TOP CROP MANAGER

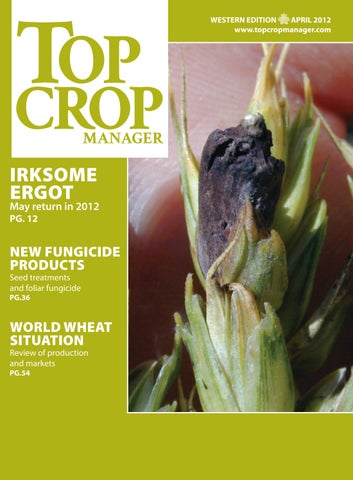

IRKSOME ERGOT

May return in 2012

PG. 12

N E w fu NGI c I d E

p RO duc T S

Seed treatments and foliar fungicide

PG.36

wOR ld w h E aT S IT uaTION

Review of production and markets

PG.54

May return in 2012

PG. 12

N E w fu NGI c I d E

p RO duc T S

Seed treatments and foliar fungicide

PG.36

wOR ld w h E aT S IT uaTION

Review of production and markets

PG.54

15 | Soil testing - The art of the science Interpretation of tests critical to recommendations.

By Rigas Karamanos

AND SEEDING 6 CTF 2011: a year in review

Craig Shaw, Durango Farms, Lacombe

effect of seeding date on yield

Donna Fleury

Irksome ergot may return in 2012

Bruce Barker

re-evaluating economic thresholds

Lisa Guenther

World wheat production and markets

21 | Farming lessons with variable rates in MZTRA

The jury is still undecided but things have been learned. By John

Dietz

Bean breeding program at Morden

Donna Fleury

AND NUTRIENTS

Cold temperature did not remove the risk of ammonia loss

Richard Engel, Clain Jones and Tom Jensen

getting the most from pre-seed weed control

Bruce Barker

precionpac explained

Donna Fleury

40 | New seed treatments foliar fungicides a review of new fungicide products for the 2012 growing season. By Bruce Barker

Help wanted: Spacetime consultants

planning your system - Fans and Vents

Digging into rooting depth

Lisa Guenther

MANAGEMENT 48 Field records network offers regional insight

John Dietz

Readers will find numerous references to

Crop Manager. We encourage growers to check

labels for complete instructions.

BRUCE BARKER | WESTERN FIELD EDITOR

Einstein’s Theory of relativity posited that all motion is relative and time is no longer uniform and absolute. Spacetime curvature showed that time depends on an object’s velocity. Sounds like agriculture these days, as we have seen rapid change and technological innovations that have moved at light speed. If you are standing on the sidelines, change is speeding up, and time is disappearing faster and faster.

over the last 10 to 15 years, we have seen the downsizing of the public sector’s extension programs, the rise of independent (and franchised) agronomy consulting businesses, the widespread adoption of precision farming technologies, the growth of mega-farms, and the end of single-desk selling of wheat and barley.

at press time, The Canadian Wheat Board had signed its first grain handling agreement with Cargill, and Viterra was a take-over target. What is coming next – greenpeace agreeing with CropLife Canada that gMo technology helps feed the world?

This rapid change means farmers are now more dependent than ever on outside, unbiased advice from knowledgeable consultants. In the oct 2011 issue of Top Crop Manager, writer Donna Fleury wrote an article about how to hire an agronomist for your farm business. The article is still relevant and outlines how hiring an agronomist is an important investment, and that the relationship must be a good fit for both the farmer and the consultant. The article is also relevant when looking at hiring other consultants such as accountants, lawyers, precision farming IT specialists, and grain marketing consultants.

Using these consultants can help slow down time to provide informed, rationale decisions on the thousands of choices made yearly on the farm. as a result, the farm manager can spend more time where it matters the most. perhaps that means hiring an agronomist to scout fields and provide advice on production. or it means having an accountant benchmark fiscal performance.

There is a reason that variable rate technology is finally starting to become more popular – consultants. When the technology first came around, farmers were encouraged to use yield mapping to try to develop variable rate prescriptions. The task was overwhelming for all but the most techsavvy farmers. Today, though, consultants are taking over the prescription writing and handing off a memory card to drive variable rate applications.

It is with this same philosophy that Top Crop Manager strives to deliver sound, unbiased articles to farmers and agronomists (Top Crop Manager is delivered to all Certified Crop advisors in Canada). our writers sort through what is happening in the field of new research and technology, and distill it down to what it means for agricultural production and profitability.

This issue focuses on timely topics to help get the crop in the ground and off to a fast start. The article on page 32 about preseed weed control discusses how to use preseed chemistries to “extend the usefulness of glyphosate and reduce the development of future glyphosate resistant weeds.” The issue of glyphosate resistance is one of the more pressing topics for farmers. glyphosate is one of the most important technological discoveries of the last century, and it continues to be important in helping to manage other herbicide resistant weeds.

So how dependent is agriculture on consultants? Fifteen years ago we all took pride in driving a straight line down the field – without guidance. now, if autosteer isn’t working, the machinery is likely parked until the IT consultant drives out (or remotely) fixes the problem.

From agronomy through IT, grain marketing and accountancy, consultants are in demand. The question over the next few years is whether there will be enough consultants to slow down that space curve so that Canadian farmers can remain at the forefront of agricultural production, marketing and profitability.

APRIL 2012, voL. 38, no. 8

GRoUP PUBLISHER Diane Kleer dkleer@annexweb.com

WESTERn FIELD EDIToR Bruce Barker • 403.949.0070 bruce@haywirecreative.ca

WEB EDIToR David Manley • 519-428-3471 ext.261 dmanley@annexweb.com @AgAnnex

WESTERn SALES MAnAGER Kevin Yaworsky • 403.304.9822 kyaworsky@annexweb.com

EASTERn SALES MAnAGER Steve McCabe • 519.400.0332 smccabe@annexweb.com

SALES ASSISTAnT Mary Burnie • 519.429.5175 888-599-2228 ext. 234 mburnie@annexweb.com

PRoDUCTIon MAnAGER Angela Simon PRESIDEnT Michael Fredericks mfredericks@annexweb.com

4N5 e-mail: subscribe@topcropmanager.com

Printed in Canada ISSN 1717-452X

CIRCULATIon e-mail: subscribe@topcropmanager.com Tel.: 866.790.6070 ext. 211 Fax: 877.624.1940 Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTIon RATES

Top Crop Manager West - 8 issuesFebruary, March, Mid-March, April, June, October, November and December1 Year - $44.25 Cdn. plus tax

Top Crop Manager East - 7 issuesFebruary, March, April, August, October, November and December - 1 Year - $44.25 Cdn. plus tax

Specialty Edition - Potatoes in Canada - February1 Year - $8.57 Cdn. plus tax

All of the above - $76.19 Cdn. plus tax Occasionally, Top Crop Manager will mail information on behalf of industryrelated groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2012 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

A look back on a new Controlled Traffic Farming project

by Craig Shaw, Durango Farms, Lacombe

We completed year one of both the CTF (Controlled Traffic Farming) project and also implementation of controlled traffic on our farming operation in 2011. I would start by saying that we probably didn’t appreciate the scope of implementing CTF when we started nor understood the challenges of bringing all the pieces together successfully in one year.

The complexity of this issue was compounded by bringing other variables into play while trying to chart a future path based on unproven options. We have a better appreciation of the term bleeding edge. as an early adopter of direct seeding I would suggest that CTF is a much more complex situation with more variables to sort out. generally with direct seeding if we got the seeding and fertilizing issues sorted out, we still had a degree of flexibility with our other operations. With CTF every operation on the field needs planning and implementation. The message here is regardless of good planning, the process will likely take time in order to sort out all the variables.

