International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Alejandro Roberto Tello Campos 1 , Saúl García Hernández2 , William Vicente Rodríguez1 , Rodrigo Ocon Valdez3

1Researcher, Instituto de Ingeniería, Universidad Nacional Autónoma de México, CDMX, 04510, México

2Researcher, TecNM–Instituto Tecnológico de Morelia, Maestría en Ciencias en Metalurgia, Morelia, Michoacán, 58120, México.

3Professor, Facultad de Estudios Superiores Aragón, Universidad Nacional Autónoma de México, Nezahualcóyotl, 57171, México.

Abstract – In this study, a 3D thermal simulation of an ONAN power transformer using two oil inlets and two oil outletswasperformed.Asimilarsimulationwasperformed inapreviouspaperusingonlyoneoilinletandoneoiloutlet. Thebenefitsofthissimulationarethattheoilvelocityvector graphicsshowanoilcircuitthatformsattheinlets,which preventsoilfromflowingsmoothlythroughthewindingsof thetransformer, guidingoildirectlyfrominletstooutlets. Furthermore, as oil velocity increases, the transformer is cooledmoreefficiently.Alsomapsofoilbeingheatedwere found to be illustrative as the inner surfaces of the LV windingswerehotterthantheonesoftheHVwindings.This kind of simulation also helps to understand the fluid dynamicsofoilwithinthewindingsandcore.

Keywords: transformer; CFD; oil flow; 3D Model; temperature

Power transformers are electrical equipment that are necessarytotransformvoltagesfromoneleveltoanother. Theyhavebeendesignedtoconnectoneelectricalcircuitata highvoltagetoanotheratalowervoltage.Theyareelements thathavetoperformtheirfunctionforatleast25years.In thisregard,astheyareconstructedoutofwindingswhichare embeddedinacoreforminganelectromagneticcouplingof thehighandlowvoltagecircuits,theyproduceanamountof heat due to the Joule effect generated by the circulating currentintheconductorsofwindings.Thetransformeritself hastobecooleddownbyoilcirculatingthroughthewindings andcore.Thishelpstoincreaseitslifetimeandperformance. Thesepowertransformersarelargeinnumbers,sotheymust beefficient.Theelectricalefficiencyofthisdeviceishigh,but it could still be increased byoptimizing the cooling of this apparatus. That is the main reason for studying the flow phenomenathatoccur,whicharedirectlyrelatedtotheoil beingcirculatedinanaturalwayorbeingforcedbyusinga pump, which employs a radiator to dissipate the heat producedintheelectricalconductors.

Duringthepastdecades,alotofresearchhasbeendoneto investigatethehotspotwithintransformerwindings.From advancedmathematicaltechniques[1,2,3]thatareemployed tosolvetheenergyequationsthatrepresenttheheattransfer occurringinwindingsandobtainthewindingstemperatures Also,otherresearchershavesolvedthemomentum,energy, andcontinuityequationsinasimplified2DCFDmodel,which employnumericaltechniquestosolvetheseequationsand obtainamoredetailedviewofoilvelocitiesandtemperatures insimplifiedversionsofawinding.Inthisstudy[4],alotof simplification in the winding’s geometry has been done to simplifythecomputationaltimeandidentifythemaximum windingsandoiltemperaturesandtheirexactlocation.

In this study, a graphical representation of oil flow within transformers is presented. Contours of oil velocities and temperatures along with windings and core temperatures were calculated. A power transformer model with two oil inletsandtwooiloutletswasconsideredforuse

A3Dmodelwasemployedtocapturethephysicsofoilflow within windings and core, comparing it with the one obtainedinanotherstudy[5],whichusesonlyoneoilinlet and one oil outlet. This helps to understand the oil flow dynamicsobtainedatlowoilflowrateswhichareobserved in ONAN power transformers. Final remarks include an analysis of the benefits obtained from this study and the possibleimprovementsthatcanbemadetothe3Dmodelin ordertooptimizethecoolingofthepowertransformer.

