Alliance Agricultural Tyres are backed by one of the industry's most comprehensive warranties. Alliance stands by your work, season after season. Because when it comes to performance and peace of mind, we're always by your side.

Alliance Agricultural Tyres are backed by one of the industry's most comprehensive warranties. Alliance stands by your work, season after season. Because when it comes to performance and peace of mind, we're always by your side.

One million tyres. Five unstoppable years. AgriStar II has earned its place in elds across the globe. Trusted by farmers for its durability, traction, and performance. This milestone is more than a number; it’s a testament to the con dence growers place in Alliance.

Another month ticks by and we are well and truly into the swing of 2026.

This edition of packed with articles that are the magazine’s trademark – the stories of people and business powering Australian agriculture along with customer testimonials which allow readers to hear from the people using machinery every day.

It starts with this month’s cover story, which features a Victorian farmer who owns telehandlers across multiple brands.

A Bobcat has become his favourite to drive and he shares the reasons for this, along with why it will be his preferred brand into the future.

Another customer testimonial comes via a New South Wales contractor who is using an Antonio Carraro tractor for working on power poles.

While it may not be a straightforward agricultural use, it showcases the unique abilities of these versatile tractors.

Also in New South Wales, we speak to a dairy farmer who is full of praise for his JCB telehandler’s performance over many years which inspired the purchase of a second model from the same brand.

A Queensland citrus grower shares why a Godzilla wheel loader from Digger King has provided the perfect mix of everything he is after, while we also hear from a South Australian farmer who has relied on Rocky River Ag Services for more than three decades.

Continuing our trip around the nation, Tasmanian farmer Will Lyon shares his career story and ambitions to become an industry leader, while WAFarmers CEO Trevor Whittington gives his opinion on limitations to ag technician training programs.

South Australian business Longridge Olives is profiled, sharing their story of transitioning from being a dairy farm.

Every new year brings new milestones, and in this edition we celebrate Burder Ag Attachments which celebrates 35 years in operation.

We put some products in the spotlight – namely the Ferrari Growtech Futura automatic transplanter available through Vin Rowe Farm Machinery, along with Kerfab’s new K-Broom, plus Alliance Tyres.

The Tractor & Machinery Association has members across the nation and we speak to the Farm Machinery & Industry Association of WA about why TMA membership is so important to them.

The TMA’s latest tractor sales figures also provide a snapshot of 2025 compared to 2024.

A couple of appointments at both AgriFutures and the National Farmers Federation feature in our industry news section, along with a look at overall industry confidence into the new year.

As always, if you have a story you believe should be told in the magazine – please feel

Lincoln Bertelli Editor

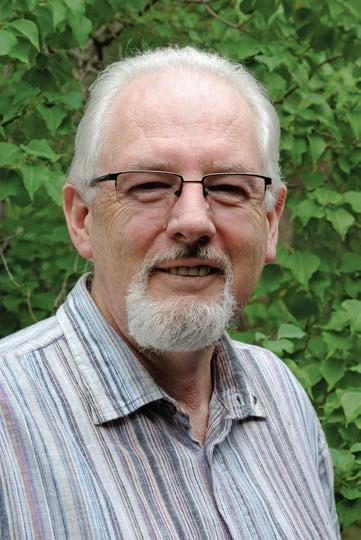

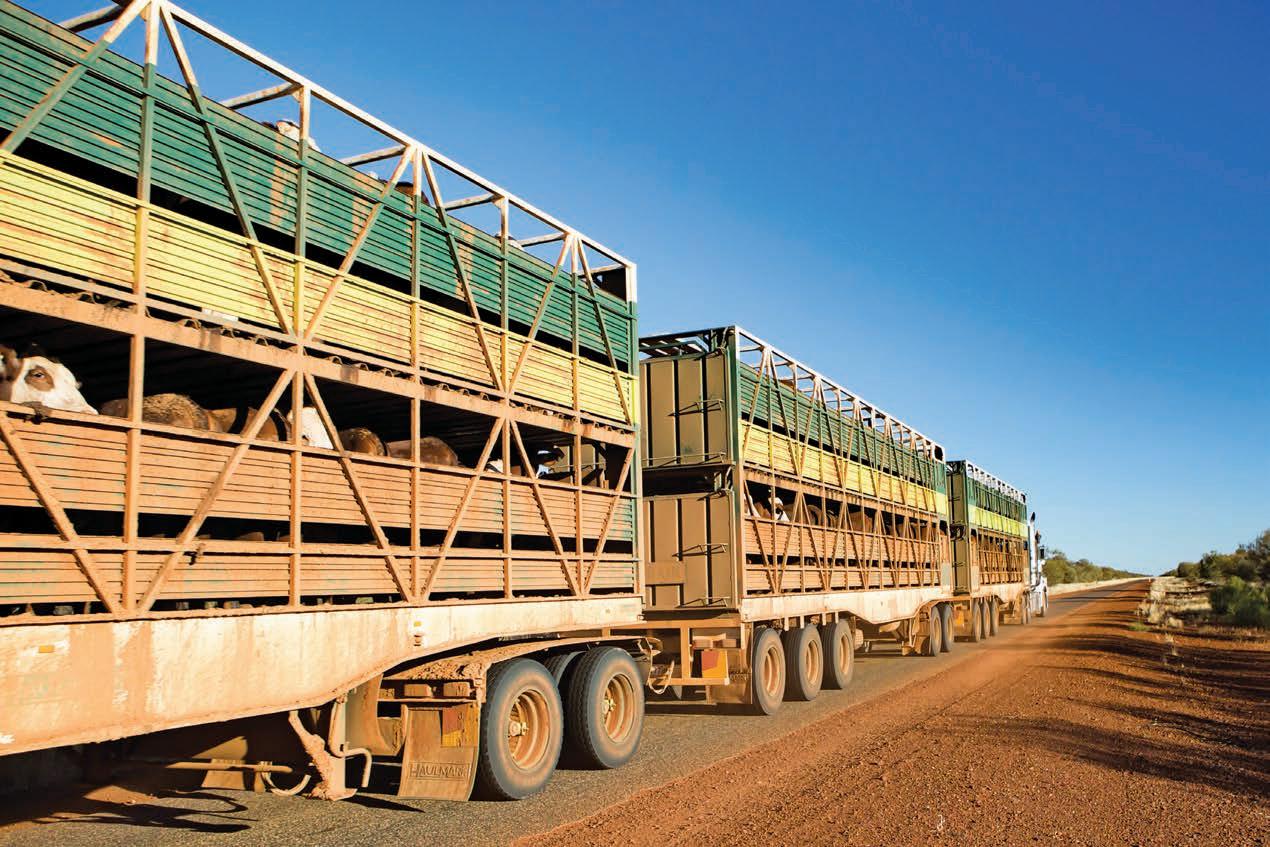

Building his career via an array of farm jobs across multiple states has given Will Lyon a passion for the industry and a long-term desire to be involved in policy making

From general farm labouring through to visiting Parliament House in a leadership program, Will Lyon’s career in agriculture has been eventful.

Now based in Tasmania, where he is farm manager of a property east of Launceston, Will has also worked in both Northern Territory and his native New South Wales and has been drawn to leadership roles as his agricultural career has developed.

He spent 2025 involved with the National Agricultural Leadership Program (NALP), a National Farmers Federation initiative where he was one of nine emerging leaders selected.

“The reason I applied was because I wanted to understand the political side of agriculture,” he says.

“I haven’t had anything to do with it through my whole career being just basically solely based on farm, so I’d never looked over the fence at what happens in Parliament and behind the scenes with the NFF.

“It was quite interesting to go to

Canberra and see what’s involved with writing policy and the stages that things go through to get funding – just all the little hurdles that you don’t generally see when you’re on your normal day-to-day job.”

Will only learned about the NALP through a friend he made via being one of three recipients of the 2022

Peter Westblade scholarship – a strong endorsement for the power of networking.

The scholarship – which was another major boost to Will’s career – is given to young leaders in the sheep and wool industry, aiming to provide hands-on experience and mentoring to develop their career in the sector.

Much of Will’s working life has revolved around the sheep and cattle industries and these are the areas he is most enthusiastic about.

“My passion is livestock and livestock handling because it’s directly related to the quality of the meat that comes out of the farm,” he says.

“If you’re handling your livestock and looking after them quite well, then

obviously that’s going to be directly related to the end result.

“That’s my passion – trying to make sure that I’m producing the optimum product.”

Origin story

Will was born and bred in the central-west New South Wales town of Orange, where studying several agriculture-related

subjects in high school helped to build his passion for the industry.

“I didn’t grow up directly on a farm, but my mum’s side and my dad’s side are both directly related to agriculture,” he says.

“Mum’s side has a family farm and dad’s side were in the meat carting industry and my dad was working in viticulture.”

After school, he spent a season working near the Queensland and Northern Territory border, before returning home and starting a diesel mechanic apprenticeship working on tractors and farm machinery.

He would ultimately not finish this apprenticeship after feeling a desire to get back into agriculture.

“I went back and started farm contracting and labouring around Orange and the central-west doing all sorts of things – drenching, spraying, tractor work and just general farmhand stuff,” he says.

From there, Will got a full-time job as a head stockman on a property just outside of Molong in New South Wales.

He spent more than four years in that role, assisting with livestock management and other general farm maintenance.

The next move was to the state’s

western Riverina region where he spent about 18 months as assistant manager of a large sheep station, a role which involved managing a team of jackaroos.

It was around this time that he got the Peter Westblade scholarship – something which he says kickstarted his career and opened up new opportunities and networks.

“I used it to improve my skills as a stockman as well as gain a lot of leadership skills,” he says.

“I did a few leadership courses, got a lot of books and managed to pick up a lot of

mentors, all of which is pretty cool.

“My wife and I also had a five-year goal and wanted to move to Tasmania.

“Through networks I made with the scholarship, and a few people from Tassie within the scholarship community, we managed to find this management job down here in Tasmania.”

That job is farm manager of Elverton Pastoral, a 2,700 hectare mixed sheep and beef enterprise which also includes about 350 hectares of irrigation and involves finishing prime lambs and growing out their own beef.

Will undertook the program to better understand the political side of ag

“I’m currently managing a team of six to nine people depending on the time of the year and it’s pretty full on,” Will says.

“The day-to-day is basically managing the team and can vary from anything from livestock right through to machinery maintenance and all the admin that goes with it.

“Through the spring we get a lot of extra casual labour in when we’re quite busy with making hay and silage and there’s a lot of rotational grazing going on.

“There are a lot of stock moves to be planned, so we get a few backpackers in for that.”

Will considers himself established in Tasmania, having a young family and being settled in the farm management role.

While day-to-day life on the farm is his top priority, he sees the opportunities and networks gained through both the NALP and Peter Westblade scholarship as being valuable for his longer-term ambitions.

In addition to everything learned after visiting Parliament, part of the NALP’s aim is to give a program for participants to develop their own policy.

Will focused his policy on red meat production, with this being the area he is most passionate about.

Moving into the policy making field and

trying to make a difference to the whole sector is something he can foresee in the future.

“At this point in time I’ve got a young family, so we plan to be based on farm until my young fella goes through school,” Will says.

“Down the track, being a part of TasFarmers and things like that is something that I’m wanting to get more involved in, so I can have my finger on the pulse a bit more of what’s going on outside

of the farm and things that directly affect the premiums we get for our meat.

“Particularly in Tassie, because we’re quite clean and green labelled, there’s a bit that goes into that to make sure that we maintain that reputation.

“That’s what I find quite interesting, plus there are a lot of little things like transport inconveniences and things like that going over the water.

“It’s definitely an area that I’d be looking at getting involved with.”

Some farmers have a brand loyalty which means they will never consider using anything else.

Others are happy to try machines from various manufacturers before settling on their preferred unit.

While both endorsements carry weight in their own ways, the story of someone who has used multiple telehandler brands before declaring which one they would buy again is a story worth listening to.

Victorian dairy farmer Corey Mitchell had never used a Bobcat telehandler before adding a TL38.70HF model to his fleet of three, but such is his love for the unit that it has become his go-to when choosing which machine to personally drive.

