TOP CROP MANAGER

RF HEATING CONTROLS INSECTS

Non-toxic, efficient and safe

PG. 6

NEW CORN HYBRIDS

Focus is on early maturity

PG. 16

CARINATA TAXIING FOR TAKE-OFF

Crop has potential on semi-arid Prairies

PG. 40

Non-toxic, efficient and safe

PG. 6

NEW CORN HYBRIDS

Focus is on early maturity

PG. 16

Crop has potential on semi-arid Prairies

PG. 40

PLANT

20 | New soybean, flax and sunflower varieties update

More choices for western Canadian growers.

By Bruce Barker

PLANT BREEDING

16 Early maturity focus of new corn hybrids By Bruce Barker

18 Canola hybrids from Syngenta ISSUES

24 Still nutritious after all these years By Carolyn King

FERTILITY AND NUTRIENTS

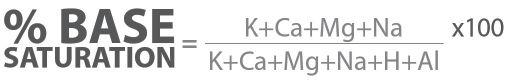

50 BCSR for making fertilizer recommendations By Ross H. McKenzie, PhD, P. Ag.

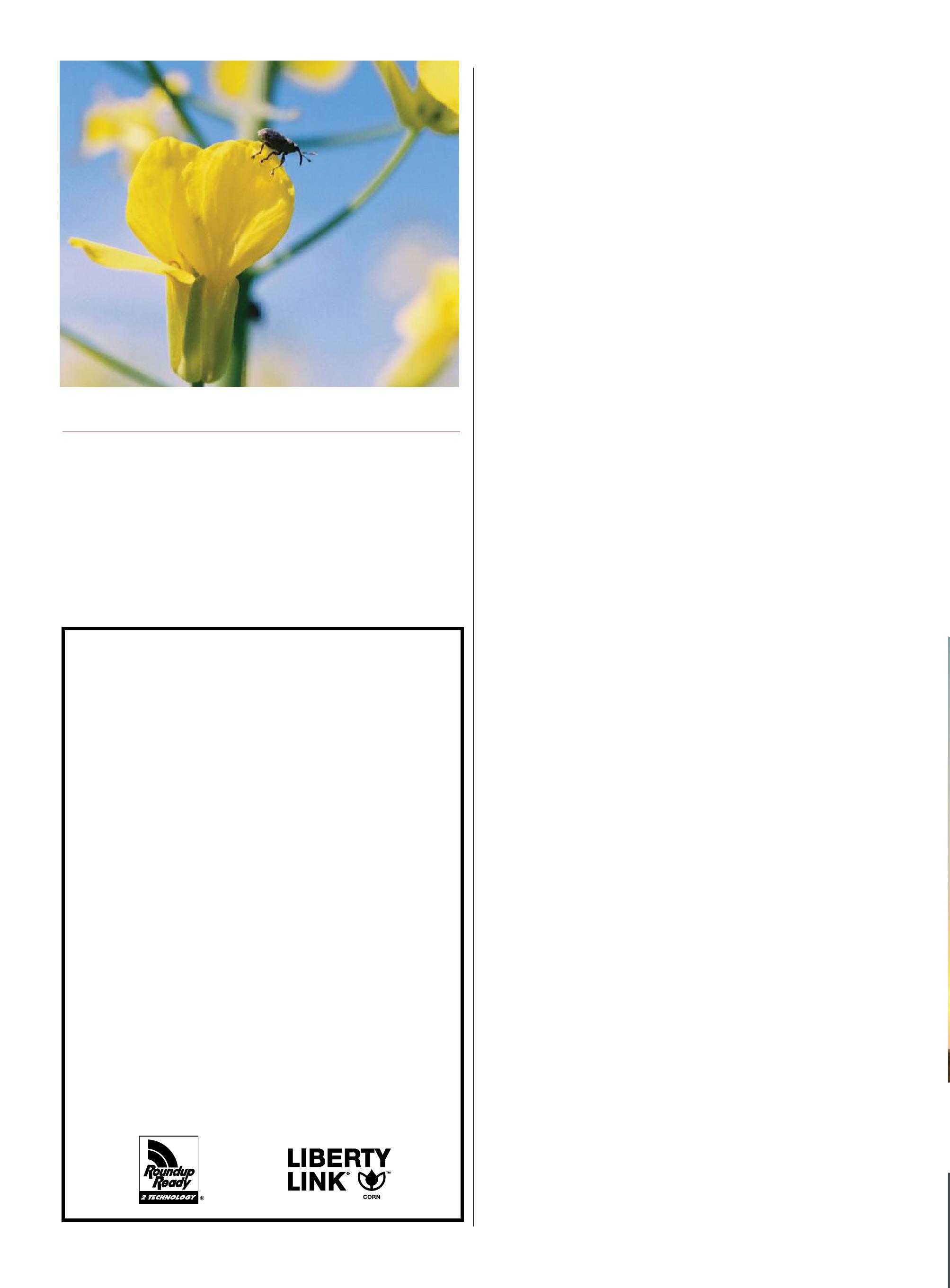

30 | Keeping an eye on swede midge

Researchers draw on Ontario experience to help monitor Prairie populations. By Donna Fleury

PESTS AND DISEASES

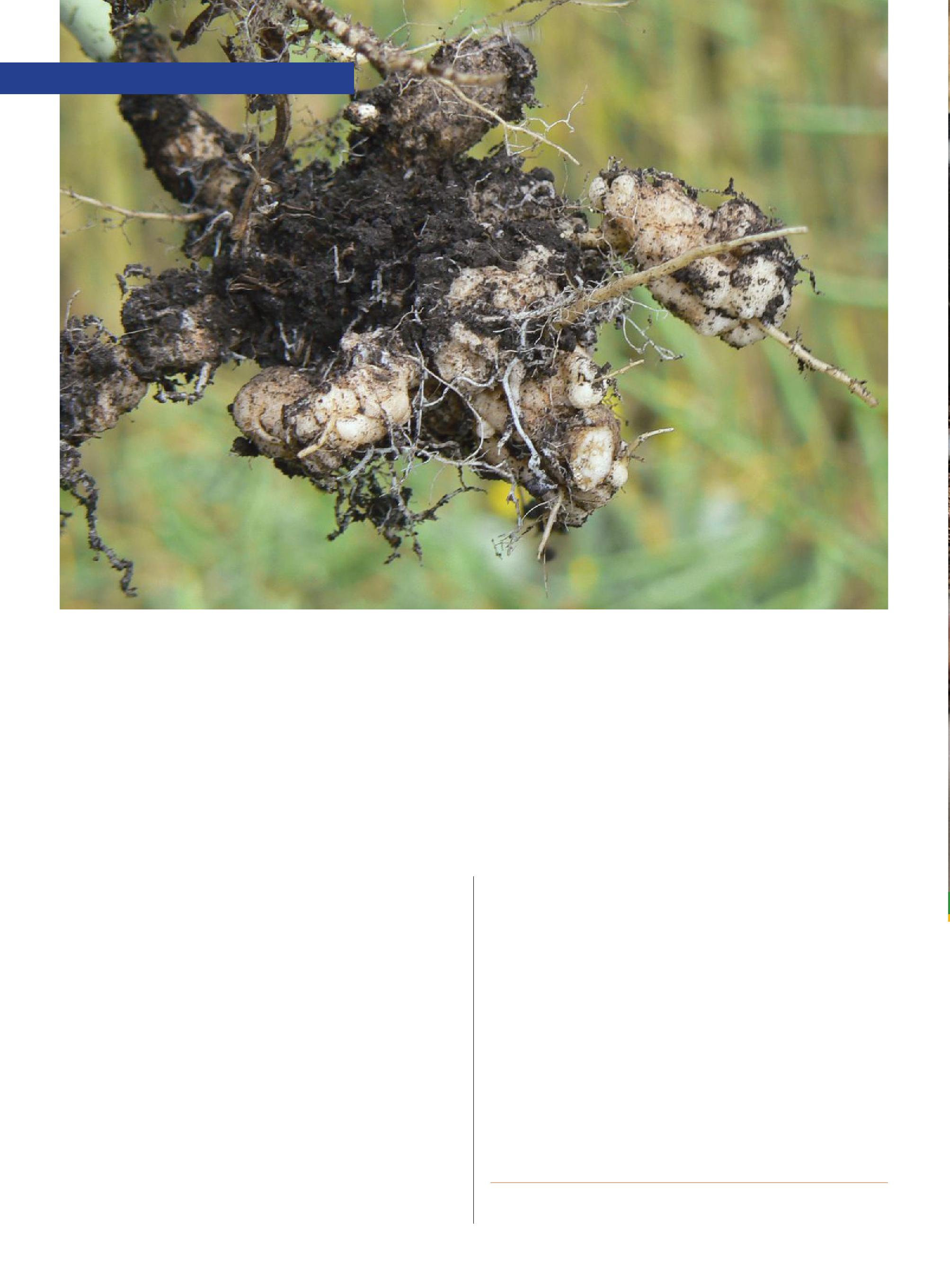

46 Industry role in clubroot management By Carolyn King

56 Cutworm “outbreaks” lasting longer By Bruce Barker

40 Carinata taxiing for take-off By Bruce Barker

6 Tuning into radio-frequency heating By Carolyn King

60 | Agronomic management of spring triticale

Tips for optimum triticale production. By Ross H. McKenzie, PhD, P. Ag

CROP MANAGEMENT

34 Integrated pest management has a fit Bruce Barker CANOLA 12 Low plant populations and reseeding options By Donna Fleury

52 Reducing clubroot spores By Donna Fleury FROM THE EDITOR

4 Clubroot: The fight continues By Janet Kanters

Readers will find numerous references to pesticide and fertility applications, methods, timing and rates in the pages of Top Crop Manager. We encourage growers to check product registration status and consult with provincial recommendations and product labels for complete instructions.

Clubroot continues to maintain its distinction as a key disease in western Canadian canola crops. Its continued march into new fields each year ensures that research into the disease continues, with new clubroot-resistant canola hybrids being introduced, and new/improved crop management advice being developed and shared.

Frustration continues, however, especially as growers seem to have so little control over the possibility of their fields becoming infested. But, that frustration is turning to action.

Growers know managing infected fields through the use of crop rotation combined with the use of resistant varieties is crucial. What’s also critical in preventing the spread of clubroot spores is restricting soil movement. The primary mode of transportation is field-to-field by contaminated equipment, so once clubroot is found in a field, the goal is to prevent the introduction of the long-lived resting spores into new fields.

The Canola Council of Canada, along with provincial canola specialists and crop agronomists, all provide excellent tips to help growers decrease the possibility of clubroot infestation. But when seed needs to get in the ground, or the spraying needs to be done, growers can sometimes cut corners in ensuring their equipment traffic is thoroughly cleaned and disinfested.

Although most farm equipment has been put away for the season, it’s never too early to start planning for the spring planting season. The Canola Council of Canada offers three steps to successfully sanitize farm equipment:

Step 1: Rough cleaning. Use a hand scraper, wire brush and/or compressed air to remove loose and clinging soil and crop debris from openers, tires and wheels. Sweep, blow or scrape residues off the frame. This should remove at least 90 per cent of the soil from the unit.

Step 2: Fine cleaning. Use a pressure washer at 2,000-3,000 psi on all areas where soil can accumulate. Turbo nozzles are generally more effective at removing soil than regular nozzles. Addition of an industrial detergent may enhance the degree of soil removal. Steps 1 and 2 in combination should remove 99 per cent of soil from the unit.

Step 3: Disinfection. Disinfect all openers, tires and wheels with a one per cent bleach solution or surface disinfectant of equivalent strength. A three-gallon backpack herbicide sprayer will work for this job. All areas should remain wet with the solution for 15-20 minutes. Disinfecting in the early morning or in the evening slows evaporation, so a second or third application may not be necessary to keep the area wet for the required time. Step 3 alone is not effective. The first two steps are required if you plan to include the disinfection step.

