COLUMNS

12 | Power Struggle

The shrimp of the future is intelligently “educated” 30 | Fresh Tips

Navigating mental hazards at work

MATT CRAZE

12 | Power Struggle

The shrimp of the future is intelligently “educated” 30 | Fresh Tips

Navigating mental hazards at work

MATT CRAZE

By Jean Ko Din

Artificial intelligence (AI) has captured the world’s imagination recently. And rightly so. This technology can open up new possibilities of how data is collected, processed and interpreted by a computer.

AI and machine learning technology have been around the aquaculture industry for many years. However, it seems as though it has seen a more accelerated development in the past decade. I’ve seen aquaculture commenters tout it as the “new oil.” I’d love to hear from those of you who have come from the oil and gas industry to confirm whether this comparison is accurate.

I like what ThisFish CEO, Eric Tamm, wrote about the subject. He said, “If algorithms are the engines, then data is the fuel that is bringing about the fourth Industrial Revolution, known as Industry 4.0.”

Its application in a recirculating aquaculture system (RAS) seems like a match made in heaven. A closed, land-based fish farming operation means that every single parameter can be monitored and controlled to create the most optimum environmental conditions for the stock.

With that level of control, naturally, it comes with a pressure for farmers and operators to consistently interpret data collected from every part of the facility – feeding regimens, biofiltration management, dissolved oxygen levels, water temperatures, flow rates, fish size, weight, and the list goes on.

The cover story explores some of the current applications of these deeplearning neural technologies. But, because this magazine can only hold so

many pages, I don’t think we can claim this issue to be a definitive update on AI applications that currently exist in the recirculating aquaculture industry. Still, my hope is that a glimpse into some of these examples can offer some insight about its future potential.

As these RAS projects get bigger, more ambitious and more expansive, AI will play an increasingly important role in the efficiency of these operations.

At the same time, my hope is that some form of AI technology can be made accessible to all aquaculture farmers. I’m thinking of those small to medium-sized, family-run RAS farms that are producing for rural markets.

Technology can only be considered transformative, if it is made to be available to all and can benefit all. Not all new technology is like that. Sometimes, they are reserved for the capital-rich megafarms that can afford the latest and greatest.

Only time will tell how AI will continue to be embraced by the wider aquaculture industry.

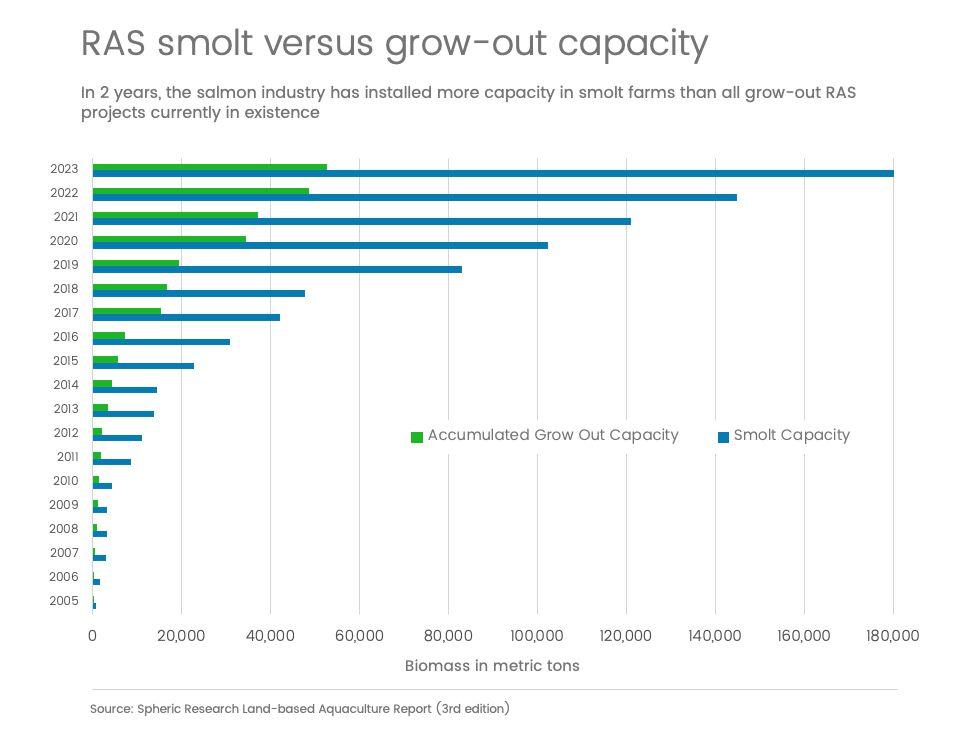

As the year 2023 nears its close, I also wanted to take some time to do a progress report. I’m grateful to Matt Craze and the Spheric Research team for sharing their most recent findings for this issue. Perhaps this can help you take stock of where the industry has come and where you plan to go. Predictions can only go so far, it might be up to you, the professionals working day-to-day to dictate where we plan to go in 2024.

As always, I invite you to join in on the RAStech conversation. Send me your thoughts and ideas at jkodin@annex businessmedia.com.

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact

Angelita Potal, Audience Development Manager Tel: 416-510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din 437-990-1107 jkodin@annexbusinessmedia.com

Associate Editor Seyitan Moritiwon 519-429-5204 smoritiwon@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Account Manager Morgen Balch 519-429-5183 mbalch@annexbusinessmedia.com

Account Coordinator Catherine Giles 416-510-5232 cgiles@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248 abeswick@annexbusinessmedia.com

Audience Manager Urszula Grzyb 416- 510-5180 ugrzyb@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com Printed in Canada

SUBSCRIPTION

RAStech is published as a supplement to Hatchery International and Aquaculture North America.

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Made possible with the support of

