International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Sayana Shaiju1 , AR. Chippy Nicholas2

1PG Student of Architecture and Planning ,Government Engineering College, Thrissur,India

2Assitant Proffesor (Adhoc) of Architecture and Planning ,Government Engineering College, Thrissur,India

Abstract - India Urban areas today face growing environmental stress due to rapid population growth and the increasingvolumeofmunicipalsolidwaste.Traditionalwaste management approaches are proving inadequate, calling for innovative, sustainable solutions. This study explores the integration of Waste-to-Energy (WtE) systems into urban planning through the lens of Circular Urban Metabolism (CUM) a concept that reimagines waste as a resource and promotes circularity within urban systems.

Theresearchaimstodevelopacomprehensiveframeworkthat aligns WtE facilities with CUM principles to enhance sustainability, resource recovery, and public acceptance. Through an in-depth review of related concepts and terminology, analysis of national and international case studies bothsuccessfulandfailed andanevaluationofsite suitability methods such as the Analytical Hierarchy Process (AHP), the study identifies key strategies for integrating circular thinking into WtE infrastructure.

The proposed conceptual framework offers a structured and adaptablemodelfor urbanplanners,policymakers,andwaste management authorities, supporting better design, decisionmaking, and community engagement in future WtE projects. This approach not only addresses pressing waste issues but also contributes to a more circular, energy-efficient, and resilient urban future.

Key Words: Circular Urban Metabolism (CUM),Wasteto-Energy (WtE), Urban Sustainability, Material Flow Analysis (MFA),Circular Economy (CE),Urban Metabolism (UM)

Ascitiescontinuetogrowrapidly,theyareproducingmore waste than ever before, putting immense pressure on traditionalwastemanagementsystems.Thisgrowingcrisis contributes to environmental pollution and the loss of valuableresources.Totacklethis,theideaofCircularUrban Metabolism(CUM)offersasmarterwayforward treating wastenotasaburden,butasaresourcethatcanbereused orrepurposedinaclosed-loopsystem.Withinthisapproach,

Waste-to-Energy(WtE)plantsofferapracticalsolutionby converting urban waste into usable energy. But while promising,WtEprojectsoftenfacechallenges rangingfrom

environmental concerns to public resistance. This study looks at how WtE plants can be better designed and integratedthroughthelensofCUM,aimingtoreducetheir negative impacts and build public trust. By aligning technology with circular thinking and community needs, cities can take a step toward cleaner, more efficient, and morelivableurbanenvironments.

Theneedforthisstudyarisefromurgentenvironmental challengesinurbanareasduetorisingwastegenerationand inefficientmanagement.Ascitiesexpand,innovativewaste managementsolutionsarecritical.CUMoffersaframework totransformwasteintoaresource,butWtEplantsoftenlack sustainableintegrationandcommunitysupport.Thisstudy aims to reimagine WtE through circularity, identifying strategiestomitigatenegativeimpactsandenhancepublic acceptanceforamoresustainableurbanfuture.

TodevelopaFrameworkforwaste-to-energy(WtE)that alignswiththeconceptofCircularUrbanMetabolism.

• ToStudytheConceptandTerminologyrelatedtoWasteto-Energyplantsandcircularurbanmetabolism.

• ToidentifyandintegrateCircularUrbanMetabolismin waste-to-energyplants.

• Toanalyzethecasestudiesofsuccessfulandfailedwaste toenergyplant’sinindia.

• ToProposeaconceptualframeworkforWastetoenergy plantbyusingtheconceptofcircularurbanmetabolism.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

1.5 Scope

• A clearer of the foundational concepts of Circular Urban Metabolism (CUM) and Waste-to-Energy (WtE),leadingtobettertheoreticalframeworksfor futureresearch.

• IdentificationofeffectivemethodstointegrateCUM principles into WtE plants, contributing to improvedsustainabilityandresourcemanagement.

• By the evaluation of successful and failed WtE plants helps to avoid previous mistakes and replicatesuccesses.

