International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Shruti Sahu1, Vaishnavi Sonone2, Shravani Waghmare3, Amisha Hate4,Ruchika Gulhane5 , Prof. A. B. Pardikar 6

Department of Electronics & Telecommunication Engineering, Prof. Ram Meghe Institute of Technology and Research, Badnera, Maharashtra, India.

Abstract - The automatic fluid dispenser introduces a systematic and efficient alternative to manual fluid dispensing and expensive industrial systems like those from Nordson EFD. These high-end solutions, while precise, are often costly and lack flexibility, making them inaccessible for many applications. This project presents a cost-effective, microcontroller-based dispenser that accurately controls the speed and duration of a peristaltic pump to ensure precise, contamination-free fluid delivery. It is especially beneficial in sectors like pharmaceuticals, food and beverage, chemicals, cosmetics, and research, where accurate dosing is critical. By automating the process, it reducesmanualeffort,preventshealthrisks,ensuresquality, andminimizes resource wastage,offeringa reliable solution forprecisionfluiddispensing.

Key Words: Liquiddispensingsystems,peristalticpumps, LCD,motors,relays,liquidmedication.

Fluid dispensingis essential in many industries, including healthcare, manufacturing, and food processing, and cosmetics where precise and consistent liquid handling is critical. The traditional method of fluid dispensing is very time-consumingandprone tohuman errorsasit requires fluids are dispensed manually after measurement. The abilitytodispenseexactvolumesoffluidsimpactsproduct quality, safety, and efficiency, making it a key focus in settings that range from administering medications to applying adhesives in production lines. It also results in wastage of resources making the process inexpensive. Despite its importance, fluid dispensing faces several challengesthatcomplicateitseffectivenessandreliability. Water is vital for human survival, yet only 0.08% of Earth’sfreshwaterisaccessibleforuse[1].Risingdemand and shrinking resources have intensified global water scarcity. According to the International Water Management Institute, by 2025, most regions in Latin America,Asia,Africa,andtheMiddleEastmayfacesevere shortages [2]. Overexploitation, blocked basins, and poor management practices have further reduced water availability[3].Modernsolutionslikeagriculturalreforms and rainwater harvesting are urgently needed [4], especially as groundwater resources continue to decline [5]. Technological innovations such as coin-operated water dispensers help minimize wastage by enabling controlled and automated distribution [6] , and their

integration with cooling, heating, and plumbing systems enhances usability [7]. Available in various models like wall-mountedordirect-piping thesedispenserspromote hygiene and efficiency [8]. In small-scale industries, automation reduces human error, spillage, and delays common in manual bottle-filling processes [9]. With IoT advancements,smartsystemsnowenableapp-basedfluid dispensing, enhancing hygiene and minimizing contact [10].Forinstance,IoT-drivenmocktaildispenserscanmix drinks via automated pumps based on customer orders [11]. Juice mixer machines also reduce labor costs and improve accuracy by preventing over-pouring [12], while moreadvancedsystemslikeCAMSoffermodular,scalable cocktail automation with precise control [13]. In broader applications such as labs, households, and industries automated dispensers ensure consistent measurement and efficient operation [14]. Moreover, automated oil fillingsystemsaddressissueslikeleakageandinconsistent volumeinsmall-scaleproductionunits[15]

An automatic fluid dispenser is a device designed to dispenseaspecificamountoffluid,suchassoap,sanitizer, or other liquids, without manual intervention. These systems are often employed in public facilities, healthcare settings, and households to promote hygiene and reduce the spread of germs. With the advent of automation, fluid dispensers have evolved to include sensors, microcontrollers, and advanced mechanisms to enhance precisionandreliability.

