International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Ashwini S Savanth1 , P S Ravindranath2 , Sukruth Raghavendra R3 , Rashmitha R Shet4, Shamitha M5

1Associate Professor, Dept of ECE, BNMIT, Bangalore, Karnataka, INDIA. Orchid ID: 0000-0003-2421-8429

2Senior Vice President, Senquire Analytics Pvt. Ltd., Aundh, Pune, INDIA

3 Student, ECE, BNMIT, Bangalore, Karnataka, INDIA

4 Student, ECE, BNMIT, Bangalore, Karnataka, INDIA

5 Student, ECE, BNMIT, Bangalore, Karnataka, INDIA ***

Abstract - TheWarehouse-MaterialHandlingAssistantisa strategicinitiativedesignedtoaddressthechallengesofmultitier stack warehouse environments through a combination of embeddedhardwareandsoftware.Theprimaryobjectiveisto enhance safety and minimize mishandling risks during material handling operations, aligning with the vision of autonomousmanufacturingandaimingforzerowastage,zero accidents, and zero defects. The methodology employs an integratedsystemcomprisingproximitysensors,cameras,and a touchpad Human-Machine Interface (HMI). This interconnectedness ensures a responsive system that aligns with the objectives. The software script processes individual framestooverlaylinesrepresentinglanesorpaths,enhancing framevisualsforcomputationalstepsorvisualinterpretation within the system. In summary, the Warehouse-Material Handling Assistant project addresses the challenges in multitier stack warehouse environments through an integrated approach that leverages hardware and software. It aims to enhance safety, minimize mishandling risks, optimize efficiency,andpromotesustainability.Thedevelopmentofthe BLOS Dashboard View system, which uses cameras and proximity sensors, redefines standards in warehouse operations, ensuring a cohesive and responsive solution for modern material handling needs.

Key Words: Forklift,Beyondlineofsight,Visionassistance, Embeddeddevice,proximitysensors,camera,GUI

In the dynamic and fast-paced world of warehouse operations,materialhandlersplayapivotalroleinensuring theefficientflowofgoods.However,theirtasksofteninvolve operatingequipmentwithinmulti-tierstackenvironments, wherealignment,anchor-basedpositioning,andorientation challengescanposesignificantsafetyandmaterialhandling risks.Theseconcernsarefurthercompoundedbymaterial handlersfrequentlyoperatingtheirequipmentbeyondthe lineofsight.Furthermore,forkliftslackingrearvisionface difficultiesmanoeuvringinreverse,hinderingtheirabilityto navigatebackwardeffectively.Thisimpedimentinreverse movementposesanadditionalchallenge,emphasizingthe need for a comprehensive solution to enhance operator

safety, minimize material mishandling, and address the difficultiesassociatedwithbackwardmovementinforklifts without rear vision. Every year, about 95,000 people are injured and 100 workers are killed in forklift accidents, according to the Occupational Safety and Health Administration (OSHA) [1]. Nearly one of every six workplacedeathsinvolvesaforklift,sosafetyisparamount inwarehouseoperations.Theuniquedesignofforkliftsalso makes them more susceptible to potential accidents. Forkliftsareheavierinthereartobalanceloadsinthefront, whichcanmakeforanunevenweightdistribution.Loads, carried in front, can block or limit the operator’s view. Besides the potential for injury or death, accidents can be costly.TheNationalSafetyCouncilreportsthateachinjury requiring medical attention costs companies $42,000 and each workplace death averages more than $1.2 million in employer expenses. These numbers include lost wages, medical expenses, and administrative and employer costs [2].Ontopofthat,theremaybepropertydamageordamage tomachinesthatrequirecostlyrepairs.Thiscombinationof factorsunderscoresthecriticalneedtoaddresssafetyand efficiency in warehouse operations. The safety of both workers and equipment operators is paramount, as accidentsandmishandlingincidentscanresultininjuries, damage to goods, and financial losses. By understanding theseissuesandseekingviablesolutions,wecanenhance workplace safety, optimize material flow, and ultimately improvetheoverallefficiencyofwarehouseoperations.For warehouseownersandoperators,thebestsolutiontothese challenges to prevent forklift accidents requires a twoprongedapproach:operatorandworkertrainingalongwith technologytomitigatesafetyconcerns.Warehousesarehubs ofactivitywithworkersmovingindifferentdirectionsatthe sametime,especiallyduringpeakhours.Employeesmaybe movingrapidlybetweenareasastheypick,pack,andshipat thesametimewhileotherworkersaremanningforkliftsto haulandunloadpallets.Besidesbeingbusyplaces,thereis oftenalotofambientnoiseinwarehouses.Pedestriansmay notseeforkliftsuntilit’stoolate.Theymayalsobecaught unaware when turns or sudden stops occur. So, there’s a highpotentialforcollisionsbetweenpedestrianandforklift accidents[6],[7],[8],[9].

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

The prototype developed here addresses the challenges warehouse material handlers face working in a multi-tier stack environment. These operators often struggle with aligningandjudgingthepositionoftheanchorbaseoftheir equipment,especiallywhenoperatingbeyondtheirlineof sight. The prototype proposed here uses embedded hardware,software,andtechnologytocreateasolutionthat enhancessafetyandminimizesmaterialmishandlingrisks for workers and equipment operators. By providing innovative assistance and guidance, this prototype will contribute to revolutionizing manufacturing into an autonomousandintelligentsystem,ultimatelystrivingfor zerowastage,zeroaccidents,andzerodefects.Thepurpose istobuilda"BeyondLineofSight"(BLOS)dashboardview for the aid of forklift operators. The concept of a BLOS dashboard view like parking assistance in premium cars showcases the potential of technology in addressing realworldindustrialchallenges.

