International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

Akshita Bangwal1

1M.Tech student, Department of Mining Engineering, College of Engineering and Technology, Maharana Pratap University of Agriculture and Technology, Udaipur, Rajasthan, India

Abstract - Blasting performance in tunneling operations is strongly influenced by geological factors and rock characteristics, which determine excavation effectiveness, cost-efficiency, and safety. This study examines theseparametersto improvedrilling andblasting outcomes. The main objective is to analyze how geological and rockrelatedvariables suchaslithology,rockmassclassification, joint orientation, and strength affect results. These factors influence fragmentation, overbreak /underbreak, and blastinduced vibrations. Different blasting techniques, including conventional blasting, pre-splitting, and smooth blasting, were evaluated against performance indicators such as fragmentation quality, vibration reduction, flyrock control, andoverbreakregulation.Empiricalobservations,numerical simulations, and field data were combined to assess the effectivenessandsafetyofeachtechnique.Acomparativecost frameworkwasdeveloped,consideringexplosiveuse,drilling efficiency,equipmentutilization,cycletime,andmaterialloss.

The economic evaluation identified the most cost-effective and feasible tunneling method. Overall, the study enhances understandingofblastingefficiencybyintegratinggeological, engineering, and economic perspectives, contributing to better excavation practices in sensitive terrains like the Himalayas.

Key Words: Tunneling, Drilling and Blasting, Blast Optimization, Rock Mass Properties, Fragmentation, Cost Evaluation, Vibration Control.

Tunneling plays a crucial role in infrastructure development, especially in regions where surface excavation is not feasible due to challenging geological conditions. Among the most reliable and widely used excavationmethodsinhardrockenvironmentsaredrilling andblasting.However,theeffectivenessofthesetechniques ishighlyinfluencedbysubsurfacegeologicalcharacteristics, the nature of the rock mass, and the specific blasting approach employed. Therefore, optimizing drilling and blasting is essential to enhance excavation speed, reduce environmentalimpacts,loweroperationalcosts,andensure workersafety.

This study primarily aims to evaluate the influenceofgeologicalconditionsandrockcharacteristics

on blasting outcomes in tunnel construction. Critical factors such as rock type (lithology), rock mass classification,jointorientation,androck strengthplaya significantroleindeterminingfragmentationquality,the extentofoverbreakandunderbreak,andthelevelofblastinduced vibrations. Understanding these variables is fundamentaltodesigningeffectiveblastingstrategiesthat improve excavation quality while minimizing structural damageandsafetyrisks.Theresearchfocusesonassessing theperformanceofdifferentblastingtechniquesbasedon parameters like fragmentation efficiency and vibration control. It included an evaluation of explosive consumption, drilling efficiency, and the overall effectiveness of blasting operations. The objective is to identify the most efficient and cost-effective blasting method using a data-driven analysis. By integrating geological evaluations, blast performance assessments, andeconomicconsiderations,thisstudyaimstocontribute tomoreefficientandsustainabletunnelingpractices.The insightsgainedsupportedthedevelopmentofoptimized drillingandblastingtechniques,especiallyforgeologically complexandsensitiveenvironments.

Tunneling in the Himalayas is highly complex due to unpredictablegeology,highoverburden,andvariablerock strength. Numerous studies have highlighted these challengesandproposedadaptivesolutions.Srivastavetal. (2024)reportedunstablerockmassesalongtheRishikeshKarnaprayagrailwayline,requiringcustomizedexcavation strategies. Similarly, Azad et al. (2022) showed that the NATM method offered more reliable assessments than RMRintheGarhwalHimalayas.Meietal.(2021)optimized blastingparametersinthePanlongshanTunnel,reducing overbreak and improving tunnel profiles. Verma et al. (2021)appliedmodifiedpre-splittingtechniquesattheKol Dam project to stabilize slopes in jointed rock. Extreme conditions in the Rohtang Tunnel were documented by Reichenspurner and Riedel (2020), where NATM and controlledblastingprovedeffective.UpadhyayandSingh (2017) stressed flexible excavation measures like preinjectiongroutingandumbrellaroofing.Historicalanalyses byCarduandSeccatore(2016)proposednewprediction methods for rock behavior, while Alipour et al. (2012) improvedchargeestimationusingneuralnetworks.Spathis

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

andGupta(2012)recommendedcomputerizeddrillingfor vibration-sensitive zones. Other contributions include Facibeni et al. (2011) on integrated risk assessments, Panthi (2006) on probabilistic design approaches, Kahriman(2002)onblastvibrationcontrol,andBartonet al.(1974)withthewidelyadoptedQ-systemforrockmass classification. Collectively, these studies emphasize adaptive, data-driven approaches to ensure safe and efficienttunnelinginHimalayanterrains.

