International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Sankalp Kukreja

Student, Step By Step School, Delhi, India

Abstract - Fossil fuels have long dominated the global energy landscape, but their environmental impact is becoming unsustainable. The burning of fossil fuels releases significant amounts of carbon dioxide (CO₂) and other greenhouse gases, contributing to global warming and severe air pollution. With the intensifying effects of climate change and dwindling fossil fuel reserves, there is an urgent need for renewable, low-emission energy alternatives. Microbial Fuel Cells (MFCs) present a promising solution by generating electricity through the metabolic activity of bacteria. These systems not only emit minimal pollutants but also offer the added benefit of organic waste treatment, making them especially attractive for integrated sustainabilitygoals.

ThispaperfocusesonoptimizingMFC designspecifically for application in India, where the availability of agricultural waste and decentralized energy needs make MFCs particularly viable. Through a systematic literature review and analysis of experimental datasets, I identify optimal design parameters such as electrode area, material, proton exchange membrane (PEM) composition, substrate concentration, and microbial culture that balance performance, scalability, and cost-effectiveness. A decision matrix was developed to evaluate and prioritize these parameters based on power density, Coulombic efficiency, andpracticalfeasibility.

The proposed design is tailored for large-scale, stacked configurations suitable for rural electrification and wasteto-energy conversion. Future research could build on this framework by exploring the long-term durability of MFC components, real-world implementation challenges, and economic feasibility in varying socio-environmental conditions.

Key Words: Fuel Cells, Microbial Fuel Cells, Sustainable Energy, Renewable Energy, Proton Exchange Membrane, Stacked MFC Configuration, Electrode Design

1.INTRODUCTION

Microbial Fuel Cells are bio-electrochemical systems that convert chemical energy, stored in organic compounds, directly into electrical energy using the metabolic processesofmicroorganisms[1].Intheabsenceofoxygen, these microorganisms break down organic matter and

release electrons, which the MFC captures and directs through an external circuit to generate electricity [4]. In addition to producing electricity, MFCs have the potential totreat organicwaste,offeringa dual-function system for energyproductionandwastemanagement.

InsidetheMFC,bacteriainanoxygen-freechamber(called the anaerobic/anode chamber), consume sucrose, breaking it down in a process that releases electrons (e⁻) and protons (H⁺) as byproducts. These electrons travel from the anode and pass through an external circuit to reach the cathode in a separate chamber, generating an electriccurrent.Thiscanberepresentedasfollows:

The protons move through a semi-permeable membrane (also known as proton exchange membrane, PEM) to join electrons in the cathode chamber, where oxygen (O₂) combineswiththemtoproducewater(H₂O).Thisprocess completes the circuit and produces electrical power, makingMFCsacleanenergysourcewithlowemissions.

In India, MFCs hold unique potential due to the country's vast agricultural biomass. As one of the largest producers of sugarcane globally, India generates large quantities of sucrose-rich biomass that can serve as an ideal fuel for MFCs. This technologycouldhelpIndia reduce itsreliance on fossil fuels, decrease pollution, and provide a

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

decentralized energy solution for rural areas with limited access to power grids, making MFCs a transformative optionforIndia'senergyfuture.

MFCs also offer distinct advantages over other forms of sustainable energy, making them particularly suited for India’s unique energy needs. While solar, wind, and hydropower are popular renewable energy sources, each has limitations in terms of geography, infrastructure, and reliability [2]. MFCs, on the other hand, can operate in a variety of settings, including small-scale, decentralized locations, making them highly adaptable. By generating electricity from organic waste, MFCs address both energy production and waste management needs, offering a dual benefitthatalignswithIndia'ssustainabilitygoals.