Theexistingworkcarriedoutbyseveralresearcherson forklift assistance has been elaborated in this section. Authorshavepublishedseveralsurveysastothedangerous situationsthatonecancomeacrosswithforkliftoperationsin differentwarehouses. EachyearinAustralia200deathsand 70,000compensationclaimsinvolveworkplacemachinery, tools, appliances, and equipment (National Occupational Health&SafetyCommission(NOHSC)[2].Mobileequipment usedinheavyindustryincludesforklifttrucks,mobilecranes, trainsandotherrailvehicles,roadvehiclessuchascarsand trucks, motorized hand trucks, and other specialized industrial vehicles powered by electric motors or internal combustion engines (Occupational Safety and Health Administration (OSHA)) [1]. Many workplaces in the manufacturing, logistics, transportation, and retail sectors havepedestrianworkersoperatingnearmobileequipment. Such pedestrian workers are typically either moving to or from workplaces at times of shift commencement, shift termination,orduringbreaks,ortheyareundertakingtasks in the workplace that cannot be conducted by mobile equipment or automation, such as maintenance or quality

control.Mostindustrialmobileequipmentsuchascranesor forklifttrucksisheavy,relativelyfast-moving,andpowerful, andincomparison,tocarsusedonpublicroads,theyarenot explicitly designed to be crash-tolerant if they encounter pedestrians. It is not surprising, then, that pedestrians account for a significant proportion of the fatality/injury figures.Pedestrianworkerswereinvolvedin45%ofcrashes involving such equipment and, of 48% mobile equipmentrelateddeathsbetween1985and2003intheAustralianstate ofVictoria,56%werepedestrianfatalities.Basedonthese points an overall work program with several activities conductedbyT.Horberryetal.willhelpimprovesystemsof safe industrial mobile equipment management and contribute to a substantial long-term reduction in severe forklift-related injuries. Likewise, it is anticipated that the information,methods,andresultswillhelpdevelopfurther scientificresearchinthisarea.Finally,theyhadhopedthat forkliftsafetywouldbeseenasalegitimatepartoftransport psychology in which behavioural scientists can have a valuable role to play. Many factors can influence forklift safety. These include logistics, the design of the site and buildings, forklift equipment, task requirements, work organization,andhumanfactors.Thisguidebookarguesthat safety should be a primary consideration and that all stakeholdersshouldlookforthebestfitbetweensafetyand productivity. This in part can be achieved by paying early attentiontothedesignofthelayout,logistics,andprocesses [2].

Erel in his work investigates both behavioral and skill dimensionsofforkliftoperationwheretheresearchseeksto identifypatternsandcorrelationsthatcaninformstrategies forenhancingsafetyinfactorysettings.Thegoalofthestudy was to provide valuable insights and guidance to forklift operators and supervisors [3]. The work by Carlos Conde Carvalhalaimstoobtainknowledgetomitigateforklifttruckrelatedsafetyhazardsaswellasunderstandhowtoeliminate risks and unsafe situations in this type of operation. This project was divided into 3 phases. Phase I consisted of understandingoperationsroutinesandtheirsafetyriskswith a safety survey, several visits and interviews, and benchmarking the most common practices based on other companies' forklift-related processes. In phase II, studies utilizingdifferentengineeringtools(SpaghettiDiagram,VSM, Fishbone Diagram, and FMEA) were performed to gather information and understand how to optimize the site's forklift-relatedsafety.Inthisphase,atailoredobservational KPI was developed to assess the site independently of incidentmeasurementregardingfourgroups:Site,Pedestrian activity,Forkliftoperation,andForkliftoperatorbehaviour. InPhaseIII,alldataacquiredwasdiscussed,andconclusions weremadebasedonthedataanalysisanddiscussionsofthe results of Phase II implementation allied with theoretical references[4].

Several authors have proposed several solutions for givingvisionassistancetoforkliftoperators.M.Seelingeret

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

al. introduced a groundbreaking vision-guided control approachnamedmobilecamera-spacemanipulation(MCSM) for robotic forklift vehicles. Unlike conventional methods requiringprecisecameracalibration,MCSMleveragesvision sensors within the robotic forklift to interact with pallets basedon their real-time positions [5].Cantinietal.delved into the concept of "smart spaghetti," which involves the automated generation of spaghetti charts through smart tracking devices. These charts serve as a foundation for conceptualizing improvements in warehouse layout and organizationalworkflows.Theprimaryfocusisonmitigating theriskofcollisionsbetweenforkliftsandenhancingoverall operator safety. The methodology revolves around the automatic mapping of spaghetti charts to identify critical areaspronetocollisionrisks.Subsequently,interventionsare proposed to avert potential near misses [6]. Baird and Renardodevelopedafullyfunctional3-wheelcounterbalance forktruckvehiclewitha4000lbloadcapacity.Equippedwith an array of sophisticated sensors, includingcameras, laser scanners,anInertialMeasurementUnit(IMU),andapotent onboard computer, the automatic guided vehicle ensures comprehensiveenvironmentalperception[7].R.G.Sheteet al. propose the implementation of ultrasonic sensors to detectandaddressblindspots,enhancingtheoverallsafety offorkliftoperations.Byleveragingultrasonictechnology,the systemaimstoprovidereal-timeinformationtothedriver, allowing themto navigatemore safely andavoid potential collisions.Thesystemincorporatesauserinterfacefeaturing aradardisplayandLEDarray.Theradardisplayservesasa visualrepresentationofthesurroundingenvironment,with detected objects appearing on the screen in real-time. Simultaneously, the LED array provides a scaled representationofthedetectedobstacles,offeringaquickand intuitivevisualreferenceforthedriver.Theintegrationofan alarmsystemfurtherreinforcessafetymeasures[8].J.Rhee etal.introduceaninnovativesafetysystemapplicableacross diverse industrial scenarios. The system employs a line detectionmethodtoidentifyboundariesandutilizesYOLO (YouOnlyLookOnce)torecognizeindividualsfromcameracapturedimages.Byincorporatingin-depthinformation,the system assesses the dangerous proximity of detected individuals[9].

