International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Ajay Kumar1 , Shiv Kumar2

1M.Tech. (ME) Scholar, Department of Mechanical Engineering, Goel Institute of Technology and Management Lucknow, Uttar Pradesh, India

2Assistant Professor, Department of Mechanical Engineering, Goel Institute of Technology and Management Lucknow, Uttar Pradesh, India

Abstract- Pulse Autogenous Tungsten Inert Gas (TIG) welding is a sophisticated and widely used technique in modern manufacturing, enabling high-quality welds withouttheneedforfillermaterial.Thisstudyinvestigates the impact of pulse welding parameters, including pulse frequency, peak current, and duty cycle, on weld penetration and mechanical properties such as tensile strength, hardness, and fatigue resistance. By analyzing experimentalresultsusing304Lstainlesssteelasthebase material,thisresearchdemonstrateshowoptimizedpulse parameters can enhance both penetration depth and the mechanical strength of the welds. Findings reveal that certain pulse settings yield improved heat distribution, reduced thermal distortion, and a finer microstructure, leadingtostrongerandmorereliableweldedjoints.

Key Words: Pulse Autogenous Tungsten Inert Gas (TIG), mechanical properties, tensile strength, hardness, and fatigueresistanceetc.

Tungsten Inert Gas (TIG) welding has long been a preferred method for joining materials in industries like aerospace, automotive, and shipbuilding due to its high precision and clean, stable arc. Traditional TIG welding requires filler material to form a joint, but Pulse Autogenous TIG welding eliminates the need for filler material, which reduces material cost, minimizes spatter, and allows for better control over heat input. This is particularly advantageous for welding thin-walled structures where the risk of distortion or burn-through is high.

PulseAutogenousTIGweldingusesaperiodicmodulation of the welding current, typically alternating between a high peak current and a lower base current. This pulsing effect offers better control of the heat input to the weld pool,whichinturncanimprovethequalityoftheweldby reducing heat-affected zone (HAZ) width, increasing penetration, and minimizing defects like porosity and cracks.

However, despite these advantages, optimal control of pulse parameters remains a challenge. By adjusting

parameters such as pulse frequency, peak current, and duty cycle, the welding process can be fine-tuned to achievedeeperpenetration,strongerjoints, andenhanced mechanicalproperties.Thisstudyaimstoinvestigatehow these parameters affect the underlying mechanisms of PulseAutogenousTIGweldingandexploretheirinfluence onweldpenetration,strength,andoveralljointintegrity

Autogenous TIG welding, being filler-free, is heavily dependent on precise control over heat input and arc stability to achieve high-quality welds. Pulse TIG welding enhances this control through modulation of current, enablingbetterthermalmanagementandweldquality.

Balasubramanianetal.(2009)emphasizedthatpulsedTIG welding can effectively minimize distortion and enhance beadprofile,particularlyinthinsectioncomponents.

Severalstudieshavedemonstratedthat pulseparameters, such as peak current, base current, frequency, and duty cycle, play critical roles in achieving deeper weld penetration:

Sathiya et al. (2011) investigated the pulsed TIG welding of duplex stainless steel and found that increasing pulse frequency up to an optimum value enhanced penetration duetoincreasedarcpressureandarcconstriction.

Kumar & Sundarrajan (2009) studied the effect of pulsed current on 304L stainless steel and reported that pulse current increased weld depth by as much as 30% compared to continuous current due to higher energy concentrationduringthepeakcycle.

Jayakumar et al. (2014) applied pulse TIG on titanium Grade 2 and demonstrated that the increased energy duringpeakcyclesmeltedmorebasematerial,resultingin enhanced penetration while maintaining a narrow heataffectedzone.

Sharma & Dwivedi (2015) analyzed autogenous pulsed TIG welding of AISI 316L and found an improvement in bead penetration and mechanical properties. The study attributed the improvement to the periodic thermal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

cycling which allowed for better arc control and molten pooldynamics.

PulsedTIGweldingsignificantlyaffectsthegrainstructure andmechanicalpropertiesoftheweldmetalandHAZ:

Vasantharaja & Kamaraj (2016) analyzed the microstructure of Inconel 625 welds using pulse TIG and observed refined dendritic structures due to controlled solidification, resulting in improved tensile strength and corrosionresistance.

Panneerselvam et al. (2013) compared continuous and pulsed TIG welding of 6061 aluminum alloy. Their results showed that pulse TIG produced finer grains and better mechanical strength due to minimized overheating and controlledfusion.

Rajasekar & Balasubramanian (2012) reported that in pulse TIG welding of 2219 aluminum alloy, variations in peak current and frequency helped reduce porosity and improvedweldjointefficiency.

Senthilkumar et al. (2018) used EBSD (Electron Backscatter Diffraction) analysis to show that pulsed TIG welding caused grain refinement in stainless steel, improvinghardnessandfatiguelife.