Table-1: AdvantagesofMFCsoverotherbiofuels

Problem Addressed by other biofuels Solved by MFC’s

High organic waste and untreated water

Limited capacity in using organic waste; mostly require refined biomass

Dependence onfossilfuels

Inefficient biofuel production

High operational cost of bioenergy technology

Biofuels can reduce fossil fuel use but often need extensive cultivation and processing

Requires complicated processes such as fermentat

Biofuels need high energy input and maintenance for continuousoperation

Usesorganicwaste as a substrate, simultaneously treating waste and generating electricity

Uses microbial metabolism to convert biomass directly into energy, reducing emissions

Directly converts chemicalenergyto electricity, avoiding complex processes

Operates at ambient temperatures with low maintenance, thus reducing costs

1.2 How MFCs Work: Process Breakdown

Fig-2:MFCProcessFlowChart

1.IntroductionofSucroseintotheAnodeChamber:

The processbegins byintroducinga sucrose-richsolution into the anode chamber of the MFC. This chamber is designed to be oxygen-free (anaerobic) to create an ideal environment for specific bacteria that thrive without oxygen. These bacteria are known as exoelectrogens because they can transfer electrons outside their cells during metabolism [10]. The absence of oxygen is crucial because it prevents the bacteria from using oxygen as an electron acceptor, directing the electrons towards the anodeinstead.

2.MicrobialMetabolizationofSucrose:

Within the anode chamber, the exoelectrogenic bacteria consume the sucrose as their energy source. Through metabolic processes, they break down the sucrose into simplercompounds,releasingelectronsandprotonsinthe process. This breakdown is part of the bacteria's natural energyextractionfromorganicmatter.Theelectronsarea byproductofthismetabolicactivity.

3.ElectronTransfertotheAnode:

Theelectronsreleasedduringmetabolismaretransferred to the anode, a conductive electrode within the chamber. Thistransfercanoccurthroughdirectcontactbetweenthe bacteriaandtheanodeorviaconductivestructuresknown as nanowires that some bacteria possess [17]. These nanowires facilitate the movement of electrons from the bacterial cells to the anode surface. Ultimately, these nanowires are responsible for the conversion of the chemicalenergyreleased,intouseful,electricalenergy.

4.ProtonmigrationthroughthePEM

Simultaneously, the protons produced during the breakdownofsucrosemigratefromtheanodechamberto the cathode chamber. This movement occurs through a specialized barrier called a proton exchange membrane (PEM). The PEM allows protons to pass while preventing themixingofothersubstancesbetweenthetwochambers, maintaining the necessary separation for the MFC to function effectively. PEMs work by allowing only positively charged protons (H⁺) to pass through their selectively permeable structure while blocking other particles, such as electrons and larger ions. This selective filteringisdonebythemembrane’schemicalcomposition, which contains sulfonic acid groups that attract and thus causethemovementofprotonsacrossthemembrane[18].

5.ElectronFlowThroughtheExternalCircuit

The electrons collected at the anode cannot pass through thePEM.Instead,theytravelthroughanexternalelectrical circuit (through nanowires) connecting the anode to the cathode. As electrons move through this circuit, they

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net

generate an electric current, which can be harnessed to power electrical devices or stored for later use. Upon reachingthecathodechamber,theelectronscombinewith theprotonsthathavemigratedthroughthePEMandwith oxygenpresentinthecathodechamber.Thiscombination resultsintheformationofwater,completingtheelectrical circuit. The oxygen in the cathode chamber acts as the final electron acceptor, a role essential for sustaining the flowofelectronsthroughthesystem.

The performance of a Microbial Fuel Cell depends on several interrelated design variables that influence the efficiency of electron transfer, the rate of microbial metabolism, and the overall electrical output. These parameters can be broadly categorized as either quantitativeorqualitative,dependingonwhethertheyare numerically adjustable or material/configuration-based. Understanding the role of each parameter is essential to optimizing power density, Coulombic efficiency, and systemscalability.

Table-2: MFCDesignVariablesandtheireffects

Parameter

Electrode Area

Electrode Material

Quantitativ e Determines the amount of space available for bacteria to break downthesubstrate.

•Greaterelectrodearearesultsin faster decomposition, and thus greater current density and overallperformance[3]

• However, an electrode that is too large can become more expensive and can also cause greater external resistance in the circuit

Qualitative Determines:

• The degree of conductivity of the circuit • The rate of the reaction as facilitated by the microbes

• The internal resistance in the circuit

• The longevity and durability of thecell

•Thecostofthecell

Electrode Spacing

Quantitativ e Determines the rate of ion transport,internalresistance and systemefficiency.

