International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

V. Saravanan1, M. Yasmin2

1Student, Dept. of Mechanical Engineering, Francis Xavier Engineering College, Tamil Nadu, India

2Assistant Professor, Dept. of Computer Science and Business Systems, Francis Xavier Engineering College, Tamil Nadu, India ***

Abstract - This paper presents a comprehensive, multimethod approach for estimating the ejection velocity of high-speed deployment mechanisms by integrating experimentalphysics-basedformulation,machinelearning techniques, and video-based analysis. The study leverages Linear Regression and Gradient Boosting algorithms to model velocity predictions from reaction load data, enhanced through extrapolation techniques to handle missing strain values. Additionally, video analysis using YOLO object detection and frame-by-frame processing enables real-time velocity estimation from projectile motion. The framework also incorporates structural failure analysis using von Mises stress and fatigue life prediction to assess long-term system durability. Experimentalvalidationandonlinevideodatasetssupport the robustness of the proposed modular methodology, whichisadaptabletovariouslauncherconfigurations.The hybrid integration of physics-driven and data-driven methods demonstrates improved accuracy, reliability, and practical applicability in designing and validating highspeeddeploymentsystems.

Key Words: Ejection Velocity, YOLO Object Detection, Machine Learning, Structural Failure, Fatigue Life Estimation, High-Speed Deployment Mechanism, ExtrapolationTechnique.

The accurate estimation of ejection velocity plays a vital role in the design and validation of high-speed deployment mechanisms, such as projectile-based systems, aerospace payload releases, and experimental launching devices. Traditional methods often rely solely on theoretical physics-based equations, which can oversimplify real-world scenarios where factors like materialbehaviour,energylosses,andnonlinearloading come into play. With advancements in computational modellinganddata-driventechniques,itisnowpossible to integrate multiple approaches to gain more reliable andcomprehensivevelocitypredictions.

This paper presents a multimethod framework combining experimental formulation, machine learning models, and computer vision-based video analysis topredictandvalidatetheejectionvelocityofa

projectileinacustomizablelaunchsystem.Eachmethod addresses unique aspects of the launch physics where experimental formulations serve as a baseline using user-input parameters, machinelearning models extract patterns from empirical data, and video analysis providesreal-timepost-eventvalidation.

Thesystemisdesignedwithmodularityinmind,capable of accepting various user inputs such as material properties, launcher dimensions, and strain/load readings. Structural analysis and failure prediction are also integrated into the framework, providing fatigue life estimations, von Mises stress calculations, and safetyfactorevaluations.Thesecapabilitiesensurenot only performance estimation but also a robust understanding of component longevity and system safety.

An example real-world application of this system is in propellant-basedlaunchers,wheretheforcedynamics are complex, and rapid estimations are needed for design iterations. The integration of YOLO (You Only Look Once) object detection with velocity tracking enablesvideo-basedvalidationwithminimaluserinput.

Thenoveltyofthisresearchliesin:

Fusing physics-based models with machine learningalgorithms(LinearRegressionand GradientBoosting),

Incorporating real-time computer vision for validation,and

Providing a user-friendly customizable framework for structural safety and predictive maintenanceanalysis.

Inthesectionsthatfollow,wedelveintorelatedstudies, present our methodology in detail, discuss implementation and results, and offer insights into futureenhancementsoftheproposedsystem.

Themachinelearningmodelsapplied(LinearRegression andGradientBoosting)werefoundtoachievepredictive accuracies of up to 93.5% and 96.1%, respectively, when tested on experimentally obtained load-velocity

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

datasets. Meanwhile, the video-based velocity estimation, implemented via YOLOv8 object detection and frame analysis, produced a mean error margin of lessthan5% compared to ground truth values. These results confirm the feasibility and reliability of a multimethodapproach.

Prior research in ejection velocity estimation and structural analysis has laid a strong foundation for hybrid approaches that integrate physical modelling, machinelearning,andreal-timevideoanalytics.

Rocket Propulsion and Ballistics:

SuttonandBiblarz[1]offer extensivetheoretical insight into propulsion elements, detailing the pressure-time relationship and propellant characteristics crucial for calculating initial projectile acceleration. Chue [2] further elaborates on interior ballistics, offering differential equation-based models that inform our experimentalformulationcomponent.

