Inthe2to6leafstageofcorn,Ultim® Total™ takesover.Itprovidesexcellentone-pass controlofbothgrassesandbroadleafweeds,withknockdownandresidualcontrol. Evenlargerweedsandtoughperennialslikequackgrassandfieldhorsetailare nomatchforUltim® Total™.

Fertility and nutrients

Tom Bruulsema takes a hard look at corn crop nutrition in light of current markets, 6, 22 genetics and soil conditions. Check the latest in soybean inoculants. 8,

Learn about your options: ethanol and biodiesel.

Markets and biofuels 26,

Tillage or not?

Crop rotation is the most important aspect of tillage.

Published by:

Annex Publishing & Printing Inc.

145 Thames Road West Exeter, Ontario, N0M 1S3 (519) 235-2400, Fax: (519) 235-0798

Publisher & Editor

Peter Darbishire pdarbishire@annexweb.com

Associate Editor Chris Skalkos

Field Editor

Ralph Pearce rpearce@annexweb.com

National Sales Manager

Kelly Dundas kdundas@annexweb.com

Western Canada Sales Manager

Gerry Hertz – (306) 771-2686

Production Manager

Julie Turkheim

Production Co-ordinator

Colleen Brennan

Circulation Supervisor

Amy Penninga apenninga@annexweb.com

Printed in Canada. All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request.

Subscription rates: Canada/USAForeign

Western editions

Top Crop Manager – seven issues: January, February, March, April, July, November and December

1 issue$9.00$18.00

1 yr.$50.00$100.00

3 yrs.$100.00$200.00

Eastern editions

Top Crop Manager – five issues: January (Winter) February (Early Spring) March (Season Ready) August (Summer) November (Fall)

1 issue$9.00$18.00

1yr.$30.00$60.00

3 yrs.$60.00$120.00

Specialty edition

February (Potatoes in Canada)

1 yr.$9.00$18.00

3 yrs.$20.00$40.00 ALL OF THE ABOVE 13 ISSUES OF Top Crop Manager

1 yr.$80.00$160.00

3 yrs.$160.00$320.00

Send cheque or money order to Annex Publishing & Printing, Attn: Circulation.

Claims for missing issues must be made in writing within three months of publication and will be subject to the availability of back issues.

Associated Publications:

• Canadian Rental Service

• Drainage Contractor

• Glass Canada

• Ground Water Canada

• Manure Manager

Publications Mail Agreement #40065543

Return undeliverable Canadian addresses to Annex Publishing & Printing Inc., 145 Thames Rd. W., Exeter, ON N0M 1S3 Canada.

February 2008, Vol. 34. No. 7 ISSN 1717-452X

Iam going to borrow a statement to illustrate a point: “Major scientific breakthroughs must occur in basic plant physiology, ecophysiology, agroecology and soil science to achieve the ecological intensification that is needed to meet the expected increase in food demand.”

That was the conclusion of a paper presented to the US National Academy of Sciences in 1999 by Dr. Kenneth G. Cassman and it also provides the introduction to the feature by Tom Bruulsema included in this issue of Top Crop Manager He made that statement before the biofuels boom we are experiencing in agriculture, but at that time Top Crop Manager was carrying numerous stories about the future markets of specialty foods, biofuels, pharmaceuticals and other bio-products derived from agricultural crops.

I’m sure there were many who did not buy in to the idea they would be producing more than food as I’m sure there are still naysayers out there.

In the same week I read the quote from Cassman, I learned of workshops that were to be held in Alberta in January to address what have been dubbed ‘the Four Western

Canada Value Chain Initiatives’ and for the more advanced participant, the ‘Customer Focussed Collaboration’ program offered in March 2008. Coincidentally, I received notice of a Food Traceability Symposium at the Guelph Food Technology Centre in Ontario. Speakers there, from all corners of the world stressed how consumers are becoming more concerned about food safety and quality.

If we cast our minds back 10 or even 20 years, there are few of us who can claim to have predicted where agriculture has led them and even fewer who foresaw the potential it now has. Many, however, grasped opportunities as they came along, learned from mis-steps along the way and prospered as a result. What’s next? Those that remain in the long-term will be the individuals who not only challenge conventional thinking and the then-new-but-now conventional methods, products and techniques. They will approach their farming operations as professionals. They will use professional advice and expect professional service, and they will sell their products to professionals.

Farming is a commercial enterprise and it will react to market forces and demands: whether the end product is ethanol, biodiesel, life-style or medical drugs, healthy fresh or processed food, or feed for livestock, the entrepreneurs who are involved, from the farm to the elevator to the processor and even the marketer, also know they carry a responsibility to do so in a safe and profitable manner.

As the demands for greater bio-production increase, it will be ever more critical to use inputs wisely. ■

Peter Darbishire publisher and editor

by Tom Bruulsema*

I NTRODUCTION : “Major scientific breakthroughs must occur in basic plant physiology, ecophysiology, agroecology and soil science to achieve the ecological intensification that is needed to meet the expected increase in food demand.”

Dr. Kenneth G. Cassman

Long before the current biofuels boom, Dr. Kenneth G. Cassman concluded a 1999 National Academy of Sciences paper with this statement. The need for ecological intensification is all the more pressing today. And managing the nutrition of your corn crop is a big part of it.

Ecological intensification has several levels of meaning. First, it means growing more on less land to preserve natural ecosystems. Second, it means growing those higher yields with less impact on surrounding ecosystems, meaning minimal losses of sediment, nutrients and agro-chemicals. But the third level is probably the most challenging: applying the principles of ecology to make cropping systems more productive.

The first principle of ecology is that each living organism has an ongoing and continual relationship with every other element that makes up its environment. Managing crop nutrients ecologically, therefore, means that more than just the crop is affected by the nutrients you apply. You need to consider the longer-term effects on the cropping system and the soil ecology as well.

Healthy ecosystems are productive. Ecologists and crop producers therefore have similar goals in enhancing primary productivity – the capture of sunlight and its conversion to plant material.

Natural ecosystems waste little in the way of nutrients. Adiversity of plants takes up nutrients as they are made available. Ecological crop nutrition also strives to match nutrient supply to crop demand. How it is best done is constantly changing. New genetics changes crop demand and new technologies change the ways in which the demand can be met. And the list of ecosystem impacts to be considered continues to grow as well.

As breeders select for yield across a range of environments, new hybrids increase their resistance to stresses. Physiological studies show that today’s corn plant keeps its leaves active and keeps taking up nitrogen later in the season. As a result, more of the nitrogen mineralized from the soil’s organic matter is taken up.

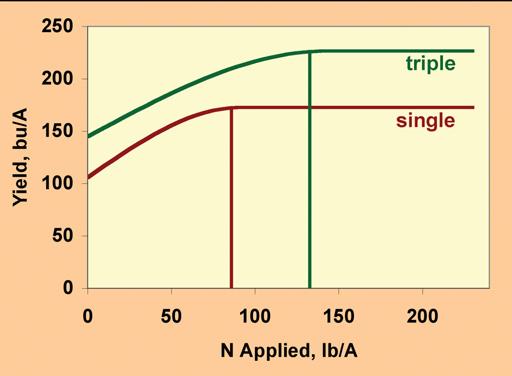

Fred Below, professor of crop physiology at the University of Illinois, recently pointed out that new hybrids respond differently to nitrogen. The general trend is shown in Figure 1, comparing a hybrid of the early 1980s to one that is grown today in central Illinois. The new hybrid yields more with less nitrogen, though the gain in yield per unit applied does not really differ. The major difference is capture of nitrogen from the soil. This historical change was also evident in Dr. Matthijs Tollenaar’s studies comparing hybrids from the 1960s and 1990s in Ontario.

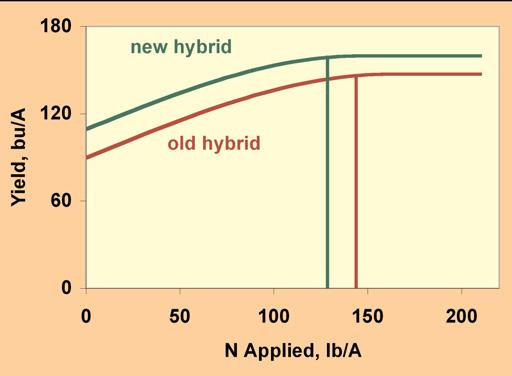

More recent work by Dr. Below shows a possibility that the Bt rootworm trait may have further altered response to nitrogen. At a single site in 2006, a ‘triple-stack’ hybrid including the Bt rootworm trait showed a large increase in both yield and optimum nitrogen rate (see Figure 2). The increased yield without nitrogen indicates, again, greater capture from the soil.

