International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Jagdish Pawar1 , Prof. Kunal Ghadge2

1PG student, Department of Civil (Structural) Engineering, Sanmati Engineering College, Washim, Maharashtra

2Head of Dept. Department of Civil (Structural) Engineering, Sanmati Engineering College, Washim, Maharashtra

Abstract - Concreteisthemostwidelyusedbuildingmaterialintheconstructionindustry,primarilyduetoitshighstrength anddurability.Astheworldprogressesrapidly,concernsfortheenvironmentandtheneedtosafeguardnaturalresources havebecomeincreasinglyimportant.Oneinnovativeapproachistherecyclingofwastematerials,includingelectronicwaste (E-waste),intheconcreteindustry.ThisresearchaimstoutilizeE-wastethatisfreefromharmfulchemicalsasanalternative forcoarseaggregate,whilealsoexploringtheuseofwireandcableresiduesasareplacementforfineaggregateinconcrete.

Aliteraturereviewrevealedthatcircuitboardwastecansubstituteforupto10%ofcoarseaggregatebyweight.However, therehasbeennopreviousattempttousewireandcableresiduesasanalternativeforfineaggregates.Therefore,thisstudy willimplementvaryingdosagesofcableresidues.ConcretemixdesignwillbecarriedoutfollowingIS10262:2019andIS 456:2000standardsforM20gradeconcrete.

ThecompressivestrengthoftheconcretewithE-wastewillbeassessedat7dayand28daysusingthreecubesofsize150mm x150mmx150mmtestedinaCompressionTestingMachine(CTM).Thesplittensilestrengthwillbeevaluatedbytesting threecylinderswithadiameterof150mmandaheightof300mmintheCTM,whiletheflexuralstrengthwillbedetermined bycastingthreeprismsofsize500mmx100mmx100mmandtestingtheminaflexuralstrengthtestingmachineforeach percentageofreplacement.

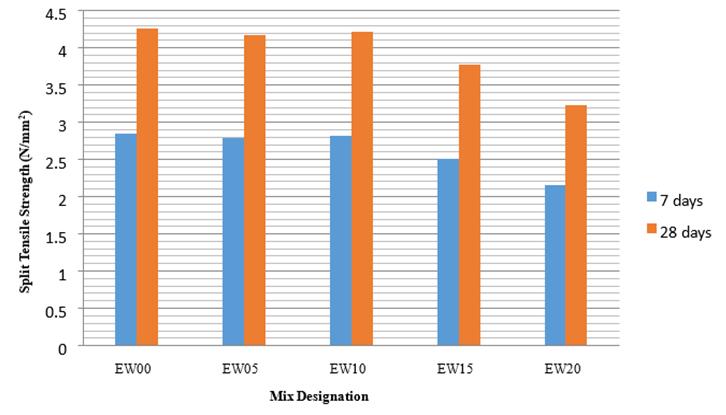

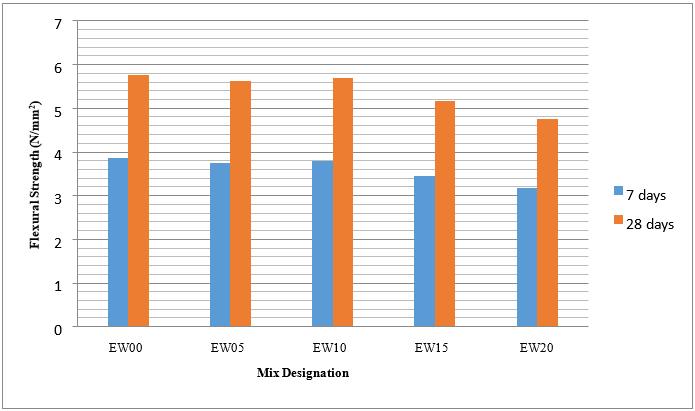

Resultsindicatethatbeyonda10%replacementofbothcoarseandfineaggregates,thecompressivestrengthfallsbelowthe requiredminimumstrengthforthisspecificgradeofconcrete.Consequently,themaximumallowablereplacementforcoarse andfineaggregatesis10%.Additionally,bothsplittensilestrengthandflexuralstrengthdecreaseasthepercentageoffine aggregatereplacementincreases.