• The development of framework will provide practical guidance for policymakers and practitioners in designing and operating WtE systemsmoreeffectivelyandsustainably.

1.6 Limitations

• TheavailabilityofdataonWaste-to-Energy(WtE) plantsmayimpactthedepthofcasestudyanalysis.

• Thisstudyprimarilyexaminestheexistingpolicies andframeworks,providinganoverviewratherthan anexhaustiveanalysis.

• The study focuses on specific Waste-to-Energy technologies,offeringinsightsintotheirapplication andpotential.

• The study does not include a detailed economic feasibility study or environmental impact assessment.

Circularurbanmetabolismisaconceptthatreferstocities functioning as living organisms that consume, metabolize and excrete, breathe, distribute and protect themselves [1].FirstintroducedbyAbelWolmanin1965,theideawasto measure what cities consume and what they produce as waste,sothatwecouldbettermanagetheirenvironmental impact.EarlystudiesincitieslikeHongKongandBrussels helpedshapethisconceptbytrackingtheflowofmaterials andenergyinandoutofurbanareas.

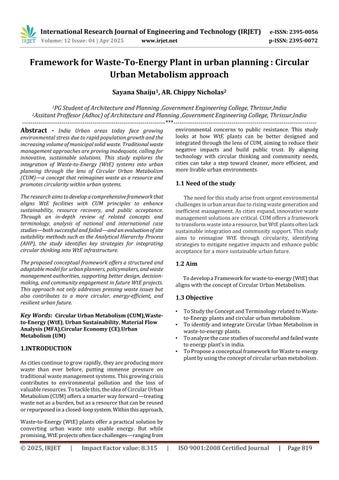

CUMbuildsonthisbypushingforacircularapproach,where wasteisminimized,andresourcesarereusedorrecovered. Thisisespeciallyimportantascitiestodayusearound70% oftheworld’sresourcesandtwo-thirdsofallenergy.Inthis framework, Circular Economy (CE) principles like reducing,reusing,andrecycling areappliedtohowcities function.Thegoalistocreatesystemsthatmakesmarteruse of resources and support long-term balance between environmental needs and urban growth. Bymappingtheconnectionsbetweenmaterials,energy,and socialdynamicsovertimeandacrossdifferentpartsofacity, CUM helps us find where circular practices can make the biggestimpact.Figure1isadaptedfromtheCircularUrban MetabolismFramework by Giulia LucertiniandFrancesco Musco[1]

The Circular Economy (CE) is an economic model focusedonusingresourcesefficientlybyminimizingwaste and keeping materials in use for as long as possible[2]. Unlike the traditional linear system of "take, make, dispose," CE promotes a closed-loop approach where products and materials are reused, repaired, or regenerated.It’sdesignedtoreducethedemandforraw resources while delivering both environmental and

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

economicbenefits.Atitscore,CEaimstocreatesystems that restore rather than deplete using strategies like cradle-to-cradledesignandhigh-valuematerialrecovery toclosethelooponconsumption.

