International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:

Kiran Gurav1

1Kiran Gurav Student, Dept. Electronics and Telecommunication Engineering, KIT's College of Engineering Kolhapur (Empowered Autonomous), Maharashtra, India ***

Abstract - This paper presents the development and simulation of an intelligent brake health monitoring system using MATLAB Simulink with Raspberry Pi integration. The system monitors three key parameters temperature (via LM35 sensor), brake fluidlevel, andbrake pad wear to assess the real-time condition of a vehicle's braking system. Sensor inputs are scaled, processed, and compared against predefined thresholds to detect faults like overheating, low fluid levels, and excessive brake wear. Based on the evaluation,appropriatewarningmessagesaredisplayed,and an emergency actuation mechanism is simulated using a DC motormodel.

The Simulink model provides a dynamic visualization of sensorbehaviourundervaryingconditions andhelps validate the system’s response. The use of Raspberry Pi for real-time data interfacing supports portability and future hardware expansion. This approach reduces reliance on manual inspection, improves maintenance efficiency, and enhances vehicular safety through timely diagnostics. The system demonstrates the potential of embedded technologies in predictive maintenance applications for smart automotive systems.

Key Words: Digital Twin,Automotive Safety, Brake Fluid Pressure, Digital Twin, Fault Localization, MATLAB Simulation,PredictiveMaintenance.

The braking system is arguably one of the most critical safety components in any vehicle. Its reliable operation is paramount to preventing accidents and ensuring occupant safety. As vehicles evolve with increasingly complex electronically controlled braking systems such as Anti-lock Braking Systems (ABS) and Electronic Stability Control (ESC) the challenge of ensuring their continuous healthanddiagnosingpotential faults proactively becomes more significant. Traditional maintenance schedules and reactive diagnostics often identify problems only after performance degradation or failure has occurred, potentially compromising safety. There is a growing need for advanced diagnostic and prognostic methods that can predict and localize faults before they become critical [1][2].

Digital Twin technology offers a promising paradigm shift in this domain. By creating a dynamic virtual representation of a physical system, synchronized through real-timedata,DigitalTwinsenablecontinuousmonitoring, analysis,andpredictionofsystembehaviourandhealth.In the context of vehicle systems, recent developments have demonstrated the effectiveness of simulation-based Digital Twin models for condition monitoring and diagnostics [3][4]. These systems leverage sensor data and simulation environments like MATLAB Simulink to replicate real-world scenarios for proactive fault detection and systemevaluation[1][3].

This paper explores the application of a Digital Twin framework for fault localization within a vehicle's electronicbrakingsystem,adoptingadata-drivenapproach implemented primarily through MATLAB simulations. The corefocusofthisworkistoutilizereadilyavailablesensor data particularly from the brake fluid pressure sensor to detect anomalies indicative of common but critical faults, such as hydraulic fluid leakage or excessive brakepadwear.Faultlocalizationisachievedbycomparing sensordataagainstthesimulated behaviourofthebraking system, using threshold-based and data-driven techniques [2][5].

Thisstudydemonstratesthefeasibilityandeffectivenessof using MATLAB-based simulations to develop and test a Digital Twin for braking system diagnostics. The proposed approach provides a cost-effective and scalable solution that can enhance real-time safety diagnostics in modern vehicles. The subsequent sections detail the system modelling approach, the MATLAB simulation setup for normal and faulty conditions, the fault detection logic embedded within the Digital Twin, and the results validatingitsabilitytolocalizepressure-relatedfaults.

The reliability of automotive braking systems is non-negotiable for vehicle safety, yet conventional diagnostic methods often fall short in providing timely warnings for potentially critical failures. Reactive maintenancestrategiesandperiodicinspectionsmayfailto captureincipientfaultslike low brake fluid (indicated by pressure loss or temperature anomalies) or excessive wear and tear on brake pads (indicated by temperature

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

or wear sensors) before they significantly compromise braking performance, contributing to the risk of accidents. Current approaches may struggle to differentiate between normal operation and the subtle degradation caused by these faults, or they require complex, costly sensor suites forcomprehensivereal-timemonitoring.Thereisaspecific need for an accessible, reliable method to enable the proactive detection and localization of these operational faults. This research addresses the challenge of developing and evaluating a Digital Twin framework, built using MATLABsimulations,thatspecificallyfocusesonanalyzing key sensor data (primarily brake fluid pressure and correlated temperature readings) to identify deviations indicative of such faults. The core problem tackled is the creation of a predictive system capable of comparing the expectedbrakeapplicationforceandresultingdeceleration under normal conditions against the diminished performancesimulatedunderfaultscenarios(likepressure loss or excessive wear), thereby providing early, specific warningsforpredictivemaintenanceandenhancedvehicle safety.