“Having three of them gives you the opportunity to work out which one’s better and I prefer the Bobcat,” he says.

“I prefer to drive the Bobcat and I actually choose that one to go and do all my jobs in.”

The 38.70 in the telehandler’s model name relates to two of its key

specifications – a 3,800kg lift capacity and a 7m lift height.

The HF relates to it being a high flow machine, which offers a 190L/min pump along with 150L/min auxiliary standard flow.

This is complemented by a 130hp (96kW) engine, while it also offers what Bobcat describes as best-in-class boom speeds.

Telehandlers have grown in popularity amongst Australian farmers for their versatility, combining the ability to reach high places with being a general workhorse that lifts both heavy and bulky materials.

For Mitchell, the variety of jobs it completes makes the Bobcat TL38.70HF an essential part of his routine.

“On a day-to-day basis, I’m using it to push up both cow manure and chook manure, putting grains into mixer wagons with grabs and buckets, stacking round and square bales of hay into sheds and seven high square bales outside,” he says.

“We use it for earthworks, doing track maintenance and things like that, around water troughs and manoeuvring dirt.

“We use it to get it to high places and

it’s also very good for lifting quite heavy items like water troughs and moving them around the farm to where we want them.”

The TL38.70HF is available in two finishing levels, with Mitchell choosing the Agri Expert configuration that offers a deluxe steering wheel, air suspension seat and four steering modes as some of the many benefits.

Entering the cabin – which has a low position for easy access – reveals everything from colour-coded controls and an all-in-one joystick, low dashboard to a 5-inch (13cm) display.

With Mitchell choosing the Bobcat over his other telehandlers for the jobs which he personally does, there are plenty of benefits he has observed along the way.

“I find it has better awareness around it –over your right shoulder you just seem to have that little bit more vision,” he says.

“It’s got the reversing camera which is exceptional. Obviously you’ve got your backing beacon as well, but you’ve got a 360-degree vision of what’s around you

Bobcat telehandlers are designed to excel with plenty of farm jobs

because of the reversing camera and the safety aspect of that is very important.”

The safety features Mitchell highlights are further bolstered by a well-balanced overall construction, low centre of gravity, heavy counterweight and long wheelbase, which Bobcat says allows it to easily and safely handle heavy loads at any height.

Safety is also enhanced by all vital components such as the cylinders, hydraulic systems and electric harness being located inside the highly rigid frame, and a robust box section inside the frame means these are well protected at all times.

The simplicity of driving the Bobcat is another aspect that Mitchell cites as a major advantage.

“All the other telehandlers have got four gears in them, whereas this is just a straight drive and I find that really good because you’re not flicking through gears,” he says.

“You hop in it, and it just seems to be more versatile and probably a bit more

“Because you’ve got that hydraulic component at the back of the machine, that means you’ve got that other aspect of being able to move more machinery around.”

It was the recommendation of a friend which first put the idea of a Bobcat telehandler into Mitchell’s mind.

A positive interaction with his local dealer at a field day solidified the purchase.

Bobcat Australia is a division of Clark Equipment, with the brand represented by a wide national dealer network.

This network includes Bendigo-based Delecca’s, located about an hour’s drive from Mitchell’s farm at Lockington in northern Victoria.

“I got to know Jason and his team at Bendigo really well and then, when I went to the field days, they just said ‘we’ll do you a deal you won’t be able to refuse’ and they did a pretty firm deal,” Mitchell says.

He also praises the backup support provided by Delecca’s, which included an instant solution to a minor issue with the telehandler.

“Within probably an hour and a half, Jason and the guys had another machine there and they took that one back and fixed it,” he says.

“They’re second to none. If I ring up for parts, they’re really good, but also coming out and servicing it too.

“The backup has been really good and because you build that relationship up and you get that bit of trust, it means if I do have any little issues I can ring Jason and have another machine out here in an hour and a half.

“If you look at our dairy operation, if we can’t load feed into mixer wagons, there’s thousands of dollars a day I could potentially lose.

“That’s where Delecca’s are good – the quality of service and making sure there’s a reasonable number of spare parts there that keep me operating, because downtime is the biggest killer.”

The need for backup support has been rare though, with the Bobcat TL38.70HF having proven a winner since joining Mitchell’s fleet.

Having been able to compare its merits to other telehandler brands, his decision about what comes next is unequivocal.

“I’ve got no hesitation in a couple of years to swap it over and get another Bobcat –that’s what we’ll be staying with,” he says.

The full Bobcat telehandler range can be viewed online at www.bobcatofaustralia.com.au

MACHINERY

Burder Ag Attachments will celebrate its 35th anniversary in 2026, marking a milestone for an experienced hand in Australian manufacturing

Milestone years are always a reason to celebrate – and Burder AgAttachments will be doing just that throughout 2026.

Operating in a market where Australian agricultural manufacturers are increasingly rare, Burder AgAttachments continues to reinforce its long-term commitment to local manufacturing through ongoing reinvestment in facilities, people and technology.

The business began in 1991 with just five employees, producing 25 front-end loaders in its first year.

Since then, growth has been steady and substantial.

Today, Burder employs around 65 people and remains proudly family-owned by the Fendyk family, manufacturing from its base in Wangaratta, northern Victoria.

“We’re 35 years in, still family owned and still Australian made – something we’re incredibly proud of,” says Burder sales manager Campbell Fendyk.

“We plan to make the milestone a theme of the year and really celebrate it.”

Since the company’s last major milestone – its 30th anniversary – Burder has made significant investments to expand and modernise its manufacturing capability.

“This has really resonated with both

customers and dealers, as it demonstrates our commitment to producing highquality Australian-made products,” Campbell says.

“We’ve reinvested heavily back into the business, including a new office space and major upgrades to factory equipment, all with the goal of increasing productivity.

“In the past couple of years, we’ve added a Bystronic steel laser cutter and three automated robotic welding stations.

“We also hosted our second Burder open day early last year, where dealers from around Australia were able to tour the factory and see both our new and existing product range. It was a very exciting event.”

A key factor behind Burder’s longevity has been the breadth and diversity of its product offering across multiple agricultural sectors.

While Burder also operates as farm machinery importer, importing high end complementary products required by farmers, general manager Adam Fendyk describes the business at its core as an engineering company.

“Burder specialises in the design, manufacture and wholesale of front-end loaders, forklifts and materials-handling equipment for the Australian market,” Adam says.

Burder AgAttachments is located in Wangaratta, Victoria

“We also import a range of farm machinery products that add value to farming enterprises.”

Burder’s product catalogue is extensive, with more than 2,000 subframe designs and the capability to manufacture and customise loaders, forklifts and attachments for both new and older tractors.

Front-end loader models are available for tractors ranging from 15hp to 300hp and can be tailored to suit different tractor brands and applications.

Built from Australian-made steel for strength and durability, Burder loaders feature mechanical self-levelling for safer, more productive work, a variety of single lever quick-change systems that allow the end user to have a new loader to fit their existing implements, hydraulic dampeners for smoother operation and the XP series includes replaceable wear bushes at all pivot points.

Options include joystick controls compatible with both cab and ROPS tractors, hydraulic quick couplers, and a wide range of bucket sizes and dump heights.

Beyond loaders, Burder manufactures an extensive range of attachments including bale forks, standard and four-in-one buckets, market leading front and rear mount

forklifts, post-hole diggers, rear loaders and feed-out wagons just to name a few.

The company also imports and distributes selected overseas products, primarily servicing the horticulture, viticulture and dairy sectors.

These include Anderson hay and silage equipment, Stoll front end loaders, Zuidberg front linkage and PTO systems, and Martignani electrostatic sprayers, all of which are market leaders in their fields globally.

While part of Burder’s product lineup is imported, 85 per cent of the company’s turnover lies in the heart of the business – local engineering and manufacturing.

Australian farming conditions are unique, and machinery working in local paddocks requires local expertise to perform reliably.

“Anyone who imports machinery will tell you that Australian conditions can be particularly demanding,” Adam says.

“Some of the world’s biggest tillage manufacturers need to ‘Australianise’ their machines to be competitive here.

“That means Australian manufacturers are often competing directly with global brands – and in many cases setting the benchmark for local conditions.”

According to Adam, local manufacturing may not always win on scale or price, but it excels in adaptability.

“We may not be the biggest or the cheapest, but what we can do is customise equipment to Australian conditions and the specific needs of

farmers – whether that’s for an individual operation or an entire industry sector.”

Another major advantage is speed.

With design, engineering and manufacturing all handled in-house, Burder can respond quickly to market demands without relying on overseas shipping or lengthy approval processes.

“The ability to innovate and deliver quickly is incredibly important,” Adam says.

design and deliver something like a new tractor subframe for a loader or forklift in three to four weeks – something that might take an importer three to six months.”

Australian manufacturing is also about people, providing skilled career pathways across a wide range of trades.

“It’s incredibly rewarding to train local apprentices and help people build longterm careers,” Adam says.

robotics, CNC machinery, fitters and machinists – all under one roof.

“We’re really an end-to-end operation, from design through to delivery, with our own engineers, factory teams and transport fleet.”

Burder AgAttachments’

manufacturing facility is located at 4-8 Kerr Street, Wangaratta, with products supported by an extensive nationwide dealer network.

“Speed to market matters and having a strong manufacturing capability is critical.

“With our engineering team, we can

“People often think of metal manufacturing as just welding, but we also have hydraulics, painting, assembly,

