International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Aleena

Biju1 , Anwar Sadath M A2 , Muhammad Bijas3 , Neja Fathima V.M4 , Lekshmi M S5

1234UG Student, Dept. of Electronics and Communication Engineering, Ilahia College of Engineering and Technology, Kerala, India

5Assistant Professor, Dept. of Electronics and Communication Engineering, Ilahia College of Engineering and Technology, Kerala, India

Abstract - Inefficientwastesegregationremainsacritical environmental challenge, leading to health hazards, contamination of recyclables, and increased processing costs. To solve this, we introduce autosort an intelligent and automated system to make waste management efficient. The system integrates a hand picking robot based on image recognition and machine learning to classify waste into plastic, metal and bio-degradable categories. A smart dustbin with sensors monitors the waste levels and sends automated notifications and sanitization. Autosort increases recycling efficiency, minimizes manual labour and encourages sustainablesanitarywaste disposal.

Key Words: Waste Segregation, IoT, Object Detection, YOLO, Smart Waste Management, Robotic Arm, Arduino, Raspberry Pi.

1.INTRODUCTION

Waste mismanagement is an environmental challenge, causing pollution, ineffective recycling, and health risks. Manual segregation of waste through labor is timeconsuming, inefficient, and dangerous to workers as it involves exposure to toxic materials. The absence of automation in the waste sorting process results in incorrect disposal, causing landfill waste and lowering recycling efficiency. There is a necessity for an intelligent system that can automate waste classification and sorting withlesshumaninterventionandincreasingtheefficiency of waste management. To overcome these challenges, an IoT-based automated waste segregation system is suggested. It utilizes machine learning algorithms, image processing algorithms, and sensor-based classification to sort waste into biodegradable, plastic, and metal streams. Utilizing real-time data processing and IoT connectivity, the system provides efficient sorting as well as monitoring.Ourproject,autosort,includesahandpicking robot, smart dustbin, and rotary bin. The hand picking Robot has image recognition and sensor waste classification, whereas the smart dustbin has an automated sanitization unit. Raspberry Pi, Arduino, and ESP8266 are used to power the system, providing a costeffective, efficient, and scalable solution for intelligent wastemanagement

Pamintuan, Reyes et al. [1] (2019) introduced an IoTbased Smart Waste Management (SWM) system to mechanize segregation of waste and enhance disposal efficiency. The system employs sensor-fitted bins to track fill levels in real-time, optimizing collection schedules and minimizing overflow. Machine learning processes waste generation patterns to optimize route planning and encourage segregation into dry and wet streams. This methodenhanceswastemanagementefficiency,minimizes operational costs, and maximizes urban hygiene. The research illustrates how IoT technology has the ability to enhancewastemanagementaseffectiveandsustainable.

Sharma et al. [2] (2020) segregates waste into metal and non-metal. The system is an improvement in waste management by minimizing landfill waste and facilitating recycling. The system also identifies toxic gas emissions from organic waste, alerting users for early disposal to avert pathogen development. Further, an automatic alert system reminds users when the bin is full to facilitate effective waste collection. This method enhances public safetyandenvironmentalhealththroughthesimplification ofwastedisposalprocedures.

Jaswal et al. [3] (2023) suggested an IoT-based smart dustbin for enhanced household waste segregation. The system classifies waste as dry or wet based on moisture sensors and fill levels using ultrasonic sensors, triggering alerts through theBlynkapp when 90 per cent capacityis reached. The smart dustbin efficiently routes waste into correct compartments, maximizing recycling and minimizingenvironmentalfootprint.Inspiteofissuessuch as sensor effectiveness and the requirement for sophisticated algorithms, the research emphasizes the promise of intelligent waste management solutions for a cleanerandgreenerworld.

Harithaetal.[4](2023)designedanimageprocessingbased automated waste segregation system that categorizes waste as recyclable and non-recyclable. The systemutilizesaconveyorbelt,acamera,andaCNNmodel on a Raspberry Pi to detect the type of waste with more than 89 per cent accuracy in classification. An L-shaped clamp segregates waste into respective bins, minimizing manual handling and health hazards. Through efficient

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

recycling, the system facilitates sustainable waste managementandencouragesenvironmentalpreservation.