3.

OBJECTIVE

i.Develop a real-time EBS simulation model in MATLAB.

ii.Establish a Digital Twin framework integrating sensordata.

iii.Implement fault localization strategies within the DigitalTwin.

iv.Evaluate the Digital Twin's effectiveness against conventionalmethods.

v.Demonstrate KPI comparison under normal and faultyconditions.

vi.AlignstrategieswithISO26262andrelevantASILs.

LITERATURE REVIEW

4.1. Digital Twin Fundamentals and Applications

Originally proposed by NASA, Digital Twins (DTs) are real-time virtual models of physical systems (Grieves & Vickers, 2017). In automotive contexts, DTs enable component simulation, analysis, and lifecycle monitoring (Fulleretal.,2020).

4.2. Digital Twin in Automotive Engineering DTs enhance system insight and predictive capabilities. Boschert&Rosen(2016)andTaoetal.(2018)emphasized their role in performance monitoring and real-time decision-making.

4.3. Data-Driven Fault Localization Machine learning techniques like PCA, SVM, and LSTM are widely used for fault detection in braking systems using sensordatasuchasbrakepressureandwheelspeed(Liuet al.,2019).

4.4. DT and Machine Learning for Predictive

Combining DTs with ML allows predictive diagnostics. Tao et al. (2018) and Wang et al. (2021) showed that hybrid DT-MLmodelsimprovefaultdetectionaccuracy,especially inbrakingsystems.

Present Methods and Tools for Fault Detection Visual Inspection

o Description:Manual examinationofcomponentsfor visiblewear,damage,orleaks.BrakeTesters

o Description: Devices that measure the braking performance of a vehicle under load Acoustic Emission(NoiseAnalysis)

o Description: Analysis of sound or vibrations produced by mechanical components. Hydraulic LinePressureTesters

o Description: Used to monitor pressure changes in thehydraulicbrakesystem.

o OBD An OBD tool, or on-board diagnostics tool, is a device that connects to a vehicle's computer systemtoreadandinterpreterrorcodesandother data

5.

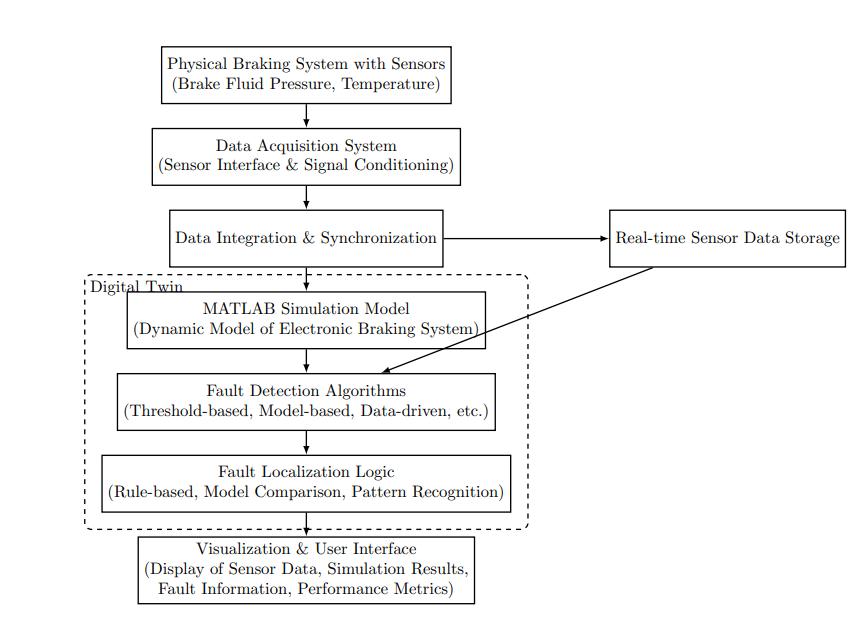

Figure 1: SystemArchitecture

This architecture presents a comprehensive system for themonitoringanddiagnosticanalysisofaphysicalbraking system. The foundation of the system lies in the Physical Braking System with integrated Sensors, such as those measuring brake fluid pressure and temperature, which capturereal-timeoperational data.Thisraw sensor data is processed by a Data Acquisition System, encompassing sensor interfacing and signal conditioning to ensure data quality and format compatibility. Subsequently, the Data Integration & Synchronization block aligns data streams

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

from various sensors, critical for coherent analysis and modelling. The processed data is then directed to Real-time Sensor Data Storage for logging and historical access.