Y. Kita et al. present a refined method for detecting and localizingpalletsonshelvesusingawide-anglecamera.The three proposed improvements, including a new similarity measure,maximumsimilaritysearch,andconsiderationofRcorners, collectively enhance the system's robustness and accuracy[10].N.KitaandT.Katointroducedamethodfor automatingtheinsertionofaforklift'sforkintoapallethole, acriticaltaskrequiringprecisecontrolofforkheight,reach position,andtiltangle.Theproposedsolution,designedfor an Autonomous Guided Forklift (AGF), leverages image measurement techniques using a wide-angle camera. To achieve automatic fork insertion, the paper focuses on measuring the pitch inclination of the pallet in the camera coordinatesystem.Thisiscrucialforaligningtheforkwith

the pallet hole accurately [11]. P. Sun et al. proposed a method that addresses the inherent challenges posed by confined spaces, ensuring that unmanned forklifts can effectivelyoperateinscenarioswheretraditionallocalization methodsmayfallshort.TheirsystemadoptsYOLOv5anda combinationofimage-processingtechniquestocontributeto theefficiencyandaccuracyofpalletlocalizationinnarrow aisles[12].D.IlangasingheandM.Parnichkundelveintothe navigation control of an unmanned autonomous forklift, focusing on its autonomous navigation within an indoor environment through waypoints following the algorithm. Equippedwithonboardcomputationandsensors,theforklift autonomously maneuvers based on predefined waypoints, and the paper provides an in-depth exploration of the algorithm's efficiency through experimental results comparedtothegroundtruth[13].M.M.Arefetal.addresses thecomplextaskofpalletpickingbyanArticulated-FrameSteering(AFS)hydraulicmachine,presentinganovelmacromicrovisualmobilemanipulationarchitecture.Theproposed systememploysaseamlessswitchinglogicthatnavigatesthe robottopickanobject,adaptingtovaryingdegreesofvision accuracyandrobotfreedom[14].G.Chenetal.introduceda method for locating an automatic forklift, emphasizing enhanced image processing efficiency and robust object identification. The system demonstrates notable improvementsinbothaccuracyandefficiencyoflocalization. This is particularly significant for automatic forklifts operating in dynamic environments, where precise localizationisessentialforsafeandeffectivenavigation.The utilization of colour space transformation, mid-point determination, and the camera space model collectively contributetothemethod'ssuccessinaddressingchallenges related to forklift localization. The incorporation of the Kalman filter further refines the system's performance, showcasing its adaptability and robustness across varying conditions[15].B.Sarupurietal.explorestheapplicationof AugmentedReality(AR)toenhancetheoperationofforklifts in modern warehouses, where challenges such as higher shelves and narrower aisles make traditional tasks more complex. The primary focus is on investigating how AR technologycanassistforkliftoperatorsinperformingpallet racking and pick-up tasks by superimposing virtual guidelinesontoareal-worldcamerafeed[16].P.R.Patiletal. address the imperative task of designing a Smart Forklift modelwiththeprimaryobjectiveofreducingaccidentrates associated with traditional forklift operations. This innovative model incorporates modern technologies, includingArduinoandgyrosensors,toenhancesafetyand reducetheincidenceofaccidents.Thegyrosensorservesasa crucial component, detecting deviations from normal operatingconditionsthatmayindicateapotentialthreator danger.Intheeventofsucha detection,theSmartForklift modelisprogrammedtotriggerasecuritythreatindication. The integration of Arduino allows for efficient sensor integration,dataprocessing,andreal-timecommunication, enablingaseamlessandresponsivesafetysystem[17].L.Cao

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

et al. explore the sensor-based assistance systems as a promising solution to providing real-time assistance to forklift operators [18]. Roger Bostelman has presented advancedthree-dimensional(3D)imagingsensorsandtheir use in manufacturing to improve forklift safety. Several forklift safety statistics were listed along with recommendationsforimprovingforkliftsafety[19],[20].

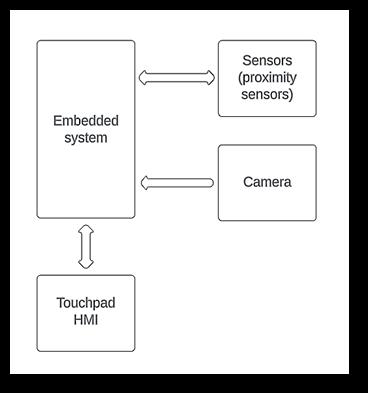

A system is developed to provide a solution for operator assistance with a BLOS (Beyond Line of Sight) dashboard viewtoguidetheoperatorforefficientandsafeoperations. Thedashboardviewislikethatofparkingassistantguidance in premium cars today for ease of operations, safety, and efficientparking.Theforkliftoperatorgetsafrontviewof the ‘Beyond Line of Sight-dashboard view of the forklift position’fromhisseat.Thedashboardconsistsofproximity sensorsandcamerasconnectedtoanembeddedsystemand atouchpadtoestablishaconnectionwiththeoperatoracting as a Human-Machine Interface (HMI). This configuration empowersforkliftoperators,grantingthemcontroloverthe equipment while significantly enhancing safety within warehouseoperations.Thesystemleveragesthedatafrom thesensorsandcamerasforreal-timemonitoring,allowing operatorstomakeinformeddecisionsand avoidcollisions, thereby optimizing the overall safety and efficiency of material handling in multi-tier stack environments. The blockdiagramrepresentationofthesystemandthecircuit diagramareshowninFigure2.

DesigninganeffectivedashboardforBeyondLine-of-Sight (BLOS) forklift operations involves creating an intuitive interfacethatprovidesreal-timeinformationtooperators, and supervisors. The dashboard gives a live feed from onboardcamerasorsensorstoprovidereal-timevisibilityof the forklift's surroundings, compensating for the lack of directlineofsight.Theproximitysensorsalerttheoperators of obstacles or potential collisions in their path. It also displaysdatafromproximitysensors,indicatingthedistance and location of detected obstacles. An emergency stop button allows operators to halt the forklift in critical situations. The dashboard includes additional features. A checklist of safety protocols is displayed for operators to ensure that all safety measures are checked before operation.Itshowstheremainingbatterylifeandindicates when a recharge is required. System diagnostics are displayed to highlight any potential issues with sensors, cameras,orothercriticalcomponents.Thesystemprovides a secure login system to identify and authenticate forklift operators, tracking their activities. It provides remote monitoring allowing supervisors or managers to monitor forklift operations through the dashboard remotely. The dashboard design is visually appealing, user-friendly, and provides the necessary information at a glance. Regular updates and improvements based on user feedback and

technologicaladvancementswillcontributetotheongoing successoftheBLOSforkliftdashboard.

