The rebirth of the Twin Otter

4 McCarthy

It wasn’t raining when Noah built the Ark.

6 On the Fly Industry news that’s important to Canadians.

9 On the Web

A sample of our comprehensive online coverage of the Canadian aviation industry.

10 Airline Insider

Brian Dunn covers the latest developments in the Canadian airline industry.

12 100 Years of Powered Flight in Canada

Raymond Canon looks back at the role of the de Havilland Mosquito. Also, coverage of the Silver Dart replica flights, an aviation quiz and 100 Year celebrations and events.

16 Carr

Canadian firms eye U.K. Prize.

20 Gregorash Aviation

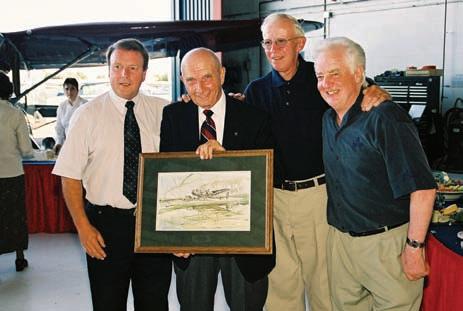

Formed out of the remains of Standard Aero’s piston engine servicing division, Gregorash Aviation is now a successful umbrella corporation. James Careless reports.

24 Pilots NextGen

The real world approach to training at Seneca College’s School of Aviation and Flight Technology is preparing our next generation of pilots, by Blair Watson.

30 Preparing for SMS

Glen Priestley discusses effective strategies to help prepare a company-specific Safety Management System.

34 One on One

Darren Locke speaks with Barry Lapointe, president of Kelowna Flightcraft.

46 Purser

Corporate jets take a PR hit.

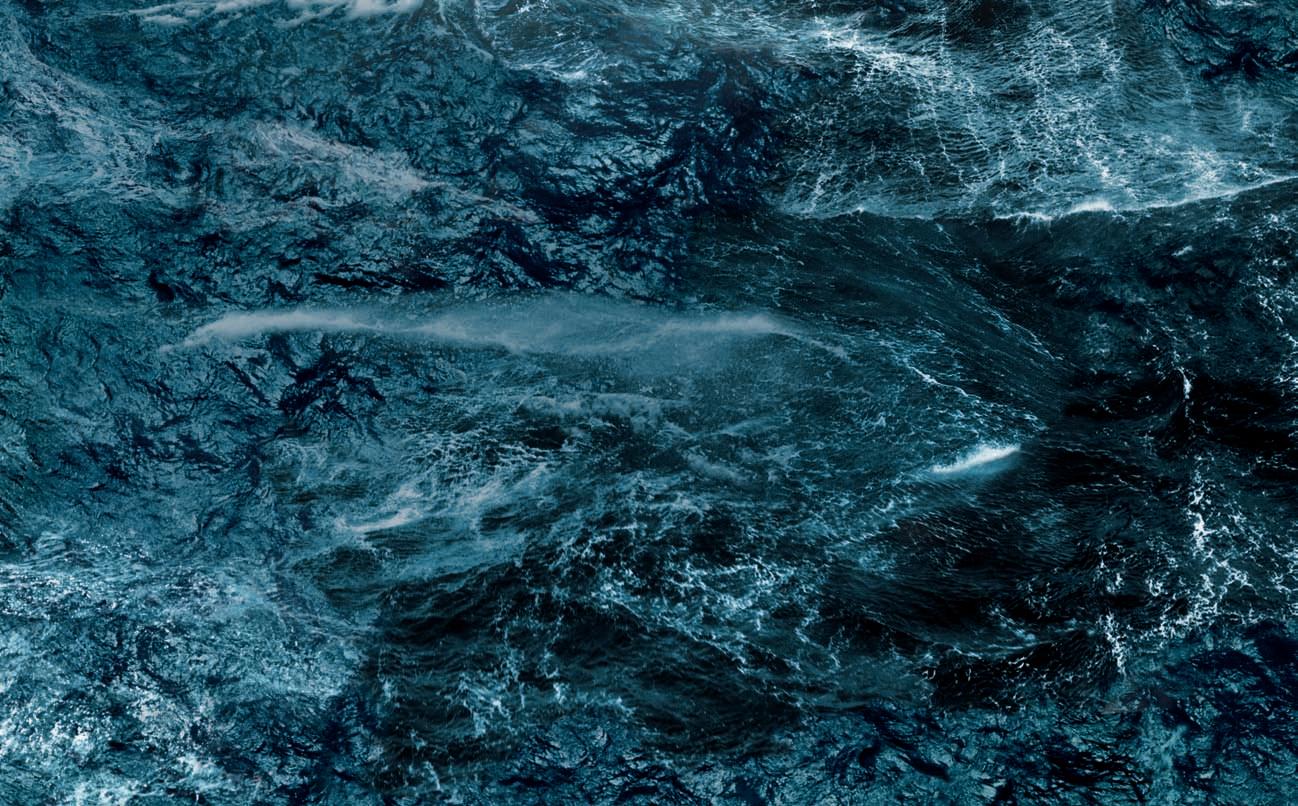

ON THE COVER

The all-new Viking Twin Otter 400. (Photo courtesy of Viking Aircraft)

DREW MCCARTHY is the editor of Wings.

In April of 2007, the federal government made a commitment to Canadians to invest in aerospace by launching the Strategic Aerospace and Defence Initiative (SADI). The purpose of the project was to support strategic industrial research and pre-competitive development (R&D) projects in the aerospace, defence, space and security (A&D) industries.

It wasn’t raining when Noah built the Ark

During the election campaign last October, Prime Minister Harper promised that his party would expand the program by $200 million over the next four years. At a joint gathering of the Canadian Club of Toronto and Empire Club of Canada, the prime minister told his audience, “Let me be clear. These will not be bailouts of yesterday’s problems. We will support the development and deployment of new technology.”

The dual strategies of investment and procurement must be viewed as fundamental and separate.

The intent and direction of that election promise was widely viewed as good news by the Canadian aerospace industry. Then came Budget 2009, and the election promise mysteriously disappeared from sight.

Claude Lajeunesse, head of the Aerospace Industries Association of Canada (AIAC), immediately expressed his concern that the government had abandoned its election promise.

On the government side, Industry Minister Tony Clement insisted that the aerospace industry in Canada is in solid shape and is not in need of federal financial aid. This sadly belies the government’s commitment to the industry and suggests an unwarranted level of complacency.

In a recent conversation with Lajeunesse, he explained to me that while he agrees there’s currently no need to panic, it is equally not the time to abandon our investment in the future. Lajeunesse says that if we don’t want the industry to have major problems in two, three, four or five years, then something needs to be done now.

From the AIAC’s point of view, the $200 million election promise is a minimum dollar amount. Recent figures show that the Europeans are investing in the vicinity of US$1.5 billion per year in research and development. American figures are more difficult to come by, but we all know that it’s a considerable amount.

In the world of aerospace, these countries are both competitors and potential partners. In either case, we need to be playing in the same league.

This is not to say that there aren’t good things happening. On Feb. 13, Prime Minister Harper and Public Works Minister Christian Paradis announced that the government of Canada had awarded a $329.5 million contract for a comprehensive aircrew training equipment and service solution to a pan-Canadian team led by CAE.

This is, of course, excellent news, but should not be viewed as an alternative to crucially needed R& D investment. The dual strategies of investment and procurement must be viewed as fundamental and separate. Both are necessary to continuing our role as a global aerospace leader. In order to maintain that goal, we need the minimum investment promised and a total commitment to industry involvement in the procurement process from the very beginning of all government programs. It is imperative that we be proactive as a nation; it wasn’t raining when Noah built the ark.

WINGS MAGAZINE

PO Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Tel.: 428-3471 Fax: 429-3094

Toll Free: 1-888-599-2228

EDITOR DREW MCCARTHY dmccarthy@annexweb.com

519-429-5192 • 888-599-2228 ext. 265

ASSOCIATE EDITOR ANDREA kWASNIk akwasnik@annexweb.com 519-429-5181 • 888-599-2228 ext. 238

SENIOR ASSOCIATE EDITOR RICHARD PURSER

PRODuCTION ARTIST kELLI kRAMER

OTTAWA CORRESPONDENT kEN POLE

AVIONICS EDITOR ROB SEAMAN

FLIGHT DECK RAY CANON, JAMES CARELESS, DAVID CARR, BRIAN DUNN, DARREN LOCkE, CARROLL McCORMICk, BLAIR WATSON

SALES ASSISTANT PAULINE CECILE pcecile@annexweb.com 519-429-5182 • 888-599-2228 ext. 273

PuBLISHER TIM MUISE tmuise@annexweb.com

GROuP PuBLISHER SCOTT JAMIESON sjamieson@annexweb.com

PRESIDENT MIkE FREDERICkS mfredericks@annexweb.com

PUBLICATION MAIL AGREEMENT #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: ncuerrier@annexweb.com

Periodical postage paid at Buffalo, NY. USPS 021-029, ISSN 0701-1369. Published six times per year (Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec) by Annex Publishing & Printing Inc. US Office of publication c/of DDM Direct.com, 1175 William St., Buffalo, NY 142061805. US postmasster send address change to P.O. Box 611, Niagara Falls, NY 14304.

