MODERN.CLEAN.SAFE.

Residential wood biomass heating technology from Viessmann

Celebrating 100 years in the business, Viessmann has been providing homeowners with industry-leading heating solutions for generations.

The Vitoligno 300-C wood pellet-fired boiler is a modern, compact and fully-automatic heating solution for residential and light commercial applications.

High efficiency up to 85%

Environmentally-friendly, carbon neutral heating

Easy conversion from automatic to manual fuel feed

Easy to obtain, locally and sustainably sourced wood fuel

WINNER of the 2015 German Design Award

16

The long game

Huska Holdings in the B.C. Interior has been in the wood residuals grinding game for nearly 25 years. Second-generation owner Justin Huska explains what makes his family-run grinding business a success.

20 Silo safet y

A wood pellet silo fire has a number of risks that may cause serious injuries or death for plant personnel and emergency services personnel. Fahimeh Yazdan Panah outlines best practices in silo fire prevention and response.

24

Money matters

Reg Renner has been financing biomass projects for more than a decade. He takes stock of typical challenges and successes when it comes to securing financing in 2019.

28 Wood-fibre insulation

New Canadian developments in wood-fibre panel insulation could mean a new standard in building construction while ushering in an era of green, sustainable, and high-performance building insulation.

CFishing for ‘Likes’

The heating pellet industry can learn from social media

anadian Biomass doesn’t often venture into the consumer world. As a trade magazine, our audience is industry insiders, like you, looking to improve their businesses or processes by understanding shared challenges and solutions. Consumer magazines (fashion, home decor, auto, and so on) are an entirely different ball game.

Anyone with a Facebook account can tell you the consumer world is a fickle one. If Joe Blow had an unhappy experience at his local restaurant, his next step could be logging on to write a nasty review warning others to stay away. His opinion, irrespective of the facts of the matter, can inform the decisions of future customers.

And that’s not a customer base anyone can ignore. According to a 2017 report from Ryerson University’s Social Media Lab, 84 per cent of Canadian adults are on Facebook. For young adults aged 18 to 24 that number jumps to 95 per cent.

In 2018, WPAC ran a social media campaign tied to the website to promote its content. The campaign generated nearly half a million views. More importantly, campaign organizers learned a great deal about what consumers think about wood pellet fuel and stoves.

“Nice heat comfortable but way too expensive,” one commenter wrote.

This unprecedented access to the consumer can also be a tool. There is a lot to glean from knowing what customers are saying about your product.

In the fall of 2017 the Wood Pellet Association of Canada (WPAC) launched a new website – woodpelletheat.ca – designed to meet heating customers online. The website promotes the use of wood pellets for residential heat by educating consumers about the benefits of switching to pellet fuel. Canadian Biomass’ parent company, Annex Business Media, designed and built the website for WPAC. The site frequently references studies or stories published in Canadian Biomass that give testament to the efficiency, sustainability and affordability of pellet heat.

“No electricity the stove doesn’t work,” another noted.

“Wood pellets add three times as much CO2 to the air as natural gas and the emissions are a threat,” another wrote.

There are hundreds of comments to read through, many with strong negative or positive opinions about our industry. The takeaway from all this is to understand common consumer misconceptions in order to directly address them. That’s the goal of woodpelletheat.ca. It’s an important voice for the industry to counter misinformation and to market the entire concept of heating with pellets from a customer perspective, right down to which wood pellet stove or furnace to purchase.

Knowing what Canadian consumers are saying about wood pellets allows us to respond effectively with our facts.

I commend WPAC for taking on the challenge of marketing directly to Canadian consumers, and I encourage pellet producers who aren’t already meeting their customers on social media to consider adding their voices to the conversation.•

CANADIAN

Volume 19 No. 2

Editor - Maria Church (226) 931-1396 mchurch@annexbusinessmedia.com

Associate Editor - Ellen Cools (416) 510-6766 ecools@annexbusinessmedia.com

Contributors - Gordon Murray, Fahimeh Yazdan Panah, Reg Renner, Dutch Dresser, Silvia Cademartori, Nicolas Mansuy, Ian Thomson

Account Coordinator - Stephanie DeFields Ph: (519) 429-5196 sdefields@annexbusinessmedia.com

National Sales Manager - Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexbusinessmedia.com

Quebec Sales - Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

Western Sales Manager - Tim Shaddick tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Curtis Martin

Circulation Manager – Jay Doshi jdoshi@annexbusinessmedia.com Ph: (416) 442-5600 ext. 5124

COO Scott Jamieson

President/CEO Mike Fredericks

Canadian Biomass is published four times a year: Winter, Spring, Summer and Fall. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710

Printed in Canada ISSN 2290-3097

Subscription Rates: Canada - 1 Yr $57.00; 2 Yr $102.00 Single Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $93.50 US; Foreign – 1 Yr $106.00 US

CIRCULATION mchana@annexbusinessmedia.com Tel: (416) 510-5109 Fax: (416) 510-6875 or (416) 442-2191 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2019 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

ALWAYS INNOVATING

AT PETERSON WE NEVER STOP DEVELOPING THE ULTIMATE INDUSTRY LEADING EQUIPMENT.

For over 35 years, we’ve built our business around building the most productive mobile chipping and grinding machines in the industry. Day after day, we partner with our customers by giving them the best tools for the job and exceptional support when they need us.

Visit us at www.petersoncorp.com today and see why Peterson is the industry leader for disc and drum chippers, horizontal grinders, blower trucks, screens and stacking conveyors.

Get the right sized product, sort it out, and stack it higher with Peterson!

Let us know how we can help grow your business!

Horizontal Grinder 3310 Drum Chipper

BIOMASS update

WPAC APPOINTS NEW DIRECTOR OF

RESEARCH AND TECHNICAL DEVELOPMENT

Gordon Murray, executive director of the Wood Pellet Association of Canada (WPAC), is pleased to announce the appointment of Fahimeh Yazdan Panah as Director of Research and Technical Development.

Dr. Yazdan Panah joins WPAC from the University of British Columbia, where she was a research associate with the Biomass and Bioenergy Research Group. For the past 12 years, she has carried out bioenergy research on behalf of the university, governments and private industry clients, focusing on biofuel densification, pretreatment, storage, biomass handling and safety.

A prolific writer, Dr. Yazdan Panah

has co-authored more than 80 technical reports and peer-reviewed publications on the topic of bioenergy.

Dr. Yazdan Panah also serves as the project lead within ISO Technical Committee 238 (Solid Biofuels) and as the chair within ISO Technical Committee 300 (Solid Recovered Biofuels).

She received her Ph.D. and MASc from UBC and a BASc from the Amirkabir University of Technology in Iran. She is registered as a professional engineer with the Association of Engineers and Geoscientists of B.C. and as a professional project manager with the Project Management Institute.

Dr. Yazdan Panah also volunteers as the

Nihtat Corporation eyes pellet plant development in Beaufort Delta

The Nihtat Corporation in the Northwest Territories is receiving a $220,000 federal investment to conduct a capacity development study looking into wood-based biomass options in the Beaufort Delta region.

The study will explore options for wood pellet plant development, wood-based biomass opportunities and biomass supply chain enhancements.

According to a news release, the goal is to encourage the use of biomass as a healthy, economical choice for heating that will reduce costs and greenhouse gas emissions.

The funding is part of a larger $3.5 million investment in the Nihtat Corporation from Natural Resources Canada’s Clean Energy for Rural and Remote Communities Program, the bulk of which is supporting a solar power with battery storage project.

“The Nihtat Gwich’in are excited to partner with the government of Canada on this cutting-edge opportunity that will reduce the cost of living and operations for the people and businesses of Inuvik, while at the same time reducing the impact of greenhouse gas emissions from our community,” Jozef Carnogursky, president of the Nihtat Corporation, said in the release.

“We see this as a strong example of how Indigenous peoples and the government of Canada can work together in the interest of sustainable development in the North,” he said.

regional director of the B.C. chapter of the Canadian Society for Bioengineering. Her appointment is effective April 1, 2019.