A core component of this architecture is the Digital Twin, a virtual replica that utilizes the real-time sensor data to mirror the physical system's state and behaviour

Within the digital twin, a MATLAB Simulation Model providesadynamicrepresentationoftheelectronicbraking system's expected performance. This simulated behaviour is compared against the actual system data by Fault Detection Algorithms, which can employ various methodologies including threshold-based checks, model-based deviation analysis, and data-driven techniques to identify anomalies. Upon fault detection, Fault Localization Logic, potentially utilizing rule-based systems, model comparison, or pattern recognition, works toidentifythespecificsourceornatureofthefault.Finally, the system's operational status, including raw sensor data, simulation results, detailed fault information, and key performancemetrics,ispresentedthrougha Visualization & User Interface, enabling effective human monitoring, diagnosis,anddecision-making.

Sourcesandrelatedcontent

The system functions by consistently tracking essential vehiclebrakeindicators,suchasfluidforce,thermal levels, and material degradation, using an array of detectors. Analog signals from these detectors are transformed into digital values by an embedded converter within a processing unit. This unit then evaluates the live information against established operational limits to spot irregularities. Utilizing computational methods or behavioral models, the system works to ascertain the nature and source of any detected anomalies, effectively isolating the specific component responsible for the issue. All pertinent details, including the problem description, its location, and recommended corrective measures, are presented instantly on a user interface screen, offering crucial, immediate feedback. A practical demonstration of this concept involves a simulated environment where a small computer platform acquires temperature measurements from a thermal gauge via an analog-to-digital converter. Software on the platform interprets this temperature data based on predefined boundaries, signaling conditions that may suggest insufficient fluid or binding caliper issues, and provides suitableadviceonthedisplaypanel.

6.

The proposed system simulates an automotive brake monitoring system using MATLAB Simulink. It processes inputsfromtemperature,brakefluidlevel,andbrakewear sensors. Voltage signals are scaled to real-world values using gain blocks. Thresholds and logic blocks evaluate

systemstatus.The model supports predictive maintenance andfaultdetection.

