International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

Mr. Akshay Pankaj Chaudhari1, Mr. Pratham Paresh Mistry2, Mr. Vaibhav Dnyaneshwar Wadkar3, Mr. Gyan Umesh Suvarna4, Mr. Tejas Patil5, Mrs. Nehal Muchhala6

1Student, Diploma in Mechanical Engineering, Thakur Polytechnic, Kandivali, Maharashtra, India

2 Student, Diploma in Mechanical Engineering, Thakur Polytechnic, Kandivali, Maharashtra, India

3 Student, Diploma in Mechanical Engineering, Thakur Polytechnic, Kandivali, Maharashtra, India

4 Student, Diploma in Mechanical Engineering, Thakur Polytechnic, Kandivali, Maharashtra, India

5 Lecturer, Diploma in Mechanical Engineering, Thakur Polytechnic, Kandivali, Maharashtra, India

6 Head of Department of Mechanical Engineering, Diploma in Mechanical Engineering, Thakur Polytechnic, Kandivali, Maharashtra, India

Abstract - Humidityinfiltrationintoairpollutantsposesa significant challenge, negatively impacting combustion effectiveness, energy frugality, and overall machine continuity. Our proposed result employs state- of- the- art accoutrementsandaunique designtorepelhumidity,icing sustainedfiltrationeffectivenessindeedinstickyconditions. The sludge's composition includes hydrophobic accoutrements and strategic walls, precluding water intrusion into critical filtration rudiments. Laboratory testing and real- world simulations confirm the superior performance of our humidity- resistant air sludge, showcasing its capability to outperform conventional pollutantsunderdifferentenvironmentalconditions.Beyond securing against humidity- related issues, our result contributes to bettered air quality within the combustion chamber.Byenhancingmachineeffectivenessandreducing conservationcosts,thisinventionholdstheimplicittorevise automotive air filtration technology, offering a more dependable and durable result for the challenges posed by humidityinthevehicularterrain.Theperpetrationofsimilar advanced pollutants stands to significantly elevate vehicle performance, life, and environmental sustainability in the automotive assiduity.

Key Words: Humidity infiltration, air pollutants, combustion effectiveness, energy frugality, machine continuity

In the realm of automotive engineering, the effective functioning of internal combustion machines is vital to vehicle performance, energy frugality, and overall continuity. Still, one patient challenge that has garnered adding attention is the mischievous impact of humidity infiltration into air pollutants. The intrusion of moisture into these pivotal factors poses a significant trouble to combustion effectiveness, energy economy, and the sustaineddurabilityofcommonmachineoperations.Feting theurgencyofaddressingthisissue,ourexplorationdelves into the development and evaluation of a humidity-

ResistantAirFilterexpresslydesignedformotorcars.This paperexploresapioneeringresultthatleveragesslice-edge accoutrements and a technical design to repel humidity, icing sustained filtration effectiveness indeed in adverse andstickyconditions.Throughcomprehensivelaboratory testing and real- world simulations, we check the performanceofourproposedmoisture-resistantairsludge, comparing its capabilities with conventional pollutants under different environmental circumstances. Beyond securing against moisture- related goods, the envisaged result contributes to bettered air quality within the combustionchamber.Thisexplorationmarksavitalstride toward advancing automotive air filtration technology, offeringamorereliableanddurableresulttothechallenges posed by moisture in the vehicular terrain. The counteraccusations extend beyond bare technological invention, holding the eventuality to elevate machine interpretation,extendfunctionallife,andfosterenhanced environmental sustainability within the automotive assiduity.

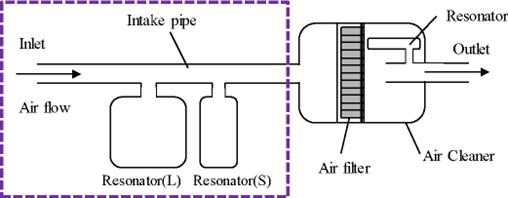

Packaging involves optimum operation of space in machine.Butthisisn'talwayscompatiblewiththeasked performance.Tosustainhighperformancefrommachines, clean air inflow plays a vital part, which is necessary for combustion in machine. This is handed by Air sludge system.Theairsuppliedtocombustionchamberthruair induction system contains colorful substances of atmosphere.Thismaydamagethemachinecorridorsimilar aspistonorcylinder.Thepartofairsludgeistofilterout theaircontainingforeignsubstancesandtoreducetheair inflowrateintheairsludge,sothatthenoisegeneratedby input system can be reduced. The air induction system consistsoffollowing:

1)Anairinputconduit,wheredirtyairenters.

