International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Ajith Krishnan K

(Lecturer, Department of Marine Technology, National College, Kerala, India) ***

Abstract – The biodegradable palm leaf cup making machine is developed to produce eco-friendly, disposable cups and plates from areca nut leaves.Theprocessincludewashing, soft

pneumatic configurations are available, with low power consumption and high productivity. The machine eliminates plastic usage. Addressing soil, water and air pollution concerns. The products are chemical free, hygienic, light weight, leak proof and capable of holding liquids for several hours. They are safe for micro wave and refrigerator use and can be molded into various shapes and sizes. The technology supports small-scale and cottage industries while offering sustainable, cost-effective alternative to plastic tableware for events, tourism hubs and religious gathering.

Key Words: Eco-friendly manufacturing, Sustainable disposable plates, Plastic waste reduction, Biodegradable tableware,Arecanutleafproducts

Leafcupsandplateshavebeentraditionallyhandcraftedin Indianvillagesforservingfoodduringmarriages,religious ceremonies and social functions. The introduction of machine-based production enable these products to be manufactured in uniform shape and size, enhancing dimensionalstabilitywhileremainhygienic,inexpensiveand biodegradable.

The market potential for biodegradable leaf plates is significant,withmorethan5000leafcupmakingmachines operatingacrossstateslikeUttarPradesh,MadhyaPradesh, Gujarat, Andhra Pradesh, Karnataka. Demand exists in hawkermarkets,starhotelsandmasscateringworks. The manufacturing process involves heating and pressing leavesusingmanually,hydraulicallyorpneumaticmachines, ensuringuniformity,durabilityandlowpowerconsumption. Post-use, the plates decompose naturally and supporting circulareconomy.

By replacing plastic disposables, especially in large gatherings and high-footfall religious events such as Sabarimala, this technology supports cottage industries whilecontributingenvironmentalpreservation.Continuous designimprovements,advancecuttingtechnologyandcost-

effectivemanufacturingfurtherenhancingproductivityand marketcompetitiveness.

Market research properly conducted and use on a regular basis is just valuable to manufacture. Technical research ensure the continued vitality of business market research may be defined asa organized approach which includeon researchactivitiesinvolvedinmarketingproblems.

Conductedapreliminarymarketsurveybyvisitinghousein bothruralandurbanareasandalsocarriedoutsomeshops. Theyallaregaveanideaaboutscoreofthisproject.Almost 92% of people really encourage preceding project. I have donemarketsurveyonAlappuzhadistrictandIgotaheartya acceptance of this project from people whosuffering from lack of disposable plate. I found that no other industry producingthisproductatthisarea.

Productanalysisiscarriedouttosimplifyproductlinesby eliminatingthosewhichhavealimiteddemandtodetermine the method of packing which may be accepted characteristics. If the customer knows the relative advantages of this product with the other, they will be persuadedtopurchasethisproduct.

The main objective of the market analysis is to find the locationofmarkets,scopeofscale,whoarethecustomers fortheproject,buyinghabitsofcustomersandpotentialof market for the product. The size of the industry has to be increasedwithdemandoftheproduct.

Thisconsistofthechannelsofdistributionmethodofpricing resale price maintenance, ware housing, distribution cost analysis and other policies and practices required for product distribution. The economical selection of the best channels of distribution for a product. It is essential to successinmarketanalysis.

Theaveragereturnexpectedabout20%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Thedryleavesarewashedandsoftenedbysoakinginwater for10to30minutes.Thelengthofthetimedependsuponthe typeofleaves.Thecorrectpointofdrynessisreachedwhen

Tubes are seamless steel precision pipes specially manufacturedforhydraulicsystems.Thestandarddiameter upto100mmandlengthis6m.Theyareinterconnectedwith flanges.

Theleafofadequatesizeissymmetricallyplacedonthebase plateabovethedieopeningandfootpedalispresseddown. Asitlowers,theholdingplateskeeptheleafinposition.The pedalisloweredfurtherholdingtheleavesinthispositionfor a short period (5 to 10 seconds for thin leaf and 20 to 30 seconds for thick leafs), not only dries and set the leaf in shape of die but also destroy the micro-organisms, thus makinghygienic.Bypressingthepedalwithajerk,thecutter incorporated in the machine trim the edges of the leaves. When the reversal operation of the pedal, the leaf cup is readyandcouldbeliftedoutbyhand.

Anoperatorusingthismachinecanproduce250to300cups perhourfromthinleavesandabout100cupsfromthicker leaves.

3.1

Itconsistsoftwooppositefacingpistonsurfacesthatcontrol theoperationofhydraulicfluids.Thistypeofcylinderwith linearmovementisespeciallysuitableforpressingoperation.

3.2 Die

Die is the core part of the machine. It is made up of aluminiumand its alloys. Itconsists of two parts;theyare separatelyheatedwithassistanceofheatingcoil.

Gearpumpsareusedinthissystemanditworkingagainst highmechanicalloadsoperatingupto200barswith3000 rpm. The pump may mount in any position. The units are suppliedwitheithertwoorfourboltflangesandwithaspigot location.Thefixturethatreceivesthemountingflangespigot chamferoensureproperinstallation.