Is the new trait extending the life of the root system? Will this hybrid show the same difference next year? More testing will be needed before we can make any general conclusion on the effect of this genetic trait on nitrogen use efficiency. It is encouraging to see that,

Are new genetics keeping corn R roots alive longer to capture more soil nitrogen?

Figure 1. A new hybrid yields more with less nitrogen, compared to one popular 20 years ago. Mean of four years of data (Below, 2007).

so far, the direction of genetic change seems consistent with ecological intensification.

One of the keys to minimizing waste is to ensure the timing of supply matches that of plant demand. Alarge number of new nitrogen products are moving to market: some polymer coated, some chemically stabilized, some with inhibitors of urease and/or nitrification, and some with combinations of these. Are these products better than split application? Not necessarily everywhere, but for many soils and conditions, split application entails risks. Soil may be too wet at side dress time to get on to the field. In 2007, many soils were so dry that side dressed nitrogen – even fluids – did not get to the roots.

Controlled release products can potentially be more reliable and more convenient. But weather and many other soil factors can influence the rate of release, so it is important to evaluate these products to find which performs best in your own specific growing conditions. On-farm testing is key.

Soil ecology depends on organic matter. Soil organic matter needs inputs of roots and crop residues. Higher corn yields supported by optimum nitrogen management have been shown to contribute toward building soil organic matter. Crop rotations that include wheat under-sown to forage legumes also contribute toward this goal; and they need to be integrated with livestock.

Figure 2. A ‘triple-stack’ Bt rootworm hybrid responds differently than one with a single herbicide resistance trait. 2006 data (Below, 2007).

Nitrogen management affects not only the yield of the crop, but also the environment. Risks of nitrate in drainage water, ammonia gas transfer to forests and a possible contribution to smog, and nitrous oxide emissions related to greenhouse gases and ozone depletion all need to be considered. Each of these processes has different controls. Limiting one process can increase another.

Can you cost effectively manage to limit each of these loss processes? Owing to their complexity, not likely. The best you can do is improve nitrogen use efficiency to a level that gives you optimum effectiveness. Ecological corn nutrition depends on using time-tested best management practices to ensure the right source is applied at the right rate, time and place.

Key best management practices for nitrogen include:

• Crediting previous crops and applied manure.

• Determining yield goals from reliable information.

• Maintaining non-limiting levels of other nutrients.

• Crop management and hybrid selection for maximum economic yield.

• Timing supply to match plant need by either controlling release or split application.

• Placement below the soil surface, or incorporated where possible.

• Placing a balanced starter fertilizer close to the seed.

• Maintaining and calibrating application equipment.

• Designing the crop rotation to capture surplus nitrogen.

• Evaluating success using on-farm trials and soil and stalk nitrate tests. Global demand for food and fuel has returned profitability to crop production. This is the opportune time to test technologies to sustain those profits, using best management practices that enhance productivity, increase sustainability and improve environmental health as well. Doing so ecologically intensifies your corn nutrition. ■

References:

• Below, FE, M Uribelarrea, M Ruffo, SPMoose and AW Becker. 2007. Triple-stacks, genetics and biotechnology in improving nitrogen use of corn Proc. North Central ExtensionIndustry Soil Fertility Conference, Vol. 23:5-13.

• Cassman, KG. 1999. Ecological intensification of cereal production systems: Yield potential, soil quality, and precision agriculture Proc. Natl. Acad. Sci. USAVol. 96:5952–5959.

*Tom Bruulsema is director of the northeast region, North America Program of the International Plant Nutrition Institute in Guelph, Ontario.

by Jeanine Moyer* MARKETS

As biofuels continue to garner interest and support within the agricultural industry, many farmers who produce oilseed crops are at the centre of an exciting and evolving industry. Not only are farmers responsible for producing the soybeans to make biodiesel, but many are investigating ways in which they can add value to their crops by producing their own biodiesel. Throughout the month of November, farmers across Ontario had the opportunity to learn first-hand the science, methods and process of turning their soybeans into fuel.

canola, reaction and wash tanks, a resin filtration system to wash the biodiesel, a heater and generator that run on biodiesel and a methanol recovery system used in the production of the biodiesel.

“This is a unique opportunity to show producers how they can maximize the value of their oilseed crops and grow a product suitable for the expanding biodiesel market,” says Newkirk. Participants took part in each step of the biodiesel production process and learned not only how to make biodiesel but how to add value to their own crops by discussing various

Aseries of biodiesel short courses sponsored by Ontario Soybean Growers (OSG), Canadian International Grains Institute (CIGI) and the Agricultural Adaptation Council was offered to farmers. The short courses featured a hands-on approach where participants observed and participated in the various stages of the production of biodiesel, even making their own batch.

The course was led by Dr. Rex Newkirk, CIGI Director of Biofuels and Feed, who travelled to Ontario with a trailer outfitted to house the equipment necessary for the production of biodiesel. Completely self contained, the biodiesel trailer does not require any outside source of power to operate. The trailer features an oilseed expeller to squeeze oil out of the soybean or

aspects of plant design and the economics of biodiesel.

Adding increased value and providing opportunities like the biodiesel course to soybean growers is part of the OSG mission statement, guiding the organization towards a viable and profitable industry. Ontario soybean production represents approximately 80 percent of total Canadian soybean production. More than 2.1 million soybean acres were planted in Ontario in 2006, with an average yield of 46 bushels per acre (1.25 tonnes per acre). Total soybean production for 2006 was approximately 98 million bushels (2.67 million tonnes). In 2006, Ontario soybeans averaged 21.4 percent oil, making the crop a natural choice for biodiesel production.

Soybeans are the largest source of oil produced from agricultural crops in Ontario; the 2006 crop resulted in 618 million litres of soybean oil.

In the past, soybean markets have been driven by the value of soybean meal used for animal feed, however, the soybean market now has the added influence of biofuels. With the constant fluctuation of petroleum prices, a trend has formed and more are turning to biofuels as an alternative. Looking forward, Ontario could see an increase in biodiesel production as demand for renewable fuels grows.

“We expect to see an increase of biodiesel production of various scales,” says Crosby Devitt, Research Manager, Ontario Soybean Growers. “Small groups of farmers are interested in knowing that biodiesel production is one way to diversify their farming operations and increase on-farm value.”

In addition to the biodiesel short courses, OSG participates in policy development, government relations and communications towards the development of the biodiesel industry. ■

*Jeanine Moyer is Communications Co-ordinator for the Ontario Soybean Growers in Guelph, Ontario.

Option® Liquid is the only post-emergent sulfonylurea herbicide available in a liquid formulation. That means it’s easier to measure – especially when your fields don’t come in exact 20-acre increments.

Option® Liquid is the only post-emergent sulfonylurea herbicide available in a liquid formulation. That means it’s easier to measure – especially when your fields don’t come in exact 20-acre increments.

Option Liquid can be used from the oneto eight-leaf stage of corn. And it comes with a long list of broadleaf tank-mix partners for one-pass weed control.

Option Liquid can be used from the oneto eight-leaf stage of corn. And it comes with a long list of broadleaf tank-mix partners for one-pass weed control.

So you’re not doing laps out there.

So you’re not doing laps out there.

Don’t miss this opportunity to get special financing on everything you’ll need to be more productive this season—featuring genuine Case IH parts and factory-certified machine inspections. It’s the early bird that catches the savings! So hurry in now before this event ends.

Going on now at your local CASE IH dealer. www.CaseIH.com

by Karen Dallimore CROP MANAGEMENT

Forecast system assists spray decisions.

