International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

Mr. Vagesh Ramanbhai Nai1 , Dr. Vineet Kumar Goel2, Mr. Dharmang Patel3 , Mr Kaushal

Rajkishor Shukla4

1 Research scholar of Bhagwan Mahavir college of engineering and technology

2Dean of engineering , Bhagwan Mahavir university

3HoD of mechanical engineering of BhagwanMahavircollegeofengineeringandtechnology

4 Research scholar of AH TECHNOCAST PVT LTD

Abstract - Nowadaysmanufacturingsectorhasenteredanew era. Conventional and manual manufacturing system is replaced by modern manufacturing technology. Sand casting processes like green sand casting in general involve a large number of parameters that affect the various casting quality features of products. Some parameters are controllable and others are uncontrollable, they are essential responsible for variation in casting quality.

In this research work present the design of experiment based approach which is adopted to obtain an optimal setting of moisture content, grain particle size and temperature of pouringmetalrelatedparametersofgreensandcastinginA.H TECHNOCAST PVT LTD at PIPODARA, SURAT. The casting parameters identified for green sand casting process are moisture content, green strength, mould hardness, permeability, sand particle size, pouring temperature ramming pressure, cooling time.

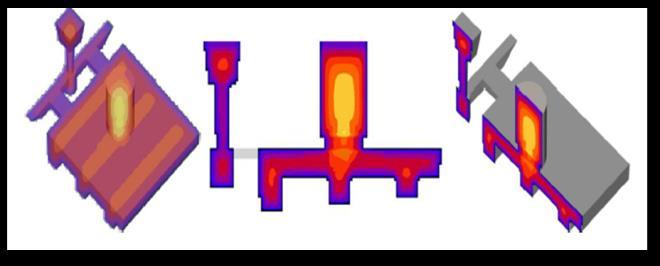

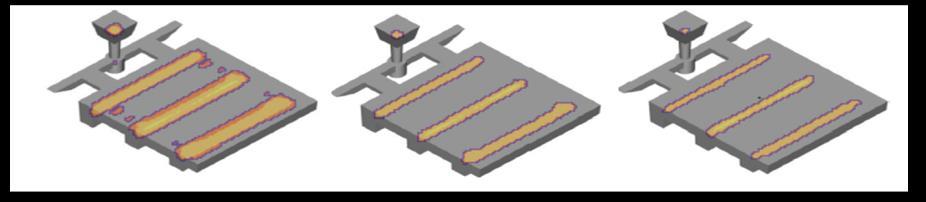

For defect analysis, the possible causes are grouped into design, material and process parameters. The effect of suspected cause parameters on casting quality is ascertained through simulation. Based on the results and their interpretation, the optimal values of the parameters are determined to eliminate the defects. Simulation tool to be use to introduce new gating system of cast iron housing to improve its quality and yield. computer programs have been inventedto enable designerstotakecontrol over liquidmetal behavior and help to eliminate defective part, especially porosity defects inside the casts

Key Words: Casting defects minimization, Casting SimulationProcess,castingdefect,castingdefectanalytical technique.

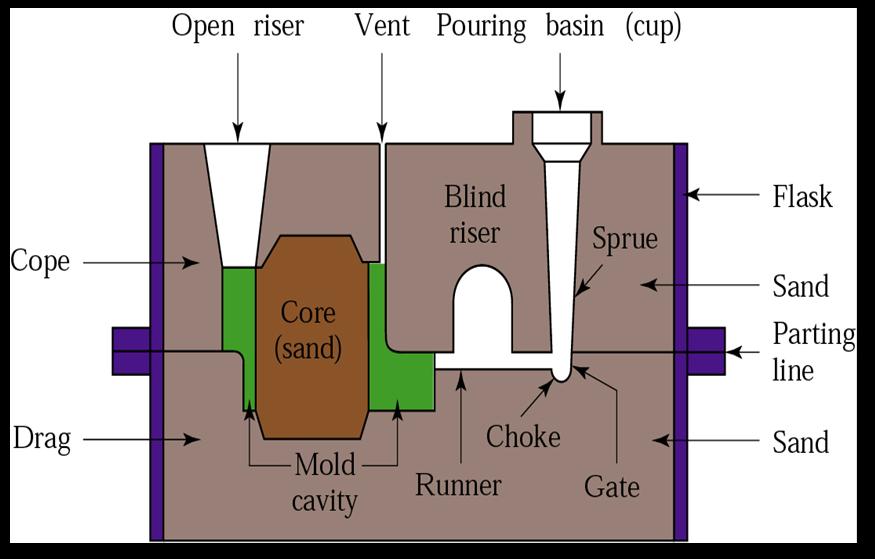

1.1 SAND CASTING [13]

Castingisoneoftheoldestmanufacturingprocessdates backto4000B.C.whencopperarrowheadswheremade. Casting produced by foundry as per customers’ specifications,theirqualitylevelotherwisethecastingis term as defective. If casting is defective then it is

