International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Jenish V. Panchal1, Kunal J. Bhandari2

1,2 UG Scholar, School of Civil Engineering, MITAOE, Pune Maharashtra, India

Abstract - Flexible pavement is a commonly used type of pavement in road construction, and it typically includes layers of materials such as sub-base, base course, and surface course. The surface course is typically made of asphalt concrete, which serves as a binder that holds the pavement layers together. However, the use of traditional asphalt concrete in pavement construction can have environmental and economic drawbacks. Therefore, researchers are exploring alternative binder materials that can offer improved sustainability and cost-effectiveness. One such alternative binder material that has been studied is waste rubber tire, which is a byproduct of the tire industry. [1] The use of waste rubber tire in flexible pavement construction could provide an eco-friendly solution for waste tire disposal, while also offering improved pavement performance [2]. This is because waste rubber tire has been found to possess properties that can enhance the durability, flexibility, and elasticity of the pavement.

Key Words: Bitumen, CRMB (crumb rubber modified bitumen),sustainability,ductility,MarshallStabilitytest.

1.INTRODUCTION

There are several alternative materials for flexible pavements that have been developed and tested over the years.Thesematerialsareusedassubstitutesfortraditional asphalt mixes and are often used in combination with traditionalmaterialstoimprovepavementperformance.

PorousAsphalt:Porousasphaltisatypeofasphaltthathasa highpercentage ofvoidsthatallowwatertoflowthrough thepavementandintotheunderlyingsoil.Thismaterialis designed to reduce the amount of stormwater runoff and improvedrainage.

Stone Matrix Asphalt (SMA): SMA is a high-performance asphaltmixthatisdesignedtoresistrutting,cracking,and other types of distress. It is made by adding a high percentage of crushed stones to the asphalt mix, which providesadurableandstablepavementsurface[3].

Geosynthetics:Geosyntheticsaresyntheticmaterialsthatare used to reinforce the pavement structure and improve its performance. Thesematerialsareoftenusedtostabilizesoft subgradesandpreventtheformationofpotholesandother typesofdistress.

RecycledAsphaltPavement(RAP):RAPisamaterialthatis madebyrecyclingoldasphaltpavements.Thismaterialcan

beusedasasubstitutefortraditionalasphaltmixes,which reduces the amount of virgin materials needed for new pavements.

WarmMixAsphalt(WMA):WMAisatypeofasphaltthatis produced at lower temperatures than traditional hot mix asphalt.Thismaterialrequireslessenergytoproduceand can reduce greenhouse gas emissions. It also has the potentialtoextendthepavingseason,reduceconstruction time,andimprovepavementdurability[4].

CRM (Crumb Rubber Modified) is a technology used in flexiblepavementconstruction,whichinvolvestheaddition of crumb rubber to the asphalt binder. The use of crumb rubber in flexible pavement construction is gaining popularity due to its many benefits, including improved durability,reducedcracking,improvedskidresistance,and reducednoiselevels.

The crumb rubber used in CRM is derived from recycled tires,whicharefirstprocessedtoremoveanymetalorother contaminants.Theresultingcrumbrubberisthenblended with the asphalt binder to create a modified binder. This modified bindercanbeusedintheconstructionofa wide rangeofflexiblepavementtypes,includinghotmixasphalt (HMA),warmmixasphalt(WMA),andopen-gradedfriction course(OGFC).

Theadditionofcrumbrubbertotheasphaltbinderhasbeen showntoimprovethe performance offlexible pavements, particularlyinareaswithhightrafficvolumesandheavyaxle loads.Theimproveddurabilityofthepavementreducesthe needformaintenanceandrepairs,leadingtocostsavingsfor pavementownersandusers[5].

By using recycled tire rubber in pavement construction, wastetiresaredivertedfromlandfills,reducingtheamount of waste that must be disposed of. The use of CRM also reducesthedemandforvirginasphaltbinder.

Overall, the use of CRM technology in flexible pavement constructionoffersarangeofbenefits,includingimproved performance,costsavings,andenvironmentalbenefits.As such, it is an increasingly popular choice for pavement ownersanddesignerslookingtocreatedurable,sustainable, andcost-effectivepavementsolutions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net

2.1. Materials Used

Bitumen: The bitumen utilised in the present study underwentlaboratorytesting.Theevaluationofthephysical characteristics, including penetration, softening point, ductility,viscosity,flashandfirepointandspecificgravity,is showninTable1.

Table 1: PropertiesofpureBitumen

CrumbRubber:Crumbrubberobtainedfromrecycledtires withbitumen,apetroleum-basedbinder.

2.2. Methodology

3. Tests Performed

3.1. Penetration test –

Penetration test is a common laboratory test used to determinetheconsistencyofbitumenorasphalt.Itmeasures the depth to which a standard needle will penetrate vertically into a sample of bitumen under specified conditions of load, time, and temperature [6]. The test measuresthehardnessorsoftnessofthebitumen,whichis an important property for the use of the material in road construction.

-2: Penetrationtestapparatus

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Table -2: Penetrationtestresults

Table -3: SofteningPointtestresults

3%CRMB 59 61 60 60

4%CRMB 60 65 625 625

5%CRMB 62 65 635 635

Chart -1: Penetrationvaluev/sCRMBpercentage

3.2. Softening point (Ring and Ball test) –

Softeningpointisanimportantcharacteristicofbitumen that indicates its ability to resist high-temperature deformation.TheRingandBalltestisacommonlyused methodtodeterminethesofteningpointofbitumen.