2.2 Urban Metabolism Concept

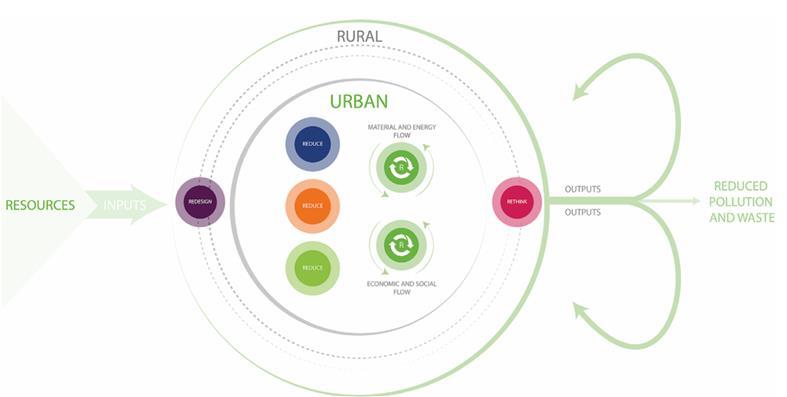

UMis‘‘thetotalsumofthetechnicalandsocio-economic processes that occur in cities, resulting in growth, productionofenergy,andeliminationofwaste.’’[3].Ittracks the flow of materials, energy, people, and information throughurbanspacestounderstandhowcitiesfunctionand grow. The goal is to measure these flows to improve efficiency, reduce environmental impact, and guide sustainabledevelopment.UMalsoexploresdeeperthemes suchassocialequity,economicconnections,andecological transformation,positioningthecityasaninterconnectedand evolving ecosystem. Figure 2 shows urban metabolism concept is adapted from the Circular Urban Metabolism FrameworkbyGiuliaLucertiniandFrancescoMusco[1].

Urban metabolism is assessed using two key approaches: accountingtoolsthatmeasureresourceflows,andindicators thathelpinterpretimpactsovertime.

AccountingApproaches:

Material Flow Analysis (MFA): Tracks how materialsenter,movethrough,andleaveacityto identifyusagepatternsandlosses.

ExergyAnalysis:Measureshowmuchusefulenergy isavailableinasystem.

EnergyAnalysis: Calculatesbothdirectandindirect energyusedinurbanprocesses.

Input-OutputAnalysis: Mapstheexchangeofgoods and services between sectors, highlighting economicandresourceconnections[4][5]

Indicator-BasedApproaches:

Ecological Footprint: Estimates the land area neededtosupportapopulation’sresourceuse.

Life Cycle Assessment (LCA): Evaluates the full environmental impact of products from productiontodisposal.

SystemDynamics:Examineshowcomplexsystems evolveovertime,helpingtoshapelong-termurban strategies.

2.3 The similarities and differences between urban metabolism and circular economy

UrbanMetabolismandCircularEconomybothfocuson using resources smarter and cutting down waste. This sectionlooksathowtheyconnect andwheretheydiffer.

Table -1: Thesimilaritiesanddifferencesbetweenurban metabolismandcirculareconomy

Aspect Urban Metabolism (UM) Circular Economy (CE)

Definit ion Focuses on quantifying and analyzing resource flows in cities, likeningthemtothe metabolicprocesses oforganisms. Aimstodesignsystems that minimize waste andmaximizeresource reusethroughclosedloopcycles.

Scope Descriptive and analytical framework for understanding urban resource consumption and wasteproduction. Prescriptive framework emphasizingactionable strategiesforreducing resource inputs and wasteoutputsthrough reuse, recycling, and efficiency.

Focus Areas Systematic studies of inputs and outputs, used for monitoring and evaluation.

Approac h Analytical and diagnostic, focuses on studying resource flows withincities.

Emphasizesstrategies like industrial symbiosis, remanufacturing, and material recirculation forsystemredesign.

Action-oriented,seeks to design and implementsustainable business and productionpractices.

Role of Waste Wasteisanalyzedas part of the city's overall resource flow. Waste is minimized throughdesign,reuse, andrecyclingtoclose materialloops.

Framewo rk UM provides the foundational data forCEbymeasuring material flows and inefficiencies in urbansystems. CEcanuseUMdatato guide the implementation of circular strategies in cities.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Policy and planning UM data helps evaluate resource flows, providing a basisfordeveloping effective CE strategies.

Practical Applicati on UM insights help identifyareasforCE interventions, like resource recovery and waste reduction..

CE strategies, like recyclingandindustrial symbiosis, can be modeledusingUMto predictoutcomesand optimizeresourceuse.

CEprinciples,informed by UM data, can be appliedtocreatemore sustainable urban systems.

