International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Irshad Ansari1, Mohit kashyap2, Pradeep Kumar Gurjar3, Vicky 4 , Alok Verma5

1,2,3,4Student, Dept. of Civil Engineering, Delhi Technological University, Delhi, India 5Professor, Dept. of Civil Engineering, Delhi Technological University, Delhi, India ***

Abstract - This paper presents a comparative study on theperformance ofPrestressedConcrete (PSC) electric poles at Corner of street/road with rectangular and square crosssections. Aimed at improving structural integrity, safety, and cost-efficiency, the study analyses key parameters such as load-bearing capacity, crack resistance, deflection, installation practicality, and overall economic feasibility. Field observations, analytical calculations, and experimental testingconfirmthatsquarecross-sectionpoles offer improved load distribution, reduced torsional instability,andeasier maintenance.The transitiontosquare sections demonstrates enhanced performance under various loading conditions, particularly at critical installations such as 90° turns in power lines. STAAD Pro-based modeling, IS code design compliance, and cost comparison further validate the advantages of adopting the square crosssectioninPSCpoledesign.

Key Words: PSC Pole, Rectangular Cross-section, Square Cross-section, Load-bearing, Crack Resistance, Cost Efficiency, STAAD Pro

Pre-Stressed Concrete (PSC) poles are widely used in power transmissionand distributionsystems dueto their high strength-to-weight ratio and resistance to environmental stresses. Traditional PSC poles are often constructed with a rectangular cross-section, which provides directional strength but suffers from structural inefficiencies when subjected to multidirectional forces, particularly at line corners. this study proposes the adoption of square cross-sections in PSC poles to address these inefficiencies. Square poles offer uniform structural stiffness and strength along both axes, improving overall stability and performance. The goal is to validate the superiority of square designs through analytical comparison,fieldtesting,andcostanalysis.

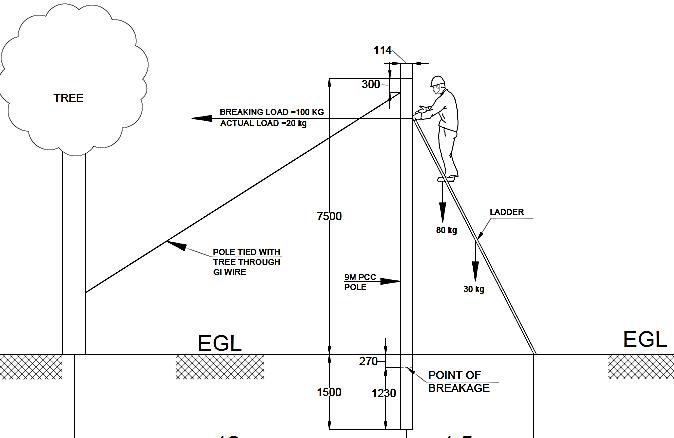

The combined effect of axial, lateral, and torsional forces exceeded the moment capacity of the rectangular pole’s cross-section. The design’s inherent weakness along the minor axis, compounded by the lack of prestressed

reinforcement in that direction, resulted in the pole fracturing at the base. The failure caused operational delays, increased maintenance costs, and exposed safety hazards.

The corner pole, generally designed with a rectangular cross-section, experienced an unanticipated combination ofdynamicforcesduringthecablereplacement/Stringing. Theseincluded:

Fig:DiagramShowingPlacementofPoleandits Installation

Tensile force from the new conductor being tensioned along the line. Concentrated load from the lineman’s weight,appliedatalocalizedpointviatheladder.Bending and torsional moments resulting from asymmetrical load distribution,exacerbatedbythesharpturninthelineand theabsenceofcounteractingforcesfromothercables.

These factors led to a critical stress condition in the pole, particularly in the direction of the line, exposing its structural vulnerability. To Counter these forces, conventional practice involves installing two rectangular poles(amainpoleandanauxiliary/supportpole).

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net

During routine maintenance and infrastructure upgrades in Low Tension (LT) electrical distribution networks, structural failures of electric poles pose significant operational risks. A recent field incident revealed the limitations of conventional rectangular Prestressed Concrete(PSC)poles,particularlyatcriticalpointssuchas 90-degreelineturnsorroad/streetcorners.