-3: RingandBallapparatus

Chart -2: SofteningPointv/sCRMBpercentage

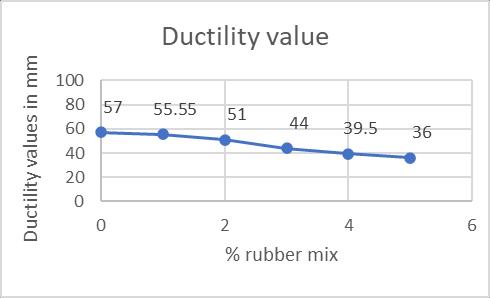

3.3. Ductility test -

Duringthetest,abriquette-shapedsampleofbitumenis placed in a water bath to bring it to a specified temperature.Thetestisimportantbecauseitindicates theelasticityandtensilestrengthofthematerial,which areimportantfactorsinitsperformanceasabinderin roadconstruction.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Fig -4: Ductilitytestapparatus

Table -4: Ductilitytestresults

Chart -3: Ductilityv/sCRMBpercentage

3.4. Viscosity test -

Viscosity test is a common laboratory test used to determine the viscosity or flow characteristics of bitumenorasphalt.Viscosityisanimportantpropertyof

bitumenbecauseitaffectstheworkability,pumping,and mixingofthematerialduringroadconstruction.

Fig -5: Viscositytestapparatus

Table -5: Viscositytestresults

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor

Chart -4: Viscosityv/sCRMBpercentage

3.5. Flash and Fire point test -

These tests are used to determine the flammability and safety of bitumen or asphalt. These tests measure the temperatureatwhichthematerialemitsflammablevapors thatcanigniteandsustainaflame.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

-6: FlashandFirepointresults

Sample Flash 0C Fire 0C

PureBitumen 292 325

1%CRMB 283 312

2%CRMB 240 272

3%CRMB 233 264

4%CRMB 224 258

5%CRMB 220 250

-5: FlashandFirepointv/sCRMBpercentage

3. Results And Conclusions

Rubber waste is a major issue for today’s world as it is a majorcauseofpollutionandburningitemitsharmfulgases whichishazardousforthehealthaswellastheenvironment [7].Recyclingitisthebestoptionforsuchrubberwastesand onesuchmethodiscrushingtherubberintosmallerpieces andusingitin bitumen for roadpavement.Addingcrumb rubberinbitumenhasasignificantimpactonthephysical

properties of the bitumen such as penetration, softening point,ductilityetc.

Fromthepenetrationtestconductedonthepuresampleand crumb rubber mixed bitumen it was observed that the penetration value decreased with increase I amount of crumbrubber.Thereforlowerpenetrationvalueresultsin increasedhardnessofthebitumenandreduceddamagedue towater.

1. Theductilityvaluealsokeptondecreasingresultingin increasedhardnessofthebitumen.Thelowestvaluewas observed for 5% CRM. Therefor to obtain more hardenedbitumenCRMBcanbeused.

2. The softening point test was performed and was observed that the softening point of the bitumen increased with increased percentage of CRMB. This means that bitumen is protected to hot climatic conditions.

Overall, the addition of crumb rubber to bitumen can leadtoasignificantimprovementinthesofteningpoint ofthebinder

3. The addition of crumb rubber to bitumen can have a significant impact on the viscosity of the resulting binder.Viscosityisameasureofafluid'sresistanceto flow and is an important property of bitumen as it affectsitsworkabilityandhandlingcharacteristics.

4. Theadditionofcrumbrubbertobitumenincreasesthe viscosity of the binder due to the presence of rubber particles,whichcanhindertheflowofthebinder.Asthe concentrationofcrumbrubberincreases,theviscosityof theresultingbinderalsoincreases.Higherviscositycan lead to better resistance to deformation and cracking, andcanresultinbetteradhesionbetweenthebitumen andaggregateparticles.

Theviscosityincreasedupto86%.

5. The addition of crumb rubber to bitumen can have a significant impact on the flash and fire point of the resulting binder. Flash point is the minimum temperature at which a material gives off enough vapourstoigniteinthepresenceofanignitionsource, while the fire point is the temperature at which the materialignitesandcontinuestoburn.Theadditionof 1%CRMBincreasedtheflashandfirepointofbitumen andthenitdecreased.

[1]Aziz, Md Maniruzzaman A., et al. "An overview on alternativebindersforflexiblepavement."Construction andBuildingMaterials84(2015):315-319.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

[2]Hake,S.L.,R.M.Damgir,andP.R.Awsarmal."Utilization ofplasticwasteinbitumenmixesforflexiblepavement." Transportation Research Procedia 48 (2020): 37793785.

[3]Gautam,PradeepKumar,etal."Sustainableuseofwaste in flexible pavement: A review." Construction and BuildingMaterials180(2018):239-253.

[4]Deshmukh,NituH.,andD.Y.Kshirsagar."Utilizationof rubber waste in construction of flexible pavement." International Journal for Advance Research and Development2.7(2017):70-77

[5]Kamal, M. A., et al. "Comparison of CRMB test sections with conventional pavement section under the same trafficking and environmental conditions." Arabian JournalforScienceandEngineering34.2(2009):415.

[6]Heukelom,W."Abitumentestdatachartforshowingthe effect of temperature on the mechanical behavior of asphaltic bitumens." Institute of Petroleum, Journal of (1969).

[7]Mashaan, Nuha S., et al. "Effect of crumb rubber concentrationonthephysicalandrheologicalproperties ofrubberisedbitumenbinders."Internationaljournalof thephysicalsciences6.4(2011):684-690.