• Less space between the electrodes results in more efficient ion transportation, greateroutputvoltageandoverall morepowergeneration[6]

PEM Material

Reactor Volume

Substrate Concentratio n

Microbial Culture

Operating Temperature

Reactor Configuratio n

Qualitative Determines:

p-ISSN: 2395-0072

lefttooclose,thereisariskofthe substrate mixing between the anode and cathode chamber, whichcanruinthedecomposition processes

• The conductivity of the membrane

• The rate of transfer of protons fromtheanodetothecathode

• The degree to which unwanted substancesarekeptfromreaching thecathode[5]

• The internal resistance of the cell

•Thecostofthecell

•Thedurabilityofthecell

Quantitativ e Determines the amount of power the cell is capable of producing, and the scale to which it is to be used.

Quantitativ e Determines the availability of organic material for microbial metabolism, which drives electrongeneration.

•Aconcentratedsubstrateresults in generation of more electricity, greater power output and power density[3]

• Overconcentration of the substrate,however,resultsin the microbes getting overwhelmed and thuscarrying outincomplete oxidation

Qualitative Determines:

•Theelectrontransferefficiency

•Thepoweroutput

• The cell’s ability to process substrates

• The cell’s scalability and maintenance equirements • The costofthecell

Quantitativ e Influences microbial activity, electrochemical reactions, and overall system performance. This parameter’s effects change depending on the culture of bacteriaandthesubstrateused.

Qualitative Determines the efficiency of ion transport and the overall performance of the system. Variousconfigurationsareusedto optimize certain variables for very specific tasks. The choice of configuration depends on the scale and primary purpose of operation. International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

• However, if the electrodes are

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Duetotherarityandhighcostofmicrobialfuelcell(MFC) systems, I focused on theoretical research and data analysis to optimize the design of an MFC. Practical experimentation was not feasible, so I employed alternative methods to ensure the robustness of the proposeddesign.

Ibeganbyconductinga systematic reviewofliteratureon MFCs.Ianalyzedresearchstudiestounderstandtheeffects of various parameters such as substrate type, electrode materials, reactor designs, and microbial strains on performance metrics like power density, Coulombic efficiency, and scalability. This comprehensive review formed the foundation for identifying promising optimizationstrategies.

Next, I compiled a detailed data log from previously conductedexperiments.Irecordedkeyvariables,including substrate concentration, electrode spacing, and reactor configurations, alongside output metrics like voltage and power density. By doing this, I ensured the project relied on diverse and high-quality experimental results, compensating for the lack of direct experimentation. All papers that I extracted data from for my experimentation arelistedinthereferences.

Ithendevelopedadecisionmatrixtoanalyzeandoptimize theparametersofanMFC.Iweighedvariousfactors such asefficiency,cost-effectiveness,andscalability withinthe matrix to finalize the “optimal” MFC design. Using statistical tools and comparative analysis, I identified parameter combinations that would maximize performancewhileminimizingcosts.

For recording observations, I compiled data from 18 published papers related to Microbial Fuel Cells, which gave me access to 27 unique MFC experimental data points. The data includes all independent variables discussed in section 1.3 and shows how their variance effectsperformancemetricslikeCoulombicEfficiencyand PowerDensityofanMFCReactor.Theseexperimentsused allsortsofdifferentmaterials,configurationsastheyeach also had diverse goals. Each data point was carefully selected to ensure that the trends derived from this table are representative, reliable, and grounded in real experimentation.Thisdatasetthusformsacomprehensive foundationfortheoptimizationprocess.

Byanalyzingandcomparinghoweachvariableinfluenced performanceacrossvaryingreactorsizesandcelldesigns, wecanidentifywhichcombinationsconsistentlydelivered high output and operational stability. The goal is to filter

throughthisdiversitytofindvaluesbestsuitedtobuilding a practical, stackable MFC system one that balances efficiency with long-term feasibility for large-scale deployment, especially in a context like India where decentralized, low-maintenance energy solutions (such as thisone)areessential.

