pulpandpapercanada.com

pulpandpapercanada.com

With the threat of U.S. tariffs looming during the time this editorial was written, I cannot help but think about the relentless trade disputes that Canada’s forest products sector has had to endure for decades.

U.S. President Donald Trump is preparing to hit our country with 25-per-cent tariffs on all Canadian goods (with the possible exception of oil) on February 1, which will undoubtedly wreak havoc on economies on both sides of the border in the forms of higher costs, lower profit margins, and added pressure on American and Canadian companies and consumers alike. For many companies outside of the forest products sector, this will be their first experience dealing with tariffs. The only advantage that the forest products sector has over many other industries (if we want to call it that) is that is has grown accustomed to dealing with trade disputes and tariffs with our neighbours to the south, so companies in this sector have more experience in how to navigate these challenges.

Andrew

Snook Editor

While our government officials scramble to Washington to try and negotiate for lighter tariffs for various industries, many companies have no choice but to plan as best they can for the worst possible scenarios.

In the meantime, what should Canada’s industries do?

Well, if you ask Richard Kunst of Kunst Solutions, he suggests focusing on what you can control, which is your operations. In Kunst’s recent article, “How to navigate Trump’s promised tariffs: Focus on what you can control,” he offers suggestions for optimizing operations as a means of managing the threat of tariffs. His tips include:

• Finding and fixing hidden inefficiencies, such as production delays, reducing waste in the production processes, and looking for cost sinks that can be reduced or removed;

• Shortening lead times by optimizing workflows through more efficient resource allocation, automation, and streamlining processes; and

• Engaging employees to gain their insights on ways processes can be improved.

While this is not a perfect answer to 25-per-cent tariffs, it is sound advice. In a world where costs could spike, investing additional time in reducing costs and improving efficiencies in every aspect of an operation may be the difference between surviving the tariffs and shutting the doors forever. PPC

READER SERVICE

Print and digital subscription inquires or changes, please contact

Angelita Potal, Customer Service Administrator

Tel: (416) 510-5113 Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor ANDREW SNOOK

416-510-6801

asnook@annexbusinessmedia.com

Brand Sales Manager

SONYA HESSON

416-510-5224 shesson@annexbusinessmedia.com

EDITORIAL/SALES OFFICES

CEO SCOTT JAMIESON

519-429-5180 sjamieson@annexbusinessmedia.com

Group Publisher

ANNE BESWICK

416-510-5248 abeswick@annexbusinessmedia.com

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Phone: 416-442-5600

Audience Development Manager Shawn Arul 416-510-5181 sarul@annexbusinessmedia.com

Media Designer Emily Sun

Print in Canada

ISSN 0316-4004 (Print)

ISSN 1923-3515 (Digital)

Account Coordinator SHANNON DRUMM sdrumm@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Canada $58.65- 1 year; $94.35 - 2 year; $19.50 - Single copy

USA $141.78 CDN per year

Overseas - $153.00 CDN per year

Occasionally, Pulp and Paper Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

The editors have made every reasonable effort to provide accurate and authoritative information but they assume no liability for the accuracy or completeness of the text or its fitness for any particular purpose. All rights reserved. The contents of this publication may not be reproduced in part or in full without the publisher’s written permission © Annex Publishing & Printing Inc.

Sustaining member, Pulp and Paper Technical Association of Canada; Member, Alliance for Audited Media.

High-pressure cleaning systems for optimized cleaning, improved efficiency, and increased production.

DOCTORING, CLEANING, AND FILTRATION • FIBER PROCESSING • DRYING

Thank you for over 35 years of dedication to Papier Masson. Your loyalty, teamwork, innovation, and long-term vision have left a lasting mark, not only on our facility but also on the entire pulp and paper industry. Through your expertise sharing and leadership, you have inspired—and continue to inspire— your colleagues while contributing to the growth of our teams.

Congratulations and heartfelt thanks!

Domtar states commitment to environmental sustainability will not change under ownership transfer

Domtar recently reiterated its commitment to its independent operation from Asia Pulp & Paper (APP), as it was announced by the European Commission that it has received notice of a proposed transfer of ownership of APP to Jackson Wijaya, owner of Domtar, from his father, Oei Tjie Goan, as part of his succession planning.

In a press release related to the ownership transfer, Domtar stated that 100 per cent of its forest management, chain of custody and controlled wood adhere to internationally recognized standards, and that would not change.

“The Domtar companies have been a proud supporter of the Forest Stewardship Council (FSC) since its inception, with a strong track record of adhering to the highest standards of sustainable forest management and responsible fibre sourcing. Domtar has enthusiastically taken many tangible steps to demonstrate our commitment to FSC principles over many years, and our full commitment to sustainable forest management and responsible fibre sourcing will never waver. Domtar is engaging directly and cooperatively with FSC to ensure that its certification, which is a result of its long history of sustainable forest management and responsible fiber sourcing, is unaffected by Jackson’s proposed ownership of APP,” the company stated.