IntegratingproximitysensorsintoaforkliftforBeyondLineof-Sight(BLOS)operationsiscrucialinenhancingsafetyand preventingcollisions.Proximitysensorsdetectobstaclesin the forklift's path and provide real-time feedback to the operator, contributingto improvedsituational awareness. InfraredSensorsuseinfraredlighttodeterminethedistance between the sensor and an object. The sensors are strategicallyplacedondifferentsidesoftheforklifttocover blind spots and areas with limited visibility. Sensors are placedonthefront,rear,sides,andpossiblythetopofthe forklift for comprehensive coverage. Audible and visual alertsaregivenwheneverobstaclesaredetected. Detected obstaclesaredisplayedonthedashboard.

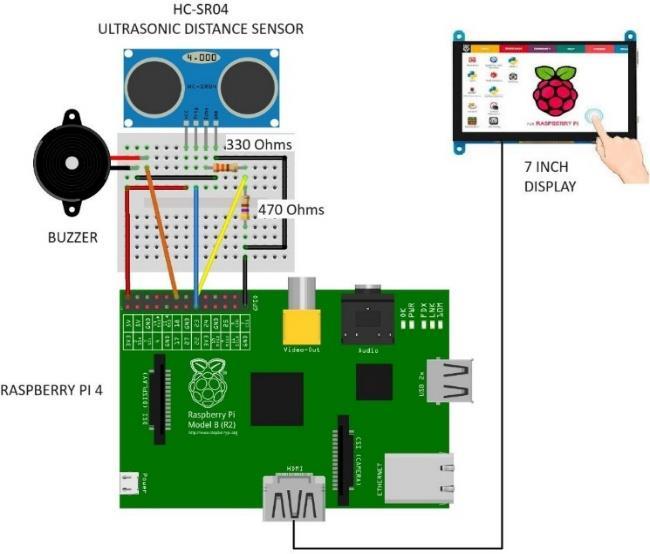

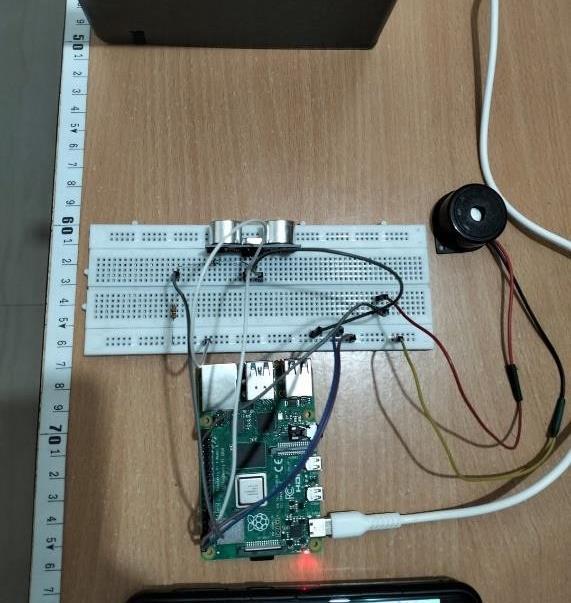

Figure2showsall theconnectionsoftheproposedmodel whichconsistsofRaspberryPi4connectedtoanultrasonic sensorandbuzzerthroughGPIOpinsandtoa7-inchdisplay throughHDMIportandcables.IntegratingRaspberryPiwith the proximity sensor helps develop a versatile distance measurement system. The Raspberry Pi serves as the foundationalembeddeddevicewithinthesystem.Despiteits

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

compact size, it offers sufficient processing power and memory capacity crucial for effective AI-based vision processing. Integrating proximity sensors, high-resolution cameras, and a touchpad HMI, the Raspberry Pi drives innovation in safety and operational efficiency for forklift operations. Its compact form factor ensures seamless integrationintoforkliftswhiledeliveringswiftandaccurate outcomes through the execution of complex algorithms. Real-timeanalysis,objectrecognition,anddataprocessing areefficientlyhandledattheedge,makingtheRaspberryPi thecentralpowerhouseofourBLOS(BeyondLineofSight) dashboard view system. Its resourcefulness enables it to navigate the demanding tasks within warehouse environments, contributing significantly to the system's overall efficiency and responsiveness. Raspberry Pi's versatility and affordability make it an ideal choice for empowering the system and enabling it to deliver robust performanceandgroundbreakingcapabilitiesinwarehouse materialhandlingoperations.Inthecontextofwarehouse applications,whereprecisionandaccuracyreignsupreme, the careful curation of the camera ensures the system's adeptnessinexecutingcriticaltaskssuchasobjectdetection, path planning, and the issuance of safety alerts. In the dynamic landscape of warehouse operations, where seamless coordination and optimal performance are indispensable, the integration of high-quality cameras emergesasacatalystforelevatingtheoverallefficacyand reliabilityoftheBLOSDashboardViewsystem.TheHC-SR04 proximity sensor is connected to the Raspberry Pi as outlinedinthecircuitdiagramshowninFigure2b.

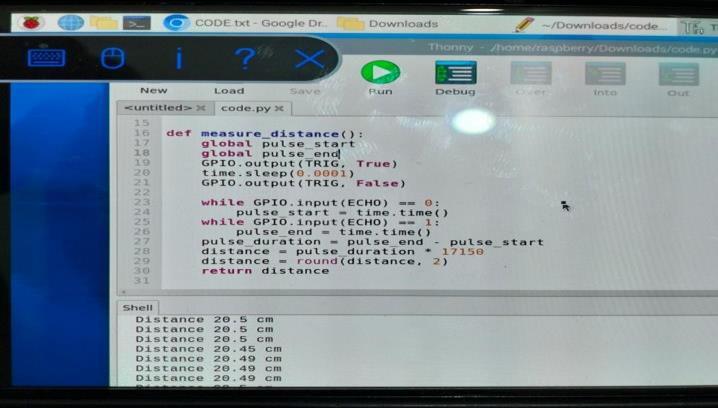

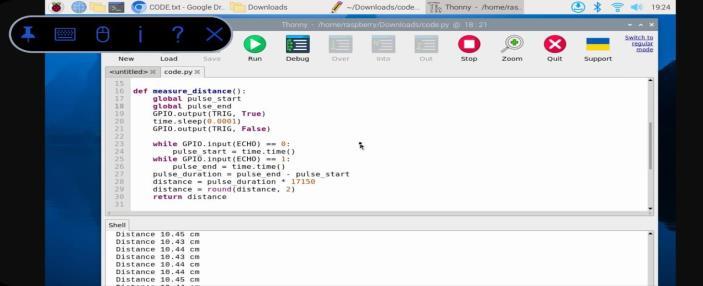

APythonscriptiswrittentointerfacewiththeGPIOpinsof the Raspberry Pi and control the proximity sensor. Visualization tools are used to display real-time distance measurementsgraphically,eitherlocallyontheRaspberry Pi's display or remotely via a web interface. The buzzer connectedtoRaspberryPi4givesaloudsoundalertwhen the distance measured by the proximity sensor reaches belowthethresholddistancefixed.Thebuzzerisconnected totheGPIOpinoftheRaspberryPifromwhichitreceives thesignalforthebuzzeroperation.