The second comment is that there truly is a lack of support in this sector. There is a degree of frustration in that for the most part you are working counter to most current trends in agriculture. The one exception is precision ag. but even there we are still ahead of the adoption curve and seeking solutions that are not priorities for that sector. The biggest frustration is working through compatibility and serviceability issues.

a third comment is that there is a certain degree of frustration with the fact that our system somewhat ties our hands down the road. This is not an issue that can’t be dealt with but will be a factor in adoption. We are in an industry that is continually evolving and putting restrictions on that will not be welcome.

This leads into the fourth comment and that is it takes a strong conviction and dedication to move forward in something that has yet to prove its value in our conditions. This conviction and dedication needs to be by all involved. I look forward to the day that we can show the consequences of doing things right or wrong. These comments only reinforce the need for the project and a focus to make sure we do things right.

It would seem that maybe Mother nature wasn’t keen on CTF as it brought its full fury to our project field. our runoff in the spring did some severe erosion and washed enough sediment down in the field that it actually changed the flow of water. This

<LEFT: The combine auger was extended to allow the grain cart to follow the tramlines.

BOTTOM: The Salford drill performed well but needs fine tuning in the system.

created some extra ponding that had to be dealt with. We did manage to seed the crop without too much difficulty although we did get stuck a few times and found traction with our seeding system was an issue. The seeding unit worked fine although with all new equipment there were some start up and operations issues. although we used two-year-old high germ seed we did run into some areas of the field where the seed literally rotted in the field.

The crop eventually started coming around but was then hit with a 4-inch deluge of rain and hail that left drifts in the field on July 11. Hail damage came in at over 80% on the balance of the field. We were then forced to weigh some different options of how to proceed. It was decided that we would silage the northeast corner of the field that was the check part of the field (26 acres). Silaging happened about mid august after the field had a chance to dry a little. By this time the majority of the field had stooled out and left us with two stages of growth.

We then tried to pick a time to desiccate the rest of the field at a time where we hoped the late growth would shrivel up and be blown out the back of the combine. We combined a small patch ahead of the field and found our next issue. The field was loaded with ergot and well above levels even for feed. on harvest completion we delivered the grain to Clive seed clean plant where the ergot was separated. It was interesting that after thins and ergot were removed the remaining crop graded a #2 and was high protein. estimated yield was about 25 bushels to the acre. We did some renovation of water runs fall 2011 and proceeded to fall band nitrogen and potash requirements. The field is slated for feed barley in 2012. We did not do yield for the field but do have yield data for the CTF area.

It was our intent to move forward quickly on the balance of the farm implementing CTF but that plan has had a major re-think. It was felt that with the investment and the fact that it will take time regarding the compaction issue to resolve itself that the correct strategy was to implement quickly. We have now taken a more conservative approach for the following reasons. our biggest issue that arose was that when we finally got our swather (30 ft.) home and started fall operations we discovered that the table was a few inches smaller than that of the combine tables. This became an issue in canola where we found we were leaving some strips in the field. The fact that we never resolved our swather auto steer issue did not help this situation. We feel that the option of using the swather was important so we have decided that for the balance of the farm we are going to establish new tram lines based on a narrower seeder width (29.6 vs. 29.10 feet). We will maintain the CTF plot as is and if necessary straight cut canola when it is in the rotation.

This changing of widths means we need to start over for next year. The next issue is that we want to use the disk drill for canola and we have a large acreage next year. Finally we have about 600 acres of hay and sod breaking for which we also want to use the Salford drill. We are currently quite concerned that with the lack of heat units we have experienced the last two years there is a need to seed as quickly as possible in the spring. Therefore the plan is working more around keeping both seeding units going and getting the job done quickly. In a year’s time we feel we will be in a better position to implement more CTF. For 2012 we plan on bringing one more field (175 acres) into CTF.

We bought a Fendt front wheel assist as our CTF tractor and would say that we are very happy with this decision. pentagon Farm Center was very good to us and exchanged back axles and got us the axle extensions for the front to get to a 120-inch wheel gauge. The tractor has performed well and has seen a lot of use. The fast highway speed has shaved down time but makes us feel like turtles in other equipment. The spools on the front have worked fine with no problems but we have a wheel seal to fix at the end of the season. If we do have any issues it is one of traction and in this very wet year we did have problems pulling the drill. The compact design of the drill is good for transport but can put the tractor and drill in wet spots at same time. We are not sure if this will be an ongoing issue or how we will address it. The tractor worked very well on the grain cart.

Salford 522 double disk seeder.

The drill we purchased also performed very well. We did have to go to a different tire on the rear of the drill to get to our 120-inch wheel gauge. We are not sure if this impacted our pulling issue but should improve as our tramlines harden. The drill is well built and we have had no breakage issues until late this fall when we bent two openers that hit a large rock. one thing we don’t like is the distance needed to turn around on headlands. This is because of the two tank, two rank system. We have in fact increased our headland length to accommodate the drill. The seed metering was good although we plan to add a slow meter kit for canola. The drill has worked fine being run by the Trimble FMX but we do plan to add run blockage sensors over the winter 2011. The stainless steel meter rolls are a plus as are the plastic tanks but we do have some caulking to be redone on the tank.

our drill is set up with cutting coulters running just ahead of the seed disks and just off to the side of the seed disk. We are starting to question the value of these coulters as their only true value is to cut straw ahead of the seed disks. While for the most part it does that and that has a value the question become is that the right place and right tool for the job. at higher speeds the coulters will move more soil and if that is what you want then maybe the coulters would be better on a different unit. We also found that in extremely hard conditions the coulters tend to carry some weight of the drill and that can impact penetration of the disks.

For the most part the sprayer, which we already owned, has worked fine. Since we had extended the booms out to 96 to tramline off another drill we just purchased four blank caps for reducing the width for spraying CTF fields. an issue that arose was that you needed to trick the controller settings as the controller would not allow changing boom configurations once you started the field. We still need to do a little

work getting boom configurations set right. We are still having issues with auto steer and tramlines. It would seem that when we got into side hills the auto steer would want to climb off the tramlines. This could be caused by some different issues: tilt, yaw, drift of the drill, etc. From the old school if you have good tramlines it’s easy to follow manually. our plan is to add crop dividers to give us a little more leeway.

a thank you to Hammer new Holland who flipped our drive tires (900’s) to get us to a 120-inch wheel gauge. We moved steering wheels so they followed the outside of front tire, which gave us some more frame clearance. They also set us up with unload auger extensions. We found we can hit the grain cart following tramlines although we are not quite centered on the cart. We could use another one or two feet to center. We did set up the combine with auto steer and installed our own new Holland kit. This was quite a process as it took us a few times to get the right cabling and then quite a process to get it running properly. The biggest issue was we could not get the rTK signal into the Intelliview. We think there is a solution that we will pursue over winter. We did have a steering ram breakdown near end of harvest so have some repairs to do there.

We are currently using easy Steer on the Fendt because it was not auto steer ready from the factory. We feel we are making a compromise using this system so are planning to upgrade to easy pilot (electric steer) when the bracket becomes available for Fendt. We have struggled with the precision farming aspect of CTF. We have a number of different systems and they all come with their own issues. The hope is that we will be able to standardize over time but that is not as easy as it sounds. Support is often poor and we have issues that some others don’t deal with. For the most part the Slingshot system (rTK correction) has worked well but it does add cost when you are running multiple units. We will be looking at own base station options. We are looking at some options in terms of guidance in the field and are planning to improve visual referencing as a back up to gpS and guidance. our plan is to move openers at the center of the drill so that we have visual reference on each 30 foot run. We are still not sure how we plan to handle tramlines but will continue with sprayer tramlines for sure.

our experiment with paired rows on the drill (7.5 and 12.5 inches) does not look like it will give us enough room to put the two rows between stubble next year. We had not counted on how much the crop spreads out. We will likely move to straight ten inch spacing for next year but remain intrigued by the paired row concept. If we were to move to putting openers on both ranks of the drill and removing the cutting coulters we would open up lots of options. We are still pursuing the planter concept for canola and that may come into play on our row spacing issues down the road.