Agood weather forecast will tell growers what to expect from the skies but the team at Weather INnovations Incorporated (WIN) in Chatham, Ontario, will tell growers what they expect that forecast to mean. “We try to find relationships with weather and specific issues,” explains Ian Nichols, WIN’s business manager. WIN takes weather information, analyzes it and produces advisories to help producers with their management decisions relating to spraying advisories for fungicides, irrigation and a wide range of other specific services.

Collecting raw weather data is just the beginning. The question Nichols asks most frequently is: “How can we package it to make it useful for a grower?” So far the possibilities seem endless.

Up until 1999, the Ontario Ministry of Agriculture, Food and Rural Affairs delivered the weather-based TOMcast program to tomato producers. The TOMcast program aids in decision making for fungicide application for early blight, septoria leaf spot and anthracnose control on processing

tomatoes. When the government revised its delivery of services, Nichols and plant pathologist Dr. Ron Pitblado, the author of TOMcast and now WIN’s research manager, stepped up to the plate and developed their own delivery system for the program.

Nichols remembers thinking, “We’ve got a good model. Producers are using it. Let’s do it.” They bought three weather stations and began the Ontario Weather Network (OWN), which has now evolved to become Weather INnovations Incorporated, or WIN, as of January 2007.

WIN’s services are as varied as the weather itself. In addition to TOMcast they offer DONcast for wheat producers, a service that provides maps to forecast the amount of deoxynivalenol toxin (DON) in winter wheat that allows producers to decide at the time of heading whether a control measure is desirable, and BEETcast for cercospora leaf spot control in sugar beets. SPUDcast, a program that addresses fungicide application for early and late blight in potatoes, is now in the development stage.

Aside from their specific forecast models for agriculture, they also provide accurate weather data to companies as an independent service, such as rainfall data for the forage

derivative program at Agricorp, temperature validation for the ice wine harvest for the Vintners Quality Alliance (VQA) program, or data for weather derivative insurance plans at the Saskatchewan Crop Insurance Commission.

In 2006, WIN teamed up with Environment Canada to develop a pilot program for a Spraying Conditions Advisory. Until recently, Health Canada’s Pest Management Regulatory Agency has required certain pesticide buffer zones – unsprayed areas that have the potential to create management issues as reservoirs for insects and diseases. This project offers a three day weather forecast, narrowed down to specific regions, in order to more accurately identify the best spraying times during the next three day window. This is being studied as an alternative to adjusting the size of the currently required buffer zones.

One hundred growers were asked to participate in the pilot project; one-third of those responded to the survey and 62 percent found the program useful enough to adjust their practices in 2007. The balance indicated that they would like the information available for 2008 even though the information did not change their plans in 2007. According to Nichols, the forecast model that WIN

NewDuPont™ Galaxy™ goesbeyondglyphosatetoprovideresidual,one-passweedcontrolinglyphosate-tolerantcorn. Itimprovescontroloftroublesomeweedsincludingfallpanicum,greenfoxtailandredrootpigweed.Withtwoactiveingredients fromdifferentherbicidegroups,Galaxy™ helpsprotectagainstweedshiftsandresistance.Takeyourweedcontroltoahigher levelthisyear–withnewDuPont™ Galaxy™.

Questions?Askyourretailer,call1-800-667-3925orvisitwww.dupont.ca/ag

Withanycropprotectionproduct,readandfollowlabeldirections. TheDuPontOvalLogo,DuPont ™,Themiraclesofscience™ andGalaxy ™ areregisteredtrademarks ortrademarksofE.I.duPontdeNemoursandCompany.DuPontCanadaisalicensee. MemberofCropLifeCanada.©Copyright 2008DuPontCanada.Allrightsreserved.

has developed has the potential to provide the Spraying Conditions Advisory right across Canada and they are now sorting out the business plan to do so.

Another project has WIN working with Marc Knight, agriculture manager with France based Bonduelle North America, which recently acquired Carriere Foods in Tecumseh, Ontario, near Windsor.

In 2003 the bean leaf beetle began to migrate northward from the US to threaten Bonduelle’s 2500 acres of green and wax beans, causing some severe damage to bean pods just prior to harvest and affecting quality at the consumer level. The same beetle has been targeting soybeans as well. “We weren’t prepared,” Knight admits.

How does the pest behave? Is the beetle more active in warmer weather? When do the first and second generation adult beetles develop and how is that correlated to weather? Will mild winters increase the threat? In a co-operative effort with the Ontario Processing Vegetable Growers, Bonduelle is now working with WIN as part of their effort to better understand the life cycle of the bean leaf beetle as it relates to the weather.

“In the food business we need optimal product without spraying more than you have to,” says Knight, who needs to know when it is best to start scouting and when to spray. Although they do have a spraying plan in place, Knight hopes to use the data they will collect to optimize their program by the end of 2008 in case the bean leaf beetle decides to migrate further to the 3500 acres of beans they have in the Strathroy area.

Potato growers can look forward to SPUDcast, a system presently under development, to assist them in deciding when to spray to control early and late blight in potatoes. WIN uses ‘SPUD’ values to rate the weather conditions of each day according to their favourability to the development of these foliar diseases.

For irrigation purposes WIN also creates charts from multilevel soil moisture readings that allow growers to almost ‘see’ the soil moisture on the graphs. With water issues becoming more prevalent, this data will become very important to help producers decide when to irrigate. One company even has temperature probes stuck in their sugar beets to help growers decide when to harvest.

Already, programs like DONcast have taken the leap onto the worldwide stage, running in Uruguay in collaboration with researchers there. “Crops are similar and disease patterns are similar,” says Nichols, adding that with a few adjustments there is no reason that WIN’s forecast programs cannot be used around the globe.

Nichols sees his company as playing an intermediary role between meteorologists, researchers and growers, helping producers to use science on a regular basis. While some programs such as wind machine operation in grape vineyards or irrigation need to be one-on-one to provide the accuracy needed, Nichols advises smaller independent growers to contact their grower organization to work together to make the best use of the time and resources required to deliver custom programs.

Producers need to be able to access information that is timely, precise and clear, while researchers need to improve their models using field data. WIN plays a role in ensuring that information continually flows both ways. ■

Circle 6 on reader reply card

Although the Canadian farming industry has experienced some difficult and challenging times during the past two decades, ranging from inclement weather, soft crop prices to increased competition from growers in South America and Eastern Europe, to the BSE and Avian Flu outbreaks – I would venture to say that this is one of the most exciting and promising times to be in agriculture in Canada.

Commodity prices in corn and wheat in particular had an amazing rally in 2007 and are currently at peak levels. This bullish trend, which will likely continue over the coming years, thanks to various global macro-economic and environmental factors, is expected to bring crop prices to new levels never attained before. We are looking at a potential market shift that is even more profound than the ones that occurred during the 1970s and ‘80s.

Some of the factors that have been driving crop prices upwards are attributed to the ongoing increase in crop consumption that surpasses production volumes (demand-supply) and have depleted global carryover stocks and inventory; the changing diets of the continuously growing middle class in China and India; and the rise in crude oil prices coupled with a strong environmental agenda that pushes for alternative energy resources such as corn produced ethanol.

The emergence of the bio-economy

The surge in crude oil prices in recent years along with consumer pressure and governments’ understanding of the need to reduce greenhouse gas emissions have been driving the quest for renewable and environmentally friendly energy resources as an alternative to fossil fuels.

As a result, ethanol production from corn continues to rise not only south of the border but in Canada as well. It is expected that in the very near future, ethanol produced from corn in eastern Canada will reach 1.3 billion litres, sufficient to cover about two percent of the overall Canadian fuel for transport

by Jay Bradshaw*

requirements. Indeed, the debate about the feasibility of ethanol as a renewable energy resource is still on, but I strongly believe we have passed the point of no return on this front. Ethanol production from agricultural commodities as a major energy resource is here to stay.

The continuous investments in research and development, and technological advances such as corn amylase technology which enables the use of a special enzyme already contained in the corn grain to improve the ethanol production process, are only some examples of the forces that will continue to drive this industry further.

Another evolving sector that has the potential to positively impact the Canadian agricultural industry has stemmed from the global trend of reducing dependency on petroleum. The emergence of biodegradable products usually produced from petroleum, such as machinery lubricants, synthetic rubber, paints and various plastic products from bags and cups to auto parts, can now be made of canola, corn and soybean oils, leaving limited environmental footprints, if any.