The full range can be viewed online at www.burder.com.au

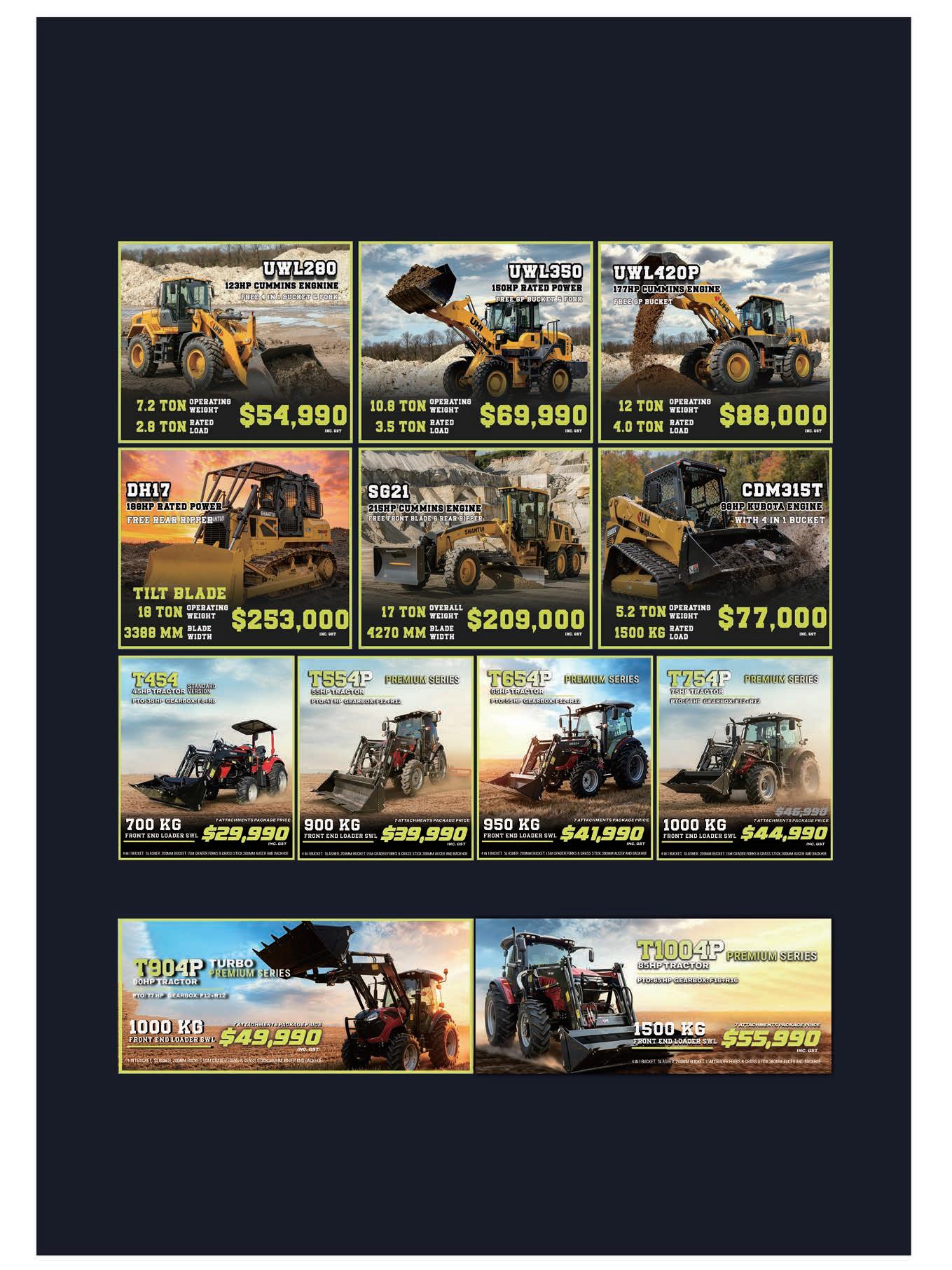

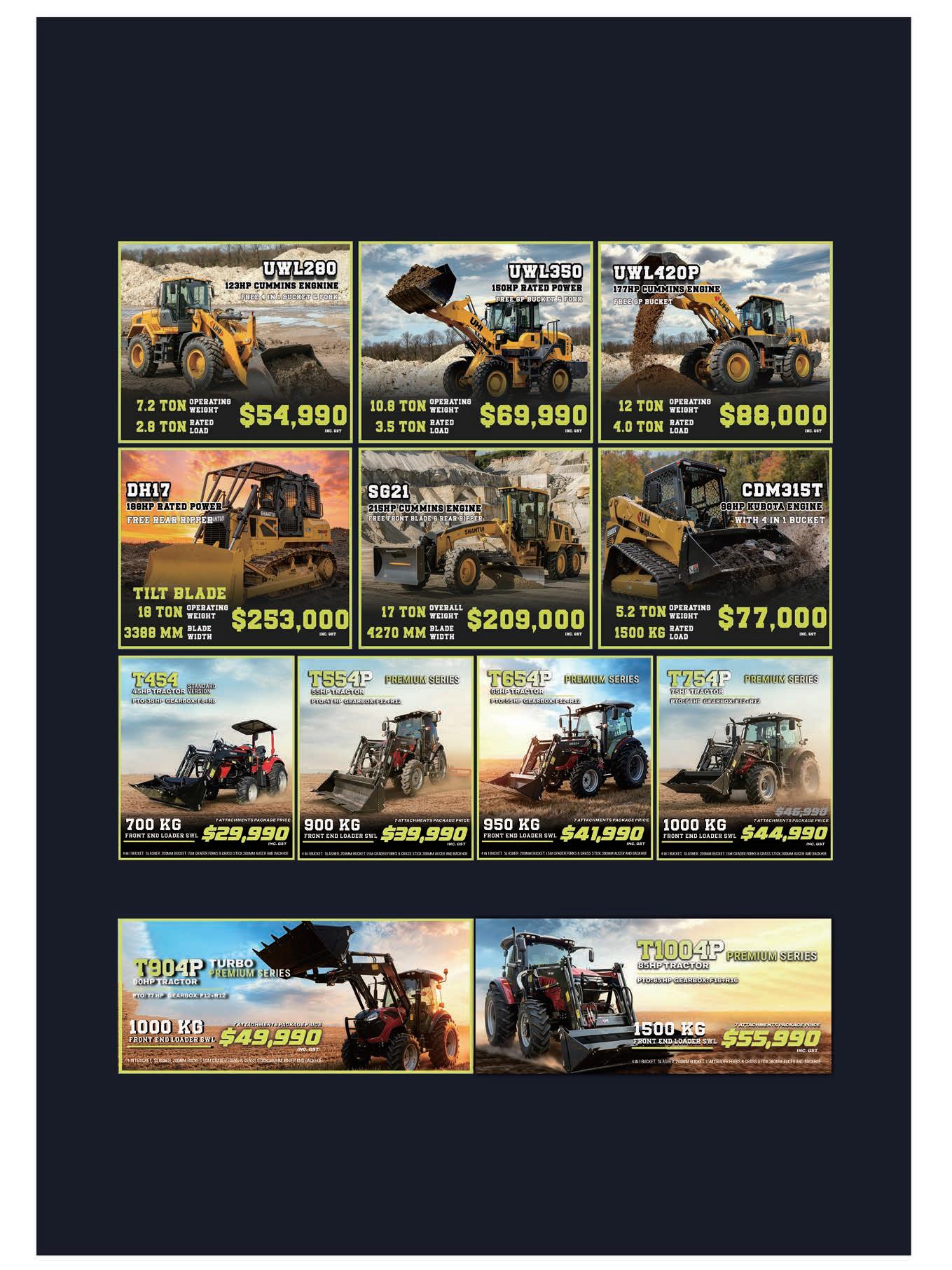

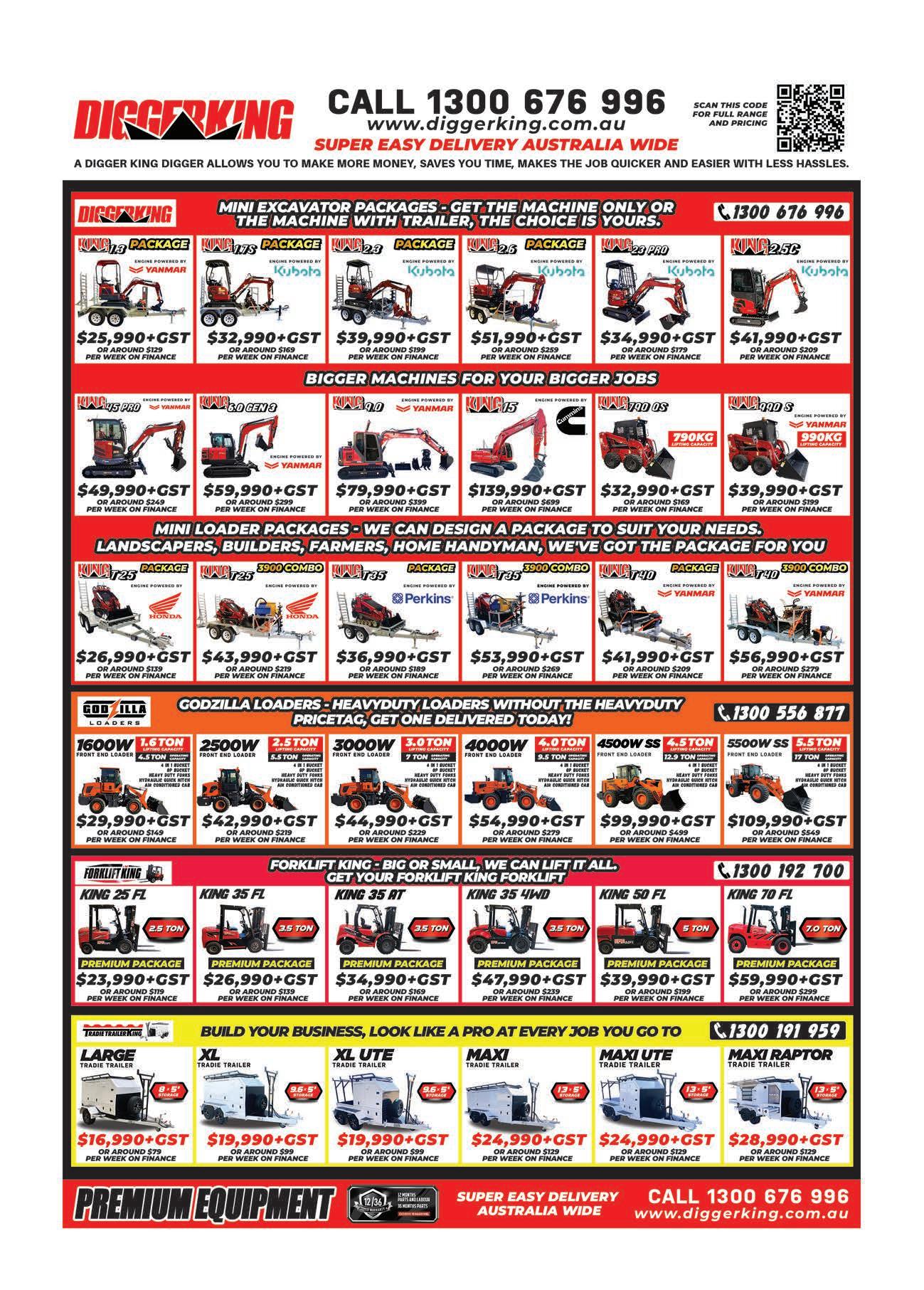

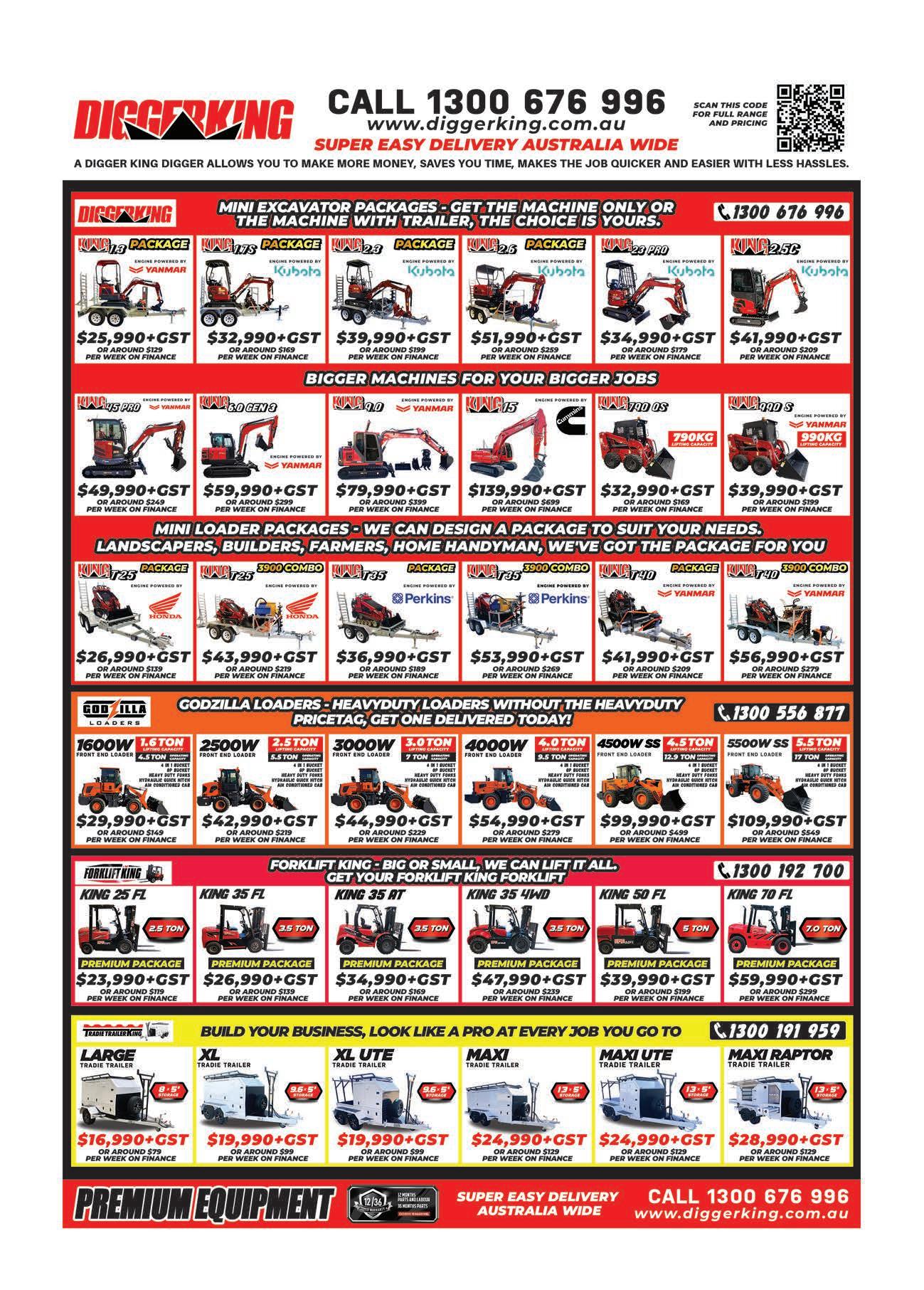

A Queensland-based citrus grower has found a Godzilla wheel loader from Digger King to be the perfect balance of being value for money, robust and feature-rich

Before making a heavy investment in a new piece of machinery, most farmers want more than just a brochure and big promises, they want real-world proof a machine can provide value to their paddock.