Key Words: E-Waste, Circuit board, Compressive strength, Flexural strength.

1.INTRODUCTION

Concreteisthemostcommonlyusedbuildingmaterialintheconstructionindustry,primarilyduetoitshighstrengthand durability.Asourworldadvancesrapidly,thereisgrowingattentiontowardenvironmentalpreservationandtherecyclingof wastematerials.Oneemergingwastematerialutilizedintheconcreteindustryiselectronicwaste(E-waste).E-wasterefersto discardedelectricalorelectronicdevices,includingsecond-handelectronicsdestinedforrecovery,resale,salvage,recycling,or disposal.Theriseofelectronicwastehasbecomeasignificantconcernduetoitspotentialforseverecontaminationofboth humanhealthandtheenvironment.UtilizingE-wasteintheconcreteindustryisseenasafeasiblesolutiontomanagethelarge volumesofwastegenerated.

In developing countries, the release of electronic waste can lead to serious health and pollution problems, as electronic equipmentoftencontainshazardousmaterialssuchasmercury,nickel,silver,zinc,lead,cadmium,beryllium,arsenic,copper, chrome,andcobalt.Thispaperfocusesonnon-hazardousmaterialssuitableforuseinconstruction.Amongthemostcommon materialsfoundinelectricalandelectronicequipmentareironandsteel,followedbyplastics,whichconstitutethesecondlargestcomponentofe-waste.Dependingonitschemicalcomposition,e-wastecanberepurposedascoarseaggregate,fine aggregate,orfinefillerinconcrete.

In recent years, there has been an increasing awareness of our environmental impact stemming from consumer habits, emphasizingtheneedforamoresustainableapproach.Thisshiftisparticularlyrelevanttoindustriesinfluencingconsumer behavior,especiallyintheelectronicssector,whereshortlifecyclesandrapidlyevolvingtechnologyhave ledtogrowing volumesofe-waste.Unfortunately,asignificantamountofe-wasteultimatelyendsupinlandfills.Yet,thepartialrecyclability ofmanye-wastecomponentshaspromptedthedevelopmentofretrievaltechniquesfortheirrecyclingandreuse,underscoring theimportanceofe-wastemanagementfrombothawasteminimizationandmaterialrecoveryperspective.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

InMalaysia,thee-wasteproblemisescalating,withanestimatedgenerationof24.5milliontonsofe-wastefromelectrical equipment,whichcontinuestorise.Theincreaseine-wasteisprimarilyattributabletoconsumerelectronics,asreflectedin datafromtheDepartmentofEnvironment(DOE):estimatesfortelevisionsets,personalcomputers,andrechargeablebatteries havesurgedfrom463,866metrictonnesin2011to832,692metrictonnesin2020,representinga44%increase.Thistrendis expectedtocontinuegiventheincreasingusageofelectricalequipment.