Thevalveusedinthismachineis monoblocksinglespoon directional control valve. The maximum flow rate of this valveis40lpmandmaximumpressureis320bars.Ithasin builtreliefvalvesgivesadvantageofcostsavingandcompact. Speedcontrolispossibleforthistypeofvalve.Orientationis possible for valve handle and its sturdier and selectable length.

Athreephasemotorisusedfordrivingoilpumps.Here1hp motorisused

Itconvertselectricityintoheatthroughtheprocessofjoule heating. Elements are used nichrome 80/20 (80% nickel, 20%chromium).Heretwoheatingcoilsareused.

Forcontrollingheatingdiesinthemachineaheatregulatoris used.Automatictrippingmechanismisusedinthissystem.It ispreventingoverheatingofthesystem.

3.9 Tank

Itisusedtostorethehydraulicoil.Here6litercapacitytank isused.

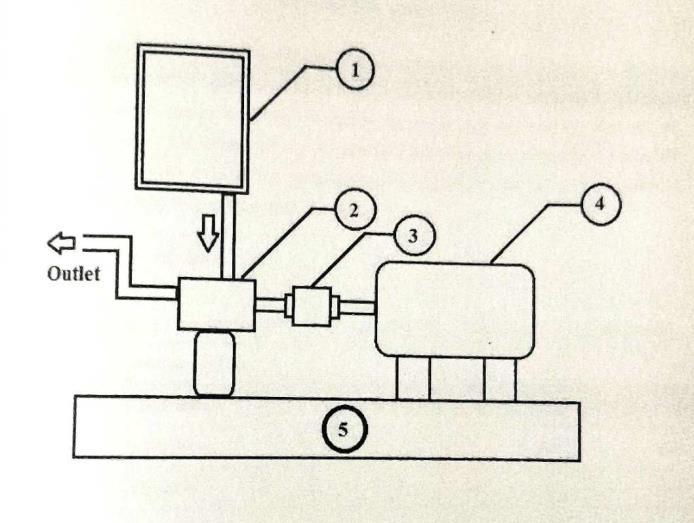

:HydraulicPowerPack

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Costingisthesystemofaccountingswhichaccuratelyrecords expenditureinordertodeterminethecostofmanufacturing aproduct.Itisverymuchessentialforefficientmanagement ofanenterprise.Inordertocomputethecostofeachfactors tobeconsideredarematerialcost,laborcostanddirectand indirect expenses. Estimating and costing of this leaf cup making machine is done very carefully by considering all elements.

Table -1: CostofTools

Table -2: CostofMachines

Table -3: OfficeExpenses

3.1 Selling Price Calculation

PrimeCost =DirectMaterialCost + DirectLabour Cost =35,000+1,000 =36,000

FactoryCost =PrimeCost+Factoryoverhead =36,000+205 =36,205

ProductionCost =Factorycost+Administrativeoverhead =36,205+50 =36,255

TotalCost =ProductionCost+SellingOverhead =36,255+20 =36,275

SellingPrice =TotalCost+Profit =36,275+13725 =50,000

3.2 Annual Production Cost

TotalSalaryexpenses =28,600

Cost

Rawmaterial/product =35,000

ofproducts/month =10

Totalcost =3,50,000

Costofpowerandwater =1,300 Rentofbuilding =3,000 Insurance =1,270 MaintenanceandRepair =

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Saleofproductperyear =110

Sellingprice/product =50,000

Turnover/year =55,00,000

Profit/product =13,725

NetProfit/year =15,09,750

NetProfitRatio =(NetProfit Year/Turnover)x100 =(15,09,750/55,00,000)x100 =27.45%

Table – 5: LabourCost

Table – 6: SalaryDetails

3.3 Fixed Capital

Costofmachinesandequipment =65,000

Electrificationcharge =18,000

Otherequipmentcharge =19,860

Securityforlandandbuilding =2,00,000

Firefightingequipment =5,000

Wasteremoving =3,000

Total =1,30,860

Workingcapital/year =3,67,887x12 =46,42,644

Returnoninvestment =(Netprofitperyear/Working capital)x100 =32.51%

Workingcapital/month =3,86,887

=

=Fixedcost/(SellingPrice–

=1,30,860/(55,000–48,000) =65Products BreakEvenPeriod =65/9 =

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Fig-2:BreakEvenAnalysis

FromBreakevenanalysischartweknowthatthebreak-even pointis65productsthatisafterselling65productswestart gettingprofit.