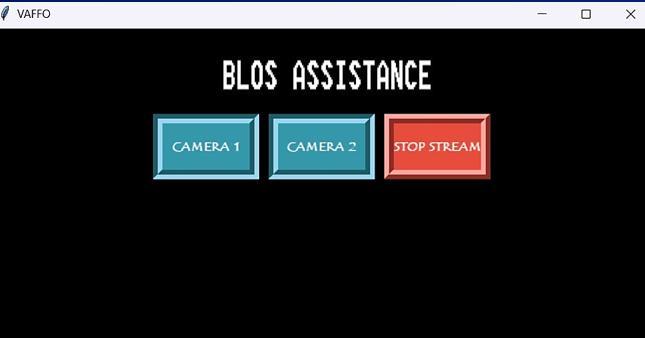

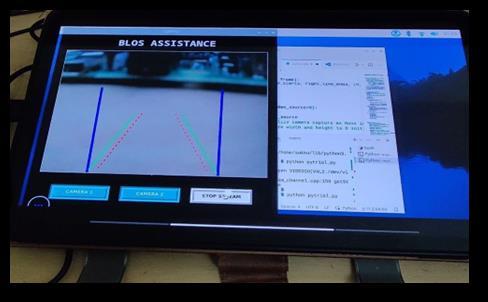

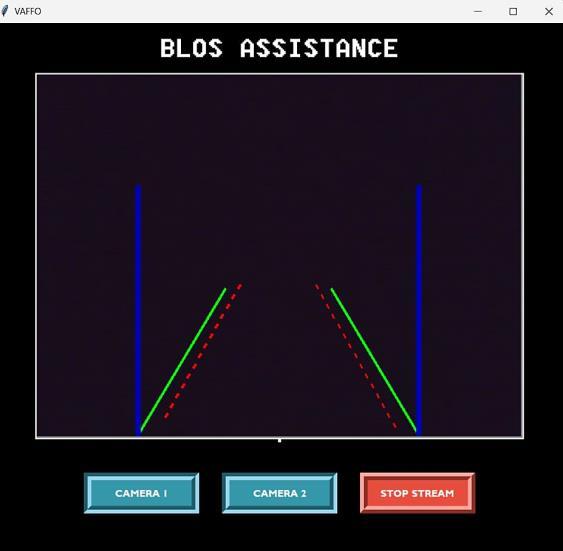

ApythonsourcecodeiswrittenusingtheTkinterlibraryto createagraphicaluserinterface(GUI)andOpenCV(cv2)for capturingandprocessingvideostreamsfromoneormore cameras.TkinterisastandardGUItoolkitthatcomeswith Python, making it easy to create simple interfaces for desktopapplications.Threebuttons(Camera1,Camera2,and StopStream)arecreated,andeachbuttonisassociatedwith aspecificfunctiontobeexecutedwhenthebuttonisclicked. Alabelisusedtodisplaymessagesbasedonbuttonclicks. Thegridlayoutmanagerisusedtoarrangethebuttonsand labels in a grid. The GUI, when implemented on the dashboard device, will provide complete visual and proximityguidancefortheforkliftoperator.Theapplication

consists of multiple classes and functions responsible for initializingthevideostreamdisplays,drawinglinesofsight onthecamerafeed,controllingthestreamingprocess,and managing the user interface elements. The GUI design is showninFigure3.

The `VideoStreamDisplay` class is defined to handle the display of a single video stream. It contains methods for drawing lines of sight on the camera feed, updating the framewiththelinesofsight,togglingthestreamingprocess, andstoppingthestream.The`draw_lines_of_sight`method withinthisclassisresponsibleforprocessingeachframeof the video stream and drawing lines of sight representing differentperspectivesonthescene.Theselinesarecrucial forassistingforkliftoperatorsinnavigatingthewarehouse environmentsafelyandefficiently.

Similarly,the`VideoStreamDisplay2`classisintroducedto handle a secondary video stream display, assuming the applicationhasaccesstomultiplecameras.Itsharessimilar functionalitieswiththe`VideoStreamDisplay`classbuthas different parameters or configurations depending on the specific requirements or characteristics of the secondary camera.The`stop_streaming`functionisacallbackfunction associatedwiththe"StopStream"buttonintheGUI.When invoked, it stops the streaming process for both video stream displays by calling their respective `stop_stream` methods. Additionally, the `start_dual_view` function is defined to initiate the streaming process for both video streamssimultaneously.

The main application window (`root`) is created using Tkinter,withspecificconfigurationssuchassize,title,and background color. The GUI includes a label indicating the purpose of the application ("BLOS ASSISTANCE") and buttons for controlling the streaming process for each camera stream, as well as a button to stop the streaming altogether. These buttons are styled with custom fonts, colours, and dimensions to enhance the visual appeal and userexperience.

Thecodepresentedlaysthegroundworkforauser-friendly application designed to offer real-time visual support to forklift operators navigating warehouse settings. Through theintegrationofvideostreamssourcedfromoneormore

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

cameras,theapplicationenhancessituationalawarenessand augments safety protocols within the warehouse environment.ByleveragingOpenCVfunctionalities,suchas imageprocessingandframemanipulation,theapplicationis capableofoverlayinglinesofsightontothecapturedvideo frames.Theselinesofsightserveasguidingindicatorsfor forklift operators, aiding them in identifying obstacles, gauging distances, and navigating through the warehouse spacewithprecision.Moreover,theapplication'sabilityto drawtheselinesdynamicallyallowsforcontinuousupdates andreal-timeadjustments,ensuringthatoperatorsreceive up-to-datevisualcuesastheymaneuverthroughthefacility. Through its intuitive user interface, the application streamlinestheprocessofaccessingandinterpretingcritical visual information, thereby promoting safer and more efficient warehouse operations. The inclusion of customizablefeatures,suchastheoptiontotogglebetween different camera views or adjust streaming settings, enhancestheflexibilityandadaptabilityoftheapplicationto suitvaryingoperationalrequirements.