Anita Joshi et al. [1] developed an Arduino-based automated liquid dispenser aimed at delivering precise liquid measurements using sensors, pumps, and valves. KiranPatiletal.[2]implementedasimilarsystemwithan IR sensor, solenoid valve, and pump to dispense accurate amountsofliquidefficiently.AyushVatsetal.[3]proposed a smart dispenser equipped with an LCD and Arduino, targeting safe and accurate fluid handling in medical applications. Chaitanya Salunkhe et al. [4] presented a customizablemulti-liquiddispenserusingmicrocontrollers andsolenoidvalves.KalpanaM.andSnehalB.[5]designed a smart beverage dispenser with Arduino and a GSM module to reduce manual intervention. Isha Sharma et al. [6] developed a voice-controlled dispenser using a voice recognition module, making it accessible for differentlyabledusers.PoojaPawaretal.[7]introducedanautomated

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

system with a user interface to select liquids and volume, operatedbysensorsandmicrocontrollers.SushantKadam etal.[8]builta juicedispenserwithArduinoandsolenoid valvestoeasebeverageservice.SarveshChaudharyetal.[9] created a drink mixer using Raspberry Pi and peristaltic pumps for precise ingredient blending. Tehreem Naeem [10] implemented a GUI-based flow control system using Arduino and a peristaltic pump for monitoring and controlling fluid dispensing. Sahil Bendale et al. [11] designed an IoT-based automatic mocktail maker with Bluetooth and flow mixer technology to ensure precision and avoid leakage. Naing Kyaw Soe [12] proposed a fivechannel juice mixer machine using gear pumps, allowing percentage-based or manual mixing options. Cameron Glass[13]introducedtheCocktailAutomationManagement System (CAMS), a scalable and modular solution that automates cocktail preparation using a central controller andingredientmodules.AnotherpaperbyAnitaJoshietal. [14] highlighted the use of Arduino in liquid dispensing withauser-friendlyinterfaceandsafetyfeatures.Lastly,S. Menaga et al. [15] developed an IoT-based automaticoil dispenserthatusessensorstomonitorquantityandshares stock information remotely, aiming for cost-effective and precisedispensinginsmallindustries.

Manual fluid dispensing often results in inaccurate measurements, leading to either wastage or insufficient application. Physical contact with manual dispensers increases the risk of cross-contamination and spread of infectious diseases. Inconsistent output from manual systemsreducesoperationalefficiencyandincreaseslongterm costs. There is a growing need for a hygienic, touchless dispensing mechanism, especially in healthcare andpublicsettingspost-COVID-19.

Existing manual methods are unsuitable for applications requiringprecision,suchaslaboratoriesandagriculture.

1. A reliable, low-cost automated system is required to provide consistent, safe, and user-friendly fluid dispensing.

2. Thegoalistodevelopascalablesolutionthatminimizes waste, enhances hygiene, and improves user convenienceacrossmultipleindustries.

4. PROPOSED SYSTEM

4.1 Components

LCD20x04 Display

The 20x4 LCD display is a versatile and cost-effective solution for visual output in embedded systems. It can show 20 characters per line across 4 lines, making it suitable for displaying more data compared to smaller

displays. Its ease of programming and ability to display custom characters and animations make it ideal for projectsrequiringaclearandcustomizableuserinterface

Hitachi HD44780-based LCDs use I2C piggy-back boards with the PCF8574 I/O expander for easy communication with microcontrollers. These boards simplify wiring by using only two I2C lines. The default I2C address is 0x27 forPCF8574Tand0x3FforPCF8574AT,assumingaddress pinsA0–A2areleftunconnected.

A rotary encoder is an electro-mechanical device that converts the angular position or movement of a shaft into digital oranalogsignals.Itiscommonlyusedforadjusting settings, navigating menus, or detecting rotation in applications like robotics, industrial controls, and user interfaces.Therearetwomaintypes:absolute,whichgives exact position, and incremental, which detects movement orspeed.

Aperistalticpump,alsocommonlyknownasarollerpump, isatypeofpositivedisplacementpumpusedforpumpinga variety offluids. The fluid is contained in a flexible tube fittedinsideacircularpumpcasing.Mostperistalticpumps work through rotary motion, though linear peristaltic pumps have also been made. Therotorhas a number of "wipers"or"rollers"attachedtoitsexternalcircumference, whichcompresstheflexibletubeastheyrotateby.