Whether it be from test driving equipment or speaking to other farmers who have found success with a product, social proof goes a long way in making a purchasing decision.

Queensland citrus grower Frank Vecchio-Ruggeri can attest to this, having procured a new Godzilla 3000w wheel loader from Digger King after talking to another local farmer with the same machine.

“I was getting sick of repairing my old wheel loaders, so I wanted to buy a new one,” he says.

“I did some research and was looking at some other brands but quickly changed my mind after coming across Godzilla.”

Initially unsure about the brand but

captivated by the price of the machine and the various standard features –including a 1.2 cubic metre GP bucket, 4-in-1 bucket, heavy duty 1.1m forks, and a hydraulic quick release hitch – VecchioRuggeri sought out more information from Digger King.

After ringing up the team, Digger King gave him the run-down of the brand, including its product portfolio, which comprises everything from excavators, skid steers and compact track loaders, through to wheel loaders and forklifts.

Digger King also put him in touch with another local Mareeba-based farmer who owned a Godzilla wheel loader, enabling Vecchio-Ruggeri to see the machine in the flesh.

“I went to go and have a look at the loader in person, and I liked it compared to the other brand I was looking at,” he says.

“I was impressed with the size of the machine and its price value for what you were getting, so I kept on researching about

it and it met the specifications I was looking for.”

For just over a year now, VecchioRuggeri has been using the seven-tonne Godzilla wheel loader for general farm maintenance on his operation which grows lemons, limes, and pomelos.

Some of the tasks it has thrived in include pulling out dead trees, fixing up waterways and carrying dirt to fill up holes, thanks largely to its 132hp (98.4kW) engine and three-tonne load capacity.

With a cabin offering heating and air-conditioning, Vecchio-Ruggeri has been able to complete all these jobs with maximum comfort.

“The Godzilla has been really good so far. It’s a solid built machine and is value for money. I can’t believe the size of it and the buckets it has got,” he says.

“I want to buy a mulcher attachment to expand the jobs I can do with it even further.

“A stick rake would also be good to push some the dead trees I’m pulling out.”

He adds the aftersales support provided by Digger King has been excellent, with the business delivering parts for minor issues quickly and effectively.

“I haven’t had many problems with the loader, but when there’s been one, I’ve received parts instantly, I can’t fault their service,” Vecchio-Ruggeri says.

Having been left so impressed with his experience using the Godzilla loader and the service provided, Vecchio-Ruggeri says he’s considering buying more machinery from Digger King to enlist on his farm.

“I’m thinking about getting another Godzilla loader, but a bigger one around 160 or 180 horsepower,” he says.

“The extra horsepower would be good to have, because it’s better to have too much rather than not enough.”

For more information on Digger King’s Godzilla 3000w wheel loader, visit diggerking.com.au or call 1300 676 996.

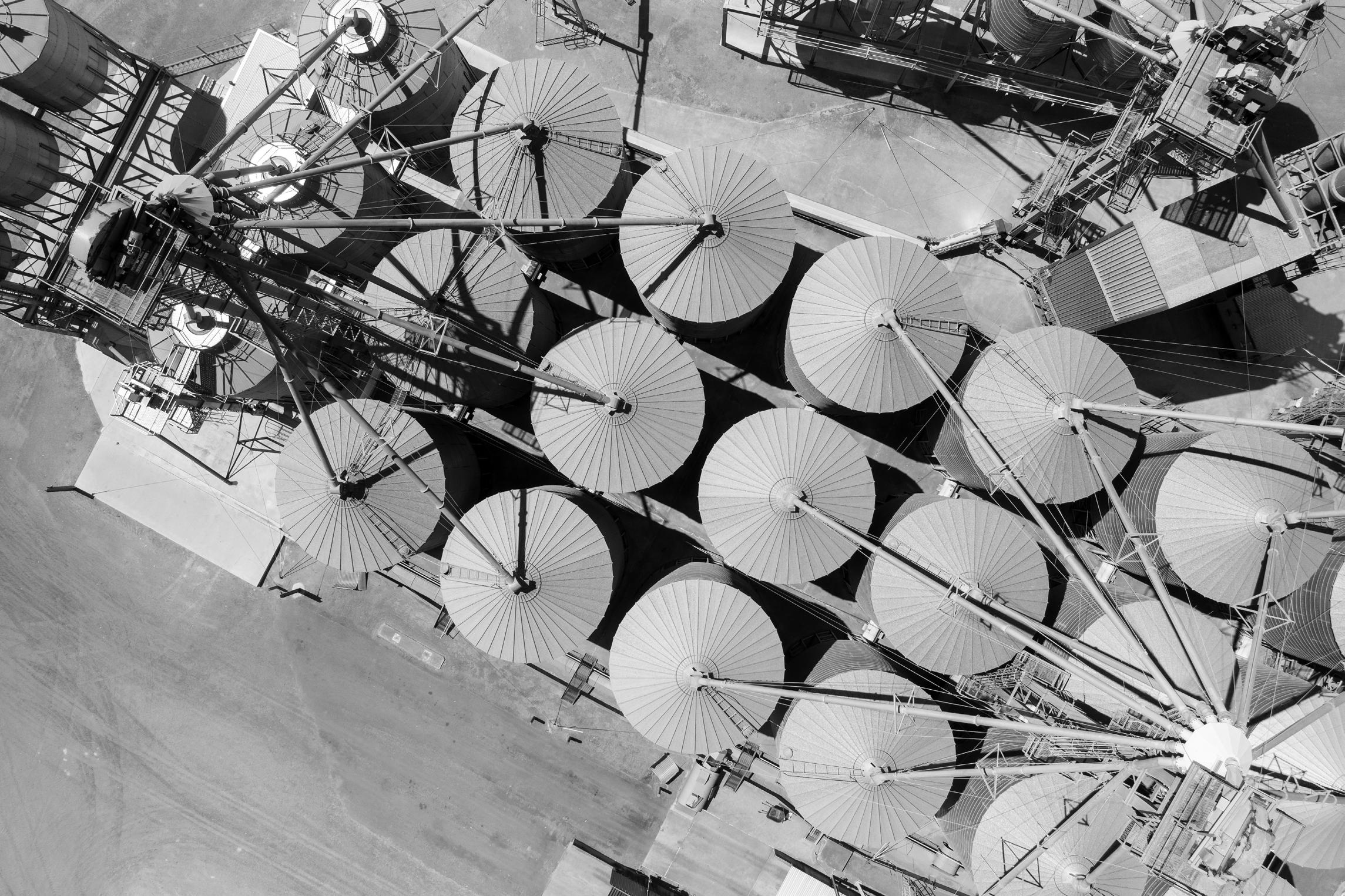

As the only state-based group on the Tractor & Machinery Association board, the Farm Machinery Industry Association of Western Australia sees plenty of value in national representation

The varying nature of Australian agriculture, where different farming regions have their own climates and challenges, can often create a localised approach to problem solving.

One state-based organisation – the Farm Machinery Industry Association of Western Australia (FMIA) – was formed to provide a unified representative body for its home state.

While much of what FMIA deals with is related to Western Australian matters, the association is also aware that many issues impacting its members also have national relevance.

It is for this reason that FMIA is a proud member of the Tractor & Machinery Association of Australia and sees the benefit of the broader representation which the machinery industry’s national body can provide.

“For things that affect us on a national basis, we get representation through the TMA and it’s giving a voice to WA dealers on a national basis,” FMIA executive officer Ken Brown says.

“We represent the interests of the dealer network and also the West Australian regional manufacturers.

“We’re the only state dealer representative at the TMA. None of the other states have a body similar to ours, so it does then give us a door into the national scene as opposed just to WA.”

Its geographical location can often mean Western Australia is overlooked on national matters, making its voice within the TMA an important one.

The man responsible for instigating the partnership is John Henchy, who was Brown’s predecessor as FMIA executive officer.

Henchy, who passed away in 2023, spent much of his career working in management roles at John Deere and saw the value of Western Australia’s interests being represented nationally.

Brown says Henchy initially approached the TMA about the FMIA having a seat on its board, something

which he personally held for several years.

Brown, who continues the legacy by sitting on the TMA board, praised Henchy’s work in establishing the representation.

“John was an amazing stalwart of the industry and he had contacts right throughout every part of the industry and outside the industry,” he says.

The Tractor & Machinery Association of Australia was established more than 70 years ago “to represent the interests and development of importers, manufacturers and sellers of agricultural tractors and machinery in Australia”.

It describes itself as providing “one voice for the industry on issues relating to government regulation and legislation, occupational health and safety, industry training and development and market sales statistics for the industry and its members.”

The TMA has a substantial and varied

Image: scharfsinn86/stock.adobe.com

member base, encompassing everything from multi-national corporations to rural-based engineering and manufacturing businesses.

This means the TMA provides a powerful and united voice that can engage with governments and other regulators – both nationally and statebased – to represent the industry’s needs on relevant issues.

Brown cited the introduction and evolution of autonomous vehicles as being one “major” issue which will need regulatory attention and representation from the TMA.

“A major issue relates to autonomous vehicles, in terms of a code of practice,” he says.

“Nothing really exists yet and we can’t seem to get any traction with the WA government on this, yet it’s an issue that needs to be addressed.

“There will be situations where accidents will happen and the question will be about who’s responsible and what things are in place to help prevent this.

“If there’s not something in place, it’s going to impede the progress or rollout of these autonomous vehicles because people will get a bit nervous about what happens in these situations.”

Another ongoing issue which Brown has highlighted the TMA’s work on – and

which recent progress was made on –relates to right to repair.

“The TMA has got a much more powerful voice on this issue and it’s something that affects dealers everywhere in the state,”

Brown says.

“The fact they’ve been able to indirectly battle on our behalf has been quite beneficial.”

Brown sees plenty of value for FMIA members in TMA involvement, as some issues which impact major multi-national manufacturers also affect local dealers.

“At the end of the day, there are a lot of similarities in interests between dealers and OEMs as well,” he says.

“For example, right to repair impacts on OEMs and it impacts on the local dealership.

“The TMA does represent things from a national point of view.

“Sometimes it’s relevant just to stick to state issues, but there are also a lot of national issues that the TMA can help dealers with.”