Printed in Canada ISSN 0701-1369

CIRCuLATION e-mail: ncuerrier@annexweb.com Ph: 866-790-6070 ext. 208 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SuBSCRIPTION RATES

Canada – 1 Year $ 34.00 (includes GST - #867172652RT0001) USA – 1 Year $ 50.00 Foreign – 1 Year $ 65.00

From time to time, we at Wings Magazine make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement

You know that every ight is mission critical today. What you want to know is what we’re doing to support you every day. Everything listed below comes with our commitment that “whatever-it-takes” is not just a promise – it’s our Standard Operating Procedure.

World’s

Three of them, strategically placed around the world, link you to all the information and brain power you need for virtually any situation. Our cadre of experts use our world-leading technology to give you details on every part, system and service record for every Falcon ying. Plus voice/data access to technicians.

The Leading-Edge Global Service Network

Over thirty Service Centers in 14 countries are linked to our Technical Command Centers and Parts Centers.

Giving you some of the best trained experts and most seasoned technicians. Ready to welcome you – or come to you – wherever you y.

The World’s Most Efcient Parts Delivery

“Whatever Way Is Fastest!” Our nine Parts Centers are located at inter-modal shipping hubs around the

world, so we can nd the part nearest to you and deliver it the fastest way possible – commercial, courier, charter or one of our own planes.

You can’t get better quality, or longer warranties, than with Genuine Falcon Replacement Parts. And we’ve not only lowered the prices on thousands of them, we have new price-matching and return-without-cost policies. Check our website for all the details.

“Go-Teams” began as an emergency service, dispatching our technicians anywhere in the world on a moments notice. Today that spirit of urgency has spread to become part of every aspect – and everyone – at Falcon Service worldwide. We’re all committed to the Go Team Spirit –whatever-it-takes-to-keep-you-ying.

Visit us at : Falconjet.com Or call: U.S.

Mark Neely was appointed as the new vice-president of sales for ATR North America in January. Prior to joining ATR North America, Neely held the position of Regional VP of sales with Embraer leading several sales to major airlines and leasing companies in North America, including the first Embraer sale into Canada.

Previously, Neely held similar positions with Fairchild-

Dornier and British Aerospace. Early in his career, he held various analysis and marketing positions with USAir and People Express airlines.

As the company’s VP of sales, Mark Neely will be responsible for all commercial and sales issues, and will be a primary staff member interfacing with current and prospective airlines. He is married with two children and resides in Haymarket, VA.

The Government of Canada has awarded CAE a contract valued at approximately $329.5 million for a comprehensive C-130J aircrew training equipment and services solution. CAE leads a pan-Canadian team that includes xwave, St. Johns, Newfoundland; Bombardier, Saint-Laurent, Quebec; Atlantis Systems International, Brampton, Ontario; and Cascade Aerospace, Abbotsford, British Columbia.

Air force gets new training squadron to play the bad guys

The air force has resurrected a squadron with a historic record to play the bad guys in electronic warfare training. The reborn 414 Electronic Warfare Support Squadron is a direct descendant of a Second World War formation that flew the famous Spitfire, among other aircraft. It was disbanded and reassembled several times since the war.

In its new variation, the Ottawa-based squadron will help train pilots in CF-18 Hornet jets and sailors aboard combat ships by simulating enemy attacks using radio and radar jamming equipment and other electronic gear.

Under the program called the Operational Training Systems Provider (OTSP), CAE won a competitive procurement to serve as the prime contractor to provide the training systems and services for Canada’s tactical airlift, medium-to-heavy helicopter, and potentially other aircraft fleets.

The contract announced mid February, in support of Canada’s new fleet of 17 C-130J Hercules tactical airlift aircraft, is the

first contract under the OTSP. The C-130J program will create and sustain approximately 330 jobs for the first three years and 50 jobs for the next 20 years throughout Canada.

Canadians will benefit from enhanced airport safety thanks to funding from the federal government’s Airports Capital Assistance Program. The Honourable Tony Clement, Minister of Industry, in early February announced

funding under Round Two of the 2009-2010 program.

The Airports Capital Assistance Program (ACAP) finances capital projects related to safety, such as the rehabilitation of runways, taxiways, visual aids and

heavy airside mobile equipment. Since the inception of ACAP, the Government of Canada has invested a total of $489 million for 598 projects at 167 airports. Over 99 per cent of these projects were airside projects.

The squadron will operate Dassault-Dornier Alpha jets, French/German-built aircraft owned by Top Aces Consulting Inc., a Quebec firm which has been involved in electronic warfare training on a contract basis since 2005. They may also fly aboard American air force EKC-135 electronic warfare aircraft.

Goderich Aircraft Inc. (GAI), a luxury aircraft refurbishment business located at the Huron Air Park airport in Ontario is strengthening its competitive position in the VIP conversion business sector.

GAI, which has traditionally concentrated its business within the North American aviation industry, is now expanding its client base further in the global market. Over the past 15 years of business, Goderich Aircraft has grown from an operation of five employees located in Brantford,

Ontario to a corporation that employs over 130 skilled craftsmen, engineers, trades persons and apprentices drawn from all over Canada.

Goderich Aircraft broke ground on a new 43,000 square foot facility in September of 2008 that will have the capability to accommodate two Boeing Business Jets and the required back shops for heavy maintenance, modification and installation of structures, avionics and interior refurbishment.

Final hangar design modi-

fications are in progress and Goderich Aircraft is on target to meet the March 20, 2009 completion date.

Algonquin College is now accepting applications for the Fall 2009 start of its new Aviation Techniques – Aircraft Maintenance program, a joint program with Centennial College.

Algonquin College has signed an agreement with Centennial College to offer the first year of its two year Diploma program as an Ontario Ministry approved Certificate program. The first year of the Centennial College program is common to both Aircraft Maintenance Technicians and Avionics Technicians. A block transfer agreement with Centennial College

will provide a seamless transition for those who plan to complete the full two year Diploma program. Students will spend the first nine months at Algonquin College (Fall and Winter Term). After a short (approximately three months) first year apprentice work term (Summer Term) students will complete the final nine months (Fall and Winter Term) at Centennial College in Scarborough, Ontario.

Graduates who maintain the required academic standard and attendance record may be eligible for an 18-month experience credit towards their appren-

Jean Kayanakis was recently named vice-president, Falcon Worldwide Spares for Dassault Falcon. Kayanakis was previously director, Eastern Hemisphere Spares and replaces Frank Youngkin who was promoted to vice-president, Western Hemisphere Customer Service in April of 2008.

ticeship to become a Licensed Aircraft Maintenance Engineer. Students will also benefit from the resources and reach of both Algonquin College and Centennial College when evaluating potential job opportunities.

Offering more than 140 fulltime programs to approximately 16,000 full-time and 30,000 parttime learners, Algonquin College has more than 100 computer labs, wireless laptop business programs, state-of-the-art media facilities and a new Advanced Technology Centre. For more information visit www.algonquincollege.com/aviation

MARCH 2009

AQTA 33rd Annual Convention and Trade Show

March 25-27

Laval, QC www.aqta.ca/en/default.asp

Aircraft Interiors Expo March 31-April 2 Hamburg, Germany www.aircraftinteriors expo.com

APRIL 2009

Canadian Technical Security Conference & Trade Show

April 27-29 Mississauga, ON www.pdtg.ca/CTSC005. htm

Canadian Aviation Safety Seminar (CASS) April 28-29

Calgary, AB www.tc.gc.ca/civilaviation/ systemsafety/CASS/ menu.htm

Airports Canada Conference and Exhibition April 28-30

Ottawa-Gatineau, ON www.canadasairports.com/

MAY 2009

EBACE 2009 (European Business Aviation Association)

May 12-14 Geneva, Switzerland www.ebace.aero/

Kayanakis started his career at Dassault more than 20 years ago as an engineer working on the Rafale fighter prototype flight control laws. In addition to his most recent position, he also held positions in spares purchasing and as director, Service Center Customer Support at Dassault Aircraft Services in Le Bourget.

CBAA 2009 Annual Convention, Trade Show and Static Display May 27 - 29

Montreal, QC www.cbaa.ca/portal/c

For a full list of events, please visit www.wingsmagazine.com

Production of Boeing 787 Dreamliners resumed late January with the join of the fifth airplane designated for flight test. This airplane, designated ZA005, is the first to be powered with General Electric GEnx engines. The major assemblies were loaded in final body join in late January. The fuselage and wing joins occur simultaneously.