We have also come across an issue as it relates to the combine. our custom combiner was not in a good mood this fall and it looks like this will become an issue if we increase CTF acres. We started to look at combine options and have become concerned that if we go to bigger combine capacity 30 feet may not be wide enough to keep the combine at capacity. In terms of one machine it will work much better with yield monitoring, etc.

We currently cover about 200 acres a year with liquid pig manure on the farm. Custom application does not work well with CTF. Hail ran us head on into the issue this year and silage and baling don’t work well for CTF. I make these comments because they will arise at sometime.

Adding PRE-PARE™ to your glyphosate gives you a longer lasting burndown of grassy weeds like wild oats and green foxtail. It also takes care of aggressive weeds like Roundup Ready® volunteer canola* and foxtail barley** PRE-PARE gets the weeds that can rob valuable nutrients and moisture from young wheat. So your wheat gets the head start it needs. And you get the yields you deserve. For the whole story, visit preparefortheseason.ca.

For a longer lasting burndown that includes grassy weeds

*Contact control only

**Contact control with 900 gae/ha of glyphosate

With thE support, stEWardship and innovation that only CErEal hErbiCidE pErformanCE Can providE.

Farming has become a business of higher technology. Only Cereal Herbicide Performance provides a full range of high-performance, technologically-advanced crop protection options to help safeguard your investment. So you can produce the highest cereal crop yields possible. Plus real-time planning and advice. Investment in research and development. Innovations in formulations and packaging. Cereal Herbicide Performance. We set the standard with twelve highperformance products for grass and broadleaf weed control in western Canada. Contact our Solutions Center at 1.800.667.3852 or visit www.dowagro.ca today.

C E r E al hErbiCidE pErformanCE

With high levels over the last two years, ergot may return in 2012.

by Bruce Barker

Fuelled by a variety of factors, ergot was a grading factor over the last several years. Whether it returns in 2012 depends on a number of factors, but with fungicides ineffective, farmers who saw ergot in 2010 and 2011 should be wary.

In 2011, the Canadian grain Commission’s harvest sample program found that across the prairies, where western hard red spring wheat was downgraded from a #1 CWrS, ergot was the factor in about 26 percent of the cases. Those ergot figures were up over 2010, when about 9 percent of downgrades in CWrS were from ergot.

provincially, alberta was harder hit with 32 percent of CWrS downgraded in 2011 to #2 had ergot as a factor. Daryl Beswitherick with the CgC in Winnipeg cautions the harvest sample program is a voluntary program and isn’t statistically sound. However, it does provide a glimpse into the ergot situation.

“It isn’t a trend and isn’t getting worse. The amount of ergot

varies year by year, but 2011 was a bad year,” explains Beswitherick. plant pathologist Kelly Turkington with agriculture and agri-Food Canada at Lacombe, alberta says one of the driving factors for increased ergot infections in 2011 was cooler, wet weather that favoured the development of ergot spores in the spring. With more spore development, there is greater opportunity for the pathogen to infect a susceptible host. The key time for infection is during flowering of a cereal crop.

The fungus Claviceps purpurea, which infects many cereals and grasses, including rye, triticale, wheat, barley and crested wheatgrass, causes ergot. The black, grain-sized ergot sclerotia overwinter and germinate in the spring under favourable weather

TOP: Ergot in wheat south of Edmonton Aug 1999.

INSET: Infected florets produce a sticky, honey-like, secondary spore stage.

With revolutionary new technology like the UltraPro Canola Meter, Zone Command, and the Nova XP-820 Smart Cart, we help you drive yields and profitability higher than ever.

SeedMaster is the only farm equipment manufacturer to win multiple Innovation Awards – including the coveted Gold Innovation Award –at the 2011 Farm Progress Show.

■ Gold: UltraPro Canola Meter

■ Sterling: Nova XP-820 Smart Cart

■ Sterling: Zone Command

» Massive 820-Bushel Capacity

» 10-Zone Overlap Control

» Real-Time Product Weighing

» Flexible, Modular Design: 4-Tanks-In-1

» Move More Product Without Plugging

conditions to produce drumstick-like structures that release ascospores. These infectious spores are carried by the wind to host plants where they land on open florets, penetrate the ovary and initiate the disease cycle.

a secondary infection can be generated when infected florets produce a sticky, honey-like spore stage, which can be spread by insects, or dispersal by rain droplets to the florets of nearby plants for as long as flowering occurs. eventually, the infected seed ovaries become replaced by hard, dark sclerotia. These ergot bodies are then either harvested with the grain or fall to the soil. e rgot bodies rarely survive more than one year in the soil.

The most susceptible crops are rye, triticale and some grasses. These plants are open-pollinated, and have open flowers that allow easy entrance of the spores into the floret. Wheat and barley crops are self-pollinating, which provides much less opportunity for the spores to land on the female parts of the plant to initiate infection. Under some conditions, self-pollinating cereals may open their florets and become susceptible to infection.

Stress factors that lead to pollen sterility in wheat and barley can induce normally closed flowers to open, exposing them to ergot infection.

“If there is a bona fide deficiency, copper in wheat or boron in barley, that will lead to a reduction in pollen viability, will send a signal to the flower to open up and can lead to infection,” explains Turkington.

Copper deficiency in wheat has been correlated to ergot. research in alberta on park wheat showed that the application of 10 pounds of copper per acre applied as copper sulphate to the soil resulted in a yield increase from 13 to 43 bushels per acre, and the reduction of ergot sclerotia from 11 to 2 per square yard. The copper soil test showed 0.6 ppm DT pa extractable copper, which is considered marginally deficient.

Copper fertility levels were revised in the late 1980s to reflect research findings at that time.

Alberta soil copper levels for mineral soil diagnosis.

DTPA extractable. 0 – 6 inch depth

*In fields with high variability, where the copper may range from 0.2 to 2 ppm with a mean of 1 ppm, up to 50 percent of the land could be deficient and therefore responsive to applied copper, particularly when growing wheat or barley.

Source: Copper Deficiency: Diagnosis and Correction, a gdex 532-3. a lberta a griculture and r ural Development

a lberta a griculture and r ural Development ( ar D) information describes the usual order of response to copper deficiency is winter wheat>spring wheat>flax>barley>oats>peas>tritic ale>rye. Canola has not shown copper deficiency symptoms or responded to copper fertilizer when grown on soils considered very copper deficient for wheat or barley.

r esearch has identified copper deficiencies in the Black, g ray-black and Dark Brown soil zones in a lberta, and about three million acres are estimated to be significantly deficient. Under optimum conditions of high nitrogen and phosphorous levels, another three million acres could be deficient for sensitive crops like wheat.

a Finish study showed that where boron levels were low, boron application reduced the level of ergot in barley. In o regon, though, where boron and copper levels were considered adequate, the addition of boron did not produce a difference in the level of ergot infection.

“In this situation, with adequate levels of micronutrients, other factors are contributing to the ergot infection,” says Turkington.

If a micronutrient deficiency is suspected, farmers are encouraged to conduct strip fertility trials to determine crop response.

a number of other factors, including heat and cold stress at flowering, delayed maturity and late herbicide application may create stress that increases the potential for pollen sterility.

In wheat and barley, management factors that minimize stress on the crop will help prevent pollen sterility and the opening of the flower to infection. Turkington says increasing the seeding rate to produce a uniform stand will help to reduce tillering. Secondary tillers are often under stress from competition with the main plant, and can be the cause of infection. a uniform plant stand also helps to prevent a longer flowering period when cereals are more susceptible to infection.

Cultivar selection isn’t a major issue with ergot. Turkington’s colleague, Jim Menzies a plant pathologist with aa FC in Winnipeg says that all varieties of wheat and barley are susceptible to ergot, and small differences in infection rate are likely due to things like the timing of flowering or minor differences in the extent of flower opening.

“Differences in our current varieties aren’t due to any inherent differences in resistance to the fungus,” says Menzies.