Waste-to-Energy (WtE) plants convert non-recyclable municipalwasteintousableenergy likeelectricity,heat,or fuel.Thesesystemshelpreducelandfillusewhilerecovering energy from trash that would otherwise go to waste[6] Therearetwomainapproaches:

• Thermochemical methods (like incineration, gasification,andpyrolysis)usehightemperaturesto convert dry waste into energy. Incineration is the mostcommon,oftensterilizingharmfulpathogensin the process. These methods are widely used in Europefortheirefficiency[7]

• Biochemical methods (likeanaerobicdigestionand fermentation) use microbes to break down wet, organic waste such as food scraps producing biogas that can be used as fuel. This approach is especially effective when waste is well-sorted and biodegradable[7].

• WtE plants are particularly useful in areas with limitedlandfillspace.Whiletheyhelpmanagewaste and generate energy, they can pose challenges in recyclingandenvironmentalimpact.

According to the Solid Waste Management (SWM) Rules, 2016,severalkeyresponsibilitiesandoperationalstandards havebeenoutlinedforwastehandlingandenergyrecovery:

• Clause 15 outlines that local authorities are responsiblefororganizingandoverseeingsolidwaste collection,transportation,andtreatmentwithintheir jurisdiction.

• Clause 18 mandatesthatindustrieslocatedwithina 100-kilometerradiusofarefuse-derivedfuel(RDF) or waste-to-energy facility must utilize such wastebasedfuelswhereapplicable.

• Clause 21 states that non-recyclable waste with a calorificvalueof1500Kcal/kgormoremustnotbe senttolandfills.Instead,itshouldbedivertedtoward energyrecoveryprocesses.

Multi-Criteria Decision Making (MCDM) methods are powerful tools for solving complex planning problems especiallyinurbanwastemanagementandWaste-to-Energy (WtE) infrastructure. They help break down multifaceted issuesintosimpler,structuredchoices,makingthemideal forevaluatingdiverseenvironmental,social,andeconomic factors.

The study highlighted the Analytical Hierarchy Process (AHP) as the most widely used method, valued for its simplicity and ability to rank alternatives based on clear criteria[8].However,morerecenttrends(2015–2019)show a shift toward hybrid approaches, combining AHP with methodslikeTOPSIS,PROMETHEE,andELECTREtohandle morecomplexdecisionenvironments.

AHPstillproveshighlyeffectiveforsitesuitabilityanalysis duetoitstransparent,step-by-stepapproach.

Turning Waste into Energy: Waste-to-Energy(WtE)plants play a key role in resource recovery by converting nonrecyclablewasteintousableenergy.Thisprocesssupports theidea ofcircularurban metabolism, wherewasteisnot discardedbutreintegratedasavaluableinput

Creating Closed Loops: Inacircularsystem,thegoalisto keep resources flowing. WtE helps close the loop by producingnotonlyelectricitybutalsoheatandbyproducts thatcanserveotherurbanfunctions,likedistrictheating.

Less Waste to Landfill: Bytransformingwasteintoenergy, theseplantsreducethepressureonlandfills makingwaste managementcleanerandmoreefficient.

Smart City Planning: When WtE is included in urban planning, cities can build systems that treat waste as a resource deliveringenergyandsupportingotherneedsina moreintegratedway.

People at the Center: Getting communities and stakeholders involved in the planning process helps build trust,encouragesinnovation,andensuresWtEprojectsmeet localneeds.

Policy Makes It Work: Strong,supportivepoliciescanguide cities in blending WtE with broader circular economy goals helpingurbanareasmovetowardmoresustainable andresilientfutures.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

5.1 Waste to Energy plant in Sewden

Swedenstandsasagloballeaderinwaste-to-energy(WtE) technologies, effectively transforming waste into valuable energy and minimizing landfill usage. Nearly all waste is recycledorconvertedintoenergy,exemplifyingasuccessful circulareconomy.WtETechnologiesinSweden:

• Incineration with Energy Recovery: Utilizesmass-burning and fluidized-bed techniques to efficiently convert wasteintoenergy.