Holistic and synergetic

To ensure the sustainability of the Canadian agricultural industry as a whole, all of us will have to re-think the way we operate. Taking a holistic approach that looks at the entire production and growing cycle of crops will ensure the sustainability of growers’ businesses – financially, operationally and environmentally – for the short and long-terms.

Coupled with these new and unique initiatives, we continue developing strong partnerships with our customers. One example, Leadership At Its Best (LAIB), is a partnership that targets grower associations across Canada. Aimed at providing these influential groups with a variety of leadership and business development tools to enhance their skills, LAIB encourages strong and effective grower associations that demonstrate agricultural leadership in Canada.

At Syngenta, we are looking at new ways we can support growers in this ‘total approach’ model, providing sound agronomic counsel coupled with best practices in seeds, seed care and crop protection, all the while ensuring good land stewardship as well as environmental and social responsibility.

From an industry-wide perspective, to capitalize on these market shifts and global trends, the Canadian agricultural industry has to work in synergy through co-operation with all stakeholders in the value chain. To be successful, not only in capturing new opportunities but to maintain a competitive edge on a global basis, strategic alliances will be formed.

As the global agricultural sector continues to expand its role as a major resource for other industries – such as energy, cosmetics, pharmaceutical, automotive and others – the Canadian agricultural industry is on the verge of a turning point with great opportunities and challenges lying ahead. New approaches to farming and the establishment of partnerships with traditional and new players within and outside the industry will become major keys for success. ■

*Jay Bradshaw is president of Syngenta Crop Protection Canada, Incorporated.

AgricultureisthebackboneofastrongandhealthyCanada. Food,health,energy,theenvironment–theseareexcitingtimes.

Asaleaderinourindustry,FCCisadvancingthebusinessof agriculturebytakingthismessagetoCanadians.Tohelp, we’vedevelopedaTVcommercialseenbyover10millionCanadians, aswellasavarietyofotherpromotionalproducts.

Weencourageyoutotellthestory,too.Gotofcc.ca/advancingortoyour localFarmCreditCanadaofficetopickupstickers,bagsandmore.

Whileyou’rethere,discoverFCC’sinnovativefinancingproducts, managementtrainingservicesandevenventurecapital–alldesignedto helpyourbusinessgrow.Inthisbusiness,noorganizationcanmatchFCC’s depthofknowledgeandexperience.Andwhenitcomestoagriculture, nocountrycanmatchours.

Formoreinformationcall1-888-332-3301.

The first new mode of action in cereals in more than 20 years.

New Infinity™ represents a giant leap forward in broadleaf weed control. Infinity belongs to an entirely new group of herbicides (Group 27) that provides superior control of the toughest weeds in cereals – including Group 2-resistant weeds.

It is a simple and flexible broad spectrum solution that gives you infinitely better control in wheat, durum and barley.

In late 2004, word of the spread of Asian soybean rust from Venezuela to the Gulf Coast of the US put researchers across the US on high alert as to the potential for the disease. Yet despite presentations, publications and other printed materials, the threat never materialized much beyond states such as Tennessee or Louisiana.

However, the 2007 growing season has seen the arrival of Asian soybean rust (ASR) in some of the mid latitude states. Oklahoma and Kansas had confirmations of ASR in August and September, respectively, and it was confirmed in Indiana on October 23, yet discounted as posing no significant threat. Yet as of October 29, the disease was confirmed in two counties in Illinois and 14 counties in Iowa, with the northernmost of those confirmations at roughly the same latitude as southern Ontario.

While that might cause concern for growers in the Great Lakes Basin, there is still a cushion: Iowa and Indiana are still several hundred kilometres away.

The fact is, ASR spores were detected in Ontario during the 2007 growing season. However, thanks to dry weather conditions in the southern US and the size and concentration of spores found in Ontario, growers have been spared any ill effects, at least for now.

“Conditions were not favourable for soybean rust development in the

southern US early on in the spring and throughout most of the summer in 2007,” details Albert Tenuta, field crop pathologist with the Ontario Ministry of Agriculture, Food and Rural Affairs.

“They’ve gone through three incredibly dry periods in the southeastern Gulf states, all the way through to Texas. The result has been that spore development in the US was not exceptionally quick and early, but as we see, spores still make their way north during the summer.”

Tenuta agrees the hope is that ASR will never be an issue for Ontario growers, yet conditions during at least one year since 2005 indicate there is a need for greater diligence. “If we get back

to a normal situation where those southern states have a normal spring with good rainfall and half-decent weather conditions, there’s the potential for those spores to be produced early on and make their way across into the corn belt and potentially into Ontario,” says Tenuta. “We can see that just by our detections this year, there is the ability for those spores to make it into the province.”

Detection methods improving

Although spores were detected using PCR or polymerase chain reaction molecular techniques, the potential for infection in Ontario was limited. Spore numbers were either so small as to not be a threat, or they were effectively sterilized by higher levels of UV radiation or cool temperatures in the atmosphere.

“More than likely, these were small events or small clusters or single spores that migrated, because we didn’t have a lot of inoculum down in the southern US,” says Tenuta, noting the weather’s impact on the size and collective nature of the spores as they were blown northward. “But with significant storm fronts where they’re sheltered from the sunlight and with cloudy, rainy conditions, you get a lot of spores clumping together. So you can get 100 or 200 or more spores surviving together and with that, you do have a zone of protection in the centre of that cluster and that increases the likelihood of those spores surviving.”

Ultimately, the detection levels in Ontario in 2007 were very low in terms

ROLL CONTROL for superior performance in all terrain.

NORAC’s patented ROLL CONTROLTM system provides unmatched response speed and boom stability.

“Soil Mode” to “Crop Mode” with the flip of a switch.

SMART SENSOR TECHNOLOGYTM gives the operator the target choice that best suits the stage of the crop and weed profile.

Center section height control comes standard.

True height control for the entire length of the boom. Unfold, hit AUTO and go.

100% satisfaction or your money back. Guaranteed. We stand behind our product.

Performance and value that can’t be beat!

of the number or amount of DNAthat was extracted from collectors. “In Ontario, we used three types of collectors: a funnel which is open to the elements at all times, another that is automated to open only when rainfall is detected, and a unit that continuously samples the air, regardless of weather conditions.

“Locations where we have all three of those units, whether it’s Ridgetown, Ottawa, downtown at the University of Toronto or at Harrow, throughout the summer at different times we found that all three of those units would show up positive for soybean rust spores,” explains Tenuta. Indications were that spores were being collected, but not enough to make it a ‘major event’.

Confirmation came when some of the isolates from the collectors were tested using PCR technology and as a further check, the DNAwas cloned or sequenced, confirming the Asian soybean rust detection. Tenuta stresses this work could not have been done without the assistance of Dr. Sarah Hambleton and Ray Tropiano at Agriculture and Agri-Food Canada’s Eastern Cereal and Oilseed Research Centre (ECORC) in Ottawa.

Glass half empty or half full?

How a grower reacts to news like this depends on his personal level of optimism. Yes, ASR spores have been detected in Ontario; no, the levels are not significant, for the time being. And it is worth noting that detection methods have improved considerably since the alarm on ASR was first sounded in 2004/05.

“With the new protocols and DNA techniques, we’re able to fine-tune the detection process more,” confirms Tenuta. “That’s something we’d like to continue in the future, as well. That and sentinel plots, all of these things are integrated to provide Ontario producers and the soybean industry with a co-ordinated early warning system for soybean rust across the whole continent.”

Funding for many of the Ontario soybean rust projects was provided in part through the Canada-Ontario Research and Development (CORD) program, administered by the Agricultural Adaptation Council (AAC), as well as the AAFC Pest Management Centre, the Ontario Soybean Growers and the Ontario Soybean Rust Coalition through AAC’s CanAdvance program. ■

‘New’bacterium complements the old.

For most growers, the practice of inoculating soybeans has been a bit of a tough sell in recent years. Whether it is the perceived inconvenience of applying the inoculant or the added cost of having a seed dealer apply it or the debatable value of the bacterium is not known for certain. However, one company recently launched its new line of inoculant for soybeans, adding a ‘new and different‘ species of bacteria and the potential for higher yields.

