Canada’s

Taking

Raymond Canon looks back at the demise of Avro’s flyer saucer, a lesser known Avro project more popularly known as the AvroCar

The Slow Boat to China Bombardier is well positioned to break into corporate aviation’s largest untapped market. They will have to be patient.

BILL WAS HERE when he discovered that the thrill of hanging 10 has nothing on hanging around Cloud 9.

“When I see the beaches from my Skyhawk, I realize that the people down there don’t know what they’re missing.” –

Bill Bradley, Cessna Owner

In a brand new Cessna Skyhawk, you too will discover life in a brand new way.Whether you’re learning to fly or fulfilling the lifelong dream of owning a new Cessna. Call 1-316-517-6056. Or visit CessnaYouAreHere.com/22.

RICHARD PURSERis the senior associate editor of Wings.

Two recent reports appearing a day apart in the US media highlighted the dichotomy between first-world and third-world aviation safety standards.

On Sept. 30 the New York Times reported on the end of a 10year White House mandate to the airline industry and its regulators to cut the domestic rate of fatal scheduled airline accidents by 80%. The mandate followed two notorious crashes in 1996 – TWA off New York’s Long Island and ValuJet in the Florida Everglades –that together killed 375 people.

The 1997 mandate was set by a national commission on aviation safety headed by then Vice-President Al Gore, and at its end the three-year average rate of fatal crashes was down by 65% from the three years ended Sept. 30, 1997. It wasn’t the targeted 80%, but a still-satisfying drop from one fatal accident per 2 million departures to one per 4.5 million departures.

As of Sept. 30, there had been no fatal scheduled airliner crashes at all in the US in 2007.

Improvements have included analyzing patterns in ‘safe’ flights that may indicate impending problems (since there are so few crashes to investigate), improving procedures (such as in ‘unstabilized approaches’) and equipment (such as enhanced ground proximity warning systems).

To further head toward the 80% reduction target as traffic increases and very light jets are entering the scene will require replacement of the FAA’s old ATC system, a move now stuck in the political gridlock that affects everything in Washington, DC from immigration reform to health-care reform to how to fight wars. But many safety specialists fear most the rise in ‘ground proximity events’ or runway incursions. The FAA is said to be working on improving the tracking of airplanes on the ground.

That report was on the bright side. On the next day, Oct. 1, came a report in the Wall Street Journal that brought up the dark side. It came from Port Harcourt, Nigeria, the capital of that country’s important oil industry. The 2004-06 passenger airliner fatality rate in Africa was 2.73 fatal accidents per million flights, compared with 0.1 in North America and 0.44 worldwide.

That overall figure was shocking enough, but the WSJ article dwelt on a specific case: the Dec. 10, 2005 crash of a Sosoliso Airlines DC-9 at Port Harcourt Airport with 108 deaths, including 60 children returning from boarding school at the national capital of Abuja 300 miles away. (There were two survivors.) The plane landed in a sudden local storm about whose severity and wind shear conditions the pilots had not been warned (the airport had no meteorological equipment), and the runway edge lights were off. (The runway had no centreline lights.) The crew went well below the decision altitude without having visual contact with the runway; they tried to abort at the last instant, but too late.

The airline has lost its operating licence and the airport, shut down for repairs after the crash, is still closed. The findings of the Nigerian Aviation Ministry’s report on the accident make for unpleasant reading.

WINGS MAGAZINE

PO Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Tel.: 428-3471 Fax: 429-3094

Toll Free: 1-888-599-2228

PUBLISHER TIM MUISE tmuise@annexweb.com

EDITOR DREW MCCARTHY dmccarthy@annexweb.com

ASSOCIATE EDITOR ANDREA KWASNIK akwasnik@annexweb.com

SENIOR ASSOCIATE EDITOR RICHARD PURSER

PRODUCTION ARTIST KRISTA MISENER

OTTAWA CORRESPONDENT KEN POLE

AVIONICS EDITOR ROB SEAMAN FLIGHT DECK RAYCANON, JAMES CARELESS, DAVID CARR, BRIANDUNN, DARREN LOCKE, CARROLL McCORMICK, CHRIS ORESCAN, FRED PETRIE, BLAIR WATSON

ADVERTISING SALES JAYLYN CORPUS jcorpus@annexweb.com

SALES ASSISTANT MARY BURNIE mburnie@annexweb.com

VP/GROUP PUBLISHER DIANE KLEER dkleer@annexweb.com

PRESIDENT MIKE FREDERICKS mfredericks@annexweb.com

PUBLICATION MAIL AGREEMENT #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: alados@annexweb.com

Periodical postage paid at Buffalo, NY. USPS 021-029, ISSN 0701-1369. Published six times per year (Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec) by Annex Publishing & Printing Inc. US Office of publication c/of DDM Direct.com, 1223 William St., Buffalo, NY 14240. US postmasster send address change to P.O. Box 611, Niagara Falls, NY 14304.

Printed in Canada ISSN 0701-1369

CIRCULATION e-mail: alados@annexweb.com Ph: 866-790-6070 ext. 208 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Canada – 1 Year $ 34.00 (includes GST - #867172652RT0001) USA – 1 Year $ 50.00 Foreign – 1 Year $ 65.00

From time to time, we at Wings Magazine make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2007 Annex Publishing & Printing Inc. All rights reserved. opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

With more than 80 customers and upwards of 200 aircraft in our portfolio, Capital Solutions takes pride in being Canada’s

international capabilities include the ability to fund in local currencies, complete cross-border transactions and work with our network of in-country representatives, our focus remains on building one-to-one, long term relationships

Capital Solutions has a AAA-debt rating, more than $24 billion

800 786 4942

www.gecapitalsolutions.ca

Boeing Co. is delaying initial deliveries of the 787 Dreamliner by six months due to continued challenges in completing assembly of the first airplanes. Boeing said deliveries that had been scheduled to begin next May will be pushed back to late November or December 2008.

The first flight, already pushed back once from the initial target of earlier this fall, now is anticipated around the end of the first quarter of 2008.

The delay highlights inherent problems in building new airplanes and could slow the momentum Boeing built

up after years of lagging behind European rival Airbus in commercial airplane manufacturing.

The 787, Boeing’s first allnew jet since airlines started

Porter Airlines is growing its operations base at Toronto City Centre Airport to accommodate increasing passenger levels as it prepares to begin service to New York and other destinations in 2008.

Construction has begun on an extended terminal, including three additional arrival and departure gates. The project is scheduled for completion by Dec. 31, with passenger areas continuing to feature leather lounge seating, complimentary wireless Internet access, beverages and snacks, while offering greater availability of computer work stations.

Scott Associates Architects

Inc. will continue the work it began on Porter’s original terminal project. BECC Construction Group is the project’s contractor.

Porter’s terminal investment is driven by the airline’s strong financial performance, including average monthly revenue growth of over 20% since beginning flights Oct. 23, 2006.

flying the 777 in 1995, will be the world’s first large commercial airplane made mostly of carbon-fibre composites, which are lighter, more durable and less prone to corrosion than aluminum.

But the company’s effort has been shadowed by difficulty getting the right parts from its suppliers on time, among other issues, and it is facing a global shortage of fasteners that hold large sections of the plane together.

Boeing said the postponement will not materially affect its earnings or guidance for next year.

In the September/October issue of Wings, in the article “Essential Utilities, Filling the Cargo Niche” starting on page 20, we incorrectly reported that the Cessna Caravan has been in production for 17 years with 1,300 units delivered worldwide. In fact, the Caravan has been in production for 22 years with 1,750 units delivered to date, with the fleet hours now in excess of 10 million flight hours.

Thank you to Ken Wilson, Cessna Caravan Sales, Canada for bringing this to our attention.

ExelTech Aerospace Inc., Canada’s largest publicly listed commercial aircraft MRO organization, has signed a long-term contract to provide Bombardier Dash 8 regional turboprop aircraft maintenance services for Piedmont Airlines, which operates as US Airways Express. Piedmont is a wholly-owned subsidiary of US Airways Group, Inc., the sixth-largest airline in the US. Under the exclusive agreement, valued at up to $17 million, ExelTech will

perform major maintenance, including structural inspections and repairs, in its Dash 8 Heavy Maintenance Facility at Quebec City’s Jean Lesage International Airport. The initial term is 30 months, with an option to extend for a further two years.

ExelTech first began providing maintenance services for Piedmont in April 2006. Under this new contract, ExelTech commits to provide between one and two lines of continuous nose-to-tail maintenance until September 2009.

Piaggio Aero Industries and Avantair signed a milestone agreement at the NBAA that calls for 22 Piaggio P.180 Avanti II aircraft to be delivered to Avantair starting in 2011 and continuing through 2012. The pending deal is worth more than US$150 million. When the new order is completed, Avantair’s fleet will include 107 P.180 Avanti aircraft.