Peristalticpumpsmovefluidbycompressingaflexibletube with rollers, creating a peristalsis motion similar to biological systems like the gastrointestinal tract. This design ensures no direct contact between the pump and fluid. Kamoer's latest peristaltic pumps use a 24V DC supply, offer up to 360 ml/min flow rate, and support speed control via a PWM signal, making them ideal for cleanandpreciseliquidhandling.

CalculationofFlowrate:

Theoreticalflowrate(ml/min)

F=V*L*NRPM

Where,

V=volumeofocculatedtubing(mm/mm).

L=tubinglengththatwillbeoccludedbypumproll(mm).

N=numberofrollersontherotor.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

ChannelRelayBoard

Arelayisanelectricallyoperatedswitchthatcontrolshighvoltage devices using low-voltage signals. The 4-Channel Isolated5V10ARelayModulesupportsuptoAC250V/10A or DC 30V/10A per channel, with opto-isolation for safety and LED indicators. It works with 1.0V–5V inputs, making it compatible with Arduino, AVR, PIC, and ARM. Common uses include industrial automation, PLCs, and smart home systems.

DFPlayerMiniAudioModule

TheDFPlayerMiniisalow-cost,compactMP3modulethat supports direct speaker output and works standalone or with microcontrollers like Arduino via UART. It supports 8KHz–48KHz sampling, 24-bit DAC, FAT16/FAT32 file systems, and up to 32GB TF cards. Key features include a built-in 3W amplifier, multiple control modes, support for 100 folders (1000 files each), 30 volume levels, 10 EQ settings,andbackgroundaudiopauseforpromptplayback.

StepDownTransformer

Astep-downtransformerreducesACvoltageusingmutual induction, where the primary winding induces a lower voltageinthesecondarywinding.The2-0-122AmpCenter TappedTransformerstepsdown230VACto12V-0-12VAC. It features a center-tapped secondary, a high-permeability silicon steel core for efficiency, and is ideal for generalpurposeapplications

BridgeRectifier

A bridge rectifierconverts alternating current (AC) to direct current (DC) by using four diodes in a bridge configuration, ensuring current flows in one direction during both positive and negative half-cycles of the AC input.

VoltageregulatorIC’s

TheLM78XXseriesofthree-terminalpositiveregulatorsis available in the TO-220 package and with several fixed output voltages, making them useful in a wide range of applications. Each type employs internal current limiting, thermal shut-down, and safe operating area protection. If adequate heat sinking is provided, they can deliver over 1 A output current. Although designed primarily as fixed voltageregulators,thesedevicescanbeusedwithexternal componentsforadjustablevoltagesandcurrents.

CircuitDesign:

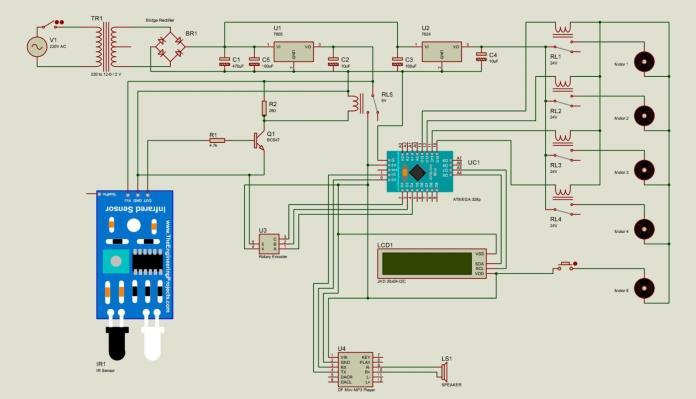

Fig -1:CircuitDiagram

Automaticfluiddispenserisasystemdesignedtodispense precise amounts of fluid across four channels using a peristaltic pump. It utilizes a rotary encoder to get input from the user, which helps to control the amount of fluid dispensed. ATMega328p acts as the central controller to manage the dispensing process, while an LCD display provides real-time feedback and control options for the user, along with audio feedback given by the machine to theuser.TheentiresystemhasinbuiltACtoDCconverting circuitry so, external it can be directly connected to 220v ACmainssupply.

Working:

The device is powered by an AC 220V supply, which is stepped down using a center-tapped transformer to 12-012VAC.ThisACoutputisthenrectifiedusingaFullBridge Rectifier and filtered by electrolytic capacitors to obtain a smooth DC voltage. Voltage regulator ICs 7805 and 7824 provideregulated5Vand24Voutputsforthecircuit.

