International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

ANJALI

1PG student, Dr. Subhash University, Junagadh

2H.O.D, Department of Civil Engineering, Dr. Subhash University, Junagadh, Gujarat

3Assistant Professor, Department of Civil Engineering, Dr. Subhash University, Junagadh, Gujarat

4Assistant Professor, Department of Civil Engineering, Dr. Subhash University, Junagadh, Gujarat

5Assistant Professor, Department of Civil Engineering, Dr. Subhash University, Junagadh, Gujarat

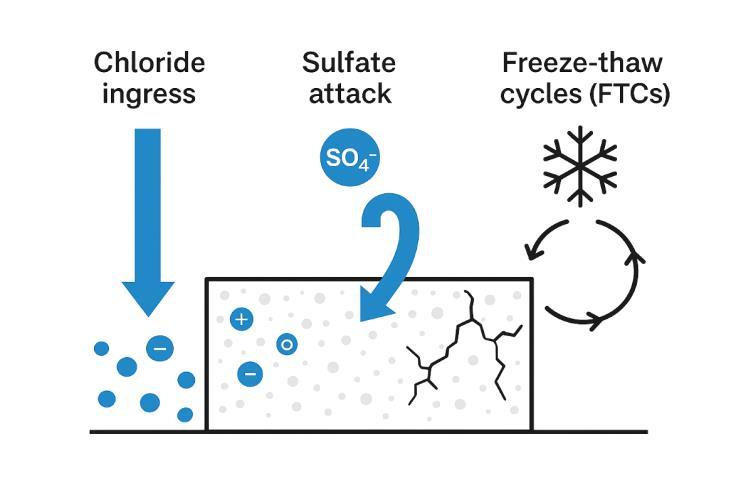

Abstract – High-Performance Concrete(HPC)isessentialfor resilient structures inaggressivemarine environments,which are characterized by severe chloride ingress, sulfate attack, and freeze-thaw cycles (FTCs). Curing, which dictates the cementitious matrix's microstructure and pore network, is a pivotal factor in achieving HPC's inherent durability. This review synthesizes recent research on the impact of different curing methods including standard, accelerated, internal, andshort-terminitialcuring ontheperformanceofHPCand advanced cementitious materials when exposed to marine deterioration agents. Findings indicate that advanced curing techniques, particularly internal curing with Superabsorbent Polymers (SAP) and accelerated methods like microwave curing, significantly enhance resistance to shrinkage, permeability, and sulfate attack. Furthermore, the incorporation of Supplementary Cementitious Materials (SCMs) enables robust long-term chloride durability even under short initial curing regimes. This research underscores the need for tailored curing strategies to maximize the longtermdurabilityofHPC inthe demandingconditions ofcoastal and offshore infrastructure.

Key Words: High-Performance Concrete (HPC), Marine Environment, Curing Methods, Chloride Ingress, Sulfate Attack, Superabsorbent Polymers (SAP), Supplementary Cementitious Materials (SCMs), Durability.

Concretestructuresinmarineandcoastalareasaresubject tooneofthemostaggressivedeterioratingenvironments, primarilyduetothesynergisticeffectsofchlorides,sulfates, moisturegradients,andfreeze-thawcycles(FTCs).Theuse ofHigh-PerformanceConcrete(HPC),whichoftenincludesa high volume of SCMs and a low water-to-binder ratio, is mandatoryforachievingthenecessarydurability.However, thesuperiorperformanceofHPCiscriticallydependenton effectivecuring.Curingsuppliesthenecessarymoistureand temperature conditions for optimal cement hydration, therebyreducingpermeability,refiningtheporestructure, andmitigatingearly-agecracking,whichareallessentialfor marinedurability.

Theselectionofa curing methodsignificantlyimpactsthe microstructure of the concrete matrix, which directly governs its resistance to external ingress of aggressive ions.

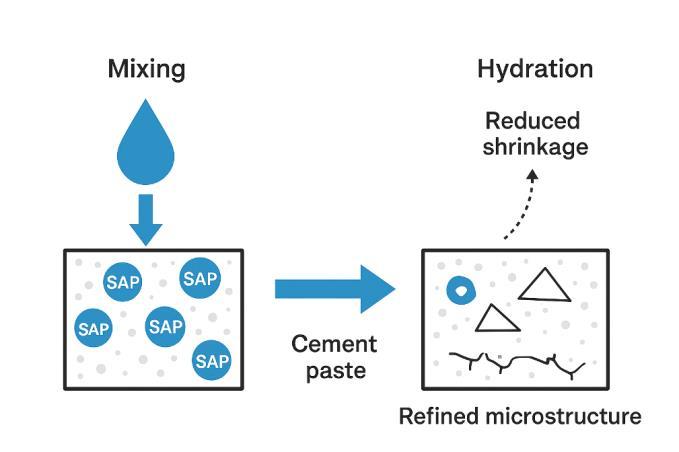

Internalcuring,typicallyachievedthroughtheincorporation of Superabsorbent Polymers (SAP), is a vital strategy for HPC,particularlyUltra-High-PerformanceConcrete(UHPC), whichsuffersfromhighautogenousshrinkage.

