International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Swaraj Bankar1 , Shubham Chavan2 , Yash Anerao 3

1 Prof. Kalpana Patil (Assistant Professor) (Department Of Civil Engineering, JSPM’s Rajarshi Shahu College of Engineering, Tathawade-411033, Pune, India) (Department Of Civil Engineering B. Tech, JSPM’s RSCOE, Pune, India)

Abstract - This project is all about creating eco-bricks from plastic waste and recycled construction materials like crushed concrete and sand. The research dives into how we can use plastic waste and crushed bricks from demolished buildings as sustainable alternatives to the usual building materials. By looking at the physical properties of these eco-bricks, the study showcases their strength, durability, and the positive impact they have on the environment. The goal is to lessen the environmental footprint of plastic waste and construction debris while providinga cost-effectiveandsustainable building option. The findings reveal that using recycled materials in brick production not only tackles the waste disposal problem but also helps reduce the need for natural resources, supporting circular economy practices. Additionally, the study assesses the economic viability of producing ecobricks, taking into account material costs, energy needs, and potential market demand. Overall, it shows that developing eco-bricks from plastic waste and recycled materials can play a significant role in promoting sustainableconstructionpractices.

Key Words: Eco-bricks, Plastic Waste Recycling, Recycled ConstructionMaterials,SustainableBuildingMaterials.

Foraconstructionmaterialtobetrulysustainable,itneeds to have four essential qualities: it should be environmentallyfriendly,structurallysound,cost-effective, andeasytoproduce.Whiletraditionalbricksareknownfor their strength, they also play a big role in depleting resources, consuming energy, and emitting carbon. That's whyeco-friendlyalternativesarestartingtocatchpeople's attention, especially those that use waste materials. Eco bricks, made from plastic waste and recycled construction debris like crushed bricks and artificial sand, present a promisingwaytotackletheseissues.

The modern construction industry is grappling with serious challenges like waste management, material shortages,andenvironmentaldamage.Plasticwaste,which doesn’t break down, piles up in landfills and oceans, creating significant environmental risks. At thesame time, if demolished construction materials aren’t reused, they

just add to urban solid waste. By incorporating this waste into brick production, we have a chance to turn environmentalproblemsintovaluableresources.

This study is all about figuring out how swapping out natural sand for crushed construction debris and plastic waste impacts brick performance. We’re looking at important factors like compressive strength, water absorption, density, and durability. Bricks face all sorts of physical and environmental challenges think moisture, temperature changes, and weight so what they’re made ofissuperimportantfortheirlong-termsuccess.

Waste-based bricks are particularly significant in areas where plastic use and construction are on the rise. By redirecting plastic and demolition waste away from landfills and using them in building materials, we’re promoting a circular economy. Plus, using these ecofriendly bricks in non-load-bearing roles, like pavements, partitionwalls,andruralhousing,canreallyhelplessenthe environmentalimpactofconstructionprojects.

While traditional bricks rely heavily on natural sand and clay,thisstudyisdivingintothepossibilitiesofsustainable alternatives that don’t sacrifice key engineering qualities. Successfullycreatingtheseecobrickscouldleadtogreener infrastructure, lower material costs, and better waste management making it a vital move toward sustainable developmentinourbuiltenvironment.

Dinesh S. and colleagues [1] took a closer look at how we can use waste plastic to make bricks and paver blocks. Their research laid out the specific mix ratios and casting methods for creating these plastic-infused bricks, highlighting how this approach not only reduces water absorptionbutalsoboostsstrength.Theypointedoutthat waste plastic serves as a binding agent and enhances the thermal resistance of the bricks, making it a promising alternativetotraditionalclaybricks.

Nitin Goyal and Manisha [2] delved into the use of ecobricks in contemporary construction. Their findings stressed the importance of substituting natural resources

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

withrecyclablematerialslikeplastictodevelopsustainable and budget-friendly building units. Their experiments showed that these eco-bricks achieved acceptable compressive strength and lower water permeability, proving their practicality for low-cost housing and nonload-bearingstructures.

Puttaraj M.H. and his team [3] carried out an in-depth experimental study on plastic-soil bricks by mixing waste plastic with different types of soil. They aimed to find the right balance of plastic content to maximize compressive strength while keeping water absorption low. The results suggested that bricks made from these plastic-soil blends could be ideal for pavement and partition wall uses, promoting environmental sustainability through effective wastemanagement.

Sharma and Bansal [4] conducted a thorough assessment ofhowplasticwastecanbeutilizedinbrickmanufacturing. Their research involved creating bricks with various proportions of plastic andevaluating theirperformancein terms of compressive strength and durability. The study confirmed that plastic bricks present a sustainable construction option, particularly in regions facing high plastic pollution and limited access to traditional raw materials.