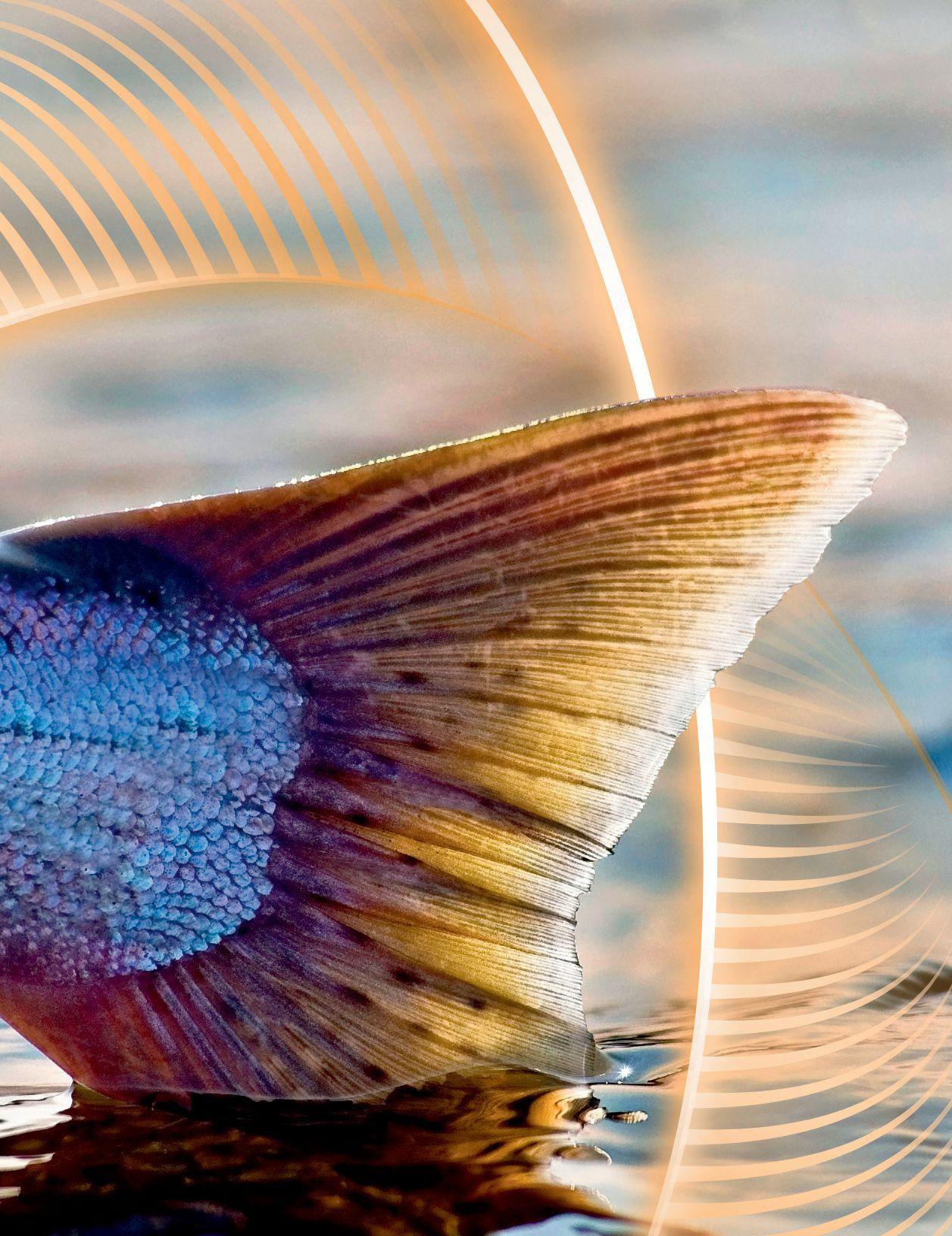

Salmo Terra, the company that would have built Norway’s largest land-based salmon farm, filed for bankruptcy after racking up NOK 32 million ( US$3 million) in debt and failing to attract enough investors. Graintec, a Danish recirculating aquaculture system (RAS) contractor that was hired by the Norwegian aquaculture firm in 2021, also filed for bankruptcy just days after Salmo Terra.

Salmo Terra was having trouble attracting investors. The company was also sued by Øygarden Næringspark AS, a Norway-based landowner, for failure to pay rent amount to NOK 4 million, according to the publication, We Are Aquaculture. Norwegian district court proceedings indicated that Salmo Terra’s total debts amounted to NOK 32 million.

Salmo Terra was founded in 2017. The company planned to build a RAS facility will be located in Øygarden, just outside Bergen, Norway. The total production capacity of the facility was estimated at 8,000 tons annually. This would have made it the largest such facility in the country. Salmo Terra hoped to start construction by the summer of 2022.

The company hired Graintec to provide it with RAS technology. At that time, Graintec had been supplying salmon feed plants and feeding solutions to aquaculture companies for more than two decades. This was, however, Graintec’s first time to wade into RAS construction. Graintec would later provide the RAS feeding system for Proximar Seafood’s RAS operations in Japan in February 2023.

Salmonid genetics firm, AquaGen, has opened Profunda, its new broodstock facility to produce salmon eggs in Barstadvik, in the municipality of Ørsta, Norway.

Back in 2021, AquaGen signed a contract with Artec Aqua to provide the recirculating aquaculture system (RAS) equipment for the US$18-million project that would be Norway’s only land-based full-cycle broodstock and egg production facility.

The facility is designed so that the fish spend their whole life within the facility and under optimal conditions.

“The fish is physically separated from the environment, ensuring a unique biosecurity and exceptional production conditions,” explained in a company press release.

“The river Storelva in Barstadvik has distributed glacial deposits formed during the last ice age, thus creating the foundation for naturally cleaned groundwater through the valley and into the

fjord. We have established wells for fresh and marine groundwater which supplies the facility with totally pure water, and Profunda is thus unique in Norway.”

AquaGen purchased Profunda in 2017, at a stage when the facility produced broodstock salmon for other customers. In 2018, the facility was expanded with 2,000 m3 tank volume for expanded capacity. In 2020, the company started the work to turn Profunda into a full-cycle land-based operation for egg production. The first batch of eggs were delivered in May 2023. The Profunda facility has a capacity of about 100 million eggs per year, throughout the year. It will deliver eggs to sea-based and land-based productions in Norway, with plans to prioritize the export market once necessary permissions from the World Organization for Animal Health are in place.

Land-based salmon producer AquaBounty Technologies has named David F. Melbourne Jr. as the company’s new president.

Melbourne, a 30-year-veteran of the consumer packaged goods (CPG) industry, was AquaBounty’s chief commercial officer for four years before being promoted to the role of the company’s president.

“I am pleased to announce that Dave Melbourne will take on the position of president of AquaBounty, as part of our leadership progression to drive continued growth and expansion,” said Sylvia Wulf, board chair and chief executive of the Massachusetts-based pioneer in the commercial production of genetically engineered salmon.

“In his new role, Dave will oversee the day-to-day business functions for the Company, including current farm oper ations in the U.S. and Canada, R&D, quality, people manage ment, and commercial operations.”

Wulf said that Melbourne’s promotion will allow her to “focus on strategic initiatives, including investor relations, financing alternatives to complete the Ohio Farm, business development including geographic and species expansion.”

“I am excited about my new role as president and working closely with the entire AquaBounty team to deliver future success. The company continues to lead transformative solutions that will benefit the future of aquaculture, our customers and consumers,” said Melbourne.

Prior to joining AquaBounty in 2019, Melbourne was senior vice-president of marketing and corporate social responsibility at Bumble Bee Foods. Prior to that, Melbourne was vice-president of marketing and strategic planning with Castleberry/Snow’s Brands. He was also an assistant product

manager at US Tobacco Sales and Marketing Company.

Wulf said she is confident of her company’s future.

“While land-based farming using recirculating aquaculture system (RAS) technology is still developing, the timing could not be better for the company to leverage our advantages of vertical integration from broodstock to harvest, as well as our several decades of proven expertise in operating land-based RAS facilities; especially as we consider the negative impacts from climate change on food security and the environment,” said Wulf.

Kingfish Maine’s recirculating aquaculture system (RAS) project in Jonesport has cleared another hurdle.

On Aug. 29, the aquaculture company reported that the state’s court rejected an appeal of the project and that Kingfish Maine’s state permit was upheld.

The Maine Superior Court upheld the Maine Board of Environmental Protection’s (BEP) affirmation of the company’s Site Location of Development Act (SLODA) and Natural Resources Protection Act (NRPA) joint permit. The permit was initially issued in 2021 and finalized after an appeal in 2022.

Kingfish Maine is part of the Netherlands-based The Kingfish Com-

pany, which produces high-value Dutch yellowtail. Kingfish Maine announced in 2019 its intentions to build a RAS facility in the town of Jonesport, in Washington County, Maine. However, the company has faced stiff opposition over environmental and permit issues.

The Roque Island Gardner Homestead Corp. and Eastern Maine Conservation Initiative had earlier sought to overturn the SLODA and NRPA joint permit. In their appeal, the two organizations cited what claimed to be the BEP’s “failure to independently assess the project’s impact on wildlife under NRPA.” The two groups said the BEP did not independently assess the project’s effluent discharges.

However, the court concluded that “the Board did not violate NRPA or otherwise act unreasonably by failing to independently assess the project’s effluent discharges.”

The most recent dismissal was the second state-level denial involving appeals to stop Kingfish Maine’s project.

“The opposition from Roque Island continues to be unsuccessful in its appeals of the Kingfish Maine project. This latest appeal denial is a clear victory for Kingfish Maine and more importantly the residents of Jonesport,” said Megan Sorby, operations manager for Kingfish Maine.

Ocean Harvest, a recirculating aquaculture system (RAS) company based in Abu Dhabi, recently appointed venture capitalist Jawad Jamil as its new chief executive officer and co-founder.

The appointment was announced even as Ocean Harvest continues to move towards the completion of its first commercial-scale landbased salmon farm in the United Arab Emirates (UAE).

Ocean Harvest designs, builds, and operates technology-based RAS facilities. With

its strategic partners BESIX and Tech Group, the company designs its own farms from scratch and sources equipment from industry-leading suppliers. Its aim is to “localize the production of Atlantic Salmon in import-dependent markets.”

“Ocean Harvest is a technology-enabled agribusiness based in the UAE, addressing systemic challenges by delivering tangible food security, water conservation, economic diversification, and environmental sustainability solutions,” said Jamil. “I am truly honoured

to join Ocean Harvest at this exciting time and to lead our efforts to harmonize our mission with pivotal goals set by the UAE Government’s visionary agenda.”

Jamil is a senior C-suite executive who has more than 20 years of strategic leadership and finance experience in private equity, wealth funds and the professional services space. Before joining Ocean Harvest, he was co-founder of Quantum Leap Ventures.