In addition to equipment sanitation, paying close attention to farm practices can also mitigate the change of clubroot entering your fields, or spreading to others. For instance, whenever practical, do not work infested fields when they are wet because more mud will stick to equipment and could be transported to clean fields. Reduced tillage or direct seeding also may help combat a clubroot infestation by reducing the movement of contaminated soil.

Also, if a farm has only one field known to have clubroot, work that field last. In this way, you reduce the risk of transferring contaminated soil from infested to non-infested fields, and should have extra time to give your equipment a thorough cleaning.

The clubroot risk for your location and your individual risk tolerance will determine the best clubroot sanitation method for you. The Canola Council of Canada maintains an excellent website on clubroot, that includes proper sanitation practices, www.clubroot.ca.

1717-452X

CIRCULATION email: subscribe@topcropmanager.com Tel.: 866.790.6070 ext. 202 Fax: 877.624.1940 Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Crop Manager West - 9 issuesFebruary, March, Mid-March, April, June, September, October, November and December - 1 Year - $45.00 Cdn. plus tax

Top Crop Manager East - 7 issuesFebruary, March, April, September, October, November and December1 Year - $45.00 Cdn. plus tax Potatoes in Canada 4 issues Spring, Summer, Fall, Winter 1 Year $16.00 Cdn plus tax All of the above - $80.00 Cdn. plus tax Occasionally, Top Crop Manager will mail information

Introducing AFS Connect.™ An advanced farm management system that puts total control of your equipment and data in your hands. No one can be everywhere at once. But you can get information from every piece of equipment across every acre you farm anywhere you are. All while keeping every bit of your data from becoming common knowledge. Learn how AFS Connect lets you track your equipment from anywhere at caseih.com/afsconnect.

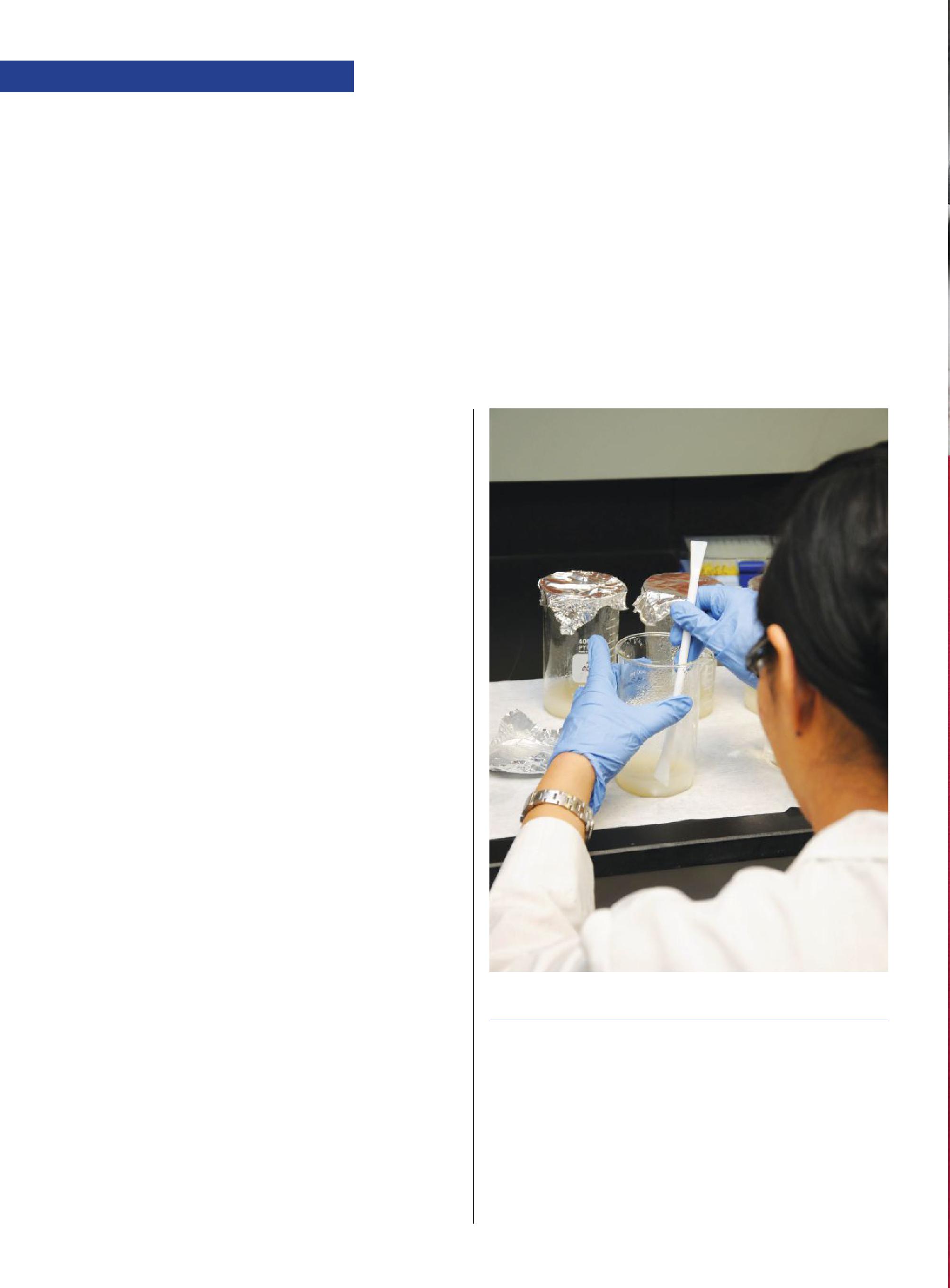

Researchers are scaling up a non-chemical method to control insects in stored grain.

by Carolyn King

An emerging technology called radio-frequency (RF) heating has the potential to be a rapid, non-toxic, efficient and safe method to disinfest various food and agricultural products. The technology is starting to have some commercial applications for treating products like nuts and spices. Now, Saskatchewan researchers are developing RF heating to control insects in stored grains on the Prairies.

Dr. Oon-Doo Baik, a professor of chemical and biological engineering at the University of Saskatchewan, is leading this research. “Radio-frequency is a kind of electromagnetic wave, like a microwave. RF heating works similarly to microwave heating, but RF heating has a greater penetration depth,” he explains.

“Radio-frequency heating is very effective, energy-efficient and fast heating, and provides uniform heating. It can also be used for selective heating or targeted heating, which allows killing of insects in grain without damaging the grain quality.” Insects have very different electrical properties than grains, so at certain RF frequencies the insects heat up much faster than the grain. As a result, the insects can be killed while the grain remains at a moderate temperature.

“There are clear advantages to using RF technology compared to other conventional methods to control insect pests in grain,” says Baik. “Conventional methods include using chemicals or non-chemical methods such as [conventional] heating, which is not efficient and takes a large amount of energy. Chemicals can be toxic, and they are specific to certain insect species and certain stages in the insect’s life cycle.

“In contrast, radio-frequency heating is non-toxic, it efficiently kills all stages of the insect’s life cycle – the egg, larva, pupa and adult – and it works for all different kinds of insect pests. It’s cheaper in the long run and it’s safe.”

Baik and his research team, Dr. Bijay Shrestha and Daeung Yu, recently completed a study to use RF heating to control rusty grain beetles in bulk spring wheat samples at a lab scale. Rusty grain beetle is one of the most common stored-grain insects. The researchers tested the technology with wheat at three moisture contents (12, 15 and 18 per cent) and at temperatures between 15 and 75 C. They examined the effects of RF heating on the wheat and the insect.

“By heating the bulk wheat sample to about 60 C for three minutes with our 1.5 kW lab-scale RF unit, we were able to get 100 per cent mortality of the rusty grain beetle [at all life stages],” says Baik. “Also, we observed no significant quality degradation in terms of

Using this 1.5 kW lab-scale radio-frequency heating unit, Baik and his research team were able to achieve 100 per cent mortality of insects in stored grain quickly and efficiently.

wheat germination and wheat flour properties.”

Following up on these promising results, Baik is now leading a new project to develop a prototype RF heating system as the next step towards the practical use of RF technology in Prairie agriculture. Funding for this project is from the Saskatchewan Ministry of Agriculture’s Agriculture Development Fund and the Western Grains Research Foundation.

Baik and his research team will be developing the prototype RF technology for use with a variety of grain storage and handling systems commonly found on the Prairies. “This technology is very flexible

In the spring of 2014, a limited release* of over forty 7000 Series air seeders equipped with ASC were retailed to Operators across western Canada. The general response to its first year of release has been extremely positive whereby ASC Operators report estimated input cost savings of 5%, 10% and even up to 15% in areas with many obstacles! Operators reported sound mechanics and durability with few performance issues.

Talk to your Bourgault Dealer today about how you can increase your operation strategy with ASC.

BOURGAULT ASC The Game Changer.

Our team farmed 14,000 acres of crops and surpassed one million bushels last year. Teamwork is the key to everything. And Syngenta is part of our team.

year. Teamwork is the key to everything.

and can be used for all different types of applications – grain elevators, grain storage bins, any type of grain storage system – because the main body of the RF heating system can be separate from the applicator,” he explains.

Coaxial cables can be used to connect the RF generator to the RF applicator, with the generator up to about 30 feet away. “The applicator is basically composed of two electrodes. We can install the two electrodes in an inlet or outlet of a grain storage system, so the grain can be treated with RF heating as it flows past the applicator.”

The electrodes can range in size from about 20 cm to 1 m long and can have various shapes like a plate or a tube, depending on the characteristics of the specific grain handling system and the needs of the people who want to disinfest the grain.

In an exciting advance, the researchers will be using a sophisticated 3D computer simulation system to design and make the applicators. “Using a computer simulation, we will test the RF system with different shapes of applicators, different configurations and sizes of electrodes, and different grain handling systems, like augers, conveyor belts and bin-to-bin and bin-to-chute transportation systems. The simulation calculates the electromagnetic field generation and then the volumetric heat generation, heat transfer, mass transfer, momentum transfer (fluid flow), et cetera,” says Baik.

“So multiple physical effects can be calculated and simulated, and then that can be used for in-house fabrication and implementation of the technology. So this is a powerful tool for theoretical understanding and for scientifically solid virtual protoyping. Based on this, we will fabricate applicators and then test them with a real system as well.”

The researchers will be testing the prototype technology on rusty grain beetles in spring wheat and on red flour beetles, another common stored-grain pest, in canola. The RF treatments will be done for all life stages of the two insects, and for a range of moisture contents and temperatures for the wheat and canola.

Before and after each RF treatment, the researchers will measure germination of the wheat and canola, as well as the wheat’s flour properties and the canola’s oil properties. And they will determine the insect mortality rates.

This new project involves somewhat different RF technology (50 ohm technology) than the researchers used in their earlier project (self-oscillator technology). As well, they will be using a more accurate way to measure the selective heating rate of the insects. With

this greater accuracy, Baik suspects they may be able to achieve 100 per cent insect mortality with even less energy input and shorter process time than they used in their initial study due to more rapid selective heating at higher RF power.

According to Baik, there are a couple of issues that could be hurdles in the adoption of RF heating to disinfest stored grain.

“The first one could be an advantage, or disadvantage, depending on your point of view. Based on our preliminary research, we need to heat the grain moderately up to about 60 C for about three minutes or less to kill the insects, so there might be some drying of the grain when you use RF heating. However, many farmers want to dry their grain for storage, so it could be an advantage,” he notes.

“The second issue is the initial capital cost of the RF technology. At present a moderate scale RF generator costs about $20,000 to $50,000. However the capital cost per kW of power output is dropping significantly. I am expecting the fall in cost will be like the case of the microwave; initially microwave technology was expensive, but now we buy it very cheaply. Also, the capital cost will be paid back over time because [RF operating costs] are cheaper than the conventional methods.”

To assess the relative costs, the researchers calculated the operating costs for RF heating compared to chemical treatment for the example of wheat stored in a medium-sized bin with a diameter of about 27 feet, a height around 19 feet, and a capacity of about 8,750 bushels.