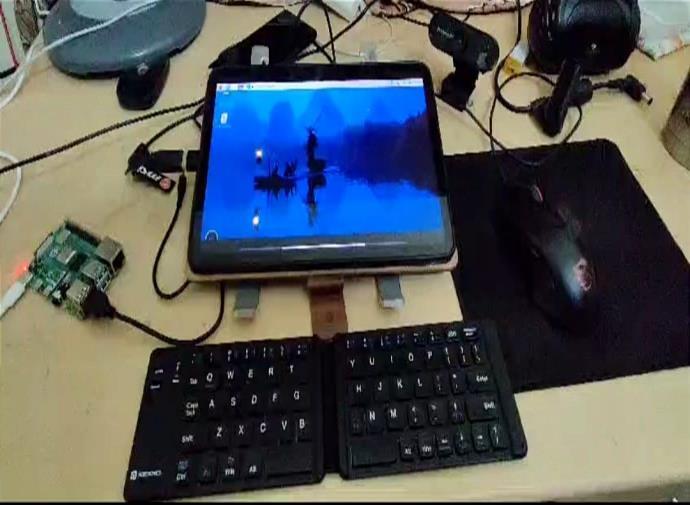

Furthermore,theapplication'sfocusonuser-friendlydesign principles underscores its commitment to usability and accessibility. By prioritizing clear and intuitive visual elements, coupled with responsive user controls, the applicationaimstominimizecognitiveloadandstreamline userinteractions,ultimatelycontributingtoamoreseamless andefficientuserexperience.Inessence,thecodedesigned for the system represents a foundational framework for a sophisticated,yetuser-friendlyvisualassistanceapplication tailored specifically for the demands of warehouse environments.Throughitsinnovativeintegrationofvideo streaming technology and advanced image processing capabilities,theapplicationstandspoisedtorevolutionize how forklift operators navigate and interact within warehousespaces,pavingthewayforsafer,moreefficient, andmoreproductiveoperations.Figure4aand4bshowsthe setup ofthedisplaywiththeGUIdesignwhere theline of sightisseen.Figure4cshowstheoperationoftheproximity sensorandbuzzerverifiedwiththehelpofameasuringtape.

The results obtained for the BLOS Vision assistance for forkliftoperatorsareprovidedinthissection.Itconsistsof two parts, the first part shows the output detected by the distance sensor, and the second part gives the GUI design withtwocameraoutputs.

ThehardwaresetupinFigure5showstheproximitysensor integrated with Raspberry Pi 4. It monitors the distance every one second and displays it continuously on the GUI screen. It gives an alert sound through the buzzer if any objectisdetectedwithinthethresholddistancesetbythe user. The alert sound will help the forklift operator to be awareandcautiousofthepresenceofanobstaclenearthe forks.Figure5aand5bshowthedistanceof20cmand10 cm measured by the proximity sensor when it detects an objectinacontrolledatmosphere.

2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

The GUI window is shown in Figure 6. The graphical user interface(GUI)aspectoftheapplicationplaysapivotalrole inprovidinguserswithanintuitiveandefficientplatformfor controllingandmonitoringthecamerastreams.Developed usingTkinter,aPythonlibraryrenownedforitssimplicity and versatility in GUI development, the main application windowencapsulatesvariouselementscarefullydesignedto enhanceuserexperience.

Attheforefrontofthewindowliesaprominentlydisplayed labelbearingthetitle"BLOSASSISTANCE."Positionedatthe top, this label serves as a header, immediately communicatingtheprimarypurposeoftheapplicationtothe user.Toensureoptimalvisibilityandreadability,thelabelis styledwithwhitetextsetagainstablackbackground,with the font rendered in bold for added emphasis. By establishingaclearfocalpoint,theheaderlabeleffectively setsthetonefortheuserinteractionjourney.

Directlybeneaththeheaderlabel,thewindowisdividedinto twodistinctsections,eachdedicatedtodisplayinglivevideo streamsfromCamera1andCamera2,respectively.These videostreamdisplaysserveasthecorecomponentsofthe

application, allowing users to visualize real-time footage captured by the connected cameras. Implemented as instances of the `VideoStreamDisplay` and `VideoStreamDisplay2`classes,thesedisplaysleveragethe OpenCVlibrarytocaptureandrendervideoframesfromthe specifiedvideosources.Throughseamlessintegrationwith Tkinter,thevideostreamdisplaysseamlesslyblendintothe overallGUIlayout,providinguserswithacohesiveviewing experience.

Adjacently below the video stream displays, a series of interactive buttons are strategically positioned within a separate frame, forming a user-friendly control panel for managing the streaming behavior and initiating specific actions.Amongtheavailableoptions,the"CAMERA1"and "CAMERA 2" buttons stand out as primary controls for togglingthestreamingoftherespectivecamerafeedsonand off. Crafted with rounded corners and bold text, these buttonsaredesignedtoattractattentionandencourageuser engagement. Upon clicking either button, the associated camera stream is activated or deactivated, granting users direct control over the visual output displayed within the applicationwindow.

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Complementing the primary camera controls, a distinct "STOP STREAM" button occupies a prominent position withinthecontrolpanel.Distinguishedbyitscontrastingred colorscheme,thisbuttonservesasacriticalsafetymeasure, allowing users to halt all streaming operations simultaneously with a single click. When triggered, the `stop_streaming()`functionisinvoked,initiatingtheorderly terminationofthevideostreamsandclearingthecanvasto prepareforpotentialrestarts.Byincorporatingthisfeature, the application prioritizes user safety and convenience, offering a reliable means of quickly halting streaming activitieswhennecessary.

In summary, the GUI design of the application is meticulously crafted to prioritize clarity, ease of use, and usersatisfaction.Throughthoughtfularrangementofvisual elements,intuitivebuttonplacements,andconsistentstyling, theinterfaceprovidesuserswithanimmersiveandintuitive platform for interacting with the camera streams. By

seamlessly integrating functionality with aesthetics, the application strives to deliver a seamless and enjoyable experienceformonitoringandmanaginglivevideofeeds.