2)Casepresludge,wheredirtgetsaccumulated

3)Airsludge,wheredirtyairgetsfiltered

4)Casepostsludge,whichaccumulatesthefilteredair

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

5) Resonator, it helps in making machine paradoxically quieterandimportant.

6)Airoutletconduit,whichsuppliescleanairtomachine

The air introduced into the air induction system is smelled into the case through the sludge and also transferredtothemachine.It'simportantthattheairthat passes thru the sludge should be slightly distributed. Optimumoperationofsludgeelementcanreducethecost of sludge relief constantly and thus keep the sludge in operationforlongertime.TheAirinductionsystemfigure playsahugepartinunderstandingthequalityofairinflow. Whenthediffusersmellsairin,theshapeofthediffuserand the inflow around it affects the machine’s performance. This is due to the large quantum of air gathering characteristics.Reductioninenergyconsumptionresultsin reducingthe pressurelosses in the air induction system. Theaskedairinductionsystemshouldhavehighairflows whilekeepingtheminimalpressurelosses. Tooptimizeair inductionsystem,thoroughunderstandingofoverflowsand pressure drop through the system is essential. To prognosticate the inflow as well as trials performed in inflow equipages are prognosticated with the help of numerous tools. One of the significant tools to prognosticate the same is CFD (computational inflow dynamics) analysis. CFD is the most effective result for inflow analysis of complete air induction system. Then we’refasteningonthereviewofairsludgeperformances criteria for its optimum operation in the motorcycle operation

1.1 Type of filter

Air filters are mainly classified on basic of following2categories:

1.2 Based on geometric Shape:

1.Rectangular

2.Circular

3.Polygon

1.3 Based on Material Used:

i. Foam Air filter.

In the dusty dawn of automotive history, before paper daredtobreathe,reignedthemightyfoamfilter.Denseand defiant,itstoodguardagainstthecavalryofgritandgrime, asilentshieldfortheengine'sdelicateheart.Today,itstill whispersitsvaliantballadinthethroatyroarofdirtbikes, theirtireschurningbattlefieldsofclayandgravel.Costlier thanitspaperykin,yes,butaloyalsquire,everreadyfora bathandanotherround.Andforthosewhodancewiththe dustiestdevils,oiledvariantsstand,stickyknightsarmed againstthefinest,mostnefariousparticles.So,whenthe windwhipssandacrossyourfaceandyourenginepurrsa song of gratitude, remember the unsung hero, the foam filter,foreveretchedintheannalsofautomotivegrit.

ii. Paper Air filter

Paperfilters,theRobinHoodsofairfiltration.Theysnatch dustfromthe rich(engine air intakes)and giveit tothe poor (garbage can), all while keeping your wallet fatter thanRobin'squiver.Thesesimpleheroesarethego-tofor single-cylinder workhorses, chugging happily along highwaysandcitystreets.Amerebreathofpressurizedair istheirelixir,revivingthemforanotherdustyduel.Sure, they're not Lancelot when mud monsters attack, but for everydayknightsoncommutersteeds,paperfiltersarea trusty squire. So, when you zip past on your trusty twowheeler, remember the quiet guardian whispering "breatheeasy"–thepaperfilter,championofcleanlungs andfatwallets.

Cotton air filters rule the high-performance roost. Crafted from the whisper of angels' wings (okay, cotton plants), these bad boys don't just block crud, they choreographtheair'swaltzintoyourengine'ssoul.Dust dances aside, a mere fly before the tornado these filters unleash. Cotton’s the maestro, conducting every microsecond of air into a symphony of untamed horsepower.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

2.Literature Review

K.L. Srinivasulu outlines a study focused on enhancing the design and performance of an air filter throughtheutilizationofComputationalFluidDynamics (CFD)analysis.Tooptimizetheflowcharacteristicswithin theAirIntakeSystem(AIS),astrategicdecisionwasmade to implement a rectangular type of filter. Additionally, modificationswereintroducedtotheplacementofbaffles withintheinletplenumofthefilter.Theoutcomesofthe analysis clearly indicated a substantial pressure drop in conjunction with a prominent recirculation zone. Recognizingtheneedtomitigatethehighpressuredrop inherent in the existing filter design, the introduction of baffle plates in various positions was proposed. These modifications aimed to achieve a notable reduction in pressure drop, with the analysis indicating an improvementofupto14%.[1]