“The cost to treat that volume of wheat with RF heating was approximately $25, based on the provincial energy cost of 11.7 cents per kilowatt hour. To treat that same volume of wheat with a pesticide or fumigant, the chemical cost plus the operating costs, based on our preliminary research, ranged from about $250 to something like $2,500. So the chemical treatment cost is much higher than the RF heating,” says Baik. “Of course, there is the initial capital cost to purchase the RF heater, but that cost is falling. And RF heating is safer than using chemicals, it can also dry the grain, if that’s required, and it’s fast and efficient. So I think it’s promising.”

AGROTAIN® DRI-MAXX nitrogen stabilizer is a new and improved dry formulation that offers a reduced per-ton treatment rate and improved product consistency and flowability. This patented formulation adheres to the urea granules without adding additional moisture to the blend, minimizing build-up during the blending process. And it contains the same, proven urease inhibitor technology that’s made AGROTAIN® stabilizer the one growers trust year after year. For the whole story, visit agrotain.com.

Hit with early spring frost on canola, when does it make sense to reseed?

by Donna Fleury

Maximizing canola yield and net returns depends on many factors, including establishing adequate plant populations early in the season. Even at recommended seeding rates and good stand establishment, previous seeding rate research shows that, on average, canola establishment is about 50 per cent. The question is, then, what happens when growers are faced with low plant populations due to poor spring conditions, frost or other factors?

“In recent years, some growers were experiencing poor canola establishment and lower plant populations for a number of reasons, including early spring frosts,” explains Anne Kirk, former research manager with the Western Applied Research Corporation (WARC) in Scott, Sask., and now at the University of Manitoba. “Growers were faced with lower plant populations than they typically had and were not sure whether or not they should reseed or when it would be too late to do so. As well, crop insurance adjusters were also asking similar questions, so in 2010 we initiated a study to try to find some answers.”

Led by Kirk, researchers in Saskatchewan initiated a three-year project in 2010 to update the research on low plant populations in hybrid canola. There have been numerous studies looking at canola seeding rates; however, there was limited data on the response of canola, particularly hybrids, to extremely low plant populations. Although hybrid canola is able to compensate for low plant populations, knowing the yield response to low plant populations would assist producers with decisions for reseeding.

The objectives of this project were to determine the plant populations at which canola hybrids yield 90 per cent of maximum, the effect of plant population on maturity, seed size and green seed, and the minimum plant density at which reseeding would be recommended for hybrid canola. Researchers also wanted to determine the risks with each reseeding option in terms of maturity, yield and quality. Experiments

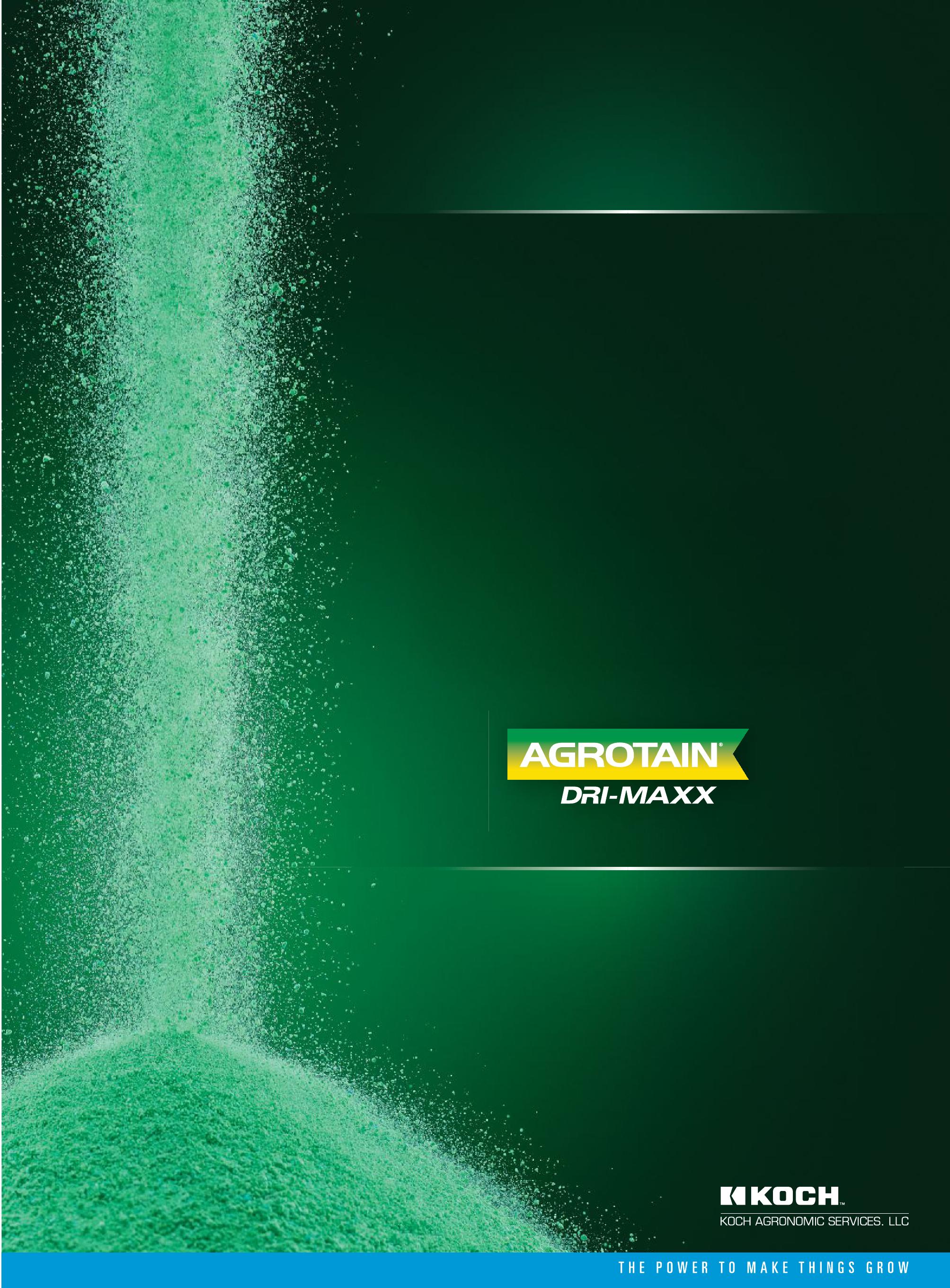

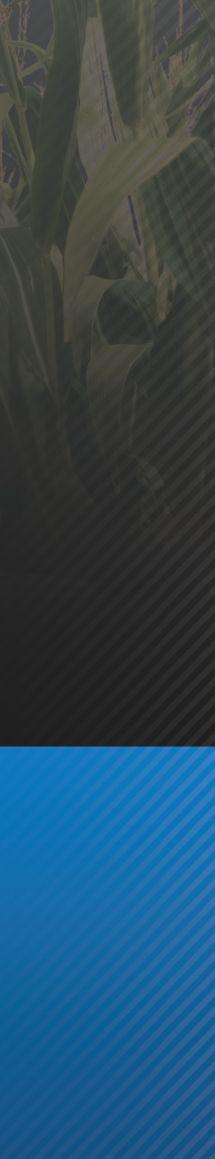

ABOVE: Reseeding canola trials comparing early June (left) with mid-June (right).

As a farmer, you have a lot of decisions to make. The DEKALB® brand team is here to empower you with expert advice, agronomic insight and local data. With every important decision you face on your farm, we’re behind you. And we’re ready to help you turn great seed potential into actual in-field performance. DEKALB canola... Empowering Your Performance.

Table 1: A comparison of reseeded canola gain or loss compared to the low population canola Reseeded Crops

Source: WARC.

Comparison of seeding rates and plant population trials with the seeding rate of cultivar 5440LL at 40 seeds/ m2

were conducted at five locations in Saskatchewan: Indian Head, Swift Current, Saskatoon, Melfort and Scott, in 2010, 2011 and 2012, to encompass different growing regions and a wide range of growing conditions.

“We compared a variety of seeding rates and plant populations to evaluate the response of hybrid canola to low plant densities canola,” explains Kirk. “The glufosinate-tolerant canola (Brassica napus) cultivar 5440LL was seeded at rates of five, 10, 20, 40, 80, 150 and 300 seeds/m2. The 150 seeds m2 rate is considered to be a standard seeding rate and was referred to as the check for comparison purposes. We also compared the various plant populations and how they affected factors such as lodging, days to start and end of flowering, maturity, grain yield, per cent green seed and fall plant density.” Plots were fertilized to soil test recommendations, and registered herbicides, insecticides and fungicides were applied as required by each site.

“Overall, the results from the low plant

Comparison of seeding rates and plant population trials with the seeding rate cultivar 5440LL at 150 seeds/m2, considered to be a standard seeding rate.

population study showed that we were able to reduce plant population by half in all sites with no significant effect on yield,” says Kirk. “The results from all of the site years combined showed that a plant population of 18 plants/m2 was required to achieve 90 per cent of maximum yield. With hybrid canola, when the plant density was reduced, the canola plant was able to compensate by increasing the number of branches and pods per plant. However, it is important to note that moisture was not a limiting factor in any of the years of the study, so in a year when moisture may be a limiting factor, then a lower plant population may be more detrimental than our results show.”

Seeding rates of five to 300 seeds/m2 resulted in plant densities ranging from five to 125 plants/m2, when averaged across all site years. Kirk adds that there was also a big range of branching and podding from low to high plant populations. Averaged across years and locations, the number of pods per plant increased from 150 at seed-

ing rates of 150 and 300 plants/m2, to 851 at a seeding rate of five plants/m2. In general, the increase in pods per plant was due to increased podding on primary and secondary branches, while the number of pods on the main stem stayed about the same.

“However, there are some drawbacks to reduced plant populations, including increased days to maturity, lodging and green seed,” explains Kirk. “Increased lodging at lower plant densities occurred due to the canola plants becoming so large that the stem was unable to support the plant at maturity, and in some cases was susceptible to breaking. In terms of maturity, averaged across locations, the highest plant populations matured nine days earlier than canola at the lowest plant populations. Higher green seed counts were found at lower compared to higher plant densities at most site years.”

Another important consideration is uniformity and distribution of the canola plants in the field. “At low plant populations, growers might not expect the plants to be uniform across the field,” adds Kirk. “In a non-uniform low plant population field, you would expect more of a yield penalty than if the stand was more uniform. Therefore, if faced with a canola stand with lower than the optimum plant density, the decision to reseed will be based on plant density, date and uniformity of the plant stand.”

In the second part of the study, researchers evaluated reseeding options. Two hybrid canola cultivars, 5440LL and 9350RR, and a synthetic Polish canola variety were reseeded into existing stands of low density canola at two reseeding dates, early and mid-June. A seeding rate of 150 seeds/m2 was used in one treatment, and a rate of 20 seeds/m2 to simulate poor stand establishment in the remaining treatments. One of the treatments planted at 20 seeds/m2 was later killed with glyphosate prior to reseeding to mimic a

reseeding situation in which a poor plant stand is terminated and canola is reseeded.

Results from the reseeding trials showed a yield benefit from reseeding with B. napus in early June but no yield benefit to reseeding in mid-June. There was also no advantage to reseeding with B. rapa, even when reseeding was postponed to mid-June. Reseeding in early June to hybrid canola when plant stands were at 20 plants/m2 or less provided a yield and economic benefit compared to leaving the stand of low density canola. However, if conditions do not allow for reseeding to occur in late May or early June, producers are not recommended to reseed to canola.

“The best practice for maximizing yields and net return is to target good plant populations in the first place at 70-140 plants/ m2, because generally at plant stands below 40 plants/m2 or four to five plants/ft2 then you start losing yield, says Laryssa Grenkow, WARC research manager. “However, if for some reason you do manage to have lower plant populations than you are looking for, this study showed that reseeding with a hybrid variety only provided a positive economic return about half of the time and only at the early June timing. Reseeding with Polish canola did not pay.

“This also ties in quite well with the Saskatchewan Crop Insurance Corporation (SCIC) reseeding benefits program,” adds Grenkow. Below 12 plants, the crop is considered not established. Between 12 and 40 plants is the “choice” range where growers have the choice of whether or not to reseed and are eligible for the SCIC establishment benefit (EB). Above 40 plants/m2 is considered established.