CO2 SOLUTIONS STARTS UP CARBON CAPTURE UNIT AT SAINT-FÉLICIEN

A CO2 capture unit installed by CO2 Solutions Inc. has started commissioning at a Resolute Forest Products pulp mill in Saint-Félicien, Que.

The project is in conjunction with Fibrek General Partnership, a subsidiary of Resolute Forest Products Inc., and Serres Toundra Inc., and involves the deployment of a 30-tonne per day (TPD) CO2 capture unit and ancillary equipment at the pulp mill, as well as the commercial reuse of the captured CO2 by the adjacent Toundra Greenhouse complex.

Start-up of the CO2 capture unit officially took place on March 14, preceded by the successful pre-operation verifications of each of the capture unit’s systems, after which the unit was put into operation and the first tonnes of CO2 were captured.

“This unit, a three-times scale-up from our currently operating 10-TPD unit in Montreal-East, confirms the position of our proprietary enzymatic technology as the world’s most advanced second-generation carbon capture technology,” said Richard Surprenant, chief technology officer at CO2 Solutions.

Once the Saint-Félicien capture unit reaches its nominal capacity of 30 tonnes of CO2 per day, a six-month demonstration period will begin, after which the commercial phase will begin and CO2 Solutions will generate revenues from the sale of the CO2 to Toundra Greenhouse.

WHEAT-BASED BIOFUELS FACILITY

SET FOR CONSTRUCTION IN ALBERTA

Strathmore, Alta., is the chosen site of a new $285-million construction project that will see a first-of-its-kind wheat-based biofuels facility producing denatured ethanol, biogas, and electricity.

Carbon Clean Energy Inc. (CCE) is the lead developer of the project, known as Project Wheatland. The facility is designed to produce 160 million litres of denatured ethanol for fuel blending, 1.76 mmBtu of biogas and 12 MWh of green power generation annually.

The project received $5 million in funding from Emissions Reduction Alberta, one of three announced through its new Partnership Intake Program.

The Project Wheatland facility is expected to generate 1.3 million tonnes of

Alberta carbon offset credits annually, the first of its kind in North America. Production is anticipated to begin in early 2021.

“This project meets the provincial and federal government’s mandate to focus on new technologies that assist in the overall economic diversification of the province,” Bruno Rizzuto, vice-president of corporate development for CCE, said in a news release.

“With the support of both governments, CCE will continue to be a catalyst for local companies to test their innovation for scalability purposes in the energy, agricultural, supply chain, and transportation industries in an operational setting.”

CELLUFORCE SCALING UP CELLULOSE NANOCRYSTAL FACILITY

CelluForce’s cellulose nanocrystal facility in Windsor, Que., is set to become the world’s first full commercial demonstration-scale plant of its kind.

The federal and Quebec governments announced a combined $6.4 million investment in the facility’s upgrade in early February.

The funding will allow CelluForce to double its annual production to produce 300 tonnes of nanocrystals a year. Extracted from wood fibre, the nanocrystals can be used in everything from papers to paints, electronics to adhesives and cement to cosmetics.

“CelluForce has been working hand in hand with industrial partners, helping them develop high-performance and sustainable products using cellulose nanocrystals,” CelluForce CEO Sébastien Corbeil said in a news release. “This investment will allow us to maintain our leadership in the field and expand the development of improved products with our customers. It will further enable our continued growth.”

The federal funding is provided through the Natural Resources Canada’s Investments in Forest Industry Transformation (IFIT) program, and the provincial funding is through Quebec Minister of Forests, Wildlife and Parks’ Innovation Bois [wood innovation] program and the Ministère de l’Économie et Innovation’s Fonds du développement économique [economic development fund].

The increase in capacity is expected to help create more than 100 jobs.

“This project is a terrific example of the brighter, bio-based future ahead of us. Congratulations to CelluForce for leading the way in forest sustainability and providing eco-friendly development solutions in Canada,” Paul Lefebvre, parliamentary secretary for Natural Resources Canada, said in the release.

CANADA INVESTS IN BIOMASS RESEARCH CLUSTER TO GROW BIOECONOMY

The federal government is investing up to $7 million in a biomass research cluster led by the BioFuelNet Canada Network. Funding for the research cluster will include an additional $3.1 million in contributions from industry, for a total investment of $10.1 million.

The cluster’s research aims to drive innovation and help improve technologies for processing agricultural biomass that can then be used as a renewable and sustainable starting material for production of cleaner bioenergy, and other bio-based products.

The focus will be on three key areas of research including:

• Advanced technologies to boost biomass production;

• Using biomass heat and energy to extend the greenhouse growing season in Northern Canada; and

• Reducing production costs and expanding export markets for biomass.

McGill University is receiving up to $888,061 to fund a project focusing on the development of biological inputs that will enhance the growth of biomass crops including switchgrass.

“This investment in biomass research will help farmers manage agricultural waste, reduce energy costs and environmental impacts, while creating new market opportunities for Canadian bioenergy,” Agriculture Minister Lawrence MacAulay said.

Donald L. Smith, CEO of BioFuelNet Canada, said the agricultural sector has a key role to play in the full development of Canada’s bioeconomy.

“The potential payback of a thriving agro-bioeconomy to Canada is enormous in that it will cause meaningful reductions in Canadian greenhouse gas emissions and create new wealth and employment in the agricultural sector. The Biomass Canada cluster is focused on research that will help make this happen,” he said.

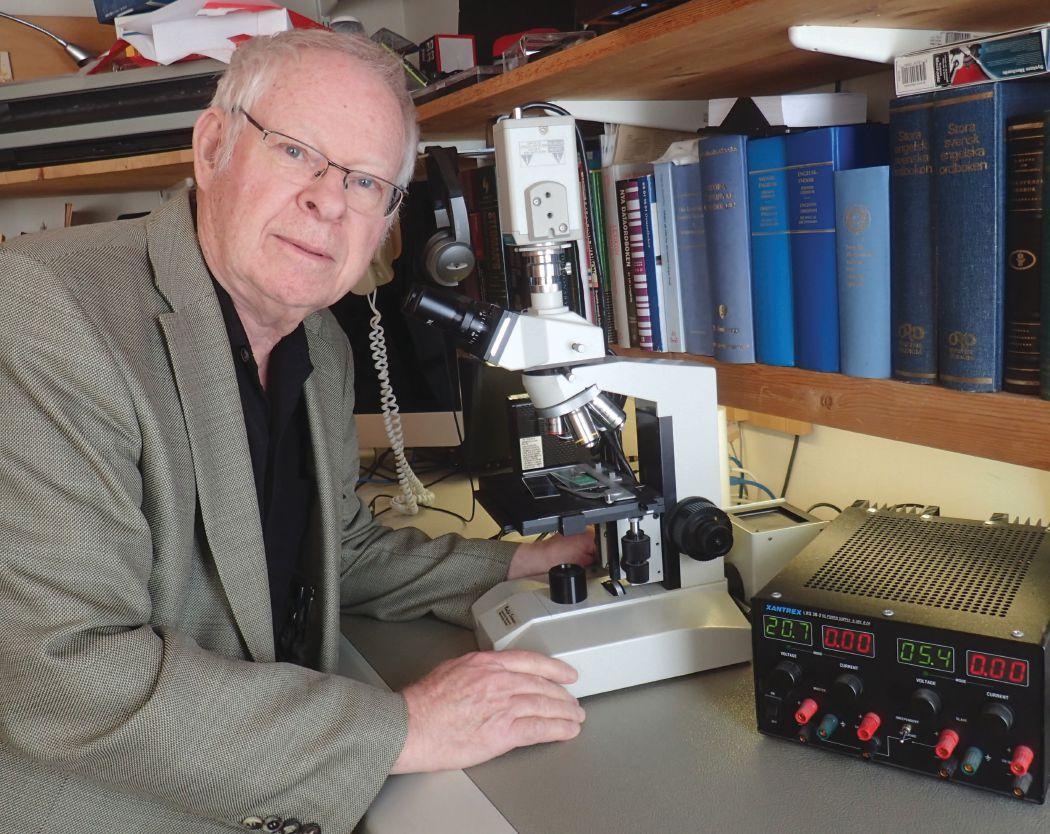

Staffan Melin retires

AWPAC reflects on Staffan Melin’s 25-year career in the wood pellet industry

By Gordon Murray

fter 25 years in the wood pellet industry, Staffan Melin, the Wood Pellet Association of Canada’s director of research, has retired, effective March 31, 2019.