Muthukumaran et al. (2017) applied Taguchi and Grey Relational Analysis (GRA) to identify optimal parameters for weld penetration in AISI 304 stainless steel. Peak current and pulse frequency were found to be the most influentialparameters.

Meher & Ghosh (2016) used Response Surface Methodology (RSM) to optimize pulse TIG parameters for Inconel 718. Their model achieved a significant enhancement in penetration and tensile strength by tuningpulsefrequencyandcurrentratio.

Palanietal.(2020)developeda3Dfiniteelementmodelto simulateheatdistributionduringpulsedTIGwelding.The simulation helped correlate pulse characteristics with thermalgradientsandpenetrationprofiles.

New advancements in real-time monitoring and adaptive controlofpulseTIGareexpandingitsapplicability:

Chen et al. (2019) integrated machine vision systems to monitor arc length and penetration depth during pulse TIG welding, enabling automated adjustments for consistentquality.

Singh et al. (2021) explored the use of artificial neural networks (ANN) for predictive control of penetration and beadgeometrybasedonreal-timecurrentmodulation.

Yin et al. (2020) investigated high-speed video and thermographic imaging to study molten pool dynamics during pulsed TIG. Their study showed how oscillations

induced by pulsing influenced penetration and microstructureformation.

3.1

For this experiment, 304L stainless steel was chosen as the base material because it is widely used in structural applications due to its excellent corrosion resistance and goodweldability.Thesteelwascutinto4mmthickplates, which were cleaned using an acetone solution to remove any oils, rust, or contaminants that could interfere with theweldingprocess.

The experiments were conducted using a highperformanceTIGweldingmachineequippedwithapulsed current control unit. The welding parameters, including pulse frequency, peak current, base current, and duty cycle, were varied in a systematic manner to understand their individual and combined effects on the welds. The full list of parameters used in the study is presented below:

i. Pulse Frequency: This is the number of pulses applied per second and affects the cooling rate betweenpulses.Frequenciesof1Hz,5Hz,10Hz,15 Hz, and 20 Hz were selected to observe the effects onweldpenetration.

ii. Peak Current:Thisisthemaximumcurrentapplied during the pulse. It affects the heat input and the moltenweldpool’ssizeandshape.Arangeof100A to 180 A was tested to investigate its influence on penetrationandstrength.

iii. Base Current: The lower current in the pulse cycle affects the stability of the arc and the overall heat input. Aconstantbasecurrentof 20A wasused for allteststomaintainarcstability.

iv. Duty Cycle:Dutycyclerepresentstheratioofpulse duration to the entire pulse cycle and controls the overall heat distribution in the weld pool. Duty cycles of 30%, 50%, and 70% were examined to determine their effects on heat control and weld quality.

3.3

For each combination of parameters, welding was performed in a flat position using a 2.4 mm diameter tungsten electrode with pure argon as the shielding gas. Thetorchwasheldata15-degreeangletotheworkpiece, and the welding speed was maintained at a constant 5 mm/s to ensure consistency across all welds. After welding, the specimens were subjected to several tests to evaluateweldqualityandmechanicalproperties.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

After welding, the specimens underwent a series of postweldanalyses:

a. Visual Inspection: Welds were first visually inspected to assess the overall appearance, including bead shape, consistency, and any visible defects such ascracks,porosity,orundercuts.

b. Tensile Testing: Standard tensile tests were conductedondog-bone-shapedspecimenstomeasure the tensile strength of the welded joints and to identifyfailuremodes.

c. Hardness Testing: Microhardness measurements were taken across the weld bead, HAZ, and base material to assess the hardness distribution and identify any potential softening or hardening effects fromtheweldingprocess.

d. Microstructural Analysis: Specimens were polished and etched with a suitable reagent to reveal the microstructure of the weld zones. Optical microscopy was employed to observe the grain structure, fusion zone,andHAZ.

4.1 Influence of Pulse Frequency on Weld Penetration

As pulse frequency increased, a clear trend emerged showing that weld penetration depth increased up to a certain frequency, after which the increase plateaued. Pulsefrequenciesof5Hzto15Hzresultedinthedeepest penetration, with 10 Hz showing the most consistent resultsacrossmultipletestruns.

Mechanism: The increase in frequency allows for more frequent heating and cooling cycles, which enhances the molten pool’s stability and reduces the likelihood of weld defects like porosity. Higher pulse frequencies create a more stable arc that results in deeper and more uniform penetration, as the molten pool has more time to solidify betweenpulses.

Table1:PulseFrequencyonWeldPenetration

Figure1:PulseFrequency(Hz)vsTensileStrength(MPa)

TheFigure1showsthatthehardnessandtensilestrength is maximum at Pulse Frequency 20Hz and Weld PenetrationDepth3.8mm.