“Therefore, if reseeding to high-yielding hybrid canola in early June when in the choice range (12-40 plants/m2), then there is a 50 per cent chance of showing positive returns,” she says. “The SCIC EB ($60/acre) makes reseeding in early June the more economical choice and helps cover risks.”

Reseeding would be recommended when plant density falls below the level required to achieve 90 per cent of maximum yield. However, the decision to reseed will have to take into account factors such as plant uniformity of field, ability to control weeds, soil moisture conditions, and forecasts and harvest management. When reseeding is required, it is recommended producers reseed as early as possible to reduce the risk of poor stand establishment, and yield and quality reductions due to fall frost.

Table 2: Influence of seeding date, variety and seeding rate on mean yield Seeding

Mid

*Significantly greater yield than 5440 LL seeded in early May at a low

Source: WARC.

“On this farm, we’re the experts.”

Sean

Gorrill – FCC Customer

More of Canada’s farm experts choose to do business with FCC Together, we’ll create the financing plan that works for you. We get to know you, your farm and how you want to grow. If you’re ready to get down to business, talk to one of our farm business experts.

fcc.ca/Expert2Expert 1-800-387-3232

by Bruce Barker

Corn breeders continue to focus on early maturing corn hybrids, and are bringing myriad stacked traits to western Canadian corn growers. Seed companies have supplied information on the new corn hybrids for 2015, and growers are advised to check local performance trials to help in variety selection. Listing is by corn heat units (CHU).

A4177G3 RIB is a Genuity VT Triple PRO RIB Complete PRIDE G3 hybrid, rated at 2000 to 2125 CHU with above- and below-ground insect control. It has early maturity and is a multi-purpose grain, silage and high moisture corn. The hybrid has consistent and reliable performance in early zones with exceptional spring vigour. Refuge in the bag provides enhanced trait protection with the benefit of automatic refuge compliance. Available from PRIDE Seeds dealers.

P7332R is a Roundup Ready Corn 2 hybrid with early maturity of 2050 CHU, built for Western Canada. It provides excellent yield potential with 104 per cent of Pioneer brand and competitor corn hybrids in five Pioneer Proving Ground sites across Western Canada in 2013. P7332R has excellent root strength for ease of harvest. Available from all local Pioneer Hi-bred sales representatives across Western Canada.

DKC23-22RIB is a Genuity VT Double PRO RIB Complete hybrid at a maturity of 2075 CHU, with excellent yield potential. It is an early-flowering, early-maturing hybrid with excellent harvest appearance and agronomics. DKC23-22RIB stands strong and has excellent test weight. Available at your local DEKALB dealer.

P7410HR is a Roundup Ready Corn 2/LibertyLink corn hybrid with 2100 CHU and Herculex 1 technology for above-ground insect control. It is an early corn hybrid with drought tolerance. Excellent yield potential with 105 per cent of Pioneer brand and competitor corn hybrids in 127 Pioneer Proving Ground sites across Western Canada in 2013. P7410HR has good stalk and root strength. Available from all local Pioneer Hi-bred sales representatives across Western Canada.

A4025G3 RIB is a Genuity VT Triple PRO RIB Complete hybrid rated at 2150 CHU, that delivers above- and below-ground insect control. It is a very early season grain corn with superior late season intactness. This hybrid is very suitable for early planting, cold soils and late harvest timings. It has strong agronomics with very good spring vigour, stalk strength and full dent grain. Refuge in the bag provides enhanced trait protection with the benefit of automatic refuge compliance. Available from PRIDE Seeds dealers.

A4414RR is a new 2150 CHU Roundup Ready hybrid with very good emergence and spring vigour conducive for tough cold soils. It is an early, high-end performance grain hybrid with early flowering and finish. Available from PRIDE Seeds dealers.

A4415G2 RIB is a 2200 CHU

plete product, delivering above-ground insect control for grain use. Very good emergence and spring vigour conducive for tough cold soils. Refuge in the bag provides enhanced trait protection with the benefit of automatic refuge compliance. Available from PRIDE Seeds dealers.

P7632HR is a Roundup Ready Corn 2/LibertyLink corn hybrid with 2200 CHUs and Herculex 1 technology for above-ground insect control. It is an early corn hybrid with drought tolerance all in one package. It provides excellent yield potential with 106 per cent of Pioneer brand and competitor corn hybrids in 305 Pioneer Proving Ground sites across Western Canada in 2013. P7632HR has good stalk and root strength for ease of harvest. Available from all local Pioneer Hi-bred sales representatives across Western Canada.

P7632AM is an Optimum AcreMax corn hybrid with 2225 CHUs and Roundup Ready Corn 2/LibertyLink, Herculex 1 and YieldGuard

Since 2007, our Research and Development team has been working to improve our Classic Rocket design; resulting in an innovative, stronger and even more reliable rocket. We are pleased to introduce The Next Generation Rocket.

Hopper bottom bins without aeration? It’s not too late to dry your grain!

The revolutionary Retro Rocket is the only do-it-yourself rocket system that allows you to retrofit existing hopper bottom and smoothwalled bins with farm proven Grain Guard aeration.

Corn Borer technology for above-ground insect control. It can provide high yields along with a superior agronomic package. With an integrated refuge in the bag, P7632AM provides the ultimate simplicity for the grower where no separate refuge is required. Available from all local Pioneer Hi-bred sales representatives across Western Canada.

A4939G2 is a 2175 to 2300 CHU RIB Genuity VT Double PRO RIB Complete full-season hybrid delivering above-ground insect control. It is a high yielding, dual-purpose for silage and full-season grain use. It has long-lasting health and stay-green characteristics. Refuge in the bag provides enhanced trait protection with the benefit of automatic refuge compliance. Available from PRIDE Seeds dealers.

4078 is a 2250 CHU hybrid with Roundup Ready 2/Liberty Link and Herculex Extra corn borer protection with excellent yield potential. It has early flowering and finish for early production areas. 4078 has strong stalks and late season intactness, and good husk cover and grain drydown. Available from Hyland Seeds.

TH4126RR is an exciting new 2250 CHU silage hybrid that is a sister line to the successful TH2146RR. It has a showy pineapple leaf, flint dent cob, and is a high yielder with quicker dry down than the 2146. Available from Thunder Seed dealers.

P7958AM is an Optimum AcreMax corn hybrid rated at 2275 CHU and with Roundup Ready Corn 2/LibertyLink, Herculex 1 and YieldGuard Corn Borer technology for above-ground insect control. It is a corn hybrid with excellent yield potential and very good drought tolerance. It provided 109 per cent of Pioneer brand and competitor corn hybrids in 305 Pioneer Proving Ground sites across Western Canada in 2013. Available from all local Pioneer Hi-bred sales representatives across Western Canada.

AS1047RR EDF is a grower and feedlot Roundup Ready hybrid choice rated at 2275 to 2450 CHU. It provides performance for high moisture corn use and heavy tonnage silage feed due to its big, very tall plant with girthy, stout ear size. It has a white cob with very good starch levels to provide quality silage. Slow grain drying rate preserves reliable and consistent feed. Available from PRIDE Seeds dealers.

4093 has the Roundup Ready 2/Liberty Link and Herculex Extra corn borer protection traits and is rated at 2300 CHU. It has excellent yield potential and is broadly adapted across variable soil types and environments. It is well suited to early maturity environments and has very good early vigour and solid agronomic characteristics. Available from Hyland Seeds.

MZ 1624DBR is a Genuity VT Double Pro RIB Complete hybrid rated at 2300 CHU. It has strong seedling vigour for uniform ear de-

velopment. Early flowering results in rapid grain setup. This hybrid has exceptional stalk strength for harvest ease, and above average test weight. Also available as Roundup Ready (MZ 1625R). Available from Maizex Seeds.

DKC 30-19RIB is a Genuity VT Double PRO RIB Complete hybrid at a maturity of 2325 CHU with excellent yield potential. This hybrid offers outstanding emergence and seedling growth, with excellent test weight and grain quality. Available at your local DEKALB dealer.

LF 730CBR is a Genuity VT Triple Pro RIB Complete rated at 2350 CHU, bred specifically for silage production. It has rapid spring vigour and early-season growth for uniform plant establishment. Tall, robust plant increases silage yield. Also available as Roundup Ready (LF 728R). Available from Maizex Seeds.

DKC 31-09RIB is a Genuity VT Triple PRO RIB Complete hybrid at a maturity of 2400 CHU with exceptional yield potential. It is an ideal choice for corn-on-corn rotations with its excellent foliar disease package. This hybrid is well suited for early planting, with very good stalk and root strength. Available at your local DEKALB dealer.

DKC 37-85RIB is a Genuity SmartStax RIB Complete hybrid at a maturity of 2650 CHU with outstanding top-end yield potential. This product demonstrates above average drought stress tolerance, and early season agronomics and flowering. DKC 37-85RIB is stable across yield environments, offering girthy ears with open husks for fast drydown. Available at your local DEKALB dealer.

TH7677VT2P is a big-yielding grain corn rated at 2750 CHU. It looks very similar to TH7578 with the same or better bushel potential but a quicker dry down. It is a strong plant with mid cob placement and looks great coming out of the ground. Strong genetic lines. Available from Thunder Seed dealers.

TH4689RR is a high heat, 2750 CHU tall grazing hybrid with large cob potential. With strong stalks and excellent roots, it also features good ear placement for ease in grazing. Available from Thunder Seed dealers.

DuPont Pioneer is constructing a new 22,250 sq. ft., multi-million dollar research facility in Lethbridge, Alta., focused on developing ultra-early maturity corn products for growers in Alberta and Western Canada. Research plots were planted at the site this past spring, and the facility itself is expected to open within the coming months. In the future, this facility could be expanded to serve other crops or other DuPont businesses as well.

For the 2015 growing season, Syngenta Canada is launching three new canola hybrids. They can be purchased from a Syngenta seed dealer, and more information on the Syngenta canola seed portfolio can be found at SyngentaFarm.ca.

SY4135 is a Genuity Roundup Ready canola hybrid selected through rigorous field trialling. This mid-season hybrid is rated R (resistant) for blackleg, and is a competitive option for growers looking for a solid return on investment. SY4135 flowers earlier, matures quicker and yields competitively compared to industry checks. SY4135 is available for 2015 seeding.

SY4114 is a mid-season Genuity Roundup Ready canola hybrid that offers high yield potential and fits well across all

growing regions of Western Canada. Rated R for blackleg, SY4114 has demonstrated strong yield performance and very good standability versus industry checks in large-scale trials conducted across the Prairies in 2013. SY4114 is available for 2015 seeding.

SY4157 from Syngenta is a new, high-yielding Genuity Roundup Ready canola hybrid, rated R for blackleg. SY4157 is best suited for mid- to long-season growing zones across Western Canada. In extensive public and private trials, SY4157 consistently demonstrated excellent early-season vigour, strong blackleg resistance and good lodging scores. SY4157 is available in limited quantities for 2015 seeding.

More choices available for western Canadian growers.

by Bruce Barker

Seed companies continue to expand the potential for soybean production in Western Canada with earlier maturing and higher yielding varieties suited for short season areas. As soybean acreage on the Prairies moves past the one million acre mark, breeders have shown greater interest in developing varieties specific to Western Canada.

Three new flax varieties are also rolling out for 2015, which may help restore the bloom to flax acreage in Western Canada. And Nuseed Americas, formerly Seeds 2000, is introducing two new sunflower varieties, including the first Express-tolerant confection sunflower hybrid.

The seed companies supply information on the varieties, and growers are advised to check local performance trials to help in variety selection. Listing is by crop heat units (CHU) for soybean, and alphabetical order for flax.

22-60RY is a Genuity Roundup Ready 2 Yield soybean variety with a maturity of 2275 CHU and excellent yield potential. This variety is soybean cyst nematode (SCN) resistant, Rps 1c with excellent phytopthora field tolerance. 22-60RY is a very short, bushy line, which will stand well. It performs best on fertile soils with lower pH, and has excellent white mould tolerance. Available at your local DEKALB dealer.