o SAP functions by regulating early cement matrix hydration, absorbing water, and releasing it internally to ensure long-term stability and structuralintegrity.

o ThecombinedapplicationofSAPforinternalcuring andaWaterborneEpoxyCoating(WEC)forexternal protection has been shown to be highly effective against complex marine attacks, resulting in a significantreductioninmasslossanddegradation

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

of the relative dynamic elastic modulus under compoundsulfateattacks.

Acceleratedcuringregimesutilizeelevatedtemperaturesto rapidly enhance early-age strength and refine the pore structure. These methods are frequently used for precast elementsinmarineconstruction.

Steam and Autoclave Curing: Thesearecommon methods for UHPC, and while they can achieve satisfactory compressive strength values, the optimal regime requires careful monitoring to maximize the output and avoid adverse effects. Steamcuringathightemperatures(e.g.,90∘Cfor3 days)isacommonregimestudiedforitseffectson UHPCproperties.

Microwave Curing: Low-pressure microwaveaccelerated heating, also known as accelerated dewatering, has been shown to improve the properties of Portland cement pastes, specifically enhancing ultra-durability by minimizing drying shrinkageandimprovingwaterpermeability.

The durability of sustainable alternatives, such as alkaliactivated concrete (AAC) utilizing materials like raw rice huskashandblastfurnaceslag,isalsohighlydependenton curingconditions.Crucially,theuseofpozzolanicSCMs(e.g., blast furnace slag, metakaolin, nanosilica) in low-cement blendsallowsfortheachievementofremarkablelong-term chloride durability even when the initial curing age is shortenedtojustoneday.Thisfindingishighlyrelevantfor constructiontimelinesandsustainabilitygoals.

Surface treatments are a common and economical anticorrosion technique that involves applying protective coatingsorsurfacepreservativestothehardenedconcrete.

● Protective Coatings: These surface curing and treatmenttechnologiesactasaphysicalbarrierto preventtheexternalenvironment,suchaschlorideladen seawater, from penetrating the concrete cover.Thismethodisfavoredforitsconveniencein constructionandcost-effectiveness.

Internal curing (IC) and the more advanced self-healing concrete methods address the need to maintain moisture internally, particularly in low water-to-cement ratio HPC, whichispronetoautogenousshrinkageandmicrocracking.

● Internal Curing: Internal curing, often achieved through pre-saturated lightweight aggregates or Superabsorbent Polymers (SAPs), ensures continuous hydration and better microstructure formationthroughouttheconcretevolume.

● Self-Healing Curing: Thisrepresentsacutting-edge approach where healing agents (e.g., induced microorganismsandbacteria)areembeddedinthe concrete.Whenmicrocracksformduetostressor early-ageshrinkage,theseagentsareactivatedby water (e.g., seawater) to precipitate calcium carbonate(CaCO3)orotherminerals,activelyfilling thecracksandrestoringthematerial'sintegrityand durabilityagainstioningress.

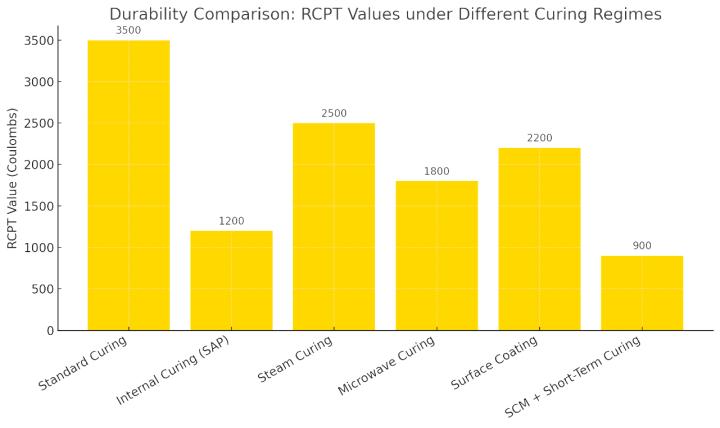

Table 1: Comparative influence of different curing methods on HPC durability in marine environments

