Address: 379 Docklands Drive, Docklands VIC 3008

Phone: 03 9690 8766

Email: editor@bigrigs.com.au

Web: bigrigs.com.au

Accounts: 03 9690 8766

Subscriptions: 03 9690 8766

Classifieds: 0403 626 353

Circulation and distribution

queries: 03 9690 8766 info@bigrigs.com.au

EDITOR

James Graham: 0478 546 462

james.graham@primecreative.com.au

SENIOR REPORTER

Danielle Gullaci 0478 844 797

danielle.gullaci@primecreative.com.au

DESIGN

Alejandro Molano – Art Director Daz Woolley – Art Director

GENERAL MANAGER

Peter Hockings: 0410 334 371

peter.hockings@primecreative.com.au

BUSINESS DEVELOPMENT

MANAGER

Treena Heit: 0403 626 353 treena.heit@primecreative.com.au

CLIENT SUCCESS MANAGER

Katharine Causer: 0423 055 787

katharine.causer@primecreative.com.au

CONTRIBUTORS

Truckin in the Topics/Spy on the Road: Alf Wilson, 0408 009 301

David Vile, Graham Harsant, Geoff Middleton and Jonathan Wallis.

Big Rigs National Road Transport Newspaper is published by Prime Creative Media. It is the largest circulated fortnightly truck publication in Australia with 22,248* copies per fortnight.

*Average circulation per issue in 2025

FAIRFIELD mayor Frank Carbone has sent a warning to illegal dumpers in his Sydney local government area that they will be prosecuted and fined if caught.

Carbone’s message comes after two drivers allegedly dumped building materials on a private property in Fairfield to save on paying tip fees.

“They have no shame, we need to make examples of these people and they will be prosecuted and fined,” Carbone said on social media.

“Residents should remain vigilant, particularly if you own an empty block of land or are about to commence construction.”

Carbone said two large trucks attended the site and unloaded demolition waste, with one of

the trucks caught in the act. Unknown to the offenders, the property was still occupied.

“The driver of the second truck was confronted but fled the scene, leaving the truck behind.”

Carbone said council’s Regional Illegal Dumping Squad, working in conjunction with the NSW Environment Protection Authority, has now referred the matter to NSW Police.

“Although the trucks did not have number plates, we are confident those responsible will be identified and held accountable.

“Illegal dumping is an ongoing issue, both on public and private property.

“Our community are our eyes, please stay vigilant and

report any suspicious activity to council or NSW Police im mediately, so we can stop this illegal activity.”

Under the Protection of the Environment Operations Act 1997, anyone caught dumping larger scale waste can cop a $15,000 on the spot fine, rising to $30,000 for corporations.

For large scale “strict liability waste dumping offences”, such as building materials, individ uals can be fined $500,000 and corporations $2 million – and those figures double if asbestos is involved.

For the wilful disposal of waste that can cause environ mental harm, individuals face up to $2 million and/or seven years’ jail, with corporations on the hook for up to $10 million.

RESULTS from a recent joint operation on the Bruce Highway show that almost one in three intercepted heavy vehicles were found to be non-compliant, said the National Heavy Vehicle Regulator (NHVR).

Operation Overwatch, which ran ahead of the Christmas holidays, saw NHVR Safety and Compliance Officers (SCOs) work in partnership with Queensland Police to conduct roadside inspections along the highway between Maryborough and Miriam Vale.

NHVR Chief Operations Officer Paul Salvati said of-

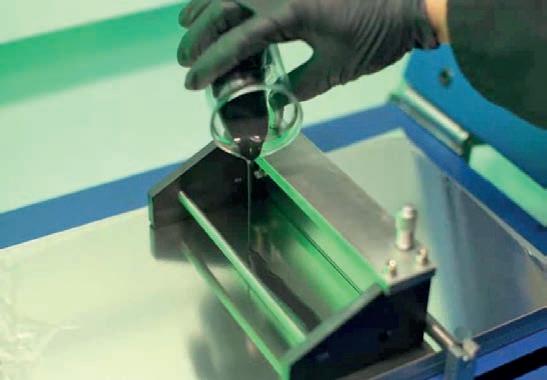

The Penrite Convoy range offers comprehensive solutions for heavy-duty vehicles, from the latest fully synthetic, semi-synthetic, and mineral oils to suit all engine types. The Convoy heavy-duty engine oil range is designed to protect the engine between service intervals keeping your vehicles on the road and performing at peak efficiency, saving you time and money.

▪ Australian owned and manufactured for Australian conditions

▪ OEM and latest industry approved specifications

▪ Our advanced formulations are designed to significantly reduce engine wear and enhance fuel efficiency, ensuring your vehicles perform at their best

ficers completed more than 140 intercepts, with around a third resulting in detection of non-compliance with the Heavy Vehicle National Law (HVNL).

“Operation Overwatch aimed to reduce high-risk behaviours on one of Queensland’s most dangerous stretches of road, with three fatal crashes recorded in the weeks leading up to the operation,” Salvati said.

“SCOs and police spoke to drivers about a range of issues, including mechanical requirements, dimensions, fatigue, permits, loading and mass.

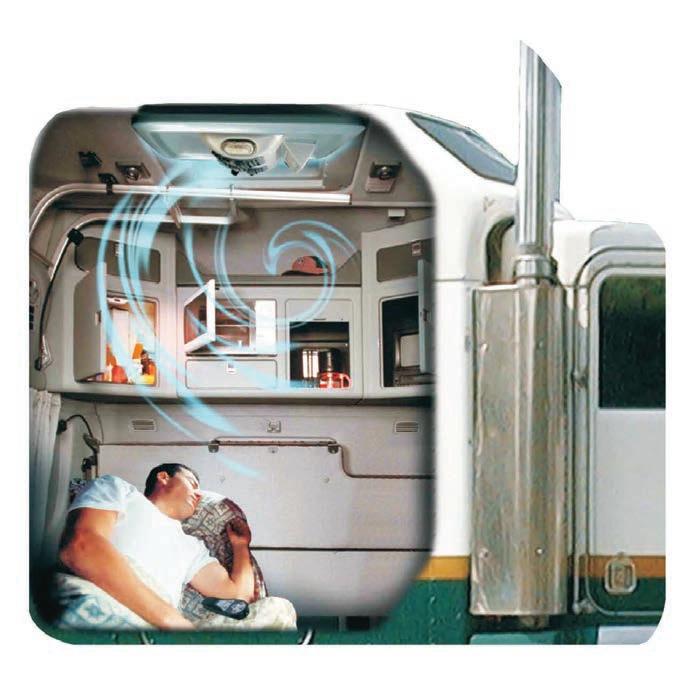

“Concerningly, we saw 10 infringements related to fatigue, which we know is one of the most dangerous behaviours across industry.”

Salvati said areas such as Iveragh, Miriam Vale and Gin Gin were considered a hot spot for traffic crashes, with many heavy vehicle drivers appealing for the presence of officers in these areas.

“While some of the figures from this operation are disappointing from a compliance standpoint, we are really pleased with industry’s positive response to an increased officer

presence around the highway,” he said.

“It’s encouraging for the NHVR and our partners to hear first-hand from truck drivers that they appreciate our efforts in educating more motorists on how to comply with the HVNL.

“We are also pleased that no crashes occurred during the operation in areas where officers focused.”

• Intercepts: – Total intercepts 143

– Non-compliant intercepts 49

– Vehicle units inspected 319 (individual prime movers, trailers, dollies, etc)

– Education interactions 14

• Infringements:

– Fatigue 10

– Dimension 5

– Registration 3

– Permit & Vehicle Configuration 3

– Mechanical 3

– Mass 2

• E nforcement activity:

– Total distinct notices: 72

– Defects: 47

BY JAMES GRAHAM

AT first, Stuart Devine thought it was just another routine problem to solve when his phone began to vibrate beside his bed at 6am.

It was the Refrigerated Road Express (RRE) warehouse alerting the transport manager, who had just finished work at 10pm the previous night, that they were having trouble locating truckie Michael ‘Mick’ Shelton.

Alarm bells were immediately ringing in Devine’s head. Shelton, 50, had been doing the same return milk run for nearly two years and was one of the most dependable drivers at RRE, the transport division of parent company First Choice Dairy, one of the biggest milk distributors on the east coast. Everything Shelton did was like clockwork.

The pair had also just spoken at 9.40pm the previous night with all on track for another trouble-free delivery from Saputo Dairy Australia to Nick's Food and Milk in Peakhurst.

Devine immediately jumped on the Cooltrax real-time tracking system installed

on all RRE’s trailers which showed that Shelton’s truck, a new Kenworth K220, was nowhere near the supposed final destination and instead near Greenhills Road at Berrima on the Hume Highway.

“The more I zoomed in the more it showed the dot was in the middle of the highway and there’s no rest bay there,” Devine recalled.

“When I looked at the temperature on the trailer, the return air was up to 20 degrees which tells me that normally happens when you open the back doors – I knew there was a problem.”

Fearing the worst, Devine instantly asked his staff to check on Live Traffic NSW for any reported accidents in that area.

“The round circle where that accident was on Live Traffic was exactly where Mick’s truck was and that’s when I started to panic.”

After a frantic call to Berrima police station for more information, Devine’s worst fears were soon confirmed.

“They rang me back within three minutes to tell me my driver has been airlifted to Liverpool Hospital in a critical condition.

“I just burst into tears – he’s my mate. It’s just that shock.”

Although police had yet to release details on the exact cause of the horrific January 8 crash at issue deadline, Devine understands that Shelton came around a corner at 100km/h to find a B-double crawling along the highway at no more than 2-3km/h.

Shelton, who was hauling 24 pallets weighing 44-tonne, had nowhere to go and just a split second to move the wheel centimetres off a square-on impact. The horrendous collision left the beloved grandfather of four with multiple rib fractures, a cracked sternum and punctured lungs, among other injuries.

Somehow, he still managed to stay conscious throughout the harrowing ordeal as first responders fought to free him from the mangled cab.

The other driver in the incident from Tasfreight was uninjured.

Composing himself as best he could after hearing the news, Devine helped raise the alarm amongst Shelton’s family to head to the hospital as quickly as they could.

“He was touch and go right up to the Saturday [two days after the crash] when they finished the operation,” Devine said.

Devine added that he’ll never forget the wave of relief he had when chatting to Shelton via a video call from his hospital bed just a week after the horrific smash.