Inhispaper,HoseopSongdelvesintotheoptimization of diffuser shape for improved engine efficiency. The investigationinvolvedassessingtheflowcharacteristics, flow noise, and pressure drop of a standard air cleaner without any alterations to its shape. Finite Element Analysis was employed for this purpose. The analysis revealedthattheairintroducedthroughtheinletfollowsa rotational path along the wall of the upper box, passing through the filter and displaying a specific shape as it is drawnthroughthediffuser.Thestudyassumedtheflow within the air cleaner to be an incompressible perfect

turbulentflow.Theanalysisutilizedthewidelyadoptedk-ε realizable model for simulating turbulent flow, ensuring stabilityandaccuracyintheresults.[2]

Inhisresearchpaper,M.R.Chopadedetailstheefforts to enhance the performance of an air filter through the optimization of the Air Intake System (AIS) design. The focusofthestudyrevolvesaroundreducingthepressure dropacrossthefilterbyimplementinganeccentricdesign forthehousing.Here,thecasing,servingasacylindrical element, safeguards the filter and the housing while creatinganannularspacetofacilitatethemovementofair. [3]

ChangMingTsangconductedathoroughinvestigationin his thesis, examining the various factors that impact pressuredropandflowpatternsacrosspleatedairfilters through a numerical study. Utilizing FLUENT and numericalanalysis,theresearchdelvedintotheinfluences ofairvelocity,geometry,andtheshapeoffilterpleatson thefilter'spressuredrop.Thestudyprovidedinsightsinto the intricate relationship between these factors, contributingtoacomprehensiveunderstandingofpleated airfilterperformance.[4]

FollowingarethefunctionsofAIS:-

1. Thesystemstartsbydrawingairfromoutsidethe vehicle, usually through an opening in the front grille or bumper. This ensures access to fresh, unheatedair.

2. Beforeenteringtheengine,theairpassesthrough an air filter to remove dust, debris, and other contaminantsthatcoulddamagetheengine.

3. Dependingontheengine,theairintakesystemmay have sensors that measure the volume and temperatureoftheincomingair.Thisinformationis used by the engine computer to optimize the fuel mixtureforefficientcombustion.

4. Theamountofairenteringtheengineiscontrolled by a throttle body or butterfly valve. This valve opens and closes in response to the driver's acceleratorpedal,regulatingthespeedandpower outputoftheengine.

5. The filtered and measured air is delivered to the engine'sintakemanifold,whereitismixedwithfuel andthensenttothecylindersforcombustion.

To induce the power to crankshaft; the combustion chamberofmachineneedsairaswellasenergy.Theairis guidedbyAIStothecombustionchamber.Dependsupon the type of vehicle; the position of AIS is defined. The quantum of air demanded in the combustion chamber dependsonnumerousfactorsbutsubstantiallyitdepends onthespeedandaccelerationof the machine. Whenthe vehicle accelerates from low to high rpm; the energy consumption is high. And thus, the quantum of air (or

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

oxygen)demandedinsidethecombustionchamberisalso high.ThequantumofairissubstantiallycontrolledbyECU inthemachines.ThealternatepurposeofAISisdrawingof theincomingairfrompatcheslikebeach,leavesetc.Thisis done by using air sludge inside the sludge box. The standarddemandofairsludgefiltrationisapproximately. 99.8oftheincomingair.Airsludgealsohelpsinreducing thenoisefromthemachine.AconceptionimageofAISis shown below for understanding point of view where air hasteisdenotedbyU∞.Infactualoperation,thedesignand layoutmaydiffer.