VarshaRathoreandArunaRawatdefineconcreteasamaterialcomposedofvariouscomponentsmixedbasedontheirmaterial composition.Itincludescoarseandfineaggregatesthatactasfillers,combinedwithcementpaste.Thepropertiesofconcrete dependonthesizeoftheaggregates(Rathore&Rawat,2019).Concreteservesasthebackboneofmoderninfrastructureandis producedinlargequantitiestomeettheincreasingdemandfordevelopment(Rautetal.,2018).However,excessiveproduction of concrete material may lead to a scarcity of raw materials. Therefore, it is essential to adequately replenish suitable constituentstoensureasustainablesupplyofconcreteinconstruction(Alagusankareswarietal.,2016).Concreteisrecognized foritsexcellentcompressivestrength,stiffness,anddurability.However,itisbrittleandweakundertension.Plainconcretehas twosignificantweaknesses:lowtensilestrengthandlowstrainatfracture(SrinivasaRaoetal.,2010).Economically,inflation posesaseriouschallengethatmanycountriesface,makingitcrucialtoreduceconstructioncostswhilemaintainingstructural strengthanddurability.InMalaysia,electronicwaste(e-waste)isdefinedasnon-usefulelectronicproductscategorizedas wasteundertheFirstScheduleinCode110(MinistryofMineral andEnvironment,2017).AccordingtoMohammadTapir Mapa,e-wastecancontainpollutantssuchaslead(Pb),mercury(Hg),cadmium(Cd),nickel(Ni),polybrominateddiphenyl ethers (PBDEs), and polychlorinated biphenyls (PCBs). The increasing generation of e-waste primarily results from both industrial and household usage. Currently, legislation focuses mainly on industrial e-waste disposal methods, with no regulationsenforcedforhouseholde-waste,leadingtoariseinhome-generatedelectronicwaste(MohammadTapirMapaet al.,2018).E-waste,alsoknownaselectronicwaste,referstoanyelectronicproductthathasreachedtheendofitsusable humanlifecycle.E-wastecanbedividedintotwomaintypes:industrialandhousehold.AccordingtoMarketWatchin2018, consumerstypicallyreplacetheirmobiledevicesevery15months.Today,manypeoplepreferbuyingnewappliancesrather thangoingthroughthehassleofrepairingoldones(SunilAhirwaretal.,2016).Examplesofe-wasteincludemobilephones, tablets,laptops,andotherelectronicdevices.Thisproliferationofdigitaldevicescouldbecomeasignificantprobleminthe futurebecausee-wastecontainshazardouschemicalssuchascadmium,lead,antimony,nickel,andmercury.Thesesubstances canposehealthriskstohumansandcanpollutetheenvironment,impactingrivers,lakes,andseas,aswellasreleasingtoxic gasesthatharmtheecosystem.Meanwhile,SalmbanuLahar,inanarticleaboutthepotentialapplicationofe-wasteinthe constructionindustry,definese-wasteasunwantedelectronicproductsthatcanberecycled,resold,salvaged,disposedof, reused,orrestored.Eachyear,asignificantamountofe-wasteendsupinlandfills,contributingtoenvironmentalpollution.The materials in e-waste may include potentially envorantment harmful components like cadmium, lead, beryllium, and brominatedflameretardants.E-wasteincludeselectronicdevicesthatoperateonelectricity,suchasmobilephones,machines, refrigerators,televisions,andotherelectricandelectronicitems.Forexampleofewaste,smartphonescontainmercuryintheir batteries,whileelementslikecadmium,tin,aluminum,andcopperarefoundinprintedcircuitboards(PCBs).Additionally, polychlorinatedbiphenylsarelocatedincapacitorsandtransformers,germaniumispresentintransistorizedelectronics,and siliconisusedasthematerialintransistors(SalmabanuLuharetal.,2019).

3.1

NaturalsandparticlesobtainedthroughminingprocessesthisisknowasFineaggregates.Thesematerialstypicallyinclude naturalsandorcrushedstoneparticlesthatare¼inchorsmallerinsize.Thistypeofaggregateisoftenreferredtoas"1/4inch minus,"indicatingitssizeorgrading.

Fineaggregate,orsand,playsacrucialroleinconstruction.Itfillsthevoidsbetweenlargeraggregates,formsthebulkof mortarorconcrete,andcontributestothematerial'sresistanceagainstshrinkingandcracking.Whilenaturalsand,commonly knownasriversand,isdiminishinginavailability,manufacturedsand(M-Sand)hasemergedasaneffectivesubstituteforuse inconcreteconstruction.

Manufacturedsandisproducedbycrushinghardgranitestone,resultingincubicalparticleswithrounded edgesthatare washed and graded for construction use. The size of Fine aggregates is less than 4.75mm. With the rapid growth of the constructionindustry,thedemandforsandhassurged,leadingtoasignificantshortageofsuitableriversandinmanypartsof theworld.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Theincreaseintheuseofmanufacturedsandcanbeattributedtothedepletionofqualityriversandanditsadvantagesin availabilityandtransportationcosts.SinceM-Sandcanbeproducedfromgraniterocks,itisoftenreadilyavailablenearby, reducing the transportation costs associated with sourcing river sand from distant locations. Consequently, using manufacturedsandcanhelpcontrolconstructioncosts.