“This agreement is one of the largest sales in the history of Piaggio Aero,” said José Di Mase, Piaggio Aero Industries CEO. “The demand for Avanti II aircraft continues to increase and this agreement will assure

Avantair has a steady stream of aircraft for its fractional fleet through 2012.”

The P.180 Avanti II is equipped with fully digital automatic flight control and the latest-generation Rockwell Collins Pro Line 21 avionics system. Offering a cabin that is more than six feet wide and five feet nine inches tall, the aircraft also sets new standards in quietness – the P.180 Avanti II cabin is rated as low as 68 dbA speech interference level. The pusher engines direct sound toward the tail of the aircraft, leaving the cabin virtually free of powerplant noise.

The Italian-designed and

CAE has launched an expansion of its global training network by adding 16 new business jet training programs to its operations. With this expansion, CAE will offer training on 90% of all business aviation platforms.

The new training programs address the six largest business jet aircraft manufacturers:

Bombardier, Cessna, Dassault Falcon, Embraer, Gulfstream and Hawker Beechcraft. The training programs will be located in the US and in a range of global locations. The new programs will enter service within the next two years.

CAE has also announced that its Gulfstream 550 full-

built aircraft is certified for single-pilot operation and seats up to nine passengers. Holder of numerous speed records, the P.180 Avanti II is capable of flying over 1,700 nautical miles at up to 402 kts and cruises at altitudes up to 41,000 feet.

flight simulator at EmiratesCAE Flight Training in Dubai has been certified ready for training; and that its Sikorsky S-76B simulator at CAE SimuFlite’s North East Training Center in Morristown, NJ, has received FAA Level D qualification – the highest qualification for flight simulators.

Vancouver-based Harbour Air says you can fly in good conscience on all its routes. The all-seaplane airline, which offers charters and regularly scheduled flights between Metro Vancouver, southern Vancouver Island and the Gulf Islands, says it will be the only airline in North America – and the only seaplane fleet globally – to be completely carbon-neutral by the end of 2007.

As of Oct. 1, Harbour Air tickets included a “carbon offset surcharge” ranging from 50

cents on a flight from Richmond to Nanaimo, to $10 an hour on some charters. By Jan. 1 the company will institute a policy to track, reduce and offset its corporate greenhouse gas emissions. The airline is working with the Vancouver-based Offsetters Climate Neutral Society, which provides high-quality carbon offsets for those trying to reduce their climate impact.

Air Canada president/ CEO Montie Brewer has announced that Michael Rousseau, formerly president of Hudson’s Bay Company, has joined Air Canada as executive vice-president and chief financial officer. Reporting directly to the CEO, Rousseau will have responsibility for the overall financial strategic direction of the airline, including all aspects of financial reporting and planning, investor relations, treasury and controller’s operations, taxation, pension administration and internal audit as well as procurement and corporate real estate. His appointment was effective Oct. 22.

Rousseau joined The Bay as executive vice-president and CFO in 2001, a position he retained until his appointment as president upon change of control of the company in 2006. He played a significant role in the sale of the company in response to a hostile takeover bid.

Earlier, Rousseau was senior vice-president and CFO of the Moore Corporation in Chicago. He is a chartered accountant and holds a bachelor of business administration degree from York University.

Kelowna InternationalAirport is investing $36 million to expand facilities to meet the growing demand as passenger numbers are forecast to grow by one-third to 1.6 million passengers in 2015.

The centrepiece of the Kelowna International Airport 2010 Development Program is a new international arrivals concourse capable of handling 250 passengers per hour. Improved ground access and expanded vehicle parking, a new car rental facility and two new aircraft loading bridges are also included in

Avcorp gets US$4.2-million Boeing contract

Avcorp Industries Inc. has won a five-year contract to supply aircraft giant Boeing with details and subassemblies for the Chinook CH-47 military helicopter.

The deal is worth about US$4.2 million to Avcorp, the company said. Avcorp designs and builds airframe structures for some of the world’s leading aircraft companies, including Boeing, Bombardier and Cessna. The company employs 650 people at its plant in Delta, BC.

Said president Paul Kalil, “Avcorp continues to pursue the supply of integrated metallic and composite aerostructures with Boeing ... as well as other customers developing new aircraft programs.”

the program.

In addition to the program approval, Kelowna City Council authorized airport administration to retain services of a multidisciplined consulting company to design, supervise and commission the individual program elements.

As part of the 2025 master plan a runway extension to 8,900 feet was previously awarded to EBA Engineering and is expected to begin this fall.

Competitive air service is key to success in the global marketplace and Kelowna

NOVEMBER 2007

2nd Annual Dangerous Goods Shipping Symposium For Instructors

November 28-30

Deerfield Beach, FL http://www.airregs.com/conferences

International provides a vital link to the economic prosperity of the entire region. Kelowna International is responsible for generating an estimated $310 million of annual economic activity and sustaining 1,835 full-time jobs.

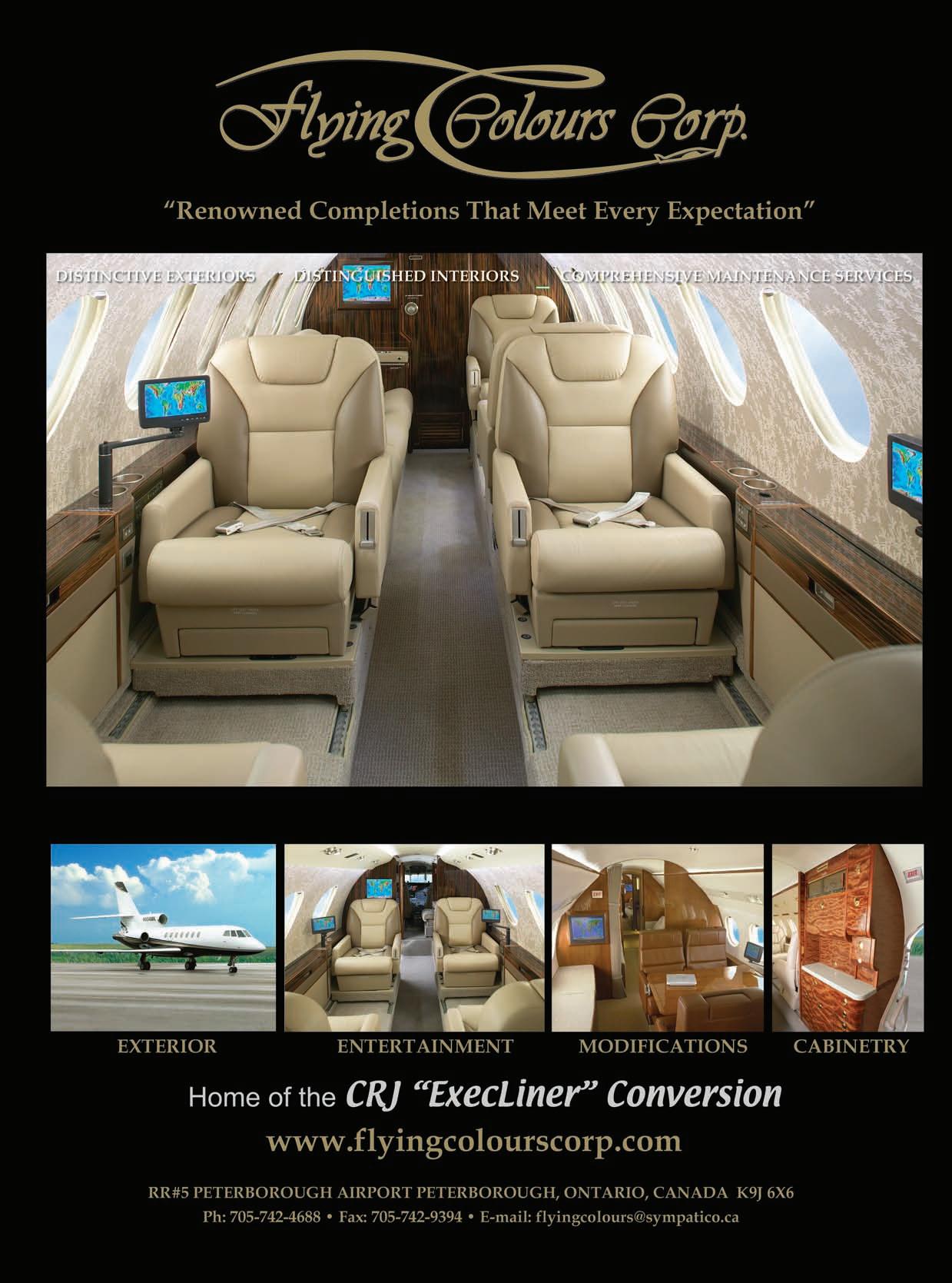

Construction is under way on the 45,000-square-foot expansion of Aero Toy Store’s Montreal facility. Located at Trudeau International Airport, the company’s FBO will add a 31,000-square-foot aircraft hangar and a 14,000-squarefoot completion centre to its current facility. The approximately $8-million project is scheduled for completion in December.

