International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Chetan Ravindra Zade

Flat no 205 Manish Nagar, Nagpur 440037

Professor: Dr. Pritam Malakar, Dept. of Civil Engineering, GH Raisoni University Amravati Maharashtra India

Abstract - Water hardness, primarily caused by dissolved calcium (Ca²⁺) and magnesium (Mg²⁺) ions, poses significant challenges in both domestic and industrial water usage. Excessive hardness leads to scaling in pipelines, boilers, and householdappliances,therebyreducingoperationalefficiency and increasing maintenance costs. In this study, a Resino Hydrosoftener, an advanced ion exchange-based water softening system, has been utilized for the reduction of total hardnessingroundwatersamplescollectedfromruralregions near Nagpur. The Regino Hydrosoftener operates ona strong acid cation exchange resin, wherein calcium and magnesium ions are replaced with sodium (Na⁺) ions during the softening cycle. Experimental procedures involved passing hard water throughthehydrosoftener unitandanalysinghardnesslevels pre- and post-treatment using the standard EDTA titrimetric method, as per APHA 2340-C. The study demonstrated a significant reduction in total hardness from initial values of 320–450 mg/L (as CaCO₃) to below75 mg/Lafter treatment, falling well within the BIS (IS 10500:2012) permissible limits for potable water. The performance efficiency, resin regeneration frequency, and water flow rates were also monitored and analysed. This paper highlights the applicability and efficiency of Regino Hydrosoftener in rural water treatment setups, especially for sustainable and lowmaintenance water purification in resource-constrained environments.

Keywords: Water Hardness, Ion Exchange, Regino Hydrosoftener, Calcium, Magnesium, EDTA Titration, Rural Water Treatment, BIS Standards

1.INTRODUCTION

Water is one of the most essential natural resources requiredforsustaininglife.However,the quality of water, especiallyintermsofitschemicalcomposition,playsavital roleindeterminingitssuitabilityfordomestic,agricultural, and industrial purposes. One of the major issues affecting water quality in both rural and urban regions is water hardness, which is primarily due to the presence of divalent metal ions, mainly calcium (Ca²⁺) and magnesium (Mg²⁺). These ions react with soaps, reduce lather formation, and cause scaling in plumbing systems, boilers, and industrial machinery. Hard water is not only inefficient for daily use but also results in increased maintenance costs, energy consumption, and reduced appliancelifespan.

InruralareasnearNagpurandotherregionsacrossIndia, groundwater is the principal source of drinking and domesticwater.However,inmanycases,thisgroundwater exhibits high levels of hardness, often exceeding the permissiblelimitsprescribedbyBureauofIndianStandards (BIS:IS10500:2012)forpotablewater.Thisnecessitatesthe implementation of effective water softening technologies that are both affordable and sustainable in decentralized settings.

The present study focuses on the utilization of the Resinohydrosoftener,acompactandefficientionexchangebased water softening unit. The Resinohydrosoftener employscationexchangeresintechnology,whereincalcium andmagnesiumionsareremovedbyexchangingthemwith sodiumions,thussignificantlyreducingthetotalhardnessof the water. This process is both chemically effective and operationallysimple,makingitsuitableforuseinruraland small-scaleapplications.

This research aims to evaluate the performance of the Resinohydrosoftener through a series of controlled experiments.Theobjectiveistodetermineitsefficiencyin hardness removal, regeneration cycles, flow rate compatibility,andoverallapplicabilityinaruralcontext.The findingsofthisstudyareexpectedtosupporttheadoptionof such technologies for improving rural water quality and publichealthoutcomes.