“I just told him, ‘I love you man, I’m so glad you’re okay’.

“He’s devastated. He said he remembers seeing nothing, it was dark. He said all he could remember seeing was these back doors and in the last second he swerved as hard as he ould – and then just bang.

“It would have been seconds he had in warning. I’ve driven that road since [the crash] and as you approach that corner there is a bush that blocks

out what’s around that bend.

“You cannot see until you’re on top of it.”

Driving through the crash site a few days later, Devine said the layout of the road made it clear just how little warning Shelton would have had.

Devine said Shelton told him he owed his life to Moss Vale owner-driver Brian Wallder who was first on scene, along with another young truckie carting live ducks who ran back to grab a pinch bar from his cab to tear open the door.

“Mick kept saying, ‘I just want to get out, I’m stuck’, but they kept telling him, you can’t move. Brian was talking to the emergency services at the same time and they were telling him, don’t move him.

That saved his life.

“As soon as they got him out of the truck, he went into cardiac arrest because the blood filled his lungs.”

Shelton said Mick can’t

wait to meet up with Wallder again and thank him.

“He kept telling me that guy saved my life – he’s my saviour, an absolute gentleman.”

A humble Wallder, who was quick to follow-up on Shelton’s condition and offer support, later told Big Rigs he “didn’t really do much” to help at the time.

He had been following Shelton soon after leaving his Moss Vale depot and heading north on the Hume from the Medway Road on-ramp.

Shelton had moved over at the time into the right-hand lane to allow Wallder to enter the highway.

Shelton then moved into the left lane in front of Wallder and the pair stayed in that formation for around 5.5km, at around 80-100 metres apart.

“I was probably only 80 metres behind him when all hell broke loose,” Wallder recalled. “It was unbelievable to see. There were no lights or anything. He just ploughed straight into it [the truck and trailers] doing 100km/h.”

Continued on page 4

From page 3

LUCKILY truckie Brian Wallder was ‘empty’ at the time but still didn’t come to a halt himself in his Mack Fleet-Liner until around 1015 metres beyond the impact area – the force had pushed the trailers that far down the road.

“I’ve seen a lot of prangs in my 46 years of driving but I’ve never seen one that big,” Wallder said.

“I got out of the truck and didn’t hurry because I thought he had to be dead. But when I got to the door and tried to get it open, I heard him saying, ‘Help me, help me’. I ran back and a young bloke who’d pulled up beside me had a big pinch

bar in the truck, so he got the door open and pulled it back. He was really good.

“Then I was on the phone to triple-0 by that time and said, ‘What do we do? Do we try and get him out of the truck or leave him there? And they said, ‘No, don’t touch him.

Just leave him there, just keep talking to him and try and reassure him there’s someone coming to help him.

“The poor bugger was in a mess – he was jammed up in there pretty bad.”

Wallder said it was only 25 minutes or so before the emergency services arrived but they felt like an eternity.

“I just kept saying, ‘Hang in there mate, someone’s coming’. He must be fairly tough to live through that.”

A shaken Wallder admits that after the accident he was a “bit spooked” leaving so early in the morning on his usual run. He has no doubt that if Shelton’s truck hadn’t collided with the trailers, it would have been him. The truckies have since spoken on the phone and made plans to reunite again while Shelton is recovering in hospital.

Meanwhile, police told Big Rigs no charges would be laid and while the investigation into the cause of the crash continues, no further details were available at issue deadline. The National Heavy Vehicle Regulator said it’s gathering evidence to determine if it will investigate further.

Tasfreight declined Big Rigs’ request to comment.

In the wake of the crash, Mick’s daughter Teghan Shelton has launched a GoFundMe campaign to help ease the financial strain facing the family.

With Mick unable to work and requiring full-time care, Teghan said his wife Paula, a trauma nurse at Campbelltown Hospital, will need to stay home to support him while still meeting ongoing expenses, including their mortgage.

“This was a traumatic experience,” Teghan writes on the fundraiser page. “Something Mick will have to live with for the rest of his life.”

Teghan said the accident resulted in shattered ribs requiring extensive surgery to stabilise his chest with metal plates as he had multiple rib fractures and a cracked sternum.

“The surgeon and anaesthetist reported that he was very lucky to have survived the accident,” Teghan said.

“He also required 12 staples in his head for a large laceration, as well as torn muscles in his shoulder.

“He was on life support and an induced coma for four days, until they could stabilise his chest and keep his pain under control.

“But the physical injuries aren’t the only thing my dad will suffer with.”

Teghan said her father will have eight months of physical recovery.

“But in terms of his mental recovery, we don’t know if my dad will ever be able to get behind the wheel of a truck ever again.

“My dad is lucky to be alive today. He is so incredibly loved by his family, colleagues and close friends.

“He is a loving father and grandfather, as well as a husband.”

To donate, visit gofundme.com and search ‘Victim of the Berrima truck accident’.

At deadline for this issue, the campaign had already raised $15,412 from 135 donations.

AFTER a restful night at a Marlborough servo, Brisbane truckie Drew William was all set to make the final push up to Townsville from Brisbane driving a semi full of cars for Western Vehicle Movers.

He got one kilometre up the Bruce before he hit the ever-expanding queue of truckies stopped in their tracks by a flooded creek.

William said traffic was brought to a complete standstill after heavy rain in the wake of ex-Tropical Cyclone Koji caused flooding between the two service stations at Marlborough.

the wheel, William said the disruption was far from unusual during Queensland’s wet season.

“Every couple of years you get the wet season and you’re on the highway.”

This time last year, he was caught out by similar conditions, spending days stuck at Proserpine and Greenvale.

“Still no improvement by the look of it,” he said when asked about the general road conditions on the Bruce Highway since last year’s flooding. “No improvement whatsoever. It’s disappointing.”

“I’ve been stopped since five o’clock this morning,” William told Big Rigs. “It’s just one little creek that’s holding us up and it’s stopped the whole Bruce Highway.”

By the time he spoke to Big Rigs, he had been sitting in the queue for several hours, with word on the UHF suggesting a possible contraflow might be opened to move traffic one lane at a time.

“There’s a fair few here,” he said, adding that rain was continuing to fall, even if it wasn’t particularly heavy at the time.

A veteran of 28 years behind

William was particularly critical of the state of the Bruce Highway north of Gympie, saying investment appeared uneven and slow to deliver meaningful change.

“North of Gympie is shit,” he said bluntly. “They do a couple of intersections up near Maryborough, but that’s it. It took them 12 months to fix one pothole at Clairview.”

He also questioned whether decision-makers truly understood the highway’s condition.

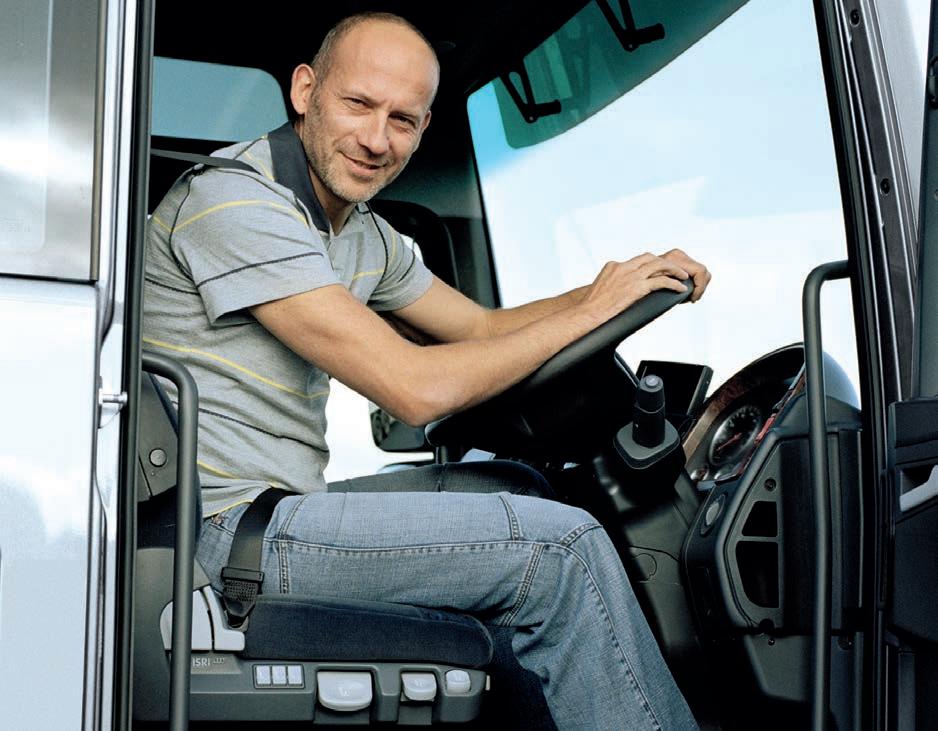

“You never see them hop in a truck and ride the highway,” he said. “They do it in their nice comfortable cars. I’d like

to see them in a truck one time.”

Later that same morning, William was on the move again, but the weather event continued to play havoc with the freight industry throughout the month, prompting the Queensland Trucking Association (QTA) to issue an urgent plea to the state government for industry subsidy support.

The QTA said the current wet season has left many truck fleets immobilised for more than 10 days, leading to daily losses for businesses ranging from an estimated $10,000 to $80,000, depending on fleet size.

The association warned that without intervention, essential supply chains are at risk, and local economies face severe disruption.

This “dire” situation is exacerbating existing economic pressures on an industry a lready operating with tight margins, the QTA added.

“This isn’t just about trucking businesses; it’s about the availability of food, medicine, and critical supplies for every Queenslander.”

The association noted that during the February 2025

flood event, fleets were forced to apply cost levies, ultimate ly increasing the cost of living in affected areas – a scenario likely to repeat this season without support.

“The inability to recover costs during disruptions places immense strain on businesses, many of which are major employers in regional areas, providing hundreds of local jobs. Without assistance, some may be forced to close, leading to job losses and diminished competition in the market,” Mahon added.

“I know they haven’t done it before but it’s time for them to rethink their approach be-

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164 Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

“There’s a cost related to being stuck somewhere and you’ve got to support your drivers.”

While frustrated by the continued subsidy snubbing, Mahon, however, said he refutes the criticism from some quarters that the $9 billion in Bruce Highway fixes aren’t being rolled out quick enough.