Aero Toy Store’s Montreal FBO encompasses 200,000 square feet, including ramp space, and features a 41,000square-foot showroom, hangar and offices equipped with the most advanced security and technological aviation equipment available. With the addition of its new aircraft hangar and completion centre, the facility will offer an expanded line of Aero Toy Store services, such as aircraft interior refurbishment and completions.

Aero Toy Store provides

clients with turnkey solutions for sale and purchase, financing, modifying and enhancing new and pre-owned aircraft. With full-service FBOs and sales centres in Fort Lauderdale and Montreal, as well as a sales facility at Las Vegas, Aero Toy Store’s inventory focuses on luxurious wide-cabin, long-range aircraft, including Challenger, Falcon, Gulfstream, Global Express and Boeing. The company also owns a variety of light and mid-sized aircraft, such as the Citation, Hawker and Lear.

FEBRUARY 2008

Asian Business Aviation Conference and Exhibition (ABACE 2008)

February 14 Hong Kong http://web.nbaa.org/public/ cs/amc/

APRIL 2008

20th Annual Canadian Aviation Safety Seminar (CASS)

April 28-29

Calgary, Alta www.tc.gc.ca/civilaviation/ systemsafety/cass/menu.htm

Aircraft Interiors Expo 2008

April 1-3

Hamburg, Germany http://www.aircraftinteriorsexpo.com

MAY 2008 EBACE 2008

May 20-22

Geneva, Switzerland http://www.ebace.aero/ email:info@ebace.aero

Regional Airline Association (RAA) 2008 Convention May 5-8

Indianapolis, IN http://www.raa.org

The rite of passage: Some pilots still opt for the north, with its reduced comforts and amenities

Not so long ago, the only choice for starting a career in aviation was often to go north. Countless young pilots made the desperate road trip to various northern communities in search of that first flying job. Many had to settle working for a season or two or more on the dock loading aircraft for other crews, while others were a bit more fortunate in securing an actual flying position. For many, this is not a very distant memory, and still there are some struggling to get started even now, amid the highest demand for pilots our industry has seen in over three decades.

Hundreds of pilots over the years were told to go north and that’s where they had to go to get work. It is still a challenge for the brand-new pilot to find work – he or she is told to go north, take a road trip. Getting established, however, is a great deal less difficult and timeconsuming than it was even as little as five years ago. One aspect interests me, though: there are still many who righteously believe that serving time in the north is a must; that it makes a person a better pilot and it’s simply a requirement.

I am not one of those people. I don’t believe that flying in the north makes a person a better pilot. Yes, it will broaden your experience but it will not assist you very much when flying into Chicago or Atlanta – it’s not a rite of passage.

Obviously, northern flying is very, very different from flying in southern domestic airspace; the short summer season with 22 hours of daylight and two hours of dusk can make for long days and sleepless nights. The winters, with 22 hours of night and two hours of dusk, can contribute to some serious cases of SAD (Seasonal Affective Disorder). The cold is equally hard on aircraft and people, who are forever trying to keep aircraft warm and reduce the cold effects on various components – removing batteries and bringing them inside to keep warm, hand propping a turbine engine to loosen up the gear box. Countless VFR flying hours in minimum and below-minimum visibility, literally weeks of flying without a horizon, flying with minimal nav aids, a lack of suitable alternates and lastly, insufficient fuel, have been and remain commonplace for some operations.

CHRIS ORESCANis a Wings columnist.

Flying in the north will certainly challenge a person, but it remains a dangerous and unforgiving environment. The north may as well be a completely different country, and to some it feels like a different planet; it can be a desolate place, which can easily and without consideration take lives.

As I see it, there are three groups of people who fly in the north; first, the people who are born and raised there – to them there is no other place they would rather be, it’s home. The other two groups are the ones that went for the experience; the majority leave as soon as the opportunity becomes available. However, there are a number of individuals who go for the work and something clicks inside for them and they stay. Some pilots have stayed for a very long time until whatever it was that kept them there can no longer hold them, and yet there are some that go and never leave.

What is it, then, that makes a person stay? What kind of person is this? Let’s face it – there are certain aspects that cannot be argued and for most of us northern living would be very difficult and challenging. The cost of living is exceptionally high but there are factors which offset these high costs such as tax credits for northern living and increased salaries; when worked properly, they can be quite profitable.

Personally, I don’t care for the north. Anyone who knows me knows that I consider winter to be a natural disaster. However, I have known some exceptional people from the north, but living and working there requires a certain type of person: independent, self-sufficient and confident in their skills. This person needs to be self-reliant and to possess a broad array of abilities that would not be required by their counterparts to the south.

To succeed and survive in the north for the long term requires an individual who is very comfortable with reduced comforts and amenities. Typically, this person is someone who would be at ease hiking out into the deep of the forest for a week or so with only a backpack and think they had won the lottery! I’m not trying to stereotype or label, rather I’m simply attempting to draw a picture for the inexperienced pilot that unless he/she is accustomed to this lifestyle, lifestyle change would be extreme and shocking to them.

Chris Orescan is an industry observer, pilot and author of the book, Becoming a Professional Pilot in Canada. You can contact Chris at: corescan@shaw.ca.

Aeroplanesandhelicopterstrailviolent spiralsofairfromtheirwingtiporrotor.

TheVortex

Asawingorrotorgeneratesmorelift,pressuredifferences aboveandbelowincrease,puttingmoreenergyintothevortices. So…foreachaircraft,increasedweightmeansstrongervortices.

Asanaircraftslows,thepressuredifferenceaboveand belowincreases.So…asanaircraftslows,totalvortexenergy increases.

Thepositionofflapsandlandinggearaswellasthelocation ofenginesandtailconfigurationallhavetheirinfluence,asdoes twinrotorversustailrotorhelicopterconfiguration.So…aircraft configurationmodifiesthevortexpatternandpersistence.And persistenceisamajorproblem.

Sincecoldairismoredensethanwarmair,ithasmore“punch”. So…airdensityinfluencesvortexstrength.

Avortexwilldecaywithtimeastheswirlincreasesindiameter andmixeswiththesurroundingair.So…untilthevortexcollapses, itremainspotentiallydangerous.

Asthewingorrotormovesthroughtheair,thetrailingairis thrustdownwards.So…vorticesdescendbelowtheflightpath.

Athigheraltitudes,whereaircraftflyveryfast,avortex,which persistsforthetypicaltwominutes,isactiveasfaras16NM behindand1000ftbelowtheaircraft.

Atloweraltitudes,morecommontotheVFRpilot,thetwo minutespersistencetimetranslatesintoshorterdistances becauseoftheslowerspeedsatthesealtitudes.

Atverylowaltitudes,suchasduringtakeoff,landing,oran

overshoot,vorticesbehaveinasubstantiallydifferentmanner.

So,yousee,theareaofhazardisnotnecessarilyalignedwith theflightpathoftheaircraftahead.

Thetowercontrollerwillprovideseparationfordeparture, dependingontheweightcategoryofyouraircraftandtheone ahead:ultralight,light,medium,heavy.Undersomeconditions, youmaywaivethatseparation.However,atuncontrolledairports andattimesotherthantakeoff,youwillhavetoprovideyourown safespacing.

Plantorotatepriortothepreviousaircraft’srotationpoint.Keep yourflightpathabovetheirsorconductanoff-centrelineclimbon theupwindside.Afteranotheraircrafthaslanded,donotliftoff untilbeyondthetouchdownpoint.

Stayabovetheprecedingaircraft’sflightpath,andplanyour touchdownpointpasttheirs.Thatmeansavoidingalonglow final.

Keepasharplookoutatalltimes,andlistentotheradioas aguidefortrafficmovement.Helicoptersarehardtospotbut theyoperatealmostanywhere,andtheygeneratevorticesmore violentthanthoseofafixed-wingaircraftofcomparableweight. Waketurbulenceisinvisibleonlytothosewhocannotseeitin themind’seye.Bealerttothehazardandtaketheappropriate avoidanceaction.

Tips are intended to increase overall safety awareness and are not a substitute for compliance with regulatory guidelines. Source:TP 2228E-24 Living with Vortices. http://www.tc.gc.ca/civilaviation/systemsafety/pubs/tp2228/Vortices.htm. Originally published by Transport Canada. Reproduced with the permission of the Minister of Public Works and Government Services Canada, 2007.

One of the frequent questions asked of me comes from the FBOs and Charter Providers I work with and goes something like this – “we do not seem to be doing all that well on the surveys that get published. Any idea why?” And then it is followed with something to the effect of “we think we are doing a really great job – so either these things are wrong or we are missing something.” I always equate this sort of questioning to a troubled marriage. When you ask your best friend how do you know when a marriage is over – it usually already is.