AnotherbenefitofM-Sandisthatitcanbeproducedtobedust-free,anditssizecanbeeasilyregulatedtomeettherequired gradingspecificationsforvariousconstructionapplications.Inthisproject,weutilizedM-Sandwithaspecificgravityof2.58

Coarseaggregateisthelargestcomponentofaconcretemixtureandplaysacrucialroleintheoverallcompositionofconcrete. Its properties, such as strength, maximum size, shape, and water absorption, significantly affect the concrete mix design, impactingthewaterdemandandthequantitiesofcementandfineaggregateneeded.

Researchshowsthatusinglargercoarseaggregatesizesresultsinlowerwaterdemandforthemixture.Thisisbecauselarger aggregateshaveasmallersurfaceareacomparedtosmallerones.Intermsofshape,roundedaggregatesareidealforcreating economical mixdesignsfor normal-strengthconcrete, whileangularaggregatesarepreferredforhigh-strengthconcrete. Propergradingofcoarseaggregatesisessentialtominimizetherisk ofsegregation,emphasizingtheimportance ofgood gradinginconcretemixdesign.

Whenitcomestostrength,usinghigher-strengthaggregatescanenhancetheoverallstrengthoftheconcrete,providedthat othercontributingfactorsareappropriatelymanaged.Inthiscase,weusedacoarseaggregateblendconsistingof70%20mm aggregateand30%12.5mmaggregate.Thecoarseaggregateselectedhasaspecificgravityof2.85.

Cementisabinderusedinconstructionthatsets,hardens,andbindingthemtogether.Itiscommonlycombinedwithsandand gravel(aggregate)tocreatedifferentmixtures.Whencombinedwithfineaggregate,cementproducesmortarformasonry. Whenmixedwithsandandgravel,itformsconcrete,themostwidelyusedmaterialgloballyandsecondonlytowaterasthe mostconsumedresourceonEarth.

Inthisproject,weusedPortlandPozzolanaCement(PPC).PPCisablendedcementmadebycombiningOrdinaryPortland Cement(OPC)withpozzolanicmaterialsinaspecificratio.Thistypeofcementisoftenconsideredeco-friendlybecausethe materialsusedinitsproductionarederivedfromnaturalrecycledwaste.PPCisveryfine,makingitparticularlyeffectivefor plasteringwork.

Pozzolanaconsistsofsilicamaterial,whichmakesitcost-effectiveandeconomicaltouse.PPCexhibitsexcellentresistanceto sulfateattacks,makingitsuitableforhydraulicstructures,marinestructures,andconstructionnearcoastlinesanddams.Itis utilizedinbothprestressedandpost-tensionedconcretecomponents.

Furthermore, PPCreducescarbonmonoxide emissionsfromconcrete, enhancing its environmental friendliness. Thefine natureofthepozzolanicmaterialscanfillgapsbetweenreinforcementandaggregate,minimizingissuessuchasshrinkage, honeycombing,andbleeding.Thisisgivenstrengthanddurabilityoftheconcrete

A circuit board is a valuable component derived from electronic waste (e-waste) materials, showcasing the potential for recyclingandrepurposingdiscardedelectronics. Weusedlowgradecircuitboardsplasticase-waste.WecollectedtheewastesfromarecyclingfirmcalledGreenEraRecyclerswhichislocatedinEdayarpalayam,Coimbatore.TheseE-wastesare usedaspartialreplacementforcoarseaggregateincementconcrete.Theywereintheformofchips,whichareflakyinshape. Thepropertiesofthecircuitboardsareshownintable3.1givenbelow.Thepicturesofthecircuitboardsarealsogivenbelow,

International Research Journal

Volume: 12 Issue: 05 | May 2025 www.irjet.net

:

3.5. RESIDUES OF WIRES AND CABLES

Residuesofwiresandcablesarealsoaproductofe-wastematerials.Here,thepowderedformofthecoveringsofwires andcablesareusedfortheproject.ThecoveringsofwiresandcablesaremadeupofPolyvinylChloride(PVC),whichare plastics.ThesematerialsarealsocollectedfromthesamerecyclingfirmcalledGreenEraRecyclers.Thespecificgravityofthis materialisfoundbypycnometertestandthevalueis1.014.