Inidlecondition,thesystemremainsinsleepmode.When a glass is placed on the holder, an IR sensor detects its presence and activates the relay, powering the entire circuit.AnLCDgreetstheuserandaDFMiniplayerplaysa welcome audio clip. The LCD then prompts fluid selection startingfromFLUID1.Theusercanrotatearotaryencoder to select the desired quantity (e.g., 60 ml) and press the encodertoconfirmandmovetothenextfluid.Thisprocess continuesuptoFLUID4.

After finalizing the input, a “THANK YOU!” message is displayed,andanexitaudioisplayed.Themicrocontroller processestheselectedquantitiesandsequentiallyactivates thecorrespondingrelaystocontrolfourperistalticpumps, dispensingeachfluidinthespecifiedamount.TheDFMini player is also controlled via UART to play appropriate audioprompts.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Once dispensing is complete, if the glass remains on the holder, the system returns to the selection screen. If the glass is removed, the system goes back to sleep mode to conserve power. A stirring mechanism is also provided, whichcanbemanuallyactivatedusingaswitchtomixthe dispensed fluids. Fluid input tubes are connected at the back, and all outputs are channeled through a single dispensing nozzle equipped with an IR sensor above the glassholder.

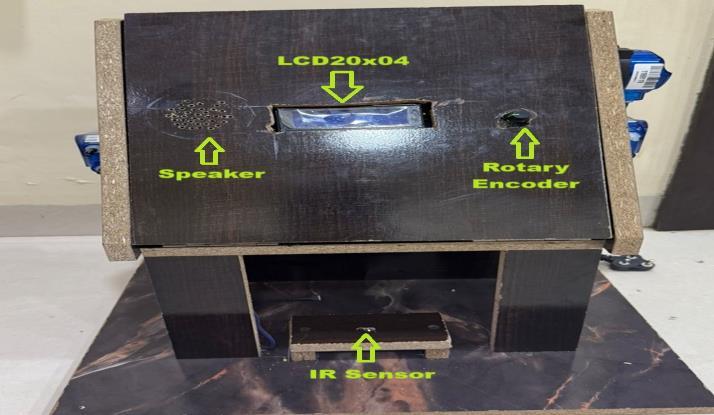

4.3 Actual Enclosure

5. ADVANTAGES AND USE CASES

The automatic fluid dispenser ensures accurate and consistentfluiddeliverywithadjustableflowrates.Itoffers real-time feedback, manual control options, and audio alerts to improve user interaction and operational reliability.Thesystemislow-power,easilyprogrammable, andsupportsadditionalfeaturesliketimeddispensingand batch modes, making it suitable for compact and costeffectiveapplications.

Typical use cases include medical dosing, reagent mixing, foodandbeveragedispensing,personalcareproductfilling, and industrial fluid handling. It also supports automated soapandcleaningdispensersforhygieneandmaintenance applications

Based on the specifications of the peristaltic pump, which has a flow rate of 560 ml/min , the system is expected to dispensefluids accuratelyand efficiently withina rangeof smalltomoderatevolumes.

Forex:-

Theestimationtimetodispense100mlis~10.7seconds.

The estimated time to dispense 250 ml should be ~ 26.8 seconds.

The system is anticipated to achieve a high degree of accuracy, witha margin of error ± 5%, ensuring that even smallquantitieslike50ml,aredispensedreliablywithina range of 47.5 ml -52.5 ml. Once implemented,the systems isprojectedtobecapableofefficientlydispensingvolumes ranging from 10 ml to 500 ml, making it suitable for diverse applications. These theoretical results provide a strongfoundationforfurthertestingandoptimizationonce theprototypeisfullydeveloped.

The project successfully demonstrates the design and implementation of an automatic fluid dispenser system leveraging the ATmega328P microcontroller. The system combines precision hardware components such as peristalticpumps,IRsensors,androtaryencoders witha user-friendly interface provided by the LCD display and DFPlayerMiniforaudiofeedback.

