International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Prashant

Mandora1 , Anurag Kedar1 , Onkar Padale1, Ravi Nitta1, Prof. P.V. Deshmukh 2

1student, Department of Mechanical Engineering, AISSMS College of Engineering, Pune, India

2Professor, Department of Mechanical Engineering, AISSMS College of Engineering, Pune, India ***

Abstract - Abstract - The current research investigates theenhancementinthethermalefficiencyofcarradiators using nanofluids. Going beyond the limitations of normal coolants, the research theoretically and experimentally developed the thermal efficiency of Magnesium Oxide (MgO) and Zinc Oxide (ZnO) nanofluids. Results consistently revealed that nanofluids demonstrate higher heat transfer rates and overall cooling efficiencies. The findingssuggestthatnanofluidsofferapromisingsolution forimprovedthermalmanagement.

Key Words: Radiator Efficiency, Nanofluid, Heat Transfer Enhancement, Thermal Conductivity, Magnesium Oxide (MgO), Zinc Oxide (ZnO), Specific Heat Capacity, NTU Method (Effectiveness-NTU), CoolantPerformance,HeatExchangerDesign

The ongoing improvement of automotive and mechanical systems has enabled the development of highperformance engines with voluminous heat outputs upon operation.Effectivethermalmanagementhasthusbecome essential to ensure that overheating is prevented, components are safeguarded, and optimal performance levels are maintained. Arguably the most important component of the cooling system of a vehicle is the radiator,whosefunctionliesintransferringheatfromthe circulating coolant to the surrounding air. Traditional radiators coolants, being primarily water or an ethylene glycol water mixture, are limited by their relatively low thermal conductivity. With engine configurations increasingly requiring more cooling performance, the limitations of conventional fluids have spurred the development of alternative coolants. Some of the most promising developments in this regard are nanofluids, which are specially designed fluids with suspended nanoparticles that enhance the thermal performance significantly. Nanofluids are nanoscale particles (usually less than 100 nm) of metal oxides or carbon-based materials suspended in a base fluid. These particles enhance the fluid's heat-conducting and heat-transfer abilitiesbyprovidingextrathermalpathwaysandaltering fluid dynamics at the micro-level. Consequently, nanofluids have been observed to have high potential in increasing heat transfer rates, enhancing convective heat transfer coefficients, and reducing temperature gradients in radiators and heat exchangers. This paper investigates the relative performance of nanofluids compared to

conventionalcoolantsinacontrolledradiatortestrig.The work revolves around evaluating the influence of adding zinc oxide (ZnO) and magnesium oxide (MgO) nanoparticles to a base fluid under controlled operating conditions. Particular attention is focused on measuring temperature reductions, examining heat transfer characteristics, and comparing overall cooling efficiency. Through the use of nanofluids in the radiator system, this paper aims to determine whether enhanced thermal conductivity results in measurable differences in performance.

Conventionalradiatorcoolantssuchaswaterandethylene glycol mixtures have low thermal conductivity, which limitstheirabilitytotransferheatfromhigh-performance enginesefficiently.Thislimitationnormallyresultsinpoor cooling, reduced engine efficiency, and increased susceptibility to overheating. In response to ongoing demands of high-output and compact systems, there is an urgent need to introduce enhanced heat transfer capacity without the redesignofalreadyavailablecoolingsystems. The current study investigates this limitation by consideringtheuseofnanofluidscontainingZnOandMgO nanoparticles for improving thermal performance of radiators.

Themethodologicalapproachusedinthisstudyintegrates experimental design, material medication, and performance dimension to probe the effect of nanofluids on radiator effectiveness. The entire process is divided intocolorfulimportantway

1. Literature Review:

Acriticalreviewofthescientificliteraturewasacceptedto interpret the geste of nanofluids in thermal systems. The exploration involved the study of their parcels, conflation routes, and former uses in auto radiators and heat exchangers.