• District Heating Integration: WtE plants supply heat to residential and commercial sectors, exemplified by facilitiesinStockholmandGothenburg[9].

• Flue Gas Cleaning Systems: Advanced technologies that significantly reduce emissions, contributing to Sweden'sminimalcarbonfootprint[10]

5.2 Waste to Energy plant in Jabalpur

The Jabalpur Waste-to-Energy (WtE) plant, developed by EsselInfra,hasbeenrecognizedbytheMinistryofHousing and Urban Affairs and CII as India’s top project in the integratedMSW-to-energycategory.Theawardhighlights excellence in 3R practices, resource recovery, and sustainablewastemanagement.

• Cleaner Cities: Theplanthashelpedreducelittering andimprovedsanitationacrossJabalpur.

• Smart Waste Governance: An Integrated Command andControlCenterenablesreal-timemonitoringand efficientwastehandling.

• Public Participation: Mobileandwebplatformsallow citizenstoreportissues,enhancingengagement.

• Technology Integration: Withover276,000RFIDtags, theICT-backedsystemoptimizesdoor-to-doorwaste collection.

• Energy Contribution: Electricitygeneratedsupports the regional grid through MP Power Management Company.

• Zero Landfill Goal: Advancedincinerationtechnology minimizes landfill use and prevents groundwater contamination.

6.1 Comparative Evaluation of MFA Application and Waste-to-Energy Strategies in Sri Lanka (Western Province) & Serbia

Material Flow Analysis (MFA) is a vital tool for tracking waste generation, movement, and recovery. This study compares its implementation in Sri Lanka’s Western ProvinceandSerbia.

Table -2: MaterialFlowAnalysis(MFA)Utility

Aspect Sri Lanka (Western Province) Serbia

MFA

Objective Trackwastefromsource tofinaldisposal,quantify flows Identify inefficiencies, optimize WTE options

DataDepth Detailed household-level dataonwastecomposition andflow Limited, hindered by infrastructure anddatagaps

Waste

Breakdown Quantified MSW into recoverables (compost, paper,plastic) Highbiodegradables (~60%), poor calorificvalue

Recovery

Matrics MRFandERFcalculatedto evaluate material & energyrecovery Used to inform suitable WTE tech (e.g., anaerobic digestion)

Table -3: Waste-to-Energy(WTE)Implementation

Factor Sri Lanka (Western Province) Serbia

CurrentStatus Operational WTE (~600 tons/day), RDFused Limited WTE infrastructure;mostly landfilling

Energy

Recovery Calculated ERF, energy conversion fromMSW Potential via anaerobicdigestion& landfillgas

Infrastructure

Readiness Partial (needs composting/source segregation) Inadequate, needs investment and modernization

TechnologyFit Incineration+RDF Anaerobic digestion fits waste profile (wet/organic)

• MFAisCrucial:Bothstudieshighlighttheimportanceof MFAinmeasuringwasteflow,identifyinginefficiencies, andoptimizingrecovery,particularlyinthecontextof Waste-to-Energy(WTE).

• Circular Economy Requires Grassroots Engagement:

-SriLankahasmadepromisingprogressbutrequires wider implementation of composting, recycling, and public awareness initiatives.

-SerbiaalignsitspolicieswithEUstandardsbutmust focus on enforcement, financial mechanisms, and gainingpublicsupporttomakethecirculareconomya reality.

Jos, located in Nigeria’s middle belt, is undergoing rapid urbangrowth,withapopulationincreaseof5.5%annually. Thecitycurrentlyproducesaround221tonsofmunicipal waste daily, projected to rise to 299 tons by 2032 highlighting the urgent need for sustainable waste management solutions. Approach & Methodology:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

The study used the Analytical Hierarchy Process (AHP) withinaGIS-basedframeworktoevaluatesuitablelocations foraWaste-to-Energy(WtE)facility.Keyfactorsconsidered includedproximitytoroads,rivers,powersubstations,land cover,andslope.[11]

• Data was gathered from diverse sources such as Sentinel-2satelliteimagery,SRTMforelevation,and OpenStreetMapforinfrastructuremapping.