“Ironically, it’s being held up by flooding at the moment but as soon as that has cleared there are quite a few projects that will be underway.”

Mahon said there has been more “glitches” this year on

the Inland Freight Routefall and flooding in Clermont.

“It’s been the reverse of what we had in February [2025]. The Bruce was cut off all over the place and we were using the IFR and this year, to a lesser extent, we’ve been cut off in a number of places on the IFR and we’ve been using the Bruce more.

“But that’s been part of our argument as to why the IFR is so important – we need redundancy between those north-south routes.

“If you haven’t got one, you’ve got the other. You can’t just be cut-off full stop.”

3/120 Gardens Drive, Willawong QLD 4110 Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

BRISBANE NORTH

1/259 Cullen Av, Eagle Farm QLD 4009 Ph 1300 11 4774, email: seats@isrinb.com.au, www.isrinb.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY

110 – 120 Maggiolo Drive, Paget QLD 4740 Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH

408 Welshpool Rd, Welshpool WA 6106 Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

NEWCASTLE/HUNTER VALLEY

Ph 02 4932 0600,

Unit 2/13 Hinkler Ave, Rutherford NSW 2320 email: sales@hvss.com.au www.isri.com.au

Amid the heartache and devastation caused by Victoria’s bushfire disaster, the trucking community has banded together to lend a helping hand.

BY DANIELLE GULLACI

IT was just a week into the new year, when on January 7, as Victorian temperatures peaked past 40 degrees, a number of grass and bushfires began to break out across various parts of Victoria. As fires burned, farmers, businesses, property owners and emergency services braced for the catastrophic fire conditions that were to come on Friday, January 9. High temperatures and strong winds served to fuel existing fires and spark new ones.

Across the next week or so, over 400,000 hectares were burned, hundreds of struc tures destroyed and over 20,000 animals killed. Tragi cally, a cattle farmer also lost his life in the Longwood fire near Seymour in central Vic toria.

A s those impacted were forced to grapple with their losses, livestock farmers were also faced with the challenge of how to feed their surviving livestock.

With that, the true Aussie spirit has shone through, with countless people donating hay and funds. There have been numerous hay runs making their way into fire ravaged towns.

Aussie Hay Runners (AHR) was among the organisations that quickly sprung into ac tion. By Monday, January 12, 28 of their semis had already travelled 19,448 kilometres, delivering 952 bales valued at $114,240 to farmers in Alexandra, Goomalibee, Harcourt, K atamatite, Longwood, Murrindindi and Ruffy. And that was only the beginning.

Recognising that the big trucks couldn’t access some of the roads, the AHR team assembled what was dubbed the “Cute Ute Crew”.

On Saturday, January 17, over 100 utes, numerous trucks and pilots headed into Longwood.

AHR’s Jenny Clear-Boucher said, “It was a massive and a mazing day. There were so many beautiful people doing beautiful things. The Cute Ute Crew donated their time and their petrol, and most borrowed or hired trailers from family, friends or their bosses. Many of them bought farm equipment and purchased hay themselves to take on these runs for the farmers and to support AHR.

“We had four AHR trucks and then other trucks met us along the way, already fully loaded with hay and pallets of food. Everything went to a depot that’s been set up in Longwood and is run by volunteers, and they’ll distribute it all to where it needs to go.”

With the run into Longwood complete, AHR has its

sights set on its next major run, heading into the town of Streatham on January 31, as that town has also been badly impacted. As we went to print, Jenny said she was expecting this run to be even bigger.

From the moment the fires began, Need For Feed has also been hard at work, getting hay to farmers. Just a week after the fires broke out, Need For Feed founder Graham Cockerell told Big Rigs, “We have done a bit already, starting the day after the fires – and we haven’t stopped. There’s been something happening each day. There have been requests for assistance for all the fires, but most of them have been for Longwood,” he said.

“Need For Feed has a depot set up at Euroa and Alexandra, so that’s where we’ve been dropping off the hay. But we’re also really focussed on Longwood, where a lot of properties have been impacted.”

Each year Need For Feed holds an Australia Day Hay Run. While initially planned to head into South Australia’s Riverland area, that trip has been postponed, with the trucks instead heading into fire impacted parts of Victoria.

Graham added that it will take some time for livestock farmers to recover from the impacts of the recent fires.

“This will go for at least three

months, until they get decent rains and feed growing.”

A popular stop for truckies, the Mortlake Roadhouse, in Victoria’s west has also done its bit to show its support to bushfire victims. On Monday, January 12, Mortlake Roadhouse held a special fundraiser to assist those impacted by the fires, with all proceeds from the day donated to Need For Feed.

There was also a bucket on the counter for customers to make donations, and they set up an account for those who wanted to donate but couldn’t get to the roadhouse in person.

Mortlake Roadhouse was able to raise $8388.86, which was donated to Need For Feed.

The Victorian Farmers Federation (VFF) has been coordinating fodder relief for farm-

ers impacted by the Victorian b agreement with the Victorian Government, the VFF enacted the Emergency Fodder Support Program to coordinate the donation of fodder and deliver it to bushfire impacted farmers across Victoria.

Within the first week of its efforts, VFF sent truckloads of donated hay to farmers who needed it. According to the VFF, this went towards feeding over 8000 cattle, over 30,000 sheep, over 300 horses, and more.

Along with the various support organisations, there have been transport operators who have coordinated their own support efforts.

Among these operators was Morris Transport, which was there to help as fires continued

Transport drivers headed into the Longwood, Meredith and Kawarren fire zones to transport cattle to safer areas.

“Our drivers didn’t hesitate –dropping their own plans to be there when it mattered most, ensuring livestock was moved quickly and safely to secure paddocks away from danger,” the company said.

While owner of Hendy Transport, Troy Hendy, was also quick to help. His company is located in St Arnaud in Victoria’s Wimmera region.

Together with good mate Darren Petrie and cousin Gordon Hendy, who both have their own trucks and farms, the trio headed into the town of Alexandra on January 12 to deliver three truckloads of hay.

For those wanting to assist, there are a number of organisations looking for donations and/or drivers to volunteer their time including:

Aussie Hay Runners

Search Aussie Hay Runners on Facebook

Need For Feed

Visit needforfeed.org

Victorian Farmers Federation

Visit vff.org.au/vff-emergency-fodder-program

For those who have been impacted by the bushfire disaster, the Victorian and Australian Governments have recovery support available. Details can be found at vic.gov.au/january-2026-victorian-bushfires.

“We have a great network of farmers around here so all of the hay was donated from farms around St Arnaud. Most farmers donated 10 bales or more,” said Troy.

“During the Black Saturday bushfires where Marysville was hard hit, a lot of those people moved to Alexandra. People lost everything and there were kids who had lost everything. We were the first ones down there on the Sunday night to get toys to those kids.

“When this happened, I called my good mate in Alexandra to see what I could do to help. He said they needed hay.

“It’s going to take a long while to get everything going again there, but it was surprising to see a fair amount of stock still floating around which was really good to see.”

EDITOR JAMES GRAHAM

thing that matters. You stick your nose where it’s not always welcome, and sometimes doors are slammed in your face. And don’t get me started on social media, with its constant barrage of trolls. Call me a dinosaur if you like – at my age, I don’t really care.

But every now and then, the old spark is reignited. It happens when you read stories like those about our hay run heroes on page 6, and if you’re lucky enough to interview truly wonderful, kind and humble people – the sort who quietly reaffirm your faith in humanity.

People like truckie Brian Wallder who was first on the scene at a horrific smash on the Hume earlier this month (see story on pages 3-4). Brian’s first words to us were: “I didn’t do much.” Yes, you did, Brian. You’re a bloody legend.

[In response to: ‘Veteran truckie opens up on why he’s almost ready to hand in the keys after 35 years on the road’]

I’M coming up to 47 years in the industry.

I started on the old Hume Highway. I was on Razorback in the blockades as a young keen fella Anyway, enough about me.

I moved to WA in the late 90s and glad I did.

What’s going on over east is criminal re these overseas drivers.

I did three trips with a single earlier this year [in 2025] from Perth to Queensland. What I saw and the danger I felt crossing the Nullarbor was insane.

I came across local trucks towing B-triples from Melbourne that should never have been allowed on the road.

Drivers that didn’t even know where they were. Main Roads even put up a sign in Coolgardie as these guys were going into Kal completely lost. Break down after breakdown, rollover after rollover and the authorities turn a blind eye.

That’s just one of many very dangerous situations they put me in and that was only over three trips.

I live in the Wheatbelt in WA, the amount of rollovers we have here is a joke and it’s all these idiots.

No one is monitoring these

guys for maintenance and fatigue. Some of the trucks are only a couple year old and they are destroyed.

No idea about keeping a truck safe.

So, who’s responsible? The farmers? CBH? The companies they contract to? Why aren’t they stopping this crap? Of course, $$$$$

I can go on and on about it.

I love what I do, I love going for my drive. I absolutely despise the industry for what it has become.

Haven’t liked the industry for a lot of years now. I ask, who’s to blame?

Mike

[In response to: ‘Truckies urged to help instead of pressing record button’]

BACK in our days of getting a licence, we had to reverse a B-double 70 metres in a straight line, reverse a single trailer around a left blind corner using mirrors, let alone a ll the other hoops we had to jump through to get the license class. These rude arrogant muppets don’t want education, they want a paycheck.

The licence system is about as good as Albo as prime minister – up a croc-infested creek, no paddle and a sinking boat. Back in our days, we didn’t have automatic trucks, and a car licence done in an auto-restricted.

You can’t fix the bottom on the food chain when the roof up top is leaking like Niagara Falls.

The only reason the industry is suffering is because they imported cheap labour, expected us to work for a bowl of rice a day and people left in droves. Companies back in the day employing people sent drivers off for an assessment to make sure they knew how to drive, didn’t f###k their trucks up, drop gearboxes every third set of lights, etc.

GKR drivers stood up…. when is the rest of the industry going to stand up, park up and demand the government fix the issues they created?

Drivers don’t stick together anymore because mainly these imports think of no one but themselves.

They are not interested in learning to drive properly, or they would get appropriate lessons. They don’t stop to check on

people broken down, not even a radio call to check, so I’ll be stuffed if I’m ever going to try help them again.

They can pay a driving school a couple grand, maybe more these days, and learn to drive like we did back in the day. They rely on yardies to put their trailers and trucks together and companies are allowing this.