Prior to that, Jamil was CEO of UAE-based laboratory firm, Medsol Diagnostics. Jamil was

also chief financial officer at Gulf Healthcare International where he worked for 12 years.

- NESTOR ARELLANO

After what it described as an “intense selection process,” Swiss Blue Salmon announced that it has chosen Norway -based VAQ to design its recirculating aquaculture system (RAS) for a 3,400 metric ton facility in Mollis, Switzerland.

“We have spent the last six months reviewing our strategy and developing a clear vision for how we are going to develop and execute our vision in collaboration with our project partners,” said Sune Møller, Swiss Blue Salmon chief technology officer.

“This has led us to do an extensive assessment of the RAS designers out there and VAQ have come out on top of all the candidates we assessed.”

VAQ supplies complete RAS facilities with fish welfare and focuses on water quality, operational ease, and quality.

From conceptualization to completion, VAQ is involved in project development and takes care of biological production planning, mass balances, construction, and training.

Swiss Blue Salmon wants to be known as a sustainable salmon farmer. The company aims to use the Internet of Things (IoT), big data, analytics, artificial intelligence, and machine learning solutions in land-based fish farming. It was founded by Ruedi Ryf, a fly fisherman who spent hours on water and is focused on protecting the wild population of Atlantic salmon.

“We have many years of experience which are complimented well by the team (Swiss Blue Salmon) brings to the table. They have a lot of local, Swiss, and international experience, which is needed to deliver a project of this kind successfully,” said Marius Hægh, VAQ chief operations officer.

The youngest son of Ikea’s founder, along with other investors, have formed a consortium to own a stake in Re:Ocean, one of the largest land-based aquaculture projects in Sweden.

The Cibonum Group AB is formed by investors focused on promoting sustainable and local salmon farming in Sweden. Re:Ocean bills itself as the “first large-scale investment in salmon farming in Sweden.” The company aims to produce 10,000 tons of salmon annually by 2026.

Re:Ocean’s planned recirculating aquaculture systems (RAS) plant in Säffle is expected to be in full production by 2025.

Among the high-profile investors in Cibonum are Mathias Kamprad, Per Josefsson, Pelle Törnberg and Per Lindberg. Kamprad is the youngest son of Ivan Kamprad, founder of the multi-national Swedish furniture conglomerate, Ikea.

Mathias and his brothers own Ikano Group, which manages Ikea’s real estate and financial services businesses. Ikea is one of Sweden’s largest buyers of

salmon fillets.

Josefsson is a Swedish investor and philanthropist. He is one of the founders and principal owners of Brummer & Partners. Törnberg is an experienced chairman and director of more than 10 international companies including the Modern Tims Group. Lindberg has held several executive positions, including chief executive officer at Epiroc, CEO at Korsnäs, and vicepresident at Kinnevik.

“We want to be the financial anchor for Re:Ocean and together with our industry knowledge we provide a solid foundation for Re:Ocean’s expansion and its mission to innovate salmon farming in Sweden,” Anders Svensson, chairman of the Cibonum Group, said in a press release.

“Re:Ocean is revolutionizing the fishing industry with land-based salmon farming in Säffle, which can meet 20 per cent of Swedish consumers’ demand for salmon.”

Land-based salmon farmer, Laxey (formerly known as Icelandic Land Farmed Salmon) recently announced that it has raised ISK 6 billion ($45 million) from Islandic investors. The company is building a fish farm in Vestmannaeyjar, an archepelago in Iceland, a fry farm in Friðarhöfn and a rearing farm in Viðlagafjörður.

Laxey said it expects the rearing station to produce about 32,000 tons of salmon in 2031. Currently, about 2,000 tons of salmon are produced in land-based farms in Iceland.

The company said the farm in Vestmannaeyjar will be built in six equal phases. The first phase is expected to be ready in mid-2024 and the first slaughter is planned for late 2025.

“We are extremely happy that this milestone has been reached and the trust that investors show in Laxey. We have been working on this project since 2019 and see great opportunities in the production of Icelandic land-farmed salmon in the Vestmanna Islands and sales on international markets,” said Lárus Ásgeirsson, chairman of the board at Laxey.

“The first phase alone will be operationally sustainable, but each additional phase will increase the efficiency of production, with lower investment expenses and operating costs per kilo of salmon

produced,” a press release from the company said.

The company chose the location because conditions in Vestmannaeyjar are favourable for land-based aquaculture.

“A continuous water recycling system is used, where about 65 per cent of the sea is reused, while 35 per cent is fresh ground sea pumped up from boreholes in the area. The water temperature is particularly favourable for salmon farming,” according to Laxey.

The company also said the local municipality is supportive of the project. More than 100 people will work at the company when it has reached full production capacity. The operations will also produce some secondary jobs throughout the year.

“Laxey will base its production on green values, where 100 per cent renewable energy is used and waste will be processed for fertilizer production. In addition, it will be emphasized that the salmon will be transported by sea to the market in order to reduce the carbon footprint,” the company said.

By Maddi Badiola

Maddi Badiola, PhD, PM, is a RAS engineer and co-founder of HTH Full Spectrum based in Basque Country, Spain and USA. She is executive director of the Florida Marine Aquaculture Coalition. Her expertise include energy conservation, lifecycle assessments and RAS global sustainability assessments. Email her at mbadiolamillate@gmail.com.

Shrimp is one of the most widely eaten seafood in the United States where sales volume has increased from 275 to 415 million pounds per year in the last five years, and coincidentally, it is one of the most valued and consumed fish (seafood) in the Basque Country. We eat it throughout the year in great quantities, especially on special occasions such as Christmas.

In such context and talking about such a valued species with huge potential, its farming methods need to be improved to be environmentally friendly, efficiently produced and thoroughly traced.

Traditional shrimp farming has devastating environmental costs. It is here where RAS farming has great importance, and it is expanding its presence in the industry. There are already numerous RAS shrimp production companies worldwide – to name a few, Atarraya in Oaxaca, Mexico; Noray in Medina del Campo, Spain; TransparentSea in Downey, Calif.

Their farming methods are diverse –biofloc farming, Clear Water or hybrid technologies. Each manager has his/her own preferences. They show off ultra-fresh cultivated shrimp, from the tanks to the table, in a few hours.

Shrimp farming has had exceptional growth, but the industry is still plagued by many issues such as disease outbreaks, general health management and poor environmental management protocols leading to mass mortality events and disrupting the supply chain.

Also, despite the growing application of RAS technology, digital precision aquaculture has a long way to go.

Umitron, the Singaporean firm that first launched real-time, AI-based analytics solutions for shrimp farming, stated

that the poor uptake and adoption of digital technology by shrimp producers has been one of the limiting factors stunting the sector’s growth, both economically and with regards to sustainability. And the sector is huge!

Every single shrimp counts as a very valued species, both economically and socially. The attention should go into analyzing and checking their real-time condition in terms of behaviour, comfortability, and happiness. Remember that a happy shrimp is a tasty shrimp!

Umitron’s technology, called Umitron Eagle, is said to use “advanced Artificial Intelligence (AI) detection to track multiple real-time biological conditions and other factors in highly turbid and intensive production environments.”

As I mentioned in my previous Power Struggle column, AI can help to reduce the energy consumption of a RAS farm by 20 per cent by improving feeding regimen and strategies. Also, it can make manag-

ers focus on operational issues that are otherwise hard to see.

AI is helping producers improve feed conversion rates (FCRs); biosecurity measures and work protocols; reducing feed waste (which contributes to undesirable environmental conditions such as poor water quality and highly turbid conditions requiring frequent water changes); and refining long-term farming management protocols and optimizing operations using the accumulated production data.

Oceanloop is another pioneer in shrimp farming, implemented in 2022. It is an AI-based technology that was developed by researchers and engineers. A computer-vision-based system can count the number of shrimp and measure their length at up to 95 per cent accuracy. This technology gets real-time data under actual farming conditions (i.e. high stock densities and cloudy water). Moreover, mainly due to the new animal policies in

Europe and worldwide, ethical farming methods need to be applied and as such improved, and this technology directly covers it.

Atarraya Inc., a Mexican company that has invested in a model farm in the U.S. State of Indiana, shows that its system

for shrimp farming can work on a large scale, producing shrimp in shipping containers powered by a computer running AI algorithms (ShrimpBox). One of their main goals is to reduce anywhere from one-third to one-sixth of the energy used to heat the water. This can allow for a very efficient and less polluting technology.