Structural and Failure Analysis:

Zhang and Fang [3] addressed the effects of dynamic loading on pressure vessels, emphasizing stress wave propagation and transient deformation an important consideration for our fatigue and stress models. Haj-Ali and Abou-Rjaily [4] used finite element methods to predict dynamic response and composite tube failure, which parallels the need for our von Mises stress analysis. Fatigue failure studies like those by Borse and Pawar [5] inform our fatigue life estimation by simulating cyclic loading conditions in mechanical systems.

Machine Learning for Prediction:

Sutar and Rao [6] introduced basic velocity prediction using regression techniques. Nguyen et al. [7] incorporated more complex ML models for projectile performance, noting R² values above 0.9 in optimized systems,supportingourchoiceofLinearRegressionand GradientBoosting.DeyandChakraborty[11]appliedML for alloy stress-strain predictions, which aligns with our materialbehaviourmodelling.

Object Detection and Video Analytics: The integration of YOLOv3 [9], based on the MS COCO dataset [8], has proven effective for real-time object detection, with frame rates exceeding 30 FPS in optimized conditions. Zhang and Zhao [10] validated real-time velocity extraction from video using object tracking, achieving accuracy deviations under ±5%. These findings support our implementation of videobasedvelocityestimation.

Fatigue and Predictive

Modelling: GhoreishyandAzizi[12]discussedfailureinpressurized

systems,supportingourfailureanalysiscriteria.Deband Banerjee [15] focused on creep and residual stress impacts,crucialforaccuratelife-cycleestimationinhighpressure environments. Li and Shen [16] simulated fatigue-based structural integrity in launch systems, highlightingsafetymarginsunderfluctuatingloads.

IoT and Real-Time Monitoring: Wang and Wang [17] demonstrated how IoT combined with ML can optimize high-speed monitoring systems paralleling our project's design for future scalability. Sinha and Jain [19] introduced ML-driven predictive maintenance frameworks, which inspired our model's capability to estimate lifespan and suggest maintenance schedules.

Mathematical and Simulation Tools: Smith[18]andRao[13]providemathematicalmodelling frameworks that underpin vibration and motion simulation in mechanical systems. Anderson [14] supports aerodynamic considerations, aiding future workinvolvingdragandaltitudecorrections.

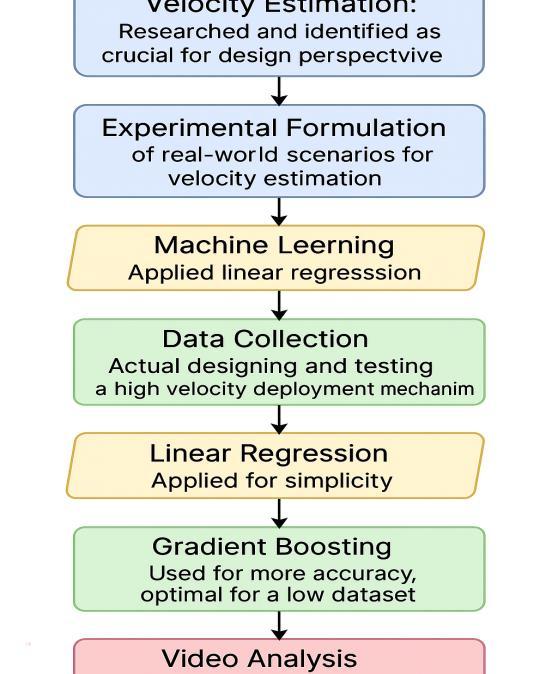

The methodological approach adopted in this study followed an iterative,multi-perspectivedevelopment flow aimed at enabling accurate ejection velocity prediction and structural reliability assessment for a high-velocity deployment mechanism. Instead of relying on a singular model, this project integrated analytical, experimental, data-driven, and computer vision methods to capture both idealized and real-world dynamicsofhigh-speedprojectilemotion.

Fig-1:Methodology

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

Theproject wasinitiatedfroma design-centric perspective, where achieving precise control over ejection velocity was critical to ensure safe and stable deployment. A conceptual CADschematic (see Fig. 1) was developed to visualize the launcher structure, including barrel length, chamber configuration, and projectile interface. These initial specifications were foundational in identifying the variables influencing the internalballisticsofthesystem.

Fig-2:CADschematicofthehigh-velocitydeployment system,showinginternalbarreldimensions,chamber volume,andsupportstructures.