Thepowertransformeriscomposedbasicallyofwindings surroundingacentralcore.Thisassemblyiscontainedina tankandimmersedinmineraloil.Supportingstructuresare other components that help maintain the assembly in a vertical position within the tank. Also, the whole power transformerusesexternalair-cooledradiatorsthathelpcool downthehotoilcomingfromthewindingsandcore.This effect of heat generation produced by the circulation of electricalcurrentswithinthewindingsandcoreiswhatis normallycalledJouleeffect.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Power is normally converted from low to high voltage throughthesewindings,whicharedecomposedintotheLV and HV winding. Using ceramic isolators, power is transmittedtoplaceswhereitisneededtoenergizehighor lowvoltageloads.

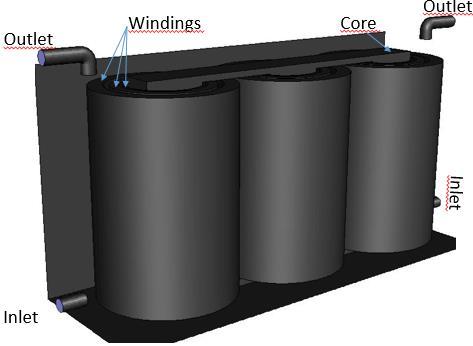

The 3D model considered is depicted in Figure 1. It is a three-phase winding and core assembly contained in a containercalledatank.Inordertosimplifythemodel,allthe internalsupportingstructuresandexternalradiatorswere not considered. Only the three windings composed of cylindricalinnerLVandouterHVwindingwereconsidered andsetinthethree-columncore.

In this case, two oil inlets and two oil outlets were considered. The real geometry of the transformer is composedoffouroilinletsandfouroiloutlets.Oilvelocities intheorderof0.002,0.05and0.1m/swereestablishedat theinletsandzeropressurewassetattheoutlets.

Theequationsrepresentingtheoilflowandtemperatureand thesolidcopperconductors considerthepropertiesofthe oil, windings, and core, which vary with temperature as follows(Table1)

Table1.Propertiesoftheoil,thewindings,andthecore

Thecontinuity,momentum,andenergyequationsalongwith the turbulent energy equations are solved by means of a finite volume code named ANSYS-Fluent, which uses an algorithmtoobtaintheoilvelocitiesandtemperaturesofthe fluidandthewindingstemperatures.

Thepowerdissipationofeachwindingandcoreandtheone includedinthe3Dmodel,isdepictedinTable2.

Table2 Thepowerdissipationofeachwindingandcore, andtheoneincludedinthe3Dmodel

In this study, oil flow dynamic is one key point in the analysis. That is, as oil velocities are quite low, which is typicalofanONANpowertransformer,thedynamicsofflow depend highly on the geometry of the windings and core assembly. In simple words, oil follows the path of least hydraulicresistance.Then,threedifferentoilvelocitiesare establishedattheinlets,whichformourstudycases