Thisstudyaimedtoevaluatedifferentdrillingandblasting methodstoidentifythemostcost-effectiveoptionforthe givengeologicalconditions.Specifically,thisstudytriedto determinethefollowing:

1.Tostudythegeologicalconditions,rockpropertiesand understand their effect on blasting performance in tunneling.

2. To evaluate the performance of different blasting techniques for various blast design by analyzing blast results.

3. To compare cost of different blasting techniques for variousdrillandblastdesign.

2.

a) Objective of study- To optimize drilling and blasting operationsinHimalayantunnelingbyrefiningdrilling patterns,chargedistribution,andvibrationcontrolfor safer,accurate,andcost-effectiveexcavation.

b) Literature of Review- Tunneling efficiency in the Himalayasdependsonoptimizeddrillingandblasting practices, supported by predictive models and controlled blasting techniques. Previous studies emphasizetheroleofthesemethodsinminimizingrock damage, reducing costs, and addressing the unique geologicalchallengesofHimalayanterrains.

c) Field Study- The field study examined rock mass properties,tunnelalignmentwithvaryingoverburden, andgeologicalconditions.Theseevaluationsprovided critical inputs for planning excavation methods and ensuringtunnelstability.

d) Datacollection&Compilation-Datacollectioninvolved recording drilling patterns and hole orientations, explosivechargedetails,andexcavationperformance throughadvance,overbreak,andunderbreakrecords. This information was compiled to analyze blasting efficiencyandoptimizetunnelingoutcomes.

e) Analysis- Theanalysisfocusedonevaluatingdrilling andblastingefficiency,correlatinggeologicalconditions withblastperformance,andassessingpullefficiency

f) Final Outcome- The study resulted inoptimizeddrill and blast guidelines tailored to site conditions and provided recommendations specific to Himalayan tunneling.Theseoutcomesaimtoenhanceexcavation efficiency,reducecosts,andimprovetunnelstabilityin challengingterrains.

The project is situated in the tectonically active Lesser Himalayanzone,whichischaracterizedbyhighgeological complexityandintensestructural deformation.Thearea encompassesthreemajorgeologicalformations namely, the Tal Group, Krol Group, and Jaunsar Group each comprising a unique set of lithologies that include dolomites, quartz arenites, phyllites, and shales. These formations are interbedded with minor siltstones and limestones,andfrequentlyintersectedbyshearedzones, thrust contacts, and folded bedding planes. Rock Mass Rating (RMR) values across the study sections vary significantly,rangingfrom30to55,indicatingthepresence of fair to poor quality rock. The presence of weathered zonesandjointedrockmassesfurtheraddstoexcavation difficulties. Structural mapping revealed joint sets with varying dip angles, spacing, and infill materials, which directly influence blast design and support system requirements.The overburden depth in the alignment corridorsofTunnel-2andTunnel-3rangesfrom600to670 meters, introducing high in-situ stress conditions that increase the risk of rockburst, deformation, and groundwater ingress. Additionally, groundwater percolation observed in several tunnel faces indicated activeseepagezones,necessitatingdrainagecontrol and pre-supportmeasures.

In tunneling projects, the choice of drill hole diameter plays a vital role in achieving maximum output at minimumcost.Smalltunnels,withcross-sectionalareas between10and30m²,usuallyemploydrillholesof32–38 mm diameter. However, these smaller holes are less

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

efficientandposeoperationaldrawbacks.Formediumto largetunnels,moderndrillingjumbosaregenerallyused, capableofdrillingholesintherangeof40–65mm,with 44–51 mm being the most common sizes. The required number of blast holes depends largely on the tunnel’s cross-sectional area, the rock mass strength, and the selected hole diameter. To design an effective and economical drilling and blasting pattern, empirical equationssuchastheSwedishequationareapplied.These formulas provide reliable estimates for the number of holesneededunderdifferentrockconditions,helpingto balance productivity, cost, and stability.Formula for NumberofHoles(SwedishEquation)

For hard rocks (UCS > 50 MPa):

N=37.6+1.36A

For medium to soft rocks (UCS = 2–50 MPa):

N=30.9+1.0A

Where:

N=Numberofblastholes.

A=Tunnelcross-sectionalarea(m²).

Controlling factors for hole numbers:

Tunnelcross-sectionalareaandgeometry.

Rock mass classification and strength (UCS, Qsystem,RMR).

Drillholediameter.