They are just as bad as the government allowing them on the roads without due care for everyone else using it.

Allan Williams

I don’t know of, or have met Jerry Brown-Sarre but finally something to work with from someone who obviously is an industry top gun and sits on our side of the fence.

The most profound and compelling words from Jerry are at the start of his 28 point plan to save our industry [‘Veteran truckie unveils 28-point plan to save trucking’]

“The industry needs peo -

ple to stand up, start an a lliance and LEAD this action. Injustice ONLY survives while good people do nothing.”

This blueprint and initiative of Jerry’s has the ability to transform the transport industry as we know it and create the reform WE deserve.

Nicely done……I’m in!

Cam Deans Corrigin, WA

Toowoomba Bypass

Operators and truckies with wider loads should factor in detours when using the Toowoomba Bypass between the Warrego Highway West interchange at Charlton and the Gore Highway interchange at Athol until March.

The Department of Transport and Main Roads (TMR) advises there will be fixed lane closures on the southbound and northbound lanes to carry out pavement stabilisation works.

Restrictions will apply during and after the work hours of 6am-6pm. Vehicles with a ground contact width over 3.5m wide must use the approved detour. Vehicles with load widths over 4m wide must use the approved detour during work hours between 6am-6pm.

Following the closure of the Birdsville Track in June 2025 due to floodwaters and the subsequent opening of the Cooper Creek barge to ferry vehicles across, waters have receded and the final closed section of the Birdsville Track in South Australia reopened to traffic in mid-January.

Re-opening this final 5 kilometre section allows freight operators and other road users to fully access the Birdsville Track in South Australia.

It also means the Cooper Creek Barge will no longer be required. The $27.4 million barge transported approximately 13,200 cattle since opening in early November.

A total of 760 vehicles, including 330 heavy vehicles, used the barge while it was in operation.

Upgraded truck stops

Ampol has opened its redeveloped dual Ampol Foodary Eastern Creek service centres in Sydney, featuring new amenities for truckies.

Located on the M4 Motorway in Sydney’s West, the dual truck stops feature separate fuel and diesel canopies, along with parking, a new truckie’s lounge and shower facilities. For electric trucks, both sites feature the AmpCharge network first-of-its-kind, drivethrough EV charging bays, allowing for larger commercial vehicles and EVs with trailers to easily access charging.

On the retail front, the sites include Ampol Foodary, Soul Origin and Hungry Jack’s, among others.

Flood recovery works

Following intense rainfall and flooding in early 2022, which caused significant damage to sections of the Stuart Highway, upgrades have now been completed at Lake Windabout.

An important freight route between South Australia and the Northern Territory, the Stuart Highway runs for almost 1000 kilometres through South Australia, linking Port Augusta to Darwin. The area near Lake Windabout sees an average of 900 vehicles each day, with about 300 of those being heavy vehicles.

In the cooler months, traffic volumes here can peak at 1300 vehicles each day, with up to one third being heavy vehicles.

BY MICHELLE PILLAR

FOUR years. It’s been four years since I’ve felt the grass underneath my feet. Four years since I ran around kicking the tyres of my truck and trailers to make sure they had air, before heading off for what would normally be the week on the road.

It’s been four years since I danced around on my own two legs and feet. Four years ago I went to work and never returned the same. It’s been a heavy weight to carry that sort of loss around.

Not just the loss of my legs, but the loss of my career, the loss of what I thought my life would look like.

The surgeries that never seemed to end, the medication that filled me with anxiety and made me so tired. The flashbacks and reminders every time I saw a truck.

Nothing could prepare me for the seemingly never-ending grief that comes with that sort of trauma.

I AM PROOF THAT EVEN IN LIFE’S DARKNESS MOMENTS, WE CAN RISE, REBUILD AND CREATE SOMETHING BEAUTIFUL, EVEN IF THAT LOOKS DIFFERENT NOW.”

Twelve hours I spent hanging upside down in that ruck, mostly awake, in pain and terrified, screaming out for my dog who was in the

accident and lived to tell the tale, but what a blessing it was to have a paramedic that would go against his orders to eventually cut my foot off to get me out of that truck, barely alive.

My surgeon ended up having to cut both of my legs off above the knees. It took me almost six months to remember anything about that day.

For the next three years I watched myself slowly fading away mentally. My loud laugh became rare.

I shut the world out not knowing how to explain how completely dead and worthless I felt inside. My spirit was gone and I was in physical pain every hour of the day. I felt trapped and the world around me seemed so distant and scary to face.

One year ago I decided to choose myself. I moved away from the town that felt hard to be in. I threw most of my medication away. I learned that my value doesn’t rise or fall based on who chooses me. I learnt that my scars aren’t shameful, but a symbol of strength.

I am proof that even in life’s darkest moments, we can rise, rebuild and create something beautiful, even if that looks different now.

This past year I made the choice to show up, sometimes strong, sometimes figuring it out, but I learnt that connection is everything. I’ve met so

many genuine people, that I look up to every day. I learnt that I am not the only one who is in this position.

I looked at those people and thought wow, they are amazing, and I started to see that in myself too.

Everyone eventually goes through hard times, loss and grief. That looks different for every single person. It’s about feeling your emotions, accepting that things don’t always go to plan.

I’ve cried so many tears I could have filled a swimming pool, but then I picked myself back up, went to therapy, found happiness in the small

things, and slowly came back to life. I started to believe in hope again and started believing in myself.

I started remembering who I am again and genuinely laughing and appreciating the fact that I am still alive.

I no longer worry about what people think of me, and however long I am lucky enough to live, I will be grateful for everything I have and everyone who has stuck by me because when times are tough, you are the people I think about and am so lucky to have in my life. I hope that I can one day help people the way that you have helped me.

IT was the cruelest of blows for brave truckie widow Delphine Mugridge at the time. her beloved husband Neville ‘Slim’ Mugridge in a twotruck crash on the Eyre high

way about 27km west of Yalata on April 4, 2024, Delphine got news that the roadside memorial in his honour had been

“Who would do something like that? It’s something so

unique that nobody could say, ‘Look what I’ve got’. Everyone’s going to know now that it was stolen,” she told Big Rigs at the time.

Fast forward to January of this year, however, and Delphine is once again thanking the industry for rallying in support.

Earlier this month, Slim’s long-time colleagues at TML Transport, truckie Simon Morrison and wife Cathy, sent her these pictures of a new memorial being re-erected in its original location.

TML Transport boss Lewis Magro said he was only too pleased to play his part in getting the memorial back in its rightful place. Many truckies have stopped there to pay their respects to Slim since the accident that also claimed the lives of two other drivers.

“I did a changeover there the other night and I saw where the accident happened for the first time – it was a bit daunting,” Magro said.

Delphine said she was thrilled to get the news from Simon who was also instrumental in having Slim’s name added to the memorial wall at White Hill, SA, last year.

“Simon knew Nev very well and he got in touch with me after he died. He just goes out of his way to do things – it’s just so much appreciated.

“I wouldn’t have known where to start, especially now being based in Queensland. He obviously had the contacts, and the people donated the work that went into it.”

Delphine said she now wants to make sure the newly cemented memorial stays in place and has contacted the local Yalata council to push her case.

“I have to make sure it stays put, even if I have to pay a fee each year to keep it there.”

While the memorial’s return is welcome news, Delphine continues to advocate for broader change on the licensing laws around overseas drivers she’s campaigned so tirelessly to change as a legacy for Slim.

“I did hear back from the Queensland Parliament and they’re going to make a decision by the end of the year as to what law reforms are going to happen,” she added.

“Victoria is working with the Australian Trucking Association too so everybody’s on board.

“It’s just that they’re not keeping me in the loop about it.”

South Australia is so far the only state or jurisdiction to tighten the licensing pathways open to foreign truck drivers in Australia.

Delphine also recently sent the full 23,319-signature petition supporting changes to Senator Pauline Hanson, hoping she may champion the cause in federal parliament this year.

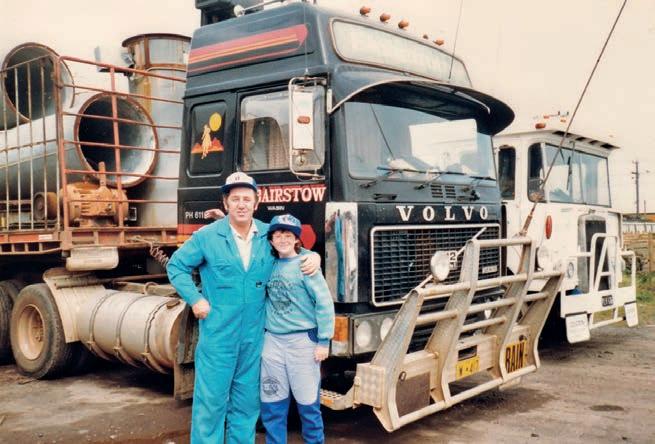

At 83 years of age and with over 6 million kilometres under his belt, this legend of the road recently set off on his final run in his beloved Volvo.

BY DANIELLE GULLACI

FOR Terry Bairstow, 83, trucking has been in his blood since he purchased his first truck – a brand new red International Acco petrol powered V8 – back in 1971.

Though he admits he never really loved that truck, the move sparked a career that spanned close to six decades, carting sheep and grain across Western Australia. Terry even went on to inspire his children and grandchildren to enter the industry too.

“The Acco was a brand new one when I got it but I had lots of trouble with it – and it had no air con!” Terry told Big Rigs

“The Acco had two seats. I used to take a mattress and throw it over the seats and then sleep over the engine in Port Hedland in the heat. One day it was that hot, I saw some water in the river and jumped in. I walked 50 metres back to my truck and my shorts were already dry. Sometimes, I’d get five or six flat tyres in one run. But I just did it and I got the job done.”

Terry has lived in Wagin in Western Australia’s Wheatbelt region for most of his life, however was born and raised on the family farm in Dumbleyung, around 40 kilometres to the east.

“I’ve always enjoyed driving and started learning to drive trucks on the farm from about eight years of age. They were the best apprenticeships back then!

“My brother Musso was also part time in trucks when I was 16 or 17 and we’d do the sheep sales. Loading at midnight, then travelling 300 kilometres to the sheep yards in Perth. I’d be that tired that I’d sleep on the floor in the truck.”

