates the optimizationtechniquesemployedtoenhancethe3Dprinting process for both ABS andPETG andcompares the mechanical properties of both the materials.

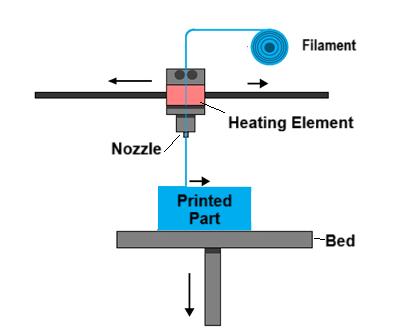

Theprocessof3-Dprintingentailsproducingtangibleitems fromageometricrepresentation,layer-by-layeradditionof material.

Originally developed for rapid prototyping, additive manufacturing has evolved into a robust manufacturing solutionforusablepartsinaerospace,automobile,medical, consumerproducts,andarchitectureindustries.Ithasability ofcreatingdifficultgeometrieswithminimalwastecoupled withcustomization which makes ita vital tool formodern engineeringanddesign.

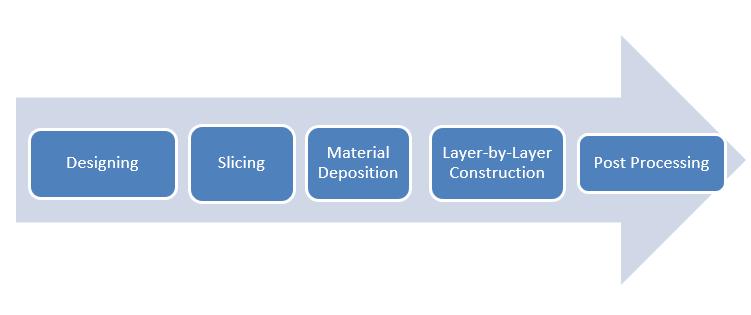

Figure 1.2: Steps involved in 3D Printing

3D printing emerged in the late 20th century as a revolutionary shift in the field of manufacturing and prototyping. Its origin is tacked to early 1980s, when advancements in Computer Aided Design and laser technologiesenabledthedevelopmentofthefirstlayer-bylayerfabricationtechniques.

Thefirstpatentfora3DprintingprocesswasfiledbyDr. Hideo Kodama in 1981, who described a method for producing 3D plastic models using a photosensitive resin. However,itwasCharlesHull,co-founderof3DSystems,who in1986patentedStereolithography(SLA) thefirstwidely recognizedandcommerciallyviable3Dprintingtechnology. Hull's invention developed the base for modern additive manufacturing.

a. PrototypingandProductDevelopment

b. Rapidprototypingisthemostcommonuse.

c. Lightweight, strong components for aircraft and spacecraft(e.g.,brackets,ducts).

d. Customizeddronepartsandcomplexgeometriesnot possiblewithtraditionalmachining.

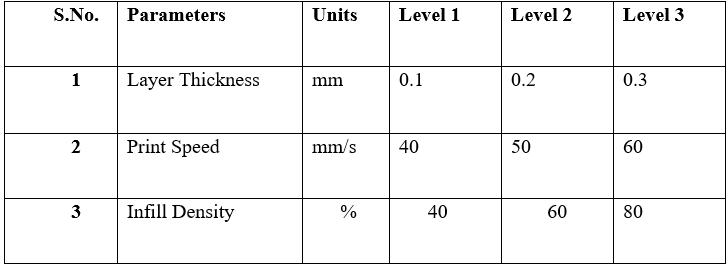

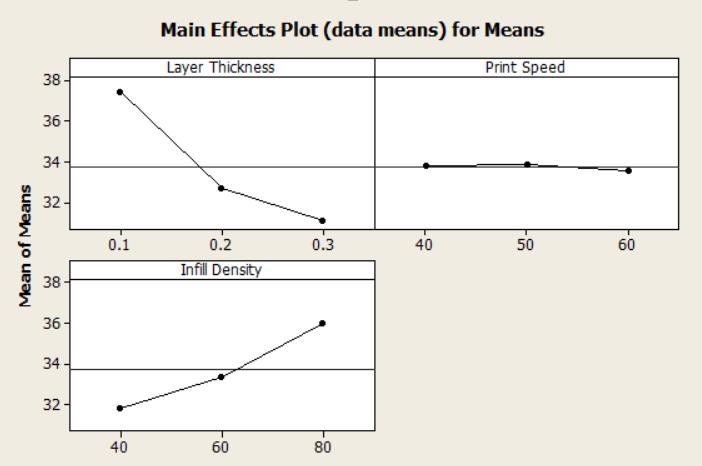

KhabiaandJain[1]comparedthecharacteristicsof partsprintedthroughABSfilament.Theycarefullymodified theprocessparametersandthehighesttensilestrengthof 35.7MPawasachievedatlowerlevelofmachinevariables.