Table -1: Suggestednumberofholesforvarioustunnel cross-sectionareasandrockstrength

Number of holes for various tunnel cross- section areas and rock strength

Requirednumberofholesperroundof blast(Heading/fullface

Tunnelcrosssection(m2)

Weakrockmass (UCS<8Mpa)

Strongrockmass (UCS>50Mpa)

10 23-27 35-50

25 45-50 60-70

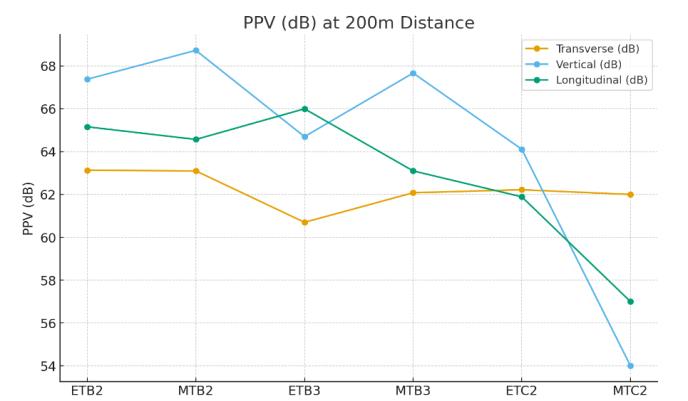

The prediction of ground vibrations from the current blasting pattern is a prime requirement to ensure adequateoperationalsafetyandstructuralstability,notto

mentioncompliancewiththetermsofregulations.Onecan estimate the peak particle velocity (PPV), gravely impacting parameters such as the charge per delay and distance from the blast face, using empirical equations such as Powder Magazine's USBM method or Indian methodslikeDGMSguidelines.Vibrationanalysisbasedon the anticipated vibrations checks the satisfactory application of the present blasting design within permissible vibration limits and whether it requires modificationstoachieveoptimumblastefficiencywithout endangeringsafety.

Fig -2. PPV(dB)at200mdistanceforTransverse, Vertical,andLongitudinaldirections.

Table -2: Predictedvibrationsforexistingblasting pattern

R=200m(Taken values of vibrations at 200m distance from blast location)

A1(Stable):Minor,short-liveddeformation;nospalling.

A2 (Over-breaking): Small deformation; limited crown spallingduetodiscontinuities.

B1 (Friable): Slight deformation; blasting + weak structurescauseblocklooseningatcrown/sidewalls.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

B2(Veryfriable):Quicklooseninginunsupportedzones duetoweakstrength,poorinterlocking,blasting.

B3 (Rolling): Rock inflow even in small sections; poor cohesion/interlocking.

C1 (Rock bursting): Violent failure from sudden energy release.

C2(Squeezing):Large,slow-stabilizingdeformationswith failure/plasticzones.

C3(Heavilysqueezing):Extensivedeformation;rapidthen slowstabilization,deepfailurezones.

C4(Flowing):Weak,plasticrockflowsintoopeningswhen unsupported.

C5 (Swelling): Volume increases on water absorption (swelling clays, salts, anhydrite). Where ET tends for EscapeTunnel&MTtendsforMainTunnel.

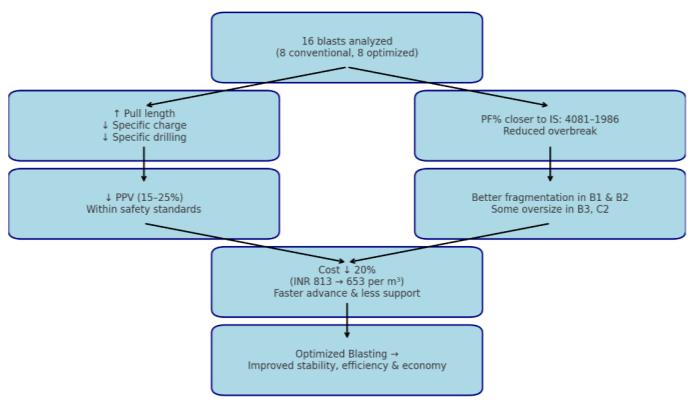

6. RESULT

The field results showed that optimized drilling and blasting significantly improved tunnel performance by reducing the specific charge, vibration levels, and overbreak, while simultaneously enhancing pull length androckfragmentation.Thisimprovementtranslatedinto nearly20%costsavingsandensuredsafer,moreefficient tunneling operations under Himalayan conditions. Moreover, the optimized approach resulted in better advance per round, reduced cycle time, and improved utilization of drilling and blasting equipment. The reduction in overbreak also minimized unnecessary excavationandmaterialhandling,contributingtooverall projectsustainability.

Fig -

7.