Five of the six airplanes designated for flight test are now in varying stages of production. Power was restored to the first flight-test airplane, ZA001, and

production testing has resumed as the airplane prepares for first flight in the second quarter.

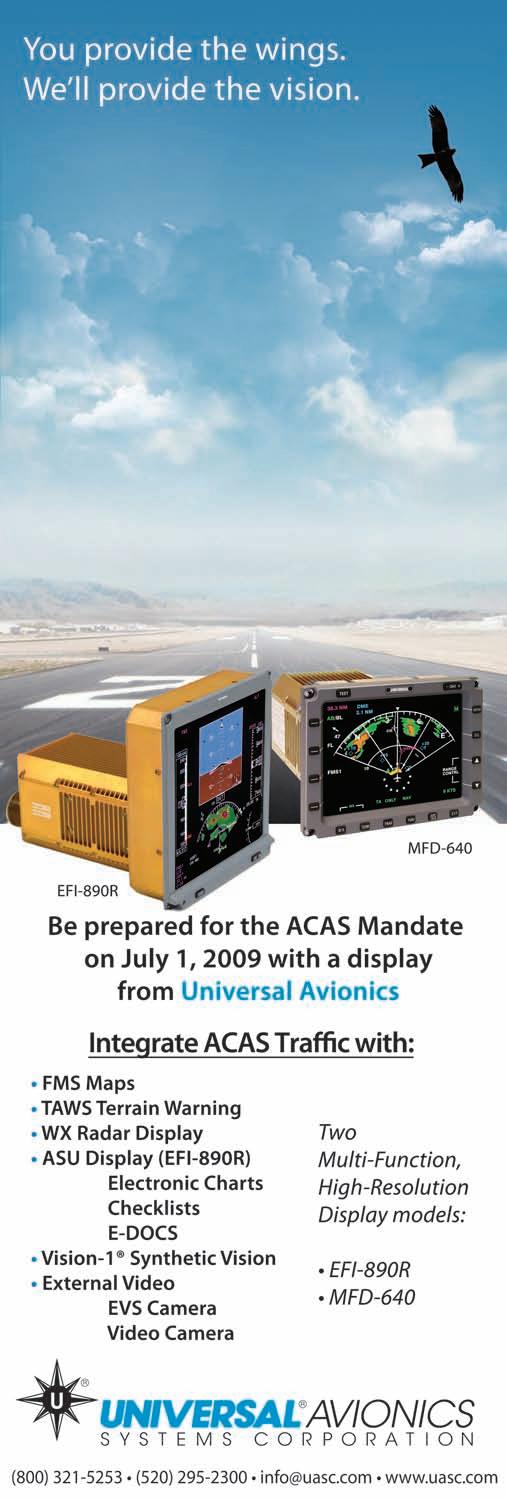

Bombardier Aerospace announced in early February that it is now offering a Wide Area Augmentation System (WAAS) capable Flight Management System (FMS) on Learjet 40 XR and Learjet 45 XR aircraft. The new system is available as a Supplemental Type Certificate (STC) for in-service Learjet 40, Learjet 40 XR, Learjet 45 and Learjet 45 XR aircraft customers and will also be offered as an option on new aircraft.

Provided by Universal Avionics Systems Corporation (UASC), WAAS enhances navigation capabilities through

the use of a network of ground reference stations collecting global positioning system (GPS) satellite data. This data is broadcast to user aircraft through two or more geostationary satellite communication links. The aircraft uses the WAAS signal, in addition to the GPS service to fly area navigation and localize performance with vertical guidance (LPV) instrument approaches. LPV approaches offer pilots lower landing minimums, resulting in more flexibility for landing decisions.

The WAAS system is managed by various representatives

Rolls-Royce engines are hung on ZA002, in the fourth and final production position in the fac-

tory. The third and fourth flighttest airplanes, ZA003 and ZA004, are in the third and second production positions, respectively.

Fastener rework is done on ZA001, nearly complete on ZA002 and progressing well on the third and fourth airplanes. Assemblies for the final flighttest airplane, ZA006, are in production at partner sites worldwide. In all, assemblies for 30 Dreamliners are in production at this time. The 787 Dreamliner has orders for 895 airplanes from 58 airlines.

from the Federal Aviation Administration (FAA) and the aerospace industry. The FAA recently announced that a total of 1,390 new WAAS approach locations are available and capable of allowing Learjet operators to utilize this

system. Currently it is only available for North America. WAAS can be installed at all Bombardier Aerospace Service Center locations. Operators should contact their Bombardier regional manager for additional details.

The Honourable Denis Lebel, Minister of State for Canada Economic Development, recently announced that DAC Aviation International Ltd. will receive $200,000 in repayable funding to upgrade its aircraft maintenance facility. This project will result in the creation of

14 high-end aeronautics positions, bringing the company’s staff to a total of 36 people.

DAC Aviation International Ltd. offers aircraft engine and accessory refurbishment services as well as flight operations in countries receiving humanitarian aid from such

organizations as the UN World Food Program.

This funding is provided through the Productivity Support component of the Business and Regional Growth program. This component supports enterprises which, like DAC Aviation Inter-

national Ltd., are actively working to improve productivity. Through its programs and consulting services, Canada Economic Development stimulates the growth of entrepreneurship and promotes the sustainable development of the regions.

Pilots consistently train for the “what ifs” – their regimented training spills over to their everyday lives in how they handle and confront life’s issues and its “curve balls.” Scott Lyon, an Air Canada overseas Boeing 777 pilot, was thrown such a curve ball when he checked himself into the hospital after an overseas flight when he felt more fatigued than the normal jetlag and was diagnosed with a rare T-cell lymphoma cancer.

Friend and Air Canada colleague Glen Baxby has taken up the daunting challenge of biking across Canada in honour of Scott Lyon and cancer research. Glen’s trek, adopting the logo coast2coast2cure , will launch May 15 in Victoria B.C., ending 60 days later in St. John’s, NF.

Baxby plans to raise $500,000 and hopes the aviation world will jump on board with generous donations to support Scott Lyon and the gnarled flight plan he received. To follow the trek and donate to the cause, please log onto www.coast2coast2cure.com.

To read Captain Doug Morris’ article about the coast to coast journey, visit www.wingsmagazine.com and click on web exclusives.

The Canadian Aviation Guide (A-List) is the only reference tool to bring the entire Canadian aviation industry together in one directory.

Visit www.wingsmagazine.com

to sign up for a free trial of Wings magazine –digital version.

Have your say on a variety of industry topics...

• Celebrating Canada’s Century of Aviation Achievement

• Buttonville ‘s future in question?

Flexjet , the fractional business jet ownership program of Bombardier, has rolled out an innovative incentive program for owners making quick turnaround trips.

expected to be a permanent part of Flexjet’s pricing structure.

Flexjet’s Round Trip Pricing Program can be found at Flexjet. com/roundtrip. ON THE FLY

The Round Trip Pricing program, launched on February 3, 2009, reduces the cost of one- or two-day round trips for owners committed to at least 100 flight hours per year. The program, the first of its kind in the fractional jet ownership market, comes in response to feedback from owners looking for more cost-effective, short-haul travel. The program is

The new program rewards the increased operational efficiency gained when a fractional owner books both legs of a round trip in advance. Efficiencies are gained through the ability to maximize active flight and crew time. Flexjet owners will see savings applied to both their hourly rate and Fuel Component Adjustment fees. The result is a 15 per cent price reduction for each hour of a qualifying round trip and can

Flexjet owners will see savings applied to both their hourly rate and Fuel Component Adjustment fees.

save owners thousands of dollars for each flight flown. More information about

LABOuR NEWS FROM AIR CANADA

Air Canada announced that its U.S.-based customer service workforce, represented by the International Brotherhood of Teamsters, has ratified a new labour agreement. The three-year agreement takes effect July 1. The Teamsters represent approximately 650 Air Canada airport, cargo and call centre employees.

The airline has also reached a tentative, three-year labour contract with the Canadian Auto Workers that covers approximately 5,000 CAW customer service and sales agents employed by Air Canada. The proposed agreement also provides for a detailed plan for Air Canada employees currently working in Aeroplan contact centres to move to Air Canada and vice versa.

Air Canada announced the temporary layoff of up to 345 flight attendants effective March 2, as it takes a hit from reduced travel due to the sluggish economy. But if ticket sales pick up, many could be recalled for the traditional busy summer season, the airline says. The reductions are the result of a plan to use one less flight attendant in business class on transatlantic routes and plans to reduce flight frequencies or use smaller aircraft on certain routes.