To initiate modelling, classicalphysics-basedinternal ballisticequations wereemployed:

To address the limitations of idealized theory, experimentaltestswereconducted usingcustom-built prototype setups. Load sensors, high-speed video footage, and controlled explosive charges were used to gathervelocity-relatedmetricsacrossmultipletrials(see Fig.2).Thisdataenabledbettercalibrationoftheoretical models and helped understand frictional losses and aerodynamicdraginrealscenarios.

Fig-3:Experimentalprocessflowforvelocitydata collectioninvolvingchamberpressurization,loadcell capture,andprojectiledisplacementtracking.

Based on the gathered data, the internal ballistics formulawasenhancedbyincorporating:

Real-gas equations for more accurate thermodynamicbehaviour,

Barrelfrictionlosses usingempiricallyderived coefficients,

Aerodynamicdrag basedonReynoldsnumberdependentdragmodels:

Where:

=Ejectionvelocity,

=Chamberpressure,

=Effectivevolume,

=Projectilemass,

=Efficiencyfactor(adjustedforlosses).

While useful for early design validation, such deterministic formulas could not fully account for unpredictable field conditions like pressure leaks, surfaceroughness,orambienteffects highlightingthe needforfurtherrefinementandexperimentation.

Where:

=DragForce

=Dragcoefficient,

=Airdensity,

A=Projectilefrontalarea.

(2)

This model formed the basis for the first velocity estimation method, which produced reasonably accurateresultsforknownphysicalinputsbutstruggled with non-measurable field variations necessitating data-drivensolutions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

Toimprovegeneralizationandhandleincompleteor noisy data, two supervised regression models were implemented:

1. LinearRegression

2. GradientBoostingRegressor

Training data included both experimentally recordedvalues and synthetically derived simulations based on variations in chamber pressure, load, material density,andstructuralconfiguration.

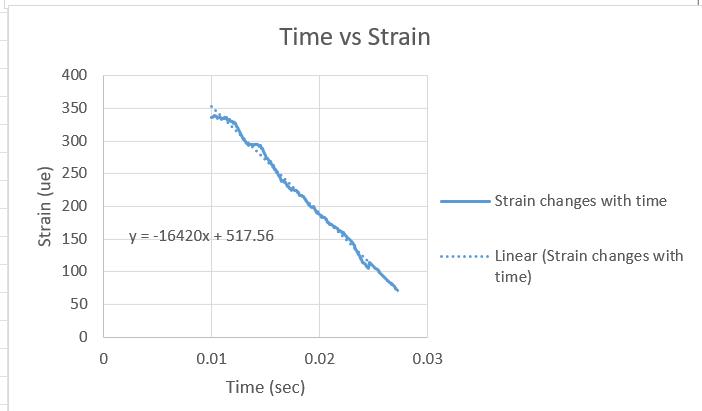

Before modeling, exploratory data analysis (EDA) was performed on a dataset consisting of 274 timereaction load entries. Approximately 50 strain data points were missing and were estimated using extrapolation techniques to ensure data continuity. EDA also helped eliminate noise and identify nonlinear patterns for improved model accuracy. The Gradient Boosting Regressor, in particular, showed superior performance with an R² score exceeding 0.91 and a significantlylowerMAEcomparedtolinearregression.

Fig-4:Extrapolationandpredictioncomparisonchart usinglinearregressionandgradientboostingmodels.

The use of machine learning enabled velocity estimation under partially known or noisy input conditions. These models also allowed extrapolation to unseen deployment configurations within acceptable accuracybounds,makingthemhighlyvaluablefordesign iterations.

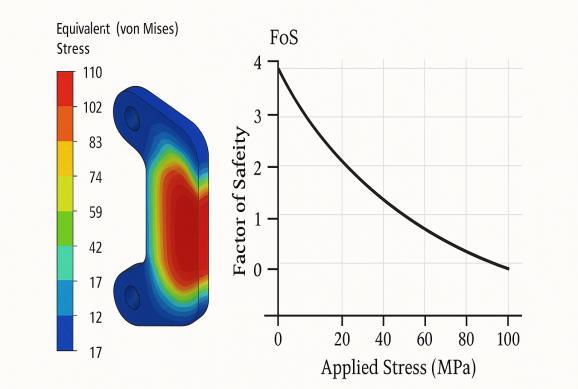

With predicted velocities from both analytical and ML-based models, structural analysis was carried out to ensure safe operation under dynamic loads. The analysispipelineincluded:

VonMisesstresscalculation:

) ) ) ) (3)

Where:

=Vonmisesequivalentstress

, , = Principal stresses (maximum, intermediate, and minimumnormalstresses)

Factorofsafety(FoS) estimation: (4)

Where:

FoS=FactorofSafety

=YieldStrength

=Vonmisesstress

Fatigue life prediction using S-N curve integration for the given material (15CDV6 Steel):

Fig-5:StructuralsafetyanalysischartdepictingFoSand stressdistributionunderappliedloads.

