International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

1Mr. Onkar Kachare, 2Mr. Anup Kulkarni, 3Mr. Omkar Chavan, 4Ms. Shraddha Bhosale

5Dr. Jahier Shaikh

1,2,3,4 Student, Mechanical Engineering, JSPM’s Jayawantrao Sawant College of Engineering, Hadapsar, Pune, Maharashtra, India.

5prof. & Dr., Dept. of Mechanical Engineering, JSPM’s Jayawantrao Sawant College of Engineering, Hadapsar, Pune, Maharashtra, India. ***

Abstract - The aim of this project was to evaluate the suitability of E-glass with RTM resin compositematerialjoints as replacements for metal joints. Tensile strength and compressive strength tests were conducted using a Universal Testing Machine (UTM), resulting in values of 410 MPa and 340 MPa, respectively. These findings suggest that the composite material joints exhibit promising mechanical properties comparable to traditional metal joints. The high tensile strength indicates the ability of the joints to withstand pulling forces, while the significant compressive strength demonstrates resistance to crushing forces. This indicates the potential for utilizing E-glass with RTM resin composites in structural applications wherehighstrengthanddurabilityare essential, potentially leading to lighter-weight and corrosionresistant alternatives to metal joints. Overall, this research highlights the feasibility and efficacy of composite material joints as replacements for metal joints in various engineering applications.

Key Words: Composite material, E-glass, RTM resin, tensile strength, compressive strength, metal joint replacement.

Inourproject,titled"StrengthandReplacementof CompositeMaterialJointsasReplacementofMetalJoints," we address the need for alternatives to traditional metal joints in engineering applications. Metal joints often face challenges such as corrosion and weight concerns, prompting the exploration of composite materials as replacements. Composites offer several advantages, including resistance to corrosion, reduced weight, and potentiallysuperiorquality.Byreplacingmetaljointswith compositealternatives,weaimtomitigatecorrosionissues, decrease overall weight, and enhance the quality and performanceofjointsinvariousstructuralapplications.This projectfocusesonevaluatingthestrengthcharacteristicsof composite material joints, aiming to demonstrate their viability as effective substitutes for metal joints in engineering designs. Through this research, we seek to contributetotheadvancementoflightweightandcorrosionresistantsolutionsinengineeringpractices.

The problem we're addressing involves the limitations of traditional metal joints in engineering applications,notablyissuessuchascorrosionsusceptibility and excessive weight. Metal joints are prone to corrosion overtime,leadingtostructuraldegradationandincreased maintenance costs. Additionally, their weight can pose challengesinapplicationswhereweightreductioniscrucial for efficiency and performance. To overcome these challenges, we're investigating the use of composite materialsasreplacementsformetaljoints.Compositesoffer severaladvantagesovermetals,includingsuperiorcorrosion resistance, lighter weight, and the potential for higher quality and durability. By evaluating the strength characteristics of composite material joints, we aim to demonstratetheirsuitabilityasreliablesubstitutesformetal joints in various engineering applications. Through this research, we seek to contribute to the development of lightweight, corrosion-resistant solutions that enhance overallperformanceandreducemaintenancerequirements, thusaddressingcriticalchallengesinengineeringdesignand construction.

1. Evaluatethecorrosionresistanceofcompositematerial jointstoaddressthelimitationsofmetaljointsproneto corrosion.

2. Determinetheweightreductionpotentialofcomposite material joints compared to metal joints, aiming to improveefficiencyandperformance.

3. Assess the mechanical properties and durability of composite material joints to ensure reliability and longevityinengineeringstructures.

4. Investigate the feasibility of integrating composite materialjointsintovariousengineeringapplicationsto expandtheirutilization.