A. 0.002m/soilvelocity

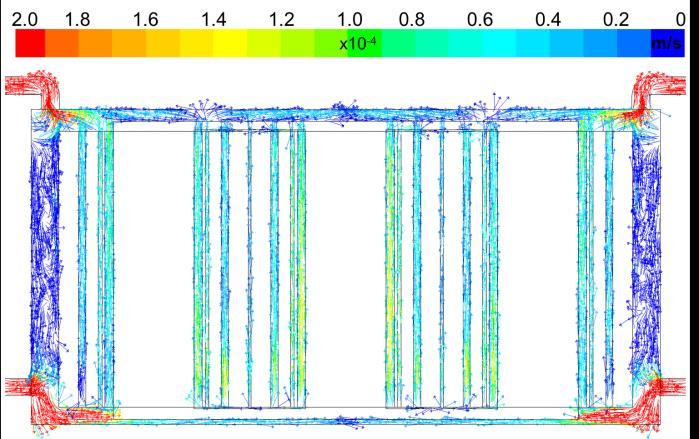

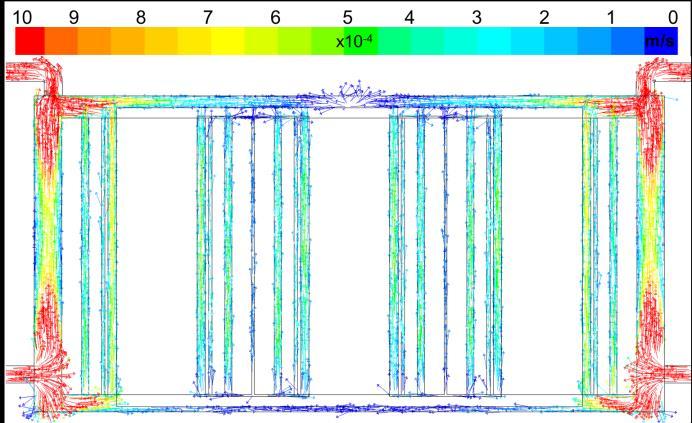

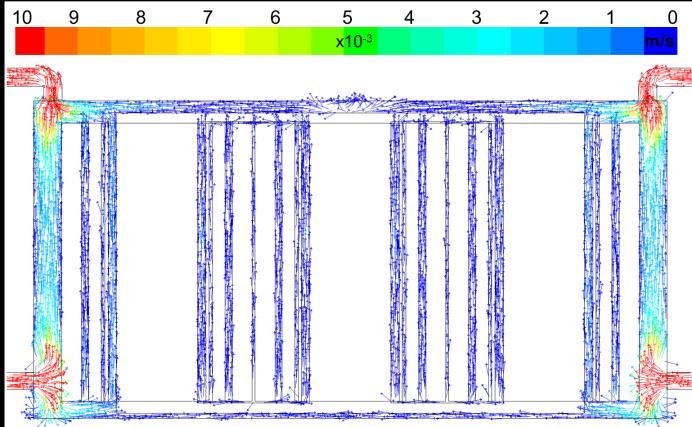

This case emphasizes a typical oil velocity encountered in naturalflowconditions.Therefore,besidestheoilpressure obtainedfromoilvelocity,thedifferenceinoiltemperature betweenthetopandbottompartofthewindingsestablishes a present flotation term. On the other hand, the pressure lossesarequitehighduetotheroughnessofthewindings andcoresurfaces.So,onceabalanceisestablishedduetothe oilcirculationinthewindingsdepartingfromtheoilinitial temperature of 20°C, oil will follow the least hydraulic resistancepath.ThisbehaviorisshownclearlyinFigure2,a velocity vectorfield ofthe power transformer. This Figure also shows that oil goes through the central part of the windings and core assembly at lower velocity while oil