Domtar currently owns 200,000 hectares of land in Quebec and Ontario. The company manages 3.9 million hectares of Crown land in Ontario; and collaborates with the Meadow Lake Tribal Council through Mistik Management to sustainably manage 1.9 million hectares of forest in Saskatchewan. Domtar’s sister companies in Nova Scotia own and manage 171,200 hectares of forest and hold a Crown license for an additional 73,000 hectares.

“Domtar’s independence and operational integrity endure, regardless of any developments outside of the company. The company’s focus on its established markets and diversified client base ensures stability and success for the long term. Together, Domtar’s employees, partners and stakeholders are not just preserving a

legacy—they are building a future rooted in sustainable growth and shared success,” the company stated.

In response to the news of APP’s ownership transfer, the FSC released the following statement:

We are informed that Jackson Wijaya, the beneficial owner of Domtar (formerly known as Paper Excellence) will become the beneficial owner of Asia Pulp and Paper (APP) too. Domtar is a company in good standing that has maintained FSC certification since 2008, covering over 7 million ha of forest area, as well as mills and processing plants.

FSC disassociated from APP in 2007 due to significant conversion of natural forests to plantations that APP was conducting in Indonesia in violation of the Policy for Association. This policy defines six unacceptable activities that associated individuals and organizations and their corporate group commit to avoid in both certified and non-certified operations.

We are evaluating what the implications of the two companies being owned by one individual will mean for our Policy for Association. To determine the potential consequences of this change in ownership a rigorous legal review of relevant company connections will be initiated.

We will ensure a consistent application of the consequences of ownership changes, and mergers and acquisitions as we have done in the past, and will invest necessary resources to resolve this case as a matter of priority.

Canfor Corporation announced that it has acquired 7 per cent of outstanding shares of VIDA AB effective December 10, 2024.

The shares were acquired from certain minority shareholders utilizing their option privileges under the February 2019 agreement in which Canfor purchased 70 per cent of VIDA AB, Sweden’s largest privately owned sawmill company. After concluding this transaction, Canfor owns 77 per cent of VIDA AB.

achieves a 12-month rolling TRIR of 0.0

Mercer Peace River (MPR) recently announced that it has reached the impressive safety milestone of a 12-month rolling Total Recordable Incident Rate of 0.0 as

The BC Council of Forest Industries has appointed Kim Haakstad as the association’s new president and CEO.

Haakstad has more than two decades of experience in executive leadership roles across government, industry, and stakeholder relations. COFI Chair Greg Stewart stated that Haakstad is a seasoned strategist and relationship builder, and has “consistently demonstrated her ability to navigate complex policy landscapes and forge strong partnerships that drive shared success.”

“Haakstad served as Deputy Chief of Staff to the BC Premier and Chief of Staff to Cabinet Ministers. Her deep understanding of governmental processes, coupled with her strong connections across sectors, positions her as a uniquely qualified leader to guide COFI and the forest sector through the challenges and opportunities that lie ahead,” Stewart stated.

Haakstad recently held leadership roles in the North American agri-tech sector, and is a current member of the Board of the BC-based DIGITAL Global Innovation Cluster.

“Kim will bring a new appreciation of the technology strategies that will be integral to a globally competitive and locally sustainable forest products manufacturing sector in B.C.,” Stewart said. “The COFI Board is confident that Kim’s strategic insight, political acumen, and leadership skills will enable COFI to continue championing a forest sector that fosters a resilient future for British Columbia.”

Haakstad replaces COFI president and CEO Linda Coady.

of November 30, 2024.

The company stated that the achievement is a testament to the hard work, dedication, and commitment of the entire MPR team.

“Reaching a Rolling TRIR of 0.0 is a significant accomplishment and a testament to ongoing efforts to create an outstanding safety culture. This achievement reflects the collective effort of everyone who has contributed to making Mercer Peace River a safe and healthy place to work,” the company stated.

TRIR is a key metric for measuring the frequency of workplace recordable injuries that require medical attention beyond first aid.

Valmet has appointed David Nelson, vice-president of sales and marketing, North America, as the company’s interim head of its North American business, succeeding Jukka Tiitinen as of January 1, 2025.

Nelson has more than 35 years of experience in pulp, paper, and related industries, with a proven track record of leadership and strategic impact. The company stated that Nelson will assume his new interim role in addition to his current responsibilities.

Before taking on his current role, Nelson served as Valmet’s Services Sales Team in North America, and was the director of sales, U.S. North, from 2008 to 2020. He has also held a variety of leadership, sales, and engineering positions across Valmet, Metso, and Beloit Corporation.

During his interim role, Nelson will report to Valmet’s president and CEO Thomas Hinnerskov.

“David is a trusted senior member of the N.A. team, and I am very happy about this interim solution. I want to thank David for accepting this additional responsibility for the time being,”Hinnerskov said.