Raut et al. [5] provided an extensive overview of bricks created from a variety of industrial and agricultural byproducts.Theirresearchgatheredinsightsonalternative buildingmaterials,includingbricksmadefromflyash,rice huskash,andmarbledust.Thestudyconcludedthatusing thesewastematerialsnotonlylessensenvironmentalharm but also improves the properties of bricks when designed withspecificmixes.

Gnanavel and Saravanakumar [6] zeroed in on creating sustainable bricks from plastic waste. They explored the thermal properties, weight reduction, and compressive strength of these plastic bricks. Their findings indicated that these bricks are lightweight, offer excellent thermal insulation, and are ideal for non-structural uses, thus supportingthesustainableconstructionmovement.

Kumar and Kaur [7] investigated eco-bricks made from plasticwasteandfoundrysand.Theirresearchlookedinto how foundry sand can partially replace traditional aggregates. The results showed that these eco-bricks can achieve the necessary compressive strength while providing a sustainable way to reuse both plastic and foundrywaste.

Khalidetal.[8]examined the useof recycledconstruction and demolition materials in brick production. Their study broughttogetherpreviousresearchonwaste-basedbricks, emphasizing the mechanical and physical properties of bricks made from concrete rubble, ceramic waste, and

plastic. The authors highlighted how these materials contribute to promoting circular economy practices in the constructionsector.

Singh and Siddique [9] assessed the structural characteristics of bricks made from plastic waste and quarrydust.Theirstudyfocusedoncompressivestrength, density, and water absorption across different mix ratios. The experimental results demonstrated that quarry dust improves the structural performance of plastic bricks, makingthemsuitableforlightweightconstruction.

1. To design and develop eco-bricks by partially or fully replacing natural sand with recycled construction materials such as demolished brick crush and artificial sand, along with plastic waste asabindingcomponent.

2. To prepare multiple mix proportions by varying the content of plastic waste and recycled aggregates and cast the brick specimens accordingly.

3. To evaluate the physical and mechanical properties of the developed eco-bricks, including compressive strength, water absorption, density, anddurability.

4. To compare the performance of eco-bricks with that of conventional clay bricks and cement-sand bricksbasedonstandardizedtesting.

Thermoplastic waste will be the main ingredient and binding agent in creating eco-bricks. This type of plastic waschosenbecauseitcanberecycledandmakesupabout 94% of the plastic waste in India. The process involves melting down the thermoplastic waste, which then wraps around and binds recycled construction materials like crushedbricksandartificialsand intoasolidbrickshape. By taking advantage of the unique properties of thermoplastics, these eco-bricks are expected to perform better,withlesswaterabsorptionandgreatercompressive strength. To maintain consistency in production, we’ll carefully identify and document the sources and specific typesofthermoplasticwaste,asillustratedinFigure1.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Thisresearchwilldelveintothepotentialofusingrecycled constructionmaterialsasanalternativetotraditionalsand. We’ll take a closer look at specific types of recycled materials, like crushed concrete and demolition waste, focusingontheiravailabilityandhowwelltheyfitthebill. The goal here is to embrace the principles of a circular economy by making use of waste products in the construction sector, which can help lessen our environmental footprint and reduce reliance on natural resources(asillustratedinFigure2).

4. 3 Water:

Watermaynotbeapartofthefinalbrickitself,butitplays acrucialroleincleaningupplasticwaste.

2.4 Equipment and Tools:

We'regoingtousesomestandardequipmentandtoolsfor brickmanufacturing,whichinclude:

A. Afurnace(Bhatti)tomeltdowntheplasticwaste.

B. Moldstogivethebrickstheirshape.

This approach takes a thorough, step-by-step look at how to research and develop eco-bricks, ingeniously using plastic waste as a binding agent. What makes it unique is its use of recycled construction materials, providing a sustainable and durable alternative to traditional sand. The whole process dives deep into the properties of variousmaterials,leadingtothedevelopmentofenhanced fabrication techniques. This is followed by rigorous performance testing and culminates in a comprehensive evaluation of both environmental and economic impacts. The ultimate aim is to create a genuinely viable and sustainableconstructionmaterialforthefuture.

1st. Material Sourcing and Preparation:

Collectionandsortingofplasticwaste;acquisition ofrecycledconstructionmaterials.

Processing of plastic waste (cleaning, shredding) andrecycledmaterials.

Preparation of any additional binding agent, if required.

2nd. Eco-Brick Manufacturing:

Developmentofmixdesignswithvaryingmaterial proportions.