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

followsthesidesofthewindingsandcoreassemblyathigher velocities

Fig -2:Oilvelocitiesat0.002m/s

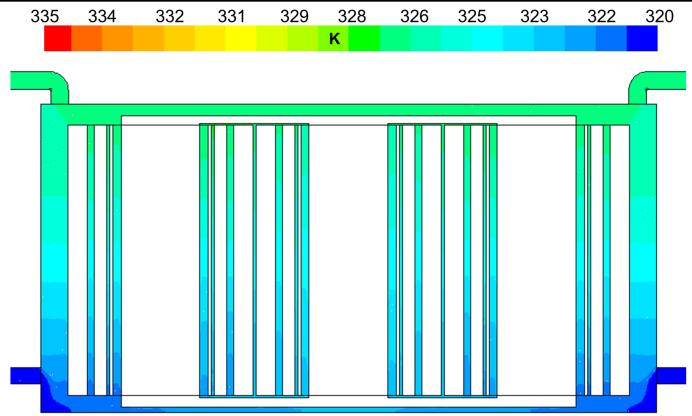

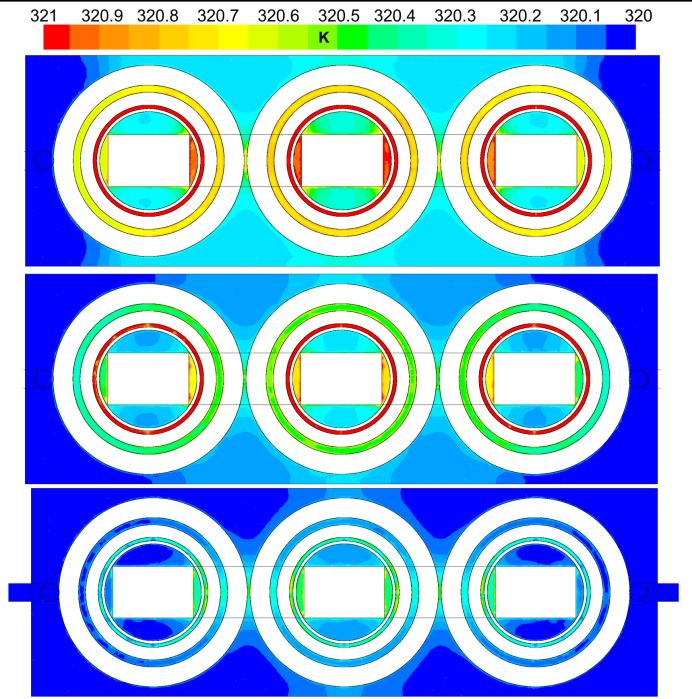

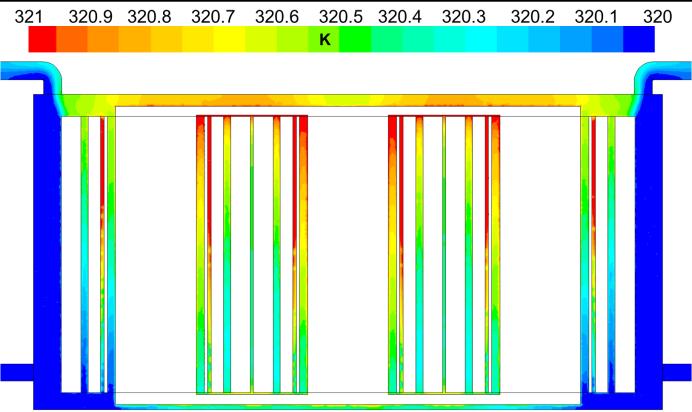

Oil temperatures encountered in this case are quite representative of how the heat being generated by the windingsandcoreassemblyrapidlyestablishesadifference intemperaturefromtoptobottom,whichisderivedmostly from the hydrodynamic force of oil coming from the two inlets.ThisbehaviorisshowninFigure3.

