International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Ninad Navale, Shreyash Musmude, Revansidh Nagure, Parag Lad, Dr. S.V. Chaitanya

Department of Mechanical Engineering, AISSMS College of Engineering, Kennedy Road, Near RTO, Pune – 411001, Maharashtra, India

Abstract - The increasing demand for automation in the pharmaceutical industry has led to the development of specialized robotic systems aimed at improving efficiency, consistency, and hygiene. This project presents the design and development of a five-degree-of-freedom (5-DOF)roboticarm tailored for pick-and-place operations of capsule bottles. The primary objective is to automate repetitive, precision-based tasks in pharmaceutical packaging processes while adhering to hygiene and safety standards. The design process began with a comprehensive requirement analysis covering dimensions, weight, and handling constraints typical of capsule bottles. Based on workspace requirements and costefficiency, a 5-DOF configuration was selected to ensure sufficient reach and orientation control. The mechanical structure was developedusingkinematiccalculationsandCAD modeling in CATIA, with materials chosen for lightweight strength. Servo motors were integrated with an Arduino Uno microcontroller and a custom control algorithm to enable smooth actuation. Components were 3D printed for rapid prototyping and assembled with high alignment accuracy. A specially designed gripper ensured gentle,contamination-free handling of bottles. The system was tested for accuracy, repeatability, cycle time, and load performance. A clear work envelope was identified, andunreachablezoneswereanalyzed for future improvement. The final prototype successfully demonstrated reliable pick-and-place of 100g capsulebottles, validating the approach. This project offers a modular, costeffective solution for small-scale pharmaceutical automation, and serves as a scalable foundation for future robotic systems in regulated cleanroom environments.

RoboticArm,5-DOF,PickandPlace,Pharmaceutical Automation,ArduinoUno,ServoMotor,3DPrinting, CATIA

Therapidadvancementoftechnologyinthefieldofrobotics hasopenednewfrontiersforautomation,enablingmachines to perform tasks with precision, consistency, and speed. Among various robotic applications, robotic arms play a criticalroleinindustriessuchasmanufacturing,healthcare, andresearch.Thesearmscanbeprogrammedtoreplicate human motions, offering efficiency in repetitive tasks, increased accuracy in delicate operations, and enhanced safetyinhazardousenvironments.

***

Thisprojectaimstodesignanddevelopafunctionalrobotic arm with multiple degrees of freedom (DOF) capable of performing complex tasks like picking, placing, and manipulatingobjects.Theroboticarmisaversatiletoolthat can be adapted for various purposes, including industrial automation,medicalsurgeries,andeducationalplatformsfor studentsstudyingroboticsandcontrolsystems.

The core motivation behind this project is the growing demandforautomationsolutionsthatreducehumaneffort, improve precision, and operate in environments where humanpresenceiseitherunsafeorinefficient.Byintegrating mechanical design, electronics, and software, this project explores the development of an affordable and scalable roboticarmsolution.

The design and development of this robotic arm follow a systematicapproach,beginningwithathoroughanalysisof the mechanical structure and movement mechanisms, followed by the selection of electronic components, programming, and testing. This report details the entire process, highlighting the challenges encountered and solutionsimplemented.

A robotic arm for pick-and-place of capsule bottles is an automated electromechanical systemdesignedtoidentify, grip,lift,transport,andplacecapsulecontainersfromone location to another within a predefined workspace. It is developedtoautomaterepetitiveandlabor-intensivetasks commonly found in pharmaceutical manufacturing and packaging lines. This robotic system consists of key components including mechanical joints (for motion), actuators (to drive the joints), an end-effector or gripper (custom-designed to hold capsule bottles), sensors (for object detection and feedback), and a microcontroller (to controlthearm’sactionsthroughprogrammedinstructions).

Therobotfunctionsontheprinciplesofrobotickinematics, dynamics,andcontroltheory.Theend-effectorisdesignedto adapt to the size and shape of capsule bottles, ensuring securehandlingwithoutcausingdamageorcontamination. Thearmexecutesaprogrammedmotioncyclethatincludes identifying the position of a bottle, reaching toward it, graspingitusingagripper,liftingittoatargetheight,and placingitaccuratelyatthedesiredlocation.Thisprocessis repeatableandcan be enhancedusing visionsystemsand industrialautomationprotocols.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Atypicalroboticarmforthisapplicationincludes:

Links: Rigidstructuralmembersoftherobot.