After finishing school, Terry had a go at sheep shearing and sharecropping. After the family farm was sold in 1970, he decided to try his hand at truck driving. “I was about 26 at the time. I got into shearing and didn’t like it so I started working with my brother, helping to cart sheep in small semis.”

At the age of 29, Terry purchased the Acco, which marked the start of Bairstow’s Transport – a business that

continues to this day under the direction of his son Todd Bairstow, who since Terry’s retirement, is the company’s only driver.

Back in the 1970s, after Terry’s Acco came a second-hand M AN, followed by a Volvo G88. “That Volvo really got me going,” said Terry, who’s been loyal to the Volvo brand ever since.

At one point during the 1980s, Bairstow’s Transport got up to a fleet of nine prime movers, today there are three – Terry’s 2007 Volvo FH16, which was purchased from new and has done over 1.5 million kilometres, a 2008 FH16, a lso bought from new and driven by Todd, and another 2013 FH16. “I’ve had over 40 drivers over the years, including Michael Taylor, who really helped us out when Todd spent a few years driving up north,”

added Terry. “Transport is a hard game. I’ve done over 6 million kilometres in a truck.”

It was during the 1980s, when Terry expanded into grain cartage that he also began running road trains.

“With all trucks you have troubles. Things can go wrong and can be expensive, but the Volvos have been good to me. I stuck with Volvo and got to know the people there.”

Terry even struck a close friendship with Max Winkless who brought the Volvo truck brand to Australia. “When Max had new trucks that needed to be delivered to WA, he’d fly me over and pay me to drive the truck back. I loved doing that, it was like a holiday. I’d get to see the countryside,”

Terry fondly remembered.

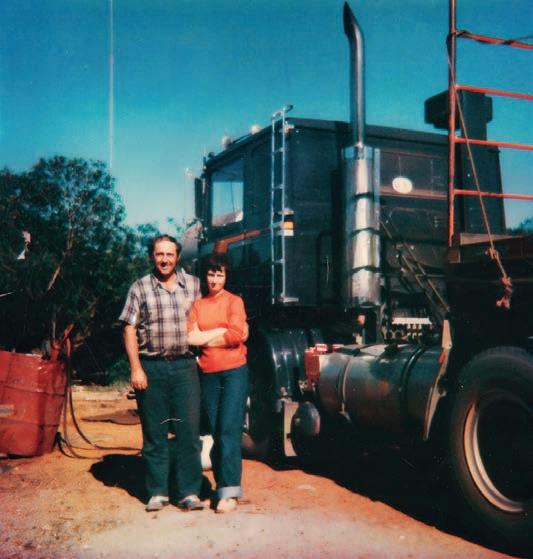

Terry and his wife Maree Bairstow had five children. Their sons Darran and Todd,

and daughter Susannah all began their driving careers working in the family business and learning the ropes from their father. Darran went out on his own to start his agricultural transport business Flexitrans over 20 years ago. Susannah and her husband Grant went on to run another transport business called McGuffie Wagin Transport. While Todd has continued to work by his father’s side. “Now he’s running the show for me,” said Terry.

While their daughter Jodie Bairstow doesn’t drive trucks, she runs a trucking Facebook group called Truckies Driving Australia and has two sons in the transport industry – one is a truck driver and one does trailer fit-outs. Her son Cody began his truck driving career working for his grandfather at Bairstow’s Transport,

while Darran’s eldest daughter Danee recently upgraded to her MC.

Terry credits Maree with being the backbone of their business. “She is the accountant, the one who kept everything together with all the kids while I was away. She kept everything going and I couldn’t have done any of it without her. She was running the office while also raising our five kids – Darren, Todd, Susannah, Jodie and Marc,” said Terry.

Spending so much time on the road, away from the family, some of the memories Terry cherishes the most is getting to take the kids with him when he did the longer runs over to the east.

“My kids all got brought up coming in the truck with me and they’ve been all over Australia. Maree was bringing the k ids up pretty much on her

own because I was away in the truck, so I loved taking them with me on the trips over east into Queensland – I’d bring them one at a time. We’d get to spend that time together and it was like a working holiday,” recalled Terry.

“Darran and Todd are both really great drivers. They started coming in the truck at around five years old and by 12, I was teaching them how to back the trucks into the yard. The only way they learnt was with me – but now they’ve been telling me how to drive for years!” he joked.

“Darran used to get up to a bit of mischief. At Mt Isa once, Darran was about 15 and I got a bit tired, so he had a drive for about an hour to give me a rest. The only way kids learnt was by being behind the wheel.”

Up until November last year, when Terry was forced to walk away from the job he loved due to his health, he was still doing road trains of grain, fertiliser, gypsum and lime around Western Australia, travelling up to 300 kilometres away. As he explained, “They took my truck licence off me at the end of November. I still miss it. I’m still very comfortable in a truck. But at 83, that’s enough I guess, isn’t it,” Terry said. “It ends up in your blood and just becomes natural.

“I loved being in the truck. Years ago, I even used to leave home late at night and travel 100km down the road so I could sleep in the cab and get a head start for the next day.” Now that he’s no longer on the road – well not in the big rigs anyway – Terry is keeping himself busy with farming and plans to do some travelling across the Nullarbor with the caravan too.

“I bought back Dad’s farm in Dumbleyung in 2011, where I was brought up. I always wanted some land and got that opportunity 15 years ago. I grow about 900-1000 tonne of grain and barley each year. That keeps me busy for part of the year and is a good income as well.

“There are also many places I used to travel to but didn’t ever get the chance to explore properly – so I’d like to go back to some of those places, be able to stop and take my time.”

When loads are heavy and roads are long, the Volvo FH16 doesn’t back down because its Australian Made for our conditions. Powered by the new D17 engine with up to 780 HP and 3800 Nm torque, it conquers heavy hauls effortlessly.

But it’s more than just power, Volvo Action Service ensures you’re always connected with roadside support. Backed by our national dealer network, it means total peace of mind when far away from home.

Volvo Trucks. Driving Progress.

What was once a patch of red dirt is now an epic display of Kenworth’s proud history in Australia – and Jim ‘JJ’ Hurley was instrumental in building it into what it is today.

BY DANIELLE GULLACI

NESTLED in the middle of the desert in Alice Springs, the Kenworth Dealer Hall of Fame is a walk down memory lane. It opened in 2005 with just four trucks. Today it fea tures 18 restored Kenworths and 29 brand new Kenworths that have never been put to work, all added over the past 20 years. The display trucks range in age from a 1965 W923 model; to the first Ken worth ever to be produced in Australia, the K125 Grey Ghost; through to the models of today.

At its peak, the Kenworth Dealer Hall of Fame was at tracting up to 80,000 visitors a year.

The idea for the museum was conceived by Jim ‘JJ’ Hurley and Andrew Wright, then Managing Director of PAC CAR Australia; together with Ken Leakes from Mildura Truck Service and Liz Mar tin who was CEO of the Alice Springs Hall of Fame at the time.

“We came up with the idea that we should build this Kenworth Dealer Hall of Fame to preserve the histo ry of building Kenworths in Australia – the idea was con ceived over a few bottles of red wine,” said JJ.

JJ formed the inaugural committee which consisted of four people – himself, Andrew Wright, Cliff Swane from Inland Trucks in Dubbo and Mike Crawford from CMV Group.

Australia, representing PACCAR’s Kenworth and DAF brands – JJ has spent a lifetime in the industry.

Asked why Alice Springs was chosen as the setting for the Kenworth Dealer Hall of Fame, JJ spoke of two reasons. “One is that the birth of the road train happened in the Northern Territory, and Kenworth’s heartland is in the road train industry, and the other is its dry climate so you don’t get the deterioration and rusting you can get elsewhere.

During Covid when planes were grounded, about 200 of them were parked in the NT for that same reason.”

JJ served as chairman of the museum from 2003, before it was even built, until his retirement from the role on August 30, 2025 – on his 83rd birthday.

Son of one of the two founders of Brown and Hurley –which sits among the largest truck dealership groups in

JJ began working at Brown and Hurley when he was 16 years old. By 1964 the business became the first Australian dealer appointed by Kenworth.

From apprentice mechanic to sales manager, to serving as managing director from 1988 until his semi-retirement in 2012, JJ has lived and breathed trucking all his life.

When JJ got his hands on the first Kenworth ever sold by Brown and Hurley – a W923 model – he set about restoring it.

A little over 60 years ago, that Kenworth W923 was sold for £12,250 – which JJ says equates to roughly $25,500 in today’s terms. Its restoration was a labour of love – and an expensive one at that, with JJ admitting he spent about $120,000 on the project.

“I bought it in the early 90s and it was in a pretty sad condition. It was still being used with a water tank when I got it,” JJ told Big Rigs

“Detroit rebuilt the engine, Goodyear did the tyres, Rockwell rebuilt the back-end – and I still spent $120,000 on it!”

That sparked a lightbulb moment. “I thought if we were to put a new truck in the museum each time Kenworth releases a new model, then in 50 years’ time, we’d already have the truck there and wouldn’t have to spend money to restore it, because it would have come straight from the factory, brand new,” explained JJ.

“I went to Kenworth with this idea – so every time a new Kenworth is sold, PACCAR and the dealer that sold it put money into a fund, then when a new Kenworth model is released, we can purchase one to put into the museum.”

The Kenworth Dealer Hall of Fame opened as a 2000 square metre space with just

four trucks – JJ’s restored 1965 Kenworth W923, a 1971 K125 (better known as the Grey Ghost) and two new trucks, a T604 and T650.

“At the opening, the President of Kenworth in the US, Mike Dosier, was there and he said there was nothing like this in the world,” said JJ.

“We have the first Kenworth ever built in Australia and as history continues, we will have every Kenworth model ever built in Australia,” he proudly revealed.

“I have some of my trucks there, we have customer trucks including from Wickhams and Lindsays, then are some prototype Kenworths that never made it into production – like the T2000. That model was running in the US so they brought some here to trial but it didn’t suit our conditions. There’s a T605 prototype that was built here in Australia but it couldn’t hack the conditions either so it was never released. There’s also a T402 that was made here and tested before being released later on, however they made quite a few changes to that original prototype. Those trucks would have gone to scrap if we didn’t have this museum.”

The most recent truck added to the collection is a C509 with a 60 inch sleeper. “That’s a brand new one, driven from the Kenworth factory in Bayswater, Victoria, to Brown and Hurley in Kyogle, where it was fitted up and then driven straight to Alice Springs,” said JJ.