In an AI-driven aquaculture environment, the next real and important step is educating people and farmers, and this reminds me of my beginnings in aquaculture and RAS.

Aquaculture education is an ongoing topic and recurring issue. Education in every level, from management, operations, husbandry, and now digital technology, such as artificial intelligence. For example, Atarraya’s main reason to turn into AI was because it used to take four to six months to train someone to maintain the ShrimpBox. This could now be lowered to several weeks with the help of AI.

That is why I will never stop requesting more attention from the industry to educational programs. The need for an industry-based animal production system is more important than ever. Biological and digital technology are driving the world. The production companies request solutions researchers offer answers, and not vice versa.

By Colin Ley

Amulti-million dollar RAS salmon farm is scheduled for development in Grimsby, on the east coast of England, with the promise that it will feature state-of-the-art technology.

The company behind the development is Aquacultured Seafood, whose directors have already commissioned the Israel-headquartered AquaMaof Technologies to give the new unit its exalted technology edge.

The Grimsby project is set to become the UK’s first major salmon farm outside Scotland with its planned east coast location, close to the busy port of Hull, being the result of extensive site research covering the length and breadth of the country. The project is meant to establish the Lincolnshire town as a pioneer of UK aquaculture and reinforce its reputation as Europe’s seafood capital.

First submitted for planning authorities at North-East Lincolnshire Council in Decem-

ber 2022, and the focus of a free-access public meeting in May this year, the company is still waiting for development approval to be granted.

Despite the slow pace of this part of the process, Aquacultured Seafood’s development prospectus remains upbeat and expansive, declaring that an initial seed round to raise in excess of £100 million (US$125 million) to support the project has already been successfully completed and that a second investment raise is being prepared, dependent on the planning application being successful.

Presented to the local public meeting as a 5,000-tonne-a-year output venture, the development is also profiled as being capable of generating “at least £100 million inwards economic investment” while creating 100 new jobs for the local area.

Asked by RAStech to expand on their topgrade technology claims, Aquacultured Seafood director, Mike Berthet, said that with

AquaMaof is due to build several RAS system iterations before embarking on the Grimsby project. He was confident there will be “a number of enhancements” by then “as technology moves forward.”

“Having evaluated many other technology providers, we chose AquaMaof for their ability to demonstrate a successful, commercial version of a salmon farm at their facility in Poland,” he said. “They have also helped enormously with their technical know-how to provide the platform for Proximar Seafood in Japan, which has also given our Grimsby team insight into how they operate, which clearly fits with our own expectations.”

On the question of how much ongoing advances in artificial intelligence (AI) will play in the final Grimsby unit, Berthet added: “The pace at which AI is expanding will no doubt mean that it will be in the mix in relation to various parts of our project: design and operation, feed formulation, genetics, or helping in ways we cannot yet imagine. We

will certainly be exploring how this new part of the fourth Industrial Revolution may be able to out-perform the methodology which is currently available to us.”

A high priority challenge for Berthet and fellow his directors, Craig Anderson and James Fox Davies, has been to present the benefits of their planned project to local officials and the general public, faced with inevitable questions over the potential disruption the development might cause.

Dealing with issues such as site noise, smell and the potential impact on the local wildlife, the company prospectus said it embraces each in turn, declaring noise to have been independently assessed as “low impact,” smell as set to be “controlled within the facility,” and wildlife issues to have been subject to surveys in 2021 in accordance with Chartered Institute of Ecology and Environmental Management. It is also declared that, where possible, wildlife habitats will be created within the proposed layout to provide additional ecological interest.

In addition, the prospectus states that the optimum location for a UK-based onshore aquaculture farm has the following attributes:

• Strong knowledge of fishing and food processing sectors close to the site.

• Proximity to existing food processing facilities to significantly reduce food miles for:

• reduced environmental impact.

• increased freshness of seafood when delivered to processors.

• Proximity to saline and fresh water sources.

• Near food waste processors.

In this context, Aquacultured Seafood makes the point that Grimsby ticks a lot of boxes by virtue of the town’s 1,000 years of fishing heritage. There are already 6,000 local jobs linked to fishing and fish processing and 70 per cent of UK salmon is already processed in the area.

“The future of sustainable fish farming in ‘Great Grimsby’ is now within reach,” concludes the company, setting the scene for an early start to the development once the planners give the final go-ahead.

By Nestor Arellano

Just as it did with the enterprise of space a few years back, artificial intelligence (AI)-driven solutions are creating quite a buzz in land-based aquaculture space. Is it time for your company to jump on the AI bandwagon?

In simple terms, AI is a field of computer science which focuses on computer software that is able to mimic the way humans perform complex tasks such as learning, analyzing, and solving complex problems.

Some general real-world examples of the use of AI include video streaming services that provide movie recommenda -

tions based on films you’ve watched previously; automated spam filters; and bank programs that can detect potentially fraudulent activities. Artificial intelligence is often used with or interchanged with the term machine learning (ML). However, ML is a branch of AI. Machine learning focuses on the use of data and algorithms to imitate the way hu-

mans learn to allow technology solutions to improve their accuracy.

Think of machine learning as one of the methods used by AI to accomplish its task. Robotics is another subset of AI. In robotics, the focus is using computer science and engineering to create machines capable of learning and performing complex tasks.

Many of today’s AI solutions have the potential to help you cut cost and boost productivity, according to Brian Jackson, research director for the chief information officer (CIO) space of Toronto-based company Info-Tech Research Group. However, as with any other business tool, it’s best to look before you leap, according to Jackson.

“Asking what AI tool you should purchase is like putting the cart before the horse,” says Jackson. “As with any technology project, you need to start with questions like: What is the business problem we need to solve? How will this technology impact my operations? Will this make me more efficient? “

Training and ease of use is

another issue. Before investing in an AI solution, operators should ensure that adequate training and support is available for the personnel that will be using the technology.

AI solutions rely on data inputs. Fish farmers should also be mindful of potential data risks when using cloud-based solutions. You could be putting proprietary data or information you don’t want competitors to know at risk when you use cloud-based tools warns Jackson. Operators need to make sure they understand what safeguards are being employed to protect their data.

Jackson also recommends that any technology implementation should have measurable results. “Make sure you

get the metrics. Measure the results. That way, you can decide if you want to scale-up.”

At the heart of AI solutions is its capacity for predictive modeling, according to Jackson. Instead of relying on predefined equations or assumptions, AI models learn patterns from past data. They are able to make predictions or decisions without being explicitly programmed.

“The core of AI solutions has always been predicting,” says Jackson. “AI is undeniably good at predicting outcomes using information that is in front of it.”

There are a number of key

areas where AI can help organizations whether they’re a conglomerate or a land-based fish farm.

In aquaculture, predictive analytics is now being used to monitor fish behavior, diagnose diseases, estimate biomass, determine feed conversion ratio, monitor fish volume and stocking density, measure water quality, and forecast events.

“Generally speaking, AI solutions can help boost economic performance, increase productivity, cut production cost, aid in reducing environmental footprint, and even assist in security measures,” says Jesse Ronquillo, an aquaculture scientist and who is an adjunct professor at the Dal-

fluctuations in pH, nitrite, ammonia, and alkalinity levels. An example of such tools would be Innovasea’s aquaEnvironment platform uses unwater sensors uses sound waves to wirelessly report on variables such as water temperature, salinity, and dissolved oxygen. The European Union funded project called SHOAL actually uses a robotic fish equipped with onboard sensors that measure salinity and detects pollutants in the water it swims through.

2. Feeding and growth statistics –There are a number of AI-powered solutions designed to help fish farm operators measure statistics around feeding and fish growth. These tools are designed to minimize food wastage, optimize consumption, and help farmers finetune growth and survival strategies.

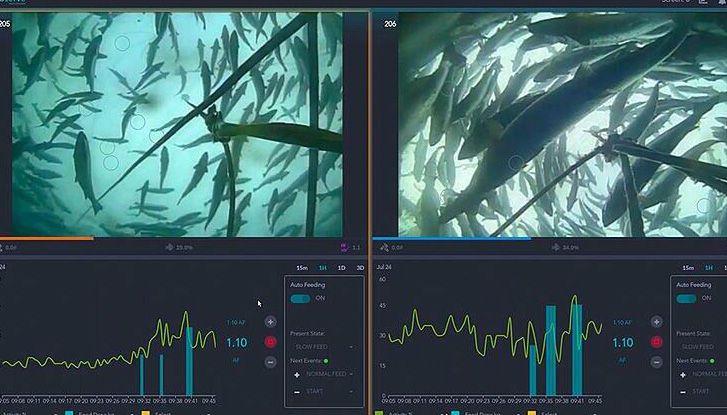

3. Tokyo-based Umitron has a plugand-play AI tool called Remora that uses real-time monitoring of the swimming behavior of fish to determine how much feed should be released. The system also allows operators to remotely release the feed without having to visit the site.