4.Problem caused in engine due to moisture in air

Themajorproblemtoengineduetomoistureinengine viaairwhichthedecreasesperformanceandefficiencyof engineare:

a. Corrosion:Exposuretomoisturecanleadtothe development of rust on crucial metal surfaces within the engine, including the engine block, cylinder walls, pistons, and other internal components.Thiscorrosion hasthe potential to compromisethestructuralintegrityoftheseparts, impactingtheirproperfunctioning.

b. FuelSystemChallenges:Thepresenceofmoisture inthe fuel systemcanresult inissuesrelatedto fuel qualityandcombustion.Waterenteringthe fuelcancausepoorengineperformance,misfires, and difficulties in starting the engine. In severe cases,itmayevencausedamagetofuelinjectors andothercomponentsinthefueldeliverysystem.

c. ElectricalComplications:Moistureandelectricity are a problematic combination. When moisture infiltrateselectricalcomponentssuchassensors, spark plugs, and ignition coils, it can lead to malfunctions. This, in turn, can result in suboptimal engine performance, reduced fuel efficiency,andthepotentialforenginemisfires.

d. Air Intake Challenges: If moisture manages to entertheairintakesystem,itcandisrupttheairfuel mixture and the combustion process. This disruption may manifest as reduced engine power,hesitationduringoperation,andpoorfuel efficiency.

e. OilContamination:Moisturepresentintheengine canmixwiththeoil,diminishingitseffectiveness in lubricating and safeguarding engine components.Thissituationcanescalatefriction, accelerate wear and tear, and pose a risk of damagetointernalparts.

f. Exhaust System Issues: Moisture within the exhaust system can initiate rust and corrosion, particularly in components like the muffler and exhaustpipes.Thiscorrosioncanleadtoexhaust leaksandunderminetheefficiencyofthecatalytic converter

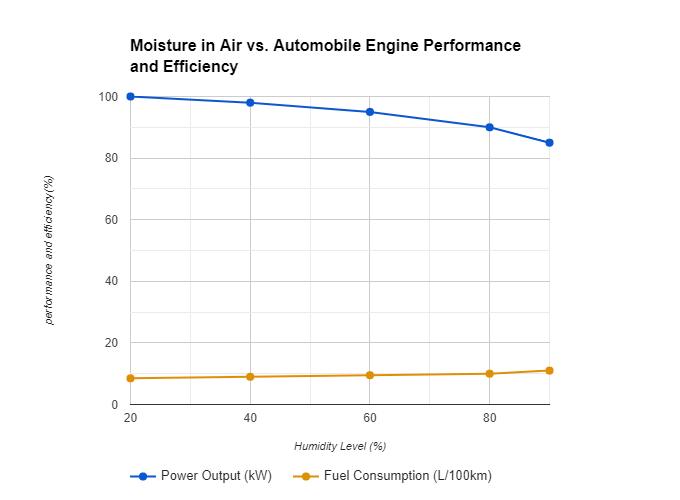

due to moisture

A. Performance Downgrade:

Powerless Punch: Imagine replacing oxygen, the combustioncheerleader,withmoisture,thepartypooper. That's what happens when humidity rises. The air-fuel mixture becomes leaner, resulting in incomplete combustionandanoticeabledecreaseinpower.Youmight feelthatsluggish,"won't-get-out-of-its-own-way"feelingas yourenginestrugglestomusteritsusualmuscle.

Ignition Hiccups:Thinkofmoistureasawetblanket smotheringthespark plugs.Ittakesmuchmoreeffortto ignitetheair-fuelmixture,leadingtohesitation,stuttering, andevenstalling,especiallyduringcoldstarts.

Efficiency Impasse: Incomplete combustion doesn't justsapyourengine'sstrength;italsoguzzlesmorefuelto achievethesameoutput.Imaginepushingthatstalledcar–energywasted!Thistranslatestoanoticeabledropinfuel efficiency,makingyourwalletlighterfaster.

Fuel Inefficiency: Pictureascenariowhereoxygen,the crucialpartnerinfuelcombustion,isreplacedbymoisture, theefficiencydampener.Ashumiditylevelsrise,theair-fuel mixture becomes leaner, compelling the engine to exert moreefforttoachievethesamepoweroutput.Thisresults inelevated fuelconsumption,reducingyourtravel range andleavingyourwalletlighter.

Challenges of Incomplete Combustion: Envision moistureasadampeningcoversmotheringtheflamesof combustion.Incompleteburning,causedbywatervapor, leadstothewastageofenergypotential.Theenergythat could have propelled your vehicle forward is lost as unburnthydrocarbons,causingtheenginetoworkharder formeagergainsinmileage.