Crop rotation is one of the better management strategies. Most ergot bodies remain viable in the soil for only one year, so rotating away from susceptible cereals for at least two years reduces the potential for ergot infection.

“When you look at the tight rotations with a canola-wheat rotation now common, one year between wheat crops is not enough time to have a significant impact on sclerotia levels,” says Turkington.

Mowing adjacent, grassy field margins prior to flowering can also help reduce the potential for ergot infection and thus the creation of a source of ergot spores. at harvest, the headlands may be more infected, and could be harvested separately. Delaying swathing or combining can also allow the ergot bodies to fall to the ground and result in lower levels in the grain sample.

Looking forward to the 2012 growing season, many areas of the prairies have a higher than usual sclerotia load in the soil. Weather will have a big impact on how well the ergot bodies germinate and spread spores. If prolonged cool and moist weather occurs again this spring, growers will need to use all their tools to help manage potential infections.

by rigas Karamanos, manager, agronomic solutions, Viterra

We all know the four steps in the soil-testing process (soil sampling, extraction and analysis, correlation and calibration, and fertilizer recommendations). The last step, fertilizer recommendations, encompasses the “art of the science” in the soil-testing process; however, it represents both a grossly misunderstood and a heavily contested part of the process. Soil-testing users are most often interested in the final outcome of the soil-testing process without being concerned with how the result came about. Is this process adhered to when new recommendations are offered? Here are some questions that I have attempted to find an answer to:

Question 1. Has the soil-testing process fundamentally changed in recent years? no, the process has remained the same. However, both interpretation and delivery of the four steps in the soil-testing process have undergone some fundamental changes as a result of:

• Changing management practices;

• a dramatic drop in soil fertility research in the last two decades;

• Increasing demands by users to have soil-testing databases adapted to current practices and cultivars without the support and the resources dedicated to research for establishing soil-testing databases that laboratories once had.

Question 2. What is different now from when soil testing was introduced in the mid 1960s?

Soil sampling – Traditional sampling schemes assumed that fields are uniform; therefore, they involved collection of randomly selected soil cores that are mixed together into one sample. Hence, the principle of “field representation” was developed. With banding of fertilizer, direct seeding, minimum tillage, no tillage, etc., statistical representation of the fertility level of a field almost seems to have become an exercise in statistics rather than a practical method of assessing the nutrient status of a field. averaging (mathematically or mechanically through sampling) of on-the-row and off-the-row nutrient levels often results in nutrient levels that relate to “nothing” and so would be inapplicable in other situations.

Chemical extraction and analysis – The soil physical and chemi-

cal characteristics represented by the soil analyses or soil tests probably represent the only factual information on a soil test report – factual because a sample was analyzed by a laboratory and a “number” was generated. Unfortunately, these “facts” are occasionally peculiar only to a certain laboratory and do not apply to another. Interpretation of these physical and chemical characteristics, however, is often influenced by a tendency to attribute “absolute” value to a soil test report, rather than accept it as an abstract.

I have argued in the past that a soil test report, usually one page in size, contains information in an abstract” form. “abstract” is defined in the oxford dictionary as “a summary or statement of the contents of an entity” (book, etc.). In the case of soil testing, the soil-test report is an abstract of all the scientific research carried out on a specific nutrient or, in some cases, the interaction between nutrients. The quality of the abstract will no doubt reflect the quality of the scientific research it summarizes and the ability and understanding

Serious growers take weed control personally. With three modes of action in a single solution, Velocity m3 herbicide provides enough raw power to take down your toughest broadleaf and grassy weeds. Take control of your Group 1-resistant wild oats and Group 2-resistant broadleafs.

For more information visit BayerCropScience.ca/ Velocitym3

Let’s DO this!

of the subject by those who wrote the abstract. That is why I often define soil testing an “art based on scientific data.” often, the “artist(s)” (e.g., state or provincial councils or committees, the laboratory agronomist) express(es) views that are difficult to trace back to scientific publications and often reflect the “artist(s)’s” experience. Therefore, knowing the “artist(s)” often is of critical importance in appending trust to the interpretive portion of a laboratory’s soil test report.”

a common misconception is that soil-test levels represent “plant available” nutrients (CaST 2000). “rather, soil test procedures sample this continuum by extracting different amounts of nutrients depending on the soil extractant. The extractant used will depend on soil properties and the overall purpose of soil testing.” [CaST (Council for agricultural Science and Technology). 2000. relevance of Soil testing to agriculture and the environment. Issue paper. CaST, ames, Iowa.]

Correlation and calibration – a soil test level by itself means absolutely nothing and, often numbers expressed in either ppm or lb/acre are given quantitative meaning that they do not have. These numbers are merely indices that obtain a meaning only when they are correlated with plant nutrient uptake and/or calibrated with plant yield. Understanding the rules of correlation is also extremely important, as highly significant correlations do not necessarily mean that changes in the yield of a crop can be fully explained by the variation in the soil test level of a nutrient. This is the one step that is the most commonly abused as people attempt to incorporate “innovations” into the soiltesting process.

Fertilizer recommendations – This is the most misunderstood, and at the same time, confusing, step in the soil-testing process. Ulti-

mately, all the effort placed in the three previous steps will culminate in a fertilizer recommendation. Contrary to common belief, there is no right or wrong recommendation as long as the soil-testing process has been adhered to and the basis (philosophy) of the recommendation has been communicated to the user. In a way, much of the problem in offering recommendations for direct-seeded and no-tilled fields probably lies with adherence by laboratories to the principle of sufficiency. This is not incorrect; however, implementation of this philosophy requires that a sample is taken and the latter is increasingly becoming a greater challenge. recommendations based on replacement can correct this problem, but at the same time, create another by generating recommendations for nutrients that are not needed.

Question 3. Who is doing the necessary research on recent farming innovations?

a lot of the research these days is in the form of demonstrations and testimonials. The advent of computers combined with “common agronomic sense” has also served as a substitute, actually often a very poor substitute, of soil-testing research. Many deductions have no scientific basis or proof that can be applied under a variety of conditions. The very limited research carried out by research units of government and universities focuses either on trendy subjects, e.g., variable rate fertilization, or environmental issues, although funding in this area is also starting to dwindle. In Western Canada, many other innovations are transferred from other areas, e.g., weak Bray/ strong Bray extraction for p, and with no calibration work or even chemical basis for their adoption in Western Canada.

Raxil® MD is the winner and undisputed seed treatment champion of wheat, barley and oats. Its new micro-dispersion technology provides uniform and thorough seed coverage resulting in strong emergence, superior plant protection and an increased return on your investment. Score an easy victory over the most serious early-season cereal diseases, including true loose smut and both seed- and soil-borne fusarium, without the application struggle.

Improved yield and disease resistance are the primary targets.

by Donna Fleury

At the Morden research Station, the edible, or field, bean breeding research program focuses primarily on pinto, navy and black market classes. However, other minor classes such as small red, cranberry, kidney and great northern bean research are also included in the program. “The navy and pinto bean market classes can eas ily reach 50,000 acres each and black beans often reach 20,000 acres per year in Manitoba,” explains Dr. anfu Hou, Scientist with a griculture and a gri-Food Canada ( aa are also working on a new market class called yellow bean, which is targeted to specialty niche markets like Mexico. This class is considered a premium market class and we hopefully will have a commercial cultivar available very soon.”