We are all so busy in corporate aviation today, rushing around and trying to keep pace with the current flurry of success, that we sometimes forget the basics of why we are there in the first place – to provide exemplary service. Regardless of your role – FBO, flight ops, maintenance, catering, ground transport, fuel supply and especially OEM of aircraft, parts or systems – the reason that we all have a job is because a lot of people have found that a private aircraft serves their travel needs best. It has been said before – but bears repeating – earning a customer is one thing. Turning customers into clients is something else entirely. And keeping them over a long period of time is yet another story.

When a customer becomes a client, you have crossed the line from someone who takes the odd bit of their business, to a trusted and valuable part of a service chain that they build and maintain. Clients are the folks who come back time and again. These are the people that a service industry business goes to the bank on and considers to be a key part of the revenue stream. The thing is –getting clients is something that you may do well – fuss the details and show your best stuff. You get their attention for doing it once. Keep it up and they keep coming back. The problem that rises is this – like a marriage there is a honeymoon period, and once that passes you start to see each other’s respective faults. The extra pounds or wrinkles and blemishes along with certain behaviour traits or habits start to show themselves more to you than before. Now, in the world of the successful marriage, we overlook these things and build on the strengths that brought us together. What I am seeing and hearing more and more in our

ROB SEAMANis a Wings writer and columnist.

industry, though, is open complaints, disrespect, and a breakdown of the service values and norms that we all worked so hard to build.

The breakdown seems to be coming from a lack of appreciation for what clients bring to us. Yes, they are demanding – but we encouraged them to be so back when we were ‘dating’. The other thing is that in reality, this is a small business. The gossip factor cannot be ignored as part of the reason clients lose their lustre over time. Stories from previous handlers can and do put a shadow over new relationships – and while a tip about bad past credit or financial dealings is just being a good neighbour – for anything else it has the unfortunate ability to taint the client unfairly before an independent and non-biased opinion can be formed. Sales people can be the worst for this and what never ceases to amaze me is that while they will openly trash someone behind their back – tomorrow they are banging on the door with gifts to woo the business.

What is all comes down to is a lack of respect. When you stop respecting the client it is time to decide if this is a client that you truly want or need. In a marriage, this would be counseling time. In business it is looking to see if you still need or value their revenue and what prestige or benefit your association with them brings. If the answers point to moving on – then by all means do so. Nobody is ever disrespected for being properly honest. If on the other hand that client is a value to you – then look at what has gone wrong and see how to fix it. The answer may involve actually speaking with the client or not. But to sit and let things go unaddressed sends the wrong message all around. It lets your support team know you do not care – which they in turn could read as permission to do likewise. And in general it creates tension and stress that is not good for anyone. The spillover effect can and does affect other client relationships too. And then over time it just becomes a cancer that slowly eats away at your business. In the end, those third-party surveys will show you what your client does not say directly. Your service is not up to standard, and that means that you are losing business.

So love your clients and keep them happy – or get a divorce. But either way, look at your relationships and take action to keep your business as it should be for today. Because the client of today will be the revenue you need when the industry corrects itself next. And believe me – there will be a correction sooner or later.

WestJet continues to bulk up with an order for 20 more Boeing 737-700s, with an option to convert the 700s to 800s. A total of 14 aircraft are scheduled to be delivered in 2012 and another six in 2013, bringing its total fleet size to 111 Boeing aircraft, including previously announced deliveries by the end of 2011.

“We have had a significant impact on the North American airline industry and require these additional aircraft to satisfy the demands … for our services in Canada, the United States, the Caribbean and Mexico,” said Ken McKenzie, executive VP of operations. It is also one of the largest orders in WestJet’s history, he said, noting that WestJet is one of the “healthiest” airlines in North America.

WestJet is also closer to introducing service to Quebec City, now that is has close to the 400 bilingual flight attendants that airline founder Clive Beddoe said it needed in a speech two years ago at a Montreal business lunch. In addition, WestJet is taking delivery of six more aircraft in 2008, giving it the option of adding the provincial capital to its schedule.

Air Canada is also acquiring new Boeing aircraft in the form of 777s which the carrier will use to boost capacity in the booming Asia-Pacific region. It plans to deploy the aircraft mainly on key routes to Japan and China. The airline has taken delivery of seven 777s and another 10 will be added by the end of 2008. It said it is

shifting some seat capacity to the region from the underperforming UK market where it is facing increased competition from both British Airways and low-cost carriers.

Porter Airlines is making Halifax a year-round destination after a successful summer season convinced the private operator that there is enough demand to add Halifax to its other destinations of Montreal and Ottawa linked to Toronto City Centre Airport. After Labour Day, Porter began offering weekend service to Halifax via Ottawa. It will take delivery of two more Bombardier Q400 aircraft in January and four more by the end of next year, bringing its total fleet to 10 Q400s.

The carrier expects to begin service to New York/Newark early in 2008, and also to add Boston and Chicago as its next destinations in that year. As part of its growth plans, Porter is expanding from two to five departure gates at City Centre Airport with construction scheduled to be completed by Dec. 31.

Porter said it has achieved

By Brian Dunn

average monthly revenue growth of over 20% since beginning flights in October 2006. June saw a net profit margin of 8%.

Skyservice Airlines has changed ownership with Vancouver-based Gibralt Capital Corp. taking a majority stake in the private carrier, leaving Russell Payson, Skyservice chairman and CEO with a minority stake in the charter carrier along with other coowners who will remain in their current positions.

The airline has a fleet of 21 aircraft, including Airbus

A319s, A320s, A330s and Boeing 757s and flies to 64 destinations on behalf of tour operators such as Conquest and Signature. It has estimated annual revenue of $500 million and carries about one million passengers annually.

The sale of the unspecified majority interest comes as many of the airline’s shareholders were looking to “monetize their investment,” said Payson. “No changes to the company’s current operations and workforce are planned. In Gibralt, we have an ideal partner bringing experience, financial strength and long-term investment perspectives that will help us realize

the full potential of our business. Our plan is to leverage our profitable base of operations, not only in the charter business, but also in aviation services and maintenance. Gibralt’s investment is the start of a new era for our company.”

Through its Business Aviation Group, Skyservice is also active in corporate aircraft management and sales, business jet charter services, fixed base operations and an international air ambulance service. These activities are not included in the sale and will continue to be owned by Skyservice Investments.

complement but not replace its current recruiting efforts.

Candidates for the program would be graduates of colleges within CAAC, whose members include Confederation College, Thunder Bay; Cégep de Chicoutimi; Georgian College, Barrie, Ont.; Mount Royal College, Calgary; Sault College, Sault Ste. Marie; Selkirk College, Castlegar, BC; and Seneca College, Toronto.

Successful completion of the same ground school and Transport Canada pilot proficiency checks on Bombardier CRJ or Dash 8 turboprop aircraft as with all other Jazz

Canada and New Zealand have signed a new air services agreement, helping Air New Zealand’s planned push into the Canadian market.

ANZ said that a new air services agreement has been signed allowing each side to have four flights per week on the Canada-New Zealand route. It plans to work with its Star Alliance partner Air Canada to extend its reach.

ANZ was scheduled to launch a thrice-weekly service on Nov. 2 from Auckland to Vancouver using Boeing 777-200ERs. Air Canada will be a codeshare partner. ANZ said the service will become twice-weekly from late March, returning to thrice-weekly for July and August. No airline has previously operated the route.

Zoom Airlines has leased one used Rolls-Royce RB211powered Boeing 757-200ER from US lessor International Lease Finance Corp. for 56 months. The Ottawa-based carrier will receive the aircraft in February 2008. It is expected to be deployed to its southern sun destinations.

With increased demand for airline pilots, Air Canada’s Jazz is developing a new program that would transform aviation college graduates to first officer positions.

Under a partnership with the Canadian Association of Aviation Colleges (CAAC), Jazz is in the early stages of studying the standards and criteria needed to initiate the pr ogram, which would

first officers would be required under the program.

The first graduates started their training this fall. It is not yet clear when they will be brought into the Jazz system. Currently, the majority of pilots applying to Jazz come from smaller airlines within Canada. But demand for commercial airline pilots in North America as well as other parts of the world is high, and continues to grow significantly.

Continental Airlines on Sept. 30 began a new nonstop service between its Cleveland hub and Ottawa International Airport. Ottawa is the fourth Canadian city and the seventh international city served from Cleveland by Continental. The new twicedaily service is operated with 37-seat Embraer 135 regional jet aircraft flown by Continental partner ExpressJet Airlines.

Strong passenger growth has offset rising fuel costs to the point that the International Air Transport Association has revised its 2007 forecast upwards by US$500 million to US$5.6 billion, the total profit the international airline industry could make this year.

The optimistic forecast also reflects “hard-won efficiency gains” made by the airlines from greater labour productivity and lower non-fuel costs, said Giovanni Bisignani, director general of IATA. It’s also a 10% increase from its June estimate of US$5.1 billion.