In September 2007, Becker Underwood Canada released its new HiStick N/T inoculant for soybeans, featuring its BioStacked technology that offers the combined action of Bacillus subtilis with existing Bradyrhizobium japonicum. The inoculant is available in both liquid and sterile peat formulations, and DeKalb and Pride Seeds are making the inoculant available on their varieties.

The addition of B. subtilis is considered significant on several different levels. According to a brief from the US Environmental Protection Agency (EPA) (www.epa.gov/ oppt/biotech/pubs/fra/fra009.htm),

by Ralph Pearce

Bacillus subtilis is a common and naturally occurring bacterium, found in air, water, soil and decomposing plant material. It can produce a number of proteases and other enzymes that allow it to break down various natural substrates and residues, and helps promote nutrient cycling. The bacterium also produces an endospore that enables it to survive extreme conditions of heat and dessication, and as a pathogen or a disease causing agent, B. subtilis is considered benign.

Another benefit of this bacterium is that it is considered a plant growth promoting rhizobacterium (PGPR) which can, in some fields, stimulate early growth in soybeans and promote earlier canopy closure. “It also appears to provide some protection against root rots,” says Dr. Dave Hume, professor emeritus at the University of Guelph and a consultant with Agri-Trend Agrology. “That’s our experience, and you don’t always see it, so it probably means that in some soils, the organism makes a lot of headway against the disease organisms that are in the soil, and in other soil types it doesn’t.”

Since 2002, Hume has tested the HiStick N/T formulation against its predecessor, HiStick+ and has found there to be some advantages. On new soybean fields containing no

Soybean plants treated with HiStick N/T (left) versus untreated plants (right) provides a visible advantage and could provide a yield boost of more than 1.5bu/ac.

It’shardtosucceedwithoutthebeststart. Havingtheproperfoundationis important.Especiallywhenitcomestoyourcorncrop.That’swhyyoushoulduseaherbicideprogramto reachthehighestyields.WecallthistheFoundationAcre.Bymanagingyourcrop’spotentialfromthe start,youwillensurefuturesuccessandmoregraintoo.Formoreinformation,talktoyourlocalretailer, callourSyngentaCustomerResourceServicesat1-87-SYNGENTA(1-877-964-3682)orvisitSyngenta.ca

Aclose-up of the treated soybeans confirms the root mass is thicker, denser with more nodules for fixing nitrogen.

populations of soybean rhizobia, the average yield gains have been 1.5bu/ac higher using the N/T compared to just HiStick+ inoculant, which contains only the soybean rhizobia. “Adding the HiStick+ gave us, on average, about a 35 percent yield advantage on new soybean soils, which you would expect,” explains Hume. “But then on average, we got another 1.5 bushels from having the B. subtilis in there.”

In fields that have grown soybeans before, Hume has found an average field response of about 1.5bu/ac from inoculating with HiStick+. There has not been enough research done yet in Ontario on fields previously cropped to soybeans to know if there will be any additional yield response when the B. subtilis is included in the inoculant.

Results from other regions

In trials at seven sites in Manitoba, comparisons of HiStick N/T to HiStick+ indicated yield increases of 1.6bu/ac. In Ohio, the average response in five trials of HiStick N/T versus uninoculated checks was 2.1bu/ac, and in Wisconsin, the yield advantage was 3.5bu/ac in seven trials comparing HiStick N/T to HiStick+. One trial in Maryland also showed an 8.1bu/ac advantage for the same comparison. “All of those US tests were obtained using ApronMaxx RTAas a seed treatment and so are ours,” says Hume. “What we don’t know yet is whether this 1.5bu/ac or 1.6bu/ac boost

that we’re talking about is on top of the 1.5bu/ac that we averaged just from adding the inoculant to soils that have grown soybeans previously. If it is, 3.0bu/ac from a grower’s perspective would be an easy choice. Even at 1.5bu/ac, to me, with $10 soybeans, that’s something I’d be looking at.”

Tough sell made a little easier

For Bill Lester, the challenge of convincing growers of the benefits of inoculants is made a bit easier by showing them that HiStick N/T is a new category of inoculant. As Becker Underwood’s district manager for eastern Canada, he acknowledges that inoculating soybeans has lost some of its lustre, and is perceived as an ‘old practice’. Yet he traces the past 10 to 15 year history of inoculants, including the passage from non-sterile types to sterile formulations.

“With a lot of growers in southwestern Ontario that have been growing soybeans for a long time, the last time they would have used an inoculant, it was likely a non-sterile formulation, which from data that we have from universities, suggests that non-sterile formulations typically will only give you a yield response of half a bushel per acre on rotated ground,” details Lester. Alarge deficiency in the old, non-sterile formulations is the presence of other competitive, nonbeneficial organisms. “But most growers

in the southwest had gone away from using inoculants before the sterilized inoculants started to come on stream. According to third party research through universities, sterilized inoculants have been proven to give anywhere from 1.5bu/ac to 2.5bu/ac yield response. That’s starting to get into the range where growers would notice that.”

Even at 1.5bu/ac yield response, Lester believes the value of HiStick N/T, at roughly $3.00 per acre, would require just a half bushel per acre increase to justify the expense. “In a year like 2007, where we have yields all over the board on soybeans ranging from as low as 5.0bu/ac to some yields upwards of 50bu/ac or more, if you’re in that range of 25bu/ac or 30bu/ac, an extra two or three bushels may mean the difference between making money or not,” says Lester.

He likens the notion of inoculating to keeping a vehicle properly tuned. “If you thought about the extra mileage, the fuel economy that you can get out of a vehicle by rotating the tires and changing the oil on a regular basis, you’d never know what you were giving up unless you’re doing that, and keeping track of the extra economy you’re getting.”

Smoothing out the rough spots

From the perspective of an inoculant providing a protective quality, Lester points to the benefits in variable sections of a field. Relying on indigenous species of rhizobium to efficiently fix nitrogen in soybeans may cost a grower money. “The zones that typically would get a yield boost from an inoculant are the areas that are tough on the survivability of these organisms,” says Lester.

“If you have eroded knolls in the fields where the organisms would dessicate due to lack of moisture or if you have flooded hollows in the field that basically choke off the rhizobium without an oxygen source for an extended period of time, those are hot zones where an inoculant will really give you a return.”

Convincing growers to ‘come back’ to using inoculants will not happen overnight, and Lester is quick to concede to that. “But as more growers come on with good experiences, definitely the use pattern will gain some more popularity.” ■

North American ethanol production in 2008 will consume just under 100 million bushels of corn.

Canada’s domestic biofuel industry is about to take off. Six new Canadian based ethanol plants are slated to come on line by the end of 2008. The plants, two on the prairies and four in Ontario, will pour 880 million new litres into the Canadian fuel market. While six plants does not sound like a big number, they will nearly triple the amount of ethanol manufactured in Canada. When the last of the group are commissioned, total production will be just under a billion and a half litres. The figure is even more remarkable considering ethanol production was only 212 million litres in 2003.

Production has expanded quickly to meet proposed government fuel mandates requiring that five percent of all gasoline and two percent of diesel fuel come from renewable sources by the end of 2010 and 2012, respectively. It will require about two billion litres of ethanol and 600 million litres of biodiesel to hit these targets. While ethanol production is on track to meet it, biodiesel production has lagged and will need to go through a five-fold expansion to fill requirements.

sunshine

Biofuels can be added to petroleum products easily because, chemically, they are very similar. Ethanol and biodiesel, just like gasoline and diesel fuel, are really plant-stored solar energy. The main difference is the time when their component plants were alive. Biofuels could come from solar energy, stored by plants, as recently as last summer. Petroleum is solar energy, stored by plants, millions of years ago.

Biodiesel, for example, is almost identical to diesel fuel on a molecular level. It is very simple to make. All that is needed is vegetable oil, or a liquefied animal fat, and a process to strip out the glucose with a reactant agent like

ethanol. In fact, in the summer months, a grower could take a bottle of vegetable oil, pour it into a diesel tank and the vehicle would run. One would not want to do this very often though: the glucose component would have the same effect as adding sugar to diesel fuel. It would ruin the engine in a very short time.