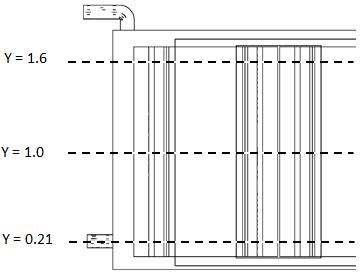

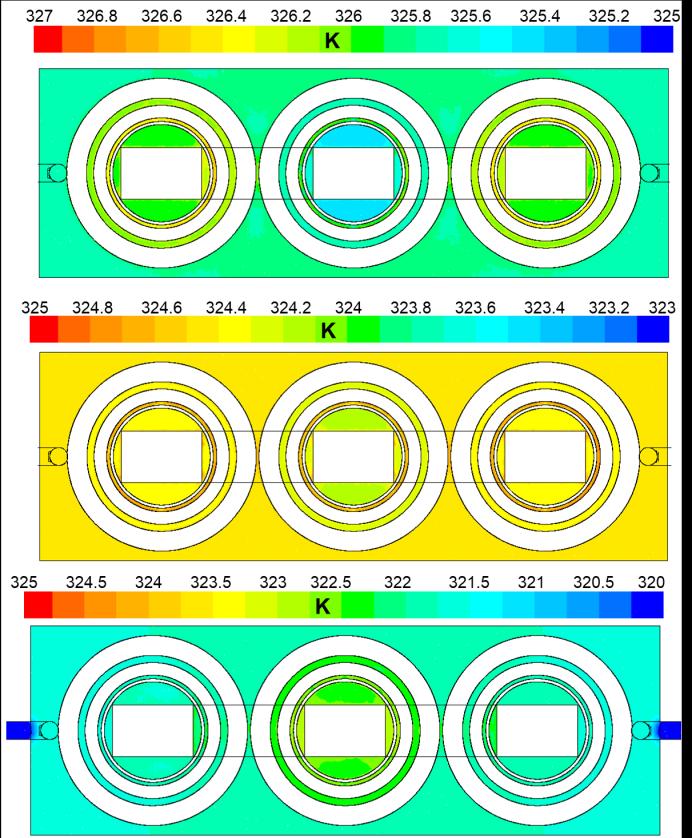

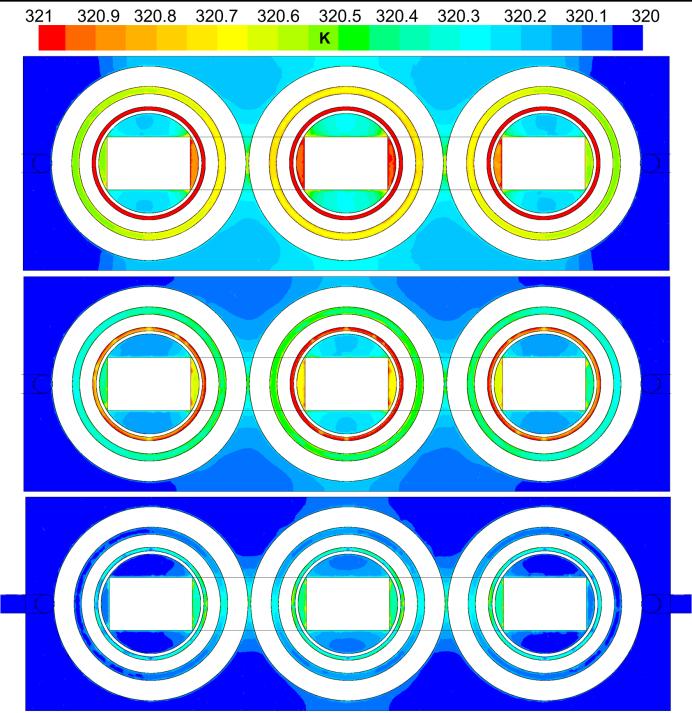

Fromthisfigure,asymmetricalpatternoftemperaturesis alsoobserved,whichhelpstocooldownthewindingsand thecoreassemblymoreefficiently.Theviewfromthetopof thewindingswhichcontainthreeverticalplanesisshownin Figure4.Clearly,Figure5showsthatoilisuniformlyheated within the windings. A more detailed graph of the oil temperature within the windings and core is depicted. Central zonesofthewindingsatplanesy=0.21andy=1.0 showhigheroiltemperaturewhileleftandrightwindings depictzonesofloweroiltemperature.Planey=1.6shows that higher oil temperature is found at the left and right windingswhileloweroiltemperatureisfoundatthecentral winding.