Mercer Peace River Pulp Ltd. (Mercer Peace River) and Woodland Cree First Nation (Woodland Cree) have signed a historic agreement extending their co-ownership relationship of Peace River Logging. The renewed partnership is a significant step forward for both parties, which extends their positive working relationship and reinforces their commitment to responsible forestry practices. By working together, Mercer Peace River and Woodland Cree have established one of the most successful logging operations in the region.

Mercer and Woodland Cree have co-owned Peace River Logging since 2004, and this new agreement ensures the longterm sustainability of the joint venture and secures the jobs of more than 80 local people.

“Mercer Peace River is committed to working with Indigenous communities and we look forward to continuing our relationship with Woodland Cree First Nation,” said Roger Ashfield, managing

Suzano inaugurates world’s largest single-line pulp mill

On December 5, 2024, Suzano inaugurated the world’s largest single-line pulp mill in Ribas do Rio Pardo, Mato Grosso do Sul, Brazil.

The pulp mill has the capacity to produce 2.55 million tonnes of pulp per year. The company invested approximately US$4.3 billion in the project, including US$3.1 allocated to the construction of the mill, and US$1.2 billion dedicated to areas such as developing outbound logistics and the forestry base. This project is the largest investment in Suzano’s 100year history.

“We can only reap what we sow if we plant properly, clean properly, fertilize properly and water properly. This makes a forest grow,” stated President of Brazil Luiz Inácio Lula da Silva during the inauguration ceremony. “The Brazilian economy is expected to grow by 3.5% this year, with the potential to reach 4%. It is one of the largest growth rates among all the countries in the world.”

The construction of the Ribas do Rio Pardo mill was first announced in May 2021. At the peak of the construction, it created more than 10,000 direct jobs, with a total of more than 45,000 people involved throughout its duration. The mill began operations on July 21, 2024 and currently employs approximately 3,000 people working across industrial, forestry and logistics roles.

director of Mercer Peace River. “Our partnership with Woodland Cree has been built on mutual respect and a shared vision for a sustainable future. Together, we will continue to be dedicated to sustainable management of forest resources.”

“This renewed agreement marks an important milestone in our ongoing partnership with Mercer Peace River. It reflects our commitment to responsible forestry and the economic well-being of the Woodland Cree First Nation,” said Chief Isaac LaboucanAvirom of Woodland Cree First Nation. “While we celebrate the progress we’ve made together, we also recognize there is more work ahead to ensure that this collaboration continues to grow and benefit our people for generations to come.” PPC

In our modern connected world, all industries, including pulp and paper, have to contend with the risk of a cyberattack.

By Jack Kazmierski

Cybersecurity is a growing concern, and no individual, organization, company or industry is safe. Cybercriminals are getting smarter and their techniques are increasingly sophisticated. Without proper security measures in place, pulp and paper mills leave themselves exposed, and many experts believe that a cyberattack is inevitable, given enough time.

The risk of a cyberattack continues to rise as mills evolve, automate, and as they become increasingly connected. Like it or not, proper security measures are a must in our modern tech-driven world.

“The cybersecurity state of pulp and paper mills in Canada is generally mixed—neither entirely secure nor completely exposed,” says Jeff Brown, regional sales manager OT for Fortinet Canada. “While some larger companies have adopted modern protections, many, usually smaller companies, still operate legacy systems that were not designed with cybersecurity in mind. The shift to Industry 4.0 and integrating IIoT (Industrial Internet of Things) devices has increased the attack surface immensely. Reports of ransomware attacks on manufacturing and industrial sectors have increased over the last several years and suggest vulnerabilities are present and need to be addressed.”

Brown explains that cybercriminals are always on the lookout for new ways to increase their profit margin, and that they can wreak havoc in a number of ways. “When it comes to OT devices,” he says, “there are three main tactics that are the most profitable for them, includ-

ing operational disruption by shutting down processes through ransomware or malware, stealing proprietary methods or trade secrets, and going for data breaches to access sensitive data related to finances, employees, or customers.”

This is why it’s important for all businesses, including mills, to create a robust cybersecurity architecture. Many vulnerabilities, if not detected, can put at risk the ability to continue with day-to-day operations. Brown offers, as an example, “Legacy systems and older outdated control systems, which often lack modern security features (or the security features are not being used), or do not have a proper ethernet protocol stack.”

Cybercriminals are also likely to exploit Industrial IoT Devices (IIoT). “These can be entry points for attackers, if not

properly secured,” Brown says. “Changing the default username and password is one of the most common techniques.” He notes that employees are often part of the problem. “Humans continue to be one of weakest links in the cyberattack chain, and the most probable entry door,” he says. “Employees may inadvertently enable breaches through phishing attacks or the misuse of credentials.”

In addition, it is important for partners and vendors to be aware of possible vulnerabilities in their own systems, and to patch them in a timely fashion, since vulnerabilities in their systems can lead to breaches in the entire supply chain.