The main breeding targets of Hou’s program are improved yield and disease resistance. “Yield is not simply a single trait, so we have to put all of the good traits together to get a good yield,” explains Hou. “We select for a balance of both good yield and early maturity for the various market classes. The challenge is to bring all of the important traits together in order to get a good cultivar with good yield potential, disease resistance and good

The grain-marketing landscape is changing. But your farm business needs are the same. You want a good return, solid risk management and timely cash flow. Our team is ready to work for you. Whether you choose pooling options, futures-based contracts or cash prices, you can have confidence in the CWB. Our programs are built on 75 years of grain-marketing experience, backed by government guarantees and focused on farmers. Don’t miss out. Register now for program updates at www.cwb.ca/email

Prairie strong, worldwide

anthracnose is another disease that doesn’t show up very often, but when it does it can be devastating. Therefore, developing resistance is important. White mould or sclerotinia stem rot has also been a big problem in Manitoba, southern alberta and o ntario over the past few years. p lant breeders from across Canada are working together to develop good resistance to white mould. Hou is also working on resistance to minor diseases such as root diseases and viruses. along with breeding efforts to improve agronomics, the program is also

working on nutritional components that are important to consumers. Hou and other researchers are working together to try to improve protein quality. “although beans are relatively high in protein, we are looking for ways to improve the quality and in particular improving the sulphur containing amino acid content,” explains Hou. “We are just beginning the work of developing populations and it will take a few years to get suitable lines.”

Two new bean cultivars were registered in 2010 and will be available

through Canterra Seeds. “We registered a navy bean called aC portage, which is the first cultivar to have common bacterial blight resistance in Manitoba,” says Hou. “In our breeding plots, this cultivar has always done very well against common bacterial blight and we expect it to perform very well on farms. aC portage is also early maturing, upright and has very good yield potential.”

aC Carman Black is a new black bean cultivar that is also early maturing and has very good yield potential. “This variety has very good adaptation to the wet conditions around this area,” explains Hou. “o ver the past couple of years it has been very wet in this area, and this cultivar has performed exceptionally well.” Hou is working with Canterra Seeds to produce pedigreed seed and expects to have commercial seeds available in 2013.

Hou and his colleagues at Lethbridge and in o ntario continue to work towards improving bean cultivars, bringing several traits together to provide improved yields, disease resistance and other traits. “We have a good number of lines developed and expect to have more releases over the next few years,” says Hou. “although it is more of a challenge, our target is to try to develop a cultivar that has multiple disease resistance so the crop can withstand disease pressure from multiple diseases. Last year we hired a post doctoral visiting fellow from australia, who is doing wonderful work of putting multiple diseases together using molecular markers, to help support our research.”

Hou is grateful for the funding support of the Manitoba p ulse g rowers a ssociation for this molecular work and many other research projects. “The growers understand the need for our research, and we really appreciate that,” adds Hou. “We also appreciate the funding support from aa FC and the a gri-Food research and Development Initiative.”

Four years later, the jury is still undecided but things have been learned. It’s a lot like farming.

by John Dietz

Good farm science takes time and good weather. at the Manitoba Zero Tillage research association (MZTra) farm north of Brandon, a study on variable rate treatments for nitrogen fertility is going into another year.

The study began with Spring 2009, and results were reasonable, says earl Silinski, farm manager. However, the study was washed out by weather in 2010 and again last year. Maybe recommendations from the effort will be ready for the research farm’s 20th anniversary in 2013.

each year, the 640-acre research farm 17 km north of Brandon conducts hundreds of agronomic trials for the farmer members of the research association.

New opportunity

When it was being discussed back in 2008, variable rate applications for fertilizer were a new opportunity for farming. plumbing and valves for sectional control on application equipment was just hitting the mainstream market, along with software for writing prescription maps.

“We’ve had yield maps here since 2002,” says Silinski. “The guys on our board of directors wanted to find the most effective means of

identifying management zones for variable rate nitrogen applications. That was the natural question, could they save money on nitrogen and keep or increase the bushels harvested.”

The farm manager at the time worked with aaFC – Brandon researchers Dr alan Moulin and andrew Kopeechuk, and MaFrI provincial crops specialist, John Heard, to set up a design for comparing variable performance at the farm.

They decided to assess how variable rate nitrogen would impact crops in different management zones. They identified six methods for defining a field by performance and applied several in the trial design. These include:

Landform analysis – classifying the landscape into upper, middle and lower slope positions based on digital elevation data. Fertilizer rates can be tailored to slope position.

Soil test results - Intensive soil tests, with grid sampling, can guide in delineating management zones. The cost of laboratory analysis is

ABOVE: Earl Silinski finishing the winter wheat before a late summer rain at the MZTRA farm.

expensive for intensive sampling.

Satellite / aerial images – In-season photos from the air or space, both color and near infrared, have become readily available and can be used to aid in defining management zones.

Soil conductivity – This has been used in the United States to delineate areas with low to high productivity, and in Canada to delineate zones where high salinity reduces crop yield.

ground based sensors – a ground-based sensor, such as the greenseeker, can measure nitrogen deficiency in a growing crop and regulate in-crop application of liquid nitrogen fertilizer.

Yield maps - Yield map analysis has also been applied to the delineation of management zones, though this approach is not common in Western Canada

Trial sites for the variable rate treatments were set up on four fields for 2009 seeding. The sites were a minimum of 120 feet wide through three management zones to accommodate four treatments on each zone. The zones measure up to 700 feet long.

prescription maps were developed for four levels of fertility in relation to a target yield. The levels amounted to 100 per cent of the recommended nitrogen, 50 per cent, 150 per cent, and zero for an untreated check strip.

access to historic and current data is crucial to developing a good prescription for a field, he says. The MZTra did intensive grid soil sampling in the fall, and brought those results into a gIS map. They also overlaid yield maps from several years along with topographic maps, aerial photography and satellite images.

The minimum to prepare for variable rate applications on a family farm, Silinski suggests, is yield data and soil sampling. The soil sampling should be extensive, though not necessarily as intense as the MZTra requires for research.

as well, a gpS reference point should be taken for each soil plug and kept with the sample for later use. It will be needed for preparing the management zones map and for field history. The best practice is to return to the same sites each year for new samples that will reveal the ‘real’ nutrient picture for crop planning.

at the MZTra farm, the sampling protocol requires collecting 72 soil samples on each of the 12 trial strips. “That’s somethingly strictly for research purposes; not something to do as a farmer,” he says.

With the aid of a dealership, or agronomist, the family farm can use gIS mapping software to plot the yields and nutrient results onto a single map of the field prior to spring.

Then, a decision is needed for the number of zones that will be drawn across the field. He suggests three zones for the first attempt -normal, low and high – unless there are special features. The MZTra has stayed with the original three zones (plus check site) for research.

“personally, I think the zone boundary should change from year to year because land is always changing. on this farm, it was set up to be static because they need that base line,” he says. “of course, the whole field gets a new rate map every year based on the crop and the nutrient supply.”

Independent agronomists and various companies will enter the data and prepare the prescription. at first, that’s probably the safest plan – to develop a feel and some understanding of the territory on the office computer.

“a few of our members are interested in doing their own prescriptions. It’s something they can do themselves, after a while. If you have a bit of know-how, you can plug that data into your own software and come up with your own map,” he says.

Questions will arise in doing the prescription. Silinski asks himself, for the lower variable rate area do I want to just maintain the nutrients here or do I want to put something in the bank to build up the soil?

He also wonders about the limits of his equipment and lag time, travelling at 4 MpH or 5.8666 feet per second. It takes a few seconds for a rate change to move from the tank to the furrow. He wonders, should I keep the management zones simple and wide, or is the technology already ahead of me?

The point is, Silinski says, collect all the mapable data you have available for a single field and get it onto one field map, then draw the lines for management zones that will be used by the gpS steering controller on the tractor.

“our board would like to see the study continue,” he says. “They think there’s more work to be done. Does the technology save you money, cost you money? Is it something you can do yourself on the farm? Can we show it does pay off in fertilizing saving?

“In the first year, the numbers were favorable. It actually was working. We have a bit of fertility left over for 2012, and it didn’t harm anything, so maybe it’s working.”

Four things can be learned from the approach and from their experience to date, Silinski says.

Collect all the field data you can. Try it on a small scale, if you can. Start with a simple prescription. Keep good records, and try again.