Melin’s career in the wood pellets industry was preceded by five years as a trade commissioner for the government of Sweden in Canada, during which time he developed relationships that resulted in the first wood pellet exports from Canada to Europe.

In 1996, Melin started the company Delta Research Corporation with the objective of developing renewable energy trade between Canada and Sweden. That same year, Melin began his relationship with the BC Pellet Fuel Manufacturers Association, which eventually became the Wood Pellet Association of Canada.

Melin partnered with another industry pioneer, John Swaan, the founder of Pellet Flame – now known as Pacific BioEnergy Corporation. Swaan’s expertise lay in wood pellet manufacturing, while Melin brought knowledge of ocean transportation and connections with Swedish customers. In

Not only was Melin a visionary entrepreneur, he also distinguished himself as a leading scientific expert on all aspects of wood pellets.

1996 they shipped their first export vessel to Helsingborg Energi AB to be co-fired with coal, pioneering the hugely successful Trans-Atlantic wood pellet trade we all enjoy today. Melin and Swaan were the first to ship wood pellets from Prince Rupert to the Panama Canal, through tropical waters in the Caribbean Sea and the cold North Sea to Sweden.

Beginning in the year 2000, over a period of 18 months, Melin negotiated the first ever long-term wood pellet sales agreement with Essent Energie BV to supply wood pellets to Essent’s Amer coal power plant in the Netherlands, thus initiating Dutch wood pellet co-firing. In addition, from 2002 to 2007, Melin managed wood pellet exports for Vanderhoof, B.C.-based Premium Pellet Ltd. – including contract negotiation, chartering of ocean vessels, draft surveys, laboratory testing and shipping documentation for deliveries of 45 ves-

sels to the Netherlands, Sweden and Denmark – a value in excess of $50 million.

A fatal accident on board the vessel MV Weaver Arrow on May 9, 2002 in Rotterdam became a milestone event, which initiated Melin’s engagement in safety, handling, and storage of wood pellets. Melin developed standard documentation for wood pellet handling and shipping which was ultimately adopted by the International Marine Organization to be used by all wood pellet shippers. Melin also developed guidelines for the safe shipping of wood pellets including the first internationally accepted material safety data sheet.

During his investigation of the MV Weaver incident, Melin met Dr. Shahab Sokhansanj, a chemical engineer and recently retired university professor. The two decided to research how carbon monoxide is generated by wood pellets in combination with oxygen depletion. They approached the University of British Columbia’s Department of Chemical and Biological Engineering and were encouraged to initiate the Biomass and Bioenergy Research Group (BBRG) within that department. Under Melin and Sokhansaj’s leadership, BBRG has produced more than 100 scientific papers and has trained more than 20 students who graduated with masters and Ph.D. degrees. Based on his wood pellet industry experience, Melin conceived much of the research. The results of this research have shaped the progress in the pellet industry in areas such as product quality assurance, testing methods, safety in handling and storage as well as raw material logistics. Signature research achievements include determination of off-gassing and oxygen depletion, permeability and thermal conductivity of wood pellets in bulk, modelling and validation of explosion pulping and torrefaction as well as gas migration in enclosed vessels containing wood pellets.

Since 2008, Melin has been a leader in developing ISO standards for wood pellets, covering quality, chemical and mechanical testing, and safety. Nearly all global wood pellet trade is based on these ISO standards.

In 2006 to 2008, Melin conducted a study onboard the ocean vessel MV Horizon in close collaboration with Chalmers Technical University and the Department of Occupational and Environmental Medicine at Sundsvall Hospital of Sweden. Their objective was to explore the thermal conditions and gas evolution in a ship-hold during a seven-week voyage from British Columbia to Helsingborg, Sweden. During the study, they discovered the previously unknown phenome-

non of barometric pumping, which causes condensation of moisture in ship-holds. The study also confirmed the thermal coupling between wood pellets and ocean water temperature.

From 2007 to 2010, Melin co-operated with the Swedish Research Institute on developing guidelines for extinguishing fires in storage silos. Together they developed procedures for using nitrogen for fire fighting.

During the period of 2009 to 2011, Melin participated in the WorleyParsons engineering team responsible for investigating the conversion of Ontario Power Generation power plants from coal to biomass. Ultimately two plants – Atikokan and Thunder Bay – were converted to using wood pellet fuel.

In 2013, Melin conducted the study, “Considerations for Grading Agricultural Residue,” for the Ontario Federation of Agriculture. The report describes pre-treatment options such as weathering, washing, torrefaction, steam-treatment and hydrothermal carbonization to maximize commercial value, including quality certification schemes.

In 2017 to 2018 Melin undertook a study to explore if wood pellets comply with the International Plant Protection Convention (IPPC) for phytosanitary certification. His study evaluated the performance of high-temperature (rotary drum) and low-temperature (belt) dryers and found that Canadian wood pellets are sterile.

However, feedstock materials are heavily contaminated with mold, yeast and bacteria. This study is used today as evidence when responding to foreign customer and government inquiries regarding the phytosanitary nature of Canadian wood pellets.

Over his career, Melin has authored or co-authored more than 80 scientific papers, reports and books on biomass processing, safety, logistics, and international trade.

Melin has had a remarkable career. During the mid-1990s when the Canadian wood pellet industry was struggling to survive, Melin’s pioneering of the trans-Atlantic pellet trade transformed the industry.

Not only was Melin a visionary entrepreneur, he also distinguished himself as a leading scientific expert on all aspects of wood pellets. We wish him all the best in a well-deserved retirement. •

Gordon Murray is the executive director of the Wood Pellet Association of Canada.

For the latest news, equipment and project profile features, plus videos, webinars and more, visit www.canadianbiomassmagazine.ca

Unlocking potential

CHAR

Technologies’

biocarbon products present new, sustainable opportunities

By Ellen Cools

Not many people can say a bag of fibre from a biogas plant sparked the idea for their company. But Andrew White, CEO of CHAR Technologies, can.

In 2009, as a masters student studying chemical engineering at the University of Toronto, White and his professor visited a biogas plant in London, Ont. that processed organic waste, manure and agricultural residues into biogas. The plant was also producing a lot of fibrous material byproduct “that didn’t have a lot of value to it,” White says.

“But they had great looking fibre so we – my professor and I – decided to take some back to the lab and see if we could turn it into activated carbon,” he explains. Their research led to the creation of one of CHAR’s biocarbon products – called SulfaCHAR – which is used to remove contaminating hydrogen sulfide from biogas.

“So, in 2011, when we saw that the research worked, that it made a product that worked, and there was a market need, we decided to start the company.”

Now, eight years later, CHAR Technologies has partnered with Anergy, an Australian company that provides energy solutions for renewable energy power plants, to develop a demonstration facility in London, Ont., that turns different waste materials into biochar.

AN ENVIRONMENTALLY FRIENDLY CHARCOAL

Biochar is a biocarbon product made by heating biomass in the absence of oxygen. “Instead of burning it as you would when you apply heat in the air, it carbonizes, so it drives off a lot of volatile material, and you’re left with basically just carbon,” White explains.

As its name suggests, biochar is similar to charcoal, but it’s much more

environmentally friendly and made from different waste materials. It has multiple end uses, including as an agriculture product or soil amendment, which helps soil hold moisture and fertilizer, White explains. Since it is made from biomass, it can be used as renewable energy without giving off the same amount of greenhouse gas

emissions as charcoal.

But within the industry, a lot of different terminology is thrown around, White says, which can make it confusing. “Some people use biochar generally to mean any material that’s been turned into carbon, while some people use biochar just to mean material that’s produced and specified for land

CHAR Technologies CEO Andrew White in front of the demonstration facility in London, Ont. The company turns different waste materials into biochar.

application or fertilizer.”

White personally believes biochar is specifically for agriculture or soil remediation, and refers to CHAR Technologies’ different products as biocarbons.

UNDERSTANDING HTP

To produce different types of biocarbon, there are three types of thermal treatment processes: torrefaction, high temperature pyrolysis (HTP) and fast pyrolysis.