On the financial front, the airline has concluded a secured financing transaction valued at $78 million US. The fiveyear loan matures in December 2013. The agreement represents an additional step in implementing Air Canada’s strategy of improving its shortterm and long-term liquidity

through both traditional and non-traditional means. Earlier, Air Canada announced it has secured up to $195 million in financing from General Electric Capital Corp. The agreement is subject to Air Canada completing the sale and leaseback of a Boeing 777-300ER aircraft with GE Capital’s GE Commercial Aviation Services unit. The sale and leaseback agreement has a 12-year lease term.

In addition, Air Canada has concluded a secured revolving credit facility with the Canadian Imperial Bank of Commerce that will provide the airline with up to $100 million of revolving credit for a term of one year. This revolving credit facility replaces Air Canada’s previous secured syndicated three-year revolving credit facility.

WestJet announced it has executed a definitive agreement with Southwest Airlines that will allow the two carriers to deliver codesharing capabilities later this year. A Memorandum of Understanding between the airlines was announced last July 7. Said Hugh Dunleavy, WestJet’s executive vice-president, “It is an important step in implementing our strategic plan and bringing us a step closer to accessing Southwest’s 64 cities and more than 3,400 flights while giving Southwest access to our network of 55 cities and more than 400 flights each day.”

Transat A.T. and the Solidarity Fund QFL have signed an unsecured financing agreement under which the Solidarity Fund QFL will provide a maximum

By Brian Dunn

credit facility of $60 million.

“This agreement with a longstanding Transat partner is first and foremost a precautionary measure that will strengthen our ability to continue growing in tune with changing market conditions,” said François Laurin, Transat’s vice-president, finance and administration and chief financial officer.

Transat A.T. is also renewing its call for projects in its 60 destination countries to support initiatives that contribute to enhancing the tourism potential of a community or region from a perspective of sustainability and that are put forward by not-for-profit organizations. To date, Transat has partnered in eight sustainable tourism projects in Canada, France, Tunisia and Cuba.

Sustainable tourism entails respect for nature, as well as for host communities and their values. Proposals can focus on natural or cultural heritage, including the restoration, protection, conservation or improvement of a natural site or ecosystem as well as projects aimed at diminishing the negative impacts related to tourism.

Starlink Aviation is offering twice-daily, Monday-Friday service between Halifax, Yar-

mouth, N.S. and Portland, Me., using 19-seat Jetstream 31 aircraft. Yarmouth has been without scheduled airline service since Air Canada Jazz pulled out in January 2003.

Go Travel Direct, majorityowned by former Zoom Airlines chairman Hugh Boyle, has signed up Finnair, Finland’s national airline, to launch transatlantic flights this summer. Go Travel, an Ottawa-based tour operator, said that its agreement with Finnair will result in discount flights to London from Winnipeg, Toronto, Halifax and St. John’s. In late June, non-stop flights will begin once a week from those Canadian cities, while Montreal-Paris service will be twice a week. The MontrealParis route will operate from June 19 to October 17. Toronto-London service will be boosted to twice a week starting in July. Go Travel’s fares start at $299 each way, said Go Travel president Ian Dodd, a former Zoom director.

The recent signing of the open skies agreement between Canada and the European Union now allows for a carrier like Finnair to operate from Canada to anywhere within the EU. The detailed schedules for these new services have not been finalized.

It is surprising how an unconventional but inspired design of an aircraft can end up taking the aviation world by storm. The de Havilland Mosquito or “Mossie,” as it was affectionately called, was one these because of the large amount of wood used in its construction.

The Mossie did not have a really long gestation period, perhaps because of de Havilland’s previous experience with wood with the D.H.91 Albatross (what a name for an aircraft!) The first attempt to turn the D.H. 91 into a bomber aircraft was a disaster; it was far too heavy. The next attempt was much more successful in that the designers opted to reduce weight even to the point of removing all defensive armament; a decision that irked some diehards in the Air Ministry who would have installed a howitzer if they thought nobody was looking.

But speed won out; the Mosquito could outrun all existing enemy fighters. That still wasn’t enough to start production but, when World War II broke out, priorities changed and an order was placed for 50 examples. That was only the beginning!

The RAF soon decided that they were interested in both fighter and reconnaissance versions of the Mossie and what they finally got exceeded their expectations. The fighter could outrun the

current Spitfire; the bomber could carry a much heavier load than expected. From then on, as far as the RAF was concerned, it was a winner.

The Canadian content of this remarkable aircraft was threefold. First of all, part of the wooden construction was made up of Canadian birch. Secondly, a goodly number of Canadian aircrew flew the aircraft in combat and finally some of the production was transferred to Canada. The exact number produced at the de Havilland factory, that was located at what is today known as Downsview, varies from source to source but was roughly 1,150, many of which were ferried to Great Britain.

In this respect there were problems with the aircraft.

Carl Christie, in his definitive book “Ocean Bridge,” the story of Ferry Command in World War II, reports that a special unit was set up at Crumlin Airport, London, Ont. (now the London International Aiport, CYXU) to get the aircraft and aircrew ready for the long overseas trip. Pilots were required to spend at least five hours in the plane they were to ferry to England. One pilot reportedly found his aircraft spread all over the hangar floor. On inquiring the reason for this, he was told: “If we are going to service these aircraft, we might as well find out what makes them tick.”

Before the war ended, the Mosquito was used in any manner of missions. The near-

est German equivalent was the Ju.-88 but the Mossie could outrun this versatile aircraft with ease. Only when the German jets came into action did it meet its match with regards to speed.

So important was the Mosquito that it remained in service after the end of the war in 1945. It then formed the basis for an advanced version - the Hornet, that also flew as a naval fighter from aircraft carriers. It saw effective service in the civil war in Malaysia before it, too, was phased out in the mid-1950s.

There is no doubt that the Mosquito, the “Wooden Wonder,” is considered as one of the most outstanding aircraft of its era.

– By Raymond Canon.

The first flight of the Silver Dart Replica took place at the Hamilton Airport on Feb. 6, 2009.

There were some taxi tests during which the main wheels got airborne, then back to the hangar for some calculations and Centre of Gravity adjustments and then several runs down the runway with flights of distances up to 3000 feet and up to 10 feet off the ground. The Silver Dart appeared quite stable in flight. Bjarni Tryggvason’s thumbs-up says it all.

Scheduled to fly again on Feb. 23 from Baddeck, Nova Scotia, the flight of the Silver Dart replica was cancelled due to poor weather conditions. A tricky crosswind and a fresh dumping of snow over the Maritimes forced

the cancellation of the recreation of the first flight in Canada of the Silver Dart, an historic event that took place 100 years ago on Feb. 23, 1909, on a frozen lake in Cape Breton. Visit www.wingsmagazine. com and click on the 100 Years logo to get the latest news and to be a part of the celebration!

1. The Halifax International Airport has a replica of a famous aircraft hanging from the ceiling in its International Hall. What is it?

a) Gossamer Albatross

b) Sopwith Camel

c) McDowall monoplane

d) Silver Dart

2. The National Research Council Institute for Aerospace Research purchased a second jet to fly 5,000-foot high parabolic curves, obtaining 22-23 seconds of zero ‘G’ time for microgravity experiments. What is the aircraft?

a) Falcon 20

b) Boeing 707

c) Airbus A-300

d) Lockheed T-33

3. Canada’s highest-scoring fighter pilot of the Second World War came from Verdun, Quebec. What was his name?

a) George Frederick Buerling

b) Vincent Woodward

c) Henry John Lawrence Botterell

d) Sydney Shulesman

4. The term “ab initio” is used to refer to both air traffic controllers and pilots at a certain point in their careers. What does this Latin term mean?

a) Absolutely incredible

b) From the beginning

c) After initiation

d) All washed up

5. In 1999 NAV CANADA deployed an air traffic control tool that makes it easier for controllers to accurately space aircraft on the arrival streams to the Calgary International Airport. What is it called?

a) CRDA

b) Direct-To c) Multilateration

d) ADSE-X

For more questions and the answers, visit www.wingsmagazine.com and click on the 100 Years logo.

Vintage Wings of Canada Open House

June 6, 2009 Gatineau, PQ www.vintagewings.ca/

Silver Dart Centennial Air Show and Youth Aviation Week

Alexander Graham Bell Museum

Baddeck, N.S.

June 14, 2009 www.capa-acca.com

Canadian Aviation Artists Association Centennial Collection

Greenwood Military Aviation Museum in Greenwood, N.S July 1-19, 2009 www.capa-acca.com

John Lovelace’s Cross Canada Century Flight 2009

July 17-28, 2009

Boundary Bay, B.C. www.crosscanadaflight. com

Canadian Aviation Artists Association Centennial Collection

Shearwater Aviation Museum, N.S.

July 20 to Aug. 10, 2009 a www.capa-acca.com

EAA AirVenture 2009 to Celebrate Centennial of Flight

Wittman Regional Airport Oshkosh, WI.

