International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Piyush Sharma*, Sayantan Ghosh **

*Master degree scholar, Department of Civil Engineering, Maharaja Agrasen University Baddi , Himachal Pradesh

**Assistant Professor, Department of Civil Engineering (MAIT), Maharaja Agrasen University Badd , Himachal Pradesh***

Abstract

The construction industry is a major contributor to global carbon emissions, primarily due to Portland cement production. This study investigates the potential of Recycled Concrete Powder (RCP), obtained from Construction and Demolition (C&D) waste, as a Supplementary Cementitious Material (SCM) in mortar. RCP was thermally treated at temperatures of 650°C, 700°C, and 750°C to enhance its pozzolanic activity. Mortar samples were prepared by replacing cement with 5% and 10% of treated RCP. Physical, mechanical, and durability properties were evaluated through standard tests. The results show that 10% replacement with RCP calcined at 650°C and 700°C yielded compressive strength with great sustainability. RCP shows promising potential as a green SCM , contributing to circular economy and reduction of environmental footprint. It can be used as alternative of cement and can contribute with cement in construction field perspective.

KEYWORDS-

Recycled Concrete Powder, Construction And Demolition waste, Supplementary Cementitious Material, Calcined Concrete Powder.

1. Introduction

Cement production accounts for approximately 8% of global CO₂emissions,drivenbytheenergy-intensive nature of clinker production. In parallel, the construction sector generates vast quantities of Construction and Demolition (C&D) waste,withover2billiontonsproducedannuallyworldwide.Asignificantfractionofthiswaste,whenprocessed,results infineparticlesknownasRecycledConcretePowder(RCP),typicallylessthan150µminsize.

This study explores the feasibility of utilizing RCP as a Supplementary Cementitious Material (SCM) in mortar mixtures SCMs such as fly ash and silica fume are already proven to enhance durability and reduce cement demand. RCP, with properactivation,canpotentiallyoffersimilarbenefitswhilecontributingtosustainablewastemanagement.

2. Materials and Methods

2.1 Materials

ThecementusedinthisstudyisofultratachOPC(grade43)andthesandisacquiredfrom naturalriversandofzone-Ⅱ, tested for silt content , water absorption and gradation . The RCP is derived from crushed and sieved demolished concrete(<75um).Thewaterusedinthisstudyisportablewater.

2.2 Thermal Treatment of RCP

RCP was thermally activated using a muffle furnace at 650°C, 700°C, and 750°C for 3 hours. The calcined samples were observedforcolorchangeandtestedforLossonIgnition(LOI).

2.3 Mix Proportion and Casting

Nine mortar mixes were prepared following ASTM C311, with water-to-binder ratio 0.5 and binder-to-sand ratio 1:2.75. Cement was replaced with RCP at 5% and 10% levels for each calcination temperature. Cubes (50 mm) were cast and testedat7and28daysforcompressivestrength.AsshowninnTable.1.

International Research Journal of Engineering and Technology (IRJET)

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net

2.4. Experimental Tests

1. FlowTableTest(ASTMC1437)

2. CompressiveStrength(ASTMC109)

2.4.1 FLOWABILITY

The flow table test revealed reduced flow with increasing RCP content and calcination temperature, indicating higher water demand and lower workability due to finer particles.By using ASTM (C1437) for mortar with RCP, it is used to evaluatetheflowabilityofRCPbasedmortar,showinchart.1.