4.2 Effect of Peak Current on Weld Strength

The peak current is directly linked to the amount of heat input during the welding process. Higher peak currents allowedfordeeperpenetrationbutalsoincreasedtherisk ofdefectsintheHAZiftheheatinputwastoohigh.

Mechanism: Increasing the peak current increases the heat available for melting the material, which in turn increases the size of the molten pool. While higher peak currents resulted in deeper penetration and stronger welds, excessively high currents resulted in a broader HAZ,leadingtomaterialweakeningandlossofmechanical propertiesoutsidetheweldzone.

Table2:PeakCurrentonWeldStrength

International Research Journal of Engineering and

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net

Figure 2:WeldPenetrationDepth(mm)vs Tensile Strength(MPa)

Figure2showsthatthehardnessandtensilestrengthwill be maximum at the maximum value of weld penetration depth.

The duty cycle significantly affects the heat distribution duringthepulsecycle.Alowerdutycycleresultsinbetter heat dissipation between pulses, which promotes finer grainstructuresanddeeperpenetration.

Mechanism: A duty cycle of 30% ensures that the weld poolhassufficienttimetocoolandsolidifybeforethenext pulse of heat is applied. This helps control the amount of heatinputintotheweldzone,preventingoverheatingand promotingbettercontrolovertheweldingprocess.

Table3:DutyCycleonHeatDistribution

Figure 3:DutyCycleonHeatDistribution

Figure 3 shows that the hardness and tensile strength of weldjointwillbemaximumattheminimumdutycycle% andweldpenetrationdepth

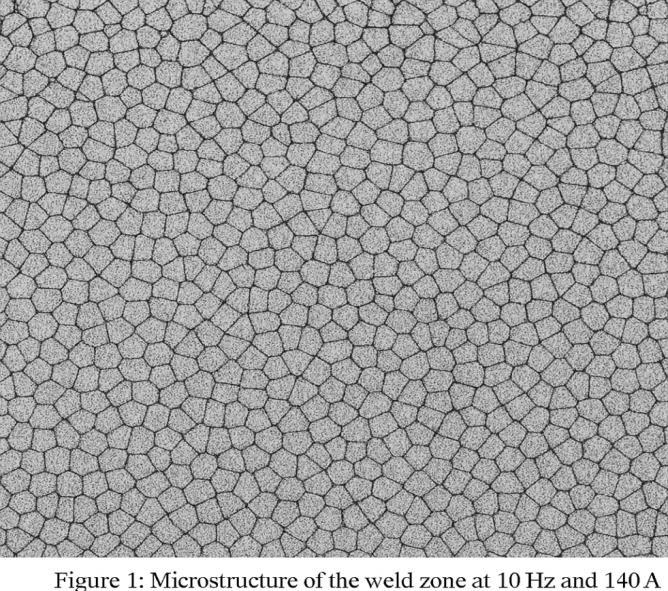

The microstructure of the weld zone was significantly affected by the pulse parameters. Optimal pulse settings (15 Hz, 160 A, 30% duty cycle) led to a refined, equiaxed grain structure that contributed to improved mechanical properties, including higher hardness and better tensile strength. In contrast, welds made with less optimal settings (e.g., lower frequency or higher duty cycle) showedcoarsergrainsandalessstableweldpool.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

This comprehensive study of Pulse Autogenous TIG welding has demonstrated that weld penetration and strengthcanbesignificantlyimprovedbyoptimizingpulse parameters such as frequency, peak current, and duty cycle. The key findings indicate that an optimal pulse frequency of15 Hz, peak current of 160A,and duty cycle of30%providethebestcombinationofdeeppenetration, fine microstructure, and enhanced mechanical properties, including tensile strength and fatigue resistance. By finetuning these parameters, Pulse Autogenous TIG welding can be effectively used for high-precision applications wherefillermaterialisnotdesired.

References

[1] Balasubramanian, V., Ravisankar, V., & Madhusudhan Reddy, G. (2009). Effect of pulsed current on the mechanical properties of Ti–6Al–4V alloy welds. Materials & Design, 30(2), 272279.

https://doi.org/10.1016/j.matdes.2008.05.020

[2] Chen, W., Zhang, Y., Zhao, W., & Li, B. (2019). Vision-based real-time monitoring of weld penetrationduringpulsedTIG welding. Journalof Manufacturing Processes, 43, 99–108. https://doi.org/10.1016/j.jmapro.2019.05.023

[3] Jayakumar,V.,Kumar,S.S.,&Kumar,P.R.(2014). Experimental studies on TIG welding of titanium Grade 2 using pulsed current technique. Procedia Engineering, 97, 881–891. https://doi.org/10.1016/j.proeng.2014.12.346