“With the new trucks we have there, many are set up as working trucks. All Truck Bodies supplied a water tank for one of them, Mixers Australia gave us a new concrete bowl for another, Tefco gave us a tipper body and hoist for one, QMW gave us the rollover protection frame for a mining truck, and Henry Zilkie gave us a bullbar for one. All of the component people we deal with have been really good, and it makes a hell of a difference having a body on the truck. It makes it more interesting.”

With the growth of the number of trucks on display came the need for a bigger facility.

For his services to the industry, JJ was inducted as an Industry Icon at the Road Transport Hall of Fame in 2014, again on his birthday. Then the following year, in 2015, a major extension to the Kenworth Dealer Hall of Fame was opened, named the JJ Hurley Pavilion in his honour. This 2000 square metre extension doubled the museum’s size to 4000 square metres.

“There were probably about 10 new trucks and 10 customer or restored trucks there at that point,” added JJ. “There was an awning being used for some of the trucks which was very dusty so they walled that all in and opened the new pavilion that they named after me. Now it’s almost at capacity so a decision will need to be made on what’s done next.” JJ is rightfully proud of what

the team of dealers involved in the Kenworth Dealer Hall of Fame have been able to achieve. “We took it from an idea with a bit of red dust on the ground to the facility we have there now,” he said.

“When I retired as Managing Director of Brown and Hurley in 2012, I said I was happy to step down as Chairman of the museum but they were happy for me to stay on – so I stayed for another 13 years.”

With JJ’s retirement, John Crawford from the CMV Group has taken over the Chairman role. “I have an enormous amount of passion for this place. John is a great lad and I hope under his leadership, it continues well into the future,” added JJ.

“We’ve had wonderful support from Kenworth management over the years, and from the dealer group and suppliers. Jim McGrath and Mal Toop also visit Alice monthly in a voluntary capacity to caretake and welcome visitors. And Drew Anderson orders all the new trucks, arranges all the fit-outs and processing before they leave for Alice Springs. Without their support it wouldn’t keep going. They’ve always been happy to get behind it and I’m very grateful for that and the work of all our committee members.

“I’d like to see the museum doubled in size to 8000 square metres, that would be my dream – but my real hope is that this museum keeps on going long after I’m gone.”

BY JONATHAN WALLIS

NO sooner had we farewelled a rather tempestuous 2025 then we were again on our way north to Epping Forest on Saturday, January 10, with a foul day forecast with high winds and cold damp weather.

And feeling at the same time so sorry and concerned for friends, including Bette Phillips, and truck drivers in Victoria suffering their catastrophic bushfires and heat.

It was feared this would deter people from attending, and no marquees could be erected for insurance purposes, but this is Tasmania, and at least 300 folk turned up on the day at the Ampol Epping Forest roadhouse for the 11th memorial service at the memorial wall there, and for the dedication of 15 new plaques on the rapidly filling wall.

This in fact brings the number of plaques on the wall to 232, and as Jonathan Price told us, this had necessitated the construction of an extension with the slab already laid in preparation for next year.

On the day we were also pleasantly surprised to see the extensive car/truck parking area had been bituminised making for a much better, drier and cleaner area, but mainly for dampening the dust and flying debris on a windy day.

Fourteen beautifully detailed rigs turned up on the day as well as a good crowd of 300 or so people, both family friends and other interested people, for a time for reflection, but also a time for a welcome get together and catch up.

A gain, there was great country music from Apache to entertain those who attended prior to the service, delivered from the trailer/stage towed by Jonathan Price’s immaculate “Huon Delivery Services” 2019 K-200.

Tia Hodgetts and Amanda Wilson manned a successful stall selling “wall” merchandise, and taking orders, with proceeds going to the “wall”.

Starting punctually at noon, Jonathan Price welcomed the crowd and acknowledged the many people who have worked to make the occasion a success and especially those who had turned up with their trucks on the day.

Following his speech Donna White read the beautiful and emotional “Truckies Poem”

which was very well received.

Then Adam Hodgetts, on behalf of the committee, thanked a ll who had contributed to the installation and maintenance of the Memorial Wall since its opening in 2015, including previous committee members, and donors with a prominent mention of Big Rigs and its much-appreciated continued support for the “memorial wall” and the Tasmanian industry.

The Reverend Rev. Philip Bentley then made a sensitive and thoughtful speech relating to the hard and demanding, and sadly often tragic, life of truck drivers, and their families, and then blessed the wall.

The 15 names were then read out for those to be commemorated this year as follows:

Michael “Mick” Gobbey, Thomas “Tommy” Bishop, James “Jimmy” Sherwood Dunster, Wayne Roberts, Greg “Triff” Triffett, Bobby BobImlach, Scott “Scooter” Craig Rimon, Paul “Vinny” Vincent, R ick “Rockstar” Augostin, Frederick “Freddy” John Williams, Barry “Bazz” Lincoln, Stuart Woolnough, William “Bill” George Free, Vernon “Stork” Lloyd Pyke and Paul “Rowey” Rowe.

One minute’s silence was observed.

Floral tributes were placed against the wall from: “The Tasmanian Memorial Wall”, “The Victorian Truck Drivers Memorial”, and the “White Hill Truck Drivers Memorial” in South Australia, being laid by Rachel Rawlings, Adam Hodgetts and Tia Hodgetts.

The flags were respectfully lowered to half-mast by Wayne Pearce and Jonty Price and then whilst Pipe Major John Fardon from the Launceston RSL Pipes and Drums played “Amazing Grace” and suitable airs, the family and friends of those newly commemorated men filed quietly along placing colourful flowers in the niches alongside their respective plaques.

The 2026 memorial was, against the odds and the weather forecast, another moving and emotional day, one thoughtfully organised with their customary efficiency and due reverence by the committee.

We once again repeat that the road transport industry in Tasmania is indeed fortu-

future memorial plaques, with funding, and council permission, already received.

The newly tarred parking area was also duly noted and greatly appreciated.

This site is situated adjacent

it is a pleasure to see the memorial wall remaining secure in the capable hands of these present committee members who have proven to be truly dedicated guard ians of this important me morial, fulfilling a deep need f hard-working men can be respectfully remembered and their lives celebrated.

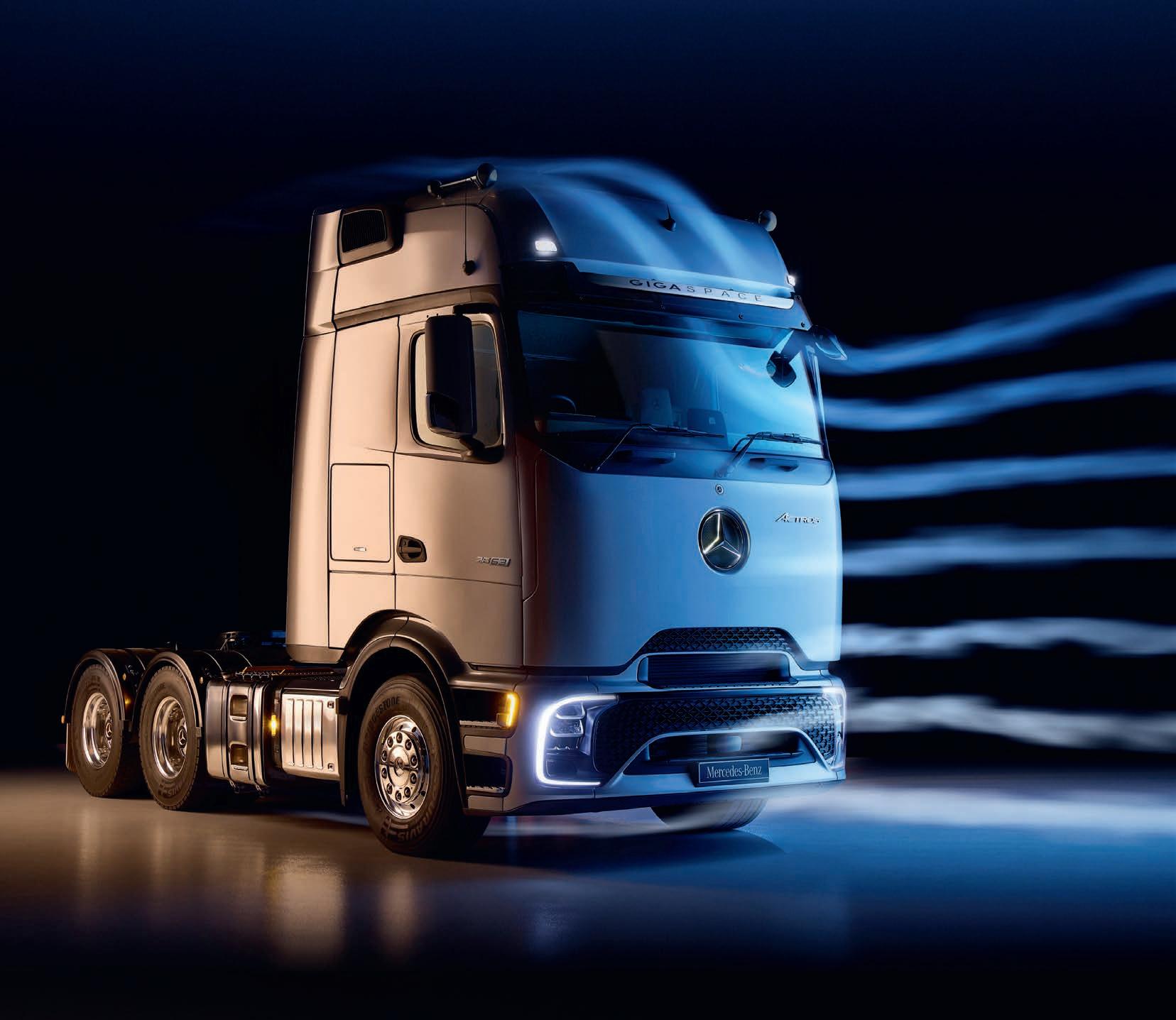

Introducing the Mercedes-Benz Actros ProCabin.

Evolution never stops. The redesigned Actros ProCabin has been reshaped to cut drag and boost your bottom line with ultimate fuel efficiency. Building on recent fuel economy and reliability upgrades, the ProCabin also delivers the kind of safety gains and driver comfort you expect from Mercedes-Benz Trucks.