5. Contribute to the advancement of lightweight, corrosion-resistantsolutionsinengineering practices, reducing maintenance costs and enhancing overall performance.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

The scope of this project encompasses a comprehensive evaluation of composite material joints as replacements for traditional metal joints in engineering applications. We will focus on assessing various aspects, includingcorrosionresistance,weightreductionpotential, mechanical properties, and feasibility of integration into differentstructures.Throughlaboratorytestingandanalysis, we aim to understand the performance characteristics of composite material joints compared to metal joints. Additionally,wewillexploretheapplicabilityofcomposite joints in diverse engineering fields such as automotive, aerospace, and infrastructure. This project offers an opportunitytocontributetothedevelopmentoflightweight, corrosion-resistantsolutionsthataddresscriticalchallenges facedbyindustries.Furthermore,itopensavenuesforfuture research and innovation in the utilization of composite materialsforstructuralapplications.

MarketSurvey

Literaturesurvey

Selectionofmaterial

Studyofvariouseffectof acidonthematerial

Design

Analysisusingsuitable software

Inferenceandresults

Ehteram A. Noor, et.al, [4] “Corrosion Behavior of Mild SteelinHydrochloricAcidSolutions”,2008.

Inthispapertheauthorspresentstudyandexaminationof the corrosion behaviour of mild steel in hydrochloric acid (HCl)solutionsthroughbothchemicalandelectrochemical methods at 25°C. Chemical analysis indicates a corrosion rateincreasewithrisingHClconcentration.Electrochemical resultsrevealanodicallycontrolledsteeldissolution,witha multistep mechanism involving electron release and potential adsorbedgroupslike[FeOH]and[FeClOH].Mild steel, commonly used in construction, faces challenges in handlingHClduetoitscorrosivenature.”

Abedin I. Gagani, et.al,[5]“Immersedinterlaminarfatigue ofglassfiberepoxycompositesusingtheI-beammethod”, 2018.

Inthispapertheauthorspresentthestudythatexploresthe degradation of interlaminar shear performance in compositesexposedtothemarineenvironment.Anoveltest method,theI-beamshortbeamshear,isusedtodetermine shearpropertiesandacceleratefluidsaturationinglassfiber epoxyspecimens.Experimentalanalysisrevealsachangein failuremodebetweendryandconditionedsamples,withdry samplesexhibitingcreep-dominatedfailureleadingtointerply cracks, and conditioned samples showing damage growth-dominated failure resulting in intra-ply failure. Opticalmicrographsindicatetheoccurrenceoffiber/matrix debonding in conditioned samples before mechanical loading,potentiallyservingasdamageonsetpoints.

Fabio Nardone, et.al, [7]“Tensilebehaviorofepoxybased FRPcompositesunderextremeserviceconditions”,2011.

In this paper the authors addresses the mechanical propertiesofexternallybonded(EB)FRPcompositesused for strengthening reinforced concrete (RC) members in extreme service environments. The focus is on the mechanicalpropertiesofglassandcarbonFRP(GFRPand CFRP)couponspecimenssubjectedtotemperatureextremes and freeze-thaw cycles. Results indicate that GFRP specimens exhibit minimal variation in mechanical propertieswithdifferentplynumbersandminorreductions in axial tensile strength and strain with increasing temperature. In contrast, CFRP specimens experience a significant reduction in mechanical properties at extreme temperatures, while freeze-thaw cycles have a limited impactonperformance.

Ourprojectfocusesonthestrengthandreplacementof metal joints with composite materials, specifically E-glass laminate. In our composite, E-glass fibers are mixed with RTM (Resin Transfer Molding) epoxy resin at a ratio of 100:27.Theresinisheatedto40degreesCelsius,andfine hard972ismeltedat100-105degreesbeforebeingmixed

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

in,ensuringahomogeneousblend.Throughtestingusinga Universal Testing Machine (UTM), we found that our compositeexhibitsimpressivetensilestrengthof410MPa andcompressivestrengthof340MPa.Thisdemonstratesthe robustness and reliability of our composite material, showcasingitspotentialasaviablereplacementformetal jointsinvariousapplications.