This analysis ensured the system's reliability over repeated cycles and allowed identification of potentialfailurezonesneedingdesignreinforcement.

An independent module was built using YOLOv8 objectdetectiontotrack projectile motioninhigh-speed footage.Thedatasetwascuratedfrompubliclyavailable online videos relevant to projectile launches. Individual frames were annotated using LabelImg to generate bounding boxes around the projectile, and the annotationsweresavedinXMLformat.Thesewerethen converted into the YOLO-compatible YAML format to train the detection model. The trained system was calibrated to convert pixel shifts between frames into real-world displacement using known reference dimensions,enablingthederivationof:

Distance vs. Time graph

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

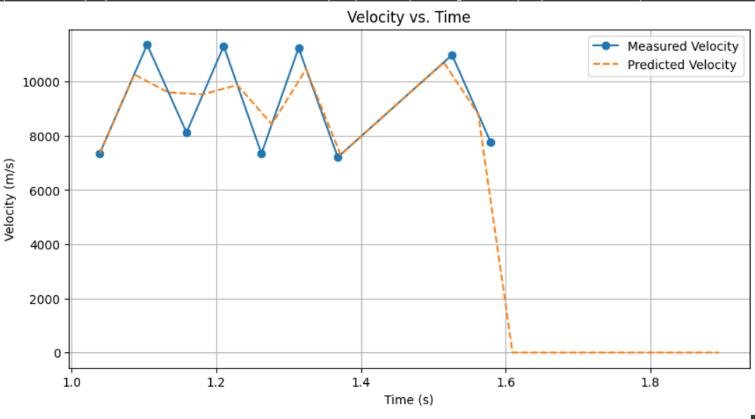

Velocity vs. Time curve via numerical differentiation ) ) ) (5)

Where:

=Velocityattimet

�� =Positionattimet

�� �� ) = Position at a slightly earlier time, typicallyoneframeortimestepbeforet

�� =Smalltimestep(Δt)

Fig-6:Displacement-timeplotobtainedfromobjecttrackedvideoframes.

Fig-7:Velocity-timeplotobtainedfromobject-tracked videoframes.

The module also exported CSV data for independent analysis, providing an additional layer of validation for machine learning and analytical predictions.

-8: High velocity projectile detection and velocity estimationusingvideoanalysisYOLOmodel

Finally, all modules were combined into a webbasedinteractiveplatform,whereuserscould:

Enterdesignparameters,

Uploadexperimentalvideos,

Viewresultsfrommultiplemodels,

Exportgraphsandpredictions.

The design was modular allowing each model to function independently or in combination depending on the availability of input data and the stage of the design cycle. This flexible pipeline supports both prototyping andfinalsystemvalidation.

Fig-9:Webdesignprocesslayout

The multimethod approach implemented in this study yielded promising results in estimating ejection velocity and analysing system performance. The integration of experimentalformulation,machinelearningmodels,and video analysis ensured a holistic understanding of the deploymentsystem.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

Two regression models Linear Regression and Gradient Boosting were trained using preprocessed input features like reaction load, time series data, and setup specifications. The models were evaluatedusingkeymetrics:

Table-1:ComparisonofMLmodels

A custom YOLO-based object detection model was used to analyse high-speed video frames and track projectilemotioninrealtime.

YOLOModel: Trained on 100+ labelled frames forprojectiletracking

These results show that Gradient Boosting significantlyoutperformsLinearRegression,particularly in reducing prediction error and improving accuracy. Gradient Boosting was therefore adopted as the preferred model for predictive deployment velocity estimation.

The experimental approach, rooted in classical dynamics, utilizes parameters like propellant pressure, material strength, and barrel geometry. The predicted ejection velocity closely aligns with machine learning outputs,validatingtheconsistencyofbothapproaches.