Joints: Connections between links that allow relative motion.Thesecanberevolute(rotational)orprismatic (linear).

Actuators: Motors (electric, pneumatic, or hydraulic) thatdrivethejointstocreatemotion.

End-Effector (Gripper): The part of the robot that interacts with the capsule bottles. For delicate and consistent handling, specialized grippers designed for cylindricalorirregularlyshapedobjectsareused.These mightemploypneumatic,mechanical,orvacuum-based mechanisms.

Sensors: Various sensors provide feedback to the controlsystem.Thesecaninclude:

o Encoders: Tomeasurethepositionandvelocityof thejoints.

o Force/TorqueSensors:Todetecttheforceapplied by the gripper, ensuring a secure grip without damagingthebottles.

Vision Systems: Camerascanbeusedtoidentifythelocation and orientation of the capsule bottles, especially in less structuredenvironmentsorwhendealingwithvariationsin bottleplacement.

Gentle Handling: Capsulebottles,especiallyiffilled,can be fragile. The robotic arm and gripper must be designed to apply appropriate gripping force without crushingordamagingthebottles.

Precision Placement: Depending on the subsequent packaging or labelling processes, accurate and consistentplacementofthebottlesisoftenrequired.

Speed and Efficiency: In high-throughput pharmaceuticalmanufacturing,theroboticarmneedsto performpickandplaceoperationsquicklyandreliably tomaintainproductionrates.

Hygiene and Sterility: In pharmaceutical environments, maintaining cleanliness is paramount. Theroboticarmshouldbedesignedwithmaterialsand surfacesthatareeasytocleanandsterilize.

The significance of developing a pick and place robotic arm for capsule bottles liesinitsdirectcontributiontothe modernization and automation of pharmaceutical productionlines.Keyaspectsofitsimportanceareoutlined below:

i. ImprovedPrecisionandEfficiency

Manualhandlingofcapsulebottlescanresultininconsistent placement, human fatigue, and errors. A robotic arm can perform the same task with consistent accuracy, ensuring each bottle is placed correctly every time. This increases overallefficiencyandthroughput.

ii. ReducedHumanInvolvementinSensitiveAreas

In pharmaceutical industries, hygiene and contamination controlarecritical.Automatingthepick-and-placeoperation helpsreducehumaninteraction,therebyminimizingtherisk of contamination and ensuring compliance with Good ManufacturingPractices(GMP).

iii. EnhancedWorkplaceSafety

By assigning repetitive or potentially hazardous material handling tasks to a robot, worker safety is improved. Employeesaresparedfromrepetitivestraininjuriesandcan focusonhigher-levelmonitoringandcontrolactivities.

iv. ScalabilityandFlexibility

Theroboticarmsystemcanbeprogrammedorupgradedto handlebottlesofvarioussizesortoaccommodatechangesin the production layout. This makes the system highly adaptable and future-proof in dynamic manufacturing environments.

v. 24/7OperationandLabourCostReduction

Unlike human workers, robots can operate continuously without fatigue, breaks, or shifts. This enables round-theclockproductionandreducesdependenceonmanuallabour, leadingtolong-termcostsavingsandoperationalstability.

vi. EducationalandResearchValue

From an academic perspective, this project serves as an excellent platform to understand and implement interdisciplinary concepts including mechanical design, electronics, and programming, automation, and control systems. It prepares students for real-world industrial challengesandencouragesinnovation.

vii. Industry4.0Alignment

Thisprojectsupportstheshifttowardsmartmanufacturing andIndustry4.0, wheredata-drivenautomation,robotics, andintelligent control systemsare central to productivity andinnovation.

i. Develop a prototype of a 5-DOF robotic arm for handling capsule bottles in a pharmaceutical setting.

ii. Study existing robotic arm systems and their functionalrequirements.

iii. Understand industry needs, bottle dimensions, weightlimits,andsafetyregulations.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

iv. Designa 5-DOFroboticarm basedonoperational constraintsandcapabilities.

v. Perform mechanical and kinematic design calculations.

vi. Develop a CAD model of the robotic arm using suitablesoftware.

vii. Selectappropriatematerialsandactuatorsforthe armstructureandmotion.

viii. Fabricateaworkingprototypeoftheroboticarm.

ix. Developandintegrateacontrolsystemforprecise movement.

x. Definetheroboticarm’sworkenvelopeandidentify anyunreachable(dead)zones.