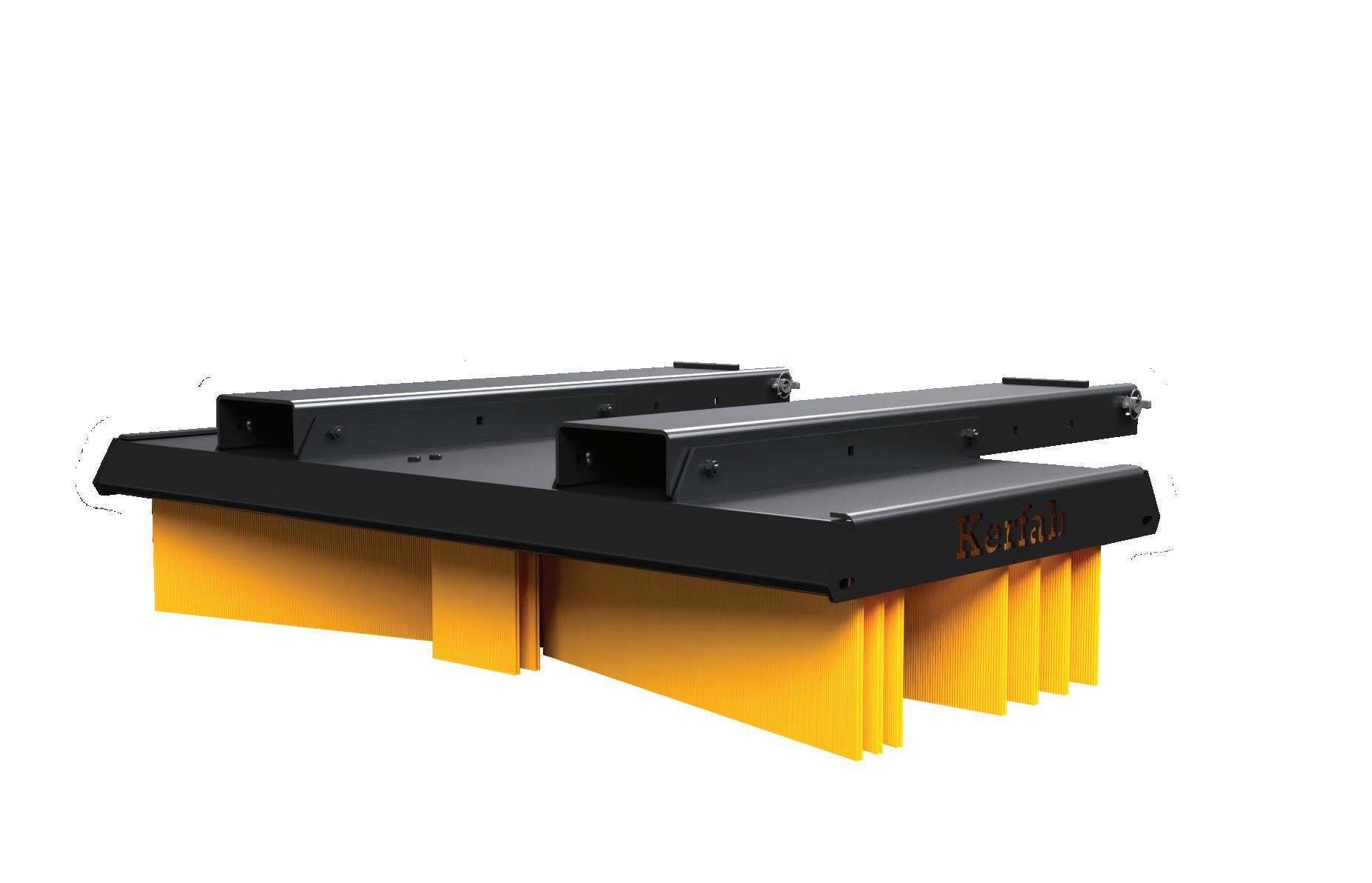

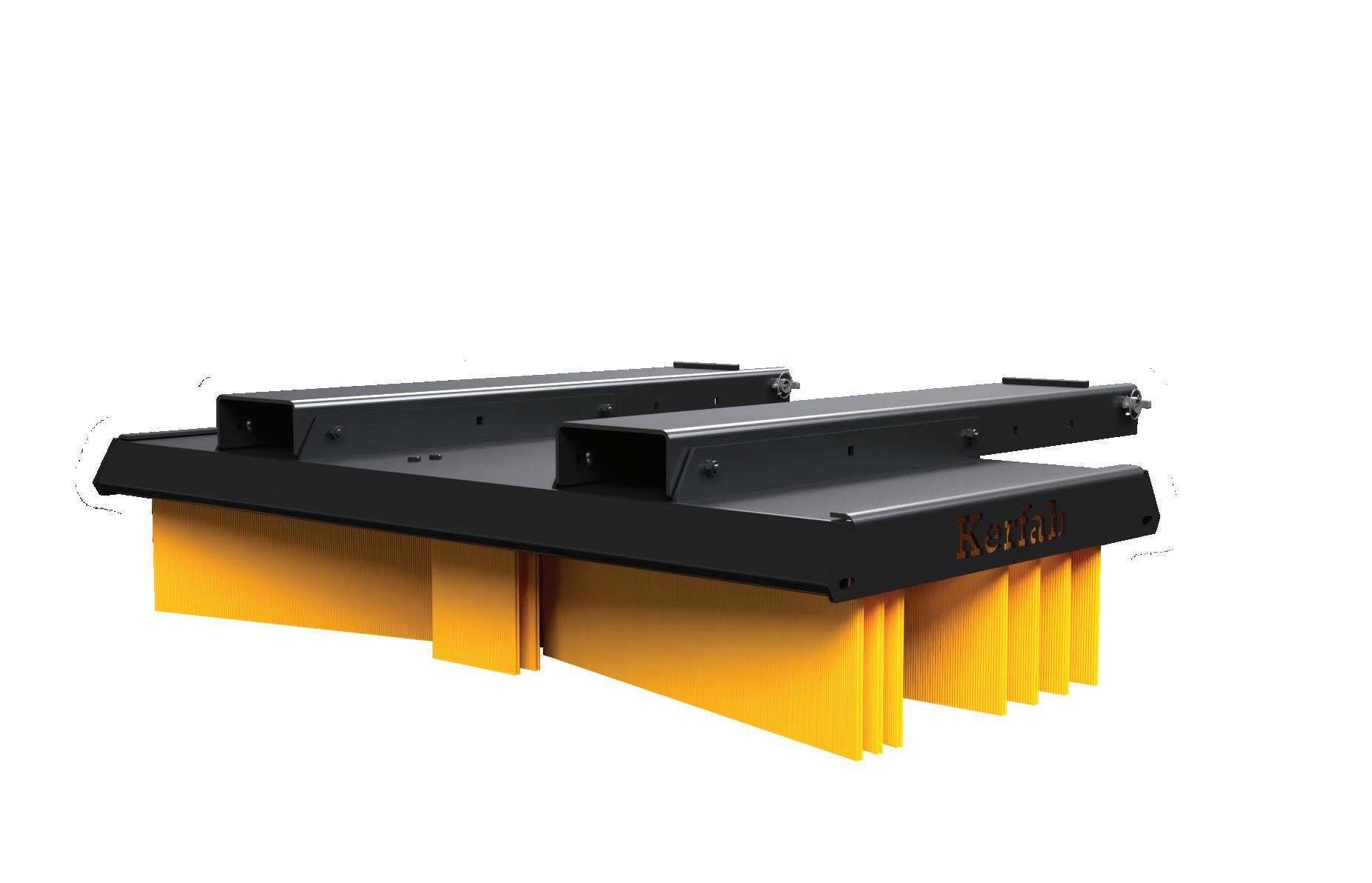

Kerfab’s K-Broom makes light work of cleaning up everything from grain to silage

Clean-up jobs might not be the most exciting part of a farmer’s routine, which only increases the desire to get these done as quickly and efficiently as possible.

Attachments manufacturer Kerfab has a solution to this tedium thanks to its K-Broom – a new and improved version of an earlier product which has been cleverly designed for maximum sweeping efficiency.

At the heart of Kerfab’s K-Broom is its seven full rows of polypropylene bristles. Its unique design eliminates side spillage, resulting in a more efficient

sweeping action and boosting overall productivity.

The secret to this is the bristle arrangement, where multiple straight rows of bristles are placed at the rear of the K-Broom with three angled rows at the front.

This configuration helps to ensure materials collection are kept at the front of the broom and therefore reducing the number of passes needed to thoroughly clean an area.

Having this unique design also improves the performance when

the K-Broom is working in tricky environments such as walls, curbs or places where other obstacles are present.

While the K-Broom can be used across multiple industries such as civil construction and waste, it has been designed with agriculture at the forefront. It is compatible with popular farming machines such as tractors, telehandlers and forklifts and various hitch types can be fitted to suit whichever make and model is required.

Fork pockets allow farmers to simply slide the broom onto their pallet fork tines and lock the K-Broom into place with two pins.

Kerfab says the K-Broom can “get rid of mould, clear grain, bark, gravel, sand, compost, silage, timber, metal recycling materials, aggregates and almost any other small loose materials in one clean sweep”, making it a one-stop shop for the often-tedious task of cleaning up these materials on a farm.

It also carries the benefit of reducing manual labour in a farming environment where this can be at a premium, something which is further bolstered by a low maintenance design where users can simply clean the brushes and rinse them off once the job is finished.

Having multiple rows of brushes means the K-Broom can easily adapt to all types of soil and terrain, making it the ideal machine for use in all of Australia’s harsh and varied agricultural environments.

Kerfab’s K-Broom is ideal for agricultural use

Victorian town of Kerang and this means farmers can be assured the K-Broom –along with all Kerfab attachments – are designed to handle local conditions with ease.

The K-Broom’s sturdy frame design is manufactured from thick folder steel to ensure it has optimal strength and durability.

High density and premium quality are features of the brushes, which can also be easily replaced when worn.

Replacing the brushes is described as “rare” by Kerfab though, as they boast an impressive lifespan by being rated for use over 1,000km.

This strength and durability are also shown by the fact the K-Broom does not need to be hung up for storage either.

It can simply be set in the corner of a workshop or shed on its brushes, which are strong enough to support the entire weight.

Versatility is shown through the range of size options available, with various K-Broom models providing working widths between 1.52m and 3.65m.

A two-year warranty also provides peace of mind for buyers, along with the after-sales support provided by dealing with an Australian company.

Kerfab’s head office and manufacturing facility in Kerang is complemented by a warehouse in Perth and office in Warwick,

Queensland, giving the company a strong national footprint and ensuring farmers are well supported.

The K-Broom is available through Kerfab’s national dealer network and can be viewed online at www.kerfab.com.au

September 2026

EXHIBIT IN 2026. BE SEEN. BE HEARD. BE CHOSEN.

Buying a second JCB telehandler was a no-brainer for one New South Wales farmer thanks to the proven performance of his first unit

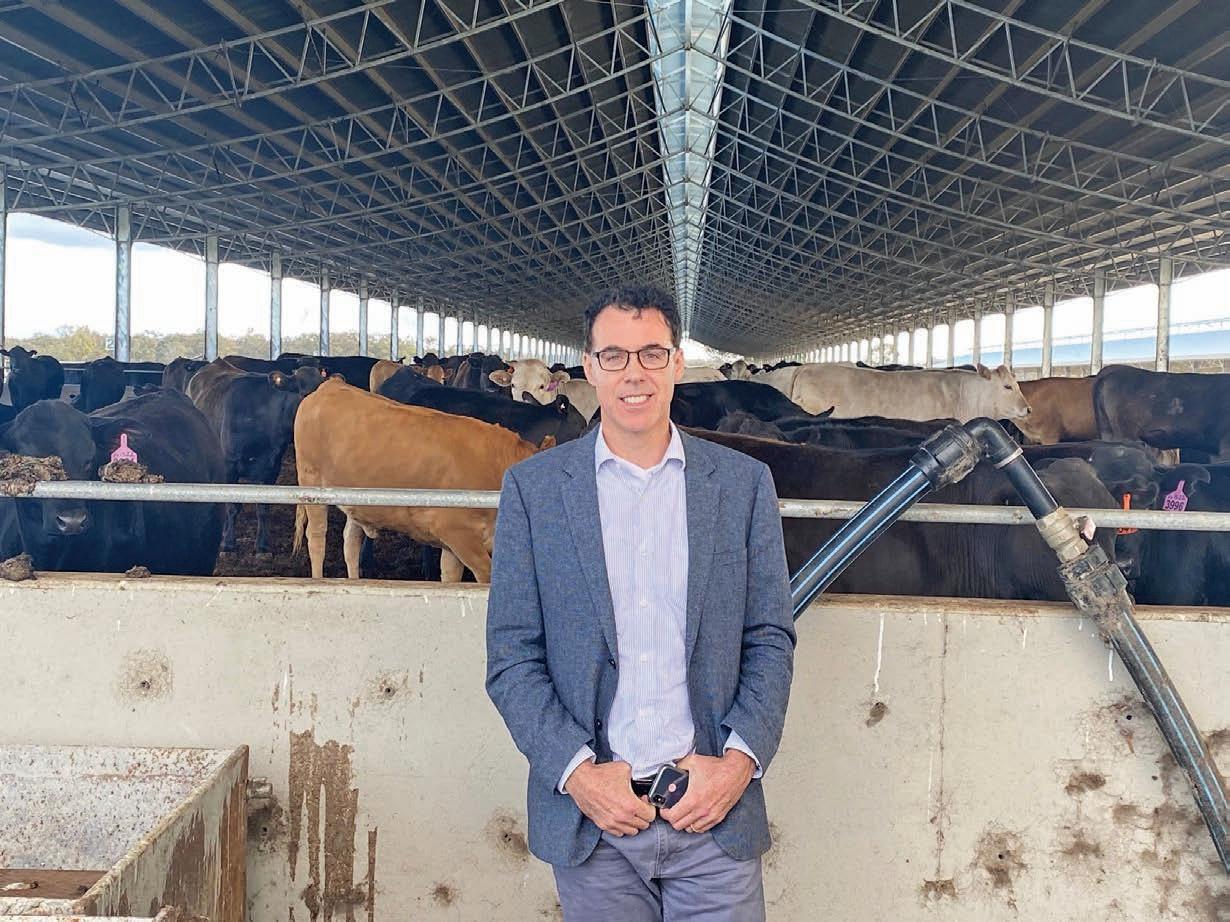

Chris Maslen admits he has worked his telehandlers hard.