Early seeding can mean higher yield potential and usually pays off in the end.

by Donna Fleury

Seeding dates vary across regions and between years, depending on weather, soil temperatures and other factors. There is a lot of research that shows an earlier seeding date usually translates into a higher yield potential for many crops.

“Seeding early normally translates into higher yields; however, it doesn’t necessarily mean that if you end up seeding later that you will have lower yields,’ explains pamela de rocquigny, provincial cereal crops specialist with Manitoba agriculture, Food and rural affairs (MaFrI) in Carman. “However, there are a lot of things that happen between when a crop is planted and when it is harvested. While important, planting date is only one of many yield-influencing factors.”

In Manitoba, cereals are usually seeded first because they germinate at lower soil temperatures and are more tolerant to early spring frosts. grain corn tends to be seeded early because it is a longer-season crop. Flax and canola usually follow, with crops such as soybeans seeded last. Seeding crops such as canola too early can put them at risk of a spring frost. Seeding early can also affect crop quality. “Seeding

early tends to mean a crop is harvested in a drier time frame,” adds de rocquigny. “as harvest moves into September or later, we tend to get showers starting that can lead to downgrading. early maturity can also reduce the risk of early fall frost resulting in crop damage and/or downgrading of quality.”

Data from Manitoba agricultural Services Corporation (MaSC) suggest that as seeding moves into the late stages of May, some crops have greater yield potential than others. The data shows that springseeded cereals, peas and corn yields have dropped to 85 percent of normal yield potential by the last week of May. However, canola, soybean and edible beans haven’t lost a lot of yield potential. If seeding is delayed into June, be sure to consider crop insurance deadlines. (See the Seeding Date effect on Crop Yields graph on page 26, taken from http://www.gov.mb.ca/agriculture/crops/cropproduction/ faa22s00.html )

ABOVE: Some crops do better seeded early, while others don’t suffer as much loss with late seeding.

“growers are reminded that one of the first steps to maximize yield potential is the seeding operation, regardless of seeding date,” says de rocquigny. “Mistakes made during the seeding operation are often irreversible, so extra care should be taken, regardless of the calendar date.” Uniformity is important for even maturity and ease of harvest. research has consistently shown that uniformity of seed placement (depth) is one of the first things that is lost once planting speeds exceed 5 mph. “In a spring wheat crop, trying to time a fungicide application

for Fusarium head blight suppression, for example, is much easier if the crop is all at one stage,” says de rocquigny. “a crop is obviously never perfect across a whole field, but anything that can be done to improve uniformity will help in the long run.”

In situations where crops are seeded later due to weather or other factors, there are still things growers can do to improve the yield potential. “If you have pushed the seeding date a bit later, look at variety selection and maturity dates,” explains de rocquigny. “Increase the seeding rate a bit, which will decrease the number of tillers, and hopefully get everything a bit more advanced in terms of maturity.” at the end of the year, if everything else goes right throughout the entire season, there is no reason growers can’t still get a 40-bushel wheat crop, which is around 10-year average.

Most growers are ready to go in the spring and seed as soon as the weather allows. “In 2010 we had producers actually seeding in a pril, with most of their cereals seeded by May 1,” says de r ocquigny. “We were getting calls asking if it was too early to seed. Typically May 1 is the usual seeding date, but if the seedbed conditions are good, it’s dry and the soil temperatures are right, then seeding cereals early should be no problem. If soils are wet and cold, it may be better to wait. With canola or other sensitive crops, it may be better to hold off until the risk of early spring frosts is over.”

For 2012, the season is shaping up for a more normal spring than in 2011, which started off with very wet fall conditions in 2010, followed by a very wet spring. The fall of 2011 was fairly dry, and de r ocquigny hopes that, depending on winter snows and spring rains, seeding conditions in 2012 will be closer to normal.

“The most important strategy for growers is to have a plan in place ahead of time, so you are prepared to modify or deviate from that plan no matter what the weather does,” says de r ocquigny. “Most growers spend time in the winter pencilling out costs of production and deciding which crops and rotations will make them the most money. That way they are prepared to make changes if necessary as the spring season approaches. Having a plan, being prepared and seeding early will set up the year for higher yield potential and better-quality crops.”

Folicur® EW fungicide protects the yield and quality of your cereals from disease pressures including rust, tan spot, septoria leaf blotch and fusarium head blight in wheat. The formulation provides growers with outstanding disease control without needing to add a surfactant on wheat, barley and oats. Solid investment protection so all your cereals are safe.

For more information visit BayerCropScience.ca/Folicur

New field research in Montana found greater than expected NH3 losses from surface-applied urea following applications to cold soil, including soils covered with a modest snowpack.

by richard engel, Clain Jones, and Tom Jensen

Common abbreviations and notes: n = nitrogen; nH4+ = ammonium; no3- = nitrate; nBpT = n- (n-butyl) thiophosphoric triamide; θv = volumetric soil water content

Surface application of n fertilizer, in particular urea, is a common management practice for dryland producers growing winter wheat in Montana and other portions of the semiarid northern great plains. Seeding usually occurs in mid- to late-September depending on weather conditions, then n is broadcast applied during the late fall, or winter if the snowpack is shallow (e.g. ≤ 15 cm), or early spring as long as fields will allow spreading equipment to drive on the surface without causing ruts. This is usually on cold soils (e.g. < 5°C or 41°F) that are either dry at the surface, frozen, or covered with a modest snowpack as described above. The practice of fertilizing fields in a separate operation is done primarily to expedite seeding operations. although most modern air-seeders, are capable of sidebanding n fertilizer below the soil surface where it is less susceptible to volatilization, many great plains growers will not utilize this practice as it slows planting operations. This is significant because individual farmers may need to seed 1,000 ha, or more, of winter wheat over a short interval of time resulting in considerable time constraints. In addition, warmer soil conditions at seeding allow the urea to be hydrolyzed and the resulting nH4+ converted to no3during the fall. The resulting no3- is susceptible to denitrification if saturated soil conditions occur at snowmelt the following spring.

Volatilization risks associated with surface-applied urea have been assumed to be minimal if applications were made during cold weather conditions. This opinion is founded, in part, on research and extension literature that often characterizes nH3 losses or risks as being greater at warm temperatures, and by inference, small at cold temperatures. numerous studies have investigated and reported on nH3 volatilization from surface-applied urea; however, we know of no study that has specifically targeted its measurement from cold soil with temperatures < 5˚C. In 2008 we began a study that focused on quantifying nH3 losses from surface-applications of urea and nBpT-coated urea performed during late-fall to early spring. The purpose of this article is to share a portion of the results obtained from this project. ammonia volatilization losses were quantified using a micrometeorological mass-balance approach with circular plots (40 m dia.), a center mast, and samplers

TOP: Field site near Harvre, Montana was covered with a trace of snow on the date of fertilization (March 26, 2009) for Campaign 5.

BOTTOM: Urea granules on frozen soil surface within one hour after application are beginning to dissolve and melt snow.

(Leuning et al., 1985) that provided for continuous measurement of nH3 losses. In all trials urea was surface broadcast applied to wheat fields at rate of 100 kg n/ha. Urea was treated with nBpT (1 g/kg) using a liquid agrotain™ formulation. ammonia losses were followed over 8 to 10 wks by exchanging the samplers approximately once per week (see engel et al., 2011 for details on gas sampling methodology and nH3 loss calculations).