1. ProblemDefinitionandRequirementAnalysis

Adetailedanalysiswasconductedtounderstandthe pharmaceutical packaging process, including bottle dimensions,handlingrequirements,andoperational constraints. This step ensured that the robotic arm design would align with industry standards and hygienerequirements.

2. Research on Existing Robotic Systems

Existingroboticarmmodelsandconfigurationswere studiedtoidentifycommonfeatures,limitations,and performance benchmarks. Particular attention was paid to similar 5-DOF systems used in industrial automation.

3. Kinematic and Dynamic Calculations

The workspace, degrees of freedom, and range of motion were analyzed throughkinematic equations. Inverseandforwardkinematicswereusedtoensure thattheroboticarmcouldreachtherequiredpositions andorientations.

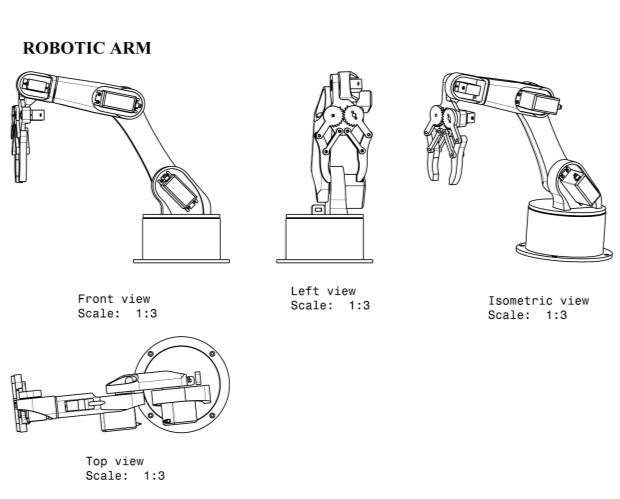

4. CAD Modeling

Adetailed3Dmodeloftheroboticarmwasdeveloped using CATIA software. This included all links, joints, base,andgripper,allowingforvirtualsimulationand refinementbeforephysicalfabrication.

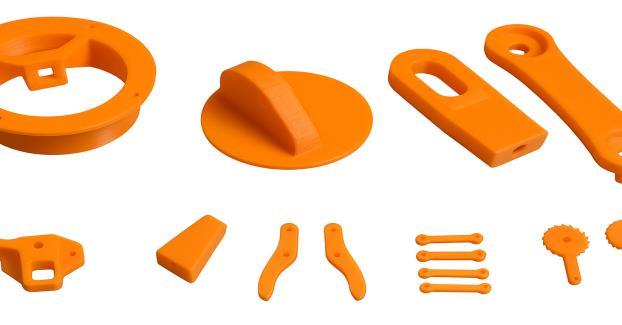

5. Material and Component Selection

Based on strength-to-weight ratio, availability, and cost, suitable materials (such as PLA or ABS for 3D printing)andactuators(servomotors)wereselected. The Arduino Uno microcontroller was chosen for controllogicimplementation.

6. Prototype Fabrication

All components were 3D printed and assembled to construct a functional prototype. Alignment and fitment checks were conducted to ensure smooth operation.

7. Control System Development

8. Testing and Validation

The robotic arm was tested for parameters such as accuracy, repeatability, speed, load capacity, and ability to handle 100g capsule bottles. Observations helpedinidentifyingunreachablezonesandrefining motionparameters.

9. Analysis and Documentation

Results from the testing phase were analyzed to evaluateperformance.Keyinsightsweredocumented forfutureenhancements,especiallyforscalabilityand integrationwithvisionsystems.