Chart.1, Flow

of mortars

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

2.4.2 Compressive Strength

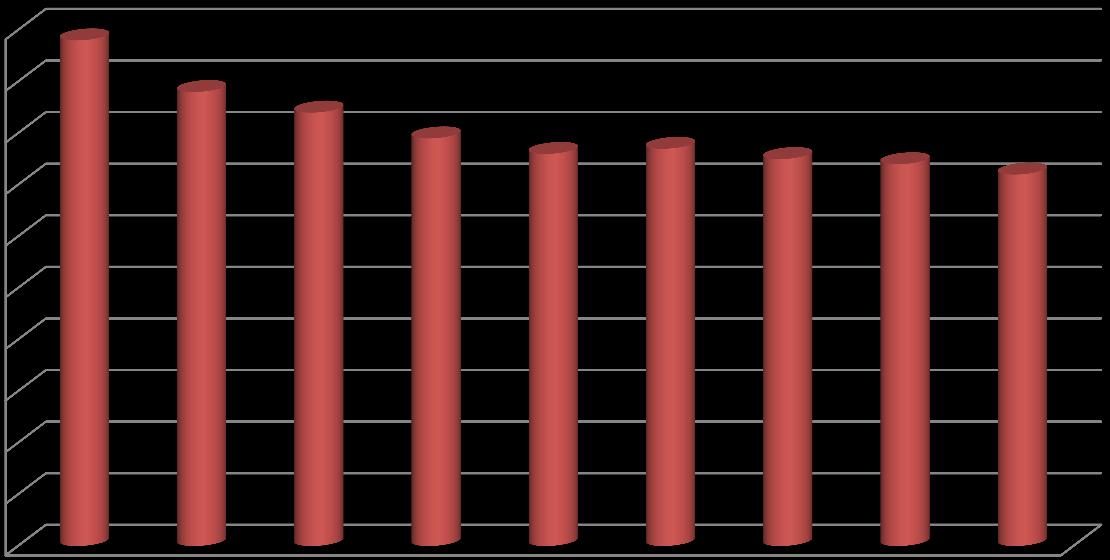

Compressive strength at 7days and 28 days of RCP mortar shown in chart.2. The 650TS10 and 700TS10 sample showed the highest strength among RCP mixes, even exceeding untreated samples and approaching reference performance. UntreatedRCPshowedlowerstrengthduetounreactedphasesandhigherporosity.

Chart.2 Compressive strength at 7 days and 28 days

7 days

28 days

2.5 Environmental Benefits

UsingRCPhelpsreduce:

1. CO₂emissionsfromclinkerproduction

2. Demandfornewaggregates

3. Landfillingofconstructionwaste

ThestudyvalidatesthatRCP,whenthermallytreated,canserveasasustainableandfunctionalSCMinconcrete.

3. Conclusion

ThermaltreatmentsignificantlyenhancesthereactivityofRCP.Thesamplewith10%RCPreplacementcalcinedat 650°C (650TS10) and 700°C (700TS10) achieved compressive strength close to traditional mortar while improving environmentalperformance.Forbetterperformancethecalcinedrangeisbetween650to700°C.Thestudysuggeststhat properly treated RCP can be a viable SCM for use in mortar and concrete, supporting sustainable construction practices andcirculareconomygoals.Calcinedconcretepowdershouldbeusedratherthanuntreatedpowder,ascalcinedpowder shows greater compressive strength as shown in the Fig.2 Calcination of RCP resulted in a 20% enhancement in compressivestrength,indicatingimprovedpozzolanicreactivity.

4. Future Scope

1. Further study is needed on chemical and thermal activation techniques to enhance its pozzolanic reactivity of RCP, makingitmoreeffective cementreplacement.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

2. MorestudiesarerequiredtoevaluateRCPsperformanceinhigh-performanceconcrete(HPC),durableconcrete,selfcompactingconcrete(SCC),especiallyinaggressiveandpollutedenvironment.

3. DevelopmentofIS/ASTM/BSstandardsortechnicalguidelinesforsafeandeffectiveuseofRCPin concretemixtureis essentialforindustry-wideacceptance.

5. References

[1] J. Rocha and F. T. RD, “The utilization of recycled concrete powder as supplementary cementitious material in cement-based materials,” 1 October 2023. [Online]. Available: https://www.sciencedirect.com/science/article/abs/pii/S2352710223014997.

[2] Q.Tang,Z.Ma,H.WuandW.Wang,“Theutilizationofeco-friendlyrecycledpowderfromconcreteandbrickwaste in new concrete,” November 2020. [Online]. Available: https://www.sciencedirect.com/science/article/abs/pii/S0958946520303139.

[3] Q.Zhao,W.Gao,Y.SuandJ.Wang,“HowcanC&Dwasterecyclingdoacarbonemissioncontributionforconstruction industry in Japan city?,” 1 November 2023. [Online]. Available: https://www.sciencedirect.com/science/article/abs/pii/S0378778823007685.

[4] X. Chen, Y. Li, H. Bai and L. Ma , “Utilization of Recycled Concrete Powder in Cement Composite: Strength, Microstructure and Hydration Characteristics,” 19 june 2021. [Online]. Available: https://www.sciencedirect.com/org/science/article/pii/S2164632521000135.