This section presents the analysis of experimental data to identify optimal values for key design parameters of a large-scale Microbial Fuel Cell (MFC). Each subsection focusesononevariable suchaselectrodearea,electrode material,electrodespacing,PEMmaterial,reactorvolume, substrate concentration, microbial culture, operating temperature,andreactorconfiguration andevaluatesits impact on power density and Coulombic efficiency. Based on performance trends across multiple studies, the most suitablevalueormaterialforeachparameterisselectedto informthefinalMFCdesign.

3.1 Electrode Area: 100cm2

Thegraphswereplottedafter excluding data ofcellswith reactorvolume<1000mLandincludingonlythedatafrom single-chamberfuelcells.Theexclusionsweremeanttofit thepurposeofourinvestigation.Amajorfuelcellwiththe intention of generating usable power for large communities cannot possibly function with a reactor volumelessthan1litre.So,datafromascaleevensmaller than that would be irrelevant to this study. In addition, I excluded all data from all MFC configurations other than

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

‘single chamber’, because their parameters function very differentlytothedesignrequiredforalargescaleMFC.To build MFCs that can power large communities, we need a stacked MFC design, which combines many individual single-chamber cells. Therefore, the configuration of each individual cell within the plant has to be single-chamber rectangular (as opposed to tubular or flat-plate), so that theycanbecombinedwiththeotherseffectively.

Consequently, the data above clearly indicates that 100cm2 is the ideal electrode area for maximizing Coulombic Efficiency and Power Density, for any singlechamberrectangulardesignwithareactorvolumegreater thanonelitre.

3.2 Electode Material: Stainless Steel with Fumion® FFFA-3

Chart-3:ElectrodeMaterial’seffectonCoulombicEfficiency

Chart-4:ElectrodeMaterial’seffectonPowerDensity

The material best suited for a large-scale, modular design we are aiming for is ‘Stainless steel with Fumion® FFFA3’.Fumion®FFFA-3isacomplexpolymerdesignedforion exchangeapplications,anditischemicallytailoredtohave functionalaminogroupsthatcontributetoitsantibacterial properties. The material has an ion exchange capacity of up to 2mmolg-1, which enhances ion conductivity and thus the amount of electrical power generated in the cell,

all while also harnessing its anti-bacterial properties to limitthegrowthofabiofilmovertheanode.Inaddition,it increases the durability and corrosion resistance of stainless steel. This reduces the need for cleaning and maintenance, thus allowing the mfc to run smoothly and forlongerdurations.

This compound will be more suitable for making the electrodes than all other substances listed in the data, even though 2 of them outperform the choice in terms of both Coloumbic Efficiency and Power Density. This is because the stainless-steel alloy is more suited for larger scale designs. In a 2022 study by D. R. Haupt, a stainlesssteel alloy was used in a cell with reactor volume of 17 Litres,whilethegraphiterodandgraphitefeltwereapart ofdesignswithareactorlessthan2Litresinvolume[13]. Tomaintainapowerdensity of0.2withareactorvolume of 17L and substrate concentration of 300mg/L, is arguablymoresignificantthanapowerdensityof0.6with 2L volume and 2000mg/L substrate concentration. It is even more impressive that their coulombic efficiencies alsodifferbyonly8%.

So, Stainless steel with Fumion® FFFA-3 is clearly the mostsuitedforourlarge-scaledesigninordertooptimize conductivity, limit bacterial biofilm growth all while also ensuringdurability.

3.3 Electrode Spacing: 2cm

2cm is the ideal spacing between electrodes for a largescale design. There is one available data set of a stacked MFC of a design modular enough for the scale requirements[6],whichreportsnosignificantoverspillof materialsthroughthePEMlayer.