This paper addresses the design and implementation of resionohydrosoftnerwhichisbeneficiallyusedforreducing thehardnessofwater

TableNo.1HardnessClassification

Villagename Observationonwatersample PH

Amra 877 86 2698

Hingna 6.22 326.08 23.44

Digdoh 611 30434 252

Wanadongri 78 270 2690

Amgaon 79 260 2322

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Water hardness is typically classified based on the concentrationofcalciumandmagnesiumions,expressedin milligramsperlitre(mg/L)ascalciumcarbonate(CaCO₃). Accordingtostandardclassification,waterisconsidered:

Soft:0–75mg/L

Moderatelyhard:76–150mg/L

Hard:151–300mg/L

Veryhard:>300mg/L

In the Nagpur district and surrounding rural areas, groundwaterservesastheprimarysourceofdrinkingand domestic water. Recent surveys and water quality assessments conducted by local water authorities and academic studies indicate that a significant portion of the groundwater inthisregionfallsunderthe"hard"to "very hard"category.Inmanyvillages,totalhardnesslevelshave beenreportedintherangeof320to450mg/LasCaCO₃,far exceedingthedesirablelimitof200mg/LsetbyBureauof IndianStandards(BIS:IS10500:2012).

This elevated hardness is largely due to the geological composition of the region, which includes limestone, dolomite,andothermineral-richstratathatcontributetothe leachingofcalciumandmagnesiumintoaquifers.Suchhigh hardnesslevelsnotonlyaffectwaterusabilityfordomestic choresbutalsoleadtoscalinginpipes,storagetanks,and electricalappliances.Therefore,theclassificationofwater hardness in this region becomes a critical parameter for selectingappropriatewatersofteningtechnologieslikethe Resinohydrosoftener

2.1 Parseoni Village, Nagpur

Inthesemi-ruralareaofParseoni,locatedinNagpurdistrict, groundwater was found to have high total hardness averaging410mg/L(asCaCO₃).AResinohydrosoftenerunit with500LPHcapacitywasinstalledatthevillageborewell. Post-treatment results showed a consistent reduction in hardnesstobelow70mg/L,improvingwaterusabilityand preventingscaleformationinhouseholdsystems.Theresin requiredregenerationevery7–8days,andthemaintenance wasmanageableevenwithminimaltechnicalsupport.The communityreportedhighersatisfactionwithwaterquality afterimplementation.

2.2 Meerut Rural Belt (Uttar Pradesh)

In a cluster of villages near Meerut, groundwater drawn fromtubewellsshowedextremehardness,oftenexceeding 500mg/L.Thecausewastracedtothelocalgeologyrichin calcium-bearing minerals. A Resinohydrosoftener was installed in one of the community centres to test its

effectiveness.Withinthefirstweek,treatedwatershoweda drasticreductioninhardnesslevelsto65mg/L.Thetreated water allowed improved cleaning efficiency, and users experiencedlesssoapconsumptionandnoscaledepositson taps and utensils. The softener system was praised for its low operational cost and easy regeneration process using sodiumchloride.

In the outskirts of Coimbatore, where textile industries coexistwithresidentialcolonies,waterhardnesslevelswere observed at around 360–420 mg/L due to borewell dependency. A pilot-scale Resinohydrosoftener was introduced in a school premises to evaluate performance under consistent daily usage. The system successfully maintainedtreatedwaterhardnessunder75mg/Lforover twoweekswithoutregeneration.Theresinshowedexcellent life-cycle performance, and even teachers noted reduced wear and tear on laboratory glassware and water heating systems.Thesuccessledtorecommendationsforinstalling similarsystemsinothernearbyinstitutions

3.1 Selection of Study Area

Thestudyfocusedonruralandsemi-urbanregionsknown forhighgroundwaterhardness,includingvillagesinNagpur (Maharashtra), Meerut (Uttar Pradesh), and Coimbatore (TamilNadu) Theseareaswereselectedbasedonprevious water quality reports, community complaints regarding scaling and soap inefficiency, and accessibility for onsite experimentation.