2. Material Selection:

Water was chosen to be the reference fluid since it's generally used in radiator systems. Zinc oxide (ZnO) and magnesiumoxide(MgO)nanoparticleswerechosendueto

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

their good thermal conductivity, chemical stability, and dispersibilityinwaterlessmedia.

3. Nanofluid Preparation:

Nanoparticles were synthesized via a chemical rush system followed by ultrasonic treatment. Applicable attention of ZnO and MgO were dispersed in deionized water with the aid of surfactants to insure invariant suspense and minimize agglomeration. Volume fragments werecalculatedtodetermineoptimalmixingrates.

4. Experimental Setup Design:

An experimental test carriage bluffing real radiator conditions was fabricated. It included across-flow aluminum radiator, submersible water pump, digital temperature detectors, rotameter, and a inflow circle constructed using PVC and mild sword factors. The setup enabled controlled rotation of nanofluids and real- time dataaccession.

5. Experimental Procedure:

The radiator was tested under identical thermal conditions using both base fluid and nanofluid samples. Inlet and outlet temperatures were recorded, along with inflowratesandambientconditions.Trialswererepeated forcolorfulnanoparticleattentiontoobservetheirimpact onthermalperformance.

6. Data Analysis:

Collected data was anatomized using standard heat transfer equations. Parameters similar as heat transfer rate, effectiveness, specific heat, and NTU were reckoned. Relative analysis between conventional fluids and nanofluids was conducted to estimate improvement in thermaleffectiveness.

7. Conclusion and Recommendations:

Grounded on experimental issues, conclusions were drawn regarding the felicity and effectiveness of ZnO and MgO nanofluids in radiator operations. Recommendations were handed for implicit artificial use and unborn optimization

2. SETUP DESIGN

1. Nanofluid Preparation:

Nanofluids are formed by suspending nanoparticles, for example, Zinc Oxide (ZnO), in a base fluid such as water. Uniform distribution and stability are achieved through proper stirring and ultrasonication. The appropriate concentrationplaysacriticalroleinthermalproperties.

2. Specific Heat Capacity:

Measurement The nanoparticle's specific heat capacity is theessentialparameterfordeterminingenergyabsorption. Introducing the nanoparticles changes this characteristic, andsuchvaluesaredeterminedfromweightedaveragesof theparticlesandthebasefluid.

3. Radiator Design and Installation:

Theradiatorisdesignedtohandlenanofluidinsteadofthe conventionalcoolant.Ithasinletandoutletvalves,apump, and measuring devices for accurately measuring temperatureandflowrate.

4. Experimental Experimentation:

Experiments are done by operating the radiator under controlled conditions with nanofluids of different concentrations. The thermal improvement due to nanoparticles is evaluated using inlet and outlet temperaturereadings.

5. Heat Transfer Analysis:

The enhancement in heat transfer is evaluated using analytical approaches such as the Number of Transfer Units (NTU) method, and the thermal efficiency of nanofluids is assessed in comparison to traditional heat transferfluids

6. Data Collection and Comparison:

Temperature gradients, flow rates, and heat capacity values are measured and documented. Results are compared for various concentrations to determine the mostefficientcompositionofnanofluid.

7. Sustainability and Efficiency:

Nanofluids improve radiator efficiency, which will save energy and lower carbon emissions. The project supports sustainable cooling systems for automotive and industrial use

1. Radiator:

The radiator acts as the central heat exchanger in the system, responsible for dissipating thermal energy from the circulating fluid. For this study, a cross-flow radiator from a Duke 390 motorcycle was used, constructed primarily from aluminum and ABS plastic, offering a compact structure with good thermal conductivity. The radiator has dimensions of approximately 320 mm × 20 mm×240mmandisdesignedtohandlecoolantflowrates between 1 to 3.5 L/min, suitable for laboratory-scale testing.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

2. Water Pump:

A submersible water pump was utilized to ensure consistent circulation of the working fluid throughout the system.Thepumpoperates at 40Watts under220–240 V AC with a maximum flow capacity of 3 L/min and a maximum head of 7.2 feet. This enabled a stable and pressurized flow of nanofluid necessary for maintaining theconvectiveheattransferwithintheradiatorchannels.