4. The AKVA Group has recently bought a stake in Observe Technologies. Observe Technologies has an ASI tool keeps track of measurable patterns in fish movement to determine deviations and abnormalities. This allows the software to determine when to minimize or increase feeding.

housie University and teaches in the aquaculture program of North Island College in British Columbia.

“For example, consistent aeration to oxygenate water in the culture system helps the fish to breathe, survive, grow, and reproduce. AI can help you monitor, manage, and maintain the oxygen levels in the water.”

Ronquillo says AI solutions for aquaculture purposes are often found in the following areas:

1. Remote monitoring – AI enables fish farmers to remotely monitor and maintain facilities. These AI driven tools can alert farmers of things such as power outages, water temperature, oxygen levels,

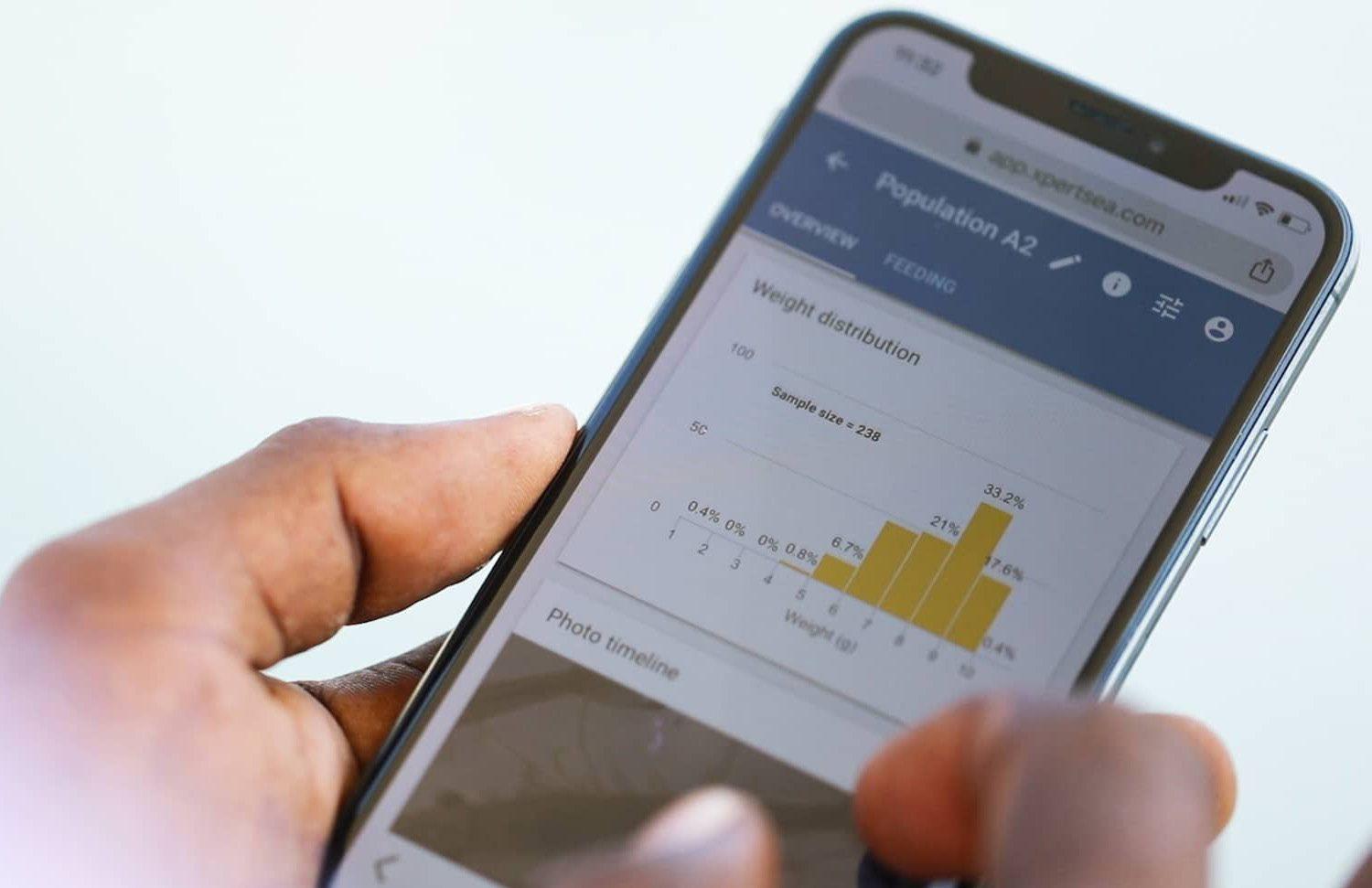

5. XpertSea takes the guesswork out of deciding when the best time is to harvest shrimp. The company’s GrowthPlatform tool uses computer vision and AI to calculate the growth of shrimp. It uses AI techniques such as deep learning to predict the most profitable harvest periods. The software is continuously learning. It collects

historical data on growth cycle to provide more accurate predictions. GrowthPlatform has an online management software that provides fish farms actionable insights throughout the production cycle.

6. The BiomassPro from Innovasea is an AI-driven camera that is able to estimate fish size and weight in real time. The tool can provide accurate growth projections and improve resource planning and sales forecasting. BiomassPro is available for six species: Atlantic salmon, cobia, Chinook, red snapper, totoaba and yellowtail kingfish.

7. Disease detection – Artificial intelligence methods can also be used to annotate data and present them in a way that predict potential disease outbreaks. Norway’s Seafood Innovation Cluster launched its cloud-based platform AquaCloud in 2017. AquaCloud uses IBM AI platform Watson in detecting and predicting lice development in water so that infestation can be dealt with earlier. This reduces the dependence in expensive medical treatments.

8. The Indian company Aquaconnect developed FarmMOJO. The mobile application records production data such as water quality parameters, biomass conversion and health status to alert shrimp farms of conditions that could be signs of disease occurrences.

The increasing use of AI in land-based aquaculture will allow operators to focus on other tasks such as strategic planning, says Ronquillo. He foresees an increasing use of AI as these tools become more powerful.

“The use of AI in aquaculture negates the need for fish farmers to manually perform tedious activities for long hours,” says Ronquillo. “Predictive analytics is also paving the way for aquaculture practitioners to obtain actionable insights to strategize their upcoming actions.”

Innovasea’s BiomassPro estimates the size and weight of fish stocks in real-time.

Since blutanQ was launched, most major RAS developers have taken advantage of our support services that cover design, technical, commercial and construction project input.

The recent award of BSI Kitemark Certification for customer service reinforces our promise of customer care from start to finish.