rejected.Rejectedpartscontributedtothewastageand lossofvaluetothefoundry.Forimprovethecastmetal yield, we need to optimize the gating system design, optimize mould filling, avoid shrinkage defects, voids, hottearsetc.castingsimulationtoolstoveryhelpfulto achieve above objectives. With advent of modern computing facilities, application of commercial software’s, packages such as casting simulation tools, enablethefoundryindustriestoaccomplishsuccessful castingdesign.

UdayA.Dabade et al[1] combinationofdesignofexperiment andcastingsimulation techniquetoanalysisthe sandand methodologydefectsingreensandcasting.Infirstsession, using Taguchi based orthogonal array use to purpose of experimentandanalysisofvariance(ANOVA)indicates in selectedparameterandpercentageofrejection.Insecond session shrinkage porosity analysis by using simulation technique using new gating system designed. Result indicatesnewgatingsystemandfeederreductioninporosity about15%andyieldimprovement5%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

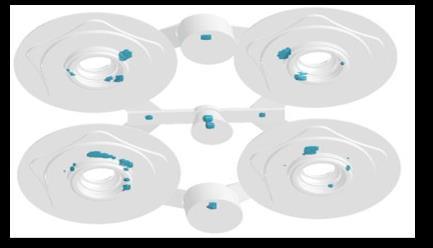

Figure: 2.1 a) Shrinkage porosity b) Shrinkage porosity with new gating design.

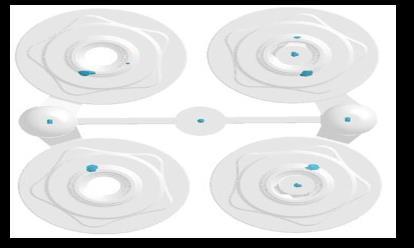

Sunanda & Raju (2021) [3] Castingisthemethodbywhich different kinds of metal products are manufactured. Sand casting is one of the commonly utilized metal casting processesbecauseofitsinherentbenefitoftheproduction, lowcost,andhighproductionrate.Thecriticalissuewiththe sand casting process is casting defects and unstable casting quality. The pulley’s quality characteristics have beenaffected by castingdefects, whichleads toa large numberof shopfloor trails,a highrejectionrate,andpoor casting performance. Knowledge of casting defects and causesisessentialforqualitycontrol.Variousresearchers havestatedthat90%ofcastingdefectsareaccumulatedonly because of the deficient design of the gating and feeding systems. Inthiswork,creosoftware wasusedto createthe Solid model of a pulley and the gating system. Using ProcastSimulationsoftware,moldfilling,andsolidification analysiswasperformed.Mediumcarbonsteelwaschosen for its wide variety of automotive applications. The Sand moldwaschosenasamoldmaterial,andpredictionanalysis has been implemented using computer-aided simulation software[2]

Mohan & et al. (2020) [2] In this current scenario of globalization, foundries play a key role for manufacturing industriesastheyarethemajor sourceof castings.Casting has various processes like Pre casting Processes, pattern making, core making, moulding and mould assembly making, Casting Processes, furnace charging, melting, holdingandpouring,andPostcastingProcesses,shakeout, inspectionanddispatchetc. InIndiatherearemanyfoundry havefollowedconventional andmanualoperations.Today’s competitive environment has, lower manufacturing cost, more productivity in less time, high quality product, defectfreeoperationarerequiredtofollowtoeveryfoundry man. Mould shifting, Crushing, Lower Surface finish, Shrinkage, Porosity, Cold shut and Extra material are common casting defects due to these manual operations. These defects directly affect on productivity, profitability andqualityleveloforganization.

Manu khare et al[3]analysis of significant parameter of green sand casting of fly wheel which is FG350 alloy [FG 260].Hetake parametersaregreenstrength, claycontent and pouring time. Result indicates that green strength is significant parameter while clay content and pouring temperaturearenon-significantparameter.