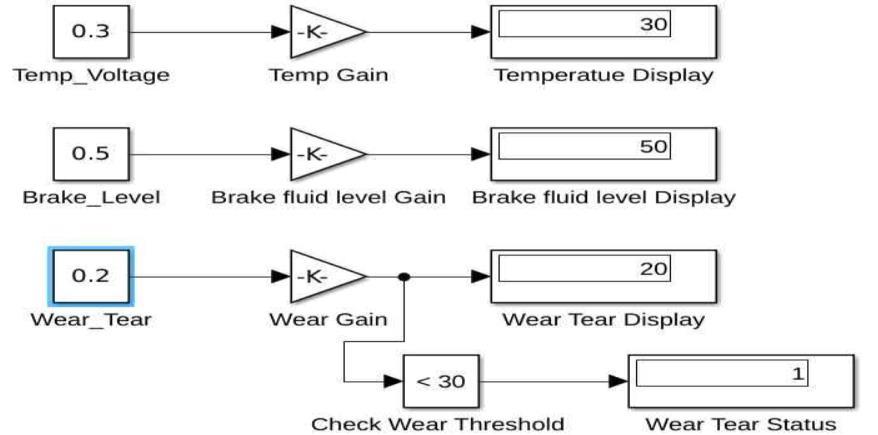

Figure 2: MATLABSimulinkModel1

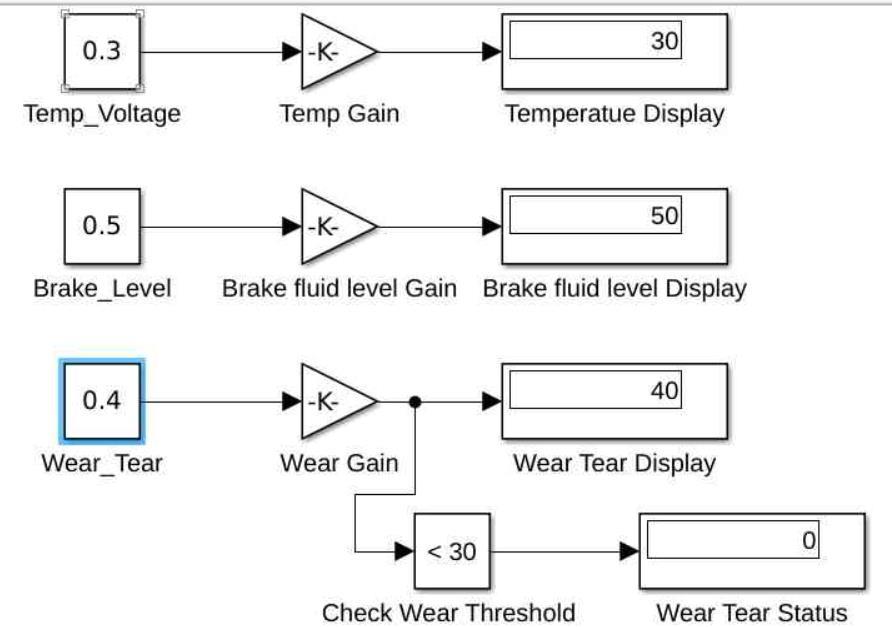

Figure 3: MATLABSimulinkModel2

Table 1: TemperatureSensorThresholdsandDisplay Actions

Temp sensor LM35

Condition Threshold/Rang e

Action/Display

LowTemp <20°C "LowTempFault"

Normal 20°C–30°C "TemperatureNormal"

HighTemp >30°C "HighTempFault"

Brake Wear

State Range Display

Critical <30% ReplacePads

Moderate 30–60% CheckPads

Good >60% PadsOK

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Brake Fluid

State Range Display

Low <20% LowFluid

Normal 20–80% FluidNormal

High >80% HighFluidLevel

6.1.

This Simulink model is designed to monitor key brake system parameters: temperature, brake fluid level, and wear and tear condition using sensor voltage inputs. The outputs help determine whether the system operates withinsafethresholds.

Table 2: BrakePadWearConditionTable

Block/Signal Description

Temp_Voltage (0.3)

Simulatedvoltageinputfromabrake temperaturesensor.

Temp Gain Gainblockscalesvoltagetotemperature: e.g.,0.3*100=30°C.

Temperature Display Showsactualbraketemperatureafter conversion.

Brake_Level (0.5) Voltagefromabrakefluidlevelsensor.

Brake fluid level Gain Convertsvoltagetobrakefluid percentage(e.g.,0.5×100=50%).

Brake fluid level Display Showsbrakefluidlevelfordriveror diagnostics.

Wear_Tear (0.4) Inputvoltageindicatingbrakepadwear.

Wear Gain Convertswearsignalintoameasurable unit(e.g.,%wear).

Wear Tear Display Displayswearpercentageafter conversion.

Check Wear Threshold Compareswearvaluewiththreshold (e.g.,30%).

Wear Tear Status Outputsbinarystatus(1ifwear>30%, else0),indicatingpadneeds replacement.

6.2.Working Logic

o Temperature Measurement:

oThe Temp_Voltage signal is multiplied by a gain (assumed 100) to calculate actual braketemperature.

oTheresultisdisplayedusingadigitaldisplay block.

o Brake Fluid Level:

oA similar process converts the voltage to a fluidlevelpercentageusingafixedgain.

oHelps ensure sufficient hydraulic fluid is presentforbrakeoperation.

o Brake Pad WearMonitoring:

oWearsignalisscaledtopercentage.

oA threshold comparator checks if wear exceeds30% ifso,thesystemmayalert formaintenance.