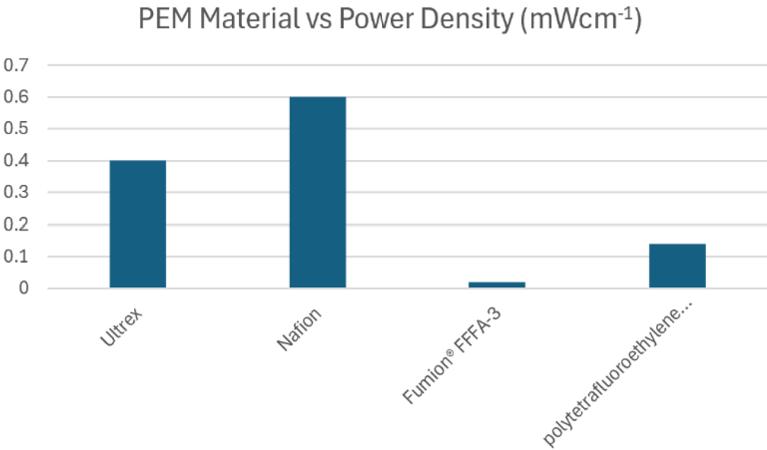

3.4 PEM Material: Nafion

Chart-5:PEMMaterial’seffectonCoulombicEfficiency

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Chart-6:PEMMaterial’seffectonPowerDensity

Nafion is a sulfonated tetrafluoroethylene-based fluoropolymer-copolymer, consisting of a polytetrafluoroethylene (PTFE) backbone (providing high chemical and thermal stability) and sulfonic acid groups attached via ether side chains, which enable excellent proton conductivity. Nafion’s hydrophilic sulfonic acid groups form interconnected pathways for proton transport, while its hydrophobic PTFE backbone ensures mechanical strength and water retention under operating conditions. This allows nafion to simultaneously facilitate the exchange of protons at a high rate through the PEM, while also preventing the flow of other unwanted substances alongside these protons. Its exceptional durability, high ionic conductivity, and resistance to chemical degradation make it the ideal PEM material, ensuringefficientiontransferandlong-termperformance infuelcells.

Nafion has been tried and tested with many large scale models also, and it has shown consistent results throughout many rounds of experimentation (for eg references [1], [9], [11], [12] etc). It leads to the second greatestcoulombicefficiencyofallmaterialstested(PTEE, thematerial withgreaterefficiencywould bea hazardfor a large-scale MFC, as it functions very differently from a traditional PEM and allows the overflow of too many unwanted substances) and the greatest power density. Whileitmayhaveaslowerprotontransferratethansome other substances, it is the safest and thus best fit for a largedesign.

3.5 Reactor Volume:

500cm3 is the ideal reactor volume for optimizing both the Coulombic Efficiency and the Power Density. So, we can incorporate this into our design also. It works for the stacked design also, as it can be packed into compact structures in a larger plant. This size will be optimal for individual reactors, and will guarantee maximum electricalproductivityfromeachindividualcell.

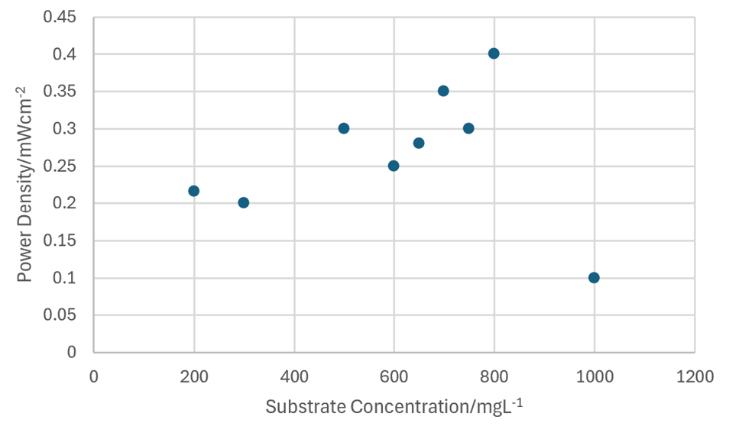

Since we have already picked a relatively small reactor volume, and a large electrode area, we need to have a smaller substrate concentration. We want to maintain greatefficiencyofiontransport,butwealsomakesurewe can implement full oxidation and retrieve maximum possible energy. For this reason, I have discounted any datapointsbeyond1000mgL-1inthisdataplot-theymay bemoreoptimalinabsoluteterms,butforthissystemwe need a less concentrated substrate to make the most of ourinput.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Chart-9:SubstrateConcentration’seffectonCoulombic Efficiency

Chart-10:SubstrateConcentration’seffectonPowerDensity

700mgL-1 is easily the most efficient point of all the data pointswehave,asitscellisthesecondmostpowerdense andthemostcoulombicallyefficientofallcells.Thiswould allow for greater efficiency of all processes in the MFC, from bacterial decomposition to flow of electrons. 700mgL-1wouldturnouttobethemostoptimalpoint,as it would increase the rate of reaction by just enough to ensurethattheoxidationdoesn’tgoincomplete.