3. Digital Thermometer Sensors:

To monitor the thermal performance, digital temperature sensors were installed at the inlet and outlet of the radiator. These sensors, with an operational range of –50°C to +110°C, provided accurate real-time data, which was essential for evaluating the heat transfer rate and effectivenessofthenanofluids.

4. Rotameter:

Flow rate measurements were conducted using a rotameter,capableofmeasuringfluid flowintherange of 1–30 L/min. This device consists of a tapered tube and a floatthatrisesorfallsdependingontheflowrate,offering a simple yet reliable method to ensure consistent experimentalconditions.

5. Nanoparticles and Base Fluids:

ThenanofluidsweresynthesizedbydispersingZincOxide (ZnO) and Magnesium Oxide (MgO) nanoparticles into a basefluidofdistilledwater.Highthermalconductivityand strong chemical resistance were the key reasons behind choosing these nanoparticles. The nanoparticles were prepared using ultrasonic-assisted precipitation methods, followed by drying and dispersion, to ensure uniform distributionandnanoscaleparticlesizes.

6. Framework and Piping:

The structural framework was constructed using mild steel (MS) square pipes, selected for their robustness. Transparent plastic circular pipes were used for fluid transport, allowing visual inspection and chemical compatibility with nanofluids. Stainless steel fasteners providedsecureandcorrosion-resistantjointsthroughout theassembly

4. WORKING

Heat Transfer Mechanism

Radiators primarily transfer thermal energy by utilizing conductionthroughsolidmaterialsandconvectionwithin fluids.Thenanofluidinitiallyabsorbsthermalenergyfrom a simulated heat source and subsequently releases it to the surrounding air through the radiator's fins and tubes.

The embedded metal oxide nanoparticles (ZnO and MgO) in the base fluid increase thermal conductivity, thus enablingquickerandmoreeffectiveheattransfer.

The nanofluid is circulated through the system by a submersible water pump. When the hot fluid reaches the upper tank of the radiator, it travels downward through aluminum pipes, releasing heat to the air that moves acrosstheradiator'sfinnedexterior.Oncecooled,thefluid is collected in the lower tank and recirculated to the heatingchamber,completingtheclosed-loopcoolingcycle.

Nanoparticles suspended within the base fluid significantly enhance the heat transfer characteristics withoutalteringthesystemgeometry.Theirsmallsize(1–100 nm) provides an increased surface area for thermal interaction, thereby improving both convective heat transfer and thermal conductivity. Additionally, their uniform dispersion achieved through ultrasonic treatment and stabilization techniques ensures consistentthermalperformance.

Temperature sensors placed at the inlet and outlet of the radiator provide real-time temperature data, enabling calculation of heat removed by the fluid. A rotameter is used to maintain and monitor the flow rate of the fluid to ensure steady-state conditions during experiments. The experimentalresults,includingtemperaturedropandflow rates, are recorded and analyzed to evaluate the effectiveness of the radiator when operated with nanofluids as compared to traditional water-based coolants

The performance of nanofluids containing ZnO and MgO nanoparticles was evaluated at a constant initial temperatureof50 °Cfordifferentmassesofthebasefluid. As the mass increased from 10 g to 30 g, the volume fractions (Vf) of both ZnO and MgO nanoparticles also increased. The rise in temperature difference (ΔT) across the radiator confirmed an improvement in heat transfer capability. For ZnO-based nanofluids, ΔT increased from 8.89 °C at 10 g to 10.3 °C at 30 g, while MgO-based

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

nanofluids showed a higher ΔT increase from 9.69 °C to 11.2 °C over the same range. This indicates that MgO nanofluids consistently exhibited better thermal performance than ZnO nanofluids under similar conditions, likely due to better thermal conductivity or dispersion characteristics.These resultsdemonstrate that boththenanoparticleconcentrationandtypesignificantly influencetheheattransferefficiencyofthenanofluid.

affect fluid flow and heat transfer efficiency. These observations confirm that ZnO nanofluids significantly improve the radiator's cooling performance over conventional water-based coolants, especially at optimizedparticleloadings.