Although Bisignani is optimistic the airline industry will also turn a profit in 2008, he cautioned that higher fuel prices and possible fallout from credit markets could erode demand for air travel. As a result, IATA has reduced its forecast for next year to US$7.8 billion from an earlier estimate of US$9.6 billion.

While airline fuel efficiency has improved 70% in the last 40 years, IATA expects a further 25% improvement by 2020.

By David Olsen

Driven by the spectacular increase in economic growth since the Alberta Oilsands hit the headlines, Fort McMurray Airport (YMM) is on track to keep pace with demand, thanks to a $100-million development strategy recently approved by the Regional Municipality of Wood Buffalo.

Airport general manager Darryl Wightman and manager of procedures and public relations Sally Beaven are coordinating the efforts of the YMM management team, consultants, architects and Nav Canada to implement a new parallel runway and air terminal building, plus associated developments.

In the red-hot local economy, this kind of project is tough to manage. Wightman calls it “the Fort McMurray factor:” Virtually every employer in the area has positions open and there are simply not enough people to fill all the jobs, while the airport is losing employees to the higher-paying airlines and oil companies. In just two years the cost estimate for the planned new Parkade “skyrocketed from $12 million to $42 million, the only explanation being the Fort McMurray factor,” says Wightman. “There appears to be a widely held belief that for any project at Fort McMurray the quote can be double the cost it would be elsewhere.”

Despite these difficulties, Wightman and Beaven are confident that the airport management team, with the support of the Municipality and the Airport Commission, will get the job done.

In 2006, Runway 07/25 was extended from 6,000 to 7,000 feet, and this spring it was further extended to 7,500 feet, allowing unrestricted operations by aircraft such as Boeing 767 and Airbus A330.

The new parallel runway 07R/25L will also be 7,500 feet and fully equipped with visual and electronic aids to the latest Transport Canada standards. Constructed to the south of the existing runway, it will be served by a parallel taxiway, appropriate high speed turnoffs and taxiway links to the existing runway, which will become 07L/25R.

The parallel runway will allow uninterrupted operations at the airport throughout the year. Until now, the long northern winter and frequent snowfalls have hampered operations during snow-clearing. The new runway layout will mean that one runway will always be unencumbered by snow-clearing equipment and, at other times, permit runway work without curtailing airport operations. Another benefit for an airport with rapidly increasing traffic will be the

increased flexibility and ability to cope with peak traffic without imposing significant arrival or departure delays.

South of the new runway, a new airport terminal building will be constructed to replace the existing overcrowded terminal which is located on the north side of the present runway.

Wightman and the Airport Commission place the highest priority on operational safety. In a proactive move, the airport hired a safety and security manager to implement the Safety Management System in

2006, as originally planned by Transport Canada. This date was delayed by Transport Canada and following the recent gazetting, will be mandatory by December 2008.

Wightman foresees no difficulty in full implementation by the due date. A comprehensive risk assessment has been undertaken by the safety and security manager in conjunction with the design consultants, to ensure that all the risks inherent in the forthcoming changes have been identified, documented, mitigated and managed.

datory Transponder Airspace around YMM. The airspace encompasses the 5 mile radius of YMM Control Zone, the Transition Area with a radius of 15 miles around YMM, above 700ft. AGL and the Control Area Extension from 2,200ft. AGL to 12,500ft, with a radius of 25 miles around the airport. Above the Mandatory Transponder Airspace, the Control Area Extension is Class B airspace above 12,500ft.

Control Centre (ACC) and the YMM FSS. No longer do controllers and FSS operators have to exchange information by telephone and wait for a call before authorizing inbound approach clearances. The interactive user-friendly screens in the ACC and FSS provide instant detailed information on the progress of every flight in and out of YMM.

The number of charter passengers may have peaked as more people use scheduled flights, although in the past many B737s were chartered to carry oil company employees in and out of Fort McMurray at the beginning and end of their work cycles.

Scheduled services connect Fort McMurray with destinations as far away as Toronto and Halifax, and during the winters of 2005 and 2006 charter flights were operated to overseas holiday destinations. Inbound international flights now have to land elsewhere to clear customs but Beavan is working with Canadian Border Services so that Fort McMurray can be designated as an international port of entry. Discussions are also being held with a US-based airline with a view to establishing daily service to the US, for which customs service will be an imperative. Wightman and Beaven believe that customs facilities will have a significant positive effect on traffic.

Wightman is concerned that “there are many private corporate airstrips being built in the Regional Municipality of Wood Buffalo and if these strips are used to ferry workers in and out, YMM traffic could

drop and with it our revenue.”

On the other hand he recognizes that “spinoffs from resource development increase our traffic and I would hope that we can cap the number of private airstrips at the present level so that this airport stays viable.”

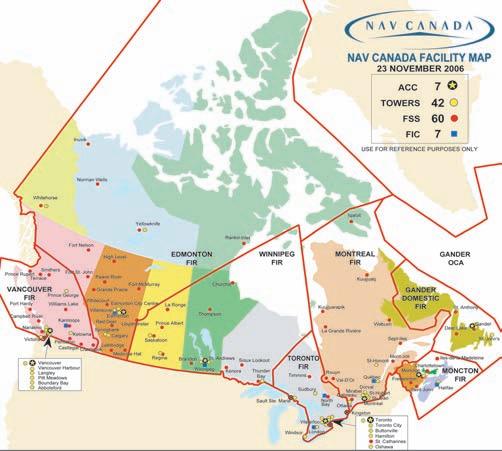

Expansion at YMM also provides challenges for Nav Canada, and Jim Strukalo, general manager of the Edmonton FIR, describes the new technologies, techniques and procedures introduced to keep pace with traffic growth and airport developments.

Fort McMurray and the oilsands area of northern Alberta lies within the Edmonton FIR, the largest Flight Information Region in Canada.

In addition to the expansion at Fort McMurray Airport, there are private airstrips at Mildred Lake and Horizon, north of YMM, with two more proposed. To ensure that development is safe and coordinated, an Aerodrome Coordination Committee has been formed, including Nav Canada, the Municipality of Wood Buffalo, Fort McMurray Airport and the oil companies.

Some major airspace changes have been made, in particular the establishment of Man-

A key procedural change is the establishment of RNAV SIDs and STARs at YMM, part of the “RNAV everywhere” initiative in the Edmonton FIR.

Similar changes have taken place or are planned in the oilpatch area, which includes the airports at Peace River and Grande Prairie in Alberta plus Fort St. John and Fort Nelson in BC. This is particularly valu-

In June, Nav Canada installed the Extended Computer Display System (EXCDS) at YMM. This groundbreaking technology, developed by Nav Canada and sold to the UK and Denmark, has dramatically reduced controller and Flight Service Station (FSS) operator workload, while adding a new level of safety and efficiency. A completely paperless system, EXCDS has automated coordination and communication between the Edmonton Area

able due to the significant amount of crossing traffic and potential conflictions in the airspace. Another cutting-edge technology development has been installed that will provide electronic surveillance down to ground level at Fort St. John Airport. Until now, a limiting factor in the radar surveillance coverage of the area has been that the conventional monopulse SSR equipment that provides radar surveillance throughout much of the land area of the FIR, only provides

coverage to a few hundred feet above the ground at most airports. New technology, known as multilateration, uses the signals from aircraft SSR transponders to provide surveillance information to ground level, updated every second. Operational testing will continue through the coming fall and winter to build up the case for Transport Canada approval for operational use, using radar separation standards.

The application of new technology by Nav Canada and the continuing implementation of remote peripheral VHF communication (PAL) stations, ground-based radar and other systems have changed the face of air traffic management service provision. In the past, providing enhanced air traffic services involved implementation of conventional labour-

intensive facilities and equipment. Now, a sophisticated planning process, managed by a Nav Canada team at Edmonton FIR, takes a holistic approach and considers numerous scenarios, involving people, equipment, technologies and procedures to come up with the most efficient and cost effective solution for the airspace customers, while maintaining the corporate

commitment to the highest levels of safety.

“We set ourselves a performance objective to reduce restrictions on air traffic in the Edmonton FIR,” notes Rudy Kellar, Nav Canada vice-president, operations. “As a result of these new initiatives and efforts from our staff, we not only reduced, but have nearly eliminated all tangible restrictions.”

In 2005 restrictions peaked at more than 140 hours in a busy month, but two years later the figure has been reduced to a mere 20 hours.

The oilpatch is just one part of the airspace management task of Nav Canada. Using the upper airspace above YMM are flights between Europe and western North America, between Asia and North America, transpolar traffic to many points in Asia, plus North American high-level domestic traffic –all controlled in a highly complex airspace system based at Edmonton ACC. Jim Strukalo manages it with a staff of skilled engineers, specialists, controllers and managers, all working as a team to provide “safety, service and efficiency through professionalism.”