Ethanol is alcohol; the same kind of alcohol found in beer or whiskey. In fact,

it is pure distilled alcohol. While typical, non-distilled alcohols like beer will have five to seven percent alcohol by volume, and distilled spirits like whiskey have up to 40 percent, fuel alcohol is 99 percent pure alcohol. It is so pure that government regulations require ethanol plants to add a small percentage of gasoline to their production before it leaves the plant to ‘denature’ it, ensuring people are not going to drink it.

Farmers are soon going to be hearing a lot about a new type of biofuel, biobutanol. DuPont and BPhave joined together to build the world’s first biobutanol demonstration facility in the UK. If all goes as planned, the demonstration facility will be online by the early 2009. Opportunities for biobutanol in North America are currently being studied.

Biobutanol, or butanol made from grain or some other biomass, is closely related to ethanol but performs more like gasoline as a transportation fuel. The only difference between the two alcohols is the number of carbon atoms in their molecules; the butanol molecule has four carbon atoms, while ethanol has only two. This small difference has a big impact. It not only allows biobutanol to pack a much larger energy punch, it also eliminates many of the blending and transportation problems associated with ethanol.

“We’re interested in biobutanol because it is 100 percent compatible with gasoline and also has the ability to improve the performance of ethanol blends,” says Scott Iverson, Pioneer Key Accounts Manager, Biofuels. “Biobutanol has the ability to improve the vapour pressure of ethanol blended fuels. Biobutanol can also be used in cars at higher blend ratios without the need for vehicle modifications. Its energy content is also higher than ethanol

and closer to gasoline. Gasoline has about 114,000BTU per gallon, biobutanol has 110,000BTU and ethanol has only 77,000BTU.

Another interesting characteristic is that, unlike ethanol, butanol does not absorb water. This means it can be transported around the continent with existing petroleum infrastructure. This avoids the transportation infrastructure logjams that are currently having such a dramatic impact on the American ethanol industry.

“The existing transportation fuels infrastructure is by far the cheapest way to move fuel. Petroleum companies put water in between fuels and pipelines to segregate different fuel lots,” Iverson says. “Since ethanol absorbs water, you can’t put ethanol in a pipeline, but you can ship biobutanol because it does not phase separate in the presence of water.”

Almost any plant that currently makes ethanol can be modified to produce biobutanol by making changes in the fermentation and distillation process. Biobutanol is not difficult to make but Iverson admits additional fine-tuning is necessary to improve process efficiency before it is truly competitive with ethanol.

“Our scientists are working around the clock to develop a high efficiency process to make biobutanol,” Iverson says. “Their work continues to amaze me.” ■

Ethanol can be made from just about anything that contains starch or sugar and, at least the initial steps in production occur naturally as part of the decomposition process. For instance, the decaying contents of a refrigerator’s vegetable drawer could be processed into ethanol.

Even though ethanol can be made from almost any form of plant life, not all feed stocks can be used to make it cheaply enough to be used in vehicles. That is why all Canadian plants, with the exception of Iogen’s small, two million litre cellulosic ethanol plant in Ottawa, will make ethanol from grain. The plants located in central Canada will use corn and those on the prairies will use wheat.

According to the Canadian Renewable Fuels Association, a bushel of grain, whether it is corn or wheat, will produce about 10 litres of ethanol. Using this 10 to one ratio, a 200 million litre ethanol plant will use 20 million bushels of grain a year. By the end of 2008, ethanol production will consume just under 100 million bushels (2.5 million tonnes) of corn and approximately 50

million bushels (1.3 million tonnes) of wheat. To put this in perspective, Canadian farmers, on average, grow 8.7 million tonnes of corn annually and grew 19.1 million tonnes of hard spring wheat in 2006.

Makers of fine whiskey can charge hundreds of dollars per litre for their best alcohol. The best extra virgin salad oils can sell for more than $20 per litre. However, biofuel has to be cheap enough to burn in vehicles. It is a high volume, low margin business. Plants are interested in extracting as much ethanol, or as much vegetable oil as possible from every bushel of grain. That is why seed companies like Pioneer Hi-Bred have started to classify their lineups to denote those products that offer improved functionality for end-use applications. This includes corn hybrids by their high total fermentable (HTF) content, soybean varieties by their oil and protein content and canola varieties by their oil content, alone.

Accurately predicting ethanol yield Pioneer developed the first grain assay to accurately predict ethanol yield potential (EYP) in corn. The calibration is useful since research shows there can be a seven percent variation in the ethanol yield potential among hybrids. Pioneer has made this calibration available to other partners in the ethanol industry.

“Pioneer’s new ethanol yield potential meter uses near infrared spectrometry to measure how many gallons of ethanol a bushel of corn will produce,” says Scott Iverson, Pioneer’s key accounts manager for biofuels. “We’ve characterized all our hybrids and have designated those with the potential to produce above average ethanol yields as HTF ethanol hybrids.”

While wheat has been graded by protein content for decades, the corn grading system has essentially remained unchanged since 1916. Iverson says this new EYPgrading system is a radical change from the standard visual grading. Ethanol plants may one day use EYPas another grading standard just like they currently use test weights.

“Corn grain is an ethanol plant’s single biggest variable cost item and every plant understands that grain quality matters,” Iverson says. “Ethanol production is all about chemistry, so ethanol plants are interested in the chemical composition of the grain. We have now installed our EYPcalibration in about 20 ethanol plants across North America and they are testing every load of grain that comes into the plant. They use this understanding of grain quality to identify preferred vendors and develop relationships with them to positively impact their actual production output.”

Government mandates for higher blends of ethanol and biodiesel are pushing more processing plants into production, with six new facilities across Canada by the end of 2008.

Iverson admits that it may be sometime before producers receive monetary impact for delivering a truckload of corn from hybrids designated as HTF to an ethanol plant.

“We’ve been grading the same way for a long period of time,” Iverson says. “It’ll take some time for us to migrate to EYP. In the long run, we all expect that there will be better and better ethanol hybrids available and this system will give us the opportunity to identify them.” ■

Grower steers clear of corn into wheat.

For some growers, the key question they ask in a situation is not ‘Why?’ but ‘Why not?’ For Paul Kernohan, the answer is better yields, less compaction and a cropping system with which he is the most comfortable.

Kernohan works nearly 3000 acres outside of Forest, Ontario, along with three partners; his son Chris, Gary Huctworth and Gerald Spruyt. For much of the past 12 years, he has rotated his corn into soybean ground instead of spring planting into wheat stubble, “which is just contrary to my way of thinking now,” he says, noting soybeans as his largest crop in terms of acreage.

“In order to get a a reasonable rotation, I rotate wheat and corn ground into beans every year. We’re getting better yields with less cost following soybeans with corn than we would with wheat because the residual nitrogen in the soybeans gives corn a good start. The other cost saver is we don’t touch the bean stubble until spring, thus saving one or two trips with the equipment. Wheat stubble is disc ripped in the fall once and left as mulch. Usually one finishing trip ahead of the planter is enough.”

The other benefit for planting corn in soybeans is that the ground is normally drier in the early spring than wheat ground, translating into less compaction. The regimen does nothing to delay his planting date; he can go as early as any other grower planting corn to wheat stubble, although for Kernohan, later planting is as much a comfort zone issue as it is agronomic.

The results he is getting are enough to keep him and his partners on the same course, year after year. In a dry 2007, his corn yields were 165bu/ac to 220bu/ac where there were timely rains. “We have some land over a road to the north that missed the middle rains when we had three good rains here, but the fields on the road north saw a reduction of 20bu/ac to 30bu/ac on the corn and

by Ralph Pearce

about a 10bu/ac reduction on the soybeans,” explains Kernohan. Acousin of his who received similar amounts of moisture was 10bu/ac to 15bu/ac behind on yield. “He disc ripped his wheat stubble in 2006 and he had a good yield, but I was that much ahead of him in 2007.”

compaction a huge plus

In the years he has been doing things ‘backwards’, Kernohan has reduced his tillage and compaction has lessened, as well. “We needed a little better and quicker rotation, but then I noticed that as the equipment got bigger, the headlands got worse, especially new corn on wheat ground, and especially when plowed,” details Kernohan. “I plowed 30 acres of very wet wheat stubble in 2006 and quit before finishing the field. The disc ripper was brought out to to finish.”