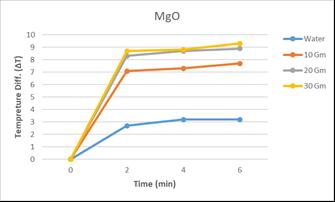

MgO Nanofluid Performance Analysis

Chart -1:Temperature(ΔT)vsTime

Chart -2:Temperature(ΔT)vsTime

ZnO Nanofluid Performance Analysis

Thegraphillustratingtheperformanceofzincoxide(ZnO) nanofluids depicts the outlet temperature variation of the coolantatdifferentnanoparticleconcentrations(10g,20g, and 30g per 3L of water). As the ZnO concentration increases, the outlet temperature of the fluid decreases, indicatinga higher rateofheat extraction by the radiator. This trend highlights the enhanced thermal conductivity imparted by ZnO nanoparticles. With higher nanoparticle content,moresurfaceareaisavailableforheatinteraction, thereby improving the coolant’s ability to absorb and transferthermal energy.However,a diminishingreturn is observed beyond a certain concentration (around 30g), likely due to increased viscosity, which can negatively

The graph associated with magnesium oxide (MgO) nanofluids similarly demonstrates a decrease in outlet temperature with increasing nanoparticle concentrations. Like ZnO, MgO exhibits excellent heat conduction properties, and its addition leads to improved thermal exchange between the coolant and the radiator surface. Although MgO shows a slightly higher thermal conductivity compared to ZnO, its chemical stability and dispersion uniformity ensure consistent performance. At moderate concentrations, MgO nanofluids provide efficient heat transfer without a substantial rise in viscosity,thusmaintaininggoodfluiddynamicswithinthe radiator channels. Both graphs collectively suggest that while MgO achieves marginally better cooling performance, ZnO offers a balance of heat transfer and flow stability, making it a viable alternative for applicationswherelong-termstabilityiscrucial.

The use of ZnO and MgO nanofluids led to a noticeable enhancement in the radiator's heat transfer efficiency. Bothnanoparticleswerechemicallystableandcompatible with the coolant, with MgO offering better dispersion and higher thermal conductivity. Thermal design involved parameters like specific heat capacity (Cp), thermal conductivity,andparticlevolumefractiontoestimateheat transfer enhancement. Radiator sizing was based on calculatedheatload,surfacearea,andflowcharacteristics tailoredtonanofluidproperties.Theoreticalanalysisusing energy balance and convective heat transfer principles predicted outlet temperature and heat dissipation, which closely matched experimental results from a custom-built setup. Minor deviations were due to practical losses. Utilizing ZnO and MgO nanofluids significantly improved theheattransferperformanceoftheradiator.

[1] Choi, S. U. S. (1995). Enhancing thermal conductivity of fluids with nanoparticles. Proceedings of the ASME International Mechanical Engineering Congress and Exposition,66,99–105.2.

[2] Khanafer, K., et al. (2003). Enhanced heat transfer using nanofluids in a flat plate heat exchanger. International Journal of Heat and Mass Transfer, 46(12),2239–2246.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[3] Namburu,G.G.,etal.(2007).Applicationofnanofluids inautomotivecoolingsystems.

[4] Khedher, S. B., et al. (2016). Study of nanofluids for automotive applications: Performance and characteristics. Applied Thermal Engineering, 105, 491–499.

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008