• Apairwisecomparisonmatrixhelpeddeterminethe relative importance of each factor, and a Consistency Ratio (CR) of 0.07 validated the reliabilityofthejudgmentmatrix

• Thefinaloutputwasasuitabilitymapcreatedusing weightedoverlayanalysisinArcGIS.

ThiscaseclearlydemonstratedhowAHPandGIScanguide smart, cost-effective urban planning, especially when integratingWtEsolutionsintothebroader circular urban metabolismframework.

8.1 Waste to Energy Plant in India : Challeneges and impacts

Waste-to-Energy(WtE)projectsinIndiaoftenstruggledue tomixedandlow-qualitywaste,frequenttechnical issues, high emissions, and financial setbacks By studying and analyzingwaste-to-energysystemsinIndia,asoutlined in [12], the associated impacts and challenges become more understandable. Many plants face legal battles and public opposition, driven by health and environmental concerns. With poor energy recovery and inefficient resource use, several initiatives have collapsed or remained nonoperational.Thesechallengesunderlinetheneedforsmarter planning,betterwastesegregation,andstrongercommunity involvement to make WtE a practical and trusted part of India'swastemanagementstrategy.

8.2 Site Suitability Using Analytical Hierarchy Method

• TheintegrationofAHPwithGIS-basedMCAoffersa structured, multi-criteria approach for identifying optimalWaste-to-Energy(WtE)sites.

• Site suitability is influenced by proximity to waste sources,infrastructureaccess,landuse,topography, and environmental constraints crucial for costeffectivenessandsustainability.

• WtE planning should align with broader urban and energy policies, using spatial analysis to guide strategic,sustainabledecisions.

• Incorporatingstakeholderinput,environmentaldata, and socio-economic factors can enhance future site assessmentsandpromoteinclusiveplanning.

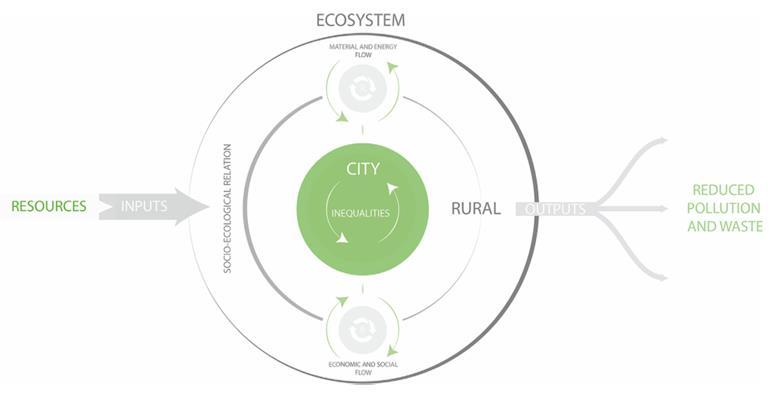

Conceptual framework for waste to energy plant in the contextofcircularurbanmetabolismisshowninthefigure4 byauthorgenerated

MaterialFlowanalysis:MFAhelpsquantifyandtrackwaste materialsfromtheirsourcestodisposalortreatment.Thisis fundamental in understanding the types and quantities of wasteavailableforenergyrecovery.

Amount of Waste: Identify the volume of Municipal Solid Waste(MSW)generatedwithinthetargetedregion.

WasteComposition:Analyzethebreakdownofwastetypes.

MassBalanceEquation:∑Ik=∑Ok+∑Sk

Where Ik : Inputs (waste collected) ; Ok: Outputs (energy produced);Sk:Storageorresiduals(landfill,ash).

• EmergyAnalysis:Assesstheavailableenergypotential indifferenttypesofwaste.

• Waste Characterization: Identify organic, recyclable, andnon-recyclablewaste.