July 27-Aug. 2, 2009 www.airventure.org

When you fly an ultralight, amateur-built or normal category aircraft that you have registered with owner-maintenance classification, you are faced with the responsibility of carrying out the maintenance of your aircraft at least once a year. This is a considerable task, as you first have to create a process that will ensure that your aircraft will remain airworthy during the period that you’ve determined to be the minimum interval between inspections. It is a major responsibility, as you must guard against any civil lawsuits that may be brought against you or your heirs following a crash or mishap.

When you carry out your own maintenance, you become the authority that attests to the airworthiness of the aircraft and therefore you are solely responsible for any outcome that may question your ability to perform such maintenance work. It is a considerable task because, unlike full-time aircraft maintenance engineers (AMEs) who stay current by performing daily inspections and repairs, you do it only sporadically. It is crucial that you have a plan of action. Like full-time AMEs, you must use checklists to ensure that your inspection covers the whole aircraft including the engine, propeller and flight controls.

Even if it is a simple aircraft, a checklist will assist in ensuring that all is covered. It may be used as evidence that you have carried out the work in case of litigation. You must also create an additional checklist consisting of items that have been known to fail or weaken over time and that the manufacturer or type club have found important to add to a maintenance checklist. The checklist can also be used to compare notes

with others who operate the same type of aircraft and ensure that nothing is forgotten or left to chance.

Do you have the aircraft and engine manufacturer’s inspection checklist? If not, look up your aircraft type or the aircraft, engine and propeller manufacturers on the Internet. You can also find assistance through discussion groups on similar websites — they can be a Godsend.

Each year, usually in the spring or early summer, pilots of ultralight and general aviation aircraft experience various engine failures, flight control failures and sometimes even structural failures that lead to injuries and death. Most of the time the mishaps can be traced back to poor maintenance practices. Aircraft and engine components are subject to fatigue, wear and tear. That is the reason for inspections. Aircraft have to be maintained diligently in a manner that will prevent any major problems from occurring. Aircraft and engine manufacturers’ recommendations are the minimum amount of maintenance required to ensure your safety; however, the more you do to ensure that your aircraft is airworthy, the better. Your first order of the day is to get out all of the maintenance manuals, checklists, and proper tools, as well as spare parts that will serve as replacements. Second, is to review inspection procedures for structural, engine and propeller components. What will you be looking for? How will you be able to assess wear and tear, and repair accordingly? Who can assist you if you are unsure of being able to do the work correctly? Lives will depend on your assessment of the airworthiness of the various aircraft parts. Can you do it? Do not hesitate to ask a professional for help.

Tips are intended to increase overall safety awareness and are not a substitute for compliance with regulatory guidelines. Source: TP 185 Aviation Safety Letter (2/2004) Originally published by Transport Canada. Reproduced with the permission of the Minister of Public Works and Government Services Canada, 2009.

World class facilities and new aircraft, along with one of the most comprehensive and standard-setting training curriculums in the world await you at MFC.

Using our Professional Aviation Training Management System (PATMS©) we ensure that your training requirements are met throughout your course and that you complete your training “On Time,On Budget and On Course”.

Give yourself the MFC advantage. Learn in an airline training environment from Day 1. Programs are:

• Diploma in Aviation Technology (2yr)

• Integrated Airline Transport Pilot Course

• Modular Pilot Training program

• BA in Science Aviation

your

As Canada plunges back into deficit, is it time to hang a ‘for sale’ sign on airports?

Britain’s second busiest airport is for sale with a Canadian airport operator and three powerful pension funds wanting a piece. Vancouver Airport Services and Borealis Infrastructure Management, an investment unit of the Ontario Municipal Employees Retirement System (OMERS), are each aligned with consortiums bidding for London’s Gatwick Airport. After being rebuffed in an earlier attempt to buy a 40 per cent interest in New Zealand’s Auckland International Airport, the Canadian Pension Investment Board (CPP) has teamed up with the Ontario Teachers’ Pension Plan and Jersey-based 3i Infrastructure plc.

Britain has run out of patience with the near monopoly abuses of BAA, operator of seven airports including London Heathrow, and has ordered Grupo Ferrovial, the Spanish-based controlling shareholder to break it up by selling two of three London airports, and one its three Scottish properties.

Gauging which direction the wind was blowing and anxious to cut some of its crippling US$37 billion debt, Ferrovial pre-empted the government order to sell and hammered a ‘for sale’ sign into Gatwick last summer.

More than 20 years after BAA was sold in an over-subscribed IPO, airport privatization appears to be heating up again, spurred by the sale of Chicago’s Midway Airport for US$2.5 billion to an investment group led by Vancouver Airport Services and Citi Infrastructure Investors, and by what is taking place in the UK. Midway is the first major airport sale in the US, and has generated interest by other cash-strapped American cities to privatize airports.

It’s not just airports. From bridges to toll roads, infrastructure investment is huge. CIBC World Markets estimates that extra infrastructure spending will reach $650 billion over the next two years as governments around the world scramble to fight the recession by building new and repairing the old. Pension funds - attracted by the long-term steady revenue stream that flows from essential public infrastructure - want in.

According to the Reason Foundation, a Los Angeles-based think tank, CPP and OMERS are among the largest current public pension fund investors in infrastructure. Caisse de Depot et

DAVID CARR is a Wings writer and columnist.

Placement du Quebec has a minority stake in BAA and the Ontario Teachers have a 48 per cent interest in the UK’s Birmingham Airport along with Australia’s Victoria Fund Management. John Hancock Life Insurance Company, a division of Canada’s Manulife Financial Corporation, is part of the Midway deal.

Ferrovial hopes to complete the sale of Gatwick by April. Some analysts expect at least two of the consortiums to have pulled out long before then as they struggle to scrape together the money to complete the deal. However Gatwick shakes out, expect a strong Canadian presence in the queue for London Stansted and whatever Scottish airport BAA puts on the block (Aberdeen, Edinburgh or Glasgow). Ferrovial has even hinted at selling 15 per cent of its stake in BAA.

As Canadian investors scope out airport properties abroad, Ottawa sits on billions of dollars of non-essential assets while the federal government plunges into deficit for the first time in 15 years. Toronto’s Pearson International Airport alone is estimated to be worth at least $2 billion.

For some there will never be a good time to sell public infrastructure and would accuse the government of holding a fire sale if it attempted to do so during the current economic downturn. It is not an entirely hollow argument. Ferrovial had hoped to pocket between £2 and £2.5 billion on the sale of Gatwick, but will likely have to settle for £1.8 given tight credit markets and a 2.8 per cent dip in passenger volume.

But turf has always trumped economics in the resistance to privatize government assets and will continue to do so even during a rebound. Still, is a trim on the asking price or the drying up of revenue from airport rents after the sale sound enough reasons to hold onto an asset if the alternative remains greater deficits and higher interest payments on the debt? Especially since privatized airports would continue to generate revenue for the government in the form of corporate taxes and capital gains off shareholders.

Commercialization was Canada’s watered down response to privatization at a time when the government could no longer afford to invest in airports and Transport Canada was incapable of unlocking the full value of the assets. It worked. But as Canadian investment looks outward, it might be time for Ottawa to force airports in Canada to take the next step.

By David Olsen

On May 20 1965, the first DHC-6 Twin Otter took to the air and rapidly became the byword for a tough go-anywhere, do-anything aircraft; with 844 sold worldwide by the time production ended in 1988. Now, thanks to the perseverance and vision of Dave Curtis, CEO of Victoria-based Viking Air, the aircraft is making history again. When the all-new Twin Otter Series 400 makes its first flight from Calgary Airport sometime this spring, it will be an unparalleled aviation historical event.

No other aircraft in the world has been returned to volume production more than 20 years after the original production ceased. That this happened with the Twin Otter, speaks volumes about its versatility and the business acumen of Curtis and the Viking team. Even more remarkable, in an industry so often the recipient of government funding, Viking Air has achieved the Twin Otter renaissance without a penny of public money.

Viking has a long history with de Havilland Canada (DHC) aircraft as the main supplier of parts and spares to previous DHC owner Bombardier. Viking VP business

development, Rob Mauracher, who was Bombardier VP commercial aviation during this period, recalls discussing the possible resurrection of the Twin Otter with Curtis. However, as Curtis points out, “the economics were not right at the time” and when Viking negotiated the rights to DHC-1 through DHC-7 from Bombardier in 2005, it was not with the sole objective of putting the Twin Otter back into

production but as the maintenance and repair organization (MRO) for the aircraft.

Nevertheless, Curtis commissioned a market study for a new-built DHC-6 and in February 2006 Viking purchased the type certificates for the DHC-1 through DHC-7, giving it the sole right to manufacture new aircraft. The “new” DHC-6 took another step toward reality in September 2006 when, armed with a

business plan, Viking called a buyers/operators conference, after which its board made a commitment to the program, provided that orders and deposits for 18 aircraft could be obtained. Curtis then had to go out and sell 18 aircraft, which he did within six months and the board gave the go-ahead with first delivery scheduled for mid-2009. Since then, orders for the new Viking Twin Otter Series 400 have surged

ahead with well over 40 orders by February 2009 and an additional 40 prospects in the current sales campaign.