Mixingandhomogenizationofthematerials.

Moldingandcompactionofthemixtureintobrick shapes.

Curingofthebricks.

3rd. Performance Evaluation:

Testingofphysicalproperties(dimensions,water absorption,density).

Testingofmechanicalproperties(compressive strength).

Assessmentofdurability(weatheringresistance).

4th. Data Analysis and Optimization:

Collectionandstatisticalanalysisoftestdata.

Comparisonwithconventionalbrickproperties.

5th. Reporting and Future Work:

Documentationofthemethodologyandfindings.

Recommendationsforfutureresearchand applications.

5.1 Analysis and design:

This section dives into the analysis of materials, the proposedmixdesign,andthekeydesignconsiderationsfor creating eco-bricks that use melted plastic waste as a binder and crushed recycled red brick as a substitute for sand.Theprocessinvolvesgettingagoodgraspoftheraw

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

materials' properties, figuring out the right mix proportionsbasedonISCode2212principles,designinga manual fabrication process with standard brick-sized molds, and outlining the quality control tests that will be carriedout.

MaterialAnalysis:PlasticWaste:Themainbinderforthese eco-bricks is melted plastic waste. It's important to document the specific type(s) of plastic being used (like LDPE,HDPE,PP,oramix).Theanalysisshouldcover:

Source and Collection: The plastic waste was collected through efforts aimed at roadsides, waste streams from hotels,anddiscardedmaterialsfromlocalmarketsinPune, asillustratedinFigure5.Thecollectedplasticrepresentsa post-consumerwastestream.

Cleaning and Preparation: The plastic waste we collected wentthroughadetailedcleaningandpreparationprocess. First off, we drained any water from the plastic items. Then,welettheplasticbaskinthesunforabout5hoursto help it dry out and maybe even kickstart some photodegradation, although that wasn’t our main goal. Aftersundrying,wemanuallytwistedtheplasticbottles our main type of collected plastic to shrink their size before sending them into a furnace (Bhatti) for melting. Inside the furnace, the plastic transformed into a thick, gooeysubstance,asyoucanseeinFigure6.

BinderProperties:Themeltedmixedplastic binder,which is sourced locally and prepared by cleaning, sun-drying, and heating twisted bottles, plays a vital role in creating

eco-bricks. Its hydrophobic qualities help keep water absorption to a minimum, while its adhesive andcohesive features effectively bind the crushed red brick aggregate. This results in a compressive strength that rivals that of traditional bricks. The binder's unique characteristics, shapedbythemixedpolymercompositionandthemelting process,areessential forthefinalstrength,durability,and overallpropertiesofthissustainablebuildingmaterial.

Recycled Construction Materials Crushed Demolished Red Brick: The manually crushed red bricks from demolished sitesserveasbothfineaggregateandsand.

Source: This crushed red brick material comes from construction sites in Pune that have been demolished, providing a valuable source of recycled aggregate and helpingtokeepwasteoutoflandfills.

The mix design for the eco-bricks was developed through experimentation, targeting a weight ratio of about 1 part meltedplasticwasteto4partscrushedbrickfineaggregate and 0.5 parts crushed brick sand. Although IS Code 2212: Code of Practice for Brickwork mainly focuses on clay bricks and their application in masonry, we took its core principlesintoaccountwhilefine-tuningtheseproportions to ensure we created structurally sound masonry units. Ouraimwastofindablendthatallowedthemeltedplastic to effectively bind with the crushed brick aggregate, resulting in a robust and long-lasting eco-brick. Each ecobrick weighs in at 2.280 kg,with the estimated weightsof itscomponentsdetailedinTable-1.

Table -1: Mix Design

Thisspecificratiomadeiteasytoworkwithduringmanual molding, leading to eco-bricks that had enough initial strengthforhandling.Weusedahigheramountofcrushed brick, which we sourced from demolished construction sites, to really make the most of recycled construction waste. The melted plastic serves as a matrix, holding everythingtogethernicely.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

RevisedMixDesignBasedona1:4:0.5Ratio:

Here’showwebreakdownthepartsbyweight:

•PlasticWaste:1x

•CrushedBrick(FineAggregate):4x

•CrushedBrick(Sand):0.5x

•Addingtheseupgivesusatotalof1+4+0.5=5.5parts.