TheoutputsofCamera1andCamera2areshowninFigure 6. Thecamera1_streamclassinthecodesnippetdefinesa VideoStreamDisplay object responsible for managing the display of a video stream from a specified video source, which in this case is assumed to be a webcam (video_source=0).Theclasscontainsmethodsfordrawing lines of sight on the video stream frame and updating the frame displayed on a Tkinter canvas widget. The draw_lines_of_sightmethodwithintheclassprocesseseach frame of the video stream to draw lines representing the linesofsightfortheoperator.Thismethodfirstconvertsthe frametograyscaleandappliesGaussianblurandCannyedge detection to enhance edge visibility. It then calculates the positionofthreehorizontallinesrepresentingthehorizonat differentoffsetsfromthecenteroftheframe.Themethod definestheparametersforthelinesofsight,includingthe lengthofeachsegmentofthedottedline,thegapbetween segments, and the offset to move the lines closer to the bottomoftheframe.Itthenspecifiesthestartandendpoints foreachlineofsight,adjustingtheendpointstoensurethey areclosertothebottomoftheframe.

After definingthepointsfor thelinesofsight,themethod draws them onto the frame using the cv2.line function, specifyingthecolorandthicknessofthelines.Thelinesare drawn indifferent colors to represent different aspects of theoperator'sfieldofview:redfortheprimarylinesofsight, greenforthesecondarylines,andblueforthetertiarylines. Finally,themethodreturnsthemodifiedframewiththelines of sight drawn on it. The __init__ method initializes the VideoStreamDisplayobject,settingtheparentwindow,video source,andotherattributes.ItalsocreatesaTkintercanvas widgettodisplaythevideostreamandsetsthedimensions of the canvas based on the width and height of the video stream frames. The update_frame method continuously readsframesfromthevideosource,processesthemtodraw thelinesofsightusingthedraw_lines_of_sightmethod,and updates the canvas widget with the modified frame. This methodiscalledrecursivelyusingtheparent.afterfunction toensureasmoothandcontinuousvideostreamdisplay.

Thetoggle_streammethodcontrolsthestreamingstatusof thevideodisplay.Whencalled,ittogglesbetweenstarting and stopping the video stream from the specified video source.Itinitializesthevideocaptureobjectifstreamingis startedandadjuststhedimensionsofthecanvaswidgetto matchthewidthandheightofthevideostreamframes.The methodalsocallstheupdate_framemethodtostartupdating thecanvaswithvideoframes.Thestop_streammethodstops thevideostream, releasesthevideocaptureobject,clears thecanvaswidget,andresetsitsattributestonone.Overall, thecamera1_streamclassencapsulatesthefunctionalityfor displayingavideostreamfromawebcamanddrawinglines

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

of sight on the video frames to assist the operator in navigating their environment. This class is designed to be easily integrated into a graphical user interface (GUI) applicationusingtheTkinterframework.

In response to the pressing issue faced by warehouse materialhandlersoperatinginchallengingmulti-tierstack environments, the current work has engineered a groundbreakingsolution.TheBLOS(BeyondLineofSight) Dashboard View system, designed to enhance safety and operationalefficiency,offersalevelofassistanceakintothe premium parking assistant technology found in high-end vehiclestoday.Byequippingforkliftoperatorswithacamera connectedtoacompactedgedevice,completewithauserfriendly touchpad Human-Machine Interface (HMI), this product grants them an invaluable front-row view of the "BeyondLineofSight"dashboard,completewithgridlines, forkliftalignment,andapproachorientationinbothX-Yand Xdirections.ThisAI-enabledvision-basedguidancesystem provides real-time visual and audio feedback, mitigating safety and material handling risks for both operators and workers.Thisproductincludesanembeddeddevice,support for up to two high-resolution cameras, and proximity sensors,allseamlesslyintegratedwithEmbeddedLinuxOS and Python. The BLOS Dashboard View system not only representstechnological advancement butalsoa strategic leaptowardsfosteringasecureandproductiveenvironment withinwarehouses.Inanerawhereprecisionandsafetyare paramount, this solution stands as a testament to our unwaveringdedicationto elevating standardsand driving positivetransformationwithinthewarehouselandscape.

ThefuturescopeoftheBLOS(BeyondLineofSight)Forklift Operator Assistance system holds immense potential for revolutionizingwarehouseoperationsandenhancingsafety measures in industrial settings. At its current stage, the system exists as a prototype, showcasing promising capabilitiesbutrequiringfurtherrefinementandintegration to realize its full potential. The primary objective moving forwardinvolvesseamlesslyintegratingtheBLOSassistance system into forklifts, ensuring compatibility with existing machinery and operational workflows. This integration processentailscollaboratingwithforkliftmanufacturersto embed the necessaryhardwarecomponentsandsoftware interfaces directlyinto the vehicle'sdesign. Byseamlessly incorporating the BLOS system into the forklift's control mechanisms,operatorscanaccessreal-timeassistanceand guidancewithoutrelyingonexternaldevicesorcumbersome installations.

Moreover, a key area of expansion for the BLOS system involves the implementation of a rear-view camera for enhanced maneuverability and safety during reverse operations. By integrating a rear-facing camera into the forklift'sdesign,operatorsgainimprovedvisibilityoftheir

surroundings,particularlyinareasobscuredfromthedirect line of sight. This addition not only reduces the risk of accidents and collisions but also enhances operational efficiencybystreamliningnavigationinconfinedspaces.

Furthermore,thefuturescopeoftheBLOSsystemextends beyondtraditionalmanualforkliftoperationtoencompass the utilization of automatic, remote-controlled forklifts in hazardous conditions. In scenarios where workers are exposed to potentially dangerous environments, such as those involving chemical substances or extreme temperatures, remote-controlled forklifts offer a viable solution for minimizing human risk while maintaining operational efficiency.Byequippingforkliftswithremotecontrol capabilities and integrating them with the BLOS system,operatorscansafelynavigatehazardousareasfrom a distance, accessing real-time video feeds and telemetry data via dashboard interfaces. This innovation not only enhances worker safety but also enables companies to optimize their operational strategies in challenging environments.