3.1.1

Universal Testing Machines (UTM):

AUniversalTestingMachine(UTM)isusedtotest both the tensile and compressive strength of materials. UniversalTestingMachinesarenamedassuchbecausethey canperformmanydifferentvarietiesoftestsonanequally diverserangeofmaterials,components,andstructures.Most UTM models are modular, and can be adapted to fit the customer’sneeds.AUniversalTestingMachinealsoknown as a material testing machine and can be used to test the tensileandcompressivepropertiesofmaterials.Thistypeof machinesiscalledUniversalTestingMachinebecauseitcan performallthetestslikecompression,bending,tensionetc. toexaminethematerialinallmechanicalproperties.These machines generally have two columns but single column types are also available. Load cells and extensometers measurethekeyparametersofforceanddeformationwhich canalsobepresentedingraphicalmodeincaseofcomputer operated machines. These machines are widely used and would be found in almost all materials testing laboratory. UNIVERSALTESTINGMACHINEScanbeofdifferenttypesbased output required like Computer operated Universal Testing Machine and digitally operated Universal Testing Machine.

The main functions of UTM are to test the mechanical properties of materials. The standard tests performed by UTMare:

1) TensileTest

2) CompressionTest

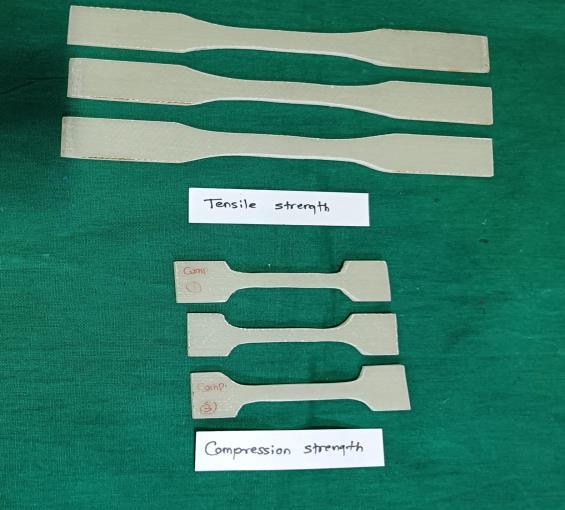

3.1.2 Test Samples

Thedimensionoftestsamplesfortheprojectareselected

from the ASTM D 638-14 & ASTM D 695-10 standard table.