• Unique and protected epoxy coated steel tanks

• BSI Kitemark certification for customer service

• Added value warranties and regular inspection options

• 40‐year track record

By Christian Pérez-Mallea

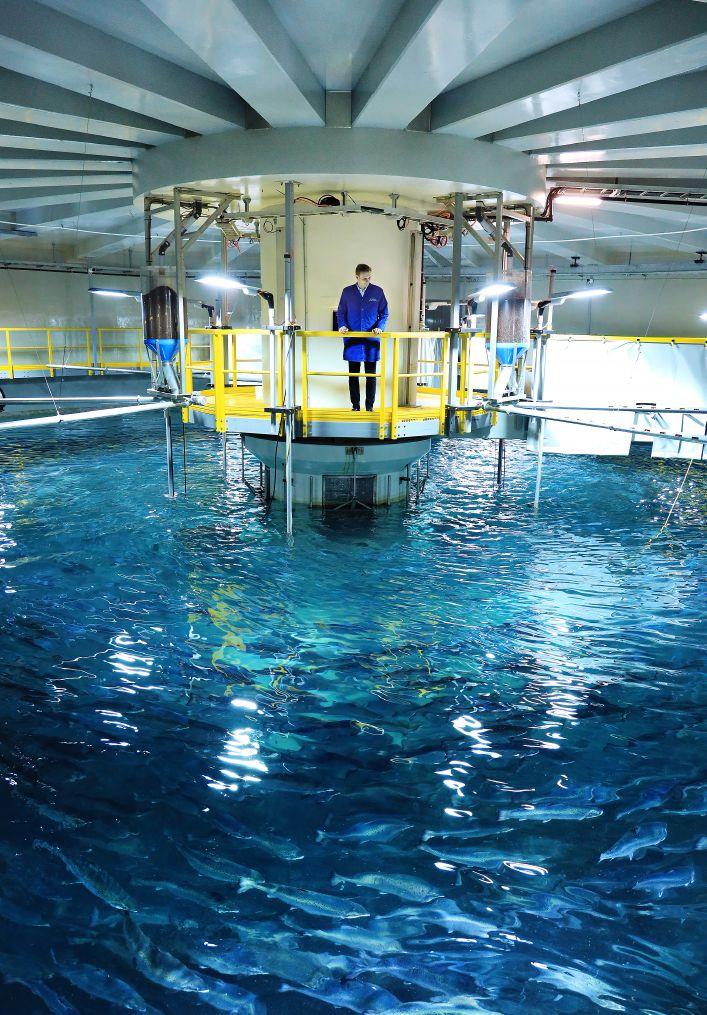

Located in Puerto de Mazarrón in the southeast of Spain, the Infrastructure for Atlantic Bluefin Tuna Aquaculture, abbreviated as ICAR in Spanish, is approximately 70 km south of the city of Murcia. This facility is one of the five land-based farms owned by the Spanish Institute of Oceanography (Instituto Español de Oceanografía or IEO) in the country.

Construction of this facility began in 2011 and was finally completed in 2015, with an investment of nearly €6 million (US$6.3 million). As the IEO is dependent on the Ministry of Science and Innovation of Spain, this facility is 100 per cent publicly owned and is in-tended to generate knowledge about the breeding of Atlantic bluefin tuna (Thun-nus thynnus) in captivity. Highly prized as a food fish, especially for sushi and sashimi, bluefin tuna is one of the world’s most lucrative commercial fisheries. This situation may

explain the severe overfishing this species faces and the importance of the farming techniques being developed here.

This research center has an installed capacity of 7,000 m 3 for tuna farming, divided into just four tanks: two for breeders, measuring 3,500 m 3 (10m deep with a 22m diameter) and 2,600 m 3 (9m deep with a 20m diameter); and two smaller tanks intended for juveniles, with capacities of 1,000 m 3 (5.5m deep with a 14m diameter) and 300 m 3 (3m deep with an 8m diameter).

The water supply is obtained from the sea through a nearby desalination plant before entering the ICAR premises. Due to its high quality, it is treated using only backwash disk filters before being incorporated into their Recirculation Aquaculture System (RAS). This RAS includes mechanical, biological, and chemical filters, as well as a skimmer and UV filters.

Other species, including sea bass

( Dicentrarchus labrax ), sea bream ( Sparus aurat a), greater amberjack ( Seriola dumerili ), dover sole ( Solea sole a), Atlantic wreckfish ( Polyprion americanus ), and Blackspot seabream ( Pagellus bogaraveo ), are also reared in this facility for research purposes. However, one of the most widely publicized recent achievements at this farm was the first worldwide on-land reproduction of bluefin tuna (see sidebar). About 10 people work here permanently.

Over the past 20 years, most of the ICAR’s operations have involved catching wild adults and subsequently using them as breeders. The resulting fingerlings were then raised at their land-based farm until they reached 5-10g in weight, after which they were transferred to sea cages in several consortiums they participated in with private companies. Once the farm became fully operational, the research team started farming and maintaining those fingerlings until they reached adult size in tanks.

These individuals have ultimately become their first breeders that have never lived in the wild. Despite their success in closing the life cycle of this species, the researchers at ICAR still face significant challenges.

Aurelio Ortega, Chief of the Aquaculture Department at ICAR, believes that working with tuna is still very difficult. “The mortality rates are extremely high. From the larval stage until first feeding, we can face mortalities of 97-98 per cent, with a survival rate of only four per cent in the most favorable case, and very often between one to two per cent,” he explained.

“Besides, their way of dealing with any source of stress is to swim very fast when at sea, where nothing happens to them. Here, if they swim very fast and don’t have a perfect perception of the tank wall, they crash into the wall and die, or collide with each

other when they are eating. We have that problem, which is more frequent in fish born in captivity than in wild individuals,” he added.

Among other future research areas, the scientists at ICAR emphasize the importance of improving spawning results and feed consumption in larval stages, reducing mortality rates before grow-out, and eventually developing a genetic program.

“We have had some successful spawnings, but not as many as we would have wanted. Figures have improved compared to last year, and we have some ideas about where the problem may lie. These are animals that require a lot of tranquility, a perfect diet, low farming density, good water quality, etc.,” Aurelio Ortega said.

Regarding pre-fattening, these Spanish researchers have a project aimed at determining all the causes of mortality that occur while also focusing on the quality of the fingerlings produced.

“Establishing a genetic program is going to be challenging, but it’s something we want to pursue. We may have to work differently than with other species, as we cannot have several tanks involved due to the large

size of these fish. We may need to rely on genetic studies of the offspring to determine their parentage, but it’s one of the lines of work we want to pursue,” he added.

Since the participation of the IEO in the European project ‘Domestication of Thunnus thynnus’ (DOTT) and its subsequent projects, the researchers at ICAR have collaborated with numerous private companies, such as the Ricardo Fuentes Group, Malta Sea Farming, and Piscifactorías Albaladejo. These initiatives recorded the first breeding of bluefin tuna in captivity and the production of 14,000 juveniles intended for grow-out, among other achievements.

“We are now collaborating with a company from Cape Verde and supporting a Swiss firm that wants to set up here in Spain. Our results and knowledge are improving every day, and these companies want to be pioneers and be prepared to become the first to industrially produce bluefin tuna from juveniles born in captivity. However, we are not yet at the point where this technology allows for industrial-scale bluefin tuna farming,” Aurelio Ortega concluded.

The ICAR research team bred bluefin tuna in captivity for the first time in 2016, although this milestone was achieved in sea cages. Later that year, a very strong storm destroyed those cages, forcing the researchers to start the process again the following year. Twenty-five fish, each weighing about 150 kg, remain from those individuals hatched in 2017. Combined with eight adults born in 2018, they complete the breeder stocks at the facility.

On July 15, some of these breeders started spawning at ICAR, establishing a new breakthrough with this species: the reproduction of bluefin tuna in a land-based farm.

By Matt Jones

Post-smolt growing, where fish are raised on land before being transferred to a sea pen to finish their maturation, has become increasingly popular over the past decade.

However, while the technique makes a great deal of sense – that giving the fish more time to grow in a controlled environment would make them more resilient to some of the stressors that they will encounter in the sea – those benefits have not been scientifically proven yet.

Moreover, as Norwegian Institute of Food,

Fisheries and Aquaculture Research (Nofima) Senior Researcher Trine Ytrestøyl explains, there are some challenges with mortalities when the fish are transferred to the sea pens that are the subject of ongoing research.

“We did a survey that had a question about how they rated the performance of these larger smolts in seawater,” says Ytrestøyl. “In Norway, this is kind of a new operation to move large smolts into seawater pens after keeping them on land – there’s not so many producers yet that are going beyond around 300 grams, but its increasing. But the majority said that the performance of this larger smolt

could be poorer than smaller smolt. And in trials we have seen this as well. There seems to be some issues that are not resolved about why these bigger smolts have more issues related to mortality and also, in growth during the first period in seawater.”

Ytrestøyl is quick to note that these findings are very preliminary and far from comprehensive. As noted, post-smolt growing is still a fairly new approach in Norway, and there is a significant amount of variation between the species that are being raised, the logistics of land-based RAS systems, and the conditions in the sea where the fish are being kept. Given

all those variables, it is entirely too early to draw conclusions and more focused research is required.

“The problem is the way the smolts are produced are quite diverse in Norway,” says Ytrestøyl. “Some give them a winter signal, some do not. Salinity may vary between freshwater up to 22 ppt. Some give them feed to induce modification. There’s so many different protocols that it’s difficult to say which one is the best one.”