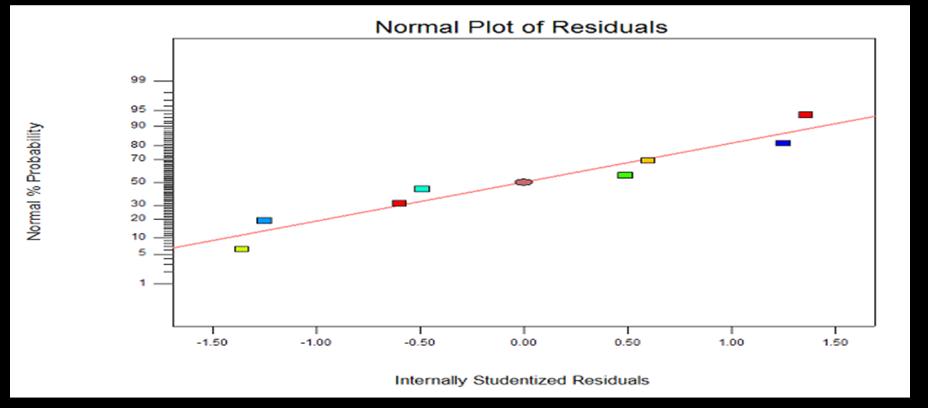

2.2 Normal Probability plot of Residuals for Percentage.

Rasik a. Upadhya etal[4] tooptimizedsandcastingprocess parameter of the casting manufactured iron foundry by maximized the s/n ratio (signal to noise ratio). Also minimized the noise factors by Taguchi Method. Taken processparametersaremoisture,sandparticlesize,green compression strength, mould hardness, permeability, poutingtemperature,pouringtimeandpressuretest.Result showtheprocessparametersareaffectedoncastingdefects inironfoundry.Improvementinreductionincastingdefects istobe37.66%.

Table 2.1 Optimum Condition and Performance.

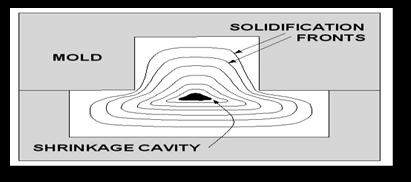

C.M. Choudhary et al[5] foundthemajorroleofshrinkage porosity in the rejection of components in foundry. Take LM6castingmaterialanddoingexperimentworkandseen the defect of shrinkage porosity and when solidification completed,thelastregionofsolidifyhotspotarethere.So using methoding and simulation technique, feeding aids helptoustogatingthehotspotcompletelyshiftedinfeeder. Simulationtechniquehelptheinimprovementinyieldand qualityofcastingcomponent

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

Figure: 2.5 Progressive Convergences of Hotspots Indicates Last Solidify Region.

Y Chang et al[6] investigation the properties of green mouldingsandandnewmodelevolutestheFlowabilityof sand compact is developed. In Sand Casting process very importancetocontrollingtheFlowabilityofMouldingsand. Study about the experiment results are indicates to show howflowabilityofsilicasandisaffectedbywatercontent, Bentonite and sea-coal content. The existing flowability indicates such as compatibility slop of stress-strain curve, hardness gradient, can not totally agree with experiment results

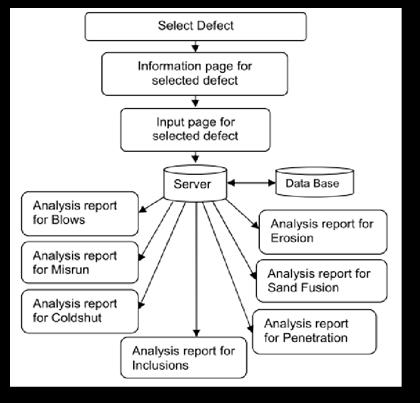

A. Rai etal[7] forfoundryindustriesveryimportantissuesto control of defects of sand casting process. Casting defects Diagnosis and analysis by multiple events like meltpreparation,mouldcorepreparation,pouring,solidification andfettling.Knowledge-basedexpertsystembeenusedto supportedtodecisionmakingforprocess.Theexpertsystem shouldcapabletoidentificationofdefectsanditsdiagnosis andhelptousdesignerandproductionengineertodecided decisionmakingregardingtoreductionindefectsofcasting.

Raghwendra et al[8] becauseofrelationbetweenthecasting defectsandgreensandproperties,traditionalmethodtrial and error based on know and experiment have many disadvantageslikeconsumingoftime,non-symmetricaland itsneededverylongtimeforexperimentdoing.

Traditional method is replaced by ANN (artificial neural network) and data mining tools for preventing the above disadvantages. So effects of riser design, gating system, moldingsand,oxidationanddeformationofcastingduring heattreatment,machiningallowanceeconomicalreview.To optimizedprocessparametersignificantlyimprovementin yield,outputratioofmetal,shortenmanufacturingperiod, saveenergy,lesspollutionandimproveincompetitivewith enterprise.