He was so impressed with the performance of his JCB machine, which has racked up about 9,500 hours of work during its lifetime, that returning to the same brand for his next telehandler was an easy decision.

Based on the mid-north coast of New South Wales, Maslen is a dairy farmer and this means the daily work for the machines is demanding.

“We’re milking 850 cows and probably feeding close to 1,000 a day, so its main job is dealing with square bales and also pit silage and bunker silage,” he says.

“It’s probably feeding 10 or 15 bales a day out, plus loading about 10 tonnes of corn silage a day.”

Maslen’s first telehandler purchase was a JCB 550-80, a model which has now been superseded by the 560-80 in JCB’s range.

The success of this as a farm workhorse made him confident in sticking with JCB,

where he recently opted for a 542-70 Agri Pro to complement rather than directly replace the older model.

The 542-70 is a slightly smaller model, which Maslen says was a conscious decision, and he has opted for the top-ofthe-line Agri Pro configuration to ensure he has maximum access to the new telehandler’s available features.

“The reason we went back a size is probably because it’s a bit more versatile for all the applications,” he says.

“The big one’s great for material handling, but when it comes to doing work around the sheds, it’s sometimes a bit too big and cumbersome.”

Having two telehandlers of different sizes gives additional versatility to his operation and he is full of praise for the work which the older 550-80 has done over many years.

“I’d hate to even contemplate how much it’s moved, because it’s got about 9,500 hours on it,” he says.

“Apart from a few little things, and even then JCB have been honourable with any

warranty issues, but honestly the machine has done a power of work and if it was a dud I would have sold the thing –but it’s not.

“As our farm and our enterprise has grown, it’s great to have an extra machine parked somewhere just to do some work, even if it’s only doing an hour a day.”

Maslen’s new telehandler – the JCB 542-70 – gives operators a 4,000kg maximum lift capacity and 7m maximum lift height.

Its various configurations, from the standard Agri fit out to the Agri Pro, mean multiple engine capacities are available and Maslen’s machine offers 145hp (108kW).

One of the Agri Pro’s particular highlights is what JCB describes as “the world’s first and only” two-in-one transmission which combines “the superior high-speed efficiency and towing ability of a JCB Powershift transmission with the low-speed control advantages of hydrostatic drive.”

This DualTech VT has been specifically designed for the agricultural sector and offers a fully automatic transmission from 0 to 40km/h, harnessing the automatic changeover from hydrostatic to Powershift.

It automatically switches from 4WD to 2WD at speeds above 19km/h, and vice versa when moving to lower speeds, helping to provide optimum efficiency and grip.

Maslen describes the improved cycle times as being one of the highlights of his newer telehandler compared to the older one, something which he attributes to the DualTech VT.

“Having a hydrostatic in the first three gears and then the last three gears being a Powershift means you’ve got the luxury of both,” he says.

“When you’re driving something with a

Powershift over the hydrostatic, there’s a significant improvement.

“When you’re doing loader work, all you do is back off the accelerator and the machine slows down.

“That’s where it’s improved the cycle time around doing the work.”

The other major area which Maslen highlights on the 542-70 telehandler is its CommandPlus cabin, describing it as another noticeable difference.

“The cabin comfort has improved and visibility has too because they’ve got seamless glass right through above your head,” he says.

JCB says this seamless one-piece, multi curved glazing increases front visibility by 14 per cent, while also providing exceptional upward visibility when operating overhead and also beyond the dashboard when switching attachments.

The cabin also boasts an increase in airflow performance along with significantly quicker defrost time for cold mornings.

Cabin noise is also markedly reduced, while the Agri Pro configuration also includes options of a half leather heated and ventilated air suspension seat with seat-mounted control pod, along with optional 360-degree LED worklight package that includes the boom and hitch.

These are not the only aspects which Maslen praises though, with its overall functionality contributing to daily success when using the 542-70.

“The boom ride is significantly better, and they’re zippier on the road, which means you don’t muck about when getting from A to B,” he says.

“It had to be factory fitted, but I’ve put

a hydraulic rear hitch and breakaways on it which has made the machine significantly more productive just from a staff perspective.”

Proven tough

Purchasing a telehandler is a significant investment for any farmer, and for Maslen it was the “old fashioned” opportunity to test one out that initially inspired his JCB purchase.

“They had an open day at Wagga where you could get in and have a play and I went down and bought one from that open day,” he says.

Its strength makes it ideal for lifting hay bales

“I knew JCB telehandlers had a good reputation but that was the deal clincher, because you don’t really get the handling capability of a machine until you can actually be a bit old-fashioned and have a bit of a dig with it.”

Maslen’s experience since that initial purchase showcases the durability of JCB telehandlers, having worked successfully for nearly 10,000 hours and counting.

Further illustrating his point is the story he tells of a friend who also owns JCB telehandlers, which have also

excelled despite being worked even harder than his own.

“I’ve got a mate of mine who’s got a couple of them and what it’s putting up with, compared to what I do with ours, shows they are good machines.

“If the JCB can put up with the rough farmers, and you look after it, then it will be seamless for the rest of its days.”

The full JCB telehandler range can be viewed online at www.jcbcea.com.au

Australia’s No1 locally built mulcher for the last 25 years. Available in Low Body or High Body models in various sizes. Great for clearing up paddocks and bush blocks.

The best value for money Front End Loader mounted post hole digger on the market. Standard with Eurohitch connection with other styles available. Various augers sizes and types available

Large range of linkage and trailing disc ploughs to suit all tractors and applications.

Aerate and level your arena with this strong and versatile arena rake. Can be used for cultivation or grooming.

Australian Made slashers with 5 year gearbox warranty. Various sizes and models in single and twin rotor set-up. Great value and strength. Also available in galvanised.

10 ‘ & 12’ Trailing Grader Blades. 2000kg in weight Best value for money blade of its type

Huge range of linkage models available also.

Making the difficult choice to transition from dairy into a new sector, family-owned and operated Longridge Olives has become olive-growing experts, with innovation always front-of-mind

What once stood as a sheep and cropping farm in South Australia’s Coonalpyn has been transformed into a successful olive growing operation at the hands of Jim and Lisa Rowntree – founders of Longridge Olives.

Now joined by their two sons Lachlan and Harrison and their partners, the business produces premium extra virgin olive oil, with all olives grown, picked and crushed across 114 hectares.

The success of the business is even more impressive given their background lies within the dairy sector, as Jim and his brother owned a farm in the early 1990s in Myponga, on the Fleurieu Peninsula.

Harrison says his father has always focused on automation and efficiency but found dairying wearying, spending all his time out in the field and not with his young family.

“The cows had to be milked twice a day, so dad had dreams of robotic dairies,” Harrison says.

“He was looking into some of the technology that was being used in

America, but he didn’t have the capital at the time to push for it.”

Wanting another farm for when the cows weren’t milking, Jim and Lisa purchased a sheep and cropping operation, which would eventually become the Longridge Olives farm.

However, Harrison says the lack of rainfall on the Coonalpyn property compared to what his parents were used to on the Fleurieu Peninsula, meant it was a challenge to grow anything consistently.

“They wanted to know what they could grow in their climate with the bore water they had and what could be mechanised,” he says.

“Olives stood out as something that would grow well, and it fit the bill.”

Leaving the dairy operation completely to explore this new venture, Jim and Lisa transformed the sheep and cropping farm, planting their first olive trees in 1998.

After deciding on olives, they travelled to Israel to learn about a new variety that

was suited to sandy conditions and to look at the different types of drip irrigation used to grow olives in a harsh desert-like climate compared to the non-irrigated European conditions.

As the only olive growers in their region, they set about learning as much as they could from as many people they could, through trips interstate and overseas, as well as from books.

Harrison says his parents knew they would be competing against Europe and that mechanical harvesting was going to be their own, and Australia’s, competitive edge on production and quality.

“Hand harvesting is slow, and by the time the olives get back to the mill, they aren’t as fresh, often compromising the olive oil’s quality,” Harrison says.

It’s why Longridge Olives has mechanised this process, ensuring it produces the best possible product, while also eliminating the cost of manual labour.

Understanding the challenges of competing against imported mislabelled

product, Jim and Lisa vigorously campaigned for the accurate labelling of olive oil in Australia, which Harrison says was a significant issue for consumers.

“In the early 2000s, the importers of olive oil in Australia were bringing in a lot of olive oil that had misleading labels,” he says.

“You would see options in the supermarkets labelled pure olive oil and light olive oil, but it didn’t really mean anything to the customer. It was generally cheaper compared to Australian olive oil, so customers would choose these products, even though they weren’t the same quality as Australian extra virgin options.”

Lisa was the first CEO of the newly formed Australian Olive Association and campaigned for the industry to get rid of these misleading labels, working with Cobram Estate and other industry leaders to develop the highest quality standard for olive oil that is being adopted in countries all around the world.

“The three labels you’ll see now are virgin, extra virgin, and refined olive oil, and it can only be classified as these if it’s been tested based on Australian standards,” Harrison says.

“It’s much easier for customers now to get high quality extra virgin options, whereas it wasn’t so clear before, customers weren’t getting what they were paying for.”

Harvester autosteer

After Harrison finished university, he returned to the farm, working alongside his parents and his brother Lachlan to transform the old sheep shearing shed into the business’ own olive mill.

By doing so, Longridge Olives no longer needed to send olives to be milled externally – eliminating one of the business’ most significant costs.

While he never imagined living and working on the farm, Harrison says this family teamwork swayed his thinking, convincing him to stay on full-time.

Building the olive mill was also the business’ first step towards complete vertical integration, in which every part of its supply chain is in-house.

Harvesting is completed by Longridge Olives with its own equipment, and the olive mill means no third party is involved in producing any of the

business’ products.

With Jim’s automation and efficiency focus, a philosophy on how to improve productivity has always been at the forefront of everything Longridge Olives does.

One of his innovations which has significantly changed the harvest process

on-farm is Longridge Olives’ homebuilt autosteer system, which has been implemented on its harvesters.

“That was one of dad’s early creations, which came out of his frustration of manually operating the harvester,” Harrison says.

“As he’d bash through the trees, the sensor bars would originally light up to tell him to steer towards the lights to get pressure off the sensor bar.

“He thought if it can tell you how far you are from hitting a tree, why can’t it just steer itself instead. It’s very simple in the way he’s mechanically built it – there’s no computer, it’s just relay logic, and because it’s so simple, it’s so robust.”

By enabling the harvester to steer itself, Longridge Olives has reduced the chance of human error and given drivers more attention-to-detail, leading to huge productivity gains with an increase in olives being caught and less downtime due to broken harvesters and trees.

The driver experience has also been made much more comfortable, by lessening the manual intervention required, which has reduced fatigue.