• Calorific Value: Measure the energy content in the waste.

• EnergyPotential=WasteVolume×CalorificValue

• Importance: Determines the suitability of waste for energyrecoveryandtheexpectedenergyoutput.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Table -4: Parametersofsitesuitability

Environmental Socialandsafety Economic Factors

Settlementdistance Lowlands distance Major road distance

RiverDistance Substations Local road distance

Sensitive areas distance Future urban growth Existing land use

Landslope Waste dumpsites

Landcover Industries

Agricultural area distance

Methodtofollow:

• Analyze Relevant Parameters: Identify key parametersthatdeterminesitesuitability.

• MapCreation:Developamapforeachparameter, indicatingtheproximityofsuitableareas.

• Overlay Analysis: Overlay the individual maps to identify regions that are most suitable based on multiple parameters.(weighted index overlay analysismethod)

• Selection of Optimal Area: From the identified suitable regions, evaluate and select the most appropriatesitebasedontherelativeimportanceof eachparameter.

• Decision-Making Approach: Use the Analytical HierarchyProcess(AHP)formulti-criteriadecisionmaking, assigning weights to the parameters and prioritizing the most important factors in site selection.

• SegregationatSource:Separateorganic,recyclable, and combustible wastes to improve feedstock qualityandWtEefficiency.

• Pre-treatmentRequirements:Basedonthetypeof WtE technology, assess pre treatment needs like shredding,dryingandRefuseDerivedFuel(RDF)to Increase calorific value and reduce contaminants, whichenhancescombustionefficiency.

• RDFUsage(%)=(RDFoutput/Totalcombustible waste)×100

9.5 Transportation and

(efficient road network and optimize the routing to reduce fuel consumption )

• TransportationInfrastructure:Establishanefficient transportation network for waste collection, consideringroadaccess,fuelcosts,andemissions.

• Logistics Management: Develop a schedule and routingsystemforwastecollectionanddeliveryto the WtE plant to minimize fuel use and optimize resourceallocation.

• Continuous Monitoring Systems : Install sensors and real-time monitoring to track energy output, emissions,andoperationalefficiency.

• MaintenanceScheduling:Planregularmaintenance to reduce downtime and ensure the plant meets regulatoryandperformancestandards.

• Cost-Benefit Analysis : Conduct financial assessments of operational costs versus energy revenuesandcarboncredits.

• Government Support and Subsidies : Identify opportunities for financial assistance, grants, or incentivestooffsetcapitalandoperationalcosts.

• EmissionControl:Implementairpollutioncontrol measures,suchasscrubbersandfilters,tocomply withenvironmentalstandards.

• Public Awareness and Engagement: Develop programs to engage the community on waste management practices and the benefits of WtE plantstofostersupport.

• Recyclable Material Recovery: R=( ∑(P+T+Pl+M+G+Cm)/a)×100;whereP,T,Pl,M, GandCmrepresentdifferentrecyclablematerials, andaisthetotalwastegenerated.

• Waste-to-Energy Recovery Factor : E= (Energy producedfromwaste/Totalorganicwaste)×100

• CompostingFactor:C=(CompostedWasteVolume/ TotalOrganicWaste)×100

• Thesemetricsgaugeefficiencyinwaste-to-material orenergyconversion.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Monitoring and Continuous Improvement

• EfficiencyCalculations:η=(Energyoutput/Energy input)×100

ThisstudyhighlightshowintegratingWaste-to-Energywith Circular Urban Metabolism can turn urban waste into a valuable resource. With community support and smart planning,citiescanreducepollution,generatecleanenergy, andbuildamoresustainable,resilientfuture.

[1] G.LucertiniandF.Musco,“Circularurbanmetabolism framework,” One Earth,vol.2,no.2,pp.138–142,2020, doi:10.1016/j.oneear.2020.02.004.

[2] P. Morseletto, “Targets for a circular economy,” Resources, Conservation and Recycling, vol. 153, p. 104553,2020.