NSC Moosomin RR2Y is an ultra early soybean variety (<2300 CHU) that is projected to be a game-changer by expanding the soybean market into areas with growing seasons currently considered to be too short or too dry. It is a compact, erect plant with short internodes and very dense podding. Good early vigour with excellent pod height despite shorter stature. NSC Moosomin RR2Y has demonstrated excellent yield potential (up to 50 bu/ac) in production fields. Available from NorthStar Genetics.

23-11RY is a Genuity Roundup Ready 2 Yield soybean variety at a

maturity of 2300 CHU with excellent yield potential. This variety has above average iron deficiency chlorosis (IDC) tolerance and Rps 1c for phytopthora. 23-11RY is a tall variety that may lean and is a good compliment to 23-10RY with more height. Available at your local DEKALB dealer.

Akras R2 is a new soybean variety from Elite in the medium/early (2375 CHU) group that has shown itself widely adapted and a top performer in trials. It is early enough to be suited to production into Saskatchewan and western and northern areas of Manitoba. It has also outperformed many of the late maturing varieties in the Red River valley over the last two years of MCVET trials. Akras is a semi-bushy plant with medium height and excellent podding height for easy harvest. It has the Rps 1K gene with very good field resistance against phytopthora. It has good tolerance to white mould and is semi-tolerant to IDC. Available from BrettYoung.

Hero R2 is a Genuity Roundup Ready 2 Yield oilseed soybean, bushy to medium-bushy for wider row spacing. It is rated at 2375 CHU and offers good yield potential in an early maturing soybean. Hero R2 is rated as semi-tolerant to IDC. Available from SeCan.

LS Northwester is an early maturity (2375 CHU / 0.02 RM) soybean that is very tall with a high pod set. It is a bushy plant that works well in narrow or wide rows. This variety is a good choice for all soil types as it has very good IDC tolerance so it works well in soils with higher pH levels. LS Northwester has very vigorous emergence so it works well in no-till applications, and it has a very high yield potential, especially for an early variety. Available from Legend Seeds retailers.

McLeod R2 oilseed soybean combines very early maturity and good yield potential. It is a 2375 heat units (HU) Genuity Roundup Ready 2 Yield soybean with excellent podding height, upright growth

ABOVE: Soybean breeders continue to push the frontiers of production in Western Canada.

habit and a medium-bushy plant type. McLeod R2 has a tolerant rating to IDC. Available from SeCan.

NSC Gladstone RR2Y is a bushy plant with very aggressive growth habit with maturity rated at 2375 HU, making this variety an ideal fit for soybean growers looking for an early variety while using planters or wider row spacing. It yielded equal to the mid-season check in 2013 public trials. Excellent complement for long-season variety growers who want to spread harvest and maturity risk. Available from NorthStar Genetics.

PS0035NR2 is a high yielding Genuity Roundup Ready 2 Yield soybean variety rated at 2375 CHU. It has a great combination of strong SCN resistance and above average IDC tolerance, and excellent standability and disease tolerance. This variety has good plant height with excellent canopy. It is a very consistent and reliable variety for earlyand mid-season growing areas. Available from PRIDE Seeds dealers.

TH 35002R2Y is the earliest soybean in Quarry Seeds’ Thunder line up and will be available for the first time in 2015. Seed availability will be limited. Its rated maturity is 0.02/2375 CHU. TH 35002R2Y is showing very good yield for its maturity. It is a semi-bush plant with very strong IDC tolerance. Available from Quarry Seeds retailers.

NSC Tilston RR2Y is an early-mid season soybean variety, rated at 2400 CHU. It has excellent early vigour and is very tall with excellent pod clearance and exceptional standability. NSC Tilston RR2Y was a top performer in public trials in terms of both yield and maturity compared to other varieties where conditions were particularly cool – which may be due to its cold tolerance. Available from NothStar Genetics.

24-11RY is a Genuity Roundup Ready 2 Yield soybean variety at

a maturity of 2425 CHU with excellent yield potential. This variety has very good phytopthora field tolerance. 24-11RY is a tall, branchy product that can lean, and is well suited to heavier soils. Available at your local DEKALB dealer.

NSC Sanford RR2Y is a tall, semi-bush mid-season soybean variety (2425 CHU) for Manitoba. In 2013 MCVET trials, it yielded 107 per cent of NSC Elie RR2Y, which it will replace in NorthStar Genetics’ portfolio. Very limited availability in 2015 from NorthStar Genetics.

P008T70R is a new high yielding Roundup Ready soybean variety rated at 2475 CHU, with very good harvest standability for ease of harvest in Western Canada. It is a large seeded soybean that provides excellent yield for the maturity and the potential increase in bushel weight. Available from all local Pioneer Hi-bred sales representatives across Western Canada.

P008T22R2 is a new high-yielding Genuity Roundup Ready 2 Yield (RR2Y) soybean variety rated at 2475 CHU. It provides excellent standability and plant height for ease of harvest. In areas with high potential for white mould infections, it provides moderate tolerance against this devastating disease. Available from all local Pioneer Hibred sales representatives across Western Canada.

Monsanto Canada continues to work on the Roundup Ready Xtend Crop System, which consists of two primary components: an innovative new trait, as well as glyphosate and dicamba chemistry options. Roundup Ready 2 Xtend soybeans contain a dicamba-tolerant trait stacked with the proven performance from the Genuity Roundup Ready 2 Yield soybean trait and technology. This stacked soybean

Elite’s focus on early maturity has created varieties of soybeans that are uniquely adapted to Western Canadian conditions. The Elite® brand of soybeans offers cutting-edge products and technology with industry-leading expertise. We select Genuity® Roundup Ready 2 Yield® varieties that are early maturing, widely adapted and high yielding. Our priority is helping you grow.

product can help deliver higher yield potential through improved weed control by offering tolerance to both dicamba and glyphosate. Allowing the use of dicamba to be incorporated into soybean weed management programs introduces an additional mode of action for enhanced weed control of both tough broadleaf and glyphosate resistant weeds. The addition of dicamba adds extended residual weed control by up to 14 days, allowing greater flexibility and convenience.

Monsanto hopes to have a full launch for the 2016 growing season with a broad maturity range of soybean varieties available in the launch year.

AAC Bravo is a new flax variety with a yield potential of up to 104 per cent of CDC Bethune. It has an MR/G rating to powdery mildew and Fusarium wilt. AAC Bravo provides a large seed size with short straw, good lodging resistance and great standability. It’s available at FP Genetics retailers.

CDC Glas flax is seen as a replacement for CDC Bethune. It offers improved standability

over CDC Bethune and a 105 per cent yield advantage in the Black soil zone (104 per cent average of CDC Bethune over all zones). It is rated as one day later and has slightly smaller seed than CDC Bethune. Available as re-constituted seed from SeCan.

CDC Sanctuary flax is viewed as a replacement for CDC Bethune in the Brown soil zones, averaging 105 per cent of CDC Bethune in the drier areas of the Prairies. CDC Sanctuary is three days later, slightly taller and has slightly weaker straw than CDC Bethune. Available as re-constituted seed from SeCan.

9180 DMR is the “first to market” Express-tolerant confection sunflower hybrid. It also has resistance to downy mildew. Available from Nuseed Americas.

Talon is a new oilseed hybrid. It is an extremely uniform, early maturing, Express-tolerant NuSun oil hybrid. Because of its large, plump kernels, it is perfectly suited for the dehull/kernel market. Processors have placed it on their “hybrid preferred” list. Available from Nuseed Americas.

A study of heritage and modern wheats is proving Canadian wheat is as good as ever.

by Carolyn King

One of the common criticisms aimed at wheat nowadays in the media is that breeders have genetically modified wheat varieties in recent decades to the point that it is detrimental to human health. These claims have been made despite the fact that modern wheat varieties have been developed steadily over the last century using only conventional breeding methods. Now, a scientific study is proving that Canadian wheat varieties today are as healthful as those from the 1800s.

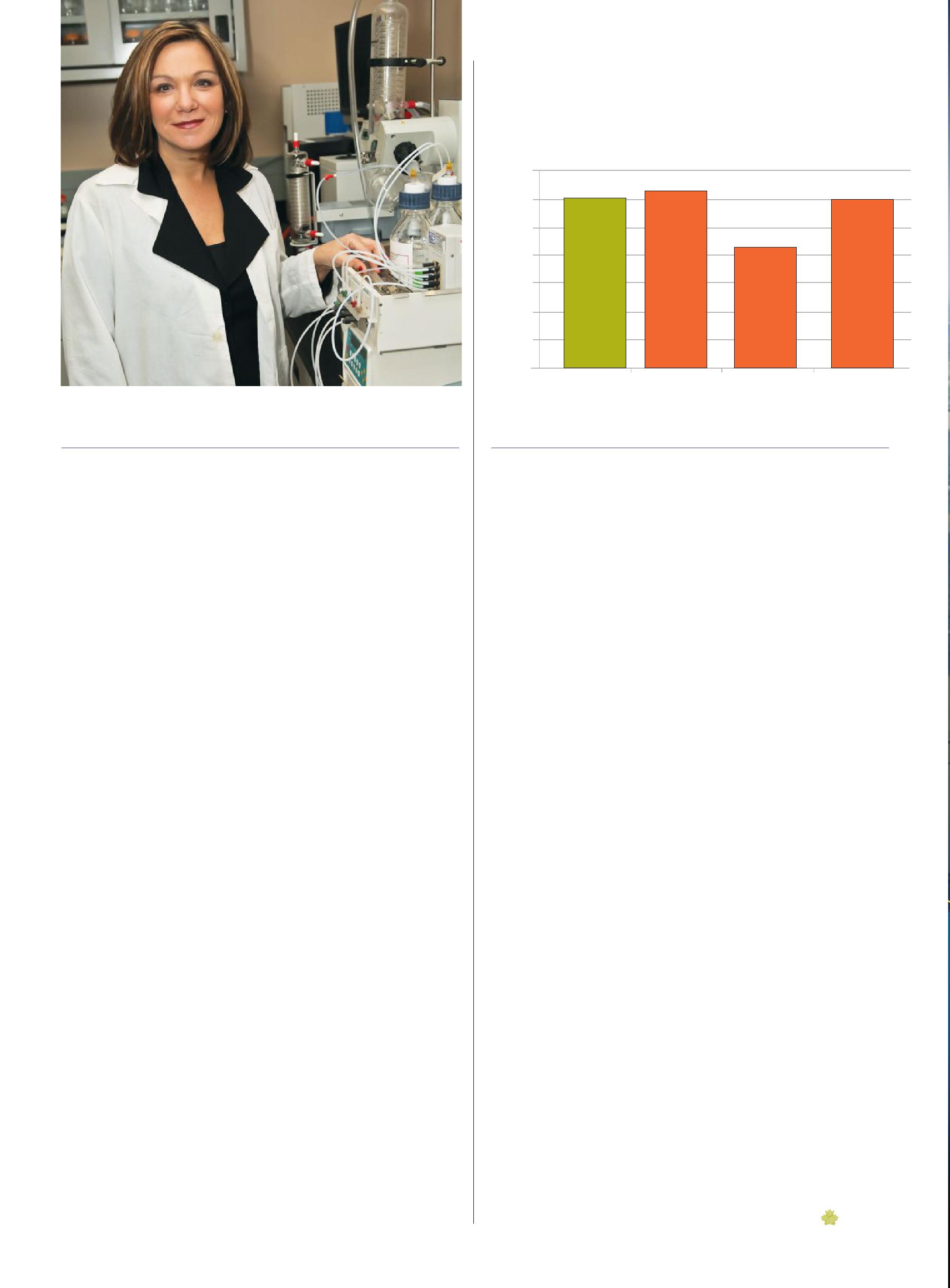

“The study was prompted by a couple of factors. One is that there is a lot of interest in this issue from consumers and the public, with people wondering if some of the original wheat varieties grown in Canada, like Red Fife, are healthier or better tasting than the wheat we’re producing now,” explains Dr. Nancy Ames, a cereal research scientist with Agriculture and Agri-Food Canada (AAFC).