Prior to that, Kernohan noticed several growers in his area plowing wheat stubble, then having compaction problems, particularly on their headlands. However, he does not have that problem. “Our headlands are just as good as the interior of the field,” says Kernohan, who also wonders if there may be better disease control with this

system. “We had comments when we did a test plot and there wasn’t a stalk down in the whole plot, and that included Bt hybrids. It’s different and it is backwards to a lot of thinking, but I am starting to get a few converts in my area.”

Kernohan notes there have been quite a few side-by-side comparisons of plow versus disc rippers, with varying results. But he adds that a grower must be ready to work that ground differently, as the disc ripper will dry out at least a day earlier. If the test is held until the plowed ground is right, the earlier ground will be too dry, thus creating a drier environment that can affect evenness of germination.”

Benefits of rotation are evident

Rotations and the subsequent success they can bring often lead to more questions: How much can conventional methods be tinkered with? Kernohan is not in the habit of trying to win over growers to his way of thinking. This system works because he makes it work, and it provides a sense of comfort, as well as better yields and improved soil health. But he admits the system is not for everyone nor does he try to convince people to adopt his methods.

AgExpert Field Manager PRO Software (Desktop and Mobile edition)

• 4 draws: December, January, February and March

AgExpert Field Manager PRO software provides a complete record keeping and crop planning system. Utilizing your desktop computer and mobile device, AgExpert Field Manager PRO provides producers with easy data entry and powerful reporting features.

UC4 Spray Height Boom Control System

• Free installation, training and delivery

• One year parts warranty

• Grand prize draw April 15, 2008

UC4 Precision Control with ...Ultrasonic Technology! Give your equipment the ability to automatically react to changes in field terrain with the flip of a switch!

However, for Bob Thirlwall, field agronomist with Dekalb, the secret may be out: growers need to ensure their rotations are diverse. “Especially in 2007, where it’s been a pretty clear picture of the benefits of a good, solid rotation,” he says. “What separates the average managers from the successful growers, regardless of their operation, is their persistent attention to details. This includes things like rotation and details surrounding planting conditions, planting depth and consistency of spacing. Attention to planting equipment and how particular you are about how that crop goes in the ground can make a big difference to getting the crop off to a great start.”

Bob Thirlwall believes the right attitude is important when trying different management practices; it works for a grower because the grower makes it work.

That certainly speaks to the system that Kernohan uses. And it says something about growers who ‘dare to be different’; often times, it is their attitude that acts as the lynchpin that leads to continued success. Once they begin to work with a system and achieve comfort or success – or both –they stay with it, regardless of what others might say or think. “It’s almost like no-tillers,” says Thirlwall. “The growers who no-till make no-till work. It suits their management style and the number of hours they’re willing to spend on an acre of land.” ■

Every year it seems there is a government extension person or crop advisor asking growers to help with on-farm trials. It is based on several points worth considering. First, government extension is limited in its ability to conduct trials in every micro-environment across eastern Canada. Second, test plots, whether private or public sector endeavours, are carefully monitored and maintained, often to the point of being hand-weeded and watered to provide the best possible results, but only in one particular location or soil type.

Maizex Seeds of Tilbury, Ontario has developed a testing system that offers growers an opportunity to conduct their own side-by-side comparisons, with results that reflect conditions on their particular farms. The Genetic Environment Tape Trial or GETT system was launched in the spring of 2007 and holds considerable promise for growers.

The system has been in development since 2001 and provides a grower with as many as 20 hybrids, wound on to a spool containing a water-soluble tape that holds each seed. The tape is extremely sensitive to moisture and under ideal conditions, will dissolve in the ground within 15 minutes. The hybrids are selected by Maizex according to five distinct growing areas across Ontario and Quebec, and mechanically inserted into the tape.

At this early stage, growers do not have the option of custom-ordering hybrids for testing, although Shawn Winter, research agronomist with Maizex Seeds, believes they will in the near future. “Right now, we place 20 hybrids in a tape with a check replicated every four hybrids as well, to account for any variation across the row,” says Winter. The task for 2007 was to find the early innovators to test the system and provide a comparison of hybrids from competing companies. “Some wanted to see what would happen if they planted later or earlier varieties, and we met those demands. Within each trial, we have

included two or three competitors to give the grower an idea of how we compare with them.”

The GETT spool can be adapted to a John Deere, White or Kinze planter by removing the hopper and seed tube from one of the row units, and inserting the spool and specialized seed tube.

Maizex is testing a new micro-plot combine which will harvest each hybrid one ear at a time. In testing the system in past years, the samples were hand-picked. As for yield, the samples are weighed, adjusted for moisture (using 15.5 percent moisture factor that is standard for corn) and then divided by the area of the strip. In this case, the GETT system represents 1/30,000th of an acre.

The design of the GETT system makes it easy for growers to adapt the spool to a Deere (as shown), Kinze or White planter box, simplifying the process of performing on-farm trials.

The concept behind GETT is to identify which hybrids will perform better according to the many micro-environments across the region. Winter notes that in 2007, 100 to 150 GETT tapes were planted between Quebec City and Tilbury, giving Maizex and their growers a wide array of potential comparisons. “Our goal is to identify those hybrids which excel in specific environments,”

says Winter, keying on the ‘genotype by environment’ interaction. “If we can identify the environments in which a specific pedigree excels, it would allow us to position hybrids for maximum product performance.”

Growers can now check the Maizex web site for information on the GETT system, including a video of the process. Trial results from 2007 also are available. Go to www.maizex.com/gett.php for more information.

The genotype by environment interaction is an important facet to understanding specific performance. According to Dr. Elizabeth Lee of the University of Guelph, the interaction helps explain why one hybrid might yield very well on one farm, yet do poorly just a few kilometres away. “And that’s without changing heat units or soil type,” she adds. “That may also be a reflection on management.”

One aspect that Lee likes is that a grower does not need any specialized equipment. Although the tests might not be as comprehensive as an Ontario Corn Committee (OCC) trial, it offers a grower the chance to see results at more locations. “If a grower has only so much seed, and if he has to do a strip trial or two or four row plots, he’s only going to be able to test at so many sites, so this will allow him to test at more locations,” says Lee.

From Greg Stewart’s perspective, GETT’s success is dependent on having some key questions answered. For instance, can the GETT system’s results provide an accurate and consistent picture of the micro-climates it is trying to define on a consistent basis, year to year? “Even if they can establish that those micro-climates exist, is a seed company ultimately prepared to deliver hybrids tailored to those specific climates?” poses Stewart, the corn lead for the Ontario Ministry of Agriculture, Food and Rural Affairs.

Still, there are distinct positives associated with the GETT system for growers and Maizex. There is a convenience factor for both parties and there is the potential for use on a broader basis, possibly including OCC trials. “Some of the testing might spill over to OCC trials, if we could gain confidence in the GETT system and its results. It might allow some public testing in areas of the province where logistically, we can’t operate now,” says Stewart. ■

Followingtheleaderjustgoteasier.Andmoreaffordable. Introducing the NEW entry-level EZ-Guide 250 lightbar.

Trimble,theprovenleaderinprecisionfarming technology,isproudtoofferthenewentry-level EZ-Guide® 250 lightbar. A farmer’s first step into the GPS guidance market. With common-sense interface andacolorscreen,thisthingiseasytooperateright outofthebox.Addprecision toyourcapabilitieswithout havingtobetthefarm.

Entry-level lightbar guidance system

4.3" color display and mapping

AllofthisandmoregointomakingthenewTrimble® EZ-Guide250adependabletoolthat’sdestinedto saveyoutime,fuelandmoneyfieldafterfield.

TolearnmoreabouttheTrimbleEZ-Guide250 system,andhoweasyitistooperate,visit www.ez-guide.com orcall 1-800-865-7438.

Built-in GPS with Trimble OnPath® filter technology

CombinewithEZ-Steer® 5OO forthemostaffordableAssistedSteeringSystem Askyourlocaldealeraboutaffordablepricingtoday

by Ralph Pearce MARKETS

In 1997, Peter Hannam and the University of Guelph jointly launched a program that reflected his long-standing belief that the soybean sector had to move into value added ventures in order to attain sustainable success. Together with his First Line Seeds marketing manager, Gary Lannin, and Owen Roberts and the university, Hannam made Project SOY an educational and development tool for students.