Jacob et al. [5] (2024) suggested an Automated Waste Segregation System (AWSS) which segregates waste into dry, moist, and metallic types by employing Automatic Speech Recognition (ASR) and IoT technology. Arduino microcontrollers and sensors are integrated in the system to identify types of wastes, incorporating voice input to permit user communication. Waste is channeled into suitable bins using a rotating chamber, and bin levels are tracked for effective collection through an Android application. The system enhances sorting accuracy and efficiency over manual sorting. Regardless of drawbacks such as collection inefficiencies and costs, it is a scalable andsustainablesolutionforwastemanagement

The currently used waste management infrastructure is mostly based on manual sorting, which is labor intensive, wasteful, and poses health risks to the workers. Conventional practices also cause improper separation, resulting in inefficient recycling and more landfill waste. There are some automated processes available, but they do not provide real-time adaptability, sophisticated classification methods, and hygiene protocols. Moreover, most of the existing solutions are not integrated with IoT for monitoring and remote control, preventing them from achieving maximum efficiency in mass usage. To address these limitations, Autosort is created as a complete automated system that improves the accuracy and efficiency of waste classification. The system consists of a hand picking robot, a smart dustbin, and a rotary bin, all coupledwithmachinelearning,imagerecognition,andIoT technologies.Thehandpickingrobotemployssensorsand real-time image processing to sort waste into biodegradable, plastic, and metal types with high precision. Identified waste is then routed to the Smart Dustbin, which has waste level detection and an automated sanitization unit for hygiene maintenance. The rotary bin facilitates proper sorting and systematic disposalthroughamotorizedsystem

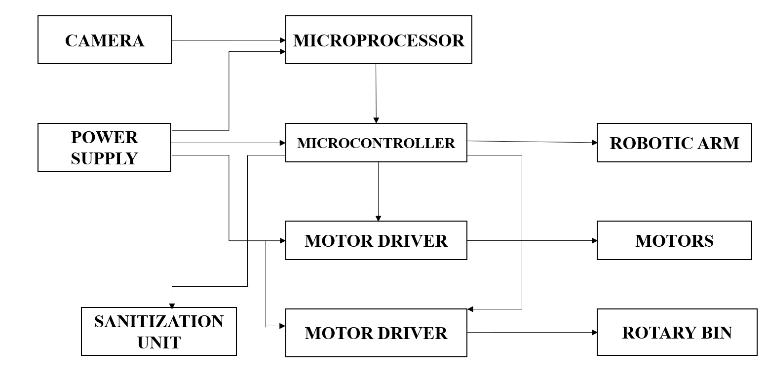

4.1 Block Diagram

Theprocessbeginswithacamerathattakesliveimagesof waste items. The images are analyzed by a microprocessor,whichexecutestheYOLO(YouOnlyLook Once) object detection model to identify the category of wasteasbiodegradable,plastic,ormetal. Theresultofthe classification is then transferred to the microcontroller, whichservesasthemaincontrolunit,makingthedecision on waste management based on the identified category. The microcontroller sends instructions to motor drivers controllingvariousactuatorswithinthesystem.Oneofthe

motor drivers is used to move the robotic arm, which loads the sorted waste and transfers it to the respective compartmentoftherotarybin.Thesecondmotordriveris used to rotate the rotary bin, directing the waste into its respective compartment. Also, a sanitization unit is built intothesystemtoensurehygienethroughdisinfectingthe waste collection area to prevent bacterial growth and odor. The whole system operates on a separate power supply to provide uninterrupted service. Through the integration of machine learning, microcontrollers, and automated actuators, this system optimizes waste segregation efficiency with minimized human effort. The process begins with a camera that takes live images of waste items. The images are analyzed by a microprocessor,whichexecutestheYOLO(YouOnly Look Once) object detection model to identify the category of wasteasbiodegradable,plastic,ormetal.Theresultofthe classification is then transferred to the microcontroller, whichservesasthemaincontrolunit,makingthedecision on waste management based on the identified category. The microcontroller sends instructions to motor drivers controllingvariousactuatorswithinthesystem.Oneofthe motor drivers is used to move the robotic arm, which loads the sorted waste and transfers it to the respective compartmentoftherotarybin.Thesecondmotordriveris used to rotate the rotary bin, directing the waste into its respective compartment. Also, a sanitization unit is built intothesystemtoensurehygienethroughdisinfectingthe waste collection area to prevent bacterial growth and odor. The whole system operates on a separate power supply to provide uninterrupted service. Through the integration of machine learning, microcontrollers, and automated actuators, this system optimizes waste segregationefficiencywithminimizedhumaneffort.