“Second, there has been a lot of discussion in the popular media claiming that modern breeding has had negative effects on wheat’s nutritional qualities, so we wanted to investigate whether any such changes have occurred in Canadian wheat.”

Ames collaborated on this study with Dr. Ron DePauw, a wheat breeder at AAFC, and Dr. Nancy Edwards, who was with the Canadian Grain Commission when the study started in 2011. They compared 20 western Canadian hard red spring wheat varieties. These included three heritage wheats from the 1800s – Red Fife, Ladoga and Hard Red Calcutta – and 17 varieties, ranging from Marquis, registered in 1904, to CDC Utmost, registered in 2010. DePauw grew the varieties at Indian Head and Swift Current, Sask., for four years. While DePauw evaluated their agronomic characteristics, Edwards analyzed their milling and baking properties, and Ames measured their nutritional characteristics.

Ames already knew from her own research and many other scientific studies that wheat has a wide variety of healthful components. In this study, her research group is measuring nutritional characteristics in whole wheat flour from samples of each of the 20 wheats, grown at each site, for each year of the project.

Her goal is to generate adequate scientific evidence to counter the negative media claims about wheat breeding and its impact on wheat composition. In addition, her research aims to demonstrate the variations in bioactive compositions with different varieties to facilitate breeding of new cultivars with enhanced health benefits, without compromising agronomic performance and processing quality.

Ames and her lab have just about finished the analysis. She says,

Fibre analysis at Ames’s lab is showing that heritage and modern wheats have similar total fibre contents.

“We’ve looked at basic nutritional profiles for components like carbohydrates, fat, fibre and protein, as well as more detailed analysis of bioactive compounds that could have significant human health benefits. For example, available carbohydrates and starch-fibre ratios were measured because those ratios can be implicated in glycemic response. We’ve looked at total protein as well as the ratio of gliadin and glutenin, which are the two proteins that form gluten. Wheat is a rich source of polyphenolic antioxidants, which have beneficial effects against major human chronic diseases. Therefore, we’ve looked at total phenolic content as well as six individual

The researchers are analyzing the samples for bioactives such as lutein, which plays a role in maintaining eye health.

phenolic compounds, which vary depending on variety, stage of plant growth and growing location.”

The researchers are also measuring the levels of specific types of fibre such as arabinoxylan (known for its role in reducing glycemic response), insoluble and soluble fibre, and two lesser known wheat bioactives: betaine and lutein, which play roles in reducing inflammation and macular degeneration, respectively.

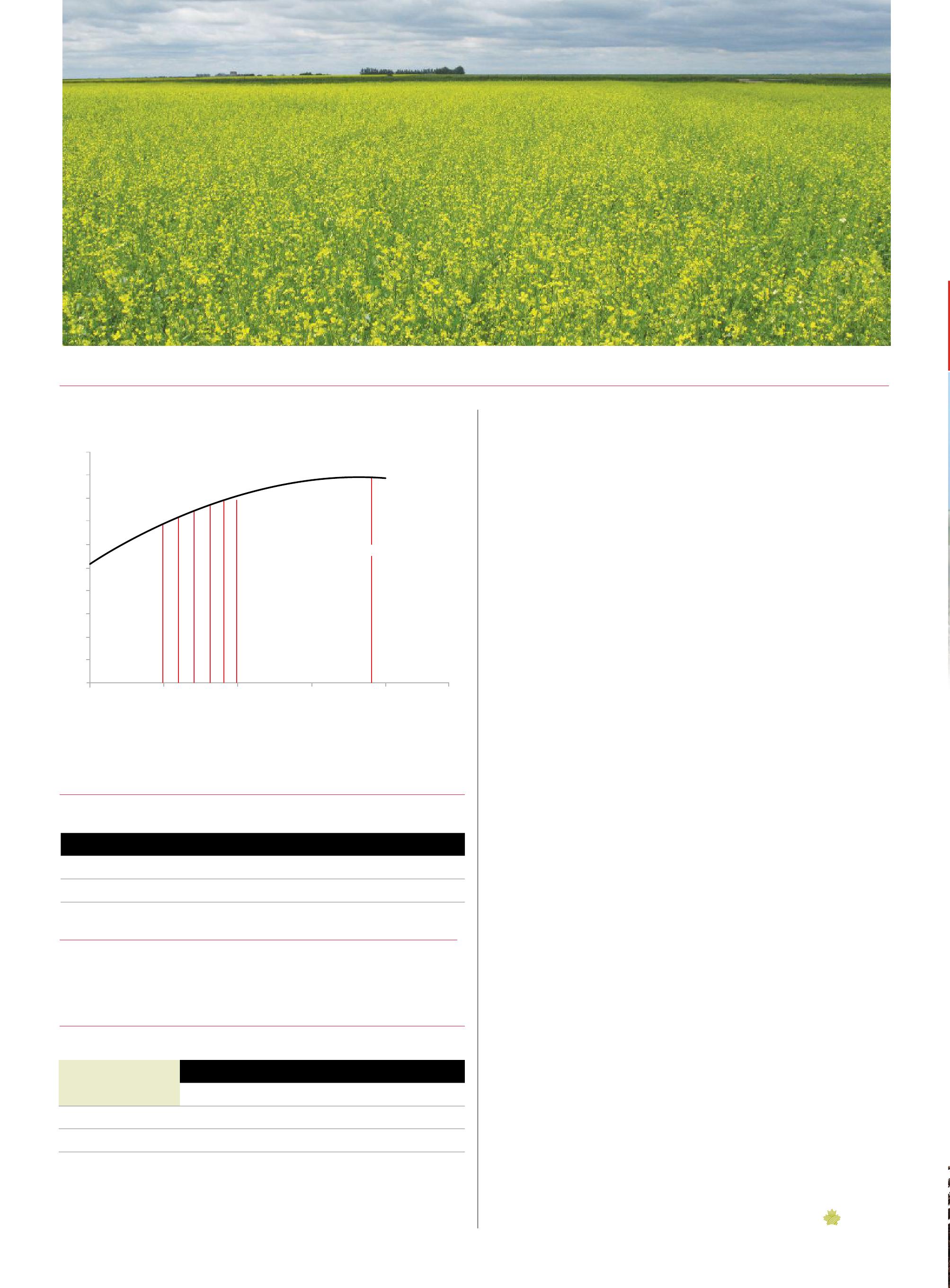

The data show genetic variation in the levels of the different nutritional components, as you would expect, but no strong trends, either positively or negatively, between the older types like Red Fife and today’s varieties. For instance, Figures 1 and 2 show some of the results for arabinoxylan and total fibre contents.

“Breeders have not selected for most of these nutritional components,” explains Ames. “They have focused breeding efforts to maintain end-product quality and improve agronomic performance, so it is good to know that none of these nutritional components have been lost.”

She adds, “The Canadian wheat industry keeps a very careful watch over the quality characteristics of our wheat varieties in Canada, ensuring bread making quality is maintained. Wheat varieties like Red Fife and Marquis were known for making really good bread. So breeding of hard red spring wheat has emphasized maintaining or improving that quality, while working on developing cultivars with superior yields and resistance to disease and insect pests.”

Ames points to another interesting finding from the study: “For a lot of the newer varieties, the levels of the nutritional components were maintained across the different locations and across the three years. But some of these characteristics in older varieties were less uniform across environments.”

Figure 1: Average arabinoxylan content of some heritage and modern wheat varieties, from 2011 to 2013 at Swift Current, Sask., and 2012 to 2013 at Indian Head, Sask.

Arabinoxylan

Source: Nancy Ames/Agriculture and Agri-Food Canada.

According to Ames, the greater uniformity of the more recent wheat varieties is likely due to advances in our wheat breeding programs, such as having more locations and more testing of breeding lines. She notes, “The uniform quality of Canadian wheat is an important characteristic for marketing wheat domestically and internationally. No matter where in Western Canada a farmer is growing wheat, buyers can count on the quality.”

Even healthier wheat products?

Could our wheat varieties and wheat products be even more nutri-

With up to 8% more yield than other inoculants, it makes a welcome addition to any operation.

Chances are if you grow peas or lentils you’re already using inoculants. What you may not realize is they’re not all created equal. That’s why you should insist on Nodulator® XL. With the most active strain of rhizobia, it improves nitrogen xation for increased root biomass and top growth. It all adds up to higher yield potential. So when you choose Nodulator XL, we suggest you think ahead to harvest time—and think big. To nd out more, visit agsolutions.ca/nodulatorxl or contact AgSolutions® Customer Care at 1-877-371-BASF (2273).

Always read and follow

tious? “There is always room for improvement,” says Ames. “Those improvements could be made through breeding, changes in processing, and genotype by environment interactions. From our work on the heritage wheat varieties and from previous studies, we know there is genetic variation for nutritional components. We also know that nutritional characteristics have not been actively selected for in most wheat breeding programs. This is unlike the oat breeding program, where emphasis is placed on increasing cholesterol-lowering fibre components to meet the well-known health claim. Therefore, with the use of appropriate screening tools, it is possible for breeders to further improve the nutritional content of modern wheat lines.”

Canadian wheat breeders have already proven their ability to enhance wheat characteristics for production of healthier end-products. “When breeders decided to focus on the type and colour of bran, they were able to develop hard white wheat. It has the same bread making quality as hard red wheat, but it has a different bran and end-product colour that is preferred by consumers. That change allowed millers and bread makers to produce high fibre whole wheat products that still looked more like white bread,” notes Ames.

From the processing side, using whole wheat flour – flour made with 100 per cent of the kernel – rather than flour made from just the endosperm really boosts the nutritional value of wheat products. The endosperm has starch and protein, but most of wheat’s beneficial components are found in the rest of the kernel. The germ has protein, lipids, folic acid and vitamin E; the aleurone (the layer surrounding the endosperm and germ) has fibre, niacin, thiamine, iron, protein, antioxidants and bioactives; and the bran layers (the kernel’s outer layers) have fibre, antioxidants, B vitamins, minerals, protein and other bioactives.

Various studies have shown healthful benefits from consuming whole wheat products. To give just a few examples, wheat bran fibre consumption has been shown to increase satiety (making you feel fuller faster), lower weight and improve insulin sensitivity. Wheat germ consumption has been reported to reduce the cholesterol absorption from the diet. Increased intake of whole grains is also associated with lower fat tissue levels in adults. Ames says, “This considerable scientific evidence strongly

Figure 2: Average fibre content of some heritage and modern wheat varieties, from 2012 to 2013 at Swift Current, Sask.

Source: Nancy Ames/Agriculture and Agri-Food Canada.

suggests that regular whole grain wheat consumption will have significant beneficial effects against obesity and associated metabolic diseases.”

In her own research, Ames is really excited about the interaction between variety and the resulting whole wheat product. “For instance, there are opportunities for improving wheat lines specifically for use in whole wheat end-products.”

This type of research could lead to the development of a wider range of whole wheat products that more consumers would find just as scrumptious as regular wheat products, while also enjoying the nutritional benefits gained from including the bran, aleurone and germ.

However, Ames emphasizes that for breeders to start developing new varieties and wheat processors to begin developing new food products, they have to be sure there’s a market. And to develop a bigger market for more nutritious wheat products, consumers need better information on wheat nutrients.

“Consumers have a lot of influence over the products that food processors produce, which is why it is important for consumers to have all the science-based information they need when making healthy food choices,” says Ames.

With no-wheat and low-carb diet books putting wheat on consumers’ radar these days, Ames thinks it’s an opportune time to give the public more complete, scientifically based information about wheat’s nutritional profile.

“Many people don’t realize that wheat has a lot of healthy compounds that are quite important to our diet. For example, whole wheat and bran products are an important source of insoluble fibre, but wheat also contains less well known bioactives such as betaine, lutein, antioxidants and arabinoxylan. Wheat is also a source of protein – gluten is a protein complex in wheat – with both functional and nutritional benefits.” She notes that gluten, like any protein, has the possibility of causing an allergic reaction, but most people are not allergic to gluten, and only about one per cent of the population has celiac disease.