While tooling up and organizing the supply chain for the 400 Series, Viking built a demonstrator aircraft, based on a DHC-6-300 Series airframe but with new electrical systems, Pratt & Whitney Canada PT-6A-34 engines and, most important, a 21stcentury flight deck based on the Honeywell Primus Apex integrated avionics system. The Twin Otter 400 retains all the operational capability of its predecessors, enhanced by new PT-6A-34 engines or, for extra performance in hot and high conditions, the optional PT-6A-35. A weight reduction program will reduce aircraft weight by 250 lbs. from the 300 version, using composites for doors, stairs, the nose and other items. Like all Viking products, the 400 is built to the demanding standards of the AS-9100 Aerospace Quality System.

The Viking DHC-6-400 offers real value for money and operators can buy this brand

new, state-of-the-art 19-seat aircraft for $4 million – which in the present global economic climate is good news indeed.

Versatility and flexibility remain the strong point of this remarkable aircraft. Like its predecessors, the 400 comes in several configurations, from a 19 seat airliner to a rugged military transport, capable of a variety of missions in almost any environment. Corporate and charter operators can have low-density seating with all the amenities for executive or VIP operations and the aircraft can be reconfigured from a 19-seat commuter airliner to a freighter in 45 minutes. With six different landing-gear options, the Twin Otter 400 can operate from any land, water or polar environment.

Building the Twin Otter 400 required major logistic and financial commitments, and financial backing has been provided by Westerkirk Capital of Toronto, owner of Viking Air. A new manufacturing and office complex is nearing completion at Victoria Airport, where Viking will build 70 per cent of the manu-

factured components for the 400 – which incorporates 800 changes from the Series 300. Curtis reports that the supply chain works well and brings leading-edge technology to the program. Suppliers range from Pratt & Whitney Canada in Montreal to Sealand Aviation on Vancouver Island and include Ameticon in the U.S., Fleet Aviation, Honeywell and many others.

Final assembly is in a new plant at Calgary Airport, with rollout and first flight scheduled for this spring. Type certification by both Canadian and European airworthiness authorities will be concurrent with delivery of the first aircraft to Swiss charter operator Zimex. Operating on behalf of oil companies and humanitarian agencies in Africa and the Middle East, Zimex is already a Series 300 operator and a member of the Series 400 steering committee. In Canada, certification will be an amendment to the original Type Certificate, with an updated certification basis.

Final assembly in Calgary maximizes availability of a la-

bour force experienced on the Twin Otter, partly due to the proximity of Kenn Borek Air, one of the world’s major Twin Otter operators. In addition, Curtis notes that Calgary Airport Authority and the Alberta government are very supportive of the program, while experience shows that smaller business units are more effective and efficient than one large plant. Furthermore, operating two manufacturing facilities provides valuable experience which may become important in the future, since high import duties in some countries may necessitate the establishment of assembly plants overseas.

Mauracher sees the low infrastructure requirements of the Twin Otter as a major marketing advantage along with that of a small noise footprint, low emissions, and the continuing high residual value of the type, making it attractive to leasing companies and charter operators. The big challenge in introducing the 400 to the market was the diverse nature of operators who have been operating the legacy Twin Otters for up to 40 years. Mauracher recalls that at the buyers/operators conference, every shade of opinion was expressed as to

how the new aircraft should be configured.

However, the key issue that emerged was standardization. For example, in the legacy aircraft there are as many as 150 vendors involved with the cockpit systems. Companies are currently operating mixed fleets of owned and leased aircraft with a wide range of equipment – virtually no two aircraft are exactly the same. With around 600 legacy Twin Otters still flying, all 20 years old or more, it can be a logistic nightmare, both for operators and for Viking as the Type Certificate holder and MRO.

Curtis summarizes what the potential buyers told him -– “We want modern standardized aircraft, with Viking as the OEM to support it – do that and we’ll probably buy it.”

Another market driver is that some countries prohibit the import of used aircraft above a certain age, or impose significant restrictions. Clearly, if the operators of more than 600 legacy Twin Otters think that there is no substitute for the type, then there is a large market for the 400 Series for many years to come, both to existing and new operators.

Viking makes a major contribution to the Vancouver Island economy with more than

nowned products. As the only Canadian manufacturer west of Ontario, the integrity of the supply chain, assurance of the employee skill base and product quality are vital elements of the Viking success story.

Aircraft manufacture is a tough, competitive business and Viking has met the challenge head-on. As Mauracher puts it, “we re-invented the manufacturing process – aircraft are built to extremely precise tolerances, so that parts are interchangeable between aircraft, reducing life-cycle costs.” Wherever something can be done better, standardized or a product improved, it has been done for the Twin Otter 400, including digitizing the original DHC drawings. Furthermore, as Curtis points out, the 400 is cheaper to maintain and enhances operational safety –the Transport Canada flight deck human factors evaluation highlights the improved situational awareness

While developing the Twin Otter 400, Viking has not neglected its other long-term core business, namely the MRO and parts manufacturing. Mauracher stresses that parts manufacture has been a main driver of the business, supplying companies such as

the world, with a strong emphasis on heavy maintenance business in Victoria.

Completion of the new hangar and 400 manufacturing base at Victoria Airport will allow Viking to refurbish the existing hangar and provide improved facilities for the MRO and associated business.

It might be thought that with this demonstration of capability, competence and expertise, federal government ministers would be hammering on the Viking hangar doors, seeking solutions to some of Canada’s military air transport and related needs. Unfortunately, however, ministers do not seem to have figured out just what an industrial gem Viking is for Canada. With Canadian manufacturing jobs disappearing like melting snow, Viking creates skilled jobs, not just directly,

“Versatility and flexibility remain the strong point of this remarkable aircraft.”

330 employees (plus 50 in Calgary). An apprenticeship and training program ensures that not only can local youth aim for a skilled technical career but that Viking can maintain the quality of its globally re-

Bombardier and Bell, but it is now redirected to the DHC legacy aircraft and new production. Meanwhile, the MRO is a stand-alone business and profit centre, supporting hundreds of DHC aircraft around

but through its suppliers and contractors – and Canadian government trade commissioners overseas are solidly behind the 400 program.

Furthermore, the Canadian Forces have an ageing

fleet of DHC-6 Twin Otters (CC-138s) and DHC-5 Buffalos (CC-115s) and musings by government ministers seem to indicate that billions of dollars may be earmarked for replacement of the DHC-5, currently used for search-and-rescue and many other missions. Although the 2005 budget included funding to replace the CC-138, the Ottawa Citizen reported in August 2008 that the government rejected a proposal for four new northern utility aircraft and decided to re-wing the old CC-138s – an odd decision for a government concerned with Arctic sovereignty.

The DHC-5 replacement is a serious issue for Canada. Should taxpayers spend billions of dollars abroad when all the facilities, equipment and skills to build a brandnew version of the successful DHC-5 equipped with 21st-century technology, exist right here in Canada? With foreign buyers also known to be interested in such an aircraft, Viking CEO Curtis recently wrote an open letter encouraging Defence Minister Peter MacKay to support the concept. Let us hope that someone in Ottawa will have the foresight to follow through - recalling Charles Kingsley’s words: “Come; and strong within us stir the Vikings’ blood, bracing brain and sinew”!

By James Careless

What would you risk to build a new business that you believed in, plus save the jobs of your friends and colleagues?

For Alvin Gregorash and his wife Shirley, the answer was simple: They bet the farm. To be specific, the Gregorashs bet their house by mortgaging it to raise the necessary capital, and Alvin was willing to do even more if necessary. “To make this deal happen, I was willing to mortgage the house, wife and kids,” he tells Wings. “It was a family effort.”

That was back in 1988, when Standard Aero of Winnipeg decided to exit the piston-engine servicing business. Gregorash had worked at Standard for years before striking out on his own as an independent parts broker. But when he heard that Standard was going to shut down its piston operation, and that Standard’s employees were unable to raise the cash to buy it, he saw an opportunity too good to pass up. “Piston engines might be old technology, but they are still a very important part of aviation even today,” he says. “I knew that if we could keep Standard’s piston division going, we could not only save it, but make it grow and thrive.”

As for the mortgaging of house, wife and kids? Gregorash indicated his willingness to do so to Standard Aero’s president, Bob Hamaberg.

“When he saw how committed I was to saving the piston division, he said, ‘that’s all I need to hear’,” Gregorash recalls. “And that was that: With a handful of former Standard Aero employees, we had a company that we called Aero Recip (Canada).”