Tofindtheweightofonepart(x),wecandothemath:

•x=TotalWeight/TotalParts=2.280kg/5.5=0.4145kg

Now, let’s figure out the approximate weight of each component:

•MeltedPlasticWaste(1part):1*0.4145kg=0.4145kg

•CrushedBrick(FineAggregate)(4parts):4*0.4145kg= 1.658kg

•CrushedBrick(Sand)(0.5parts):0.5*0.4145kg=0.2073 kg

Next,we’llcalculatethepercentageofeachcomponent:

• Melted Plastic Waste: (0.4145 kg / 2.280 kg) * 100% = 18.2%

• Crushed Brick (Fine Aggregate): (1.658 kg / 2.280 kg) * 100%=72.7%

• Crushed Brick (Sand): (0.2073 kg / 2.280 kg) * 100% = 9.1%

5.3 Molding Process:

Mold Description: The eco-bricks were shaped using standard molds that measure 19 cm x 9 cm x 9 cm (as shown in Figure 7). It's important to pay attention to the materialofthemoldaswell.

The molding technique began with melting down the preparedplasticwasteinafurnace.Afterthat,wemixedin manuallycrushedredbrickfineaggregatewiththemolten plastic, followed by a thorough blend of crushed red brick sand. This composite mixture was then carefully poured andpressedintomoldsthatarethestandardsizeforbricks (19 cm x 9 cm x 9 cm) to ensure proper compaction and shape. Finally, we let the bricks cool and solidify, as illustratedinFigure8.

8 Molding

Solidification/Cooling: Once the mixture was carefully pouredandcompactedintothemolds,wecappedthemoff andletthemsitundisturbedforavitalcoolingperiod.This important phase lasted about 3 to 4 hours. We chose this timeframetoensurethemoltenplasticbinderhadenough timetosolidifycompletely,givingtheeco-brickstheinitial strength and integrity they needed for a smooth and damage-freedemolding(asillustratedinFigure9).

Weputtheeco-brickswemadethroughaseriesofteststo seehowtheyheldup:

Hardness Test:

Procedure: We scratched the surface of the ecobrickswithafingernail.

Result: No marks were left behind, which shows theyhavegoodhardness.

Procedure:Weknockedtwoeco-brickstogether.

Result:Theydidn’tbreakandmadea niceringing sound,provingthey’resoundandintact.

Compression Strength Test:

MachineUsed:UniversalTestingMachine(UTM).

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

The compressive strength tests on the eco-brick samples using the Universal Testing Machine (UTM) gave us the followingmaximumfailureloads:

1. Specimen1:122kN

2. Specimen2:124kN

3. Specimen3:122kN

Tofindthecompressivestrength,wedividedthemaximum load at failure by the cross-sectional area of the brick. Following our method, the eco-bricks were shaped to standard dimensions of 19 cm x 9 cm x 9 cm. For the compressivestrengthtest,weusuallyapplytheloadonthe largerfaceofthebrick.So,wecalculatedtheloadedareaas follows:

A. Length=19cm=190mm

B. Width=9cm=90mm

C. LoadedArea(A)=Length×Width=190mm×90 mm=17,100mm²

Using the formula: Compressive Strength (σ) = Maximum Load (P) / Loaded Area (A), we calculated the individual compressivestrengths:

1. Specimen 1: σ₁ =(122kN ×1000N/kN)/17,100 mm²≈7.13N/mm²

2. Specimen 2: σ₂ =(124kN ×1000N/kN)/17,100 mm²≈7.25N/mm²

3. Specimen 3: σ₃ =(122kN ×1000N/kN)/17,100 mm²≈7.13N/mm²

Next, we found the average compressive strength of the eco-bricksbyaveragingtheindividualstrengths:

Averageσ=(7.13+7.25+7.13)/3≈7.17N/mm²

Thefollowingtablesummarizesthecompressivestrength testresultsfortheeco-bricks:

Table2:CompressiveStrengthTestResultsforEco-Bricks

The average compressive strength of 7.17 N/mm² for the eco-bricksshowsthattheyarequitesturdy,abletohandle heavy loads. This is especially exciting considering they’re madefromrecycledmaterials.Theresearchhighlightsthat thehydrophobicqualityofthemeltedmixedplasticbinder, along with its adhesive and cohesive traits, effectively holdstogetherthecrushedredbrickaggregate.Thisresults in a compressive strength that rivals that of traditional bricks. The measured strength of 7.17 N/mm² backs this up,providingsolidproofthatthemeltedplasticworkswell as a strong binding agent for the recycled aggregate. This showcases a successful material design where the natural properties of the binder lead to the desired mechanical performanceinthefinalproduct.