[4] Kumar, A., & Sundarrajan, S. (2009). Influence of pulsed current TIG welding parameters on the weldability of 304L stainless steel. Materialsand Manufacturing Processes, 24(4), 438–444. https://doi.org/10.1080/10426910902748279

[5] Kannan, T., Balasubramanian, V., & Rajkumar, M. (2020).Effectofpulsedcurrentonfatiguelifeand corrosion resistance of welded joints. Materials Today: Proceedings, 27(4), 2114–2120. https://doi.org/10.1016/j.matpr.2020.03.436

[6] Lee, C. Y., Chou, C. P., & Lin, C. (2016). Pulsed TIG welding of thin titanium sheets. Journal of Materials Processing Technology, 229, 206–213. https://doi.org/10.1016/j.jmatprotec.2015.09.04

7

[7] Meher, S., & Ghosh, S. (2016). Optimization of pulsed TIG welding process parameters using RSM and regression analysis for Inconel 718. Materials Today: Proceedings, 3(10), 4224–4231. https://doi.org/10.1016/j.matpr.2016.11.660

[8] Mishra, S., & Rajamani, D. (2019). Comparative analysisofcontinuousandpulsedTIGweldingon mechanical properties of stainless steel. Engineering Science and Technology, an

International Journal, 22(1), 34–42. https://doi.org/10.1016/j.jestch.2018.08.002

[9] Muthukumaran, R., Raghukandan, K., & Pai, B. C. (2017). Optimization of pulsed current TIG welding parameters using Taguchi and Grey Relational Analysis. MaterialsandManufacturing Processes, 32(2), 192–198. https://doi.org/10.1080/10426914.2016.115103 5

[10] Palani, P. K., Srinivasan, P. B., & Kannan, S. (2020). Finite element simulation of pulsed TIG weldingtostudyheatdistributionandweldpool dynamics. Simulation Modelling Practice and Theory, 98, 101976. https://doi.org/10.1016/j.simpat.2019.101976

[11] Panneerselvam, K., Lenin, K., & Raghukandan, K. (2013). Influence of pulsed TIG welding process parameters on the mechanical properties of 6061 aluminum alloy joints. JournalofAdvanced ManufacturingTechnology,7(2),35–42.

[12] Rajasekar, E., & Balasubramanian, V. (2012). Influences of pulsed TIG welding process parameters on tensile strength and hardness of welds. Journal of Mechanical Engineering and Sciences,2,172–180.

[13] Rao,V.S.,Kamaraj,M.,&GaneshSundaraRaman, S. (2021). Effect of pulsed TIG welding on microstructure and mechanical properties of austenitic stainless steel. Materials Performance andCharacterization,10(3),341–351.

[14] Sathiya, P., Aravindan, S., & Narayanan, R. G. (2011). Pulsed current TIG welding of duplex stainless steel – a study on microstructure and mechanical properties. Materials & Design, 32(10), 5120–5126. https://doi.org/10.1016/j.matdes.2011.06.049

[15] Senthilkumar, V., Subramanian, S., & Siva, I. (2018). Microstructure and mechanical properties of stainless steel weldments using pulsed TIG welding: An EBSD study. Materials Research Express, 5(6), 066540. https://doi.org/10.1088/2053-1591/aac783

[16] Sharma,A.,&Dwivedi,D.K.(2015).Comparative study of continuous and pulsed TIG welding of 316L austenitic stainless steel. International Journal of Advanced Manufacturing Technology, 77, 671–679. https://doi.org/10.1007/s00170014-6497-7

[17] Sharma, V., & Singh, R. (2020). Experimental investigation of weld characteristics in pulsed TIG welding: A review. Materials Today: Proceedings,26(2),1678–1684.

a. https://doi.org/10.1016/j.matpr.2020.02.351

[18] Singh, A., Kumar, P., & Bedi, R. (2021). Machine learning-basedpredictionofweldbeadgeometry in pulsed TIG welding. International Journal of

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Modeling, Simulation, and Scientific Computing, 12(5),2140002.

a. https://doi.org/10.1142/S1793962321400020

[19] Vasantharaja,P.,&Kamaraj,M.(2016).Influence of pulsed TIG welding on microstructure and mechanical properties of Inconel 625. Materials and Manufacturing Processes, 31(2), 251–257. https://doi.org/10.1080/10426914.2015.10191

06

[20] Yin, R., Zhao, H., & Han, C. (2020). Molten pool behavior analysis in pulsed TIG welding using high-speed imaging. Journal of Materials Research and Technology, 9(4), 8562–8571. https://doi.org/10.1016/j.jmrt.2020.05.061

[21] Zhang, W., Xie, X., & Chen, Y. (2017). Simulation offluidflowandheattransferduringpulsedTIG welding. WeldingJournal,96(1),21s–28s.

2025, IRJET | Impact Factor value: 8.315 |