“Torrefaction is generally a slow process – the residence time that the material is in the system for is half an hour to an hour, roughly,” White explains. “Torrefaction is generally done at a temperature between two and three hundred degrees Celsius, and what people do with that material generally is use it as a biocoal.”

The next step up is high temperature pyrolysis, which is the process CHAR Technologies uses. High temperature pyrolysis falls under the category of slow pyrolysis – materials are slowly heated up between 500 and 900 degrees Celsius for half an hour to an hour.

“The big difference is the quality of the product,” White says. “We drive off a lot more volatile matter, so our carbon content is higher. We’re driving off hydrogen and oxygen at those higher temperatures.”

Fast pyrolysis has a residence time of one to two seconds, and is generally used to create bio-oil.

“To give you the spectrum for an energy product, with torrefied biomass, you’ll get an energy density of between 22 and 25 megajoules per kilogram, depending on how it’s done. Highenergy coals are 28 megajoules per kilogram. We can make a product that’s 32 to 34 megajoules per kilogram because of the high temperatures in our process,” White explains.

PRODUCT PORTFOLIO

CHAR Technologies produces and markets two products: SulfaCHAR and CleanFyre.

SulfaCHAR is an activated carbon.

“Think like a Brita filter for filtering water, except we use it to filter renewable natural gas,” White says. “The benefit there is traditional activated carbons

are made from coal and generate a solid waste once you use them. Ours is made from organic material, and we actually generate a sulfur-rich soil amendment fertilizer when it’s done being used as a filter.”

This product is made using a blend of biosolid-based fertilizers, anaerobic digestates – the solids left over from biogas plants – and some other fibres. CHAR’s London, Ont., facility is located next to a biogas plant owned by StormFisher Environmental, and uses some of its anaerobic digestate in the production of SulfaCHAR.

CleanFyre is a coal replacement. “Why that’s beneficial and exciting is because that product is made from wood or woody waste – it’s carbon neutral,” White says. “So generally –high level, rule of thumb – one tonne of coal gives you three tonnes of greenhouse gas emissions. Since we can offset one tonne of coal with one tonne of our CleanFyre, each tonne of CleanFyre will reduce three tonnes of greenhouse gas emissions.”

To make CleanFyre, the company uses clean, untreated recycled wood materials, predominantly shredded shipping pallets.

AN INDIRECTLY FIRED SYSTEM

The general process for turning these waste streams into SulfaCHAR and CleanFyre starts with loading “super sacks” – large bags used to transport both the feedstocks streams and the end products – into a feed hopper. The facility can process two super sacks at a time by hanging them above the feed hopper, for a total processing capacity of 750 kilograms per hour.

Then the material goes through a bucket elevator into a rotary valve, which acts like an airlock to keep oxygen out of the system – a key factor in high temperature pyrolysis. The material is then dropped into another feed hopper and is conveyed into a slow pyrolysis kiln unit through a rotating mechanism.

“The kiln unit itself is basically a large rotating cylinder that the biomass

tumbles along through inside,” White explains. “We have a box around that, and inside that box is where our burners are and where we apply heat.

“It’s called an indirectly fired system because we’re heating up from the outside; we’re heating the cylinder that the material is in,” he continues. “The material then comes out the back end.”

This process produces both biocarbon and pyrolysis gas. The solid biocarbon goes into a cooling screw that includes a few quench sprays to prevent the material from reaching too high a temperature. It then goes up a cooling screw through a double dump valve – an airlock system that keeps oxygen out of the back-end – and it is then packaged into super sacks.

Currently, the pyrolysis gas is sent through a thermal oxidizer. The thermal oxidizer burns the gas, which is mainly hydrogen and carbon monoxide, as well as some light hydrocarbons and tar vapour, and turns it into carbon dioxide and water vapour. White plans to eventually clean it and use it as an energy product.

The majority of the equipment, including the kiln system, was provided and manufactured by CHAR’s partner Anergy. The partnership came about through “a fairly exhaustive search,” White says.

“Anergy spun out of Ansac, which did a lot of activated carbon regeneration, so they’ve been making these kilns for decades. So, they had a lot of good reference cases, and the pricing was very reasonable, compared to some of the American or European suppliers that we looked at.”

Anergy provided a basic set-up for the facility. Consequently, “the plant itself is about 80 per cent off the shelf,” White says. “Then we designed the key elements that we needed to make our product out of it.”

NEXT STEPS

White plans to build a larger plant within the next few years. The current demonstration facility produces a maximum of five tonnes per day.

The company’s future focus is scaling up production of CleanFyre, aiming for 20,000 tonnes a year. “With that, we’re targeting mainly the steel industry as

a replacement for the pulverized coal that they’re currently putting into their blast furnaces, and we’re working with a couple of partners on bringing that realization forward,” White explains.

Although biochar is a fairly new product on the market – virtually unknown in the forest products industry until two years ago – White believes the future is bright. Rather than carve out a niche, CHAR Technologies aims its products at existing markets, such as activated carbon and energy products, which should speed up market adoption.

But there are still several challenges facing widespread adoption of biochar. The issue, in White’s opinion, is twofold.

“One, is getting that agricultural market understanding – and it’s going to be a longer process, because I think you have to do lots of field trials to get people comfortable with it, to realize the value of it. Once they really realize the value of it, they have to be willing to pay for it,” he explains.

“The other is consistency of production and consistency of testing and certification,” he continues. “If you change the feedstock, you change the temperatures, you change the residence time, and you actually create very drastically different biochars.”

Initial research shows some types of biochars work better than others as an agriculture product. White believes this is because of a lack of consistency in production, testing and certification.

“There are a lot of people pushing those aspects forward, and I think it just needs to happen to, again, drive the market acceptance,” he says.

Looking to the near future, “We really want to continue to grow and push the opportunities for biocarbons in general,” White says. “When we started the company, our focus was on SulfaCHAR, and now this CleanFyre, biocoal, energy product market seems to really be taking off and we’re getting a lot of great interest from the industry, so we’re focused on that.

“As we grow and develop and as the research grows and develops, I think there are a lot of different biocarbon applications that we’ll unlock, and that’s what we’re really excited about.” •

“Raw” CleanFyre that hasn’t been processed yet for material properties.

“Raw” SulfaCHAR made from anaerobic digestate that has not yet been processed for additional material properties.

An anaerobic digestate used to make SulfaCHAR.

The long game

Huska Holdings makes wood grinding work in central BC

By Maria Church

Huska Holdings in the B.C. Interior has been in the wood waste recycling game for nearly 25 years. For those keeping count, that makes the company a longstanding fixture in an industry that’s not much older than they are.

Second-generation owner Justin Huska fondly remembers the early days of the wood grinding business, particularly their first machine: a Rexworks MaxiGrind.

“It was quite the machine. I think we worked on it more than we actually ground wood with it. It took two people to operate – the excavator operator and then someone on the ground because the controls were tethered to the machine,” Justin says.

“I always tell the guys who work for us now that they’ve got it pretty easy with the way technology has changed machinery. It would be a nice test for them to actually run one of these old grinders, because they would have a real appreciation as to how far they’ve come in terms of technology,” he says.

Today the company operates three horizontal grinding machines, employs around 10 people and contracts their services to more than 20 customers across the province.

While the woody biomass industry ebbs and flows, intrinsically tied to the larger B.C. forest products industry, Huska Holdings has managed to stay profitable and provide an environmentally responsible solution for landfills, sawmills, and biomass producers and consumers.

HUSKA HISTORY

Husband and wife team Pat and Connie Huska started up the company – then called Huska Excavating – in Williams Lake, B.C., in the early 90s. The company’s original focus was roadbuilding for the logging industry in the B.C. Interior.

Huska Excavating branched out to wood waste recycling in 1995, renaming to Huska Holdings and purchasing its first grinder to fulfill contracts with landfills.

“The majority of our work was actually landfill reductions. We would grind whatever the public brought in – branches and pallets. A lot of that was landfilled after we ground it, or used for landfill

cover. At that time the biomass industry was a real distant secondary industry for the forest industry,” Justin says.