DAVID VILE

“AUSTRALIAN made, heart and soul…she’ll be right, good as gold.”

Whilst the lyrics are from one of country music juggernaut The Wolfe Brothers’ latest songs, they apply nicely to Tim Blake’s all-Australian International C1600 4x4 truck which is still going strong after 53 years.

The bonneted 1964 ‘Inter’ today is a resident of Tim’s place at Broadford, just north of Melbourne, with the truck getting out and about to heritage rallies and get-togethers on a regular basis.

Late last year, Tim, accompanied by son Archie and father David, had made the trek up into the Riverina to the Urana Heritage Rally, where the C1600 was part of a large contingent of International product on show.

Tim has owned the International for a few years now, and like many project trucks, it has been a gradual overhaul in that time.

At the time of its purchase, Tim was over in New Zealand having found the truck on Facebook Marketplace, with the truck located at Yarram in the Gippsland region of Victoria.

“Dad went and had a look at it while I was over in New Zealand,” Tim explained.

“It was my son’s birthday and I was coming back from New Zealand for the weekend just to surprise him, but the surprise for me was Dad had bought it, so we went and picked this up and drove it back to Broadford.

“It had a blown-out manifold gasket so I drove it back with the windows down and the earmuffs on, so it was a long five-and-a-half-hour trip home.”

IT HAD A BLOWNOUT MANIFOLD GASKET SO I DROVE IT BACK WITH THE WINDOWS DOWN AND THE EARMUFFS ON, SO IT WAS A LONG FIVEAND-A-HALF-HOUR TRIP HOME.”

“It had a flat tray when we bought, we have changed that over to a beavertail.

“Ordinarily it has ramps on the back but they are off at the moment as it’s not good for the fuel economy - last year we bought a tractor up on the back but the fuel bill was monumental.

“I got the little crane for it for nothing so put that on along with the bullbar and visor.

“Some of the rims are yellow, and some army green under the paint, it’s had bits and pieces from everywhere but we have got it up to this state.

“Currently it is running a 282 petrol but have plans to re-power it with a turbo Perkins and a 5-speed at some stage,” he explained.

One of the factors that attracted the Blakes to the truck was its 4x4 capability - and back in the day the 4x4 International was a truck of choice for government departments, and so forth.

Despite some teething troubles on his first drive, Tim has found the Inter has plenty of ability off the blacktop.

Like many vehicles with a few years on the clock, the International has been through the hands of a few owners over its life span and Tim believes it was originally a fire truck with what was then the NSW Bush Fire Brigade, (now the NSW Rural Fire Service).

“I was a bit shocked when we got it out on the road - we didn’t know it was in low-range so we are punching along at about 40k’s and Dad said, ‘It’s going to be a long trip home’, so I thought I better check.

“I put it back into high range and off we went at 90 k home!

With over 30 years of experience in the Bullbar and Bumper Bar industry, we design bullbars that are technically more advanced than others on the market that can result in them being 25% stronger. We design our bars not only from our many years of experien ce but from customer and operator feedback, so that we can supply the industry with ultimate Bullbars, designed for safety, strength, aesthetics, and performance .

“The fella that owned it didn’t have a lot of history of it but I put two and two to-

gether as I had a photo of another C-Line with a fire body on it in the same colours and the same spec so we believe it was a fire truck and a couple of others I have spoken to have said the same thing,” Tim said.

“At some stage it got sold to a trade school, they did a lot of body work on it and that’s when it got painted in Nullarbor Beige and they did a lot of work on the cab as well.

“We bought it off an old couple who had been trying

to get it on the road but they had other things come up so we got it for bugger all.”

Working fairly solidly on the truck for about nine months after purchasing it, Tim just missed getting the International to that year’s

Urana Rally, with the truck making its first trek as part of the Crawlin the Hume event the following year.

While the International was in pretty good nick Tim has done a fair bit of work on it.

“But it’s good for us off the road, good for what we do we can send it up and down the hills and it just runs along, you do not even need to use the accelerator, it is just that tourquey,” he said.

Tim has had a long affinity with the beloved International brand and the fact that the

ACM BULLBARS SPECIALISE IN NEW BULLBARS, REPAIRS AND FITTING.

With over 30 years of experience in the Bullbar and Bumper Bar industry, we design bullbars that are technically more advanced than others on the market that can result in them being 25% stronger. We design our bars not only from our many years of experience but from customer and operator feedback, so that we can supply the industry with ultimate Bullbars, designed for safety, strength, aesthetics, and performance.

acmbullbars.com.au

truck is an Australian product through and through a lso means a lot.

“I have always been into ‘Inters’ and have loved them for a long time - my grandparents had a market garden and always had Internationals and the name has a lways stuck with me, and of course the name is not around much anymore.

“They did so much for

people back in the day, they were ‘the’ truck of the road. The fact they are all Australian - the engine block is f rom South Australia and it’s all Australian manufacturing which is what I love about it - and International was such an iconic brand in Australia, it is a shame it has all gone,” he lamented. With plenty of work done on the International and

some further future plans for it, Tim (and no doubt young Archie in the future) will be swinging the spanners on the C1600 and giving it a workout for some time yet.

“It was relatively decent when we got it and it had worked its whole life so now it’s just a bit of a toy and we are all just having some fun with it now.”

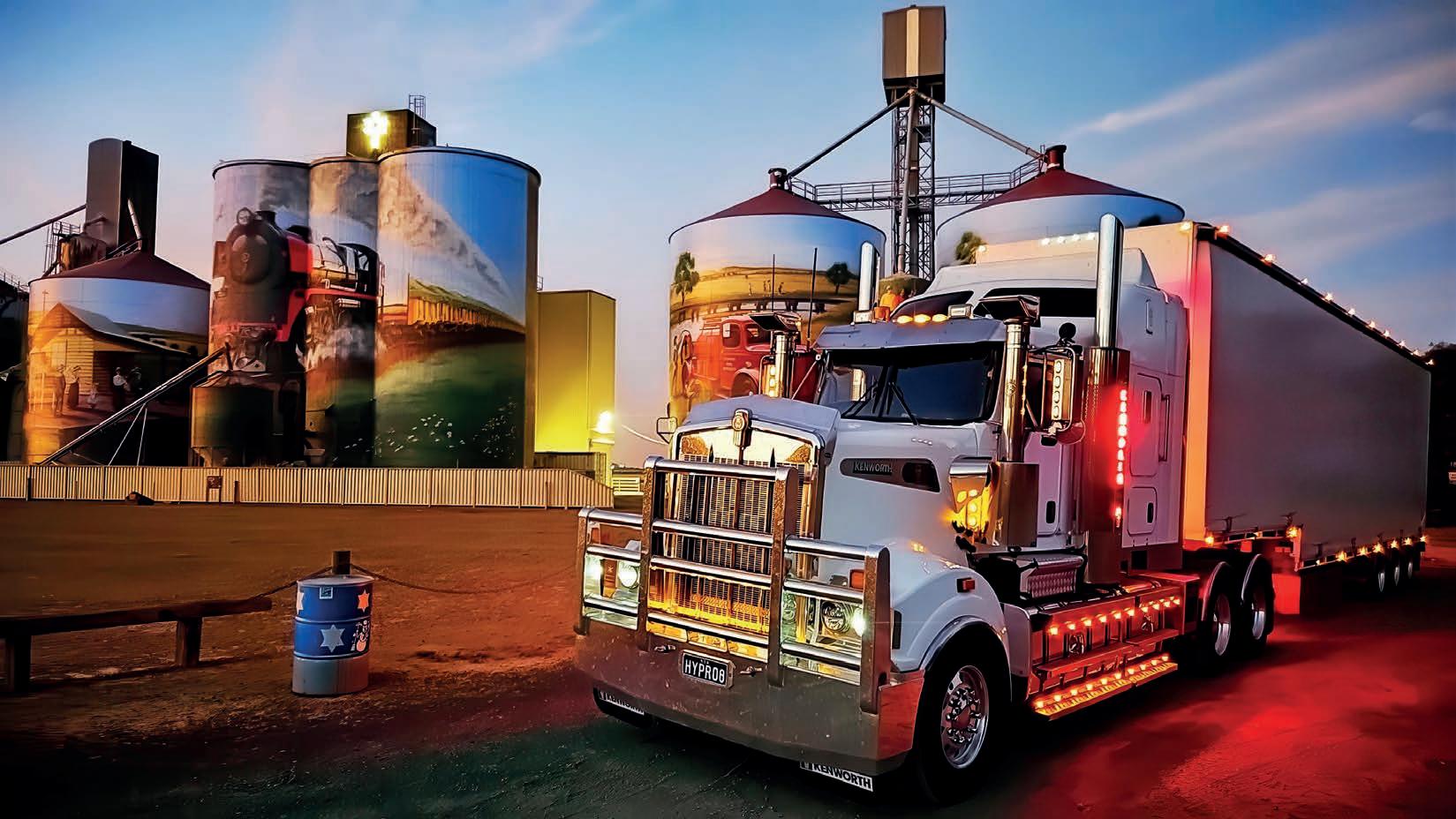

SHELL Rimula has partnered with Big Rigs in a big way – so there are even more reasons to send in your best truck shots.

Each month, the Big Rigs team will choose a #PicOfTheMonth, with the lucky winner receiving a $500 Shell Coles Express Gift Card.

Keep an eye out for our regular posts on the Big Rigs Facebook page, calling for your best truck photos and add yours in

the comments, or email them direct to danielle.gullaci@ primecreative.com.au for your chance to win the main prize.

Don’t forget to include a brief note about the truck and where the photo was taken. We’ll feature some of the best photos in each print edition of Big Rigs, with one winner announced each month.

Keep those amazing truck pics coming!

BY GRAHAM HARSANT

IF you like trucks, tractor pulls and the smell of burning rubber, then Tooradin is the place to go around the middle of January each year.

With a $25 entry fee it is not the cheapest event on the trucking calendar but you do get bang for buck if the above appeals and, looking at the queue of people lined up to get in, the organisers have created a successful formula.

This year (so I was told) there were some 112 trucks on show which was down on the number when I last attended two

plenty of quality on display as the accompanying photos illustrate.

One such was G&D Inverno from Dalmore in Gippsland, who specialise in dangerous goods, carting chemicals to wherever they are needed, and who brought four trucks along to Tooradin for the public to drool over.