“Drivers spend a lot of time out there, sometimes 10-12 hours, and you don’t want to be actively driving the harvester for that long, so we try and make the machines as comfortable as possible, so they can watch the harvest happen,” Harrison says.

“They can now drive for longer hours because they don’t have to constantly watch if the harvester is driving straight – they’re free to give more attention to other things like looking at the cameras, watching that nothing is jamming, or making sure things aren’t getting broken.

“There’s internet in the tractors so the drivers can sit happily watching movies or YouTube while catching olives – that’s the way we like to do it.”

Since Lachlan and Harrison have joined the business, many new productivity enhancement ideas have come to fruition, leading to Longridge Olives now having the ability to closely monitor irrigation line issues.

This idea was developed after noticing a valve controller stopped reporting the temperature during hot days in the summer.

“In the summertime the valve controller would get too hot, even sitting in the shade, causing it to shut down and close all the valves, so the bore water was bypassing some of the trees,” he says.

“This was a big issue because the only

telemetry in the original system was flow out of the pump.

“You would hope the water was on the trees but you couldn’t know without manually checking.”

To fix this, Longridge Olives replaced the entire irrigation control system with one of their own using Arduinos and cheap H-bridge drivers, put a flow sensor on the bypass valve and a pressure sensor on the main line, so the business would be notified if one of the valves wasn’t open and the water was bypassing.

Harrison then created a dashboard to collate all the reported data into one easyto-view setting.

“I’ve got all these thresholds for pressure and flows and if anything’s out of spec, it just alerts me, and you can click on it and see exactly what’s going on,” Harrison says.

“Instead of having to go out and visually observe what’s happening, you can look at it on the dashboard.”

By implementing these well thought out solutions, Longridge Olives is spending less time worrying about irrigation and more focusing on its productivity.

Looking ahead, there are no plans to slow down. Longridge Olives hopes to continue to expand with new equipment and a fox proof fence, and with the

Vin Rowe Farm Machinery is excited by the opportunities which Ferrari Growtech’s Futura automatic transplanter will present to customers

Simply hearing the name Ferrari automatically conjures up images of high quality and performance.

In the agricultural world, the Ferrari Growtech Futura automatic transplanter combines innovation and technology to become a high-quality machine which opens up new opportunities for the horticulture industry.

At its essence, the Futura is an automated transplanter designed to make the planting of vegetables easy and painless.

The reason for its uniqueness – and the reason why Victorian-based Vin Rowe Farm Machinery is so excited to be the distributor of it – is for the number of features and customisation options that make it perfectly suited to a range of grower types.

It can work with vegetables stored in trays of different sizes and with materials such as hard plastic, foam and disposable containers.

The manufacturer says it is perfect for vegetables such as tomatoes, celery and fennel along with others that have similar leaves between 10cm and 30cm in height.

It offers a working capacity of up to 8,000 plants per hour for each row, making it ideal for major farming operations, while

The only manual requirement is feeding trays to the transplanter robots

there is also a high tolerance for different soil types.

Ferrari Growtech says this working capacity per hour is dependent on the quality and completeness of the tray, along with the plant itself.

Vin Rowe Farm Machinery first showcased the Futura at last year’s Hort Connections event in Brisbane.

Owner Graham Rowe says this created the most interest he has ever seen in a

He believes the potential labour cost savings for growers, and the quick time to see a return on investment for major growers compared to relying on manual labour, are the reasons why it has created so much interest.

What makes the Futura stand out in a technical sense are the opportunities it presents through its automated nature.

Working by itself, the Futura only requires one operator to feed the trays to the transplanter robots.

Its adaptability to different trays means there is no need to use a specific tray to run the machine, as it will adjust to the tray selected by the user.

Every robot extracts the seedlings using a technology based on cylindrical plungers combined with moving fingers, the manufacturer says.

Each element of the machine is provided with a system, which automatically pulls out plants of the same row from the longer side of the tray.

From there, the plants will be grabbed by mobile pliers which will place them in the dispenser.

Ferrari Growtech says one of the features which makes Futura an innovative machine is the fact growers can carry out transplant operations without changing the type of panel in their possession, as the transplanter can be set in relation to the preferred panel.

There is also an electric eyes device for control and elimination of the missing plant from the tray to the transplant, with a selecting system kicking into action before dropping the plant into the cup.

Futura works best with tractors between 70-200hp depending on the configuration chosen, giving growers a wide range of options to suit their needs.

The Futura and Futura Twin versions available include self-propelled, three-point hitch, draw bar, and back steering wheels.

Wheel track is between 120cm and 225cm, again depending on the configuration, while the minimum row spacing is 70cm.

A Futura Twin model is also available, which doubles the number of rows and therefore halves the spacing between them.

Distance in the row is very customisable, with options available every 2cm between 6cm and 99cm.

Its rear pressing wheels are adjustable, while there is left-right oleo-dynamic balancing to make transplanting easy.

For this reason, Ferrari Growtech says the Futura is able to work on flat ground as much as on raised beds, along with grounds which have already been fertilised.

Other important features of the Futura transplanter are hydraulic transmission, a rubber roller with adjustable pressure, hydraulic adjustment of the back pressing wheel, along with electric depth adjustment.

The Ferrari Growtech Futura automated transplanter is available through Vin Rowe Farm Machinery and can be viewed online at www.vinrowe.com.au

Antonio Carraro’s TRX 9900 tractor is a shining example of versatility, bringing together plenty of the manufacturer’s standout features into one machine

Italian tractor manufacturer Antonio Carraro has always dared to be different.

Across its suite of orchard-focused tractors that are tailored to the unique requirements of that sector, one particular model combines many of its major selling points.

The TRX 9900 is a 90hp tractor and that power places it at the higher end of the brand’s offering.

It is also part of the TRX range, which is Antonio Carraro’s most popular model in the Australian market.

The extensive list of features helps to explain its popularity.

The TRX model is an acronym, with the letters representing its steering front axle (T), reversible console (R) and equal size wheels front and rear (X).

Its reversible console is something which Antonio Carraro has become known for across several of its tractors and is one of its most unique and impressive features.

It means the steering and driving position can be turned around 180 degrees by simply rotating a turret.

This game-changing feature allows for operators to work with rear-mounted implements while having the same vision and operating function as they would with front-mounted ones.

Having the equal sized front and rear wheels also helps the tractor’s stability while the steering position is reversed, while 16 forward and 16 reverse gears provide a high level of functionality in both driving positions.

Stability is another of the TRX 9900’s major selling features.

This tractor includes Antonio Carraro’s patented Actio chassis, where the front and rear axles oscillate independently up to 15 degrees.

This makes the tractor crawl over uneven ground and operates in constant 4WD, something which makes the tractor capable of handling up to 33 degrees

of incline without overturning when stopped either uphill or downhill in a longitudinal position, and up to 38 degrees when stopped on an incline.

While reversible driving and an exceptional level of stability are features which multiple of Antonio Carraro’s tractors can offer, the TRX 9900 goes above and beyond.

In addition to the 90hp engine, it provides a 2,400kg lift capacity that showcases its strength and working capacity.

Other features include two doubleacting hydraulic distributors – one of which has a floating position – and one oil reflow, making five rear couplings in total, plus adjustable three-point linkage arms.

Its brake system comprises of four adjustment-free hydraulically operated oil-bath disc brakes, which Antonio Carraro says guarantees modularity

during the sharpest braking and reliability even with the front-wheel drive disengaged.

Electrohydraulic differential lock for either the rear axle or simultaneous use on both is another feature which prevents wheel slip and maintains traction.

The TRX 9900 is available with the choice of a fully enclosed cabin or rollbar.

One cabin option is the StarLight cabin, which is equipped with front and rear windscreens plus a double sunroof to provide total visibility.

Its smooth design retains functionality and its compactness allows for agile operation in the narrowest of spaces without damaging crops.

Depending on tyre settings, the TRX 9900 can still measure under 1.4m wide and less than 2.2m high, providing a compact unit that still offers plenty of power.

All rounder

Antonio Carraro Australia sales manager Marco Corra says its versatility is highlighted by the number of farmers who have customised this tractor to their own unique requirements.

“The reversibility of the driving console

Local manufacturing plays a vital role in the tractor and machinery industry, contributing innovation, jobs, and economic value to regional communities.

Yet, our manufacturers face challenges that require a united, strategic approach.

By joining the TMA, you’re not just becoming a member, you’re adding your voice to a powerful group working to secure the future of Australian machinery manufacturing.

and the power at the PTO, in such a compact tractor, have made it the go-to for operations like fencing, harvesting and drilling,” he says.

This means while it is an excellent tractor for orchard and horticulture uses – with one New South Wales dealer describing it as the “pinnacle” for macadamia farmers – it also has considerable broad appeal beyond just that sector.

Corra says these jobs like fencing and drilling make it ideal for larger farms with open paddocks as a general-purpose tractor, while its low centre of gravity, tight turning radius and short wheelbase make it capable of handling challenging and uneven terrain.

One operator putting it to a different use is Mark Campbell, who uses the tractor for installing power poles in New South Wales.

He cites the compact nature of the two Antonio Carraro tractors they run as being a major benefit.

“Being small is the biggest thing, but they’re fairly lightweight and fast with

everything you need on it,” he says.

“Everything’s pretty simple on them which just makes life easy, but the compactness is what gets us – we could use just about any machine to do the job,

but nothing’s quite as compact.

“They’re just a good all round tractor.”

The TRX 9900 can be viewed online at www.antoniocarraro.it/au

Reversible driving effectively turns rear implements into front mounted ones

Built for quality and longevity, Alliance tyres promise to stand by Australian farmers for season after season

When it comes to their machinery tyres, Alliance knows that Australian farmers value performance and reliability.

Australia’s landscape includes a wide variety of soil types and ground conditions – and a farmer’s life can involve working multiple machines in different environments – making the choice of tyre both a challenging and critical one.

Alliance can take the challenge out of this critical decision by offering products which are designed for every stage of the agricultural cycle.

Its promise of “one range, every stage” means Australian farmers can have peace of mind in their purchase, knowing the tyres are built to perform under the pressure of local conditions.

Star performer

The hero of Alliance’s tyre lineup is its Agristar II.

Available in more than 80 sizes, it has been a proven choice for customers around the world, including Australia. The company recently marked a

significant milestone of over 1 million Agristar II units having been sold globally – an achievement which has taken place in just five years.

Alliance says the Agristar II has become trusted around the world for its durability, traction, and performance in demanding harvest conditions, making it a reliable choice for high-horsepower tractors and harvesters.

Part of the reason for this suitability is the manufacturer’s unique Stratified Layer Technology which ensures consistent grip and wear across varied terrain.

This technology is a dual-layered lug design which features a multi-angle profile on the bottom layer and a single angle profile on the top layer.

Working together, these two distinctive lug profiles help to prolong traction and enhance roadability of the tyres and these profiles are complemented by polyester casing construction that ensures dimensional stability and heat resistance.

Australian farmers put their tyres

Alliance tyres are proven performers in these environments, which is why they can be found as original equipment on leading harvesters, tractors and appliances from global manufacturers.

Alliance’s range also includes flotation and very high flexion tyres, showcasing the depth of product and ability to cater to all farming equipment.

Advanced tread technology on Alliance tyres helps to deliver grip, flotation, and fuel efficiency during peak harvest operations.

to the test in some of the world’s most demanding conditions, especially at harvest time.

Their tread designs promote selfcleaning and consistent traction, even in sticky or uneven terrain, helping to prove their ability to handle a wide range of field environments and terrain types.

Reinforced sidewalls and stubbleresistant compounds help extend tyre life through the toughest harvest cycles.

Offering what Alliance says are more distinct features than any other brand in the same class, these are feature-packed tyres which are designed to be durable and provide high performance.

Competitive pricing delivers the premium performance required without the premium price tag.

Alliance also trusts in the longevity of its products, offering up to 10 years of warranty coverage on workmanship and materials. Field hazard and stubble damage protection is offered for up to five years (conditions apply) and all tyres are supported by a strong national dealer network that provides fast service and support.

Alliance tyres are available nationwide through local dealerships.