A couple years later, Atlantic Power started up its Williams Lake Power Plant fuelled by wood waste. The plant was a big step forward for the woody biomass industry in a time when sawmills were still operating beehive burners to costeffectively eliminate their wood waste.

From left, Pat Huska and his son, Justin, are the first and second-generation owners of Huska Holdings, a wood waste recycling company in the B.C. Interior. Photos courtesy Huska Holdings.

“Over the years we’ve seen quite a change in where a lot of the biomass goes. There’s a lot more opportunity to utilize a lot of the wood waste,” Justin says.

While Justin was involved in the family business from the beginning, the early days were also the heyday of his professional motocross career. Justin’s career highlight was a fifth place national ranking in 1996 and 1997. His racing took him all across North America and Europe.

“When I wasn’t racing I was working the family business. It was a good job to come home to because they were pretty lenient about my hours and schedule,” Justin says with a chuckle.

In 2002, Justin retired from the sport and took on a management role with the family company.

GRINDING FLEET

With a 25-year track record, Huska Holdings is a well-known full-service grinding operation in B.C. The company offers site consultations to determine the best approach to process the material, grinding services, and hauling services to remove the wood waste.

The company owns two CBI 6800BT horizontal grinders – one 2014 and one 2017, both purchased from Frontline Machinery – and rents a third of the

same brand and model. These tracked machines are designed for high-volume throughput with 1,050 horsepower. They work well, in part, thanks to an MDS (metal detection system) from CBI.

“Metal is by far one of the worst things you can run through a machine. Rock is another. Depending on what it is, metal can do quite a bit of damage. This MDS isn’t a fail safe, but it definitely is a lot quicker of a reaction than an operator. This system senses when it hits the metal, shuts everything down for you, and opens everything up to let the operator inspect it,” Justin explains.

The grinders are remotely operated from the cab of the loader or excavator feeding them, which typically means it’s a one-person operation, Justin says.

“It’s not very often that we need a grounds guy anymore. It’s not necessary with the technology of the machines we are running now. There is the odd time that we do, but it’s when we’re somewhere like a mill yard doing clean up and it’s quite contaminated with steel, so we’ll have someone on the ground keeping an eye on things,” he says.

Huska runs two John Deere 2154 log loaders, two John Deere 200C excavators, and a Hitachi ZX210 excavator, with grapples from IMAC and Brandt.

Hauling the biomass are two trucks, one International and one Western Star, both with 53-foot Titan walking floor trailer. Huska also contracts other trucks and trailers as needed, particularly when the bush-grinding site is only accessible via a challenging logging road. In the Cariboo Region, Huska contracts Cariboo Shavings for their hauling services.

CHANGING CUSTOMERS

The company runs three crews year round. In March, one was operating in the Okanagan Valley servicing the Kelowna-Okanagan area and the other two were in the Cariboo Region operating out of Williams Lake.

About half the business is still dedicated to landfill reduction, while the rest is split between mill-yard cleanup and bush grinding of logging debris. Their forestry customers include lumber mills, pellet plants and co-gen plants.

The economic downturn in 2008 proved to be a boon for the biomass industry in B.C. “A lot of sawmills were closing and they weren’t producing as much fibre for the secondary end of their industry, so the pellets and co-gens relying on that fibre to feed their plants had to start going out into the bush to grind,” Justin says.

Today the company runs a fleet of modern CBI horizontal grinding machines designed for high-volume throughput to process around 470,000 cubic metres of fibre annually.

He’s seeing that trend surface again as B.C.’s sawmills struggle to remain open with the combination of U.S. softwood lumber tariffs, less annual allowable cut, and high log costs.

“There are a lot more pellet plants and more competition for the fibre. At this point they don’t have much of an option other than getting the fibre from logging debris,” Justin says.

The logging debris is typically clean aside from some dirt and rock, he says. This is ideal for co-gen plants that can burn hog fuel with a high percentage of bark. Pellet mills require a cleaner fibre to produce the fines required for pelletizing.

“They have to be really careful about their grinding. They can’t have a lot of needles or bark. So they’re really going after the dry wood like old forest fire burned wood or old beetle kill where a lot of the needles or bark are already falling off the wood. That makes a higher quality pellet for them,” Justin says.

At the landfill, Huska separates and grinds white wood – what they call dimension lumber – to a 2-inch minus

product that heads to Tolko Armstrong’s co-gen plant. Yard waste at the landfill, which is leafy, grassy material, is ground and stays on site to be composted.

All told, Huska grinds around 470,000 cubic metres of fibre annually from its major clients.

STEADY ON

The biomass side of the wood grinding industry is undoubtedly tied to the forest products industry, but the connection thus far has been a zero-sum game.

After the forest industry’s recovery from the 2008 recession, when sawmills were once again at capacity and producing sawdust and bark for the secondary industries, many logging residual grinders found themselves out of work. Huska Holdings was fortunate, Justin says, because they could turn to their landfill wood waste recycling contracts. Customer diversity was key.

“There was a hard time for a lot of these contractors who invested a lot of time and money in wood grinding equipment – they’re not cheap,” he says.

“You have to have a lot of work in order to keep your equipment busy.”

With lumber producers in B.C. once again facing uncertainty, pellet and cogen plants are turning again to forest residuals for a secure fibre supply. “They’re realizing that they have to put some sort of program together to keep their fibre supply consistent,” Justin says.

As forest biomass ramps up, leading to new contracts for Huska, the company is looking to purchase a third grinder for its fleet.

Justin is also in the middle of taking over sole ownership of the company from his now-retired parents. “It’s a scary but exciting time,” he says. “My plan is to continue on with what we have now and also grow the business in different ways. Right now we’re looking to diversify even more. There are some other areas we could get into to keep the business going.”

What might those be? Justin’s not saying yet, but with the company’s track record for staying strong even in slow years, we’re expecting great things for Huska’s future. •

NEW TOOLS CAN HELP SECURE ACCESS TO QUALITY FOREST FEEDSTOCKS

As forest-origin biomass use has increased, logistics of supply and storage become more complex and innovative solutions are required to improve feedstock quality for the growing bioenergy industry. The variety of feedstocks available is quite complex, with multiple feedstocks coming from different streams (at-the-stump, roadside, transfer yard, mill) and accessible under different formats (wood chips, bark, fines, tops, and branches or low grade logs). The quality of biomass is critical for many bioenergy processes and best management practices (BMPs) are required to guarantee access to quality feedstocks at any given time.

A priority in the supply chain is the need to improve the business and policy environment for biomass and biomass heat markets by developing better understanding and best practices for storage of forest biomass. With that in mind, FPInnovations has undertaken an exhaustive work aimed at compiling field data and measuring the financial implications of innovative storage practices with the intent of helping the industry better understand and manage forest feedstocks and improve financial impact of their operations.

New app to calculate roadside biomass volumes

To meet and adapt to the industry’s needs, FPInnovations also recently announced the launch of the BiOS app, a free, convenient, and easyto-use tool that can calculate roadside biomass volumes and potential greenhouse gas (GHG) benefits.

The BiOS app is intended to:

• Serve the purpose of developing the forest bioeconomy clusters for advanced biomaterial manufacturing in British Columbia and may support other related government key priorities like GHG targets.

Best Management Practices guide1

FPInnovations has recently published the Best Management Practices Guide for Access to Quality Forest Feedstocks, a document that assesses the economic benefits of best management practices on feedstock quality and process improvement for the bioenergy sector.

Common drivers in the forest and bioenergy industries are the need to demonstrate sustainable forest management and harvesting with reduced environmental impacts of operations. After identifying gaps in the management of biomass quality based on different types of forest-origin biomass, the guide highlights opportunities to create value from marginal forest stands. The best management practices for storage are outlined for various types of biomass, with key parameters influencing biomass quality during storage. The document presents cost-benefit case studies for roundwood and bark, which will help demonstrate benefits and net savings of good management practices. It also covers items and tools that have the potential to help improve the supply chain of the future.

1 The Best Management Practices Guide for Access to Quality Forest Feedstocks was made possible with financial support from the provincial Nova Scotia Innovation Hub Initiative as well as federally from Natural Resources Canada under the Program of Energy Research and Development (PERD).