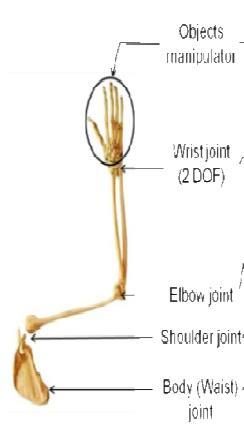

Figure 1: Arm Terminology

Table 1: Component Description

6 Servo Housings Motorsupports integratedintolinks Customfit

7 Fasteners Mechanicaljoiningof parts M3–M4standard sizes

Thepurposeofkinematicanddynamicanalysisistoverify whethertheroboticarmcanachievetherequiredmotion andtoensurethattheactuatorscanhandletheloadwithin safe operational limits. Full calculations have been

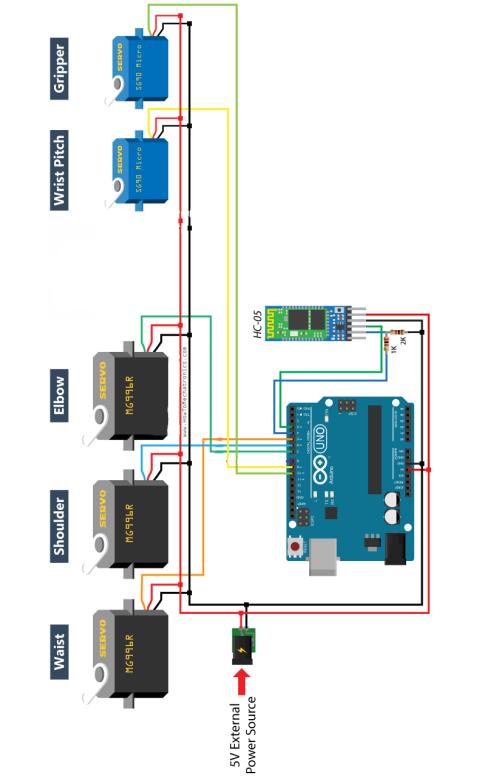

A control algorithm was programmed in C++ and uploadedtotheArduinoUno.Thecodehandledservo actuation for each joint, allowing for smooth and accuratemovements.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

performed considering actual link dimensions, mass properties,andmaterialconstraints(ABSPlastic).

Robot Specifications

Material:ABSPlastic(Density=1040kg/m³)

Link1Length(L₁):162mm=0.162m

Link2Length(L₂):161mm=0.161m

Gripper:60mmspan

Payload:100grams=0.1kg

Baseheight(d₁):56mm=0.056m

Gravity(g):9.81m/s²

Assumethecross-sectionofthelinksasrectangular(15 mm×15mm)andhollowwith2mmwallthickness.

Mass Calculation of Links

Cross-sectionalarea(A)ofhollowsquaretube:

A=(40×20)−(35×15)mm2 =275mm2=275×10−6m2

Volume(V)ofeachlink:

Link1:

V1=A×L1=275×10−6×0.162=4.45×10−5m3

Link2:

V2=A×L2=275×10−6×0.161=4.43×10−5 m3

Mass(m)ofeachlink:

Link1:

m1=V1×ρ=4.45×10−5×1040=0.0462 kg

Link2:

m2=V2×ρ=4.43×10−5×1040=0.046 kg assumingmassofENDEFECTORas: 0.035kg

Thus,thelinksareextremelylightweightdueto3D printing.

Maximumreach(frombasetoend-effector):

Rmax=L1+L2+GripperLength

=0.162+0.161+0.145 =0.468m

ApproximateWorkspaceVolume(hemisphere assumption):

Volume=2/3πR3

=2/3×3.1416×(0.468)3

=2/3×3.1416×0.1025

Volume V =0.214m3

Static Torque Calculation

Forceduetopayload:

M=m1+m2+payload

M=0.0462+0.046+0.1

M=0.192

Fpayload=M×g=0.192×9.81

=1.885N

TorqueatBaseRotation

Torquegeneratedbythepayloadatfullextension(0.468 m):

τ1=Fpayload×Rmax =1.885×0.468 =0.882Nm

Thus,TorqueatBaseRotationresist0.882Nmminimum. TorqueatJoint1(ShoulderJoint)

Sumofmomentsduetolinkmassesandpayload: DistanceofLink1centerofmass=0.081m

DistanceofLink2centerofmass=0.080+0.162= 0.242m(link1+halflink2)

DistanceofGrippercenterofmass=0.242+0.072=0.395 m(link1+link2+halflink3)

DistanceofPayload=0.468m

Now,calculatingindividualmoments: MomentduetoLink1:

M1=m1×g×r=0.0462×9.81×0.081=0.0367Nm

MomentduetoLink2:

M2=m2×g×r=0.046×9.81×0.242=0.109 Nm

MomentduetoGripper:

M3=m3×g×r=0.035×9.81×0.395=0.135 Nm

MomentduetoPayload: Mpayload=0.1×9.81×0.468=0.459 Nm

TotaltorqueatJoint2:

τ2=M1+M2+M3+Mpayload

=0.0367+0.109+0.135+0.459 =0.739 Nm

Thus,Joint2requires0.739 Nmtorque. TorqueatJoint2(ElbowJoint)

Attheelbow,Link3andpayloadcreatethetorque: Calculatingmoments: MomentduetoLink2:

M′2=m3×g×0.08=0.046×9.81×0.08=0.03613Nm

MomentduetoGripper:

M′3=m3×g×r=0.035×9.81×0.233=0.080 Nm

MomentduetoPayload: M′payload=0.1×9.81×0.306=0.300Nm

Totaltorque:

τ3=M′3+M′payload =0.03613+0.080+0.300 =0.416 Nm

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Thus,Gripperrequires0.416Nmtorque.

TorqueatWristJoint Payloadat0.1mfromelbowjoint.

Calculatingmoments:

MomentduetoWristJoint:

M′′3=m3×g×r=0.035×9.81×0.0725=0.0248 Nm

MomentduetoPayload:

M′′payload=0.1×9.81×0.145Nm

=0.0497Nm

Totaltorque:

τ3=M′′3+M′′payload

=0.0248+0.0497

=0.0745 Nm

Thus,Endeffectorrequires0.0745Nmtorque

TorquecalculationforGripper

Distancefromtheservoshafttogrippertip=0.0725m

Massofgripper=0.035kg

TotalMass,M=0.1+0.035

=0.135

GrippingForce=(M×g)/(NumberofFingers× CoefficientofFriction)

(CoefficientoffrictionforABSmaterialwouldbe0.6)

=(0.135×9.81)/2×0.6 =1.103N

Torque=GrippingForce×Distance

τ=F×D

=1.103×0.0725

=0.080Nm

Thus,Gripperrequires0.080Nmtorque

Servo Motor Selection

2:

8) Design Considerations and Constraints

Beforecomponentselection,itwasessentialtodefinethe boundaryconditionsandfunctionalneedsfortherobotic arm:

Table 3: Design Considerations

Parameter Specification

Payload Upto100grams

Reach Approximately400mmtotal

DegreesofFreedom (DOF) 5

OperatingTemperature 20°C–50°C(ambientindoor)

PowerSource 12V5ADCAdapter

ManufacturingMethod FDM3DPrinting(ABSMaterial)

ControlType OpenLoop(servo+ Microcontroller)

ApplicationEnvironment CleanPharmaceuticalLaboratory

Constraints:

Minimizeweighttoreduceactuatorload.

Ensuremodularityforeasymaintenanceand upgrades.

Ensurecompatibilityofmechanicallinkageswith motortorquecapabilities.

Costshouldbeoptimizedforprototypingwithout sacrificingreliability.

8.1 Structural Material Selection

Table 4: Structural Material Properties

Property

Density

TensileStrength

ImpactStrength

MeltingPointRange

Reasons for Selection:

Strength-to-WeightRatio:Suitableforlight-load structuralapplications.

ImpactResistance:Preventsbrittlefailureduring handlingoperations.

Easeof3DPrinting:Excellentlayeradhesionand minimalwarping.

DimensionalStability:Importantformaintaining accuracyoftheendeffectorpath

8.2 Why Use of Servo Motors in Robotic Arm Design?

1) Closed-LoopControl(withFeedback)

Servomotorsuseencodersorsensorsforposition and speed feedback, making them accurate and reliable.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Theycancorrecterrorsinposition,whichiscritical in precision tasks like picking up or assembling parts.

2) HighTorqueatHighSpeeds

Servo motors maintain torque even at higher speeds,allowingforfaster,smoothermovement.

Incontrast,steppermotorslosetorquerapidlyas speedincreases.

3) EfficientandQuiet

Servosaremoreenergy-efficientandrunquietly.

Steppermotorsgeneratemoreheat,consumemore power, and often produce vibrations or noise, especiallyunderload.

4) SmoothMotion

Servosprovidesmoothandcontinuousmovement, ideal for robotic arms requiring fluid motion and finepositioning.

Steppermotorsmoveindiscretesteps,whichcan resultinjerkymovement,especiallyvisibleinslow motion.