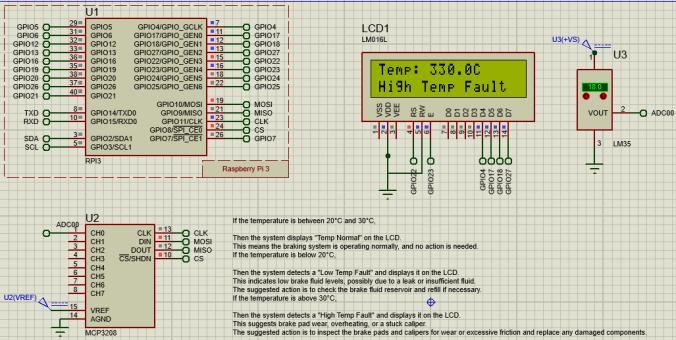

7.1. Working of the System

The system operates by continuously measuring the temperatureusingtheLM35sensor,convertingthisanalog readingintoadigitalvalue,anddisplayingthetemperature andacorrespondingstatusmessageonanLCDscreen.

o Sensing: The LM35 temperature sensor outputs a small analog voltage that changes proportionally with the surrounding temperature (10mV per degreeCelsius).

o Analog-to-Digital Conversion: TheMCP3208ADC receives the analog voltage from the LM35 on one of its input channels (Channel 0 in this case). The MCP3208convertsthisanalogvoltageintoa10-bit digital number (ranging from 0 to 1023, assuming the connected software uses 10-bit resolution, even though the chip is 12-bit). This conversion is based on the ratio of the input voltage to the referencevoltagesuppliedtotheADC.

o DataAcquisition: TheRaspberryPicommunicates with the MCP3208 using the Serial Peripheral Interface(SPI) protocol. It sends commands to the ADC to initiate a conversion on the specified channel and then reads the resulting digital data backfromtheADCviatheSPIdatalines.

o Processing: The Raspberry Pi's software (like the Pythonscript)takestherawdigitalvaluefromthe ADC and applies a conversion formula (based on the LM35's sensitivity and the ADC's reference voltage) to calculate the temperature in degrees Celsius.

o Fault Detection & Status: The software compares the calculated temperature against predefined thresholds (e.g., 20°C and 30°C) to determine the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

system's status (Low Temp Fault, Temp Normal, HighTempFault).

o Display: The Raspberry Pi controls the character LCD using several of its General-Purpose Input/Output (GPIO) pins. It sends commands to control the cursor position and sends the ASCII valuesofcharacterstobedisplayed.Thecalculated temperature and the determined status message are formatted into strings and sent to the LCD for theusertoread.

This cycle repeats continuously, providing real-time temperaturemonitoringandstatusupdates.

7.2.Components

Thekeycomponentsshownintheschematicare:

o U1: Raspberry Pi 3: Asingle-boardcomputerthat acts as the controller. It runs the software to acquire data, perform calculations, implement logic,andcontrolthedisplay.Itprovidesthepower supplyandcommunicationinterfaces(SPI,GPIO).

o U2: MCP3208: A 12-bit Analog-to-Digital Converter (ADC) with an SPI interface and 8 input channels. It's essential for converting the analog voltageoutputoftheLM35intoadigitalvaluethat theRaspberryPicanprocess.

o U3: LM35: A precision integrated-circuit temperature sensor. It provides an output voltage that is directly proportional to the Celsius temperature.

o LCD1:LCD1602: Astandard16x2characterLiquid Crystal Display. It's used to visually present the measured temperature and the system's operationalstatusmessagestotheuser.

Table 3: RaspberryPiSPIandLCDPin Configuration

Raspberry Pi Pin Connection To Device Devic e Pin Name Description

SPICommunication(MCP3208)

Pin19/MOSI MCP3208 DIN SPIDataIn (MOSI)

Pin21/MISO MCP3208 DOUT SPIDataOut (MISO)

Pin23/SCLK MCP3208 CLK SPIClock

Pin24/CE0 MCP3208 CS ChipSelectfor SPIDevice0

AnalogInput(LM35toMCP3208)

(Notconnectedto Pidirectly) LM35 VOUT LM35Analog OutputSignal

(Notconnectedto Pidirectly) MCP3208 CH0 AnalogInput Channel0

Pin7/GPIO4

Pin11/GPIO17

Pin12/GPIO18

Pin13/GPIO21

Pin15/GPIO22

Pin16/GPIO23

LCDControl(GPIO)

LCD1602 DB4 LCDDataBit4 (4-bitmode)

LCD1602 DB5 LCDDataBit5

LCD1602 DB6 LCDDataBit6

LCD1602 DB7 LCDDataBit7

LCD1602 RS LCDRegister Select

LCD1602 E LCDEnable

8.1. DataCollection:

o Sensors continuously monitor key parameters (e.g., hydraulicpressure,temperature,wearlevels).

o Sensor signals are fed into an Analog-to-Digital Converter (ADC) in the microcontroller. Data Processing:

o The microcontroller compares real-time data against threshold values: Example: If the pressure isbelowthenormalrange,aleakisdetected.

o Algorithms or predictive models identify the type andlocationofthefault.FaultLocalization:

o Identify the specific component causing the issue (e.g.,brakepad,caliper,ormastercylinder).