• Increase use of forest-origin biomass to support the bio-economy.

• Improve area planning and support decision makers by having a better understanding of the fiber potential located in each Timber Supply Area (TSA).

The development of this app was a key part of a larger initiative within the Ministry of Forests, Lands, and Natural Resource Operations and Rural Development (FLNRORD) aiming to develop a Geographic Information System for the development of British Columbia’s forest bioeconomy.

The guide and app are available by contacting: guyta.mercier@fpinnovations.ca

For a DEMO of the app, watch the webconference recording: fpi.adobeconnect.com/p3eqsa8ayoet

If you are interested to develop this kind of app in your region or if you want more information about these tools, contact: Sylvain Volpe, Senior Scientist, Fiber Supply at FPInnovations. sylvain.volpe@fpinnovations.ca | 514-782-4521

Silo safety

Best practices for handling silo fires at wood pellet plants

By Fahimeh Yazdan Panah

Awood pellet silo fire has a number of risks that may cause serious injuries or death for plant personnel and emergency services personnel. Millions of dollars of pellet plant infrastructure can also be damaged. The silo fire at Pacific BioEnergy’s plant in Prince George, B.C., in 2017 was managed successfully by following a well-crafted plan to control the silo fire. Pacific BioEnergy’s team and Prince George fire department personnel applied best practices in silo fire control.

Silo fires are unique and require a different approach than conventional fires. Since they rarely occur, fire-rescue personnel have little experience in dealing with these types of fires. But because the fire development and the emergency response processes are different from conventional fire rescue processes, it is essential to consider the specific conditions of the silo fires in order to have an effective emergency response. In the case of the silo fire at Pacific

BioEnergy’s plant, the specific emergency planning done by the Pacific BioEnergy team and the fire rescue personnel was key to success.

Smoke from smoldering wood pellets inside the PacBio silo was first noticed on the evening of Wednesday, August 23, 2017. The fire was extinguished within seven days, the silo was saved, and no one was injured. In most cases, these type of silo fires are caused by self-heating of the stored material due to different chemical and biological reactions that lead to spontaneous ignition. These fires usually start deep inside the material and thus are hard to detect early. Based on our understanding of past silo fire incidents, it is recommended to measure the concentration of gases such as carbon monoxide and carbon dioxide, as well as temperature, in the silo for early silo fire

detection. Some other fires are caused by external ignition sources, either high pyrolysis gas concentration build up in the silo or dust exposed to an external ignition source. A record of past incidents shows that gas and dust explosions may lead to very extensive damages and are thus the most serious danger associated with silo fires. One lesson learned from the Pacific BioEnergy silo fire incident and previous incidents is to always maintain the monitoring, detection and suppression systems in good working condition.

When dealing with a silo fire, it’s critical to identify the type of silo and fire. You need to know if it is a smoldering fire or a fully developed fire with open flames. There are several instances where not knowing the structure and type of fire resulted in unsuccessful outcomes.

Pacific BioEnergy’s vice-president of operations, Shawn Bells, speaks at the 2019 Silo Fires Prevention and Response workshop in Prince George, B.C., in February, put on by the Wood Pellet Association of Canada. Photo by Focal Point Studios.

June 11, 2019

Prince George Conference & Civic Centre

Prince George, BC

For example, if it is a smoldering fire, it usually develops deep in the material and spreads downwards. The pyrolysis gases and moisture slowly spread upwards but it may take days to be able to detect signs of fire. In a number of industry incidents, this has been the case. High levels of carbon monoxide may be produced and thus it is crucial to carry out an initial risk assessment and establish access rules. It’s always essential to wear detection instruments that can measure and detect both carbon monoxide and oxygen. The gas mixture presents a great risk for poisoning, and, in the worst case, loss of consciousness or death. Lessons learned from past incidents show that it is best to measure the concentration of carbon monoxide and oxygen in the silo headspace and check for flammability risk. As there is a risk of gas build-up in the silo head-space and thus explosion, it’s highly recommended that no personnel be at the top of the silo during silo fires.

The main recommended method to extinguish a wood pellet silo fire is to inert the silo using nitrogen from the bottom of the silo, then discharge the silo contents and extinguish hot materials. Nitrogen should be injected close to the bottom of the silo at a recommended rate of at least five kg/m2 per hour. However, if the explosion risk in the silo head-space is high due to high gas concentrations (meaning carbon monoxide is greater than two to five per cent and oxygen is greater than five per cent), nitrogen injection should be done in the head-space first. For silos

with a small diameter, usually one gas inlet is sufficient, but for larger silos, it is best to apply nitrogen at multiple points to ensure even distribution within the bulk of material. You should also seal the silo thoroughly to reduce the smoldering fire development and spread. This can be done by turning off the ventilation system and blocking all hatches, openings and connections to the transport system and the dust ventilation system. It’s always a good idea to check the delivery time for nitrogen as it may be long and there might be a risk of open fire. In such cases, it is best to cover the pellets with medium- or high-expansion fire extinguishing foam to prevent materials from accessing oxygen.

The discharge operation should start only if the fire is under control, oxygen concentration is less than five per cent and the concentration of carbon monoxide is significantly reduced. While removing the material from the silo, keep injecting the nitrogen to the silo bottom. Based on Pacific BioEnergy’s incident, as well as other silo fires, you will have smoldering material coming out and will get clumps and carbonized material. Consequently, it is essential that wellequipped fire rescue personnel be present in all stages of material discharge. While discharging the material, you should also continuously assess the situation inside the silo using the gas reader instruments. High concentration of oxygen or carbon monoxide may indicate you have some leakage of air to the silo or increased material reactivity within the silo. When

removing the material, always try to limit dust formation. When you remove the material from the silo, store it in an open area far from facilities and buildings. A number of lessons can be learned from past incidents. Incorrect tactics can destroy buildings and other assets, as well as result in injuries and loss of life. The following are key points when dealing with a silo fire:

• Never open a silo! Close the silo at all times when dealing with a silo fire to minimize air entrainment. Only a small opening is recommended at the top of the silo to release combustion gases.

• Do not use water to suppress the fire! It may lead to arch formation or, in the worst case, cause the silo to collapse due to pellet swelling.

• Do not enter the area without personal gas monitoring equipment or breathing apparatus.

• It is highly recommended to use nitrogen for inerting purposes as opposed to carbon dioxide.

• Build an emergency plan, communicate and practice it. It is critical to know best practices and move forward deliberately with a plan of action.

Fahimeh Yazdan Panah, PhD, PMP, P.Eng, is the Director of Research and Technical Development for the Wood Pellet Association of Canada. She has held several positions including research associate for the Biomass and Bionergy Research Group at the University of British Columbia.

The silo fire workshop brought together 65 participants including pellet plant operators, firefighters, researchers and suppliers to discuss best practices for preventing and responding to wood pellet silo fires. Photo by Focal Point Studios.

Money matters

Taking stock of biomass financing challenges and successes

By Reg Renner

Financing biomass projects in Canada is a very challenging event, with numerous participants and mixed results. The hurdles can be numerous and those who have tried to finance biomass projects have many bruises and scrapes to prove that it is difficult, but not impossible.

Personally, I have been involved in financing biomass projects since 2004, when I left the forest nursery industry and saw the opportunity to finance biomass boilers in the greenhouse industry. With that introduction to the world of financing biomass boilers, I was soon off exploring the B.C. pellet industry and the challenges of dealing with millions of hectares of dying lodgepole pine. In 2006, I attended the Prince George International Bioenergy Conference (now called the Canadian Bioeconomy Conference) and realized that there was a lot of equipment that required financing and I could follow the conversations

relating to wood waste and developing biomass technologies. What I have since discovered is that financing biomass energy projects is more challenging than any of us imagined. We often underestimate the degree of difficulty and assume that outside investors are as passionate as us and love the challenges of combining biomass technologies with the numerous variables of forest harvesting and biomass processing. Therefore, the first step in financing biomass is to acknowledge that renewable energy can be addictive and habit forming. This warning indicates that we have to work extra hard to put our passions behind us and move into the world of reality. To finance biomass projects in Canada, we must be properly trained and prepared for the race. First of all, it will be more like a marathon race with a steeplechase water jump thrown in for excitement. We need to clearly understand that the process will

challenge all our skills and patience and we must be properly prepared.