5) LoadHandlingandStallRecovery

Servos can detect overloads and adjust or stop, preventingmechanicaldamage.

Steppers can miss steps silently under too much load this can accumulate errors without detection.

8.3 TowerPro

Item Type: TowerPro Servo Motor

Rotation(Degree): 360

TorqueRating(kg-cm): 9.4to15.3

ModelNo.: MG996R

OperatingVoltage(VDC): 4.8~6.6

OperatingSpeed@4.8V 0.19sec/60°

OperatingSpeed@6.6V 0.15sec/60°

GearType Metal

No.ofTeeth: 25

Weight(g): 55

ShippingDimensions 5×3×5cm

Item Type: Digital Servo Motor

OperatingVoltage(V): 48~60

OperatingSpeed@48V 012sec/60degree

Min.OperatingSpeed(6V) 0.1sec/60degree

Torque: 16kg/cm(48V)

Dimensions 6×5×3cm

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

8.5 Arduino Uno R3

Specification Value

OperatingVoltage(VDC): 5

InputVoltage(V): 6-20V

AnalogI/OPins 6

DigitalI/OPins 14(ofwhich6providePWM output)

PWMDigitalI/OPins 6

DCCurrentperI/OPin(mA) 40

DCCurrentfor3.3VPin(mA) 50

ClockSpeed 16MHz

FlashMemory: 32KB

Dimensions(LxWxH)mm 75 54x12

8.6 HC-05 6pin Bluetooth Module with Button Item

Feature

Figure 6: DC/DC Converter

Table 7: DC/DC converter details

Specification / Description

InputVoltageRange 4V–38VDC

OutputVoltageRange 1.25V–36VDC(adjustable)

OutputCurrent 0–5A

OutputPower Upto75W

Efficiency Upto96%

ThermalShutdown Built-in

CurrentLimitFunction Built-in

OutputShort-CircuitProtection Built-in

Computer-Aided Design (CAD) modeling is a fundamental stepintheproductdevelopmentlifecycle.Ittransformsinitial conceptualdesignsandcalculateddimensionsintoaccurate three-dimensionalrepresentationsthatenablevisualization, validation,simulation,andmanufacturingplanning.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Table 8: 3D Printer Specification

The entire modeling work was carried out using Dassault SystèmesCATIAV5software,widelyusedintheautomotive, aerospace,andindustrialsectorsduetoitsrobustparametric designcapabilitiesandpowerfulassemblymanagement

10)Fabrication and Assembly Process

Fabricationandassemblymarkthetransitionfromavirtual design to a physical working prototype. In this chapter, the entire step-by-step journey from material preparation to final assembly for the 5-DOF

RoboticArmforHandlingCapsuleBottleswillbeexplainedin fulldetail.

Giventhatallcomponentsweredesignedfor3Dprintingin ABSplastic,thefabricationinvolvedadditivemanufacturing techniquescombinedwithcarefulmanualassembly

Feature Specification

PrinterModel Creality Ender 3 V2

PrintingTechnology FusedDepositionModeling(FDM)

MaterialUsed ABS Filament, 1.75 mm

NozzleDiameter 0.4 mm

LayerHeight 0.2 mm (StandardQuality)

InfillDensity 25%(Linkbodies),50%(Joints)

PrintingBedTemp 100°C

NozzleTemp 240°C

PrintingSoftware Ultimaker Cura

Final Assembly

I. MountBaseontoplatformusingM5bolts.

II. AttachLink1tobasemotorshaft,ensurefree rotation.

III. MountLink2totheendofLink1usingelbowjoint assembly.

IV. InstallLink3andwristassembly.

V. FixGripperatwristend,connectservocontrol wires.

VI. RouteWiresneatlyalonglinksusingcabletiesand protectivesheaths.

VII. ConnecttoControlElectronics(Arduinoand motordrivers).

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Thedesignandimplementationofaroboticarmforthe purpose of picking and placing capsule bottles in the pharmaceutical industry has proven to be a significant advancement toward automation and efficiency in the

manufacturing process. This projectaimed todevelopa 5DOF(DegreesofFreedom)roboticarmcapableofhandling capsule bottles with precision, speed, and safety, while reducingtheneedformanuallabourinrepetitivetasks.