While many businesses and organizations feel that they’ve fallen behind in their

cybersecurity efforts, and that they need to be reminded to put proactive measures in place, according to Ivan Orsanic, Cybersecurity Lead at Cisco Canada, everyone’s in the same boat.

“According to our 2024 Cybersecurity Readiness Index (CRI), only 1% of Canadian businesses are fully prepared for today’s cybersecurity challenges,” says Orsanic. “The reality is, 78% of companies are either just starting to deploy solutions or are only partially equipped, and still performing below average. This is the case for most Canadian organizations struggling to keep up with evolving risks.”

Orsanic notes that companies aren’t ignorant to the threats. They’re just not proactive enough. “Nearly 73% of companies expect a cybersecurity incident to disrupt their operations in the next 12 to 24 months,” he says. “This highlights a significant gap: While businesses understand the risks, the majority are still not fully equipped to protect themselves against evolving threats.”

Cybersecurity risks today are more than just ransomware or phishing, Orsanic explains. “Companies are also facing threats like credential stuffing, supply

chain attacks, and cryptojacking,” he says. “Plus, with AI on the rise, cybercriminals are now launching smarter, more targeted attacks. In fact, our data found that 11% of Canadian organizations see these threats among the top three risks in the year ahead.”

Orsanic explains that vulnerabilities aren’t just about how companies work. They’re also about where they work. “With work being done from anywhere—and the increasing number of connected devices— there is a bigger attack surface for malicious actors to target,” he says. “Network protection and controlling access have become top concerns, and worryingly, 65% of Canadian companies, including mills, are falling behind in securing their remote connections and networks.”

According to Cisco’s 2024 Industrial Networking Report, cybersecurity is a top barrier to growth for industrial sectors. “Because of this, addressing one vulnerability isn’t enough for companies that want to be secure,” says Orsanic. “All areas of security, from network resilience to machine trustworthiness, need to be protected and work together in harmony.”

Orsanic says that cybersecurity isn’t a one-person job. Instead, in order to be effective, it requires a team of experts with diverse skills. While larger companies often have dedicated security teams, advancements in AI are helping smaller organizations automate processes and improve threat detection.

“At Cisco, we’re using AI to change the way companies approach cybersecurity, shifting the balance in favour of defenders,” he says. “It’s true that companies that can leverage AI’s potential will gain a competitive edge. But as threats grow more complex, greater resources are needed— beyond just AI.”

Cybersecurity is an investment, Orsanic adds, and in today’s precarious world, many companies are ramping up their investments. “Our CRI data shows that 40% plan to upgrade their IT infrastructure in the next 12 to 24 months, with a focus on enhancing existing solutions (67%), deploying new tools (53%), and using AIdriven technologies (50%). Additionally, 96% of companies expect to increase their cybersecurity budgets, with 78% planning a boost of 10% or more,” he says.

How much of a budget a pulp and paper mill should set aside for a comprehensive cybersecurity strategy depends on the size and complexity of the mill, explains Fortinet’s Jeff Brown. “The cost of implementing a comprehensive cybersecurity strategy varies, but based on some ballpark figures, we can make an estimate,” he says.

“Small to medium-sized mills, may need to invest $50,000–$250,000 for basic measures like firewalls, segmentation, training, and endpoint protection,” says Brown. “For large mills, the investment goes around $500,000 to $2,000,000 or more for full-scale solutions, including custom [Intelligent Computer Systems] protections, 24/7 monitoring, and incident response.”

In addition, Brown explains that mills need to include annual maintenance and monitoring costs, which typically range from 10–20% of the initial investment. While this may sound like a hefty price tag, Brown notes that the cost of not investing in a sound cybersecurity strategy can be much higher.

“Keep in mind that investments in cybersecurity should be seen as protection against far higher costs associated with breaches, including downtime, lost revenue, and ransom payments,” he says.

A comprehensive cybersecurity plan needs to address both the technology and equipment within a pulp and paper mill, as well as the people factor, Brown explains.

“When we are talking about technology, network segmentation to isolate critical systems from the broader network in order to limit the spread of attacks, is one of the most effective techniques,” he says. “It is also necessary to consider including Endpoint Detection and Response (EDR) technologies to Protect devices connected to the network, Firewalls and Intrusion Detection Systems (IDS/IPS) to monitor and block suspicious activity.”

Adding secure remote access by using VPNs and multi-factor authentication for remote connections is critical, Brown explains, as well as updating software and hardware in order to close vulnerabilities, and always maintaining offline backups of critical data and systems to enable recovery in case an attack happens.

As far as the human side of the equation is concerned, Brown believes that a team of cybersecurity experts is a must, ideally with specialists who understand how to secure industrial systems, since the complexity of ICS environments often exceeds the capabilities of a single individual.