8.2.Real-TimeDisplay:

Display real-time status on the dashboard or screen: Fault description (e.g., “Low Brake Fluid Pressure”). Location of the fault (e.g., “Front Left Brake Line”). Suggestedaction(e.g.,“InspectforLeaks”).

8.2.Steps to Localize and Display Faults

8.2.1.InstallSensorsforKeyParameters:

o PressureSensors:Measurehydraulicpressureinbrake lines to detect inconsistencies indicating leaks or faultymastercylinders.

o TemperatureSensors:Monitorbrakedisctemperature for overheating due to stuck calipers or excessive friction.

o Wear Sensors: Detect brake pad thickness to identify wornpads.

o Wheel Speed Sensors: Analyze wheel rotation for ABS (Anti-lockBrakingSystem)issuesorunevenbraking.

o Fluid Level Sensors: Monitor brake fluid levels to detectleaksorinsufficientfluid.

8.2.2. DataCollectionandProcessing:

Use a microcontroller (e.g., ESP32, Arduino, or Raspberry Pi) to collect sensor data. Implement algorithms to compare real-time data with predefined thresholdsforfaultdetection.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

8.2.3. FaultIdentification:

Use logic-based analysis or machine learning to localize specificfaults.

Examples:

o Pressuredrop:Leakingbrakelineormastercylinder issue.

o Uneven temperature: Warped rotors or stuck caliper.

o Lowwearsensorreading:Wornbrakepads.

Real-TimeDisplaySystem:

Use an LCD or touchscreen (e.g., TFT Display) to present: Currentsystemstatus. Identifiedfaultswithcomponent-specificalerts. Suggestedcorrectiveactions.

Hardware Components Sensors: Hydraulic Pressure Sensor:Detectfluidpressure(e.g.,Honeywell MPR series).

Temperature Sensor: Infrared or contact-based sensors(e.g.,LM35,MLX90614).

Wear Sensor: Optical or resistive wear sensors for brakepads.

Accelerometer:Measurevibrations(e.g.,MPU6050).

Processing Unit: Microcontroller: ESP32 (Wi-Fi + Bluetooth enabled). o Raspberry Pi (for advanced processingandGUIdevelopment).

DisplayUnit: TFTorOLEDDisplay:2.4" or3.5" for fault details and system status. Touchscreen Interface:Foruserinteraction

[3] Kumar, V., & Sharma, P. (2022). "Implementation of Real-Time Automotive Fault Detection System Using MATLAB Simulink." IEEE Xplore. DOI: 10.1109/ACCESS.2022.3149876

[4] Fuller, A., Fan, Z., Day, C., & Barlow, C. (2020). "Digital Twin: Enabling technologies, challenges, and open research."IEEEAccess.

[5] Liu, R., et al. (2019). "A Review of Machine Learning Methods for Fault Diagnosis in Braking Systems." JournalofIntelligentManufacturing.

I'mKiranGurav,anElectronics andTelecommunicationstudent fromKIT,Kolhapur. Passionateaboutautomotive electronicsandembedded systems.

9.

The proposed Simulink-based brake monitoring system effectively demonstrates real-time evaluation of critical automotive parameters temperature, brake fluid level, and brake pad wear. By using sensor inputs and logical conditions, the system provides accurate fault detection and status reporting. This simulation validates the feasibility of a model-based approach to predictive maintenance and enhances safety diagnostics. The results highlight the potential for integration into smart vehicle systemstoimprovereliabilityandearlyfaultawareness

[1] Ramesh, M., & Ramya, R. (2021). "Design and Simulation of Vehicle Health Monitoring System Using Simulink." International Journal of Engineering Research&Technology(IJERT),Vol.10,Issue5.

[2] Singh, A., & Verma, R. (2020). "Brake System Monitoring Using Smart Sensors." Journal of Automotive Safety and Reliability, Vol. 7(3), pp. 102-110.