The dispenser operates efficiently in various fluid dispensingscenarios,makingitsuitableforapplicationsin industriessuchaspharmaceuticals,foodandbeverage,and chemicalprocessing.

Advanced fluid dispensing systems are evolving with the integration of modern technologies. IoT enables remote control and real-time monitoring via Wi-Fi or Bluetooth modules. AI and machine learning allow predictive maintenance and smart dosage adjustments. Multi-fluid dispensershandleseveralliquidssimultaneously,usefulin medicalandchemicalapplications.Energy-efficientdesigns include battery-operated and solar-powered models for portability and off-grid use. Advanced sensors improve accuracyandsafetybymonitoringflow,pressure,andfluid type.Thesesystemsarealsoessentialinautomatedlabsfor

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

high-throughputscreeningandinindustrialautomationfor precise,large-scaleliquidhandling.

[1]AnitaJoshi,LavanyaVeni,PranavVibhute,VirajZende, Vishwajit Virkar, Anvesha Vyas, Vyomkesh Vyas, “Liquid Dispenser”, Monthly Journal for Electronics and CommunicationEngineering,November2024.

[2] Lavanya, Dr. S. Sivasankari, R. Keerthana, “Automatic Juice Vending Machine Using Arduino”, International Research Journal of Engineering and Technology (IRJET), 2019.

[3] Samiksha Rajendra Jadhav, Shubhangi Suresh Shinde, “Automatic Juice Vending Machine Using Arduino”, International Research Journal of Engineering and Technology(IRJET),2019.

[4] V. Prathiba, A. Revathy, K. Rajalakshmi, M. Yamuna, “Semi-Automatic Juice Vending Machine Using Arduino”, International Journal of Innovative Research in Science, EngineeringandTechnology(IJIRSET),2020.

[5]AnusayaS.,DivyaBharathiT.,GomathiR.,Haripriya S., Janani S., “Multipurpose Drink Dispenser Machine Using Arduino and GSM”, International Journal of Engineering Research&Technology(IJERT),2020.

[6]K.VamsiKrishna,D.SainathReddy,N.AravindKumar, “Automatic Juice Vending Machine Using Raspberry Pi”, International Journal of Scientific Research and Review (IJSRR),2021.

[7]AkshayArora,DevanshMaheshwari,NamanJain,“IoTBased Automatic Water and Beverage Dispenser”, International Journal of Engineering and Advanced Technology(IJEAT),2021.

[8]M.Kowsalya,K.Kiruthika,P.Anitha,“SmartAutomatic JuiceVendingMachineUsingIoT”,InternationalJournalof EngineeringResearch&Technology(IJERT),2021.

[9]MaheshJ.Gadekar,AmolA.Dudhe,AvinashK.Thakare, “Fruit Juice Vending Machine Using Arduino Uno”, International Journal of Innovative Research in Science, EngineeringandTechnology(IJIRSET),2020.

[10] Tehreem Naeem, “Arduino Based Automated Flow Control System”, International Journal of Scientific ResearchandEngineeringDevelopment(IJSRED),2020.

[11] Sahil Bendale, Apurva Choudhari, Pratiksha Patil, Guruprasad Mane, Alveera Nadaf, “IoT Based Automatic Mocktail Maker”, International Journal of Innovative Research in Engineering & Multidisciplinary Physical Sciences,April2022.

[12]NaingKyawSoe,“DesignandImplementationofJuice Mixer Machine”, International Journal of Scientific and Research Publications (IJSRP), Volume 8, Issue 7, July 2018.

[13]Cameron Glass, “Cocktail Automation Management System – A Design Project Report”, Cornell University, 2014.

[14]AnitaJoshi,LavanyaVeni,PranavVibhute,VirajZende, Vishwajit Virkar, Anvesha Vyas, Vyomkesh Vyas, “Liquid Dispenser”, Monthly Journal for Electronics and CommunicationEngineering,November2024.

[15] S. Menaga, A. Gunavathi, J. Malarvizhi, Manigandan, “IoTBasedAutomatic OilDispenser”,International Journal ofEngineeringResearch&Technology(IJERT),July2021.