Urea was surface applied to soils with temperatures < 5°C in eight campaigns. The total cumulative nH3 loss, expressed as a percentage of the applied n rate (100 kg n/ha), averaged 26.3% for these trials but was quite variable among sites (Table 1). The largest cumulative nH3 loss, 44.1% of the applied n, occurred during Campaign 10, which was conducted on a Brocko silt loam (pH 8.4) soil. The total cumulative nH3 loss exceeded 30% of the applied n in three trials conducted on acidic soils, including Telstad–Joplin loam (pH 5.5, Campaigns 3 and 4), and phillips–elloam clay loam (pH 6.4, Campaign 5). a commonality of all large nH3 loss campaigns (> 30% of applied n) was that fertilizer applications were made to a high-watercontent soil surface that resulted in the dissolution of urea granules. precipitation events that followed were ≤ 5 mm and scattered at least through the first 30 d after fertilization. Conversely, comparatively small nH3 losses (i.e. < 10% of applied n) were observed during Campaigns 1 and 11. These trials were characterized by urea applications to dry soil surfaces followed by a large precipitation event (> 18 mm).

Many studies on nH3 volatilization from fertilizers have noted that large nH3 losses are associated with an initially wet surface soil followed by several days of slow drying with little or no precipitation; and that n losses from urea are mitigated when sufficient rain or irrigation, typically 13 to 25 mm, occurred to move the n into the soil profile (Hargrove, 1988). our results are consistent with this review; however, they are unique in that we found cold soil temperatures did not provide protection against realizing large nH3 losses if the surface water content was high at the time of fertilization with little or no precipitation after application. For example, nH3 losses > 10% of the applied n rate occurred over the first week post-fertilization at Campaigns 3, 4, and 5, even though mean daily soil temperature (1 cm) over the sampling period averaged only 0.8, -0.7, and 1.2°C, respectively. particularly large nH3 losses (22.4% of applied n) were observed over the first week at Campaign 5. Field conditions at the beginning of Campaign 5 were characterized by a frozen soil surface with a trace amount of snow, and a soil water content (0 to 8 cm) near saturation (θv = 50%). During the first week, no precipitation fell and the volumetric

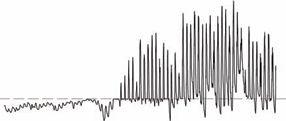

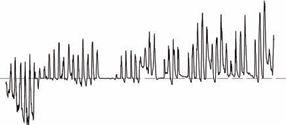

Figure 1: Urea and NBPT-urea was surface-applied (100 kg N/ha) to snow-cover fields during the winter at field sites near Willow Creek (right) and Denton (left), Montana. Ammonia N losses that resulted and soil temperature near the surface are shown below each respective photograph.

soil water content fell to 24.6%. Similarly, large cumulative nH3 losses equivalent to 24.3 and 20.7% of applied n were observed after urea was broadcast onto to field sites with modest snowpack at Willow Creek and Denton, Montana (Figure 1). The period of greatest emission activity followed the disappearance of the snowpack when the surface was drying, and soil temperatures were still cold. at Willow Creek this was associated with the 4th and 5th week post-fertilization when soil temperatures averaged -1.5 and 0.5°C. at Denton, this was associated with the 2nd week postfertilization when soil temperatures averaged 1.3°C.

The addition of the urease inhibitor nBpT to urea was effective in reducing nH3 loss in all trials. Total cumulative nH3 loss with nBpT averaged 9.7% of the applied n rate, a 63% reduction in volatilization compared with untreated urea. Mitigation of nH3 volatilization from urea by nBpT has been attributed to a number of factors

including a moderation of the soil pH rise that results with the production of ammonium bicarbonate (nH4HCo3) (Clay et al., 1990; Christianson et al., 1993); reduction in concentration of nH4+ in the soil solution around the fertilizer placement microsite (Christianson et al., 1993), thereby affecting the nH4+(sol) θ nH3(sol) θ nH3(g) equilibrium; and inhibition of hydrolysis thereby providing more opportunities for precipitation to infiltrate urea deeper in the soil where n is less susceptible to volatilization (grant et al, 1996). The benefit of nBpT was typically limited to 2 weeks on acidic soils (i.e. after 2 weeks post-fertilization nH3 losses were similar for the nBpT treated and untreated urea (Figure 1b). However, the benefit of nBpT persisted longer at the Willow Creek field site with a calcareous soil, suggesting that degradation of nBpT and/or its metabolites may have occurred more slowly at high pH. although this effect has not been documented previously in the field, a lab incubation study found degradation of nBpT and its oxygen analog

You know Raxil® seed treatment as the most effective opponent of smut in wheat, barley and oats. You trust it to have your back against seed- and soil-borne fusarium. And there is no doubt that it is the undisputed champion when it comes to return on investment.

So what’s this about Raxil WW? It’s all the above and more. It’s the sworn enemy of the dreaded wireworm. It takes it down and teaches it a lesson it will never get a chance to remember. Ring the bell for Raxil WW.

For more information visit: BayerCropScience.ca/Raxil

Weed resistance throws a wrench into herbicide selection.

by Bruce Barker

With the confirmation of glyphosate-resistant kochia in southern alberta, weed scientists are advising farmers to step back and re-assess their pre-seed weed control options. To help delay the onset of herbicide resistant weeds from developing, weed scientists are advising farmers to go beyond glyphosate-only applications and to apply products with unique or multiple modes of action.

“Look at what herbicides to apply or tank-mix together in a pre-seed application to better manage herbicide resistance,” explains Ken Sapsford, research associate at the University of Saskatchewan. “That is the short term solution, as weeds will adapt to selection pressure over time. In the long term, herbicide selection has to become a component of integrated weed management.”

Sapsford, and research scientist eric Johnson with agriculture and agri-Food Canada at Scott pulled together a pre-seed herbicide application chart, excluding glyphosate, to help guide farmers on herbicide selection to manage glyphosate resistance. glyphosate is still required in our direct seeding system, and by adding these other chemistries as a pre-seed application, we can extend the usefulness of glyphosate and reduce the development of future glyphosate resistant weeds

The chart also highlights the herbicides that control group 2

Adding other chemistries as a preseed burndown will help to extend the usefulness of glyphosate.

resistant biotypes of kochia. With most kochia populations on the prairies group 2 resistant, these red-starred herbicides would be the choice for farmers wanting to control kochia with a pre-seed application while managing glyphosate resistance. Where kochia isn’t a weed of concern, the other products not highlighted are also valuable for glyphosate resistance management.

“If you don’t have group 2 resistance issues, the group 2 products are still a good option,” explains Sapsford.

Sapsford also says farmers should consider all registered pre-seed applications, including soil-applied products edge and Treflan.

When it comes to protecting your high-value crop, you shouldn’t settle for anything but the best. Introducing DuPont™ Vertisan™, a powerful new fungicide for managing sclerotinia and other key diseases in canola, pulses, sunflowers and potatoes.

Vertisan™ is the next-generation Group 7 fungicide that stops disease in its tracks with residual, preventative and post-infection activity. No matter what the season brings, you can count on Vertisan™ to deliver high yielding, high quality crops.

More on planning your grain storage system.

In this issue, this column looks at the proper fan selection and the correct use of the time and energy-saver known as venting.

Fans a very important component of any aeration or natural air drying system is the fan. The fan is what moves air through the grain mass in the bin, causing it to be cooled or dried, depending on the application.

as briefly mentioned in the previous discussion about bin and aeration system selection, fan sizing will be determined largely by the ultimate goal of the application. For natural air drying to be successful, a large volume of air must be forced through the grain mass, which means that a larger, more powerful fan is required. For aeration or cooling however, a smaller volume of air and thus a smaller fan are required.

airflow is typically measured in cubic feet per minute (cu./ft./ min.), and there are some general guidelines you can follow to attain proper levels of airflow for each application. These guidelines are as follows:

For natural air drying, a minimum airflow of 0.75 cu./ft./min. per bushel is required when working with cereal grains, while a minimum airflow of 1.0 cu./ft./min. per bushel is required when working with oilseed crops.

When aeration is the aim, a minimum airflow of 0.1 cu./ft./min. per bushel, regardless of crop type, is required.

as you’ve probably guessed, a fan’s motor-size and horsepower will determine its ability to affect airflow, with larger, more powerful fans moving a greater volume of air. Thus, a larger horsepower fan will be required for natural air drying over aeration.

of course, fan size will also be determined by the size of the grain bin being used and the amount of crop to be aerated or dried, with larger bins requiring proportionally larger fans. another

CONTINUED ON PAGE 36

TOP: Roof vents help to prevent condensation from building up on the inside of the bin roof.