The implementation of square cross-section PSC poles provides a viable solution. Due to their geometric symmetry, square poles exhibit uniform stiffness and momentofinertiaalongbothaxes,allowingthemtoresist torsionalandlateralforcesmoreeffectively.Furthermore, their adoption at corners eliminates the need for additional poles or support systems, resulting in cost savings,reduceddeflection,andenhancedductility

2. DESIGN OF PSC SQUARE CROSS

Permissible Stress in Concrete Under Service Loads

Compressivestressinconcrete,fcw=13N/mm² (IS456:2000Table21)

Tensilestressinconcrete,ftw=4.4N/mm²(IS 456:2000AnnexB)

(A) Design of Section

Assumedwidthofpole=200mm

Maximumworkingmomentatgroundlevel:Md= 160x6.9=11.04kN-m

Requiredsectionmodulus:Zt=Zb≥2Md/(fcwftw),Zt=1268965.517mm³

Overalldepth

Provided Section (210 x 210 mm):

Sectionmodulus:Z=1543500mm³

Pre-stressinmember(p)

=3.93N/mm²

Initialpre-stressingforce(P)

Permissibleforce=17.252kNperwire h= 6����/��=195.11 mm

Cross-sectionalareaof4mmwire=12.56mm²

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Numberofwiresrequired,P/per.Fprce4mm wire=10.05

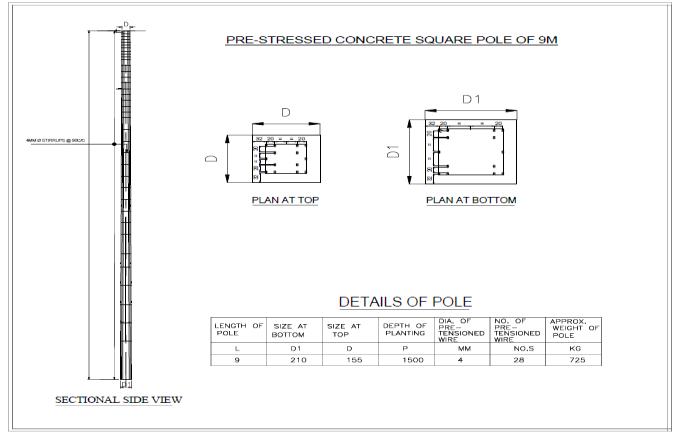

Wiresprovided=28(10oneachside)

(B) Check for Limit State of Collapse

Cross-sectionalareaoftendons=12.56mm²

Theultimatestrengthofcross-sectionasper IS;1343-1980

) 0.15

fpu=1493.79N/mm²

Xu=61.944mm

Xu,Id=0.348mm

Mu = fpbAps(d - 0.42Xu)

Loadfactoragainstcollapse=( . ) =3.13

Longitudinal Direction:

B=200mm,d=200mm

fpu=1494N/mm2

M u = [1494x125.6 200 0.42x58.464 ] 10 6 =34.52 kN/m (Apfp bdfck )=(1256x1717 200x200x40 ⬚ ) = 0.15 ))

(Xu)=(0.348x158)=58.464mm = ( .6( . . 6 ) 6 = .

Minimumstrengthrequired=0.25x32.92=8.63 kN-m

Thesectionsatisfiesthelimitstateofcollapse.

(C) Check for Limit State of Cracking

Workingmoment=11.04kN-m

Tensilestressatextremefibre=4.4N/mm²

Crackwidth= x = ( ) =

1.75x5.2x(210-105)/31622.78= 0.03 mm (< 0.1mm)

Cross-section taper: 190 x 190 mm to 145 x 145 mm

The maximum deflection at the head of the mast wascomputedbasedonthevariablecross-section ofthepoleunderworkingloads.

Maxdeflectionfor1.6kNforceattop:δ=PL³/3EI =79.66mm

The computed maximum deflection is marginally higher than the permissible value of span/250 as prescribed in IS: 456. However, the maximum windloadsadoptedactvery rarely andonlyfora short duration, and in the case of transmission poles, the deflection is not considered to be critical and hence it is not a controlling factor in design.

(E) Check for torsion due to skew snapping of wires

The maximum ultimate torsional moment is computedas

T=1.5x137500x300=6187500N-mm

Sectionattop:155x155mm

Equivalent shear due to torsion as per clause no. 43.1.1OFIS456-2000 V = 1.6 x Torsional Moment / Width) = 63870.97 N

Torsionalshearstress=2.66N/mm²

Stirrups (Clause 41.4.3 IS 456-2000):