This study concluded This study showed that geological conditionsplayedamajorroleinblastingperformance.The

useofoptimizeddrillingandblastingtechniquesimproved fragmentation,reducedoverbreak,andincreasedefficiency. Theapproachresultedinabout20%costsavings,making tunnelingintheHimalayasbothsaferandmoreeconomical. Theresultsfurtherindicatedthatcarefuldesignofblasting parametershelpstocontrolvibrationandflyrock,whichis important in sensitive terrains. In addition, longer pull lengthsreducedthenumberofblastcycles,whichhelpedto savetimeandresources.Fewerdrillholesloweredtheuseof consumables and reduced equipment wear, cutting down operating costs. Better fragmentation also improved muckingandhaulingoperations,leadingtofasterexcavation cycles. Together, these findings highlight that optimized blastingoffersbothtechnicalreliabilityandstrongeconomic valuefortunnelingprojectsincomplexgeologicalsettings.

[1] Alipour, A., Jafari, A. and Hossaini, S.M.F., 2012. Application of ANNs and MVLRA for estimation of specificchargeinsmalltunnel. International Journal of Geomechanics, 12(2),pp.189–192.

[2] Auden,J.B.,1937.StructureoftheHimalayainGarhwal. Records Geological Survey of India, 71,pp.407–433.

[3] Azad, M.A., Naithani, A.K. and Singh, S.K., 2022. Application of the NATM methodology for the excavation of rail tunnel in difficult geological conditions:acasefromGarhwalHimalaya,Uttarakhand. Journal of the Geological Society of India, 98(11), pp.1553–1559.

[4] Barton, N., Lien, R. and Lunde, J.J., 1974. Engineering classification of rock masses for the design of tunnel support. Rock Mechanics, 6(4),pp.189–236.

[5] Bieniawski, Z.T., 1989. Engineering rock mass classification.NewYork:JohnWiley&Sons.

[6] Cardu, M. and Seccatore, J., 2016. Quantifying the difficulty of tunnelling by drilling and blasting. Tunnelling and Underground Space Technology, 60, pp.178–182.

[7] Facibeni, L., Palomba, M., Carrieri, G., Russo, G. and Guvenc,A.H.,2011.Criticalaspectsinthedesignofthe Chenani–Nashritunnel.In: ThirdIndianRockConference - Indorock 2011,pp.13–15.

[8] Gustafsson,A.,1981. Design of tunnel blast rounds and criteriaforsmoothblasting.Stockholm:SwedishDetonic ResearchFoundation.

[9] Kahriman, A., 2002. Predictability of the ground vibration parameters induced by blasting during the tunneling. Mineral Resources Engineering, 11(3), pp.279–291.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

[10] Mei, J., Zhang, W., Xu, B., Zhu, Y. and Wang, B., 2021. Optimization methods of blasting parameters of large cross-section tunnel in horizontal layered rock mass. Geotechnical and Geological Engineering, 39(7), pp.5309–5323.

[11] Panthi, K.K., 2006. Analysis of engineering geological uncertainties related to tunnelling in Himalayan rock mass conditions.PhD.NorwegianUniversityofScience andTechnology.

[12] Pokrovsky,N.M.,1980. Driving horizontal workings and tunnels.Moscow:MirPublishers,pp.38–41.

[13] Reichenspurner,P.andRiedel,T.,2020.RohtangTunnel – NATM in the Indian Himalayas. Geomechanics and Tunnelling, 13(5),pp.489–497.

[14] Rustan, A., 1998. Rock blasting terms and symbols: a dictionary of symbols and terms in rock blasting and related areas like drilling, mining and rock mechanics BocaRaton,FL:CRCPress.

[15] Spathis,A.T.andGupta,R.N.,2012. Tunneling in rock by drilling and blasting.BocaRaton,FL:CRCPress.

[16] Srivastav, A., Yadav, V., Kainthola, A., Pandey, V.H., Dangwal, V. and Singh, T.N., 2024. Boundary element coupledstructuralanalysisofLesserHimalayanrailway tunnels: A case study of the Shivpuri–Byasi section, Rishikesh–Karnaprayag BG rail link, Uttarakhand, India. Journal of Earth System Science, 133(4), p.244.

[17] Upadhyay, S. and Singh, K.K., 2017. Tunneling in soft rock and hard rock in Himalayan region. In: International Conference on Dams & Underground Structures: Latest Technology on Planning, Design & Construction. NewDelhi:ASSOCHAM-National Council onPower.

[18] Verma,H.K.,Patel,P.andSingh,S.,2021.Applicationof controlledblastingtechniquesfordevelopmentofstable slope – A case study. Journal of Rock Mechanics and Tunnelling Technology (JRMTT), 27(2),pp.103–119.

[19] Whittaker,B.N.andFrith,R.C.,1990. Tunnelling:design, stability and construction.London:BlackieAcademic& Professional.

[20] Zare, S., 2007. Drill and blast tunnelling blast design Report2A-05.

[21] Zare, S. and Bruland, A., 2006. Comparison of tunnel blastdesignmodels. TunnellingandUndergroundSpace Technology, 21(5),pp.533–541.