Durgashyam et al [2] performed investigation on mechanical characteristics of PETg. They perceived the influence of machine variables on flexural and tensile strengthprintedbyFDMtechnique.Theresultdepictsthat forachievingbettertensilestrength,thicknessoflayerand feed should be lowered along with higher level of infill

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

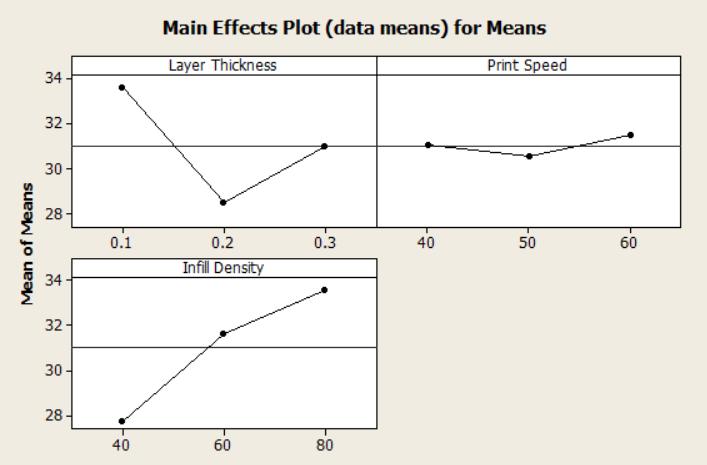

density. Furthermore, better flexural properties are experienced with low thickness of layer, medum feed and lowdensityofinfill.

Durgashyam et al. [3] investigated PETg using Taguchi approachforanalyzingtheoutcome.Theresultselucidated that layer height influences the tensile and flexural characteristicsofPETg.Furthermore,VishwasandBasavaraj [5]intheirstudyused3DprintedABSmaterialforanalyzing mechanicalstrength.Theyconcludedthatoptimallevelof3D printingparameterswillenhancethebondingstrengthand tensilestrength

JhaandNarasimhulu[4]intheirstudyinvestigatedthecreep andvibrationof3Dprintedspecimens.

Vishwasetal.[5]conductedacomparisonofABSandNylon 3DprintedsamplesbasedonTaguchiApproach.Theresult showed that a lower level of thickness of layer yield significantimpactontensilestrength.

3. Result & Discussion

3.1TABLES FOR TAGUCHI DESIGN OF EXPERIMENT

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Fig3.5MaineffectplotforTensileStrengthofPETg

Table3.2Confirmationofexpectedandactualvaluesof TensileStrengthofABS

Table3.5Confirmationofexpectedandactualvaluesof FlexuralStrengthofPETg

4. Conclusion

For both ABS and PETg, Infill density is the crucial variable for flexural property followed by thickness of layer. The impact of print speed was least among the selectedparameters.

ThecontributionofInfilldensityishighestforbothABS (76.63%)andPETg(secondhighestforPETg(41.09%). Furthermore, Infill density is the major dominating factor(68.26%).Similarly,layerthicknesswasrevealed assecondmostinfluentialvariableforflexuralstrength ofABSandPETg.

Table3.3Confirmationofexpectedandactualvaluesof TensileStrengthofPETg

The flexural property increases with increase in 3D Printingparametersforboththematerials.Strength is imparted in the sample having extra amount of material.Withhighlayerthickness(0.2to0.3mm),the intra-layer adhesion is more in the present case and hencetheflexuralstrengthofthematerialismore.

5. References

[1]S.K.Vikneswaran,P.Nagarajan,S.K.Dinesh,K.S.Kumar, A. Megalingam, Investigation of thetensile behaviour of PolyLactic Acid, Acrylonitrile Butadiene Styrene, and PolyethyleneTerephthalateGlycolmaterials.MaterialsToday: Proceedings.66(2022)1093-1098.

Table3.4Confirmationofexpectedandactualvaluesof FlexuralStrengthofABS

[2]. Hsueh,M.H.,Lai,C.J.,Wang,S.H.,Zeng,Y.S.,Hsieh, C. H., Pan, C. Y., & Huang, W. C. (2021). Effect of printing parametersonthethermalandmechanicalpropertiesof3dprinted pla and petg, using fused deposition modeling. Polymers,13(11).https://doi.org/10.3390/polym13111758

[3]. Veteška,P.,Hajdúchová,Z.,Feranc,J.,Tomanová,K., Milde, J., Kritikos, M., Bača, Ľ., & Janek, M. (2021). Novel composite filament usable in low-cost 3D printers for fabrication of complex ceramic shapes. Applied Materials Today,22.https://doi.org/10.1016/j.apmt.2021.100949

[4]M.Ramesh,K.Panneerselvam,Mechanicalinvestigation and optimization of parameter selectionfor Nylon material processed by FDM. Mater. Today: Proc., 46 (2021) 93039307.