Themicrobesbestsuitedforthedecompositionofsucrose as a substrate would be those that are derived from wastewater treatment plants and certain compost microbial consortia. Both these forms of microbes are known for their ability to break down complex organic substances, particularly the plant-based one’s, which is exactlywhatsucroseis.Someparticularbacteriumsfound in these consortia which would be particularly helpful to us are Clostridium spp. and Geobacter sulfurreducens. Clostridium spp is particularly effective in breaking down sucrose, as shown in a study by the National Library of Medicine [20], and Geobacter sulfurreducens is an electroactive bacteria that can accelerate the process of ion generation by metabolizing secondary by-products producedbyClostridiumspp’sdecompositionoftheinitial sucrosesubstrate.

ThereisnosignificantdeviationofCoulombicEfficiencyor Power Density with temperature change when a mixed microbialculture(particularlythosepickedfromdomestic wastewater) is used. Temperature fluctuations within the range 25-35 degrees Celsius have no effect on the functions of an MFC, so the temperature need not be regulatedinthefirstplace.

For a design ambitious enough to power cities, a stacked MFC plant is required. This will include a range of rectangular single-chamber cells adjoined together through elastic ‘fastening bolts’ and rubber gaskets. Each individual MFC would resemble a single-chamber design, withareactorvolumeof500cm3 .

The findings of this study underscore the potential of Microbial Fuel Cells (MFCs) as a dual-purpose technology for sustainable energy generation and waste treatment. The proposed design, incorporating stainless-steel electrodes coated with Fumion® FFFA-3, Nafion as the proton exchange membrane, and a stacked reactor configuration with individual chamber volumes of 500 cm³, demonstrates an effective balance between performance, scalability, and durability. The use of mixed microbial cultures and an optimized substrate concentration of 700 mg/L further enhances energy conversion efficiency while maintaining operational stability.

Whiletheproposeddesignaddressescriticalchallengesin MFC scalability, several aspects warrant further exploration. For instance, the long-term durability of materials under real-world operating conditions and the impactofenvironmentalfluctuationsonmicrobialactivity

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

remain areas for experimental investigation. Additionally, the interplay between substrate concentration, microbial diversity, and biofilm formation requires deeper analysis tofullyoptimizeperformance.

The study also raises important questions about the economic feasibility and adaptability of MFCs in diverse geographical and socio-economic contexts. While the current design is optimized for large-scale applications, futureworkshouldexploremodularapproachesthatcater to smaller, decentralized energy needs, particularly in rural or resource-constrained settings. Furthermore, integrating this technology with existing waste management systems could amplify its environmental benefitsandstreamlineimplementation.

In conclusion, this research provides a framework for advancing MFC technology toward practical, scalable solutions for renewable energy. By addressing the identified knowledge gaps and refining system designs, MFCs have the potential to become a cornerstone in the globaltransitiontosustainableenergysystems.

[1] Ali, H. Y., Rushdi, S. A., & Alhameedi, H. A. (2024). "Microbial Fuel Cells: Their Shapes, Designs, and Transportation Methods." Russian Journal of Applied Chemistry,97,183–197.

[2] Flimban, S. G. A., Ismail, I. M. I., Kim, T., & Oh, S.-E. (2019). "Overview of Recent Advancements in the Microbial Fuel Cell from Fundamentals to Applications:Design,MajorElements,andScalability." Energies, 12(17), 3390.R. Nicole, “Title of paper with onlyfirstwordcapitalized,”J.NameStand.Abbrev.,in press.

[3] Janicek, A., Fan, Y., & Liu, H. (2014). "Design of microbial fuel cells for practical application: a review and analysis of scale-up studies." Biofuels, 5(1), 79–92.