“These experts should have knowledge of OT [Operational Technology] and IT [Information Technology], since industrial systems (OT) require different skills than traditional IT systems,” says Brown. “Collaboration between these domains is essential to preventing incidents from [crossing over] from IT to OT, and vice versa.”

Finally, Brown adds, it’s important to understand that cybersecurity is everyone’s responsibility, which is why all employees need to be trained to recognize phishing attempts, and to follow cybersecurity best practices.

“The most valuable advice I can give is to view cybersecurity as an ongoing process, not a one-time project,” says Brown.

Jeff Brown, regional sales manager OT for Fortinet Canada says that implementing a robust cybersecurity solution is typically best done in many incremental steps, rather than a single capital expenditure. This phased approach ensures that protections are implemented thoughtfully, that they’re tailored to the mill’s needs, and integrated without causing operational disruptions. Brown offer the following tips for those who need help getting started:

1. Assessment and prioritization

• Conduct a cybersecurity risk assessment to identify vulnerabilities and critical systems.

• Prioritize addressing high-risk areas first, such as outdated systems or unsecured remote access.

• Understand that prioritization is very important, as a very critical system not connected to anything could have a lower prioritization versus a lower risk with greater connectivity.

2. Develop a road map

• Create a step-by-step plan with clear timelines, milestones, and budgets.

• Ensure the plan balances immediate needs (e.g., patching critical systems) with long-term goals (e.g., creating a cybersecurity culture).

3. Start with basic protections

• Implement firewalls, end point protection, secure remote access, and basic employee training.

• Segment networks to isolate critical operational systems.

4. Iterate and enhance

• Over time, add advanced protections like continuous monitoring, intrusion detection systems (IDS), and disaster recovery plans.

“Try to keep a budget for regular updates and monitoring, as threats and technologies constantly change. Start small but build momentum—quick wins like firewalls, network segmentation or staff training can have immediate impact.”

Cisco’s Ivan Orsanic recognizes the fact that although cybersecurity can be complicated, incremental improvements will make a big difference. “To start, mills must assess their current vulnerabilities,” he says. “Unmanaged devices and unsecured Wi-Fi networks are often the most common entry points, and addressing these gaps is crucial to building a secure foundation.”

While it’s important for mills to take cybersecurity seriously and to implement a comprehensive plan as quickly as possible, Orsanic notes that planning for the long-term is just as important. “Investments in cybersecurity must be planned with longevity in mind,” he says, “especially in the current economic climate. Identify your most critical assets and secure the most exposed areas first. Then expand your efforts to strengthen resilience across the organization.”

At the end of the day, he adds, companies that don’t prioritize cybersecurity will spend valuable time, energy, and money dealing with attacks—resources that could otherwise be invested to drive innovation and growth. PPC

Key strategies to improve lime kiln operation and reduce fossil fuel emissions

By Peter Gogolek, Etienne Bernier and Luciana Savulescu, Natural Resources Canada, CanmetENERGY

The Canadian kraft pulp industry, with already a low carbon footprint due to the biogenic nature of most of its emissions, offers unique opportunities for developing carbon-negative scenarios of operation. Lime kilns play a pivotal role in developing such scenarios. Moreover, shifting the operation of lime kilns away from fossil fuels enhances the opportunity for bioenergy with carbon capture, utilization and storage (BECCUS).

Deep assessment through modeling and simulation and experimental work are routes to evaluate the impacts of fuel transition on kiln performance and emissions. The lime kilns are key to the evolution

beyond biorefineries into carbon-negative mills, because of the high-CO2 concentration in the flue gas. By integrating CO2 capture technologies into lime kilns, the industry can reduce net emissions and create new revenue streams from captured biogenic CO2, green chemical production, or even long-term carbon sequestration.

Across Canada, more than 25 lime kilns fire fossil fuels, mainly natural gas and oil, contributing to over 1 MT CO2eq/y to the country’s overall greenhouse gas (GHG) emissions. Based on industry benchmarks, the specific energy performance of lime kilns could drop from an average of 2.5 GJ/t pulp to about 1.6 GJ/t pulp by implementing the best available technologies across the whole liquor cycle.

Going further, the kraft pulp mill can incorporate chemical production technologies to expand the range of green

products (Figure 1). Biomass conversion by gasification or pyrolysis presents a transformative pathway for supporting fuel switching in lime kilns, enabling a transition from fossil fuels to renewable syngas. Converting wood residues into a mixture of hydrogen, carbon monoxide, and other gases, provides a clean and sustainable fuel. Beyond direct syngas utilization, the incorporation of chemical synthesis and separation processes expands the range of products to include hydrogen, methanol or ammonia, with BECCUS. Pyrolysis also produces a biochar that may be suitable for the steel industry or solid carbon sequestration.