P.Prabhakara rao et al8] incementindustriesforcrushing componentandloadbearingstructure,toachievedquality requirement of superior mechanical properties. So Using CADtechnologiescombined withprocesssimulationtools areusedtooptimizedfillingandsolidificationofcast part. Here discussed new developed simulation tools and its applicationtocrushercomponent.Resultshowthatcasting trailsarehighlevelconfidenceinsimulationtools.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

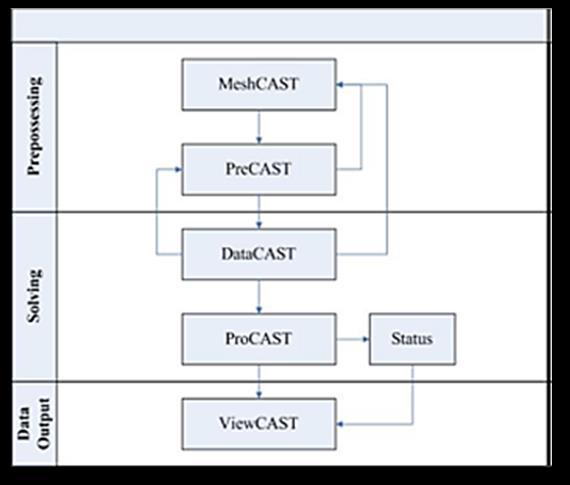

Byusingsimulationtools,itishelptofoundriestoreduced scrap and also minimized defects. Simulation tool used to identifycriticalarea,fillingpatternandsolidificationrelated problemsareaincasting.AssimulationtoolusedPRO-CAST.

2.1 Outcome from Literature Review

After studies some research papers of based on minimized casting defects, D.E.O.{design of experiment} methods like TAGUCHI, ANOVA, ANN , Responsesurfacemethod(RSM)areveryeffectiveness tooptimizedprocessparametersofcasting.

Also simulation tools are like pro-CAST, auto-CAST, magma,etc..Veryusefultonewdesignofgatingsystem andknowthehowmuchreduceddefects.Alsoimproved inqualityofcastcomponentandinyield

[1]Uday A. Dabade et al, “Casting defects analysis using design of experiment and computer aided simulation technique”,Forty-sixthCIRPConferenceonManufacturing System2013.

[2]N.S.Mohan-“Analyzingthecastingdefectsinsmallscale castingindustry”InternationalConferenceonNewerTrends and Innovation in Mechanical Engineering: Materials Science. Material Todays ProcessdingsVolume 37, Part 2, Pageno.386-394,2021.

[3]A.sunanda-“Simulationforpredictionanalysisofdefects inpulleycastedusingsandcastingprocess”.MaterialTodays Processdings Emerging Trends in Materials Science,TechnologyandEngineering.March2021

[4]RashikUpadhya,Dr.IshwarPKeswani “optimizationof sand casting process parameters using taguchi method” InternationalJournalofEngineeringResearch&Technology (IJERT),ISSNNo.2278-0181.,Vol.1,September-2012.

2024, IRJET | Impact Factor value: 8.226 |

[5] C.M.Choudhary et al, “methodology and simulation of LM6 sand casting for defects minimization with its experimental validation” 12TH Global Congress on ManufacturingandManagement,GCMM2014.

[6]Y.Chang et al,“Theflowabilityofbentonitegreenmould sand”JournalOfMaterialsProcessingTechnology113(2001) 238-244.

[7]ARai et al,“Webbasedexpertsystemforsomedefects sandcasting”InternationalJournalofAdvancedEngineering ResearchAndStudiesE-ISSN2249-8974

[8] Raghwendra et al, “optimization in green sand casting process for effeciant, economical and quality casting” International Journal of Advanced Engineering and TechnologyE-ISSN0976-3945.

[9] S.GUHARAJA PHD Thesis, “Optimization of casting process parameters using TAGUCHI method and evolutionaryheuristics”AnnaUniversity,Chennai-Feb-2009.

[10]A.HTechnocastPvtLtd.

[11] Vishal S. Jadhao , Prof. J.J.Salunke “Review Paper on Simulation Based Casting” International Journal of InnovativeResearchinScience,EngineeringandTechnology.

[12]Mr.RohanD.Ahirrao“AREVIEWPAPERONANALYSIS AND OPTIMIZATION OF ALUMINIUM CASTING PARAMETERS” International Research Journal of EngineeringandTechnology(IRJET)”

[13] Anil B Ghubade “Review on casting defects and methodologiesforqualityimprovement”JETIRApril2019, Volume6,Issue4