Asinthecaseofoilcirculatingat0.002m/s,thedynamicof oil in this case follows the same trend, which involves oil going from the inlets to the outlets through the least hydraulicresistancepath.Figure6showsthatoilfollowsthe sidesofthewindingsathighvelocity,andtherestoftheoil flowsthroughthewindingsandthecoreatlowervelocities.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Fig – 6: Oilvelocitiesat0.05m/s

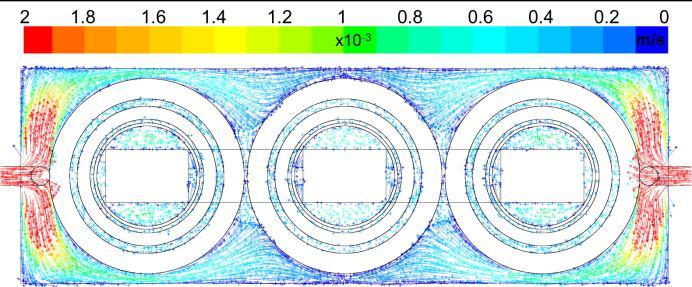

Another interesting feature of the oil dynamic is the spreadingofoilfrominletsandtheimpingingofwindings,as depictedinFigure7.

Fig – 7: Oilvelocitiesaty=0.21

Thishelpstodistributeoilmoreevenlyinthewindingsand coreandpromotesmoreareasofcoldoilatthebottomand loweroiltemperatures(seeFigures8and9).

Fig – 8: Oiltemperaturesat0.05m/s

Fig -9:VerticalplanesofOiltemperaturesat0.05m/s

C. 0.1 m/s oil velocity

Finally,a0.1m/soilvelocitywasanalyzedinordertoobtain a deeperinsight intothedynamicsofoil flow through the windingsandcoreofthepowertransformer.

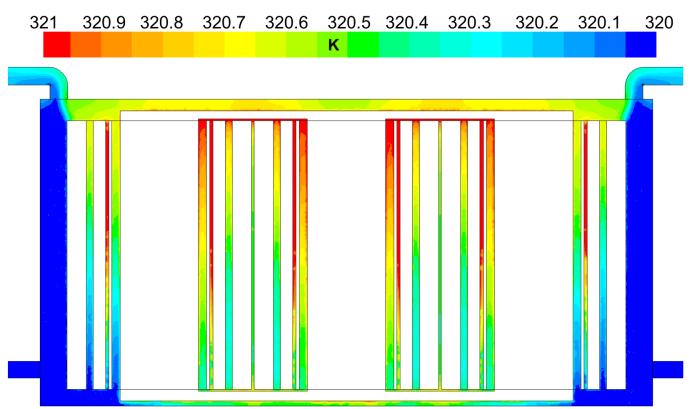

Fig – 10:Oilvelocitiesat0.1m/s

Figure10depictsthatoilflowthroughthewindingsandcore athighervelocityatthesidesbutreducedoilvelocitiesare encounteredatthecentralpartofthewindingsandcore.

Figures 11 and 12 show a similar trend for cooling the windingsandcoreasinpreviouscases,promotingabetter coolingefficiency.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Figure12depictsasimilarevencoolingofthewindingsand coreasinthe0.05m/scase.Probably,thedifferencebeing thatoilisflowingathighervelocity,thereforereachinghigher levelsofthewindingsandcorewithcoldoilandpromoting higherheatdissipation,andgivingasaresultperfectlyless defined zones of hot oil located at the inner surface of LV windings.

4.

The 3D model employed for the thermal simulation of the powertransformerwasfoundtobequitehelpfulbecauseit cangiveacomplete,detailedpictureofoilflowingthrough thewindingsandcoreassembly.Threecaseswereanalyzed here:the0.002,0.05,and0.1m/soilvelocities.Twoinlets andoutletsweredefinedandheatdissipationwassetforthe LV and HV windings and core. The maximum oil

temperaturesshownforthe0.002m/scaseareintheorder of328Kwhileforthe0.1m/scaseis321K.Thistrendgives aclearideaofhowtheincreaseinoilvelocitydecreasesthe oiltemperature.Also,thedistributionofoilhavingtwoinlets ismoreuniform,andmaximumoiltemperaturesarefoundin thetoppartofthewindings,whichareconcentratedinthe innerpartofthehighvoltagewindings.