For Hannam, the original purpose was two-fold: one, to develop new uses for soybeans and year after year, the students have proved to be an integral source of ideas for that step. The second, and larger purpose was to raise the profile of the added value in soybeans. Through a constant stream of publicity for Project SOYand other developments like Soy 20/20, the profile has been raised. The initiative has won educational awards while soybeans have been recognized within the

university and the general agricultural community for their vast potential across numerous sectors, including health and automotive.

That first year, despite there being only two participating organizations, more than 20 projects were entered in the competition. At first, Hannam thought it might be a one year phenomenon, given the number of ideas at its inception. Yet he concedes that he may have under-estimated both the innovative and competitive spirit of students. “I thought, ‘Wow, there won’t be anything left for the kids coming along in the next year’ and the next year, a whole bunch of new ideas came forward,” relates Hannam. In looking back, he realizes he was never really surprised at the students’ enthusiasm. “I’ve always believed and supported young people and their inquisitive minds, and their no-holds-barred look at innovation and new ideas.”

Following the first year, other industry stakeholders and organizations realized the value being created with the program. The Ontario Soybean Growers

and Maple Leaf Foods joined the effort by 1999, followed by the federal and provincial governments by 2001. Then in 2004, Monsanto acquired First Line Seeds and took a more active role in supporting Project SOY.

Looking back at the previous 11 years, the only surprise for Hannam has been the extent to which students must apply themselves to their respective works. From first concept to researching their product or system, to marketing and promotions to commercialization, the list of tasks to be completed is quite exhaustive. “It’s far more complex than I first estimated,” concedes Hannam, who also launched the Hannam Soybean Utilization Fund to help students through the process. “Just developing a neat idea doesn’t mean it’s going to succeed, no matter how great it is.”

Another challenge in bringing something to a commercial market is the relatively short time the students spend working together on their projects. Many of them are graduate students and find themselves headed in different directions at the end of an academic year. Thankfully, that is one aspect of Project SOYthat is being examined in the hopes of changing for the better.

Jamie Rickard, marketing manager with Dekalb/Monsanto, acknowledges the ‘here today, gone tomorrow’ quality of student life and talks about doing more to help students determine a product’s commercial viability.

“One way is to hold some workshops for the students, with the university, regarding intellectual property,” explains Rickard, who was first introduced to Project SOYwhen he worked with First Line Seeds. “We’ve also worked with the idea of getting someone like Tom Funk to hold a session with the students on marketing and developing a business plan.”

Rickard is trying to help the program through his business connections, putting some of the students in touch with individuals or company representatives who could potentially market products, including food companies or Soy 20/20. He agrees with

Hannam’s assessment about the lengthy process of bringing a product, no matter how innovative or useful, to market.

“If you think of just perfecting a recipe and then selling it and getting shelf space at a grocery store, you can only imagine how long it can take,” says Rickard. “Then you layer on top of that the patents that protect your intellectual property, doing the nutritional labelling and all the research around that, and it’s a lengthy process.”

All parties benefit

As important as it is and has been for students to have links to the industry, associating with the students has been a boon to people in the business. According to Rickard, prior to Monsanto’s involvement, there was little understanding of the potential for soybeans. “Our head office in St. Louis was more focussed on North American food applications,” says Rickard, noting the advent of Vistive soybeans as an example. “Project SOYgave Monsanto in Canada the insight to focus on new food soybean traits from our research pipeline and create opportunities for Canadian growers. These opportunities are enhanced by the identity preservation (IP) expertise of

Ontario growers as well as the existing IPinfrastructure.”

It is natural for Project SOYto have been developed at the University of Guelph, says Owen Roberts, director of research communications at the university. In the past decade, Guelph has been named Canada’s top research university four times and top comprehensive university six times in a row. Roberts sees that leadership position benefitting Project SOY.

“When you look at the number of varieties of crops that have been developed from Guelph, it’s really quite amazing how productive university researchers have been,” says Roberts. “There’s a significant number of food products on the shelf that certainly have Guelph’s signature on them, such as Omega-3 milk, and many things with Docosahexaenoic Acid (DHA) attached to them at some point had some research connected with Guelph.”

Just as Rickard has introduced individuals with Monsanto to the potential of the project, Roberts has tried to draw in members of the regional business community, many of whom help with the judging of the competition. “We also involve our business development office, so there’s

Aclose-up on soybeans will yield more opportunity with a combination of innovation and industry vision.

Peter Hannam’s commitment to value added ventures has helped considerably in raising the profile of the soybean industry in Ontario.

the potential to develop the technology or the product further,” states Roberts, who is also academic co-ordinator of the Agricultural Communications Diploma Program. “If there’s that potential, then someone from the business development office can get the students some intelligence on the process, including protection of intellectual property.”

If there is approval from the business community on the product’s commercial viability and sufficient student interest, then the university would help make the appropriate business connections.

Mentors so important to show the way From a mentor perspective, Hannam, Rickard and Roberts all extend their appreciation to those involved with their expertise and support to Project SOY. “Food science professor, Dr. Massimo Marcone has certainly been the heart and soul of the contest,” says Roberts, adding that Marcone was recognized for his contributions during Project SOY’s 10th anniversary celebration in 2006. “Others include Drs. Rickey Yada, Istvan Rajcan, Ralph Brown, Gauri Mitall and Chris Gillard from the Ridgetown Campus.”

Another very important and unique feature of the competition is that it is completely administered by a student co-ordinator. Roberts concedes that he can step in when needed, but for the most part, it is a program run for students, by students. ■

From our labs to your fields, we want to ensure that you get the best growing experience possible from start to finish. Our local seed experts will help you select the best products and provide you with ongoing support and advice throughout the entire growing season. Imagine the possibilities of combining our great thinking with your great farming. Contact your NK® representative or call 1-800-756-SEED today for more information.

First there was counting calories. Then it was finding foods with lower cholesterol, followed by the anti-carbohydrates diets which has since led to the trans fat revolution.

Now comes glycemic index.

For growers, the task of planting, harvesting and marketing is hard enough with new varieties and hybrids, changes in technology and worrying about the inconsistencies of weather. Yet for some, keeping up to speed with consumer trends is very important, and glycemic index has been getting mentions in food trade publications and the mainstream media.

Other agri-food products and their producer organizations are recognizing glycemic index, as well. Potatoes have a

high GI ranking according to some web sites while Pulse Canada has raised the issue as one of significance for Canadian diets, since edible beans have a lower glycemic index, relative to other foods. It is important to note that a food item does not really have a set glycemic index; this is established by both the nature of the item’s carbohydrate biological structure, and how it is prepared for consumption.

Glycemic index is a summary of the blood sugar response to eating different types of foods containing carbohydrates. From a wheat grower’s perspective, glycemic index may be of interest as it relates to bread making. In June 2006, Peter Ilnyckij of the Ontario Ministry of Agriculture, Food and Rural Affairs gave a presentation at a seed company’s grower day about the many changes in the wheat industry. At the time, he was working within the Cereal, Milling, Bakery and Pasta division with

the Food Industry Competitiveness Branch, and among the topics he mentioned that day was glycemic index in breads. In particular, he stated the method of preparation of bread may be more important than the ingredients, especially where the glycemic index is concerned.

Relevance can be confusing

Creating awareness of glycemic index has not come without its challenges. First coined in the 1980s from work at the University of Toronto, the index has been the subject of some controversy. It has received varying responses from health care agencies and in some countries, it is permissible, if not required to be listed on a food product’s label. Australia, considered by some to be a pioneer in acceptance and recognition of glycemic index, and the UK allow this practice. In Canada, GI is not allowed to be listed on product labels.

Goahead.Checktheimitators.Thenyou’llknowforsurenone comparetothequalityornumberofchoicesavailablewiththe UnverferthRollingHarrow® soilconditioner.

Thetime-proven,roboticallywelded12”-diameterbaskets featureeightscallopedandangledhigh-carbonsteelblades foroutstandingdurability.

• Workingwidthsfrom12’to50’

• Pull-typeorsemi-mounted

• Vertical-,stack-andcross-fold

• Free-floatingorfixed-downpressuresettings