INSET: Low-speed centrifugal fans can perform well in lower static pressure situations such as those where shorter bins.

Infinity® herbicide is the only Group 27 and controls the toughest broadleaf weeds across the Canadian prairies, even if they are resistant to other herbicide classes.

Powerful and technologically advanced, Infinity represents the first new mode of action in cereals for over 20 years, providing the highest degree of yield protection for your wheat and barley.

For more information please visit: BayerCropScience.ca/Infinity

CONTINUED FROM PAGE 30

to occur more slowly in alkaline than acidic soils (Hendrickson and Douglass, 1993).

Implications and Management recommendations

Commercial fertilizer applicators and growers in the semi-arid northern great plains have long assumed that surface-applied urea was not susceptible to large volatility losses if applications were made during cold weather months. The results from this study indicate this assumption may not be valid, and that significant losses of nH3 from urea may occur even though applications were made to low temperature soils (< 5°C). In the semiarid northern great plains, fertilizer applications that occur during the late fall, winter, or very early spring will often be made to soil surfaces that are cold or frozen, high in water content, and sometimes covered with

a modest snowpack. Urea applications under such conditions appear to be susceptible to volatility losses, particularly after the surface thaws and dries. To minimize volatility losses, growers should probably wait until the soil surface is sufficiently dry such that dissolution of the urea granules will not result. If a large precipitation event (> 18 mm as either rain or snow) is received within a few days after urea is applied to a dry soil surface then volatility losses will be < 10% of the application rate. The urease inhibitor, nBpT, applied at a rate of 1 g/kg urea reduced volatility losses by approximately two-thirds compared to untreated urea. Use of nBpT may be appropriate during cold weather months if urea is being applied to a soil surface that is wet and frozen, or covered with a modest layer of snow. application of urea to a deep snowpack over a frozen layer of soil is not advised because of the possible movement off the field of dissolved urea in the surface runoff.

Reprinted from Better Crops with Plant Food, with permission of International Plant Nutrition Institute (IPNI).

CONTINUED FROM PAGE 34

general rule of thumb you can follow when choosing a fan is that horsepower should be increased by a factor of one per every 1,000 bushels of crop you are working with. For example, if you wish to aerate a 5,000 bushel bin full of wheat, you would likely use a five horsepower fan, whereas we’d recommend that you move up to a 10 horsepower fan if you wanted to aerate a bin holding 10,000 bushels of wheat.

For the type of climate conditions found across Western Canada, high-speed centrifugal fans are recommended as the best choice for achieving maximum airflow. These fans are specifically designed to deliver larger air volumes even under high pressure. Low-speed centrifugal fans may also perform well in these conditions, and can provide appropriate airflow volumes in lower static pressure situations such as those where shorter bins or large, flat storage buildings are being used or when the crop is piled.

now that we’ve covered fans, we’ll move on to discuss venting. Venting is an important and affordable option that can greatly increase the efficiency of new or existing aeration and drying systems.

To speed up drying and reduce fan horsepower requirements, the installation of wall vents on a grain bin can turn out to be a very good investment. The use of wall vents allows a tall bin to be aerated or dried in different stages or levels, thereby reducing the need to push air all the way to the top of the bin for the entire process.

The greatest benefit of wall vents, however, is that the producer has the ability to control the flow of air throughout the bin. Wall vents also allow for greater control over the conditions in the bin, which can reduce the amount of time required to finish the task and increase efficiency, which helps keep some of your hard-earned cash in your pocket. There is no real rule of

thumb for the placement of this style of vent, as wall vents can be placed intermittently along the height of the bin.

roof vents and their placement are another important component of aeration or drying systems that can help provide proper airflow in both applications. even when fans are not running, natural convection currents move throughout the grain when its temperature is warmer than the temperature of the ambient air above it. The use of roof vents prevents the warm, moist air that travels upward from becoming trapped up in the peak of the bin roof, where contact with cold roof panels can create condensation. This condensation can then drip down into the grain creating spoilage. The use of roof vents, however, allows the moist air to escape and greatly lessens the chance of moisture collecting on the inside of the roof.

now, when it comes to determining the correct number of roof vents needed, and locating them on your bin’s roof, there are some general guidelines that you can follow. When trying to decide upon an appropriate number of vents, as a general rule, we recommend one square foot of venting for every 1,000 cu./ ft./min. of airflow required for the application. as we’ve already noted, the amount of airflow required will largely depend on the application – natural air drying versus aeration – and the size of the bin and grain mass. By now we’re sure you’ve noticed how all of these concepts are tied together.

as far as placement goes, roof vents should be positioned approximately one-third of the way up the roof from its lowest point, which will help encourage convection drafts out through the vents.

on larger-diameter bins, you should also place additional vents at two-thirds of the distance up the roof sheet.

next time the series will discussing the various styles of aeration duct and flooring perforations, and how to select the correct one for your application.

For further information, got to www.grainguardian.com

Watch your crops grow stronger than ever before.

The unique Vigor Trigger ® effect of Cruiser Maxx® Cereals goes beyond insect and disease control, causing your plants to emerge faster, resulting in stronger plants and a higher return on your investment. Cruiser Maxx seed treatment also combines a powerful insecticide with two fungicides to protect your wheat and barley crops against early season disease and wireworm attack. It’s available as a pre-mix to apply on-farm.

An innovative approach to deliver customized weed control to growers.

by Donna Fleury

Dupont has developed a herbicide technology that provides growers and agronomists with more flexibility for customized weed control. Dupont precisionpac herbicides can be customized to target specific weeds present in a field with a specific herbicide blend. This technology is based on a numbering system similar to how fertilizer products are numbered.

“In 2011, precisionpac herbicides were made available in three main categories, each blend identified by specific numbers,” explains Kirk Dammann, product Manager precisionpac Herbicides in Weyburn, Saskatchewan. “The numbers represent the key active ingredients they contain, which is much like the way fertilizer blends are numbered.” The numbers are preceded by three designations describing their primary usage. a total of 12 precisionpac herbicides are now registered for use.

The three categories are: nC for non-crop or out of crop, pp for postemergent products in the black, grey-wooded and brown soil zones and DB is a dicamba blend suited for the brown and dark brown soil zones.

IThe letters designate the herbicide category, while the numbers indicate which active ingredients make up each blend. retailer locations that have the new delivery system can blend up to six different herbicide active ingredients in various ratios. (See chart. noTe: The actual names of the precisionpac products, as registered with the pMra, don’t have dashes between the numbers, but dashes are included here for clarity in this article.)

“The numbering system is used instead of names because each blend is a customized offering targeting certain weed spectrums,” says Dammann. “Using a post-emergent numbering example, pp 25-25 is a post-emergent product blend of equal amounts of thifensulfuron and tribenuron active ingredients. another example, pp 23-23-5 is a similar post-emergent blend with a percentage of the active ingredient metsulfuron included. The blends can be customized to provide anywhere from extended weed control to non-residual control.”

dentifying the active ingredients and their mode of action in herbicide products will help growers know if they have the right combination to address their weed spectrum and for managing weed resistance. “We are working with growers to help them learn to recognize the active ingredients in the herbicides they use,” explains Ken Sapsford, Research Assistant with the Department of Plant Sciences at the University of Saskatchewan. “As new products come on the market, such as numbered products like PrecisionPac herbicides, growers are able to determine the percentage of active ingredients in the blend.”

Understanding the active ingredients and modes of action is particularly important for managing herbicide resistance. There is research data showing that a mixture of modes of action in the same year is better than just a straight rotation of modes of action for managing herbicide resistance.

Identifying which mode of action is in each product blend helps growers know if they need to add something else to control their weed spectrum.