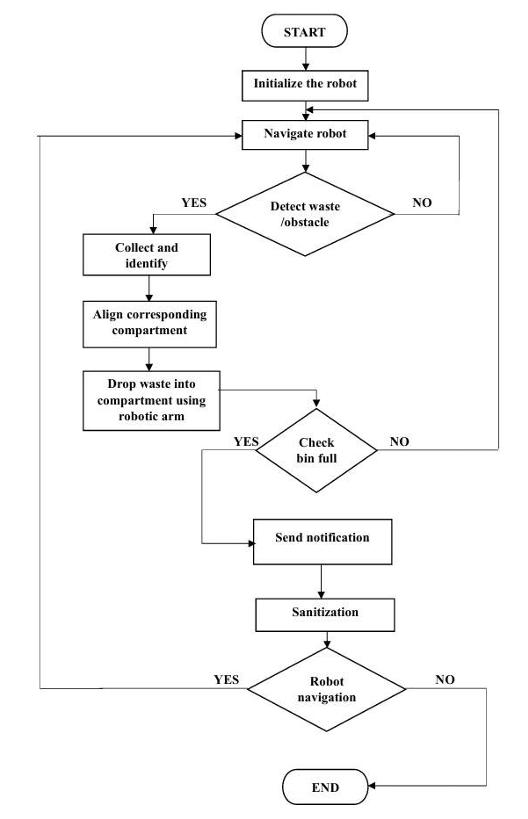

4.2 Flow Chart

Thework flowofthewastesegregationrobotbeginswith initializingtherobot,settingupitssensors,andpreparing it for navigation. Once initialized, the robot starts moving through its designated path. As it navigates, it continuouslyscansforwasteorobstaclesusingsensors.If no waste or obstacles are detected, the robot continues moving.However,ifwasteisdetected,therobotstopsand

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

proceeds to collect and identify the type of waste using yolo algorithm. After identifying the waste, the robot aligns itself with the appropriate compartment assigned for that specific waste type. Using a robotic arm, it drops the waste into the correct bin. The system then checks if the bin is full. If the bin is not full, the robot resumes navigation.Ifthebinisfull,thesystemsendsanotification to alert authorities for waste removal. Once the waste is removed, the sanitization unit activates to clean the bin andmaintainhygiene.Finally,thesystemchecksiffurther navigation is required. If required, the robot resumes movement; otherwise, the process ends. This automated workflow ensures efficient waste collection, segregation, anddisposal,reducinghumanintervention.

4.3 Hardware Implementation

• Arduino UNO: Acts as the brain of autosort, coordinatingallactions.

• Ultrasonic Sensors: Detects obstacles and helps withnavigation.

• UV-CLED: UV light emission for sanitization purposes

• Raspberry Pi: Connected to the Arduino, it handles the YOLO-based waste detection algorithmusingacamerafeed

• NodeMUC:Itgivesthealertsignaltoauthority

4.4 YOLO Algorithm

YOLOalgorithmidentifiesandclassifieswastelikeplastic, biodegradable and metal in real time. The Raspberry Pi camera captures images of waste, and YOLO processes them to detect waste. If YOLO classify the waste, it sends signals to arduino for align the corresponding compartment