3.2

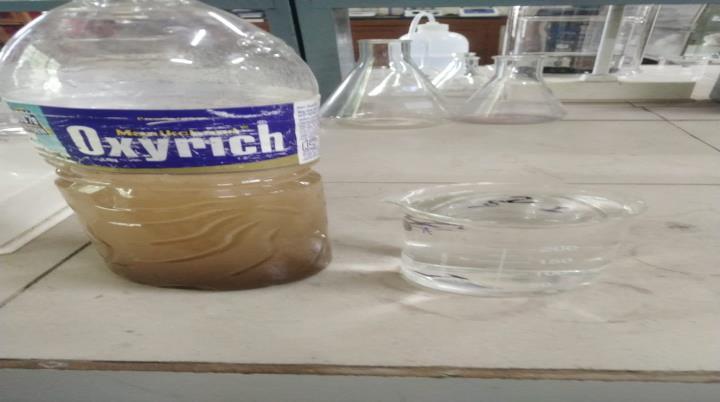

Groundwatersampleswerecollectedfromborewellsused fordomesticconsumptionineachselectedlocation.Samples were taken in 1-liter pre-cleaned polyethylene bottles, following standard water sampling techniques to avoid contamination or alteration of hardness. Bottles were labeledandtransportedimmediatelytothetestingsite

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Beforetreatment,eachwatersamplewassubjectedtothe followinglaboratoryanalyses:

Total Hardness was determined using the EDTA TitrimetricMethod(APHAStandardMethod2340C),withresultsexpressedinmg/LasCaCO₃.

CalciumandMagnesiumHardnessweredetermined separatelyusingstandardtitrationtechniques.

OtherparameterssuchaspH,TDS(TotalDissolved Solids),andelectricalconductivityweremeasured using portable digital meters to understand the overallwaterchemistry.

3.4 Installation of Resinohydrosoftener Unit

AResinohydrosoftenerunitwithacapacityof500LitersPer Hour(LPH)wasinstalledateachtestsite.Theunitisbased onionexchangetechnology,whichusesastrongacidcation exchangeresininsodiumform.Duringthesofteningprocess, calcium(Ca²⁺)andmagnesium(Mg²⁺)ionsinhardwaterare exchangedwithsodium(Na⁺)ionspresentintheresinbed.

The system was connected to the raw water outlet (e.g., borewell or overhead tank supply), and hard water was passedthroughthesoftenerundergravityorwiththehelpof aboosterpump

3.5

WaterwasallowedtoflowthroughtheResinohydrosoftener at a consistent rate. The resin inside the columnadsorbed Ca²⁺andMg²⁺ions,effectivelyreducingwaterhardness.A contact time of 5–10 minutes was maintained, ensuring adequate ion exchange. Treated water was collected after flow stabilization and stored in labeled containers for analysis

3.6 Post-Treatment Analysis

Theoutput(treated)waterwastestedusingthesameEDTA titrimetric method to determine residual total hardness.

AdditionalparameterslikepHandTDSwerealsorechecked toensurenoadversechangesoccurredduringtreatment

The Resinohydrosoftener is designed with a flow rate capacityof500litersperhour(LPH), suitablefortreating 1500–2000 liters of water per day. It operates efficiently underlowpressure(1–2kg/cm²), makingitidealforrural areas where water is supplied through gravity or small pumps. The capacity is optimized for small households or community-levelusage,ensuringeffectivehardnessremoval withlowmaintenance

The resin column is made of FRP or HDPE, ensuring durabilityandchemicalresistance.Itis1200mmhighand 250mmindiameter,containinglayersofgravelandsandto supporttheresinandallowsmoothwaterflow.Thecolumn holdsthecationexchangeresin,withinletandoutletvalves foreasyoperationandregeneration. makesitcompact,lowmaintenance,andsuitableforruraluse.