Throughout the development process, several key aspects were addressed: mechanical design, kinematic analysis, material selection, CAD modeling, component procurement, programming, and integration of control systems.Thefinalprototypesuccessfullydemonstratedthe robotic arm’s ability to pick up capsule bottles from a designatedsourceandplacethemaccuratelyinthedesired location. The use of servo motors and a microcontroller ensuredsmoothandsynchronizedmovementofeachjoint, mimickingthebasicfunctionalityofahumanarm.

Theroboticarmmaintainedconsistentgripandstability, reducingtheriskofslippageordamagetothepharmaceutical products. It operated efficiently within its designed workspace and minimized dead zones. This is especially important in the pharmaceutical industry, where hygiene, accuracy,andnon-contacthandlingofproductsarecrucialto maintainingqualityandsafetystandards.

Moreover, the robotic system showed potential for scalabilityandintegrationwithconveyorsystems,sensors, andautomatedinspectionmodules.Itcanbeprogrammedfor different container sizes or layouts, offering flexibility for variousproductionlines.

In conclusion, the robotic arm developed in this project standsasacost-effective,reliable,andadaptablesolutionfor the pharmaceutical industry. It enhances productivity, ensuresqualityhandlingofcapsulebottles,reduceshuman error,andrepresentsasteptowardsmartmanufacturingand Industry4.0practices.

Thesatisfactionthataccompaniesthesuccessfulcompletion ofthisreviewwouldbeincompletewithoutthementionof the people who made it possible, without their constant guidanceandencouragementwouldhavemadetheefforts go in vain. We consider ourselves privileged to express gratitude and respect towards all those who guided us throughthecompletionofthisProject.

Weconveythankstoourprojectguide Dr. S. V. Chaitanya of Mechanical Engineering Department for providing encouragement,constantsupportandguidancewhichwasof greathelptocompletethisfirststagesuccessfully.

Lastbutnottheleastweappreciatetheopportunitygivento us byourheadof department Dr. S.V. Chaitanya andour principal Dr. D. S. Bormane aswellasallteachingandnonteaching staff of MECHANICAL DEPARTMENT who were directlyorindirectlyinvolvedwithourproject.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

[1] https://www.google.com/

[2] https://chatgpt.com/

[3] https://www.tinkercad.com/dashboard

[4] https://www.machinedesign.com/markets/robotics/ article/21833349/a-history-of-gripping-and-grippertechnologies-and-the-available-options-for-todaysengineer

[5] https://www.researchgate.net/publication/2799650 85_Design_and_Construction_of_a_Multipurpose_Robo t

[6] https://iptmajorprojectjacobheffernan.weebly.com/hi story-of-the-robotic-arm.html

[7] https://www.ipharmachine.com/capsule-bottle-sizechart?srsltid=AfmBOoooNvGBuaFNStJQ5VMdTFhTpm Kbz1bfQO_rzd9SG-xZhweIOg7-

[8] PopovicN.,WilliamsS,Schmitz-RodeT.,RauG., Disselhorst-KlugC.,“Robot-basedmethodologyfora kinematicandkineticanalysisofunconstrained,but reproducibleupperextremitymovement”,Journalof Biomechanics,Vol.42No.10,2009

[9] WangZ.,XilunD.,AlbertoR.andAlessandroG., “Mobilityanalysisofthetypicalgaitofaradial symmetricalsix-leggedrobot”,Mechatronics,Vol.21, No.7,pp.1133-1146,2011

[10] https://bbfloorsindia.com/blog/what-is-engineeredwood/

[11] https://articulo.mercadolibre.com.co/MCO592907766-adeept-5-dof-kit-de-brazo-robotico-de-5ejes-compatible-co-_JM

[12] https://www.pharmaceuticaltechnology.com/features/robotic-drug-dispensingdigital-pharmacy/?cf-view

[13] https://www.pharmafocuseurope.com/articles/therole-of-robotics-and-ai-in-pharmaceutical-automation

BIOGRAPHIES

NINADNAVALE ninadnavale@gmail.com

PARAGLAD paraglad4349@gmail.com

Dr S.V.CHAITANYA HODMECHANICALENGINEERING AISSMSCOEPUNE svchaitanya@aissmscoe.com

SHREYASHMUSMUDE shreyashmusmude@gmail.com

REVANSIDHNAGURE revansidhn@gmail.com