The optimization of the full chemical recovery loop in kraft pulp mills is essen-

tial to achieve reductions in kiln combustion CO2 emissions and enhance sustainability. This optimization not only helps enhance kiln capacity but also minimizes chemical usage and reduces the dead load (the portion of material in the kiln that does not participate in the chemical process). By improving the recovery of sodium hydroxide and sodium carbonate, mills can reduce chemical consumption and costs, leading to lower energy inputs and more efficient operation.

In terms of load reduction strategies, techniques such as lime-mud pre-drying have shown promise in enhancing kiln performance. Pre-drying lime mud helps reduce the moisture content of the material entering the kiln, which in turn lowers the energy required for its heating and calcination.

However, gains in process and energy efficiencies are insufficient to achieve deep decarbonization at the kiln and leverage BECCUS for new revenue. Carbon capture, with or without fuel switching, with or without chemical synthesis, must enter the picture. This can be through several means, including postcombustion capture (such as with amines), oxy-combustion capture, or even calcium looping, in which recovery boiler CO2 reacts with lime and is thus repatriated to a new, larger and oxyfired kiln. This article focuses on the simpler case of oxy-firing an existing kiln to economically capture its own CO2

Oxy-firing assessment and implications

Oxy-firing is an option for retrofit to produce a sequesterable CO2 stream directly from the lime kiln by removing nitrogen from the flue gas. The combustion air is replaced by oxygen and recycled flue gas that is mostly CO2. Biogenic CO2 released by calcination is about 60 per cent of the emissions and, therefore, will

provide net negative emissions even if firing fossil fuels. There remain some technical challenges for the retrofit. These include burner stability, carbon burnout when firing solid biofuels (wood powder, saw dust or pellets), and inhibition of calcination from the high CO2 concentration with flue gas recycling.

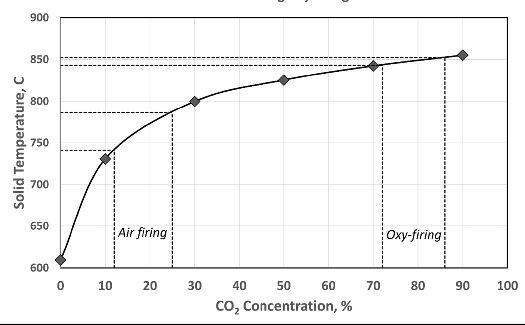

The last point, that higher stack CO2 requires hotter kilns to maintain lime quality, is familiar to kiln operators. Figure 2 shows how the concentration of CO2 immediately around the calcium carbonate requires a higher temperature for calcination to happen. There is research underway to ensure that the heat necessary to produce calcination is not so high as to induce sintering, producing ‘dead’ lime.

Advantages of oxy-firing for pulp mills is that they already have oxygen supply on site and staff trained to handle it. The CO2 concentration in the flue gas will be over 95 per cent and

will need very little treatment to be pipeline-ready. For cement plants, some published work has shown that oxy-firing has lower capital and operating costs than flue gas scrubbing, and it should be similar for lime kilns as they share the same characteristic of a large amount of CO2 captured per O2 consumed.

Recycling the flue gas introduces an additional control variable for the control of the combustion process. Too much recycle can cause flame instability and unnecessarily high flue gas temperatures. Too little recycle and the flame will be too hot and possibly damage refractory and sinter the lime. Good burner management can improve heat release and heat transfer, even with lower quality fuels, and mitigate the effects of the inhibition of calcination by carbon dioxide. This is an area of active research.

There are multiple avenues to integrate an oxy-fired lime kiln into a broader BECCUS strategy. One is to also oxy-fire the recovery boiler to capture a large amount of CO2 for storage. Another is calcium looping, as described earlier (does not work as a kiln retrofit). Another is to gasify black liquor to produce carbon-lean chemicals such as ammonia, and use the lime kiln as an incineration point for various tail gases (except those rich in noncondensables). In that case, there is also a large amount of CO2 to store. Another avenue is to only capture kiln CO2 for a dedicated CO2 utilisation project of corresponding size. In general, hydrogen-rich fuels are less preferred for oxy-firing because they tend to have higher opportunity costs as chemical precursors, and firing them “wastes” oxygen on generating water. Syngas from biomass gasification or pyrolysis is a good candidate fuel, but economies of scale tend to be insufficient without a chemical synthesis project also consuming it. For a standalone project, natural gas, low-grade liquid biofuels and low-ash solid fuels such as sawdust or wood powder may turn out the most attractive fuels for oxy-firing.

Lime kilns are essential components of the causticizing loop, but also central to future kraft mill decarbonization strategies, making them key enablers for advancing the industry toward carbon-negative solutions while enhancing economic resilience.

Fuel switching and carbon capture are promising lime kiln decarbonization opportunities, especially in combination to maximize negative emissions and generate a new revenue stream.

Oxy-firing the lime kiln is a retrofit option to produce a sequestrable CO2 stream that may improve fuel efficiency, operation and product quality, thanks to the introduction of an additional degree of freedom (flue gas recirculation).