After 20 years, Aero Recip is now Gregorash Aviation; one of a group of companies that he has put together with the help of his dedicated employees. It has grown from 16 employees in 1988 to 60 today, with locations in Winnipeg and Anchorage. As well, there is a second generation of Gregorashs in the business; daughter Tracey, who started in 1997, has recently taken on the responsibilities of vice-president.

With Standard Aero phasing itself out of piston engines in the mid-80s, Gregorash knew that there was a big pool of unserved Continental, Lycoming and P&W customers out there. These were people who owned Cessna, Piper and de Havilland aircraft who couldn’t keep flying without regular engine maintenance. Surely they would flock to Aero Recip once they heard about the company!

Apparently not. “These customers were pretty ticked off that Standard Aero had left them high and dry,”

Gregorash says. “Since our company was made up of former Standard employees, and because we had bought a lot of equipment from Standard, they thought we were essentially Standard by another name. As a result, they wanted nothing to do with us.”

Unwilling to lay down and die, Aero Recip fought back with an aggressive marketing campaign. “We put together a corporate brochure and created our own identity, then went out and talked to private owners, flying clubs, and commercial operators,” he says. “We talked about Aero Recip and what we could do for them; how we were here for the long haul to serve the piston market. We didn’t talk about Standard Aero at all; we didn’t tell people that we were ex-Standard people.”

Gradually, the strategy paid off. Over time, more and more piston aircraft started showing up at Aero Recip’s 20,000-square-foot Winnipeg facility (now 31,800 square feet). As business picked up, Aero Recip’s staff grew ... and so did its opportunities.

Having been saved from mortgaging his house and family by Aero Recip’s success, Gregorash was feeling bullish. So when the opportunity came to buy Winnipeg’s Ultimate Oil Coolers in 1993, he took it. “Every airplane needs an oil cooler,” he explains. “Since Ultimate was already operating out of Winnipeg offering products and overhauls, it made sense to acquire them.”

Some time later, a close

friend of Gregorash’s who ran a parts business – “we used to have lunch together every second Friday,” he says – was killed in a car accident. Following his family’s unsuccessful attempts to keep the busi-

ness going, Gregorash bought it and renamed it Airparts Network. Shortly before that, he bought Cantherm, which distributes European-made Arcotherm aviation heaters.

Enter Alaska. While attending a trade show in Anchorage in 1999, Gregorash learned that local piston overhauler Sea Air was up for sale. “I mean this is Alaska; everyone seems to own an aircraft here, and most are pistons,” he says. “I just had to take this chance.”

The result of all these purchases is a stable of aviationrelated companies, all with different names and identities. To provide a coherent umbrella image, Gregorash Aviation was created this year. “Our individual companies still have their own identities, but now

the family to which they all belong has been clearly branded,” says Tracey Gregorash. “This tells the world who we are, and all the integrated services that we offer.”

Gregorash Aviation has come a long way from its ex-Standard Aero roots. But even though the company has survived and thrived, challenges remain.

“Our biggest problem is the Canadian/U.S. dollar exchange rate,” says Alvin Gregorash. “Exchange fluctuations translate into real costs for us at any time, but it is really tough when a U.S. product that we bought for $500 last month now sells for $400 on the open market. To keep up, we have to eat

that loss when selling to our customers, which hurts our bottom line.”

What about turbine engines – the high-tech piston vanquisher that motivated Standard Aero to abandon piston-engine servicing in the first place? “Servicing turbines sometime in the future has crossed our minds,” he admits. “We’ve kicked around the idea, and even talked about getting into bed with someone else to add this to our service offering.”

Should piston-engine owners be worried? “Not at all!” Gregorash declares. “Our focus remains on piston engines; providing reliable service and support to our piston customers for many, many years to come. After all, Ma and Pa have to have a way to keep commuting

in Alaska, and you can be sure that a piston engine will always be more economical than converting to a turbine. So Gregorash Aviation’s piston servicing business is here to stay. Frankly, I expect the piston market to be there forever.”

If there is a moral to this tale, it is that sometimes it pays to bet the farm, family and anything else that may be at hand. Certainly for the employees of Gregorash Aviation, Alvin Gregorash’s chutzpah has paid off handsomely!

Meanwhile, for Canada’s piston-engine owners, knowing that there is a company committed to servicing this technology has to be a relief. After all, these engines have been flying for decades: With proper servicing, they stand the chance of flying for decades still.

Across the Web, businesses are trying to find new and different ways to catch their clients’ attention. But arguably no one in the aviation industry has gone to the lengths of Gregorash Aviation, which hired Winnipeg’s Ozz Media to tell its corporate history as a series of short dramatic TV vignettes.

Posted on www.gregorashaviation.com/ ozzmedianetwork, the videos are based upon the actual creation and evolution of Gregorash Aviation out of the remains of Standard Aero’s piston engine servicing division, to today’s umbrella corporation that owns and operates Aero Recip (Canada and Alaska), Airparts Network, Ultimate Oil Coolers, Cantherm Distributors and Dyno Power Xperimental.

The Gregorash story is told in three black-and-white shorts with actors playing CEO Alvin Gregorash and his daughter Tracey at various key points in the company’s growth. There are also cameo appearances by historically relevant characters and an overarching on-camera narrative by Ozz Media founder/owner John Pineau.

For the full story on Gregorash’s unique approach to marketing, please visit www.wingsmagazine.com and click on web exclusives.

Every year, thousands of people worldwide owe their lives to the search and rescue capabilities of a Eurocopter. Just one example of the vital role that EADS technologies play in the world‘s emergency services. Navigation systems, to guide help to where it‘s needed. Satellite surveillance, to warn of natural disasters. Secure communications, to provide a lifeline between rescuers and people in need. We make the systems, we make them work together, and the survivors live to tell the tale. www.eads.com/madebyeads

By Blair Watson

In the late afternoon of Sept. 3 last year, two students and a flight instructor of the School of Aviation and Flight Technology (AFT) of North York, Ontariobased Seneca College were on a cross-country flight to Vermont when their Beechcraft Bonanza suffered an engine failure. A clicking noise from the powerplant was followed by a loud bang and substantial power loss.

The 24-year-old flight instructor, Michael Denning, took control of the aircraft from the third-year student. Suddenly, the engine quit altogether, forcing the three occupants to look for a nearby landing site – the closest airport was more than eight kilometres away. The part of New York State over which they were flying has mountains, lakes and an interstate highway; landing on I-87 was the only viable option. A graduate of the AFT program in 2007 and subsequently certified as a flight instructor, Denning drew on his training as he glided the Bonanza above two transport trucks by less than 100 feet.

“You just react to the situation as you’ve been trained to do. There’s not really time to panic,” Denning told the Canadian Press, which published a news report the following day about the harrowing event. “As soon as the [truck] drivers saw the air-

plane they naturally stopped, which helped us out because it blocked traffic.”

After Denning and the students got out of the Bonanza, they saw that there was less than a metre between the wingtips and the guard rail on either side of the highway. Denning’s training to never get lax about landing on the centerline saved the college’s aircraft from structural damage.

“I think after anything like this you always look back and say that something that seemed to be a problem at the time really isn’t a big deal anymore,” Denning added philosophically.

The way in which Den-

ning and the students dealt with the in-flight emergency is proof of the effectiveness of the professional pilot training provided by AFT. The college offers “an applied degree program that contains an integrated flight and academic curriculum, with breadth and depth that exceed industry standards and provide a safety-conscious environment.”

Last year, Seneca College of Applied Arts and Technology celebrated the 40th anniversary of the AFT program.

Since 1968, about 1,000 students have graduated from Seneca; many fly for domestic and international airlines, the Canadian Forces, flight training schools,

and other aircraft operators. AFT graduates have also enjoyed non-flying careers in air traffic control, aviation management and other sectors of the industry.

Between 1968 and 2002, Seneca College offered a 3-year AFT program, with hundreds of young people applying each year and less than three dozen (typically) graduating. By the new century, it was clear that the preference of airlines was to hire pilots with a university degree so the 3-year program was replaced with a 4-year Bachelor of Applied Technology flight program starting in 2003. The last graduating class of the 3-year program was in 2005.

The AFT program was the first of its kind in Canada. Under the direction of Frank Rock, its first course coordinator, it was determined that training would focus on engineering and aeronautical subjects as well as flight training, culminating in students getting their commercial pilot’s licence with instrument and multi-engine ratings.

Initially, Toronto Airways at Buttonville Airport (YKZ) in Markham provided AFT students with flight training for their private and commercial licences. Using a Cessna 172, Piper Arrow and Cessna 310, Seneca instructors at the Buttonville campus did instrument and multi-engine training.

The college also took over flight training for the commercial licence while Toronto Airways continued to provide private pilot instruction. In 2001, Seneca College took over ab initio flight training from Toronto Airways due to a Transport Canada integrated pilot training requirement (i.e., all training was to be done by one provider).