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

3.1.3 Result Table

Sr. No Tensile

3.1.4 Graphs

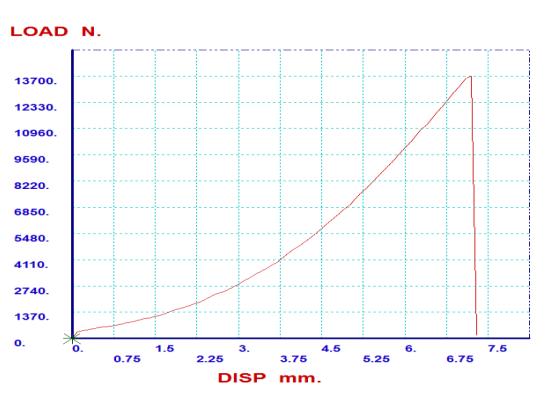

Fig -5 Tensile Test

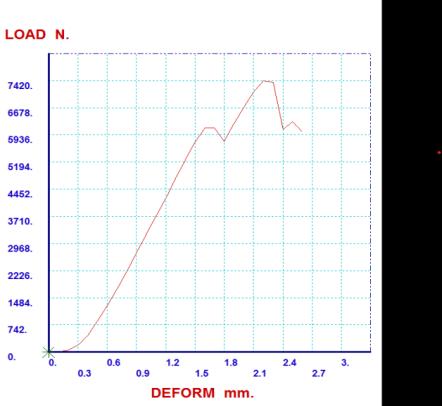

Fig -6 Compression Test

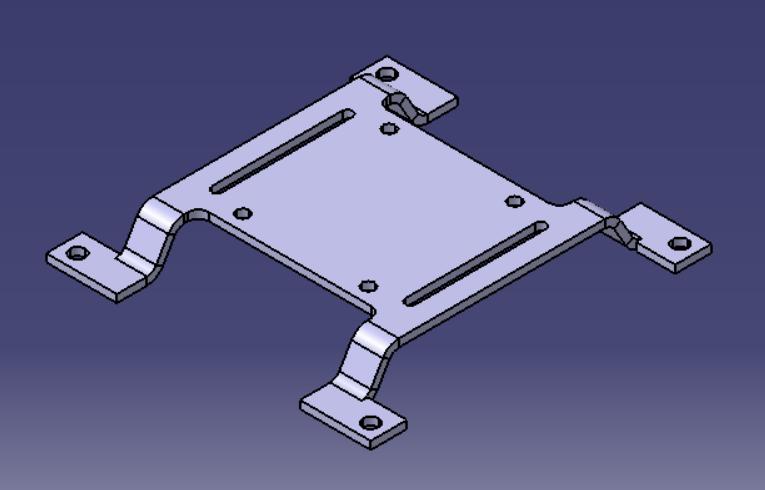

3.2 3D Design Model

Fig -7: Catia V5 Mounting Bracket

3.3 Calculations

3.3.1 Cross Sectional Area (A)

12mm 3mm m

Fig -8: Cross Section

CrosssectionalArea(A)=L*B=12*3 =36mm2

3.3.2 Force Calculations (Ft & Fc)

1) Tensile Strength

Ft/A 409.97=Ft /36 Ft = 14758.92 N

2) Compressive Strength

c=Fc/A 340.49=Fc /36 Fc = 12257.64 N

Ourprojectsuccessfullydemonstratestheviability of using E-glass laminate with RTM epoxy resin as a replacement for metal joints. By carefully controlling the mixing ratio and temperature during fabrication, we achieved impressive tensile strength of 410 MPa and compressivestrengthof340MPa,astestedunderUTM.This compositematerialoffersadurableandreliablealternative to metal joints, offering advantages such as corrosion resistanceandlightweightproperties.Ourfindingshighlight thepotentialforwidespreadadoptionofthiscompositein various industries, contributing to enhanced performance andcostsavingsinstructuralapplications.

[1] K.D. Potter, et.al., “Heavily loaded bonded composite structure: design, manufacture and test of `I' beam specimens”,2001.

[2] Y.A. Khalid, et.al., “Performance of composite I-beams underaxialcompressionandbendingloadmodes”2005.

[3] Muhammad N.S. Hadi, Jian Song Yuan, “Experimental investigationofcompositebeamsreinforcedwithGFRP I-beamandsteelbars”,2017.

[4] Ehteram A. Noor, Aisha H. Al-Moubaraki, “Corrosion BehaviorofMildSteelinHydrochloricAcidSolutions”, 2014.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

[5] Abedin I. Gagani, Emeric P.V. Mialon, “Immersed interlaminar fatigue of glass fiber epoxy composites usingtheI-beammethod”,2018.

[6] LucianoFeo,AymanS.Mosallam“Mechanicalbehavior of web–flange junctions of thin-walled pultruded Iprofiles:An experimental and numerical evaluation”, 2012.

[7] FabioNardone,MarcoDiLudovico,“Tensilebehaviorof epoxy based FRP composites under extreme service conditions”,2011.

[8] S. Guo , R. Morishima, “Numerical analysis and experimentofcompositesandwichT-jointssubjectedto pullingload”,2011.

[9] X. Han, A.D.Crocombe, “The strength prediction of adhesivesinglelapjointsexposedtolongtermloading inahostileenvironment”,2014.

[10] M. Mariama, M. Afendi, “Influence of hydrothermal ageing on the mechanical properties of an adhesively bondedjointwithdifferentadherends”,2019.

[11] XiaoquanChenga,QianZhang,“Parameterspredictionof cohesive zone model for simulating composite/ adhesivedelaminationinhygrothermalenvironments”, 2019.