Biomass gasification can play an important and unique role in conjunction with lime kilns to achieve negative emissions, notably in projects that also involve chemical synthesis. However, the required amount of biomass may be greater than the available volumes in specific areas, and its economic and effective use may call for alternative utilization.

If the emerging goal is to maximize revenue from negative emissions, oxy-fired kilns are likely to be incorporated into large-scale carbon removal projects. These projects would also address boiler emissions, involve the combustion of various fuels, and require infrastructure for CO2 transportation and sequestration. PPC

Inconsistent pulp quality, high energy consumption, and unexpected downtime are common challenges for mills, but what if they could be mitigated? What if there was a plug-and-play gap monitoring system (GMS) that could precisely measure and control disc gaps, improve product stability, and reduce energy usage?

If you’re looking for future-proof technology to pave the way for a more sustainable tomorrow, we have a GMS for you. Learn more at valmet.com

By Andrew Snook

Across all sectors there is one universal truth: no company ever succeeds without great a leader at the helm. This is especially true for the pulp and paper sector in Canada, which has had more than its share of rocky waters to navigate. Pulp & Paper Canada receives many impressive nominations for our Hall of Fame contest, and it was difficult to choose just three from the impressive list we received this year. These hard-working visionaries of the pulp and paper sector have led a variety of initiatives throughout their careers that have had lasting impacts on their companies, and in some cases, on the entire sector. From improving efficiencies with the latest technologies to impressive improvements in health and safety, and pushing the envelope for sustainable operations, this year’s winners have earned the distinction of being Hall of Fame inductees from their colleagues and the industry as a whole.

Shane Bolduc is a man who built his impressive 38-plus year career in the forest products sector from the ground up. He started at the Peace River Pulp Mill in 1989 as an operator in the Woodroom, and, through the years, worked his way up from an operator in various production departments to lead operator technician in the Fibreline, and eventually, a shift superintendent. How did he get involved in the forest products sector? It was a family affair.

“I was following in my dad’s footsteps (Ray Bolduc). Dad always worked in the forest industry,” Shane recalls. “He started at CANFOR in 1968 working in the sawmill on the green chain and eventually working his way to the logyard supervisor in Grande Prairie, Alberta; and then he moved on to what would have been BCFP at the time – British Columbia Forest Products – in Grande Cache, Alberta. And when I was in Grade 10 and just turned 16, I jumped into working weekends and summer holidays at the sawmill piling lumber. That led to working two months during the summer holidays on the production line while I was in school, and from there in 1986 when I graduated, I just carried right on into the sawmilling and pulp mill industry.”

In 2019, Shane channeled his passion for safety and embarked

on a new journey as Health and Safety Manager, which looked like a daunting challenge at the time.

“When Shane first began his role as health and safety manager, Mercer Peace River’s (MPR) Total Recordable Incident Rate (TRIR) was 5.52, eventually climbing to its highest at a staggering 7.18. At the time, MPR’s safety culture was found to be reactive and dependent,” explains Jill Noskey, HR coordinator, who works closely with Shane and the Health and Safety Resources department.

Shane’s desire to affect change in the health and safety of his co-workers is deeply personal, dating back to when he joined Mercer in 1989 to help commission its new Woodroom.

“It was May of 1990 when a friend of mine was killed in the Woodroom during the start-up,” he says. “So even right from that young age, health and safety was always drilled into me. When you go home one less in your carpool at the end of the day, that sticks with you. I have always shared those stories with people in my operational career, even more so if you have to sit down and you are having those hard discussions with people about performance management, and then you talk about your experiences back in ’90, they get it. They understand why I am the way I am today.”

In 2022, Mercer hired a new managing director, Roger Ashfield, and Shane began working with him in finding ways to improve perceptions of health and safety within the leadership.

“We didn’t need to change how we looked at safety. We needed to change the way leadership looked at safety. So, I played a major role in that part, working with our managing director and the senior leadership team in making that happen,” Shane says.

Through a lot of initiative and collaboration, Mercer implemented ‘Mission Zero,’ which has the goal of zero recordables, zero injuries, and zero harm. Through Mission Zero, several sub-ini-

tiatives followed, including GEMBA walks, where senior leadership would engage in different areas of the mill, becoming more visible and aware of safety concerns.

“Since the weekly GEMBA walks have been implemented at MPR, they have revealed safety issues or inefficiencies that can be identified and resolved before they become a problem,” Jill says.

“Safety Flashes” were also implemented, where team members can identify near misses before they become a bigger issue, which are distributed mill-wide via email. On average, around 105 Safety Flashes are sent out per month. The rollout of Mission Zero Standards, such as Safety Roles and Responsibilities, Life Saving Golden Rules, and Risk Assessment, were also put into place.

“These are only a few of the changes that the department led by Shane initiated. MPR’s safety culture visibly started to shift,” Jill explains.