I wrote a 10-part series for Canadian Biomass magazine in 2010 to 2011 on a financing checklist that is still applicable, if the chance of successful financing is to be increased to an acceptable level. Nine years later, I still believe that these 10 steps are essential to success. (Find the archived articles at www. canadianbiomassmagazine.ca.)

When reviewing this biomass financing checklist, I began to realize how far we have come and how important the team approach still is. If we were to list the successful biomass projects in the past 10 years, most of us would agree the vast majority of these projects were completed by a professional team of forestry and energy experts. Canada will produce over three million metric tonnes of wood pellets in 2019 and there are now over 50 biomass boiler projects installed in just two regions: P.E.I. and

N.W.T. Although financing biomass projects may be difficult, having a team of experts working together and focused on the same goal is critical for successful biomass financing.

Having a professional team allows the leader to delegate tasks and research requirements to experienced experts that have the necessary skills and previous financing experience. This is one of the positive developments regarding biomass financing; we now have a track record and experienced personnel who have been in the trenches and are willing to share their knowledge with other biomass project developers. Networking with other project developers is extremely important in this developing industry.

Most people who contact me are looking for an appropriate funder or investor. My first question is whether you are properly prepared for the first round of questions. There are so many financing options available that it is quite common for an interested project developer to spend more time looking for a suitable funder than preparing their business plan and financial projections. Therefore, even when you do find an interested funder or investor, you need to be able to respond in a positive manner to their initial round of questions. I have lost count of how many project developers wanted to enter into a conversation with a potential funder and yet they did not have the basic business plan completed or even started. You cannot expect a bank manager to be interested in a 64-page marketing report that does not include a single financial spreadsheet. In reality, it is probably easier to find an interested funder or investor than it is to prepare for the first round of questions and that is why a professional team approach is best.

The people I have met over the past 15 years are amazing and they are passionate about their technologies and the future of bioenergy in Canada. I’m able to sit back and look at how much progress we have made and recognize that, although progress has been slower than any of us would have predicted, it is still progress and more people than ever are now interested in renewable energy solutions and opportunities.

We must be prepared to celebrate our successes and continue to educate our

clients, consumers, and investors, but we also need to understand that working with biomass has many more moving parts than solar and wind financing. You must address the questions regarding feedstock supply and off-take agreements in a more detailed and knowledgeable manner than any other renewable energy project developer. Look in the mirror and ask the hard questions before you go into the investor’s office. Do you own or control the wood supply? You must be able to answer this question with conviction and documented proof.

As people interested in biomass, we have seen recent articles that state how much money is moving towards new low-carbon industries and yet I caution people when they think that pension funds will flock to biomass energy projects. This is because biomass projects have a multitude of interrelated factors that create complexity and unacceptable risk in the minds of most long-term investors. So, while insurance companies invest in U.S. forest lands, we continue to work in a

BIOENERGY PROJECT FINANCING CHECKLIST

different environment than most other renewable energy developers. We must acknowledge our feedstock challenges and create flexible solutions that address risk management head on, and an ideal solution is joint partnerships that share risks and rewards.

An example of developing partnerships is the federal government’s funding through Natural Resource Canada’s Clean Energy for Rural and Remote Communities (CERRC) program. This program for the promotion of biomass heating has taken time to develop and implement, but it is a significant step that is designed to launch the biomass heating industry into the mainstream and reduce the use of imported fossil fuels, such as heating oil and propane. Building momentum and a knowledge base is an important step that gives commercial funders increased confidence with biomass technologies that are now proven and suitable for specific locations and situations. Having additional grant programs gives communities added incentive to go forward with their specific biomass project. Funders prefer projects that have a combination of shared risk and accumulated experience that includes a committed community and governmental support.

While it is extremely helpful to have a suitable grant program to assist with the launch of biomass heating in rural and remote communities, it may be even more important to have the federal carbon tax program in place that will drive future energy and financing decisions. While this is a controversial subject, it is still a significant indicator regarding the potential for renewable energy project financing. When a European-based pension fund decides to move its investments from fossil fuel projects, it is a sign of a growing trend.

We must continue to work hard with a professional team and be well prepared to tell our story about the future of sustainable biomass energy in Canada to ensure that we improve our biomass financing success rates. •

Reg Renner of Atticus Financial in Vancouver finances equipment ranging from biomass boilers to densification equipment. He has been financing biomass projects for 15 years. Contact him at rrenner@atticusfinancial.com

Eliminating boiler barriers

The path to building a robust pellet central heating industry in Canada

By Dutch Dresser and Gordon Murray

Canada produces about three million tonnes of wood pellets a year, putting us in second place globally. Almost all of what we produce is exported. Despite being one of the coldest countries on earth and wood pellets being a low-cost energy source, less than one per cent of Canadian homes and businesses are heated with wood pellets.

Europe, on the other hand, uses 15 million tonnes of wood pellets annually to heat homes, commercial buildings, hospitals, schools and more. This is five times more than Canada’s total production. In southern European countries with warmer climates, like Italy and France, pellet stoves are popular and pellets are purchased in bags. In the colder climates of central and northern Europe, pellet boiler systems used for central heating are more common, and pellets are received by bulk delivery. European manufactured wood pellet boilers are fully automated – as convenient as gas or oil – and only need to be maintained once or twice yearly.

Wood pellets are a clean, renewable, low-carbon energy source. Given Canada’s ambitious GHG reduction targets and the affordability of wood pellets, why are we having such a difficult time growing our domestic pellet heating market?

There are several reasons, but the primary impediment to growing Canada’s pellet central heating market is the shortage of high-quality boilers and furnaces. Many of the world’s best pellet boiler brands are not available in Canada because the regulatory process for certifying boilers manufactured outside the country for installation in Canada is complex. Gaining access to a market that will be initially small is therefore prohibitively expensive. To encourage the development of a robust pellet central heating industry in Canada, the technical barriers to certifying European pellet boilers must be removed.

REGULATORY BARRIERS

It is common for no directly applicable standards to exist for new technologies being introduced to a region. Generally, regulators will use the standards tools they have to try to fit the new technology into their existing regulatory frameworks. In the best cases, this is a Band-Aid solution while proper standards for the emerging technology are created.

However, creating new standards is a lengthy process involving many stakeholder groups. Gaining boiler certification anywhere usually requires compliance with two sets of standards: those associated with pressure vessel and electrical safety, and those associated with performance, particularly efficiency and emissions.

The boiler pressure standard for Canada is known as CSA B51. Rule 4.10.1.2 of this standard stipulates: “Manufacturers in countries other than Canada that manufacture and export boilers and

pressure vessels to Canada shall ensure that all boilers and pressure vessels are stamped with the appropriate ASME Code product certification mark and registered with the National Board.”

These standards defer to codes published by the American Society of Mechanical Engineers (ASME) and the National Board of Boiler Inspectors (NBBI), also a U.S. organization. Although they are well-tested standards intended to protect end-users from substandard pressure vessel fabrication, these standards have a protectionist effect. Imported European boilers are forced to meet North American standards that are sufficiently different from established European standards to require expensive redesign and special fabrication.

The situation for performance standards is more complex as provinces may or may not have adopted standards consistent with CSA B415, the Canadian standard for efficiency and emissions testing of solid biomass heating appliances.

These complexities make Canada look like an expensive market for European manufacturers to enter, so the necessary amount of outside interest and marketing to encourage pellet central heating hasn’t been widely achieved. In provinces and territories where one or two manufacturers have made the large commitment to certification, the markets are growing at encouraging rates. Quebec and the Northwest Territories are the two most rapidly developing regions at this time. Both have grown sufficiently large markets to have bulk pellet delivery available for consumers of

A facilities manager monitors MESys/ÖkoFEN three boiler cascade producing up to 168 kW (573,000 BTU/hour) of thermal output and modulating down to 17kW (57,000 BTU).

Photo courtesy Maine Energy Systems.

various demand sizes.