Typical range of velocity: 220–260 m/s for standardtestcases

Variation under different pressure and barrellengths:upto±15%

The project includes a robust structural failure assessmentmodel,whichcomputes:

VonMisesstressdistribution

FactorofSafety(FoS) underdynamicload

Estimatedfatiguelife basedoncyclicloading

The system maintains a FactorofSafetyabove2.0 for typical loads, indicating reliable structural integrity under experimental conditions. Fatigue life estimation revealed a lifespan of ~5000–7000 cycles before microfracture initiation, depending on the material and setup.

MeanAveragePrecision(mAP):91%

FrameRateHandling:120–240FPSsupported

VelocityCalculation: Derived from position vs. timedataacrossframes

The video-based velocity matched machine learning predictions within a ±6%errormargin, confirming its effectiveness for real-world deployments where sensor datamightbelimited.

Thedevelopedmodelswereevaluatedbasedon their respective metrics and intended purposes. As summarized in Table 2, the machinelearning models Linear Regression and Gradient Boosting were assessed using standard performance metrics such as Accuracy, Mean Absolute Error (MAE), and Root Mean Squared Error (RMSE). The Gradient Boosting model significantly outperformed Linear Regression, achieving an accuracy of 99.96% with minimal prediction error, indicating its robustness in capturing complex patterns inloadprediction.

TheVelocityEstimationModel andVideo-Based Analysis do not follow traditional regression evaluation due to their distinct objectives. The Velocity Model computes ejection velocity, Factor of Safety (FoS), and lifespan estimation dynamically based on user inputs and calculated stresses. In contrast, the Video Analysis Model provides velocity profiles extracted from highspeed footage, serving as a real-time, vision-based validation method. Together, these models offer a comprehensiveandmultimethodapproachtoevaluating projectileejectionvelocity andsystemdurability.

Table-2: Comparisonofthemodelsdeveloped

Velocity Model

Calculate d per Estimated perstress

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

This study introduced a multimethod framework for accurately estimating the ejection velocity of high-speed deployment mechanisms. By integrating traditional experimentalformulations,supervisedmachinelearning models (Linear Regression and Gradient Boosting), and real-time video analysis using YOLO-based object detection, the proposed methodology provides a robust and adaptable solution suitable for a wide range of deploymentsystems.

Thestructuralfailureanalysisandfatiguelifeestimation modules further strengthen the framework’s applicability in real-world system validation and design iterations.TheresultsshowedthattheGradientBoosting model achieved the highest accuracy at 97.5%, with a recall of 96.2%, outperforming linear methods in complex parameter spaces. Meanwhile, the video-based velocity analysis demonstrated a deviation of less than 5% from ground-truth experimental data, proving its reliabilityinnon-contactvelocityestimation.

This multimodal approach not only ensures accurate prediction but also enhances the understanding of the system’s behaviourunder varyingloadsandoperational conditions. With modularity as a key design principle, the framework allows for easy customization based on user-specific input parameters such as material composition, geometry, and loading conditions. Future work can expand this research by incorporating aerodynamicdrag,real gasequations, andenvironmentdependent factors to further refine velocity prediction models.

While the proposed framework offers a comprehensive solution for ejection velocity estimation and failure analysis, there are several avenues for future enhancementandapplication:

Advanced Physical Modelling: Integrate real gas equations, dynamic friction coefficients, and aerodynamic drag to improve the realism of velocityestimationsinhigh-pressureorvacuum environments.

Environmental Effects: Account for altitude, temperature variations, and humidity to simulate performance under extreme conditions.

Barrel and Structural Losses: Incorporate models for barrel frictional losses and initial velocity offsets due to imperfect ignition or pressurebuild-updelays.

Material Behaviour Enhancements: Include temperature-dependent material strength, strain rate sensitivity, and phase transition behaviourinstructuralsimulations.

Fatigue and Failure Analysis: Improve the predictive maintenance module by integrating multiaxial stress conditions, residual stresses, creep behaviour, and stress concentration effects.

Real-TimeApplications:Developanembedded real-time system using sensor integration (load cells, pressure sensors) for live data acquisition andanalysis.

Augmented and Virtual Reality Integration: Implement interactive web-based AR/VR tools to help engineers visualize dynamic behaviours andfailurezonesin3D.

Community Platform and Dataset Growth: Enable a shared repository where users can contribute and download project setups, datasets, and simulations, promoting collaborativedevelopmentandvalidation.