Ames says, “I think it’s our responsibility, from a scientific viewpoint and from a wheat industry viewpoint, to provide consumers with the information that they deserve to know in a concise and easy-to-read story so they can make informed choices.”

Field

View detailed coverage maps as they are completed in the field.

Rainfall

Use virtual rain gauges for each field and create a map of rainfall.

Irrigation

Monitor and control water, fertigation, and effluent applications.

Fleet

Track fleet locations and alerts while viewing reports on productivity.

View crop health imagery to assist scouting efforts.

Soil

Understand how water and other inputs move through your soil.

Researchers draw on the Ontario experience to help monitor Prairie populations.

by Donna Fleury

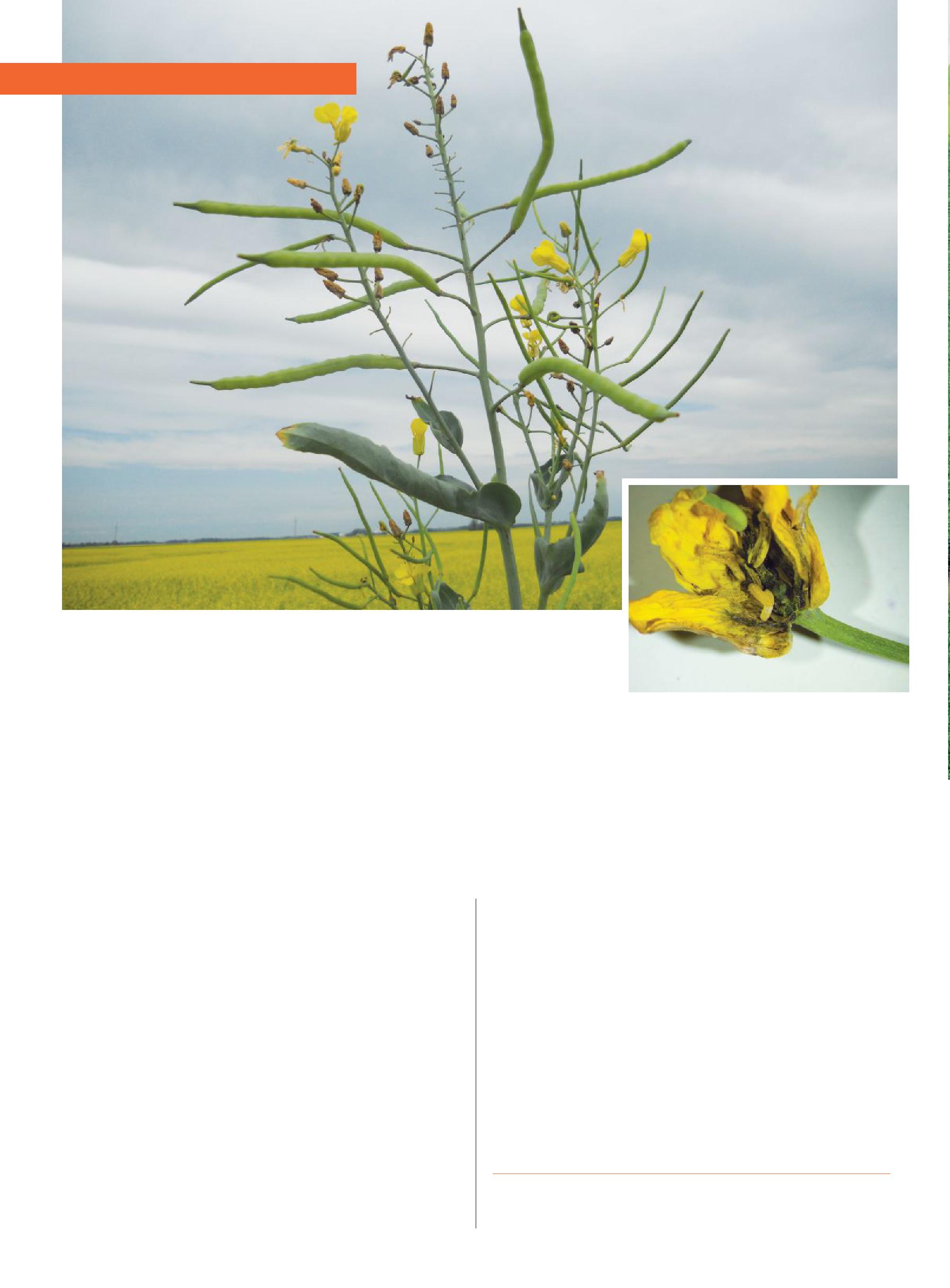

Swede midge was first identified in Saskatchewan in 2007, but, so far, populations are small and scattered. However, it is a serious pest of canola and cruciferous vegetable crops in Ontario. First identified in vegetable crops in 2000, damage to canola crops was not reported until 2003. Since then, swede midge populations have been spreading and increasing across Ontario, with 2011 one of the worst years for damage for canola growers across much of the canola growing area.

“In Ontario, years where crops are planted later because of wet weather usually result in worse swede midge damage than early planting,” says Rebecca Hallett, professor and associate director, School of Environmental Sciences at the University of Guelph. “In 2011, swede midge erupted as a serious problem in both southern and northern areas of Ontario, and currently swede midge damage can be found on most canola plants in the northern region.”

Hallett has been researching swede midge since 2000, studying its biology, life history and overwintering habits, and developing IPM

recommendations for cole crops. Most recently, she has been focusing on canola, and developing management recommendations and pheromone-based action thresholds for timing of insecticide control.

In Ontario, swede midge adults typically begin emergence in mid to late May, with the peak occurring in early June. Swede midge overwinter as larvae in the soil of infested fields. “In the spring in Ontario, there are two distinct peaks of emergence of overwintered adults: the early emergers in late May to early June, and the late emergers about one to two weeks later,” explains Hallett. “With four generations of each of these populations occurring each year, the generations overlap with each other so every stage is often present in the field at the same time. Female swede midge like to lay their eggs at the base of leaves around the young, rapidly growing meristematic tissues, so this is the most important stage to protect.”

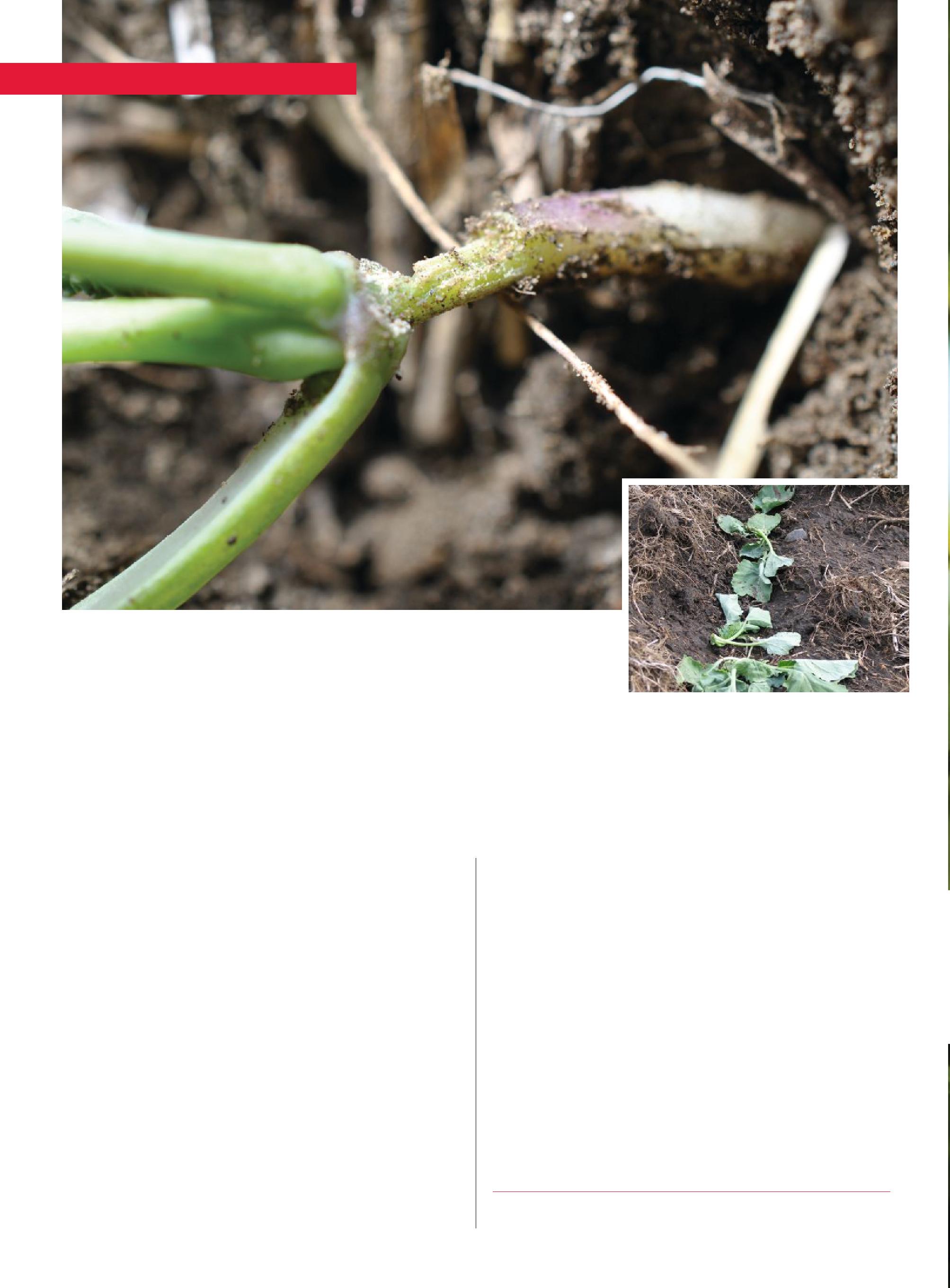

TOP: Swede midge damage to canola seed heads, Carrot River, Sask., 2013.

INSET: Swede midge larvae inside a canola flower.

On the Prairies, swede midge has not caused economic damage. In 2003, Julie Soroka, research scientist with Agriculture and Agri-Food Canada (AAFC) in Saskatoon, Sask., began monitoring for swede midge in that province, and through to 2011 never discovered any populations. However, in 2012, growers in the Nipawin and Carrot River area reported the first field damage from swede midge.

“Growers started noticing malformed flowers, and on further inspection, the swede midge larvae were identified in canola,” says Soroka. “This was the first time swede midge damage in the field was seen in Saskatchewan. The damage was seen late in July, indicating the adults didn’t emerge until the beginning of July or shortly after. We conducted a survey of 44 fields in a 125-kilometre radius of that site, and found 11 fields with minor infestation and only one field with about one acre that showed readily noticeable damage. The damage was not of economic significance in any of the fields.”

In 2013, damage was identified earlier at the beginning of July, and in a greater concentration. Soroka notes that although the damage was easily found in many fields, damage was generally low. “We did a mapping survey in 2013 that showed the population had spread west and south to about 200 kilometres away from the Nipawin-Carrot River area, as well as set up pheromone traps in 22 locations throughout the summer.”

Only a few midge were reported in the traps, and although infested flowers were readily found in many fields throughout the northeastern region, Soroka suspects the midge is at a much lower population density than in Ontario and is likely cycling through only two or three generations per year as compared to four or five in the east.

In 2014, swede midge was first detected late in the season, as in 2012, and very little damage was reported, although the area of damage is slowly extending. Both pheromone trapping for adults and examination of infested canola found swede midge present in the region near North Battleford, suggesting this area is another site of introduction. In Manitoba, swede midge was identified in 2008 and again in 2013 but in very small numbers. In 2014 it was found at several sites south of Highway 1, as well as in the Dauphin-Swan River region. To date, swede midge has not been observed in Alberta.