4. EXPERIMENTAL PROGRAM

ExperimentalProgramwascarriedoutinthreestages:

Stage1

Determinationofphysicalpropertiesofingredients.

Stage2

MixDesignforM25ConcreteasperISmethodofconcretemixdesign.

Stage3

Experimentalworkconductedonconcretebyreplacingcoarseaggregatewith E-wastewith0.42%watercontent.

4.1 Stage 1

Determinationofphysicalpropertiesofingredients

4.1.1 Fine Aggregate

Table 2 :PhysicalPropertiesofSand

International Research

Volume: 12 Issue: 05 | May 2025 www.irjet.net

Table 3 :PhysicalPropertiesofCoarseAggregates

4.2 Stage 2

MixDesignforM25ConcreteasperISmethodofconcretemixdesign.

➢ Data:

▪Typeofcement–OPC53Grade

▪Maximumsizeofaggregate–20mm

▪Workability–60mmslump

▪Minimumcementcontent–280kg/m3

▪Maximumwatercementratio–0.45

▪GradingofF.A.conformingtogradingzoneIII

▪GradingofC.A.conformingtoIS383TableNo.2

➢ Step 1:Targetmeanstrength

Targetmeanstrength=fck+1.65*S

Targetmeanstrength=25+1.65*4=31.6N/mm2

(Where,S=standarddeviationtakenfromIS:456TableNo.8.)

➢ Step 2:Watercementratio

W/c=0.42

Watercementratioistakenfromexperienceofsimilarwork.

Thisw/cistobeselectedfrombothfromstrengthconsiderationandmaximumw/c denotedin IS:456TableNo.5.

W/c=0.42<0.45,ok

➢ Step 3:Selectionofwatercontent

Max.WatercontentasperTableNo.11.23is186lit.

Estimatedwatercontentfor60mmslump=(186*3/100)+186=192lit. (3%increaseforevery25mmslumpoverandabove50mmslump.)

➢ Step 4:Calculationofcementcontent

W/cratio=0.42

Cementcontent=192/c=0.42

c=192*0.42=457.14=458kg/m3 >280kg/m3 ok.

➢ Step 5:Calculationofcoarseaggregateandfineaggregate

FromTableNo.11.24volumeofC.A.correspondingto20mmsizeaggregate.And F.A.ofzoneIIIforw/cratioof0.50isfoundtobe0.64. Inpresentcasew/cratio0.42itislessby0.08.

TheC.A.isincreasedattherateof0.01foreverydecreaseinw/cratioof0.05. (0.01/0.05)*0.08=0.016

volumeofC.A.=0.62+0.016=0.636=0.64

volumeofF.A.=0.36

(fromTableNo.3,IS10262:2009)

➢ Step 6:Calculationofmixproportion

Volumeofconcrete=1m3

Volumeofcement=(458/3.15)*(1/1000)=0.1453m3

Volumeofwater=0.1920m3

Totalvolume=0.1453+0.1920=0.3373m3

VolumeofC.A.=1-0.3373=0.6627m3

WeightofC.A.=0.6627*2.80*1000*0.64=1187.55=1188kg/m3

WeightofF.A.=0.6627*2.70*1000*0.36=644.14=645kg/m3

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

➢ Quantity:

▪Watercementratio=0.42

▪Cement=458kg/m3

▪Fineaggregate=645kg/m3

▪Coarseaggregate=1188kg/m3

➢ Proportion: Cement:FineAggregate:CoarseAggregate 1: 1.40: 2.60

4.3 Stage 3

ExperimentalworkconductedonconcretebyreplacingcoarseaggregatewithE-waste. PreparationofSpecimens

Constantparameters

•Mixproportionofconcreteselected–1:1.40:2.60

•Typeofcement:OPC

•Typeofaggregate

i) Sand<4.75mm

ii)CoarseAggregatesforflexuraltest<20mmandforcompressivetestandsplittensiletest<20mm.