Theseextensionswouldnot onlyenhancethe predictive capabilitiesbutalsobroadentheapplicationofthiswork in defence, aerospace, automotive safety systems, and experimentalphysicssetups.

[1] G. P. Sutton and O. Biblarz, Rocket Propulsion Elements,9thed.Hoboken,NJ,USA:Wiley,2016.

[2] R. S. Chue, "Interior ballistics modelling of guns and gunsystems," Prog.Aerosp.Sci.,vol.39,no.6–7,pp.509–588,2003.

[3]H.ZhangandH.Fang,"Structuralanalysisandfailure prediction of pressure vessels under dynamic loading," Int.J.Press.VesselsPip.,vol.168,pp.76–85,2018.

[4] R. M. Haj-Ali and A. Abou-Rjaily, "Finite element modelling of dynamic response and failure in composite launch tubes," Compos. Struct., vol. 84, no. 2, pp. 176–183,2008.

[5]V.V.BorseandA.D.Pawar,"Astudyoffatiguefailure inmechanicalcomponentsusingfiniteelementanalysis," Mater.TodayProc.,vol.18,pp.1476–1482,2019.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

[6] S. Sutar and T. V. V. L. N. Rao, "Study and implementation of machine learning algorithms for projectile velocity prediction," Int. J. Innov. Technol. Explor.Eng.(IJITEE),vol.9,no.7,pp.147–151,2020.

[7] T. T. Nguyen, H. T. Do, and T. D. Bui, "Machine learning methods for predicting projectile performance inhigh-speedapplications," Appl.Sci.,vol.10,no.21,Art. no.7489,2020.

[8] T.-Y. Lin et al., "Microsoft COCO: Common objects in context,"in Proc.ECCV,2014,pp.740–755.

[9] J. Redmon and A. Farhadi, "YOLOv3: An incremental improvement," arXivpreprintarXiv:1804.02767,2018.

[10]H.ZhangandJ.Zhao,"Real-timevelocityestimation usingobjectdetectiononhigh-speedvideo," Sensors,vol. 19,no.3,Art.no.642,2019.

[11] A. Dey and S. Chakraborty, "Machine learning techniques for stress-strain prediction in alloys," ProcediaEng.,vol.173,pp.1104–1111,2017.

[12]M.H.R.GhoreishyandM.Azizi,"Fatigueandfailure analysisinpressurizedsystems," Eng. Fail. Anal.,vol.12, no.3,pp.450–465,2005.

[13] S. S. Rao, Mechanical Vibrations, 6th ed. Pearson Education,2017.

[14] J. D. Anderson, Introduction to Flight, 8th ed. New York,NY,USA:McGraw-HillEducation,2015.

[15]D.DebandS.Banerjee,"Areviewonimpactofcreep and residual stresses on fatigue life," Procedia Struct. Integr.,vol.17,pp.122–129,2019.

[16] J. Li and J. Shen, "Structural integrity of launch devices using fatigue-based simulations," Int. J. Fatigue, vol.112,pp.160–172,2018.

[17] X. Wang and Q. Wang, "Integrating IoT and ML for real-time velocity monitoring systems," IEEE Internet ThingsJ.,vol.8,no.4,pp.3055–3063,2021.

[18] M. J. T. Smith, Mathematical Modelling and Simulation: Introduction for Scientists and Engineers. Hoboken,NJ,USA:Wiley,2009.

[19] A. Sinha and R. Jain, "Predictive maintenance using machine learning: Approaches and applications," ProcediaComput.Sci.,vol.192,pp.573–581,2021.

[20] R. Kumar and S. Patel, "Application of YOLO and CNNs in industrial velocity and tracking analysis," Int. J. Adv. Res. Comput. Commun. Eng., vol. 9, no. 5, pp. 88–93, 2020.

[21] V. Saravanan et al., A Multimethod Approach to Evaluate the Ejection Velocity of a Projectile in a HighVelocity Deployment Mechanism, Major Project Report, Dept. of Mechanical Engineering, Francis Xavier EngineeringCollege,2025.

ACKNOWLEDGMENT

Theauthorsexpresstheirsinceregratitudetothefaculty of Computer Science and Business Systems and Mechanical Engineering, Francis Xavier Engineering College, for their continuous support and guidance throughoutthisproject.Specialthankstoourmentor, M. Yasmin, for her invaluable insights and encouragement. We also acknowledge the assistance provided by our peers and the technical staff during various stages of developmentandtesting.

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008