The supporting media inside the resin column includes a gravellayer(5–10mm)atthebottomforproperdrainage andflowdistribution,andasandlayer(0.5–1mm)aboveit topreventresinlossduringoperation.Together,theyensure uniformwaterflow,protecttheresinbed,andimprovethe overallefficiencyofthesofteningprocess

The brine tank is used for regenerating the resin by supplyinga 10%sodium chloride(NaCl)solution.Ithasa capacityofaround30litersandrequiresabout3–4kgofsalt per regeneration cycle. During regeneration, the brine solution flows through the resin bed, restoring its ion exchange capacity. The process takes 20–30 minutes, followedbyrinsingfor5–10minutes.

The system uses a strong acid cation exchange resin in sodium (Na⁺) form, such as Indian 225 Na. It has an exchangecapacityof1.9–2.0meq/mL, workseffectivelyina pHrangeof6.5to9.0,andcanwithstandtemperaturesupto 50°C. Theresintypicallylastsfor2to3yearsundernormal usage.

TheResinohydrosoftenersystemisinstalledonaconcreteor steelplatformnearawatersourcelikeaborewell,school,or

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Panchayat Bhavan. It requires no electricity, works on gravityorlowpressure,andiseasytooperatebylocalusers. Itscompactdesignmakesitidealforruralandsemi-urban areas

IntheResinohydrosoftener,rawwaterentersthrough theinletvalve,passesthroughthe resincolumnwhere ion exchange removes hardness, and exits via the outlet as soft water. During regeneration, brine solution from the brine tankflows through the resin bedandisthenflushedoutthroughthedrainvalve.

TheResinohydrosoftenersystemprovestobeanefficient, low-cost,andsustainablesolutionfortheremovalofwater hardness,especiallyinruralandsemi-urbanregionswhere access to treated water is limited. Through the use of a strong acid cation exchange resin, the system effectively reduces calcium and magnesium ion concentrations, ensuringsoftandusablewaterfordailyneeds.Itscompact design, simple installation, and minimal operational requirementsmakeithighlysuitablefordecentralizedwater treatment. Case studies from regions like Nagpur demonstrateitspractical utility,easeofregeneration,and consistentperformance.Overall,theimplementationofsuch systems can significantly improve water quality, reduce scalingissuesinplumbing,andpromotebetterpublichealth outcomesinunderservedcommunities

6.REFERENCES

Water Conditioning & Purification Magazine. (2004). Learn it Right the First Time: Guidelines for Designing Water Softeners.

IS 10500:2012. Indian Standard for Drinking Water –Specification.BureauofIndianStandards,NewDelhi.

Maiti, S. K. (2004). Handbook of Methods in Environmental Studies: Vol. I – Water and Wastewater Analysis.ABDPublishers,Jaipur.

ArticleJuly2016jayPatelionexchangeresins

Basak N.N,” text book of environmental engineering”, volume15,June2012,

Al-Muthanna University, Al-Muthanna, Iraq International Journal of Applied Engineering Research and Development (IJAERD) ISSN(P): 22501584;ISSN(E):2278-9383Vol.4,Issue1,Feb2014,6368(c)TJPRCPvt.Ltd.

Sengupta p.s “potential health impact of hard water”, internationaljournalofpreventivemedicine,medknow publication

Mahamudfathy s.m, abdul t.h, “sulphonated ion exchangepolystyreneresin”2013.

RP.Dhok1*AS.Patil2andVS.Ghole3Vol.2(1)Jan-Mar 2013 international journal of pharmaceutical and chemicalsciencesISSN:2277 5005

K.Hanaoka,D.Sun,R.Lawrence,Y.Kamitani,andG.Fernandes,BiophysicalChemistry,vol.107,no.1,pp.71–82,2004

Aditi Pal, Monit Pal, Prosenjit Mukherjee, Anindya Bagchi*, Anusree Raha Netaji Subhas Chandra Bose Institute of Pharmacy, West Bengal, India. https://doi.org/10.31024/ajpp.2018.4.2.17 Asian JournalofPharmacyandPharmacology2018;4(2):203206