One of the theories which seems to hold the most water – no pun intended – is that temperature differences could be a significant factor. Ytrestøyl observes that Norway has a long coast with a variety of different temperatures, which then also lead to a variety of different conditions for parasites and other pressures.

“You have so many factors, it’s difficult to pinpoint which is giving the bigger smolt problems,” says Ytrestøyl. “And of course, the infrastructure is dimensioned for a smaller

fish. So is it really optimal when you want to transport and pump a fish up to one kilo? It’s a new kind of production and it’s evolving quite fast.”

A summary of the NOFIMA survey does include some general recommendations, citing that a temperature of 10-12 C is recommended to ensure good growth in seawater and to reduce early sexual maturation in male fish. The use of a winter signal to induce smoltification is recommended to ensure seawater tolerance and performance. Water velocity should be around 1.0-1.2 body lengths per second. And a salinity of 12-15 ppt has been shown to give optimal growth in several studies and is considered to cause fewer problems with skin health and wound formation.

“But it is uncertain whether 12-15 ppt is sufficient to maintain seawater tolerance in large smolts,” says the summary. “It is recommended that the fish is acclimatized to the sea temperature so that the change in temper-

ature is a maximum of 3-5 C, and transfer of large smolts at cold water temperatures is not recommended. Several breeders experience challenges with fish welfare if the density exceeds 65-70 kg/m3 and the majority believe that 65 kg/m3 is a good limit value that safeguards water quality and fish health.”

However, while Ytrestøyl and NOFIMA stand by those recommendations, there is so much variability in the different techniques and conditions both in RAS and in the sea pens that more research will be necessary before specific causes and solutions are identified. But that research is not merely being driven by academics – the industry themselves are heavily involved in exploring the challenges and potential solutions.

“It’s a huge job to find the optimal environment for fish,” says Ytrestøyl. “We are, of course, not near finding the right answer, but it’s a continuous process. And it’s important, because we have to get the mortality numbers down because they are too high.”

By Matt Craze

Matt Craze, As founder of Spheric Research, Matt Craze has carried out consultancy projects in Latin America, Europe, and Asia. The company has carried out eight multi-client studies through an exclusive partnership with Undercurrent News. Through Spheric Research, Craze conducts business with several major agricultural and aquaculture companies, governments, and NGOs.

How far away is land-based salmon aquaculture from

Four-kilo Atlantic salmon swim in perfect harmony at the huge tanks at Salmon Evolution’s Indre Harøy site in Norway in mid-August. They were due to be harvested the following week.

This is now Salmon Evolution’s third batch of fish since opening its modern hybrid flowthrough facility in 2022, and things are going well, despite a minor mortality event in May. The company is on track to grow a record biomass of 1,620 tons in Q3, and steady-state production of the plant’s 7,900 tons a year of installed capacity is expected by the end of the year.

“We thought that we had proven concept on the first batch, but proof of concept is doing it time and time again,” said the company’s finance manager, Hans Petter Mortveit. “Maybe we can say at the end of the year that we have achieved proof of concept.”

Proof of concept doesn’t necessarily translate into good news for full-blown salmon RAS. Salmon Evolution replenishes a third of its water needs, and with the constant of fjord water replenishing its tanks, it can live without a biofilter, relying only on drum filters for particle removal.

Atlantic Sapphire, which has long held the flag for a full recirculation system, is at the lowest point in its history after reporting further setbacks related to temperature, leading to a collapse in the company’s share price. The company is installing new chilling equipment in September, which it says will solve the problem. But industry observers are not convinced.

“The hope of a full capacity harvest by the end of this year has faded,” said Mindaugas Cekanavicius, an equity analyst at Norne Securities in Norway, who rates Atlantic Sapphire’s stock a “hold”. “No more harvest targets are provided, while the Phase 2 construction is basically paused until break-even results.”

With Atlantic Sapphire still far from proving concept in Miami, it will be upon others to reach steady state. In Spheric Research’s second edition of its Landbased Aquaculture Report, published in 2021 via Undercurrent News, we identified a new cohort of projects that could share the burden of being industry pioneers.

We identified 20 salmon full RAS projects that had positive traction in the third edition of our report, published in early 2022, and another nine developing hybrid flowthrough systems. None of those full RAS projects are as close as Salmon Evo -

lution in demonstrating a consistent production pattern.

Two projects that have been funded via the Norwegian stock exchange – Nordic Aqua Partners in China and Proximar Seafood in Japan – both have fish in the water and are aiming to harvest in early 2024. Both companies have reported proficient project execution so far.

Knut Nesse, CEO of the AKVA Group and the engineering firm behind Nordic Aqua Partners, predicted at this year’s North Atlantic Seafood Forum that the China project will prove salmon RAS aquaculture at scale.

There are other industry front runners worthy of close attention. Danish Salmon, now owned by Japan’s Marubeni and Nissui Corp., was among the first companies to break the 1,000-ton-a-year production barrier. Arne Baekgaard, who oversaw the early success of the project, has now delivered a first harvest at Skagen Aquaculture, a brand-new facility also in Denmark. The company has an installed

capacity of 3,800 tons a year, which is similar in size to the Nordic Aqua Partners project.

In Sweden, Matthias Kamprad, heir to the Ikea fortune, has backed Re:Ocean, one of a few projects going ahead in the world. Hima Seafood is building a 7,000-tons-a-year trout RAS facility in Norway, following a surprising US$40 million investment from impact investment funds. Japan’s Maruha Nichiro, the world’s largest seafood company, teamed up with Mitsubishi Corp to build a project.

Beyond these exceptions, there are a handful of smaller companies that are reporting good progress. Patagonia King Salmon in Chile is harvesting chinook salmon in a RAS system, a first for that species.

Mainstream investors are still on the fence. Inflation in construction materials, leading to major increases in capex estimates, has not helped. Regulatory issues, meanwhile, have dogged the go ahead of projects in the US.

With the strong performance of Salmon Evolution, and early success shown by Andfjord Salmon in ramping up another project in northern Norway, flowthrough systems are getting better access to finance when compared with full RAS projects.

Also in Norway, Gigante Salmon is moving ahead with a similar project, and Salfjord Salmon finally won a permit to build a project in the Scandinavian country. Critically, the land-based projects will not be subject to Norway’s resource tax on open net pen farming, which came into effect this year.

However, tax authorities are not issuing any new licenses to land-based projects until they have assessed the nature of hybrid farming. Some projects, where the flowthrough component of the project is caused by tidal water, might fall into a grey area, according to Anne Hvistendahl, the global head of seafood for DNB Bank in Norway.

Iceland has also become a hot spot for flowthrough projects, and most of these

• 100% Titanium Heat Exchangers

• Hot & Cold Water Loop Systems

• Available with Tube Sheet, Helical Coil, or Plate

• Compact Designs

• Easy Installation

• Salt & Fresh Water Safe

• Chiller & Heat Pump Packages

• Electric Heaters & Gas Boilers

plan to tap underground water resources available on the volcanic Reykjanes peninsula. What makes Iceland unique is the availability of freshwater and brackish water at suitable temperatures, and the fact that Samherji, a major fishing company, has been successfully harvesting fish from land-based flowthrough farms for more than two decades.

First Water, a project previously known as Landeldi, announced June 30 that it raised €82 million (US$88.1 million) to fund the first phase of construction of its farm with capacity of 8,500 tons a year. Samherji also announced in August that it got regulatory go-ahead for its 40,000-tons-a-year megafarm.

Transplanting the flowthrough concept to other countries may be difficult, given it involves discharge of fecal matter. The development of these types of projects may just be limited in scope to countries like Iceland and Norway, which have a strong fishing industry heritage and have been highly supportive of their aquaculture industries.

Rabobank predicts that salmon production from flowthrough farms may exceed 100,000 tons a year by 2030, led by the current generation of projects in Iceland and Norway. The bank’s main aquaculture analyst, Gorjan Nikolik told

Undercurrent News.

“You really see that there’s capital available for these projects,” he said. “They’re already demonstrating that there is going to be pretty good variable costs.”

While full RAS projects have an uncomfortable wait to proving concept, they may be helped by the emergence of the hybrid flowthrough sector. The building of new flow-through facilities is cultivating best practices in construction work, choice of building materials, and water treatment systems, all of which are applicable to full-scale RAS plants.

Just in the past year, dozens of industrial companies from providers of engineering solutions to oil and gas rigs to chemical companies, are introducing a new generation of products and services that can improve RAS.