[4] Logan, B. E., & Regan, J. M. (2006). "Electricityproducing bacterial communities in microbial fuel cells."TrendsinMicrobiology,14(12),512–518.

[5] Rabaey, K., & Verstraete, W. (2005). "Microbial fuel cells: novel biotechnology for energy generation." TrendsinBiotechnology,23(6),291–298.

[6] Santoro, C., Arbizzani, C., Erable, B., & Ieropoulos, I. (2017). "Microbial fuel cells: From fundamentals to applications.Areview."JournalofPowerSources,356, 225–244.

[7] Wang,H.,&Ren,Z.J.(2013)."Acomprehensivereview of microbial electrochemical systems as a platform

technology." Biotechnology Advances, 31(8), 1796–1807.

[8] Zhang, F., Ge, Z., Grimaud, J., Hurst, J., & He, Z. (2013). "Long-term performance of liter-scale microbial fuel cellstreatingprimaryeffluentinstalledinamunicipal wastewatertreatmentfacility."EnvironmentalScience &Technology,47(9),4941–4948.

[9] Aelterman, P., Rabaey, K., Pham, H. T., Boon, N., & Verstraete, W. (2006). "Continuous electricity generationathighvoltagesandcurrentsusingstacked microbial fuel cells." Environmental Science & Technology,40(10),3388–3394.

[10] Liu, H., & Logan, B. E. (2004). "Electricity generation usinganair-cathodesinglechambermicrobialfuelcell in the presence and absence of a proton exchange membrane." Environmental Science & Technology, 38(14),4040–4046.

[11] Degrenne, N., Allard, B., Buret, F., Morel, F., Adami, S.E., & Labrousse, D. (2011). Comparison of 3 selfstarting step-up DC:DC converter topologies for harvesting energy from low-voltage and low-power microbial fuel cells. Proceedings of the European Conference on Power Electronics and Applications (EPE),Birmingham,UnitedKingdom.IEEE.

[12] Jinisha, R., Regin, J. J., & Maheswaran, J. (2020). A reviewontheemergenceofsingle-chambermicrobial fuel cell on wastewater treatment. IOP Conference Series: Materials Science and Engineering, 983(1), 012002.

[13] Haupt,D.R.,Landwehr,L.,Schumann,R.,Hahn,L.,Issa, M., Coskun, C., Kunz, U., & Sievers, M. (2022). A new reactorconceptforsingle-chambermicrobialfuelcells and possible anti-fouling strategies for long-term operation.Microorganisms,10(12),2421.

[14] Aziz, S., Memon, A. R., Shah, S. F., Soomro, S. A., & Parkash, A. (2013). Prototype designing and operational aspects of microbial fuel cells: Review paper.ScienceInternational(Lahore),25(1),49–56.

[15] Sirinutsomboon, B. (2014). Modeling of a membranelesssingle-chambermicrobialfuelcellwith molassesasanenergysource.InternationalJournalof EnergyandEnvironmentalEngineering,5(1),93.

[16] Khandaker,S.,Das,S.,Hossain,M.T.,Islam,A.,Miah,M. R., & Awual, M. R. (2021). Sustainable approach for wastewater treatment using microbial fuel cells and green energy generation: A comprehensive review. JournalofMolecularLiquids,117795.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

[17] Abul, A., Zhang, J., Steidl, R., Reguera, G., & Tan, X. (2016). Microbial fuel cells: Control-oriented modelingandexperimental validation.Proceedingsof the American Control Conference (ACC), Boston, MA, USA.

[18] A. S., Bruce, P., Scrosati, B., Tarascon, J.-M., & Van Schalkwijk, W. (2005). 3-D Micro- and NanoTechnologies for Improvements in Electrochemical PowerDevices.ResearchGate.

[19] Shaikh,J.,&Patil,N.(2016).Microbialfuelcell:Design and operation. Research and Reviews: Journal of MicrobiologyandBiotechnology,SpecialIssue.

[20] Wang, Y., Liu, M., Yang, J., Xu, Z., & Xian, H. (2021). Enhanced biohydrogen production from glucose by Clostridium butyricum using artificial electron carriers.BiotechnologyforBiofuels,14(1),197.