Giuseppe, known to all as Peppi, and his wife Danielle have been in business for 26 years – since Peppi decided to branch out from working for his father and go it alone.

“My dad was a truck driver as well,” said Danielle. “So I grew

senger seat, learnt how to service trucks and I would go to truck shows with him. He told me to never marry a truckie but I knew what I was in for when I married Peppi – and who listens to their parents?

“Mind you, when we got married we said that we were never going to have a truck of our own. Now we have seven.”

Peppi added, “I figured if I was going to drive a truck I may as well own it so that’s how it started.”

Two of the trucks the Invernos brought along were Legends, an eight-year-old T900 hich was Rig of the Year in

no and the Dane Bellinger Memorial Truck Show. The other Legend, a much newer SAR won at Alexandra last year. So they are no strangers to winning, but as Danielle is quick to point out, their success is down to their two sons, Jeremy, 23, and Christopher, 19.

“They do everything to make our trucks look as they do – all the polishing and cleaning. We come to the shows to support what they are interested in doing. And it’s not just for the shows; they are like this every day of the week.

“Whenever the trucks are

ly inside. They are in the shed fiddling, polishing, whatever it takes. They will come to an event like this and walk around, studying and looking to see how they can do things even better for the next one. We are very proud of them. Their attention to detail is second to none.”

The boys’ work has paid off, as the Legend SAR will be at the Brisbane Truck Show Best of the Best next year as winner of Alexandra.

“I have the hard task of keeping it in this condition for the next 18 months until we go up there,” laughed Peppi. “I‘ll come home at the end of the week, the boys open the door and see food crumbs on the floor. ‘DAD! You’ve been eating in the truck, what’s going n?’ they’ll say.”

With that attitude the SAR should do well at Brisbane and any other event it attends.

And the Invernos did well at Tooradin winning Best Fleet, the Stuart Baker Memorial Trophy for their Kenworth Legend, and Runner-Up in Best Prime Mover 6 months-2 years, 5-10 years and 20-35 years, so well done lads.

As a postscript, the boys don’t drive for the family but both did apprenticeships. Jeremy is a full-time mechanic and Christopher is in his second year of ngineering.

first and if they want to go driving after that…”

I first interviewed David Rule – who owns Budget Tennis Courts – 10 years ago at Koroit where he won Truck of the Show with his Kenworth T650 – a rigid tautliner. Now he was at Tooradin with his other truck – a K100 tipper. It’s a 1985 model but looks superb both outside and in.

Originally a prime mover owned by Lamattina from Clyde it was a market truck. Two owners later, Dave bought it and did a bare metal restoration.

“Originally it had an 8V92 in it and that dropped a liner. Very few people can work on those now so I put a fully rebuilt Caterpillar 3406E in it. The truck has only done 900,000km from new, so barely run in.”

Apart from being “a pain in the arse to get in and out of” Dave loves the truck, so we were sad to hear that it and the T650 are both up for sale.

“Unfortunately I fractured my back. I’d like to say that I was on top of the 650 and a huge gust of wind blew me off but unfortunately nothing as flash as that. I caught Covid back in September, got really crook, went to bed and passed out for two days.

“Whilst I was unconscious, I fell out of bed and fractured my back. Luckily my son found me. Two weeks in intensive wards now. I will just have to

“I’m not selling the business but just have to do it differently and one of those differences is that my son who works with me can’t drive a manual. So I’ve bought an auto for him.”

So if anyone is looking for a classic 1985 K100 in absolute mint condition and low miles, Dave is asking around $110,000.

For that you’ll not have to spend an extra cent. If you’d like something newer, he’s after around $130K for the T650. You can call him on 0415 543 321. Good luck with your back and the future, Dave.

To view the full list of truck show trophy winners, head to bigrigs.com.au.

BY AUSSIE PUMPS

A couple of months ago the Aussie Pumps team made a point of complimenting the Big Rigs editor and journalist team. What Aussie Pumps was on about was the way the magazine pays tribute on a regular basis to the people who make the transport in dustry what it is. By that of c themselves.

The fact that Aussie Pumps is the Australian pressure cleaner industry leader, in terms of the development of high-pressure cleaning equipment is by the by. The point is that by reading Big Rigs Newspaper, the team at Aussie gets to better understand the trials and tribulations of the people who put uel in the outback service stations, groceries on the -

kets, and all those other things, there are too many to mention.

Without our road transport industry, and the people who dedicate themselves to driving and often investing everything, they’ve got the challenge of being able to experience the joys of owner driving.

Yes, it’s tough hitting metre-deep potholes and the beauty of travelling at high speed over corrugated outback roads.

“When we read in Big Rigs what Australian truckies have to put up with, we can do nothing but salute!” said Aussie Pumps’ Warwick Lorenz.

Aussie’s response

“Yes, we know that you do all that part. But from our perspective, we don’t only build Australia’s best tanker pumps. More recently we introduced water carts pumps, now sporting 316 stainless steel self-priming centrifugal pumps that will deliver up to 2200 litres a minute. Yes, we do that and lots more,” Warwick added.

We also listen to drivers, many of whom do up to 500 or 600 kilometres a day then at the end of the week have to wash their vehicle. That can be a big effort and takes valuable time which would be

better spent fishing or having a beer with your mates,” said Warwick.

That’s where Aussie comes in with cleaning equipment that is fast, time saving and most of all, safe. Everyone knows that pressure cleaners can be dangerous in the hands of the uninitiated.

Aussie Pumps has a free High Pressure Cleaning Safety Programme. They offer a certificate course, that only takes 20 to 40 minutes to do. Scan the QR Code to access the course.

If you’re using pressure cleaners to clean your rig,

you need to do the training course and see just how Aussie Pumps can literally shave hours off cleaning any ‘big rig’.

They cut their teeth on earthmoving plant and mining gear. Give them a call. Aussie Pumps’ plan is to make your life easier and safer.

For further information on the free truck wash safety training programme and Aussie’s new pressure cleaner service fundamentals, call 02 8865 3500 to get your copy. It features all you need to know about Triplex Pumps.

Scan

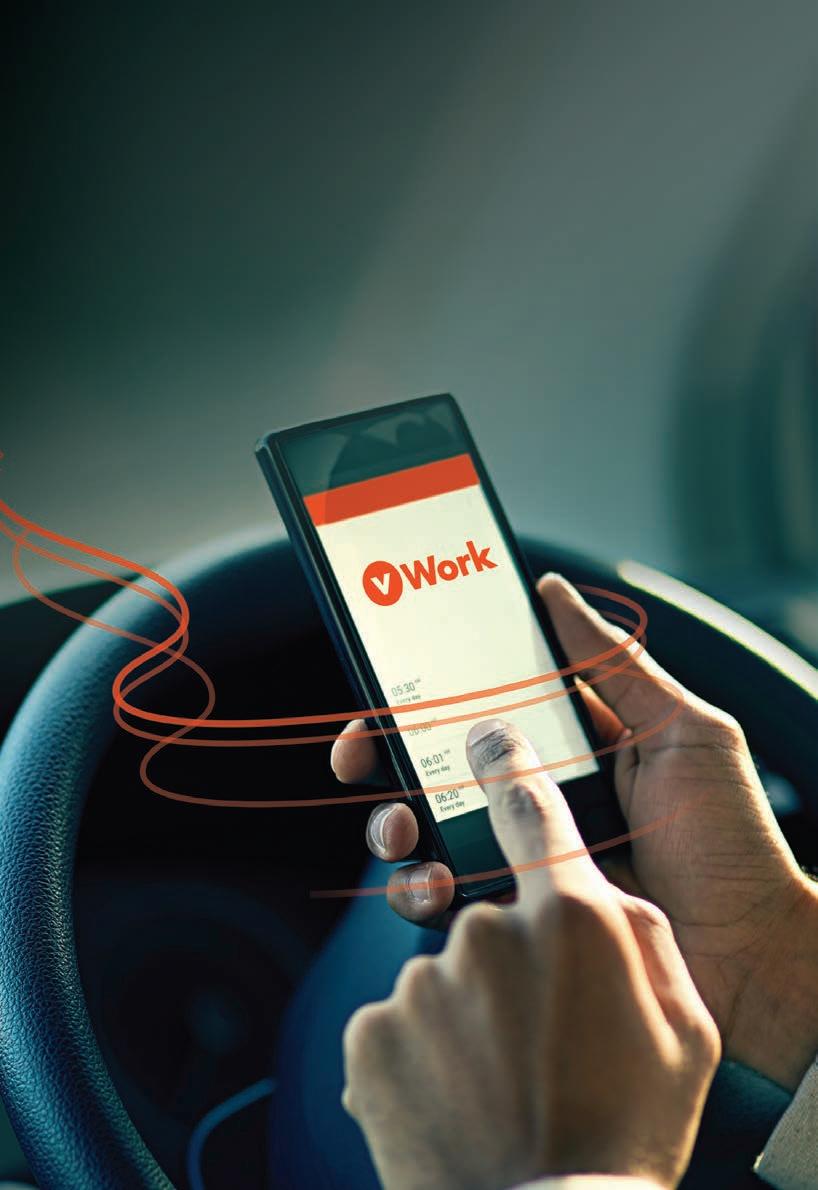

BY ROY MOODY, CEO OF VWORK

I N the heavy-duty world of bulk haulage and construction materials, the sight of a truck rolling onto a site has always been the ‘moment of truth’. But as we head into 2026, the nature of that transaction has fundamentally shifted. It is no longer just about moving a tonne of gravel or a pallet of bricks from A to B; it is about the service experience surrounding that move.

Our recently completed 2025 State of the Fleet survey, which gathered insights

from fleet leaders across Australia and New Zealand, revealed an industry in a highspeed transition. With rising vehicle costs, increased customer demands to meet new emissions standards and advanced safety features – not forgetting a growing driver shortage – the window to generate a return on investment (RoI) is narrowing. To thrive, fleet owners must move beyond simple tracking and master the ‘what’ of the work itself. Here are three ways to maximise your fleet’s RoI this year.

1. The high cost of the ‘second trip’

The most immediate drain on a fleet’s bottom line is the failed delivery. In bulk haulage, if a driver misses a window at a Tier 1 construction site or delivers to the wrong coordinate, the cost of the job doesn’t just increase – it can more than double. You have the fuel and labour of a second trip, plus the potential loss of materials in shifting the load a second time.