Sensor Confusion: Moisturenotonlydisruptsthefuel combustionprocessbutalsothrowsthesensorsysteminto confusion. Intake air sensors, acting as the engine's eyes andears,becomebefuddledbytheincreasedwatervapor. This confusion leads to miscalculations and improper adjustments by the engine control unit, further compromising efficiency as the engine operates under suboptimalconditions.

IcyChallenges: Incolderclimates,moisturetransforms intoanotheradversaryofefficiency–ice.Itcanaccumulate insidetheintakesystem,restrictingairflowandcompelling the engine toexert more effort todrawinair.This extra effort burns additional fuel, leaving you with a colder engineandaheftierfuelbill.

The Complexity of Efficiency Impact: The effect of moisture on efficiency is a multifaceted equation with severalfactorsatplay.Whileaslightincreaseinhumidity

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

may have minimal effects, elevated humidity levels can significantlyreducefuel economyby5-10%.Thisimpact maybeevenmorepronouncedinolderenginesorthose withpoorlymaintainedairfilters.

While the frame remains unchanged, a significant innovationlieswithinthis newairfilter:glassfiber.This materialboastsapowerfulhydrophobicproperty,actingas aformidableshieldagainstmoistureintheair.Thinkofitas an invisible raincoat for the engine, repelling any water dropletsormoistureencounteredasairflowsthrough.This iscrucial,asexcessmoisturecandamagesensitiveengine componentsandhinderperformance.

The science behind its effectiveness lies in its hydrophobicity.Unliketraditionalairfiltermaterials,glass fiber naturally repels water, creating a barrier against moistureingress.Thisensuresthattheairfiltermaintains itsprimaryfunctionofcapturingdustandpollutantswhile simultaneouslykeepingmoistureout,ultimatelydelivering clean air to the engine for optimal performance. Furthermore, the durability of glass fiber extends the lifespan of the air filter, offering long-lasting protection againstmoisture,wear,andtear.

Beyonditsmoisture-repellingproperties,glassfiberboasts severaladditionalbenefitsrelevanttoairfiltration:

High Filtration Efficiency: While effectively repellingmoisture,glassfiberretainsitsprimary function of capturing airborne contaminants, includingdust,pollen,andotherparticulates.This ensures clean air reaches the engine, optimizing performanceandfuelefficiency.

Durability: Compared to traditional materials, glassfiberexhibitssuperior mechanicalstrength

and resilience. This translates to longer filter lifespan,reducedmaintenancerequirements,and cost-effectiveness.

Reduced Environmental Impact: Glass fiber offers a sustainable alternative to traditional materials, as it is recyclable and requires less energytoproduce.

Inconclusion,thedevelopmentandimplementationofa moisture-repellent air filter presents significant advantages in maintaining engine efficiency and overall vehicle performance. By incorporating hydrophobic treatments, open structure designs, and other moistureresistant features, such air filters aim to counter the detrimentaleffectsofmoistureontheenginesystem.

A. levated Engine Efficiency:

The deployment of moisture-repellent air filters plays a pivotal roleinadvancingengineefficiency.Bythwarting the adverse effects of water vapor on the combustion process,thesefiltersensureaconsistentandoptimalairfuelmixture.This,inturn,empowerstheenginetooperate with enhanced efficiency, translating into an overall improvementinvehicleperformance.

Anoteworthyadvantageofmoisture-repellent airfilters liesintheirabilitytominimizetheimpactofmoistureon combustion and engine components, leading to reduced fuel consumption. This reduction is instrumental in maintainingfueleconomy,allowingvehiclesequippedwith suchfilterstocovermoredistanceperunitoffuel.Thisnot only benefits the environment by lowering carbon emissionsbutalsoproveseconomicallyadvantageousfor vehicleowners.

The prevention of corrosion and damage caused by moistureisakeyattributeofmoisture-repellentairfilters.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

Thesefiltersserveasaformidabledefenseagainstrustand corrosion, safeguarding critical engine components. Consequently, the extended protection contributes significantlytothelongevityoftheengine,mitigatingthe needforprematuremaintenanceorcostlyreplacements.

Moisture interference with the proper functioning of sensors within the engine control system is a common challenge.Moisture-repellentairfiltersaddressthisissue byeffectivelyrepellingmoisture,therebypreservingthe accuracy of readings and calculations made by sensors. Thisensuresthattheenginecontrolunitcanmakeprecise adjustments,optimizingoverallengineperformance.