Curing Method Mechanism Advantages

Standard Water Curing Maintainsexternal moisturefor hydration

Internal Curing (SAP, LWA)

Accelerated Steam Curing

Microwave Curing

Surface Curing/Coatings

SAPs/LWAabsorb &releasewater internally

High-temperature steamaccelerates hydration

Accelerated dewateringvialowpressureheating

Coatingsactas physicalbarriers

Self-Healing Curing (Biogenic, capsules) Bacteria/minerals precipitatein cracks

SCM + Short-Term Curing

SCMs(slag, metakaolin, nanosilica) compensate hydration

Simple,economical, well-established

Controls autogenous shrinkage; improves microstructure

Rapidstrength gain;usefulfor precastmarine elements

Reducesshrinkage &permeability; fastcuring

Lowcost;easy application

Autonomousrepair ofmicrocracks; innovative

Reducescement use;sustainable

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

Curing Method Limitations

Standard Water Curing Requires continuouswater supply;less effectiveforHPC withloww/bratio

Internal Curing (SAP, LWA)

Costlyadditives; mixdesign adjustment required

Accelerated Steam Curing Riskof microcracking& delayeddurability issues

Microwave Curing Limitedfield application; requiresspecial equipment

Surface Curing/Coati ngs Requires maintenance; coating degradationrisk

Self-Healing Curing (Biogenic, capsules)

Highcost;limited field-scale validation

SCM + ShortTerm Curing Performance highlydependent onSCMquality

Durability Impact (Marine Exposure)

Moderate improvementin chloride&sulphate resistance;limited effectonshrinkage

Strongimprovement againstsulphate& chlorideingress; enhanceslong-term performance

Enhancesearly strength;mixed long-termdurability results

Promisingforultralowpermeabilityin marineHPC

Effectiveshort-term protectionfrom chloride&moisture ingress

Enhancescrack sealing;improves chloride&sulphate resistanceovertime

Excellentchloride resistanceevenafter 1–3dayscuring

Chlorideattackistheprimarycauseofsteelreinforcement corrosioninmarineconcretestructures.Theabilityofthe cement matrix to bind chloride ions is essential for protection.

● The long-term durability against chlorides, even aftershortinitialcuring,ismaintainedbytheuseof blendedmaterialssuchasgroundblastfurnaceslag, metakaolin,andnanosilica.

● However, the binding capacity is severely compromised by carbonation, which is a major concern in the splash and atmospheric zones of marine structures. Interestingly, the presence of specificcations,suchasCa2+(e.g.,fromCaCl2),can weaken the negative impact of carbonation and

improvethebindingcapacityoffreechlorideionsin thecement.

Marine environments contain high concentrations of sulphateions(SO42−),particularlysodiumandmagnesium sulphates,whichcauseexpansivereactionsanddegradation ofthecementpaste.

● InternalcuringwithSAP,combinedwithanexternal waterborneepoxycoating,isaprovenstrategyto enhanceconcreteresistancetocompoundsodium andmagnesiumsulphateattacks.Thiscombination reducestheingressofsulphateionsandminimizes deterioration characteristics, leading to superior long-termperformance.

Incoldmarineregions,HPCissusceptibletosurfacescaling andmicrocrackingduetoFreeze-ThawCycles(FTCs).While curing indirectly enhances FTC resistance by improving microstructure,researchisfocusingonadvancedmethodsto quantifyandpredictthisdamage.

● Machine learning algorithms are now being employed to accurately forecast FTC-induced durability degradation in sustainable marine concrete, highlighting the complexity and critical natureofthisdeteriorationmechanism.

Fig-2

The effectiveness of curing methods is often maximized whencombinedwithmaterialoptimization,specificallythe useofSupplementaryCementitiousMaterials(SCMs).

● Application of Admixtures: SCMssuchasflyash and silica fume are key to enhancing the physical

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

properties and chemical resistance of concrete in aggressiveenvironments.

o Pore Structure Refinement: Theaddition ofadmixturesreduceserosionprimarilyby decreasingtheconcrete'sporosity.

o Specific SCM Effects: Studiesconfirmthat incorporating Fly Ash and Metakaolin significantly improves resistance to environmental deterioration by reducing critical durability parameters, including SaturatedWaterAbsorption,permeability, andchlorideionpenetration(RCPT).

● Curing Regimes and SCMs: The overall effect of mineral admixtures on the properties of concrete (such as self-compacting concrete) is heavily influencedbythespecific curing regimes applied, indicatingthatcuringandmaterialdesignmustbe optimized concurrently to achieve desired durability.