The countries that produce state-ofthe-art central pellet heating appliances are all members of the European Union. Recently, Canada and the EU entered into a trade agreement known as the Canada Europe Comprehensive Economic and Trade Agreement (CETA), intended to make trade easier among parties to the agreement. The complexity of pellet heating appliance importation into Canada from Europe represents a technical barrier to trade that should be eliminated.

A SIMPLE SOLUTION?

While this looks like a cumbersome, bureaucratic process on its face, rectification of the situation might actually be quite simple. The EU has had more than a decade to develop strong standards for the safety and performance testing of pellet boilers and furnaces. All standards related to pellet boilers are contained or embedded in EN 303-5. These standards have provided demonstrable safety for consumers and high efficiencies and clean emissions for the general good.

Several years ago, forward-looking consumers in Prince Edward Island (PEI) imported biomass boiler systems from Europe for their quality and efficiency. Since the boilers didn’t meet the CSA B51 requirement stated above, the boilers were installed as “open” systems – meaning they were installed non-pressurized. Although open systems are not generally recommended, such systems are exempt from the pressure

vessel requirements of B51. Politicians in PEI asked their technical experts for a solution to this apparently unnecessary conflict between regulations and citizen needs.

The PEI government funded a number of trips to Europe for the chief boiler inspector who worked with manufacturers and TÜV, a major global testing agency, to understand the provisions of EN 3035. Based on the inspector’s findings and recommendations, the government adopted a provision within the PEI Boilers and Pressure Vessels Act for non-ASME boiler certification. This provision expressly allows for the provincial certification of boilers formally certified to meet the provisions of EN 303-5. Similar modification of CSA B51.1 to recognize the EN 303-5 standards in place in CETA member countries would remove the technical barrier to pressure vessel certification that is inherent in the current regulatory situation.

Similarly, Ontario has adopted air quality standards regulations and guidelines for performance and emissions from small biomass combustors that expressly cite the methods and requirements in EN 303-5 (Guideline A-14). Again, recognizing EN 303-5 certification as compliant with Canadian requirements in CSA performance and emissions standards could remove technical barriers to trade.

To encourage the development of a robust pellet central heating industry in Canada, the technical barriers to certifying European appliances must be removed. It may be that the quickest solution is

including exemptions for EN 303.5 certified boilers in relevant Canadian standards, such as CSA B51 and CSA B415. This would continue to protect the public while providing an easier route for importing the equipment that has been certified compliant with EN 303-5 by a recognized testing facility in Europe.

The Wood Pellet Association of Canada (WPAC) is actively pursuing standard and regulatory change to facilitate the importation of state-of-the-art pellet central heating equipment up to 500 kW (1.7 MMBTU/hour) of useful thermal output. This is the equipment expressly covered by the EN 303-5 standards in Europe. WPAC is currently working with CSA Group, the Canadian Counsel of Ministers of the Environment (CCME), and several forward-looking regulators in an effort to engage all relevant stakeholders in a concerted effort to remove existing technical barriers to trade for pellet central heating equipment.

When this effort is successful, Canadians across the nation will enjoy access to a broad range of highly evolved pellet central heating products enabling them to heat with locally produced, renewable biomass energy.•

Dr. Harry “Dutch” Dresser was the founding director of Maine Energy Systems, and is now a consultant in North America for the emerging biomass central heating industry. Gordon Murray is the executive director of the Wood Pellet Association of Canada.

Canada’s leading supplier of commercial biomass heating systems

ASME and CSA certified

Over 100 energy efficient systems installed

Wood-fibre insulation

An effective, renewable choice for residential buildings

By Silvia Cademartori

The last nail driven into wood-fibre panel insulation in a home in B.C. could mark a new standard in building construction for the Canadian homebuilding industry, while ushering in a new era of green, sustainable, and high-performance building insulation for residential and commercial structures.

FPInnovations, 475 High Performance Building Supply, and the Canadian Wood Council have partnered to build three high-profile residential projects located in Ontario, Saskatchewan, and B.C., to demonstrate the suitability of wood-fibre insulation panels for use in residential buildings. The panels are environmentally friendly and are expected to perform better than traditional rigid foam insulation.

The B.C. home, completed in the spring, is the last of the high-performance projects built to Passive House standards in the trial. Contractors used wood-fibre insulation panels imported from Europe, where they’re a mainstay in home construction, instead of rigid foam to insulate exterior walls. The trio behind the initiative are certain the panels can be manufactured in Canada far less expensively than in Europe, with an R-value (thermal resistance) equivalent to rigid foam panels.

“Dry-process wood-fibre insulation panels are the future of building insulation in Canada because we have the natural resourc-

es and industry to produce them economically,” says FPInnovations lead scientist, Bob Knudson. “We have excess fibre from sawmills for their production, and they offer superior performance and insulation, in addition to being environmentally safer than rigid foam insulation.”

SUPERIOR PERFORMANCE

FPInnovations designed tests to determine the fire safety, stability, durability, and insulation rating of the panels. Wood-fibre insulation demonstrates superior fire performance compared to polymer foam insulation types that are currently used in North America. The panels also show superior moisture management in wall and roof systems compared to polymer foam insulation. Additionally, the panels have greater thermal mass, reducing the temperature rise and fall in an interior space.

The panels are made using a dry-processing method of refining wood chips and shavings. The resulting fibre is dried, mixed with polyurethane adhesive and paraffin, formed into a continu-

The exterior walls of the Gibsons, B.C., home are insulated with 100 millimetre-thick wood-fibre panel insulation fastened to the outside of three-ply 100 millimetre-thick CLT load-bearing walls. Photo courtesy FPInnovations.

ous fibre mat, sized to desired thickness, and cured. The resulting panels are then milled to different sizes and edge configurations. The manufacturing process allows for a homogeneous board from 20 to 300 millimetres thick. The panels offer R-values in the 3.5- to 3.9-per-inch range, while polymer foams have R-values in the 4.5to 6-per-inch range. Therefore, wood-fibre panels need to be a little thicker to reach the same R-values as polymer foams.

“We believe that wood-fibre insulation is a high-performance board that is not only breathable and highly insulating, it’s ecologically sound, renewable, recyclable, and lasts the lifetime of the building,” says municipal affairs and technical manager of Wood WORKS! B.C. and the Canadian Wood Council, Peter Moonen. “Wood-fibre insulation is not a structural panel plywood, OSB, or other structural sheathing. It’s a superb insulation panel that offers exceptional thermal and acoustic insulation in both partition and structural walls.”

The three residential building projects were selected in part for their locations in different Canadian climate regions. The Ontario building is a single-family residence near Collingwood in cold, humid climate zone 6A. The Saskatoon project is a nine-unit co-housing development in very cold climate zone 7, while the B.C. house located in Gibsons is in mixed-marine climate zone 4C.

“These panels have the potential to lead a transformation of the North American construction industry towards making durable, high-performance Passive House and zero-energy buildings more common,” says western regional manager of 475 High Performance Building Supply, Lucas Johnson. “We built three unique projects, each with

distinct features, to demonstrate the versatility of wood-fibre insulation panels.”

CUSTOMIZED USES

The Collingwood renovation project adds a two-storey contemporary addition to a 150-year-old pioneer cedar log house. Eighty-millimetre dry-process wood-fibre insulation panels are attached to the outside of 2x8 load-bearing stud walls sheathed with half-inch plywood.

The Saskatoon co-housing project showcases low cost of living through low energy use. It has both 40-millimetre and 240-millimetre panels attached to the outside of 2x6 insulated load-bearing stud walls sheathed with 3/4-inch plywood.

The B.C. single-storey prefabricated house is built to meet LEED Platinum standards. Its exterior walls are insulated with 100-millimetre-thick wood-fibre panel insulation fastened to the outside of 3-ply 100-millimetre-thick CLT load-bearing walls. The green roof has 240-millimetre wood-fibre panel insulation. Performance monitoring instrumentation is installed onto the prefabricated wall and roof modules.

“Our low-cost construction methods required a thick rigid exterior insulation product and wood-fibre insulation is one of the few products we found with negative embodied carbon,” Knudson says. “The pressed-wood fibres trap carbon and sequester it for the life of the building.”