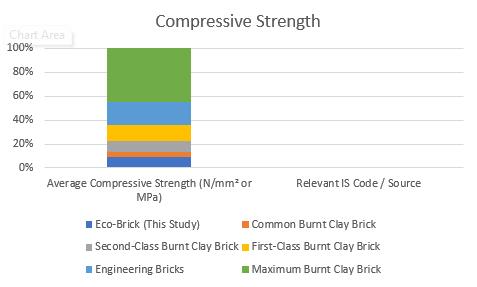

Table3:ComparativeCompressiveStrengthsofEco-Bricks vs.ConventionalClayBricks

BrickType/ Classification AverageCompressive Strength(N/mm²or MPa)

RelevantISCode /Source

Eco-Brick(This Study) 7.17 CurrentResearch

CommonBurnt ClayBrick Minimum3.5 IS1077:1992

Second-ClassBurnt ClayBrick Minimum7.0 IS1077:1992

First-ClassBurnt ClayBrick Approx.10.5(105 kg/cm²) IS1077:1992

EngineeringBricks Exceeds15 IS2185(Part 1):2005

MaximumBurnt ClayBrick Upto35 IS1077:1992

When we take a closer look, it’s clear that the eco-brick boastsanimpressiveaveragecompressivestrengthof7.17 N/mm², which is well above the minimum standard for typical burnt clay bricks at 3.5 N/mm². It also slightly surpasses the minimum for second-class bricks, which is 7.0N/mm²,andcomesprettyclosetothestrengthoffirstclass conventional bricks. This shows that eco-bricks not only meet but often exceed the strength requirements neededforavarietyoftraditionalbrickuses.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

The evaluation of eco-bricks fabricated from plastic waste and recycled construction materials unequivocally demonstrates their high compressive strength, with an average value of 7.17 N/mm². This performance notably exceeds the minimum strength requirements for common burnt clay bricks (3.5 N/mm²) and is comparable to or surpasses that of second-class conventional bricks (7.0 N/mm²), showcasing their suitability for a wide range of structuralapplications.

The successful development and validation of these highstrength eco-bricks represent a significant advancement towards sustainable construction practices. They offer a viable and effective solution for repurposing plastic waste and construction debris, thereby reducing reliance on virgin resources and actively promoting circular economy principles within the building sector. These findings stronglysupportthecontinuedresearch,development,and eventual widespread adoption of such innovative, ecofriendly building materials, paving the way for a more environmentally responsible and structurally sound constructionindustry.

The authors would like to extend their heartfelt thanks to Prof. Kalpana Patil, Assistant Professor in the Department of Civil Engineering at JSPM's Rajarshi Shahu College of Engineering in Pune, India. Her invaluable guidance, steadfast support, and insightful mentorship were crucial throughout this research journey. Her expertise and encouragementplayedakeyroleinhelpingussuccessfully completethisstudy.

[1].DineshS;DineshA;andKirubhakarank.,“Utilisationof WastePlasticinManufacturingofBricksandPaverBlocks”

International Journal of Applied Engineering Research, Vol.2(4),pp.364-368.

[2]. Nitin Goyal; Manisha., “Constructing structures using eco-bricks”, International Journal of Recent Trends in Engineering&Research.Vol.2(4),pp.159-164.

[3]. Puttaraj M.H; Shanmukha S; Navaneeth Rai P.G; and PrathimaT.B,“UtilizationofWatePlasticinManufacturing of Plasticsoil Bricks” International Journal of Technology Enhancement and Emerging Engineering Reshearch Vol. 2(4),pp.102-107

[4]. Sharma, U., & Bansal, P. (2021). Utilization of plastic waste in manufacturing of bricks – a sustainable approach. MaterialsToday:Proceedings,43,1993–1999.

[5]. Raut, S. P., Ralegaonkar, R. V., & Mandavgane, S. A. (2011). Development of sustainable construction material using industrial and agricultural solid waste: A review of waste-create bricks. Construction and Building Materials, 25(10),4037–4042.

[6]. Gnanavel, B. K., & Saravanakumar, R. (2020). Sustainable bricks using plastic waste. Materials Today: Proceedings, 33, 899–902. https://doi.org/10.1016/j.matpr.2020.03.717 [20] Pacheco-Torgal, F., & Jalali, S. (2011). Compressive strengthanddurabilitypropertiesofceramicwastes-based concrete.MaterialsandStructures,44(1),155–167.

[7]. Kumar, R., & Kaur, M. (2019). Performance of ecobricks made with plastic waste and foundry sand. International Journal of Engineering Research and Technology,8(12),491–496.

[8]. Khalid, F. S., Irwan, J. M., Othman, N., & Zahari, N. I. (2021). Recycled construction materials in bricks: A review.JournalofCleanerProduction,313,127933.

[9]. Singh, A., & Siddique, R. (2020). Properties of bricks made using plastic waste and quarry dust. Construction andBuildingMaterials,245,118424.