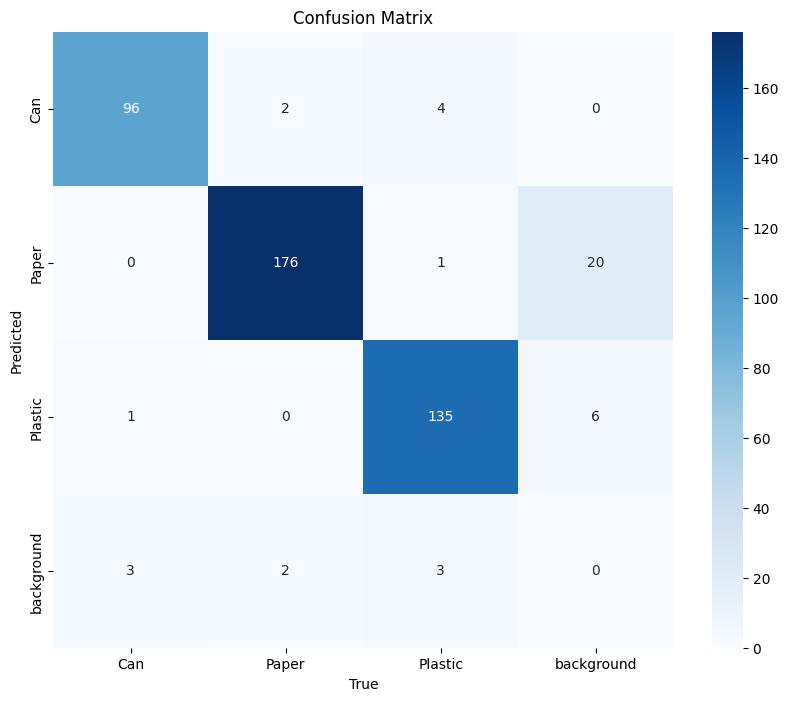

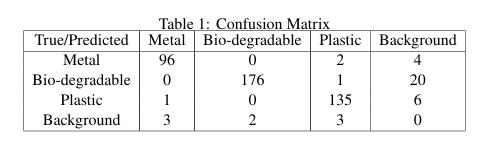

5.1 Confusion Matrix

A confusion matrix is a table employed to measure the performance of a classification model based on predicted andactualvalues

Fig -3:Confusionmatrix

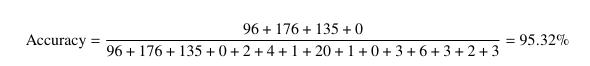

5.2 Accuracy Calculation

The classification accuracy is computed using the following equation: Based on the confusion matrix in Table1,theaccuracyiscalculatedas:

Accuracy:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

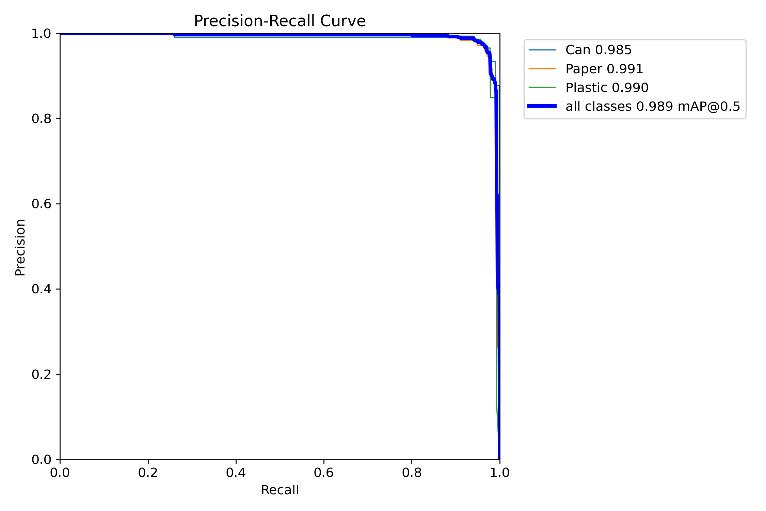

PR curve stands for Precision-Recall curve. It is a performance evaluation metric used in classification problems,particularlyforimbalancedatasets.

Precision(Positive Predictive Value): Measures how many of the predicted positive instances are actuallycorrect.