[3] T.L.SanchesandN.V.S.Bento,"Urbanmetabolism:A tooltoacceleratethetransitiontoacirculareconomy," in Sustainable Cities and Communities,W.LealFilho,A. M.Azul,L.Brandli,P.G.Özuyar,andT.Wall,Eds.Cham, Switzerland:Springer,2020,pp.860–876.

[4] A.AlleschandP.H.Brunner,“Materialflowanalysisasa decision support tool for waste management,” ACS Publications,2017,doi:10.1021/acs.est.7b02232.

[5] N. A. Hemali and A. A. P. De Alwis, “Application of materialflowanalysistomunicipalsolidwasteinurban areas in developing countries and possible solutions undercirculareconomicframework,”NatureEnviron. Pollut.Technol.,vol.21,no.3,pp.1411–1419,2022.

[6] Cucchiella,F.,D’Adamo,I., & Gastaldi,M.,"Sustainable waste management: Waste to energy plant as an alternative to landfill," Energy Conversion and Management, vol. 131, pp. 18-31, 2017, doi: 10.1016/j.enconman.2016.11.012.

[7] K.A.Karmakar,T.Daftari,K.Sivagami,M.R.Chandan,A. H.Shaik,B.Kiran,andS.Chakraborty,"Acomprehensive insight into waste to energy conversion strategies in India and its associated air pollution hazard," Environmental Technology & Innovation, vol. 29, p. 103017,2023,doi:10.1016/j.eti.2023.103017.

[8] A. Darko, A. P. C. Chan, E. E. Ameyaw, E. K. Owusu, E. Pärn, and D. J. Edwards, "Review of application of analytic hierarchy process (AHP) in construction," J. Facil. Manage., vol. 26, no. 4, pp. 436-452, Mar. 2018, doi:10.1080/15623599.2018.1452098.

[9] CTCN, “Filborna Combined Heat- and Power Plant,” Climate Technology Centre & Network,2015.

[10] SmartCitySweden,“Renova –GlobalForefrontWaste Technology for Heat and Power,” Smart City Sweden, 2019.

[11] O. I. Alubo and M. Isma’il, “Site suitability analysis for wastetoenergyfacilityinJosMetropolis,PlateauState, Nigeria,” Dutse J. Pure Appl. Sci.,vol.9,no.2a,pp.1–10, 2023.

[12] Centre for Financial Accountability, India’s Waste-toEnergy Paradigm: A Policy, Environmental and Social Perspective, New Delhi, India: Centre for Financial Accountability,Dec.2022.

[13] A.Karmakar,T.Daftari,K.Sivagami,M.R.Chandan,A.H. Shaik,B.Kiran,andS.Chakraborty,“Acomprehensive insight into waste to energy conversion strategies in Indiaanditsassociatedairpollutionhazard,”Environ. Technol.Innov.,vol.29,p.103017,2023.

[14] W.A.Qazi,M.F.M.Abushammala,M.-H.Azam,andM.K. Younes, “Waste to-energy technologies: A literature review,”J.SolidWasteTechnol.Manag.,vol.44,no.4,pp. 387–409,2018.

[15] D.N.Markic,H.S.Carapina,D.Bjelic,L.S.Bjelic,P.Ilic,Z. S.Pesic,andO.Kikanovicz,“Usingmaterialflowanalysis forwastemanagementplanning,” Pol. J. Environ. Stud., vol. 28, no. 1, pp. 255–265, 2019, doi: 10.15244/pjoes/78621.

[16] H.Corvellec,T.Bramryd,andJ.Hultman,"Thebusiness model ofsolidwastemanagement inSweden – a case study of two municipally-owned companies," Waste Manag.Res.,vol.30,no.5,pp.512–518,May2012,doi: 10.1177/0734242X11427944.

[17] H.Rylander,"WasteManagementinSweden.ANational Report,"SageJournals,1985.