Thedynamicofoilwasobtainedforeachcaseshowinghow oilisdistributedinthewindingsandthecoreaccordingto the hydraulic pressure resistance being developed. Oil is directedfromtheoilinletstotheoutletsfollowingtheless hydraulic resistance path, which was the sides of the windings. Oil is also distributed through the windings and core,butwithlowervelocities.Itwasfoundthatthecaseof 0.002 m/s oil velocity was the least efficient in terms of cooling. The other cases of 0.05 and 0.1 m/s oil velocities werefoundmoreefficientintermsofwindingscooling,and morecoldoilisdistributedalongtheheightofthewindings, reducingthepossibilityofhavinghighoiltemperatureszones withinthewindings.

As a final remark in further studies, other features of the power transformer are suggested to be analyzed, such as pursuing a simulation using different cooling oils and comparingitwiththecaseofmineraloil.

[1] M.K. Pradan, T.S. Ramu, “Estimation of hottest spot temperatureinpowertransformersconsideringthermal inhomogenietyof the windings”,IEEEtransactionson power delivery, vol 19, no.4, pp. 1704-1712, October, 2004.

[2] F. Bulnes, A.R. Tello, “ Heat flux analysis in electrical transfromersthroughintegraloperatorsofmechanics”, ModernMechanical Engineering Journal,Vol04,No.2, pp84-107,May2014.

[3] M.K. Pradan, T.S. Ramu, “Prediction of hottest spot temperatureinpowerandstationtransformers”,IEEE transactionsonpowerdelivery,vol.18,no.4pp.12751283,October,2003.

[4] M. Ghanbari, M.A. Taghikhani, “ Layer type power transformeranalysisconsideringeffectiveparameters on the temperature rise”, Advanced energy: An InternationalJournal,Vol.1,No.1,January,2014

[5] A.R.TelloCampos,W.Vicente,R.OconValdez,S.Garcia Hernandez, “A thermal simulation of a power transformer using 2D and 3D models” International Research Journal of Innovations in Engineering and Technology,Vol.6,Issue8,pp.1-10,August2022.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

ThankstoTecNM-InstitutoTecnológicodeMorelia,Centro de Graduados Metalúrgicos, and particularly to Dr Saul Garcia Hernandez for his invaluable contribution to the simulation of the 3D models of the power transformer. Thanks to IEM for its assistance in providing the temperaturemeasurementsofthepowertransformer.

Alejandro Roberto Tello Campos

HeobtainedhisB.ScinMechanical and Electrical Engineering from the National Autonomous University of México in 1979 and his M.Phil. from Cranfield University, England in 1989 and hisPhDinMechanicalEngineering, Energy Specialization from the National Polytechnic Institute, México in 2009. He has been workinginthethermalsimulation ofpowertransformersforthepast 17years

BSc Graduated in Chemical Engineering Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Michoacán in 2002. MSc in Metallurgy from Instituto Tecnológico de Morelia, Morelia,Michoacánin2007.PhDin Metallurgy from Instituto PolitécnicoNacional,Méxicocityin 2010 His interest is in vortex formation in Steel-making processes Flow visualization and imageprocessing. Hehaslectured severalBSccoursesonCFDandC programminglanguageinMéxico. Hehaspublishedseveralpapersin nationalandinternationaljournals and participated in several national and international meetings.

William Vicente is a research engineer at the Engineering InstituteoftheUNAM,Mexico.He received his Ph.D. in Fluid Mechanics in 2000 from the UniversityofZaragoza,Spain.Heis currentlyworkingonheattransfer, combustion, turbulence, and ComputationalFluidDynamics

Rodrigo Ocon-Valdez wasbornin Mexico. He obtained his B.Sc. in Mechanical-ElectricalEngineering fromtheUniversidadAutónomade Mexico(UNAM-1995)andhisM.Sc. in Electrical Engineering from Instituto Politécnico Nacional in 2004. Since 1993, he has been professor of electrical machines andpowersystemsatFacultadde Estudios Profesionales ARAGON, UNAM Since 1995, he has been working in the Engineering and development of power transformersinIndustriasIEMSA deC.V