ThedurabilityofHigh-PerformanceConcreteinthemarine environment is intrinsically linked to its curing method. Researchshowsthat:

1. Internal Curing withSuperabsorbentPolymersis an effective strategy for controlling autogenous shrinkageandmitigatingsulphateattack,especially whencombinedwithexternalcoatings.

2. Accelerated Curing techniques like microwave curing show promise for rapidly improving permeability and reducing shrinkage in cementitiousmaterials.

3. SCM-blended concretes can exhibit remarkable long-termchlorideresistanceevenwithacritically shortinitialcuringperiodofjustoneday,offeringa path toward sustainable and time-efficient construction

4. Future research should focus on optimizing the synergistic effects ofcuringmethodsandSCMsto counteract complex deterioration, such as the combined effects of carbonation and chloride ingress,wherespecificcationscanplayabeneficial role.Continuedeffortsincomputationaldurability predictionusingtoolslikemachinelearningwillbe crucial for designing resilient concrete in cold marineregions.

[1] Wang,K.,Dong,K.,Guo,J.,&Du,H.(2024).Absorption and Release mechanism of superabsorbent polymers anditsimpactonshrinkageanddurabilityofinternally curedconcrete-Areview. Case Studies in Construction Materials, 21,e03909.

[2] Makul, N. (2020). Effect of low-pressure microwaveaccelerated curingon the dryingshrinkage and water permeabilityofPortlandcementpastes. Case Studies in Construction Materials, 13,e00358.

[3] Jiang,L.,Wang,J.,Yang,M.,Lin,N.,&Liu,J.(2020).Effect ofCa2+andNa+onthecuringperformanceofchloride ions in cement under carbonization. Case Studies in Construction Materials, 13,e00430.

[4] Alomayri,T.,Adesina,A.,&Das,S.(2021).Influenceof amorphousrawricehuskashasprecursorandcuring condition on the performance of alkali activated concrete. Case Studies in Construction Materials, 15, e00777.

[5] Xu,X.,Jin,Z.,Yu,Y.,&Li,N.(2022).Impactpropertiesof Ultra High Performance Concrete (UHPC) cured by steam curing and standard curing. Case Studies in Construction Materials, 17,e01321.

[6] Hamad,H.,Alattar,A.,Tayeh,B.,Yahaya,F.,&Almeshal, I.(2022).Influenceofdifferentcuringmethodsonthe compressive strength of ultra-high-performance concrete: A comprehensive review. Case Studies in Construction Materials, 17,e01390.

[7] Li,L.,Liu,K.,Chen,B.,&Wang,R.(2022).Effectofcyclic curingconditionsonthetensilebondstrengthbetween thepolymermodifiedmortarandthetile. CaseStudiesin Construction Materials, 17,e01531.

[8] Ruiz,A.I.,delaRubia,M.A.,Massana,J.,AlonsoPeralta, F., Moragues, A., & Reyes, E. (2025). Sustainable lowcementblendsfeaturingblastfurnaceslag,metakaolin and nanosilica show remarkable long-term durability againstchloridesforonedaycuringage. Case Studies in Construction Materials, 22,e04511.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

[9] Wang, W., Shen, A., Zhou, J., Ebohon, O. J., & Zhan, Q. (2025). Combined influence and mechanism of superabsorbent polymers and waterborne epoxy coatingsonthedurabilityofself-curingconcreteunder compoundsodiumandmagnesiumsulfateattacks. Case Studies in Construction Materials, 22,e04585.

[10] Rezzoug,A.,AlAteah,A.H.,Alinsaif,S.,&Mostafa,S.A. (2025). Durability prediction of sustainable marine concreteunderfreeze-thawcyclesusingmulti-objective machinelearning models. Case Studies in Construction Materials, 22,e04787.

[11] Sajeev P S., Vijay Shankar Giri Rajagopal, & Naveen Arasu A. (2025). Investigation of concrete durability enhancement using supplementary cementitious materials. MethodsX, 15,103527.

[12] Wen, X. (2025). The Anti-Corrosion Techniques and Material Optimization to Enhancing Durability of ConcreteinMarineEnvironments. Highlights inScience, Engineering and Technology, 137,MECEME2025.

[13] Fekete,S.,Jónás,G.,Felföldi,J.,Kovacs,Z.,&Friedrich,L. (2025).InvestigationofSaltandWaterDiffusionDuring Dry Salting, Wet Curing, and Ultrasonic Wet Curing. Appl. Sci., 15(11),5939.