Using4mmdiametertwo-leggedlinks,spacingis calculatedaccordingly

�� =( 0.87 )= (2 1256 113 087 1717 6187500 )=91.97mm

Detailed Drawing of ProposedSquareCross-Sectional PSC ElectricPole

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page23

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

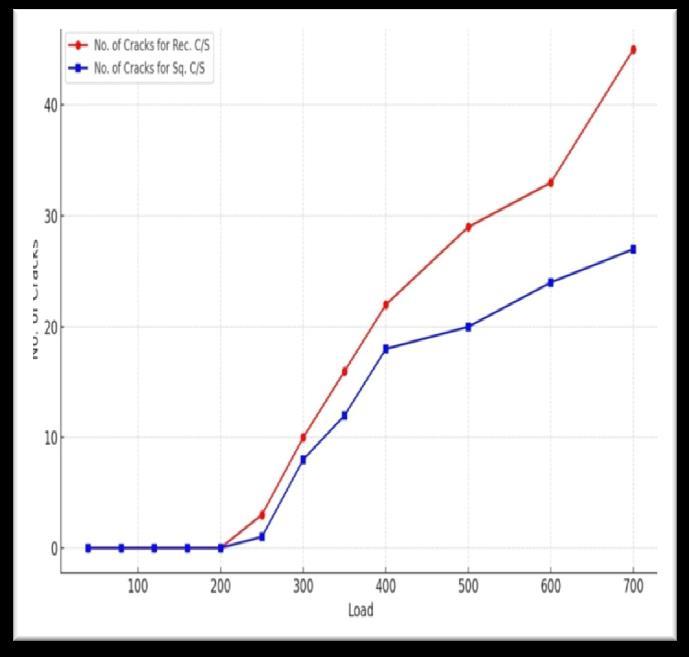

2.1 Testing observations (Rectangular Vs Square Pole)

Severaltechnicalobservationswerederivedfromthefield andlaboratory tests.Some are represented in theform of Graphsandtablesbelow:

Chart 2.1:ComparisonofLoadvs.HairLineCracksfor SquareandRectangularPrestressedConcretePoles

Table2.1: ComparisonsheetforRectangularC/Sand SquareC/SforCracks

Chart 2.2:ComparisonofLoadvs.DeflectionforSquare andRectangularPrestressedConcretePole

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Table 2.2: ComparisonsheetforRectangularC/Sand SquareC/SLoadvs.Deflection

Following comprehensive design analysis, field and laboratory testing, and cost evaluation, it has been determinedthatsquarepolesaremorecost-effectivethan rectangular poles at specific locations particularly at streetorroadcornersand90-degreebends.Insuchareas, conventional practice involves installing two rectangular poles (a main pole and an auxiliary/support pole). However, a single square-section pole can fulfill the same structural and functional requirements, effectively eliminating the need for an additional pole and thereby reducingcosts.

Beyond cost savings, square poles offer several key advantages: uniform strength distribution, streamlined manufacturing, simplified installation, reduced maintenance, enhanced safety, standardized logistics, greater versatility, and improved aesthetic appeal. These combinedbenefitsmakesquarepolesapractical,efficient, and superior choice for various engineering and infrastructureapplications.

4,000.00 6,000.00 8,000.00 10,000.00

2,000.00

Thetransitionfromarectangulartoasquarecross-section for PSC electric poles demonstrated significant improvements in structural performance and practical applicability. The square geometry enhanced the uniformity of load distribution, improved bending and torsional resistance, and offered greater durability under varied stress conditions. Analytical calculations and experimental validations confirmed that the new design met the necessary strength and deflection criteria while adheringtoestablishedsafetyfactors.Practicaladvantages, including reduced installation space, quicker setup, enhanced maintenance safety, and decreased risk of torsional instability, further emphasize the benefits of squarecrosssections.Thedesignmodificationsensurethe poles'adaptabilitytomoderninfrastructurerequirements, particularly in space-constrained urban areas and highstressenvironments.Inconclusion,theadoptionofsquare cross-section PSC poles represents a robust, efficient, and sustainable advancement in pole design, addressing the limitations of traditional rectangular cross-sections while providing a superior alternative for power distribution infrastructure.

1. IS 1678: Code of Practice for Prestressed Concrete Poles.

2. IS1343:CodeofPracticeforPrestressedConcrete.

3. IS:456 (2000), “Plain and Reinforced Concrete –CodeofPractice”

4. IS2386(Part-1):MethodsofTestforAggregatesfor Concrete.

5. IS 2905 -1989: Concrete poles for overhead power andtelecommunicationlines-Methodsoftest.

6. IS 383 -2016: Coarse and Fine Aggregate for Concrete–Specification.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Irshad Ansari, Student of Delhi Technological University, pursuing Bachelor’s degree in Civil Engineering.

Mohit Kashyap, Student of Delhi TechnologicalUniversity,Workingin Tata power Delhi Distribution Limited as Project Officer (Civil Engineering), pursuing Bachelor’s degreeinCivilEngineering.

Pradeep Kumar Gurjar, Student of Delhi Technological University, Working in Delhi Jal Board as Assistant Engineer, pursuing Bachelor’s degree in Civil Engineering.

Vicky,StudentofDelhiTechnological University, Working in Tata power DelhiDistributionLimitedas Project Officer (Civil Engineering), pursuing Bachelor’s degree in Civil Engineering.

Prof.AlokVerma, Professor,CivilEngineering Department,DelhiTechnological University,Delhi