By Andy Bateman

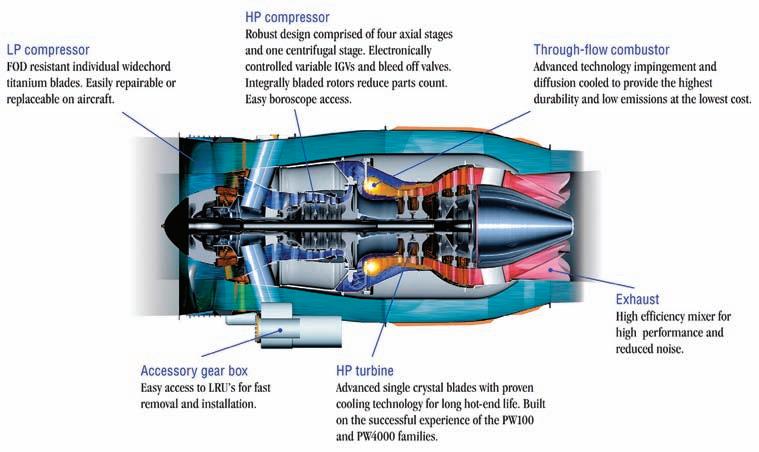

Advanced engine design and manufacturing, and a $1.5billion research and development program, underscore Pratt & Whitney Canada’s ongoing commitment to technology.

With the current focus on climate change and the environment, many companies are hastily reinventing themselves to go green while others are already there. P&WC certainly belongs in the latter category, with the development and implementation of green technology an established part of doing business. Going forward, P&WC’s five-year R&D program promises to raise the green bar further still. The program will develop new engine and fuel technologies

for the next generation of aircraft and includes a $75million investment in over 600 collaboration projects, working with the National Research Council and 20 Canadian universities.

Vice-president of engineering Walter Di Bartolomeo explains that the two main aims of P&WC’s green technology developments are maximizing customer value and minimizing environmental impact. These goals are not achieved overnight, with the development of the company’s Talon 2 combustion technology, for instance, taking several years. One of Talon 2’s main goals has been to reduce emissions of nitrogen oxides

(NOx). This goal was achieved through a detailed understanding of the combustion process and optimum burn parameters such as fuel/air mixture and burn location. The result is a lean fuel mixture burning at the optimum temperature distribution to provide complete combustion. As is often the case, green developments also make good business sense. The PW307 engine which recently entered service on Dassault Aviation’s Falcon 7X has excellent fuel efficiency; NOx emissions are 33% lower than current International Civil Aviation Organization (ICAO) standards and also meet Zurich 5 emissions requirements for

landing fee surcharges. Di Bartolomeo adds that Talon 2 technology is part of an evolutionary process, with P&WC now testing Talon 3 as part of a new 10,000-pound thrust class engine. This new engine is being developed for the next generation of longrange corporate jets and will reportedly surpass current ICAO standards by over 35% for carbon monoxide and by more than 50% for nitrogen oxides, unburned hydrocarbon and smoke emissions.

Environmental initiatives have also been successful in significantly reducing engine noise, an issue of particular

There’s only so much you can learn from assets, liabilities, ratios and balance sheets. At CIT, we know there’s more to what you do. So when it comes to getting operators and customers into the business aircraft they need, we look beyond numbers and focus on the people and potential that propel a company. We see the value of ideas and hard work. And we understand the ups and downs that your business goes through. It’s why we partner closely with our clients to design customized leasing and financing solutions that can help your business take flight today, and ensure you’re ready for whatever appears on the horizon.

To learn how we can help you get where you want to go, visit cit.ca or call us at 877.590.7356.

By Ken Pole

John Crichton hasn’t had his hands on the controls of an airplane since “sometime in the 1980s,” but as top gun at Nav Canada for the past decade he has controlled what is nothing short of a revolution in Canadian aviation: a dramatic overhaul of the second-largest air navigation service (ANS) in the world.

While his interest in flying had a fairly typical beginning, in that his father was a World War II Royal Canadian Air Force pilot and that Crichton eventually obtained a commercial licence, he quickly sideslipped into the industry’s administrative segment, managing the Ottawa Flying Club for a couple of years while at university. Then came an opportunity in 1973 to work

for Bradley Air Services Ltd., founded by aviation pioneer Russell Bradley, who co-developed with another legend, Weldy Phipps, the ‘tundra tires’ that opened up new markets.

Crichton spent 21 years there, turning it into First Air and the standard-bearer for scheduled services in a market hitherto mostly dependent on Phipps and other bush pilots. “I didn’t do that much flying commercially, mostly around here,” Crichton said. “I quickly got into the management end of it.” And that's where he has remained through a career that saw him become executive vicepresident of First Air and then president of the Air Transport Association of Canada (ATAC) before taking on Nav Canada.

During his days at Bradley/

First Air, Crichton evidently earned a place in the history books, according to Dennis Patterson, a veteran Northwest Territories politician and cabinet minister. “John Crichton’s leadership helped lay the groundwork for the new territory of Nunavut,” Patterson said, citing numerous upgrades to aircraft, airports, runways and navigational aids. “It was this infrastructure that made Iqaluit, Rankin Inlet and Cambridge Bay transportation hubs.”

Crichton’s tenure at Bradley/ First Air also saw the inauguration of direct service between Iqaluit and Nuuk, the capital of Greenland, a route that remained operational for 20 years. Crichton was called a “visionary” by Jim Britton, at the time Baffin regional director for the federal government. “Under John’s stewardship, northern transportation expanded and improved in a very material way,” Britton said. “It was an instrumental step forward ... to the creation of Nunavut.” His dedication has been recognized with an honorary life membership in the Northern Air Transport Association; he was similarly honoured by ATAC and, in 2006, was named Transportation Person of the Year by the Transportation Association of Canada.

That same vision came in handy when Crichton tackled Canada’s ANS system years later. As part of the federal transport ministry and thanks to government funding that fell

horribly short of legitimate needs, the system had become inefficient and in dire need of an overhaul. Staff shortages, chronic cost overruns on badly-needed capital upgrades, and other problems resulted in frustrating bottlenecks and flight delays.

The industry as a whole feared that unless something drastic was done, the systemic problems, which were exacerbated by political meddling, would simply compound to the point of collapse. There also were issues with ANS being under the same administrative umbrella as aviation safety and regulation.

When the concept of a private-sector operation was floated, Crichton was front and centre, working with government, industry and unions to design a not-for-profit approach to ANS. As chairman of the new corporate entity during the 1995-96 transition, he led the negotiating team that purchased the ANS from Ottawa. That was financed through a $3-billion bondbacked loan Crichton had secured from a syndicate of financial institutions. Once Parliament passed the enabling Civil Air Navigation Services Commercialization Act in June 1996, the transfer took place that November with Crichton handing Ottawa a cheque for $1.5 billion.

Crichton was appointed CEO in 1997, a position which he holds today and will continue to hold for some time to come. While management is his forte, he is certain that his operational roots have given him useful insight. “I've always considered that a commercial pilot’s licence as almost the equivalent of a university degree,” he said in a wideranging interview coming up to

his 10th anniversary as Nav Canada’s president and CEO. “Also, you develop a tremendous empathy for the people who actually fly airplanes – an understanding of their concerns and their priorities. That's a very important managerial tool. Understanding their problems and how to address them. I found that to be very valuable right to this day – being able to walk the walk as well as talk the talk.”

While he doesn’t really regret his career path, Crichton does admit that there’s the odd day “when the walls are closing in with a hundred other problems” and it would be nice to take off even though that would bring with it a whole other set of challenges. “Yeah, but those are a lot more manageable than some of the ones I have to deal with some days. But I have no real regrets because I’ve stayed in the business very closely and a lot of

more than 20 per cent to some 2,050 air traffic movements per employee.

Having been involved in Nav Canada from its conception to its birth and now seeing the operation entering its second decade, Crichton demurred when asked whether there were other challenges he would like to take on. “I usually focus on the here and now and I’m very happy with what I’m doing,” he said. “There are still lots of challenges and I consider that I have a very good job. So at this stage of my career, I’m not really trying to find new challenges.... I’m really happy with the people here and with the direction we’re going.”

friends and co-workers are pilots.... Aviation is my life’s work, very much a passion.”

Looking back at his career so far, he takes tremendous pride in having participated in helping to open up the North at Bradley/First Air. There is equal pride in what has been achieved at Nav Canada, doing things which have been commended by the global aviation community. There were early concerns in some circles that a private company could not manage such an essential service in the best interests of the public, but the facts speak for themselves. Losses-of-separation between aircraft flown under instrument flight rules, a benchmark for ANS safety, have been effectively halved since 1997. While the overall number of ANS staff has been reduced by 1,000, there has been a net gain of more than 250 air traffic controllers and productivity has improved by

Among the “lot of things” still to do is the planned introduction of what he describes as the world’s most advanced automated flight data processing system. It is expected to enhance three key Nav Canada values: safety, service and cost efficiency.