South Australian farmer John Cummins has relied on Rocky River Ag Services for his equipment needs for more than three decades, with the long-standing relationship continuing to grow

Having a trusted and reliable machinery supplier is key for any farmer. It eliminates the time taken to track down parts, equipment, or servicing when machinery unexpectedly fails, and the hassle of searching for new support.

When your supplier is local it makes even more of a difference, reducing delivery times, which in turn minimises costly downtime.

South Australian farmer John Cummins has seen these benefits to his cropping and sheep operation – named Woolacoola – thanks to having a more than 30-year relationship with Rocky River Ag Services.

The family farm consists of John and his wife Sally, as well as their two sons Joseph and Louis, with the operation making use of around 2,000 hectares to grow wheat, barley, and lentils, and a

from them.”

It all started when John was looking for a new tractor and seeder, with Rocky River Ag’s past dealer principal Rob Dingle presenting him with an impressive offer.

The decision was made easier since Rocky River Ag’s dealership is based locally in Crystal Brook, which John says is ‘just up the road’ from his farm in Snowtown.

The rest is history, with Woolacoola being a loyal customer ever since, procuring several machines including Case IH Steiger and Puma tractors, Hardi sprayers, a Flexi-Coil 4460 air cart and soon-to-be a 5500 air drill.

John says all these brands stocked by Rocky River Ag are well-respected and have been suited to his needs.

“Hardi is a reputable brand and FlexiCoil is probably the biggest sole product in tillage machinery, so it is reliable because there’s always parts available,” he says.

“For us the tractors come down to price at the end of the day, and when I bought the Case IH models they were right for us.”

More than happy with the performance

equipment purchases.

“They know what they’re talking about, so they can tell me what would be suited to my farm or what might not be,” he says.

“Getting this honesty goes a long way when making these decisions.”

John has also been pleased with the aftersales service provided by Rocky River Ag.

“If Rocky River see you’re stuck, they’ll

the time with machinery, but they do their

involvement in the local community has been a significant factor as to why John continues to choose the equipment supplier for his on-farm needs.

Over the last three years, Rocky River Ag has made donations to the RFDS Outback Car Trek, a rally John participates in to raise money for the Royal Flying Doctor Service, which delivers primary healthcare and 24-hour emergency services for Australians in rural and remote areas.

The annual event requires participants to take on remote dirt road driving in older 2WD cars, with John being part of Team Cobber.

“Rocky River Ag are a very good company because they invest in the region, such as being the major sponsor of the Hart Field Days,” John says.

“They provide great community support, machinery aftersales support, and they have most of the equipment I need.”

For more information, visit rockyriverag.com.au

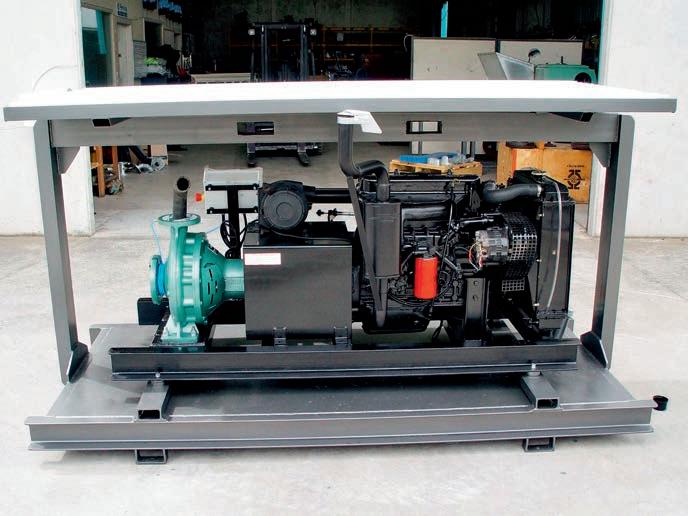

UPTO36"MININGPUMPS PUMP VXTE48791. TA206423. $14,510

PONTOONPUMP ELECTRIC Pontoonwithelectricpump. xzdef19652. TA206427. $14,910

PERKINSGENERATORS 6,8,10,13,15,20and30KVA generators,singleand 3-phase,poweredby water-cooledPerkinsheavy dutydieselengines,keyor remotestart,fueltankbase, fullengineprotection,500 hoursserviceintervalsIdeal backuporprimepowerCall foryourspecialprice!. AW54939-ST190912. DPLIn27583. POA

SOUTHERNCROSS100X65-315PUMPSET withNissanQD32(65hp),skidfueltank,oil-temp,hi/lo timerwatchdogandforkliftroof.Vel67912. TA11060. $13,750

PERKINSISOSILENCED PUMP NewPerkinsDieselIso Silencedpumpsetwithfuel tankbase..Perkisosilent1. TA223696. $26,000

GRUNDFOSVARIUOS PUMPS VariedModels.S1. TA250286. $4,500

UNKNOWNPTO GENERATOR 50KVA-ThreePhase-3 pointlinkagewithheavy dutyjackstands.VEL4156. TA10931. $8,710

It was a mixed bag for tractor sales in December, with Tractor & Machinery Association figures also providing a full-year reference point of 2025 compared to 2024

Small and mid-size tractors led the way in December with strong lifts in the under–40hp and 40–100hp ranges.

The smallest category was up by more than 26 per cent compared to December 2024, while the 40–100hp category was up by over 19 per cent in the same way.

It also meant the 40–100hp category recorded 1.5 per cent higher sales in 2025 than 2024, the only weight category to post such a figure.

Gary Northover is executive director of the Tractor & Machinery Association of Australia (TMA). He can be contacted on (03) 9813 8011 or at gary@tma.asn.au

Overall, there were around 1,000 tractors sold across Australia for December and this was 1 per cent ahead of the same month in 2024.

It takes the full year tally to just on 10,000 tractors, with this being 7 per cent behind 2024 and the lowest reported total in over 10 years.

While a lift in the small ranges was welcomed, this was offset by big declines in tractors greater than 100hp which resulted in a 28 per cent overall decline in dollar terms when compared to December 2024.

Across the states, Victoria had a 12 per cent sales increase in December 2025 when compared to December 2024.

Western Australia (1.6 per cent up) and

Northern Territory (9.3 per cent up) were the only areas to record more sales in 2025 than the previous year.

Reports of a record harvest leading to the likely achievement of the NFF’s $100 billion sales target set for the industry are encouraging indeed and dealers have played a big part in assisting farmers to achieve this.

Despite this good news, the TMA expects conditions to remain challenging into the early part of 2026 as headwinds remain in the form of interest rates, tariffs, exchange rates and commodity prices.

For other machinery types, annual sales of combine harvesters amounted to just on 700 units which was in line with 2024.

Balers were again strong in December, up 128 per cent on the same month last year which means they ended 14 per cent ahead for the year.

Sales of out-front mowers finished the year 20 per cent behind and sales of selfpropelled sprayers were down 36 per cent compared to last year.

It has also been announced that the 2026 TMA annual conference will be held in Sydney.

This will take place at the Novotel Brighton Beach on Wednesday July 29 and more details will be available on the TMA website.

To follow the TMA, visit www.tma.asn.au or connect via Facebook and LinkedIn.

Students must complete a four-year apprenticeship before becoming an ag technician. Image: andrew_ shots/stock.adobe.com

WAFarmers CEO Trevor Whittington says changes to the training system are needed to jump-start the next generation of ag technicians

If you want a competent technician who can diagnose a John Deere header that has ground to a stop, fault-find a CAN-bus issue on a Case tractor, or re-loom the electrics on a Claas baler, the Australian training system offers you exactly one answer: a four-year apprenticeship.

It does not matter how capable the kid is. It does not matter if they grew up rebuilding engines in the shed. It does not matter if they can learn in half the time.

Four years – sometimes five – through a registered employer.

For reasons nobody can clearly explain, there is no genuine private pathway that allows either local or international students to fast-track into skilled mechanical trades or encourages employers to take on apprentices who already arrive with serious skills.

This stands in stark contrast to the university sector, which happily recognises prior learning, accelerates progression and takes full fees for the privilege.

You have to ask why the same flexibility is unthinkable when it comes to skills that keep farms and workshops running.

In theory, Australia’s training system already acknowledges the truth.

A Certificate III in Heavy Commercial Vehicle Mechanical Technology or Mobile Plant Technology contains roughly 1,600 to 1,800 nominal hours of training. Delivered full-time, that equates to nine to 12 months of classroom and workshop instruction.

In practice, however, TAFE is barred from issuing a full trade outcome without an employer-based apprenticeship.

The same training is therefore stretched thinly over four years regardless of aptitude.

Australia formally recognises the skills can be taught in a year – minus experience – yet refuses to credential them unless the clock is allowed to run.

That is not competency-based training. It is time served, with a competency label stuck on the front.

At its core, Australia’s apprenticeship system is still built on the old guild model: master and servant, indentured labour, time served as a proxy for competence.

It made sense when tools were simple, machines were mechanical and labour was plentiful.

sensors, firmware updates and telematics. More and more, it is software.

We are told apprentices can be signed off early. Technically, yes, but in practice, everyone knows the truth: four years is the default, and anything less is an exception that requires goodwill, paperwork and a tolerance for regulatory risk.

Employers have little incentive to sign off early because early completion means an overnight jump in wages and the loss of subsidies.

Registered Training Organisations are conservative to the point of paralysis – early sign-off increases audit risk and administrative pain. Letting the clock run is safer.

This rigidity has real consequences. Four years on apprentice wages – often barely above the minimum – is a hard sell to bright, mechanically minded young Australians facing high rents, rising living costs and a housing market that punishes delay.

Many can earn more, sooner, in mining services, logistics, civil construction support roles or even gig work.

Governments lament that young people are “not choosing trades” but ignore the fact the system actively repels capable candidates by suppressing wages and delaying productivity.

Australia calls it training. Plenty of young people see it as four years of underpaid waiting while the property market explodes out of reach.

What makes the lag even more absurd is that modern ag and heavy diesel work is no longer dominated by spanners and grease.

Increasingly it is diagnostics, electronics,

AI-assisted diagnostics are already entering workshops and that will only accelerate.

Machines now self-report faults and require technicians who can interpret data, work with proprietary software tools, and diagnose issues that are electrical or digital as often as mechanical.

In this environment, deferring diagnostics and electronics training until the third or fourth year of an apprenticeship is backward. Skills need to be front-loaded, not drip-fed.

A system designed for mechanical simplicity is trying to train technicians for a world of code, connectivity and continuous updates.

What makes this more frustrating is that Australia has already proven a faster, intensive model can work.

During the Second World War, the apprenticeship system was set aside entirely.

Faced with existential threat, Australia trained aircraft mechanics in just 104 days –six days a week, 10 hours a day.

Once the war ended, four and five-year apprenticeships returned – and largely froze there.

That might have been defensible in the 1950s. It is indefensible in a globalised, capital-intensive economy.

Other countries quietly rebuilt their systems while Australia, by contrast, remains designed for the post-war workshop economy: surplus young labour, simple machines and rigid award structures.

We accept, even celebrate, a global market in professional education.

But suggest the same logic should apply to skills training – where a kid might pay for a fast, intensive mechanical qualification –and authorities panic.

Why is it acceptable to import and export doctors, lawyers and engineers, yet unthinkable to imagine a global market in training diesel technicians?

The irony is the market solution already exists offshore.

In the United States, Universal Technical Institute runs diesel and heavy equipment programs of about 45 weeks. In Canada, Assiniboine College offers a full heavy equipment technician program.

SAIT runs a 30-week diesel certificate designed for immediate workplace readiness. NAIT delivers industrial heavy equipment diplomas feeding directly into mining and agriculture.

These graduates are not theoretical mechanics. They work on real machines, diagnose real faults, and come out ready to earn real money.

They may not have four years’ experience – but they also have not

wasted two of those years doing low-value repetitive work.

John Deere, CNH and Agco operate worldwide. The machines are the same. The software is identical. Yet the time to competence varies enormously.

In Australia, trainees are forced through full Cert III pathways that take close to four years.

OEM training exists, but it is layered on top rather than replacing parts of the apprenticeship. Diagnostics and electronics are often delayed until late in the trade.