Take companies like VEGA Grieshaber, which provides sensors to oil wells and mining companies. Or Denmark’s Desmi, which makes pumps for oil and gas. Or Evoqua Water Technologies, a water company that is introducing filtration equipment to RAS.

The other tailwind that will serve the RAS industry is the rapid development of Norway’s post smolt industry. Just in

2023, Norwegian net pen farmers and dedicated smolt producers will commission more than 35,000 tons a year of smolt capacity, more than all installed capacity in the grow out sector to date, according to Spheric Research data. The standardization of RAS systems at the juvenile stage of mainstream farming can only help the industry in consolidating knowledge about indoor farming.

Companies like AKVA Group, for example, are honing digital systems on post smolt systems, and enabling more predictability without systems.

“The technology is not going as fast as we think,” AKVA Group’s sales director for land-based, Jacob Bregnballe, said at the recent AquaNor industry event in Norway. “There is a lot of information around that we can gather and become better in the future.”

Even with these tailwinds, it’s ultimately now beholden on the new cohort of projects, from Hima Seafood to Nordic Aqua Partners and Proximar Seafood, to demonstrate early success from first harvests. With limited supply, and the resounding popularity of salmon as a healthy, Omega-3 rich protein around the world, the type of proof-of-concept shown at Salmon Evolution will be a game changer for the industry that is short of product

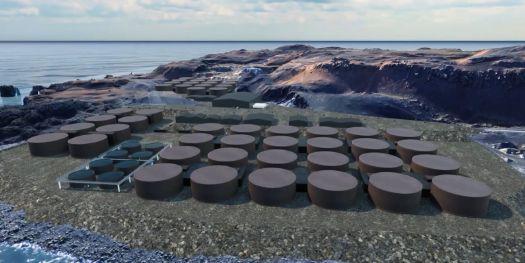

AKVA group is building RAS facilities to meet Nordic Aqua Partners’ (NOAP) goal of achieving 20,000 tons of production near Shanghai.

The company says the delivery of a 4,000-ton live salmon capacity for the first phase will be completed by the end of 2023, and an additional 4,000 tons for the second phase has begun. According to AKVA’s website, “The first salmon reached around one kg this summer of 2023, which means that NOAP is on time for the first harvest of five kg salmon in Q1 2024.”

A land-based salmon farm in Ningbo, near Shanghai, will reduce CO 2 emissions that come from importing salmon and the additional costs of long-distance transport and special packaging. The project will also benefit from a 400 GWh solar and wind power plant near the farming site, and solar panels on the roof to cover approximately 25 per cent of the energy consumption.

“Farming of salmon close to the market, and based on green energy, is an attractive combination both for consumers and investors,” says Johan Fredrik Gjesdal, COO of AKVA group Land Based.

www.akvagroup.com

Nofitech, a Norwegian supplier of module-based automated RAS systems, has intensified its work on sustainability by increasing its collaboration with Schneider Electric.

Schneider Electric is now both a supplier of digital automation systems for resource and energy efficiency and a collaboration partner on sustainability.

Both companies have developed a delivery and logistics strategy that gives Nofitech lower expenses in the form of standardization and modular thinking and have optimized the number of component variants, without compromising the solutions.

Robert Hundstad, CEO of Nofitech said the new strategy provides reduced risks in lower packaging and transport costs, a reduced number of spare parts and less need for storage space.

“Resource efficiency through digitization is something we have used even internally at Schneider Electric for almost 20 years. In many offices and factories, we have cut material waste and energy costs and achieved operational efficiencies of up to 25 per cent,” said John Hjelset, project manager at Schneider Electric.

www.nofitech.com

An aquaculture technology company, Ace Aquatec has announced the appointment of Keith Davidson as chief technology officer.

Having managed teams across the USA, Canada, India, China, Europe and Asia, Davidson brings with him a wealth of experience leading global technology teams.

A curiosity for science and technology led him to the role and his experience in aligning technology strategies with overall business goals will support Ace Aquatec’s aim of developing ethical technology for the growing global aquaculture sector.

“I plan to take this opportunity to build on the fantastic work already being done by Ace Aquatec’s world-class technology team to provide fully integrated intelligent aquiculture products that support our customers to operate efficiently and humanely,” Davidson said.

“We’re thrilled to welcome Keith to the executive team and everyone at Ace Aquatec is looking forward to working with him on the further development of our high-welfare aquaculture technologies. Keith’s core principles clearly align with our ethos, and we are delighted he is joining at a time of growth for the company and sector as a whole,” said Nathan Pyne-Carter, CEO, of Ace Aquatec.

•

• Marine and Freshwater

• Mechanical filtration

• Chemical filtration

• Ultraviolet disinfection

• NEMA enclosed controls

• Bio-filter towers

• De-gassing towers

•

•

• Protein skimmers

•

•

By Curtis Crouse, Freshwater Institute

And Laura Smith Crouse, Certified Clinical Social Worker

The hazards in a RAS workplace can range from slips and falls, toxic gas inhalation, chemical exposure, disease, and drowning. Recent occupational health studies have begun to characterize the risks aquaculture and RAS-specific workers face. These studies report the expected physical injuries but also point to potential mental health risks for workers employed in aquaculture.

The U.S. Centers for Disease Control and Prevention has reported significantly higher suicide rates for the agriculture, forestry, fishing, and hunting industry groupings.

The RAS workplace can be fast-paced and physically demanding. There will always be pressure to meet production goals in an industry with tight profit margins. When critical infrastructure demands attention, operators can be pulled away from their scheduled daily tasks. Over time, this can lead to feelings that employees lack autonomy and control over their day, which can lead to burnout.

As the RAS industry continues to grow and risks become better defined, employers and staff can also take action on their own to protect their mental health by implementing the strategies discussed in this article.

Research shows that strong relationships have a positive impact on mental health. Conversely, social isolation is a key component of depression. Simple actions such as designating a break room, eating lunch together with coworkers, investing in relationships with colleagues, and deepening connections with friends and family all benefit overall mental health. Routine interaction may also provide more opportunity to recognize if coworkers are exhibiting increased signs of stress or burnout and create space for others to check in with them.

The workload at a RAS facility can, at times, require long or odd hours, and operators are

always one emergency phone call away from having their evening or weekend plans interrupted.

A first step to good work/life balance is being intentional about the transition from work to home. A ritual as simple as a few deep breaths before opening the door can help you leave the workday behind and remain present in your home life.

Operators may need to be reached for an emergency call but could turn off email and other related phone notifications during offwork hours.

Employers should encourage employees to use their earned vacation time to keep productivity high. This can be accomplished by reminding employees to use their time and by making sure that the facility is adequately staffed so that the work can be completed while others are away. Individuals should strive to actively use their time away from work on hobbies and interests to create a more fulfilling work/life balance.

There is a link between prioritizing physical health and better mental well-being.

Exercise is a great way to improve physical health and reduce stress. Even though many RAS workers may already spend several hours a day on their feet, staying active outside of

work (ideally outdoors on a sunny day) can have mental health benefits.

Getting adequate sleep is another way to take care of your overall health. Establishing good sleep hygiene can ensure a restful night and help to reclaim some of the control lost on an especially hectic day at the farm.

Limiting substances such as alcohol, caffeine, and smoking is another way to feel more refreshed and optimize sleep and well-being.

Workers at RAS facilities should be mindful of their own mental health status and observant of the wellness of those around them. In an industry starved of a trained workforce, RAS employers should consider initiatives aimed at employee wellness and retention.

Implementing the strategies discussed can help manage mental health risks but these are not a substitute for professional help. Symptoms such as increased agitation, loss of interest in hobbies, changes in sleep patterns or appetite, fatigue, social withdrawal, feelings of hopelessness or helplessness, decreased feelings of self-worth, or thoughts of selfharm or suicide could indicate worsening depression.

If you or someone you know are experiencing these symptoms, consider seeking professional help.

Increase tank capacity and yield with Linde technology for aquaculture. Our SOLVOX® oxygenation systems work in both saltwater and freshwater to create a healthier environment for growing fish. Our range of low-maintenance dissolution and distribution solutions outperforms traditional air-based systems, providing better efficiency, utilization, and hydrodynamic conditions inside the tank. Linde experts can develop a system customized to meet your specific needs. Contact us today.

lindeus.com/aquaculture