Then there’s Nav Canada’s growing international presence in terms of marketing systems which have been developed inhouse and which other countries’ ANS providers have eyed jealously. Delegations from at least 20 countries have visited Nav Canada facilities. While most tend to think their individual air traffic situations are unique, there are common challenges and Nav Canada is well positioned to capitalize on those.

Crichton, whose tenure hasn't been totally free of labour issues – some a legacy from the company’s publicsector roots – is trying to develop “a culture of employees taking ownership of what we do and trying to raise the engagement levels” so as to complete the long and sometimes painful transition from

the government model.

Ideally, he wants Nav Canada employees to see themselves as “partners” in achieving management’s goals. That involves making them “feel good” about their position within the company, believe they’re being treated fairly and have confidence that the company is on the right track. Internal surveys evidently suggest the effort has been worthwhile, that Nav Canada’s employees take special pride in what they do for the company and, through it, for the aviation industry in particular and Canada’s economy in general.

“We’re all in this together,” Crichton said. “High-achieving companies are ones that have highly-engaged employees and on the human resources side of things that’s a big priority for us. We’re slowly making progress and labour relations have definitely improved over the last few years. Both the union leadership and the management have to work at that. I’m delighted that we’re starting to have some success, but I attribute that to both parties.”

The evolution of government-mandated local airport authorities has generally paralleled Nav Canada’s development and in many ways has made it easier for the ANS provider to deal with and resolve any issues faster and more effectively that when it was run by a centralized bureaucracy.

“It’s been positive from our point of view,” Crichton said of the relationship with the airport authorities. “Not that there aren't challenges. We’re trying to deal jointly with our mutual customers, airlines, on various issues and trying to achieve objectives and efficiencies. I think people are trying to

honestly work together and find solutions.”

While the original idea was to have a not-for-profit operation, that has become a bit of a misnomer. Nav Canada is a non-share capital corporation that has no shareholders and no share equity. It is governed by four ‘members’ who perform many of the traditional roles of shareholders: the federal government, the airlines, the business and general aviation community, and the employees’ unions.

Each member is represented on the Nav Canada board. Airlines have four representatives, the government three, the unions two and business and general aviation one. There also are four unrelated directors, plus Crichton. In other words, customers account for five of the 15 seats on the board and no member has a majority.

“Being a non-share capital corporation simply means that when we make money we don’t distribute it to shareholders,” Crichton said, likening Nav Canada to a cooperative. “If it does well in a year, then the people who buy from the cooperative get it back, generally in the form of reduced charges. We think that’s the right way to do it because we’re a natural monopoly. It’s a great way to ensure from a financial point of view that the monopoly doesn’t engage in unfair pricing practices and so on.”

There have been predictable gripes over the years from some elements of the aviation community about fee increases, but the capital investments made by Nav Canada in building a better ANS system aren’t cheap. Since their introduction, ANS charges have increased by some 10 percent; that is well below inflation,

which compounded at nearly 20 percent over the same period. Moreover, ANS charges remain at least 20 percent below the airline ticket tax which was revoked with the advent of Nav Canada.

“If you compare our charges and our financial performance against other major ANS providers around the world, it would seem that we’re pretty much leading the pack,” Crichton said. “We run like a business, there’s no question about that, and we want to run efficiently and we want to produce value for the customers both in service and in cost.”

Asked whether Nav Canada’s corporate status implies any greater liability exposure than when ANS was government-run, he said it does in the sense that governments tend to self-insure – which is facilitated by their ability to generate any needed revenues through tax increases. So Nav Canada, like any other non-public corporation, has to buy insurance on the market. “Right now we have the largest insurance policy in the world – US$3 billion through a wide variety of insurance companies.”

While Crichton still puts in the odd 12-hour day, which

was virtually routine in the early going, his work day when he’s not travelling, which is about 30 percent of the time, tends to be more conventional in length these days. However, he still tends to work six days a week while finding time to spend with his “very active” family and walking his dog.

“It’s a combination of dealing with internal and external issues. The travel is mostly in North America and Europe, and visiting employees at our more than 160 staffed sites across the country. I try to get out to meet people and talk to them and so on, which is a never-ending situation.” The board and various committees also are very active, putting even more demand on his time. “It’s just like any large corporation,” Crichton shrugged matter-of-factly.

Was there ever a point at which he thought he had bitten off more than he could chew? It seems there may have been a few early on, especially during the first negotiations. “There were days where I sort of wondered, but I never really wavered. I thought it was the right goal and even though it was pretty tough at times to get there, I never really doubted it was possible.”

By David Carr

It is two years late, has cost Airbus hundreds of millions of dollars in penalties and cancellations, and exposed the soft underbelly of the European airplane builder’s management structure. But none of these setbacks mattered on Oct. 25 as the first commercial flight of the A380 touched down at Sydney’s Kingsford Smith International Airport and entered the record books.

Launch customer Singapore Airlines (SIA) sold tickets for the inaugural flight

through a global online charity seat auction. Now the heavy lifting is under way. SIA has ordered 19 A380s and will quickly follow Sydney with service to London Heathrow and the US west coast, although concerns that LAX will not be ready to receive the double-deck behemoth before 2009 are forcing customers to look north to San Francisco. Not on the planning horizon is Vancouver International Airport, where SIA operates a threetimes-weekly service.

The A380 made a stopover at YVR last November as part of its certification process –the only North American stop during a 10-city tour.

Seven of Airbus’s 15 A380 customer airlines fly into Canada including Emirates, which began service to Toronto in October, and British Airways which recently jump-started a stalled order book with a US$8.2

billion order for 12 A380s and 24 Boeing 787 Dreamliners. Montreal, Toronto and Vancouver are each equipped to handle the A380, but without a Canadian order the airplane is expected to have a marginal presence in Canada over the immediate future.

The smart money remains on Montreal’s Pierre Trudeau

CONTINUED ON PAGE 43

By Doug Morris

At 4:01 pm on Jan. 13, 1982, Air Florida flight 90 crashed into the ice-filled Potomac River just 30 seconds after takeoff from Washington National Airport. The crash killed 78 people, including four who were in cars on the 14th Street Bridge over the river. The story of what happened on that January day is one of tragic human error in the face of extreme weather conditions.

Unfortunately, the history of air travel is filled with similar tragedies as the airline industry in Canada, the US and elsewhere took a decidedly ‘laissez-faire’ approach to the task of deicing. On Dec. 12, 1985, a DC-8 loaded with American soldiers stalled at the end of the runway in Gander, Nfld. in freezing drizzle,

killing 248 soldiers and eight crewmembers. For years the telltale scar it gouged in the terrain sent a vivid reminder of what ice on wings can cause. The crash of a commuter jet in Dryden, Ont. in 1989 also exemplified the perils of airframe icing. The Fokker 28 crashed 15 seconds after takeoff, unable to achieve enough altitude to clear the trees beyond the end of the runway because of ice and snow on the wings. The crash resulted in the death of 21 of the 65 passengers and three of the four crew.

In the early years, the decision to deice a plane was made by the captain or the airline. Throughout the industry,

there was a tendency to push resistance against deicing to the limits because of time constraints, low operating budgets, and a general lack of knowledge about the perils of ice on an aircraft.

In both Canada and the US it took a horrific crash related to airframe icing to instigate a change in deicing regulations. These days, any secondguessing is removed from the equation, and the old grey area no longer exists. Both Canadian and American regulations now prohibit takeoff when ice, snow and frost is adhering to any critical surface of the aircraft, including lifting and control surfaces, wings and tail, and upper fuselage surfaces on aircraft with rearmounted engines. The rule is

known as the “clean aircraft concept.” The main exception to the new regulations allows a coating of frost up to oneeighth of an inch on wing lower surfaces in areas coldsoaked by fuel, between the forward and aft spars. Deicing also is not mandatory if the captain expects dry snow lying on top of a cold, dry and otherwise clean wing to blow off during the takeoff roll. Although pilots are in charge of deciding whether or not deicing is needed, the lead ramp attendant can overrule a decision not to deice.

In Canada, icing conditions can lurk nearly nine months of the year, so the deicing

checklist is always within reach because it’s part of doing business. As the old aviation adage goes, “If you think safety is expensive, try having an accident.”

The Central Deicing Facility (CDF) at Toronto’s Pearson International Airport is the largest deicing facility in the world. Fully operational since the 1999-2000 cold season, this 65-acre “drivethrough airplane wash” consists of six huge bays capable of handling hundreds of aircraft daily. It has an official deicing season of Oct. 1April 30. Many pilots jokingly refer to the CDF as the “Central Delay Facility,” but the fact that most pilots are paid by the minute takes the sting out of any wait. In addition, the short time it takes to spray a plane with deicing fluid is insignificant compared with the potential for disaster if a pilot did not take the time to deice the aircraft.