•Periodofcuring:7&28days

•Watercementratio:0.42

VariableParameters

•CoarseaggregatereplacedbyE-wastefrom0%to20%attheincrementof5%. Test

•Foreachtestofconcrete,threecubesof150mmx150mmx150mmsizewerecast andtestedtodeterminecompressive strengthofconcrete.

•Foreachtestthreecylindersof150mmdia.x300mmheightsizewerecastandtestedtodeterminesplittensilestrength.

•Foreachtestthreeprismofdimension500mmx100mmx100mmsizewerecastandtestedtodetermineflexuralstrength.

5. RESULTS

Table 5:EffectofE-WasteonWorkability

E-Waste

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

2:VariationinSlumpValue

Fig. 3:VariationinCompactionFactor

Table 6:EffectofE-WasteonCompressivestrengthofconcrete

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

4 :VariationinCompressivestrengthofconcrete

Table 7 :EffectofE-WasteonSplittensilestrengthonconcrete

5 :VariationinSplittensilestrengthofconcrete

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Table 8 :EffectofE-WasteonFlexuralstrengthofconcrete

6. CONCLUSION

Inconclusion,thisstudysuccessfullyutilizedM25gradeconcretewithaminimumstrengthratingof15N/mm².Theobjective wastoexplorealternativestocoarseaggregateinconcreteproduction.Astechnologyadvances,theamountofelectricaland electronic waste is increasing, posing risks to surrounding communities and potentially elevating radiation levels in the environment.

This study also aimed to determine the compressive strength of concrete that incorporates e-waste. Tests indicated that concrete with 10% e-waste nearly achieved a compressive strength of 15 N/mm². However, some defects during the productionprocess,suchasinaccuratewatermeasurements,adverselyaffectedtheconcrete'scompressionrate.Moreover, errors in reading and weighing tools also impacted the mixing proportions of the concrete produced.

Finally,thestudyalsoevaluatedtherateofwaterinfiltrationintheconcretethatwasproduced.

7. REFERENCES

1. IS456:2000IndianStandardPlainandReinforcedConcrete-CodeofPractice.

2. IS10262:2019IndianStandardConcreteMixProportioning–Guidelines.

3. IS383:2016IndianStandardCoarseandFineAggregateforConcrete–Specification.

4. Santhakumar,A.R.,(2006)ConcreteTechnology,OxfordUniversityPressIndia.

5. Shetty,M.S.,(2008)ConcreteTechnology:TheoryandPractice,S.Chandpublishing.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

6. Punmia,B.C.,AshokKumarJain.,andArunKumarJain.,(2007)LimitStateDesignofReinforcedConcrete, Firewall MediaPublishers.

7. Mounanga,Pierre&Gbongbon,W.&Poullain,Philippe&Turcry,Philippe.(2008).Proportioningandcharacterizationof lightweightconcretemixturesmadewithrigidpolyurethanefoamwastes.CementandConcreteComposites.30.806 814.10.1016/j.cemconcomp.2008.06.007.

8. Fraj,Amor & Kismi, Mohamed &Mounanga,Pierre.(2010).Valorizationofcoarse rigidpolyurethanfoam wastein lightweightaggregateconcrete.

9. Singh, Anoop, and Vikas Srivastava. "Utilisation of E-waste in Concrete-An Experimental Investigation." Seminar Proceeding,InternationalSeminaronNonconventionalEnergySourcesforSustainableDevelopmentofRuralAreas,21st &22ndMarch2015

10. Raut,SagarR.,RoshaniS.Dhapudkar,andMonaliG.Mandaokar."ExperimentalstudyonutilizationofE-wasteincement concrete."TheInternationalJournalofEngineeringandScience(IJES)(2018)ISSN(e):2319–1813,82-86.

2025, IRJET | Impact Factor value: 8.315 |