• Recall (Sensitivity or True Positive Rate): Measures how many actual positive instances werecorrectlypredicted

Where:

• True Positives ( ) = The model accurately predictsapositivecase.

• True Negatives( ) =The model accurately predictsanegativecase.

• False Positives ( ) = The model predicts a positive case when it is not (also referred to as a Type1error).

• FalseNegatives( )=Themodelfalselypredicts a negative instance when it is indeed positive (alsoreferredtoasaType2error).

This effectively automates waste segregation using machine learning and IoT-based robotic systems. The combination of computer vision, sensor-based detection, and robotic automation allows for effective sorting of waste into metal, bio-degradable, plastic, and background classes. The YOLO-based object detection model was found to have high accuracy, as confirmed by confusion matrix analysis. The addition of a UV sanitizing unit ensures safe handling of waste, which makes the system appropriate for 7 use in smart waste management. The model was good but had slight misclassifications, which can be enhanced through refining the dataset, more advanced deep learning algorithms, and real-time calibration. Future improvements may target industrial scalability, cloud-based tracking of waste, and real-time sorting optimization. The work advances green waste management by minimizing manual labor and encouragingefficientrecycling

Future enhancements can boost accuracy, speed of processing, and responsiveness to varied types of waste. Increased dataset, optimization of the machine learning algorithm,andinclusionofadvancedsensorscanenhance performance. Real-time processing and improved robotic manipulation will also enhance efficiency, making the systemmoreviableforlarge-scaleapplications.Moreover, theinclusionofAI-baseddecision-makingandcloud-based data analytics can facilitate ongoing learning and remote monitoring. Improving the system’s capacity to identify and process intricate waste products, including multilayered plastics and hazardous waste, will further extend its uses. Embedding IoT connectivity into smart city programscanresultina more efficient,sustainable waste managementsystem.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

[1] MikoPamintuan,ShielaMaeMantiquilla,HillaryReyes,M aryJaneSamonteSchoolofInformation Technology Mapua University Makati City ”i-Bin: An intelligent trash bin for automatic waste segregation and monitoringsystem”.

[2] PratyushaSharma,PraveenKumar,RitikaNigam,Kushag raSingh,”Automaticwastesegregationand selfsanitizingdustbin”

[3] Pragun Jaswal,Mandi, Zubair Ahmad Sofi, ”Intelligent wastesegregationusingsmartIoTbaseddustbin”

[4] Haritha K N,Gopika S Pillai,Jyothi Krishnan M ”Automated waste segregation system using image processing“

[5] Haritha K N,Gopika S Pillai,Jyothi Krishnan M ”Automated waste segregation system using image processing”

[6] MaryP.Varghese,M.Krishnakumar,V.S.AnoojaArun Xavier,”IoT-basedwastemanagementsystem”

[7] L. Atzori, A. Iera, and G. Morabito, “The Internet of Things: A survey,” Comput. Network., vol. 54, no. 15, pp.2787–2805,2010.

[8] A. Meijer and M. P. R. Bol´ ıvar, “Governing the smart city: a review of the literature on smart urban governance,”Int.Rev.Adm.Sci.,vol.82,no.2,pp.392–408,2016.

[9] A. Zanella, N. Bui, A. Castellani, L. Vangelista, and M. Zorzi, “Internet of things for smart cities,” IEEE InternetThingsJ.,vol.1,no.1,pp.22–32,2014

[10] A. Mohamed and H. A. Rahman, “Study on public awareness towards recycling activity in Kota Bharu, Kelantan Malaysia,” Advances in Environmental Biology.,vol.8,no.15,pp.19–24,2014.

[11] C. Bircanoglu, M. Atay, F. Beser, O. Genc and M. A. Kizrak, “RecycleNet: Intelligent Waste Sorting Using Deep Neural Networks,” in Proceedings of the 2018 IEEE (SMC) International Conference on Innovations in Intelligent Systems and Applications, INISTA, July 2018.pp.1–7.

[12] K. S. Hulyalkar S., Deshpande R., and Makode K, “Implementation of Smartbin Using Convolu tional Neural Networks,” Int. Res. J. Eng. Technol., vol. 5, no. 4,pp.1–7,2018