Moreover, the CDF actually has reduced time between deicing and takeoff because it was built closer to the runways and has increased overall throughput and improved turnaround times. On the way

to the CDF, pilots radio “pad control,” which assigns the aircraft a deicing bay. Because this is a “live” or “enginesrunning” operation, precise terminology and electronic signboards are used to eliminate any potential for accidents. Pilots then contact the “Iceman” in the deicing control centre, appropriately nicknamed the “Icehouse.”

Once the aircraft is in position to receive the spray, a Danish-made Vestergaard Elephant Beta springs into action. The CDF has 27 Beta machines, each of which costs about $1 million. (Two Beta 15s able to stretch nearly 76 feet into the air have been acquired capable of deicing the mammoth Airbus 380). The Iceman tells the pilot the exact time deicing started, the type of fluid used, and when the vehicles have retreated to their safety zones. A safety zone is an area ensuring a safe distance between the aircraft and deicing vehicle. The deice vehicles must be behind these lines before an aircraft can exit the deicing area.

While many airports still employ the manually operated ‘cherry pickers’ staffed by two

“holdover time,” or the time from when deicing commences to the time the airplane must be airborne based on temperature and precipitation rate and type. For most operations, the deicing Type I fluid (orange) is used to remove the snow and ice and type IV (green) is to prevent further adhering of ice. (Type II, which is longer lasting, more expensive and designed for jet aircraft, is rarely used and type III is not available in the US and Canada but is found in Europe).

(one driver and one in the bucket) ground crew who must brave the bitter winds and backspray, the CDF machine is operated remotely from the heated enclosed cab. It is armed with deicing fluid, nozzles, whisker-like probes to prevent aircraft contact, and a telescopic boom to reach distant spots and critical flight surfaces.

The deicing procedure involves spraying fluids that remove or prevent ice buildup all over the aircraft. Made up of combinations of glycol and water, deicing and anti-icing fluids come in different varieties that serve a specific function. The difference between the types of fluid is the

Once an airplane has been deiced, all of the extraneous fluid that falls off the aircraft is collected in massive holding tanks to ensure compliance with environmental regulations; deicing fluid can be a hazard to nearby bodies of water. The tanks can hold a whopping 13 million litres of reclaimed fluid while it waits to be treated. Some of the spent fluid is used to make car windshield wash and engine coolant. (You may even see a large vacuum truck called the Glycol Recovery Truck (GRV) a.k.a the “slick licker” sucking up fluid). It cannot be re-used for airplane deicing because possible degradation of the fluid means its effectiveness

CONTINUED ON PAGE 33

• Most aircraft deiced/anti-iced in a day: 513 (February 3, 2000)

• Most fluid dispensed in a season: Just over 7.5 million litres in the 2002-2003 winter season

• Most aircraft deiced/anti-iced in a year: 14,299 in the 2004-2005 season

• Most aircraft deiced/anti-iced in one month: 4,200 in January 2004

Source: Joe Forbes, Senior Manager, Deicing Operations, Greater Toronto Airports Authority

By Tarek M. Sardana, MD

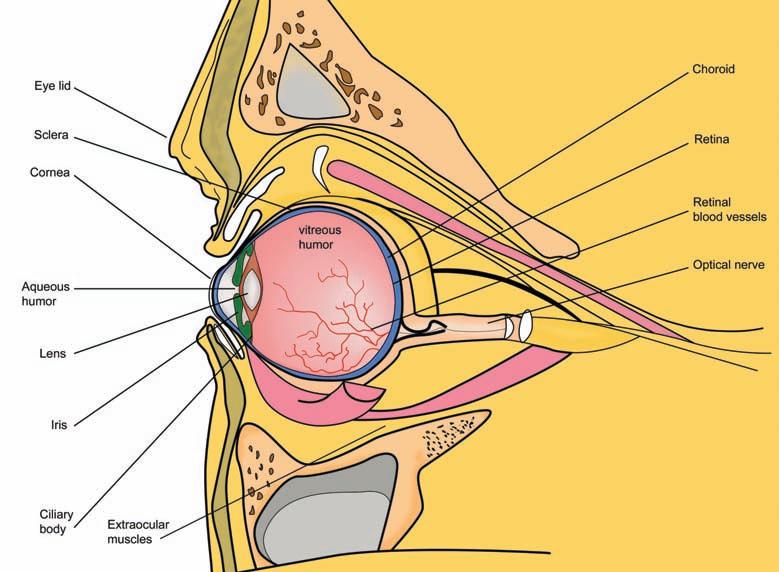

Tired of wearing glasses while flying? How about contact lenses, not the most convenient option at times! Corrective or refractive eye surgery has come a long way over the past 20 years and is becoming increasingly more common in the civilian aviation community. Most major communities have several facilities that provide corrective eye surgery. Nowadays, much more highly sophisticated technical equipment is utilized, such as lasers, resulting in procedures that are more precise and safer, with faster recovery times. However, corrective eye surgery isn’t necessarily for everyone.

The basic concept of refractive surgery involves changing the shape of your cornea which changes where a visual object is focused on your retina (the back of your eye). In people who have ‘perfect’ or normal vision, the point of focus occurs on a small spot on the retina, and you can make small changes to your lens at the front of your eye to fine-tune this focus using the muscles in your eye to change the shape of your lens.

Many pilots do not have perfectly shaped corneas. Some corneas are too flat,

resulting in far-sightedness (hyperopia), while others are too pointy or long, causing near-sightedness (myopia). Myopia is by far the more common condition for most people who wear glasses. Other corneas are curved irregularly, causing a condition called astigmatism. For most pilots who do not have perfect vision, your glasses are doing the task of changing your focal point on your retina and this is what refractive corrective surgery will change.

It is important to note that the age-related problem of

close-up vision difficulties (called presbyopia) have really nothing to do with the shape of your cornea, as it is the lens of the eye that has become less pliable over time and you are no longer able to shape your lens to focus while reading, hence the requirement for reading glasses.

There are some newer techniques available on the market which involve actually exchanging the refractive lens with an artificial lens in your

eye and this can correct both near- and far-sightedness. This procedure is referred to as a “Refractive Lens Exchange.” Another related procedure, the “Implantable Contact Lens” (ICL). is also available at some centres to correct conditions that may be too extreme for laser vision correction. However, it is very important to appreciate that these procedures are not approved by Transport Canada for use on pilots at this time. At present,

refractive corrective surgery does not fix the condition of presbyopia, so if you are now wearing bifocals you will still require reading glasses postsurgery.

one percent. However, occasionally potentially visionthreatening complications do occur, including; infection, significant haze development, scarring, night glare, perfora-

The two most common techniques performed in Canada to correct vision are Photo Refractive Keratectomy (PRK) and Laser Assisted in-Situ Keratomileusis (LASIK), with LASIK being the more common procedure. PRK involves literally burning or vapourizing the outer layer of your cornea to change the focal power of your eye, while LASIK involves slicing a thin three-sided flap off your central cornea and then reshaping the cornea underneath with a laser. Once the desired shape is obtained the flap is placed back on the cornea and allowed to heal.

AEROMEDICAL CONCERNS

It must be appreciated that, as with any surgical procedure, complications do occur, even if they may be rare. Refractive corrective eye surgery has an extremely low significant complication rate, much lower than

tionally purchased health care/ drug plans, so the individual is usually on the hook for the entire fee.

Transport Canada has strict guidelines about flying after refractive surgery which can be found on its Web site at: www.tc.gc.ca/CivilAviation/Cam/eyesurgery.htm

There are significant grounding periods between the withdrawal of eye drops after refractive surgery and medical certification ranging from three to six months depending on the correction required and type of procedure. Generally PRK has a longer grounding period than LASIK, potentially as much as three months longer. The following requirements must also be met in order to return to flying duties:

1.Visual Acuity must meet the required standards.

2.No “haloing,” haze or night vision problems.

tion of the eye and prolonged post-operative steroid drop use, which can result in cataracts or glaucoma.

Less serious but more common complications of LASIK include detachment or movement of the flap, resulting in double vision; growth of corneal tissue into the flap; bleeding into the white part of the eye; and technical problems associated with surgical instruments themselves. Very common, but usually temporary side effects include mild irritation, dryness, sensitivity to bright lights and tearing. Despite these possible complications, hundreds of pilots in Canada have had the procedure done. Its cost varies significantly but is usually in the $2,000 range for both eyes. These procedures are generally not covered by provincial health care plans and in fact are not covered generally by addi-

have had corrective eye surgery are not being accepted for enrollment.

3.Refraction and visual acuity remaining stable, as demonstrated by refraction and visual acuity measurements at 3 and 6 months post-surgery.

4.No significant reduction in contrast sensitivity measurements

5.No ongoing medical treatment of the eyes.

6.Completion of specific questionnaire by your vision care specialist (available on the TC Website).

7.Follow-up report by a vision care specialist 12 months after medical certification.