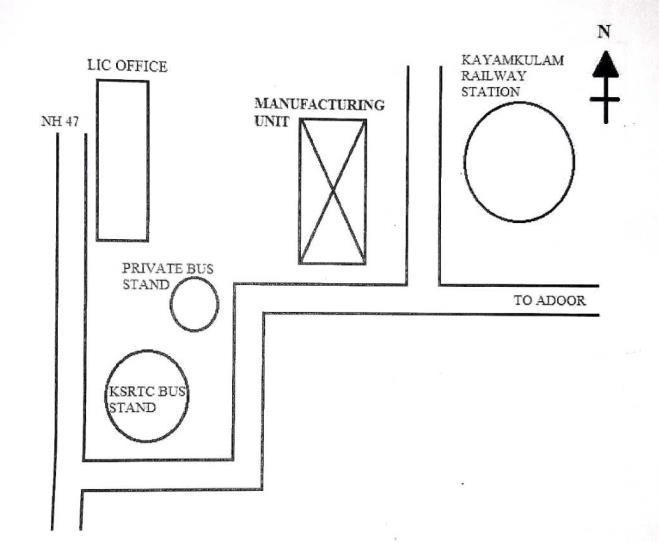

When it has been decided to start an industry, the most importantitemthatcallsourconsiderationistheselectionof suitablesiteforthefactory.Thesiteselectedforstartingthe industry is suburban area. This place got an advantage of both city and villages. Selecting this location based on technicalandfinancialaspects.TheFollowingfactorsforthe selectionofsite.

AvailabilityofRawmaterial

Nearnesstothemarket

Transportationfacility

Availabilityofcheapandefficientlabour

Availabilityofelectricityandwater

Properclimatecondition

Taxlocallawsandgovernmentcontrols

Localpeopleattitudeandco-operation

Afterthoroughlyconsideringalltheabovefactors,proposeda siteattheindustrialareaofKayamkulam.Forthegrowthof smallscaleindustries,governmenthaddeclaredsomeareas as industrial estates. Here government provides a shop buildingandlandatcheapratefortheindustrialunit.

Fromdesignoftheproduct,sheetmetalandmildsteelare important raw materials required for product. Since kayamkulam town is famous commercial center and can procure raw materials at cheap rate. Railway station and nationalhighwayisneartothesite.Sotransportationiseasy. FromthemarketsurveyIfoundthatproducthasverywide applicationintheneighborstateofkerala.Soitcanexportto otherstatesbyrailandroad.

Fig-3:SitePlan

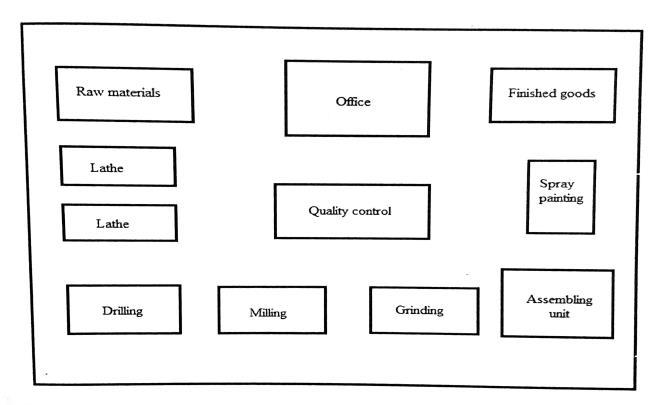

4.2 Plant Layout

Fig-4:PlantLayout

5. CONCLUSION

Thesuccessfulfabricationofahydraulicallyoperatedpalm leaf cup making machine demonstrates a viable and sustainable alternative to conventional single-use plastic products. By interchanging indigenous biodegradable materials with efficient hydroforming technology, the developedsystemensures enhancedproductivity,uniform product quality and reduce environmental footprint. A comprehensive market survey is confirmed significant demand potential, while the detail costing and estimation

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page138

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

established competitive pricing feasibility. Break-even analysis revealed favorable payback periods, affirming the economic viability of the proposed manufacturing setup. Furthermoresystematicsiteplanningensuresoptimalwork flow, resource utilization and scalability for industrial production. Overall this project is not only validates the technical and economic feasibility of palm leaf cup manufacturing but also contribute towards eco-friendly manufacturingpracticesalignwithglobalsustainabilitygoals.

[1]Yunus A. Cenegal, John M Cimbala, Fluid Mechanics, McGrawhilleducationprivatelimitedpublications.

[2]Danfoss,IndustrialhydraulicsManual,7th edition

[ ]M ’ H , 2 ,I P

[4]R.S.Khurmi&J.K.Gupta,AtextbookofaMachinedesign, Eurasiapublishinghouse,newdelhi

[5]P.S.Sudheer&M.N.Ramesh,ProcessingofArecaNutand ArecaLeafSheathsforvalueaddition,journaloffoodscience andtechnology,2002

[6] S. Senthil Kumar & M. Muthukannan, A study on propertiesofpalmleafasbiodegradablepackagingmaterial, IJIRSET,Vol.3,issue10,2014

[7] K.M.Suresh, S.A. Sreeram, R. M. Ramesh & R.R. Kumar, PhysicalandMechanicalpropertiesofarecapalmleafsheath, IJSER,Vol.5,Issue7,2014

[8] P.N.Rao, Manufacturing Technology, Vol 1&2, Tata McGraw-Hill

[9] Fisayo Adesina, Design and fabrication of a manually operatedhydraulicpress,ResearchGate

[10]O.P.Khanna,IndustrialEngineeringandManagement, DanpatRaiPublications

[11] Leland T. Blank & Antony J. Tarquin, Engineering Economy,McGraw=Hill,8th ed,2017