In 1991, the Cessna 310s were replaced with two Beechcraft Barons and the college bought five new Beechcraft Bonanzas to replace the Cessna 172s the following year. In 1995, Frasca Level 5 flight training devices (FTDs) for the Barons and Bonanzas were acquired. When the school took over ab initio

tario has provided monies to Seneca College for the AFT program, which currently costs $40,000, a bargain for a degree program and commercial multi-IFR licence.

The AFT program is rigourous in terms of its academic standards and flight training. There are typically 300 to 400 applicants each year and 80 students begin the program in September. Forty students graduate annually, plus or minus a few.

Co-op elements of the AFT program cover professional practice, a work term, and integration and career planning. Students learn résumé-writing, job search, and interviewing skills. The work term is a minimum of 14

“Students acquire the kind of multi-crew training desired by the airlines”

In 1973, the college replaced its airplanes with a new fleet consisting of three Cessna 172s, two Cessna Cardinals and two Cessna 310s. The two Cardinals were later replaced by two more Cessna 172s.

training in 2001, seven new Cessna 172s were added to the fleet. An additional C-172 was added in 2008 due to an increase in students.

In terms of funding, since 1969 the government of On-

weeks during which students gain valuable experience in roles that support flight operations. Some AFT students work on airport ramps or in dispatch and a few go to Air Canada to help out in avia-

tion safety. Nav Canada takes on one AFT student each year to assist in air navigation projects. Some students with dual citizenship temporarily leave Canada to do their coop work term with a foreign airline or other type of aviation company. After students return, they do a presentation about their experience so their classmates can have a broader perspective of the aviation industry.

AFT students attend classes in Seneca College’s Newnham campus in North York during the first year and at the school’s campus at YKZ, where all the flying takes place, for the remaining three years. With a fleet of 15 airplanes, there is a lot of activity going on at the Buttonville campus. Operations run seven days a week from early morning to late in the evening and students perform reception, dispatch and flight-following duties to prepare for the commercial aviation environment.

In April 2006, Seneca College announced that AFT received Transport Canada approval for an Integrated Airline Transport Pilot Program (IATP), the first of its kind in Canada.

New Brunswick’s Moncton Flight College (MFC) has played an important and distinguished role in the long history of flight training in Canada. Dating back to 1929, when it opened its doors as the Moncton Flying Club, the college has trained more than 18,000 pilots from around the world. Over its 80-year history, MFC has been instrumental in the evolution of pilot training philosophies and procedures that have had a far-reaching impact on aviation everywhere. Now in its 80th year, the college is celebrating both its proud history and its many recent accomplishments.

MFC had a banner year in 2008 with the introduction of important new training programs and the addition of some outstanding new aircraft. The college was also recognized for its achievements with two nationally recognized aviation awards.

In early June 2008, a Super Decathlon was delivered to the college; now in all programs, students will acquire four hours on the aircraft. The Decathlon is certified fully Aerobatic with a 180-horsepower engine and inverted fuel and oil systems. Its other features include a 40-gallon fuel system, a 100 lb. capacity baggage compartment and a two-blade MT composite constant speed propeller.

Also last June, Moncton Flight College and Mount Allison University joined forces in creating a new four-year Bachelor of Science (Aviation) degree. Students graduating from this program will earn their science degree with a major in aviation and their commercial pilot licence with a Multi/IFR rating. The first full year is done at Mount Allison University, giving students an opportunity to adjust to university life. In the second year, students start their flight training at MFC. The degree program complements the other programs that Moncton Flight College currently offers.

At the 2008 Airline Transportation Association of Canada (ATAC) conference, held last November in Calgary, the college received two prestigious awards. The first award, the David Charles Abramson Memorial Flight Instructor Safety Award, was given to Bob Henderson, Director of Flight Operations and Chief Flight Instructor at MFC. Jane and Rikki Abramson presented the trophy.

The second award was presented to Mike Doiron, Principal and CEO of Moncton Flight College. Mr. Doiron was inducted to the

ATAC Achievers Honour Roll for his leadership role in the establishment of the Safety Management System for the flight-training sector, and for his willingness to share his expertise and insights with the entire aviation community. A Safety Management System has now been in place at MFC for more than five years.

Today, there are more than 77 flight instructors working at both MFC campuses. The instructor-training program runs every three months. MFC can accommodate up to 10 students in every class. Currently, the college has 10 Class 1 instructors and six Flight Test Examiners.

International students represent a growing segment of MFC’s enrolment. The college has been training pilots from China for two years now, the first group graduated in July 2007. Since that time, the college has signed five new contracts with Chinese airlines wishing to send their cadets to Canada for flight training. To accommodate the demand, MFC has opened a second campus with Canlink Aviation in Fredericton, N.B. Between the two campuses, Moncton Flight College can now accommodate more than 400 students.

In February of this year, the college added two new G1000equipped Diamond DA 40s to the fleet. They join MFC’s 17 Diamond DA 20s at the Moncton campus, and 14 at the Fredericton campus. Along with the new aircraft, the college is also installing a DA 40 flight simulator, which was scheduled to arrive in late February. MFC’s fleet also includes five Cessna 172s, two Cessna 172 S models, a super Decathlon, six Piper Seminoles and two King Air C90s. In total, between the two campuses, there are 47 aircraft in the fleet.

MFC’s strong tradition is legendary; with the college now training the sons and daughters of many of its former graduates. Its students and instructors have made their mark throughout Canada and the world. Among its distinguished alumni are included former CFIs Don McClure and Al Lilly, both of whom are now members of the Canadian Aviation Hall of Fame.

The College is proud to be the largest flight-training centre in Canada with 80 years of making dreams take flight. The college continues to grow with the aviation industry and is looking forward to its next 80 years.

The program provides AFT students with the kind of multi-crew training desired by the airlines and credit toward their Airline Transport Pilot Licence.

Sophisticated technology is used during IATP training, most notably a Bombardier Regional Jet CRJ200 Level 5 (no motion) FTD. Multi-crew training

on modern equipment is a major reason why AFT graduates have been hired by airlines as entry-level first officers. To get accustomed to the airline environment, students are required to dress professionally. To be admitted to the AFT program, students undergo alcohol and drug testing and during their

No article about Seneca College’s Aviation and Flight Technology program would be complete without mentioning Stan J. Miller, Allied bomber pilot during the Second World War, Royal Canadian Air Force instructor, and AFT instructor, chief flying instructor and chairman. Maj Miller (ret.) – known as “Mr. Miller” to hundreds of AFT students – accumulated some 19,000 flight hours, 14,000 of them in flight training, during a remarkable flying career spanning more than six decades. He passed away in September 2007. An airport in Melfort, Sask. is named in his honour: Miller Field.

four years in the school, they can be retested if substance abuse is suspected. They also bid for time off, as do airline pilots.

Another first in Canada involving Seneca College was accreditation of the AFT degree program in February 2007 by the Aviation Accreditation Board International (AABI), a not-for-profit organization consisting of educational institutions, corporations, practitioners, trade organizations and members of the public-at-large. The AABI is recognized as a specialized accrediting body by the Council on Higher Education Accreditation.

Leading the AFT is Dominic Totino, director of academics and operations. Totino, a licensed Aircraft Maintenance Engineer who started at the college in 1978, has also been director of maintenance since 1990. John Robertson is the CFI and professor of human factors and safety systems. Robertson, a former Canadian Forces Sea King helicopter and Tutor jet pilot and chief flying instructor at the Moose Jaw military flight training base, was awarded the David Charles Abramson Memorial Flight Instructor Safety

Award in 2007. Seneca College also employs AMEs, flight professors and several flight instructors, many of whom are AFT graduates flying airline ‘big iron.’

the college’s older airplanes will need to be replaced in the next half decade. AFT management is working toward obtaining Transport Canada certification for the school to become an Approved Training Organization (ATO); relevant regulations come into effect in 2009. Once certified, Seneca will be able to reduce flying hours by utilizing simulation technology to satisfy the pilot training requirement, a prudent strategy given volatile fuel prices and limited government funding for post-secondary education. FTDs with full glasscockpit instrumentation are among the technological tools available to the school.

What began as an idea has been a remarkable Canadian college success during the past 40 years. AFT will continue to transform young people with little or no flying experience into pilots trained to the highest standard who are ready to enter the aviation workforce and enjoy long and rewarding careers.

By Glen Priestley

The purpose of this report is to provide general aviation operators with a starting point for a discussion of elements to be considered when developing a company-specific Safety Management System. Regardless of when the regulatory deadline is for 406-703 air operators to implement an SMS, the reality of liability requires all operators to do now what is reasonable and be able to demonstrate due diligence in regard to operational risk management. To achieve this there needs to be an understanding by all employees of the system and their roles within that system. For flight schools and general aviation operators, this poses additional challenges as there are a variety of customers, clients, support staff and tenants that will impact upon a company’s safety and security management system integrity.

For companies to develop a useful system, a thorough gap analysis and needs assessment