We are grateful to the authorities of Visvesvaraya TechnologicalUniversity,Belagavi,India,andBNMInstitute ofTechnology,Bangalore,Indiafortheirencouragementand supportextendedtocarryoutthiswork.Wearethankfulfor the infrastructure and technical support provided by Senquire Analytics Pvt. Ltd., Center of Excellence, BNMIT Campuswheretheexperimentalworkwascarriedout.

[1] Powered Industrial Truck (Forklift) Safety Program. 1910.178 OSHA Powered Industrial Trucks. Western California University. https://www.wcu.edu/WebFiles/PDFs/SAFETYOFFICEIndustrialTruckSafety.pdf

[2] T.Horberry,I.Johnston,T.J.Larsson,B.Corben,andJ. Lambert. (2014). An integrated approach to forklift safety. Monash University Accident Research Centre, Australia Centre for Design, Occupational Safety & Health,RoyalInstituteofTechnology,SwedenandJohn LambertandAssociates,Australia

[3] Erel,F.(2019).Safeworkingwithforklifts[Thesis(M.S.) Graduate School of Natural and Applied Sciences. OccupationalHealthandSafety.].MiddleEastTechnical University.

[4] CarlosCondeCarvalhal.(2020).SafetyOptimizationof MaterialHandlingForkliftTruckOperations.[Masterof Sciences Thesis]. KTH Royal Institute of Technology ProductionEngineeringandManagement.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

[5] Seelinger, M., & Yoder, J. (2006). Automatic pallet engagment by a Vision guided forklift. Proceedings of the2005IEEEInternationalConferenceonRoboticsand Automation, Barcelona, Spain, 2005, 4068–4073. https://doi.org/10.1109/robot.2005.1570744

[6] Cantini, A., De Carlo, F., & Tucci, M. (2020). Towards forkliftsafetyinawarehouse:anapproachbasedonthe automatic analysis of resource flows. Sustainability, 12(21),8949.https://doi.org/10.3390/su12218949

[7] Baird,Renardo(2018).Anautonomousforkliftresearch platformforwarehouseoperations.Diss.Massachusetts InstituteofTechnology(GraduateThesis).

[8] Shete, R. G., Kakade, S. K., & Dhanvijay, M. (2021). A blind-spotassistanceforforkliftusingultrasonicsensor. 2021 IEEE International Conference on Technology, Research, and Innovation for Betterment of Society (TRIBES), Raipur, India, 1–4. https://doi.org/10.1109/tribes52498.2021.9751672

[9] Rhee, J., Park, J., Lee, J., Ahn, H., Pham, L. H., & Jeon, J. (2023).ASafetySystemforIndustrialFieldsusingYOLO ObjectDetectionwithDeepLearning.2023International TechnicalConferenceonCircuits/Systems,Computers, andCommunications(ITC-CSCC),Jeju,Korea,Republic Of. https://doi.org/10.1109/itccscc58803.2023.10210722

[10] Kita, Y., Takase, R., Komuro, T., Kato, N., & Kita, N. (2022).Localizationofpalletsonshelvesinawarehouse using a wide-angle camera. 2022 IEEE 17th InternationalConferenceonAdvancedMotionControl (AMC), Padova, Italy, 187–194. https://doi.org/10.1109/amc51637.2022.9729302

[11] Kita,N.,&Kato,T.(2022).ImageMeasurementMethod for Automatic Insertion of Forks into Inclined Pallet. 2022 17th International Conference on Control, Automation, Robotics and Vision (ICARCV), 441–448. https://doi.org/10.1109/icarcv57592.2022.10004283

[12] Sun,P.,Ding,W.,Lian,M.,&Chen,H.(2023).Localization ofPalletsinNarrowAislesforUnmannedForklifts.2023 3rdInternationalSymposiumonComputerTechnology andInformationScience(ISCTIS),Chengdu,China,53, 786–790. https://doi.org/10.1109/isctis58954.2023.10212995

[13] Ilangasinghe, D., & Parnichkun, M. (2019). Navigation Control of an Automatic Guided Forklift. 2019 First InternationalSymposiumonInstrumentation,Control, Artificial Intelligence, and Robotics (ICA-SYMP), Bangkok, Thailand, 123–126. https://doi.org/10.1109/ica-symp.2019.8646051

[14] Aref,M.M.,Ghabcheloo,R.,Kolu,A.,&Mattila,J.(2016). A multistage controller with smooth switching for Autonomous Pallet Picking. 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden. https://doi.org/10.1109/icra.2016.7487408

[15] Chen, G., Peng, R., Wang, Z., & Zhao, W. (2012). Pallet RecognitionandLocalizationMethodforVisionGuided Forklift.20128thInternationalConferenceonWireless Communications, Networking and Mobile Computing, Shanghai, China. https://doi.org/10.1109/wicom.2012.6478603

[16] Sarupuri, B., Lee, G. A., & Billinghurst, M. (2016). An Augmented Reality Guide for Assisting Forklift Operation. 2016 IEEE International Symposium on MixedandAugmentedReality(ISMAR-Adjunct),Merida, Mexico, 59–60. https://doi.org/10.1109/ismaradjunct.2016.0039

[17] Patil,P.R.,Rajurkar,V.D.,Salunke,A.R.,&Pljonkin,A. (2019). Smart Forklift to Reduce Accidents. 2019 2nd InternationalConferenceonIntelligentCommunication and Computational Techniques (ICCT), Jaipur, India, 318–321. https://doi.org/10.1109/icct46177.2019.8969024

[18] Cao, L., Depner, T., Borstell, H., & Richter, K. (2019). Discussions on sensor-based Assistance Systems for Forklifts.SmartSysTech2019;EuropeanConferenceon Smart Objects, Systems and Technologies, Munich, Germany.

[19] Bostelman, R., & Shackleford, W. (2010). Advanced sensing towards improved forklift safety. PerMIS’10, September 28-30, 2010, Baltimore, MD, USA., 5, 101–106.https://doi.org/10.1145/2377576.2377595

[20] Bostelman,R.(2009).Towardsimprovedforkliftsafety. NIST 100 Bureau Drive, Stop 8230 Gaithersburg, MD 20899 (301) 975-3426, 297–302. https://doi.org/10.1145/1865909.1865968