Soroka received funding in 2014 for swede midge research with a focus on understanding differences in the biology, overwintering, challenges with pheromone trapping and other conditions that may be different from Ontario. Growth stage experiments are also underway with both early and late crops to determine the expression of damage at the various stages. Computer modelling has shown that all canola-growing areas in Canada are potentially suited to the pest.

In Ontario, canola growers should use a combination of management practices including crop rotation, planting early, monitoring and insecticides for control of swede midge. Swede midge is a crucifer specialist and a difficult pest to control, so crop rotation is very important. “Although it can be difficult for growers to rotate on a large enough scale to be very effective on a regional scale, it is still really important for fields to be rotated to keep individual field populations down,” explains Hallett.

“Without proper rotation, populations can build up in fields to levels where pesticides may not be able to reduce economic impacts. About five to 10 per cent of the swede midge population will stay in the soil and overwinter for up to two years. Therefore, a three-year crop rotation away from canola on given fields is very important.”

Planting canola as early as possible so that it is well established before midge emergence helps prevent damage by swede midge, since

females prefer to lay their eggs in the early vegetative and bud stage before bolting.

“We are still working on identifying critical stages and swede midge numbers for developing action thresholds for insecticide application,” says Hallett. “We are targeting various stages including the vegetative rosette stage, the very early bud stage and secondary bud formation stage, and then conducting spray trials in either single or combinations of those timing to find something that will be the most effective and economical for growers.”

Pheromone traps that attract male swede midge are used to develop thresholds. For broccoli and cabbage crops, the action threshold is five males per pheromone trap per day. “We are still working on the levels for canola, but for now it looks like a similar level will be an important threshold in canola,” says Hallett. “We recommend growers set up four pheromone traps around each field and check two or three times a week. When checking traps, add up all of the midges, divide by the number of traps and number of days since last counted for a threshold count.”

Swede midge requires intensive field-specific monitoring, more than for most other pests. The timing of peaks in terms of swede midge emergence is a little different in every field, and populations can vary a lot within a field as well as between fields. Therefore, it is not possible to estimate populations based on other nearby fields. Hallett emphasizes there likely isn’t any other pest in canola that has to be managed that intensively or is more challenging across huge acres like swede midge.

There are currently two insecticides from different chemical families registered for use on swede midge in canola. Matador is a synthetic pyrethroid, which is effective on both larvae and adult swede midge. Coragen is in Group 28, a new class of pesticides known as diamides with a translaminer effect, which means that although it is not a true systemic, it can slowly move into the leaves and tissue it is applied to. Coragen is effective against larvae.

“In our various field trials, both products have been equally effective,” says Hallett. “Both Matador and Coragen are limited to three applications per season. Growers also need to be aware that if they have used the new Lumiderm insecticide seed treatment for flea beetles, also a Group 28 insecticide, then they cannot use Coragen for swede midge control in the same field in the same year.”

For Prairie canola growers, swede midge has not yet been found at populations that cause economic impacts. “Growers need to be aware of the situation and monitor in areas where swede midge has been found,” says Soroka. “A positive sighting of swede midge is when you can find larvae in the plant.”

There are several symptoms that can be similar to problems caused by other conditions such as heat, nutrient deficiency and other insect pests such as lygus bugs. For example, in 2014, over much of the province, canola plants developed palm topping or truncated ends that resembled swede midge damage but in most cases were not.

For now, Soroka recommends that growers in Saskatchewan should monitor for swede midge and consider using a three-year crop rotation in the areas where it has been identified to reduce the risk of swede midge on the Prairies. “It is the first emergence of the first generation that causes the most damage, so we need to determine what triggers emergence from overwintering, and how our temperatures and growing conditions may impact the lifecycle of the pest on the Prairies,” she adds. “We have also discovered a parasitic wasp that may offer some biological control options, which so far have not been found in Canada.”

More than just chemical control for insects.

by Bruce Barker

Integrated Pest Management (IPM) principles have been thrown around frequently over the past few decades, as instances of insect resistance have developed and growers around the world struggle to contain insect outbreaks.

Scott Meers, insect management specialist with Alberta Agriculture and Rural Development at Brooks, Alta., provides an overview of IPM, and says it has a good fit in Western Canada.

“Luckily, on the Prairies we have low insect levels most of the time, and while we do get some outbreaks, for the most part, utilizing IPM principles can help keep insects below threshold levels,” says Meers.

The United States Environmental Protection Agency defines IPM as “an effective and environmentally sensitive approach to pest management that relies on a combination of common-sense practices. IPM programs use current, comprehensive information on the life cycles of pests and their interaction with the environment. This information, in combination with available pest control methods, is used to manage pest damage by the most economical means, and with the least possible hazard to people, property, and the environment.”

Meers says that as you think about IPM, think about everything you do in the field. “It has an impact on something else. Your fertilizer isn’t separate from your weed control. It is not separate from your disease control, and is not separate from your insects. It is all one ecosystem and we have to think of it that way,” he notes. “We manage that ecosystem, we manage it to quite a large degree, but there is a lot of stuff going on, and if you think one thing is unconnected to another, then you’re going to get yourself in a wreck.”

Meers says IPM is a continuum and implementing it doesn’t mean all or nothing. It’s not spraying or not. Indeed, spraying is part of IPM.

There are several reasons why IPM makes sense. Public image is one of them, and the public discussions about GMO labelling in the U.S. or neonicotinoid use and the impact on bees are examples that agriculture is becoming more closely scrutinized. IPM is one of the tools that can help show that farming uses ecologically sound approaches.

Additionally, the rules that apply to all populations in nature apply to the farm as well. If there is too much of a good thing, like a quarter section of monoculture wheat, and tight rotations, something is going to try to eat it, and will adapt to the new environment.

Insecticides may also not work, so only an integrated approach may be possible to control the pest. Wheat stem sawfly is a good example where insecticides don’t work, so researchers have resorted to IPM measures including resistant varieties and managing crop rotations.

Accurate insect identification is an important component in IPM, and ensures that insecticide applications are targeted at the correct pest and at the right control stage for the insect.

Meers says the cereal leaf beetle looks very similar to the two-spotted flour beetle. Both have the same colouring, but if

you sprayed the two-spotted flour beetle by mistake, you would have killed a beneficial insect.

“One of the things we do a lot of when we hear about cereal leaf beetle infestations is to spend a lot of time looking at them under the microscope to make sure it isn’t the two-spotted flour beetle,” notes Meers. “The difference is that the two-spotted flour beetle is hairy and has two spots that the cereal leaf beetle doesn’t have.”

Understanding the life cycle of the pest is also important. This helps to understand which pest stage is responsible for the economic damage, and can guide you if insecticide applications are warranted.

Holometabolism life cycles have four distinctive forms including the egg, larva, pupa and adult. Cutworm is a good example, and that pest’s larvae are usually responsible for the economic damage.

Grasshoppers are an example of a memimetabolish life cycle, which includes three stages: egg, nymph (juvenile of any instar) and adult. The nymphs usually cause the crop damage.

However, the stage that is monitored and the stage that is controlled may be different than the stage that causes economic damage. Bertha armyworm adult populations are monitored to predict infestations the following year.

The control stage depends on the insect species. Bertha armyworm is controlled at the larval stage, but with the cabbage seedpod weevil, the adult fly is controlled to prevent it from laying eggs in the canola pod.

“So, we have to know the intricacies of the lifecycle because once the weevil lays its eggs in the pod, you aren’t going to control it,” says Meers.

A classic case in predator-prey relationships is the one between the hare and the lynx. Scientists have studied this linkage for the past century, and even Hudson Bay trapping records have identified that lynx populations fluctuate in an eight- to eleven-year cycle closely linked to the snowshoe hare population. Meers says that same type of relationship exists in agriculture, for instance between an insect pest and a beneficial insect that preys on the pest.

“When outbreaks in hares develop, there is an increase in the lynx population. The same thing happens with bertha armyworm. Every time there is an outbreak in bertha armyworm, there is an increase in beneficial

With a broad range of high-performing wheat, durum and feed barley options, Proven® Seed ensures you have the right combination of inputs, technology and expertise best suited for your land. In fact, every Proven Seed cereal variety contains superior genetics and is designed for a unique set of local growing conditions to guarantee grower satisfaction. Talk to your CPS retailer to select the best Proven Seed cereal variety for your farm.

Learn more at provenseed.ca

insects. That’s why we have cyclical outbreaks of bertha armyworm,” explains Meers.

Meers adds that entomologists continue to gain a greater understanding of beneficial insects and their importance in Prairie agriculture. They have identified beneficial insects in many of our agricultural crops.

“What happens in the field if we go in and spray when we don’t have to and we artificially keep the bertha armyworm levels down at around threshold levels? You don’t get a build up of

Monsanto Company is a member of Excellence Through Stewardship® (ETS). Monsanto products are commercialized in accordance with ETS Product Launch Stewardship Guidance, and in compliance with Monsanto’s Policy for Commercialization of Biotechnology-Derived Plant Products in Commodity Crops. Commercialized products have been approved for import into key export markets with functioning regulatory systems. Any crop or material produced from this product can only be exported to, or used, processed or sold in countries where all necessary regulatory approvals have been granted. It is a violation of national and international law to move material containing biotech traits across boundaries into nations where import is not permitted. Growers should talk to their grain handler or product purchaser to confirm their buying position for this product. Excellence Through Stewardship® is a registered trademark of Excellence Through Stewardship.

ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. Roundup Ready® crops contain genes that confer tolerance to glyphosate, the active ingredient in Roundup® brand agricultural herbicides. Roundup® brand agricultural herbicides will kill crops that are not tolerant to glyphosate. Acceleron® seed treatment technology for canola contains the active ingredients difenoconazole, metalaxyl (M and S isomers), fludioxonil, and thiamethoxam. Acceleron® seed treatment technology for soybeans (fungicides only) is a combination of three separate individually registered products, which together contain the active ingredients fluxapyroxad, pyraclostrobin and metalaxyl. Acceleron® seed treatment technology for soybeans (fungicides and insecticide) is a combination of four separate individually registered products, which together contain the active ingredients fluxapyroxad, pyraclostrobin, metalaxyl and imidacloprid. Acceleron® seed treatment technology for corn (fungicides only) is a combination of three separate individually-registered products, which together contain the active ingredients metalaxyl, trifloxystrobin and ipconazole. Acceleron® seed treatment technology for corn (fungicides and insecticide) is a combination of four separate individually-registered products, which together contain the active ingredients metalaxyl, trifloxystrobin, ipconazole, and clothianidin. Acceleron® seed treatment technology for corn with Poncho®/VoTivo™ (fungicides, insecticide and nematicide) is a combination of five separate individually-registered products, which together contain the active ingredients metalaxyl, trifloxystrobin, ipconazole, clothianidin and Bacillus firmus strain I-5821. Acceleron®, Acceleron and Design®, DEKALB and Design®, DEKALB®, Genuity and Design®, Genuity®, RIB Complete and Design®, RIB Complete®, Roundup Ready 2 Technology and Design®, Roundup Ready 2 Yield®, Roundup Ready®, Roundup Transorb®, Roundup WeatherMAX®, Roundup®, SmartStax and Design®, SmartStax®, Transorb®, VT Double PRO® and VT Triple PRO® are trademarks of Monsanto Technology LLC. Used under license. LibertyLink® and the Water Droplet Design are trademarks of Bayer. Used under license. Herculex® is a registered trademark of Dow AgroSciences LLC. Used under license. Poncho® and Votivo™ are trademarks of Bayer. Used under license. All other trademarks are the property of their respective owners.

beneficials and you always have problems and they never go away. That’s how you can get into a cycle of always having to spray,” he explains.

Another type of beneficial control is disease. A fungal disease can kill grasshoppers, and nature has given the fungal disease a helping hand with something in the fungal reaction that makes the grasshopper climb to the top of the plant to die. This helps to disperse the spores to spread to other grasshoppers.

Beneficials are great, but pests can overwhelm them and cause crop damage. That’s when the sprayer becomes part of the IPM solution. On the Prairies, there are two kinds of thresholds.

Nominal thresholds are founded on a best guess based on experience and some limited research. The threshold for diamondback moth, for example, is based on experience.