Theadaptabilityofmoisture-repellentairfiltersshinesin diverseclimaticconditions.Whetherfacinghighhumidity, rain,orcoldertemperaturesleadingtoiceformation,these filtersofferaversatilesolution.Theymaintainconsistent airflowandengineperformance,ensuringreliabilityand efficiencyacrossaspectrumofenvironmentalchallenges.

In essence, the incorporation of moisture-repellent features in air filters represents a proactive and transformativestrategytocounteracttheadverseeffectsof moisture on internal combustion engines. Vehicles equippedwiththeseadvancedfiltersstandtogainnotonly intermsofimmediateperformanceimprovementsbutalso throughsustainedbenefitssuchasprolongedengine life and reduced environmental impact. The investment in such innovative filtration technology underscores a commitment to optimal vehicle functionality in diverse operatingconditions.Asautomotivetechnologycontinues toevolve,moisture-repellentairfiltersemergeasacrucial componentinthepursuitofefficiency,sustainability,and theprolongedhealthofinternalcombustionengines

[1] 1.K. L. Srinivasulu, D. Srikanth, K. Rafi, and B. Ramanjaneeyulu, “Optimization of Air Filter in an Automobile Diesel Engine by Using CFD Analysis,” IOSRJ.Mech.Civ.Eng.e-ISSN,vol.13,no.2,pp.78–89, 2016,doi:10.9790/1684-1302027889.

[2] 2.H. Song, B. Yang, and H. Cho, “A study on the optimumshapeofautomobileaircleanerdiffuser,”Int. J.Appl.Eng.Res.,vol.12,no.12,pp.3377–3381,2017.

[3] 3.M. R. Chopade, A. P. Valavade, S. H. Barhatte, M. Engineering, and M. I. T. College, “Performance enhancement of air filter by design optimization”

International Journal of Advanced Engineering Technology,vol.III,IssueI,Jan-March,2017/68-70.

[4] I. Engineering, “Analysis of pleated air filters using computationalfluiddynamics,”1997.

[5] European Commission. A European Green Deal: Striving to Be the First Climate-Neutral Continent. 2019.

[6] European Environment Agency. Greenhouse Gas EmissionsfromTransportinEurope.2019.Available online: https://www.eea.europa.eu/data-andmaps/indicators/transport-emissions-of-greenhousegases/transport-emissions-of-greenhouse-gases-12 (accessedon14August2020).

[7] Transport Emissions. A European Strategy for LowEmission Mobility. 2019. Available online: https: //ec.europa.eu/clima/policies/transport_en(accessed on14August2020).

[8] Marius,T.InvestigatingMaintenanceProceduresfor Engine Air Filters. In Proceedings of the European AutomotiveCongressEAEC-ESFA,Bucharest,Romania, 25–27November2015.

[9] Toma,A.;Fileru,C.S.Therestrictionproducedbythe airfiltrationsystemversustherestrictionproducedby the air filter. In Proceedings of the MATECWeb Conference,Chisinau,Moldova,31May–2June2018; Volume178

[10] Ahmed, Q.; Bhatti, A.I.; Rizvi, M.A.; Raza,M. Gasoline engine air filter health monitoring by second order sliding modes. Int. J. Adapt. Control Signal Process. 2016,27,447–461.

[11] Dziubak,T.;Szwedkowicz,S.Operatingpropertiesof non-wovenfabricpanelfiltersforinternalcombustion engine inlet air in single and two-stage filtration systems. Eksploat. Niezawodn. Maintance Reliab. 2015,17,519–527.

[12] Buchart-Korol,D.;Folega,P.Impactofroadtransport meansonclimatechangeandhumanhealthinPoland. PrometTrafficTransp.2019,31,195–204.

[13] Komorska, I.;Wolczynski, Z. Fault diagnostics of air intakesystemoftheinternalcombustionengine.Appl. Cond.Monit.2018,10,91–100.

[14] X.Wang,K.Kim,C.Lee,andJ.Kim,“Predictionofair filter efficiency and pressure drop in air filtration media using a stochastic simulation,” Fibers Polym., vol. 9, no. 1, pp. 34–38, 2008, doi: 10.1007/s12221008-0006-4