In November of 2024, MPR reported a TRIR of 0, which is a phenomenal success compared to where they stood in 20192022, and Shane’s contributions were key to this success.

Although it’s not been a major focus of Shane’s to search for new technologies to assist with healthy and safety operations,

he has done so whenever necessary. In 2023, Shane and the Health and Safety Department replaced gas-testing equipment that was more than 30 years old with technically advanced and modernized equipment.

“This new technology made gas testing more accurate and reliable, lowered the turnaround time on failed equipment, and increased the confidence of our team members, knowing they were using reliable safety equipment,” Jill says.

Another of Shane’s initiatives that assisted with improving health and safety was streamlining incident reporting.

“We streamlined how we reported our incidents and who is going to start the reporting. We did a lot of tweaking, just changing the way we looked at it,” he says.

During the COVID-19 coronavirus pandemic, organizations with Alberta Forest Products Association (AFPA) often called on Shane’s advice on how MPR was managing COVID-19.

“Shane offered insights and strategies that he and the senior leadership team successfully implemented. These strategies and policies helped MPR through its annual shutdown, which sees 700 to 800 people on site without any major interruptions,” Jill says.

When an OHS government representative from Grande Prairie showed up on site to review the COVID-19 health and safety procedures in place, they were thoroughly impressed.

“They came here, and we toured them around the facility. We showed them our procedures, our testing trailer and our temperature trailer. They said, ‘We don’t need to stay here much longer. We see what you are doing and you’re actually leading the pulp and paper sector in Alberta. We haven’t seen anything like this before,’” Shane recalls.

While Shane’s father influenced his decision to pursue a career in the forest products sector, there were other people over his time at the mill that also positively impacted his career.

“I had a shift superintendent back in the ’90s, Al Schneider, who I worked very closely with in operations. He was also

very safety focused. A top-notch, wellrounded leader,” Shane recalls. “Also, our Woodroom Superintendent (Larry Jones) back in the ’90s. He furthered his career and became an HR advisor, and then worked his way into a safety superintendent position. I was still in the wood room in those days in an operational leadership position. We worked very closely together on mill safety, even at that time.”

Shane adds that the managing director has also been very influential in helping Shane improve health and safety at the mill.

“He’s an extremely safety focused person, and the support that we’ve got from Roger over the last two years since he started has just been phenomenal. He lets you go where you think you need to go, and he supports that vision all the way,” he says.

Shane plans on retiring in a few months, but the legacy of what he’s left behind is certain to have a lasting impact at MPR and within the entire industry.

“Shane’s commitment to health and safety at MPR will leave a lasting mark. Not only at MPR but also within the pulp and paper industry,” Jill says. “The success of bringing the TRIR from its highest at 7.18 to 0 is a success story that organizations within the pulp and paper industry can use for inspiration to transform their own safety culture.”

After he retires, one aspect of health and safety that Shane would like to see underway at MPR is improved wellness initiatives.

“There’s always room to grow and to offer more to our people, especially our shift workers,” he says. “Those are the people that are working the nights and the weekends. I think that we need to try and do a better job to service that group of people.”

Sylvain Bussière Director, Technical Services and BioFiber Project, S.E.C. Papier Masson WB

One of the characteristics often mentioned of industry leaders is their commitment to their company and its goals. Sylvain Bussière exemplifies that commitment to S.E.C. Papier Masson WB in Gatineau, Que.

He has spent his entire 36-year career with the company, joining them after completing his master’s degree in collaboration

with James McLaren Industries and PAPRICAN (Pulp and Paper Research Institute of Canada) on the management of broke and white water. Sylvain joined the mill as a process engineer and has been instrumental in many of the company’s most important projects since that time. His interest in process technologies started during his bachelor’s degree.

“I did my baccalaureate at the Ecole Polytechnique of Montreal, and I was interested by process controls and environment. After that, I decided to continue with a master’s degree,” Sylvain recalls. “I saw all the jobs that were possible to realize to improve the environmental impact, and it was a good place to find new technologies and implement them.”

One of Sylvain’s professors Ecole Polytechnique, Jean Paris, was very influential in his career path when he was a young student.

“He introduced me to the industry. He gave me a lot of tips for this industry,” Sylvain says, adding that Alain Roche from PAPRICAN and André Legault for James McLaren Industries were also very influential for introducing Sylvain into the process controls environment. “André Legault was a visionary, who pushed me towards great opportunities.”

Renee Pesant, Director of Human Resources at S.E.C. Papier Masson WB, says Sylvain’s commitment towards the company is “simply phenomenal.”

“He started the TMP (First Modern Production Technology project) in 1999 and managed the implementation, start-up and training. For many years, Sylvain led several projects focusing on cost reduction, energy saving and reducing the environmental footprint of the mill. Between 1994 and 2024, his initiatives reduced the mill’s greenhouse gas emissions by 90 per cent,” Renee says.

Stantec consultant for lean energy Jean-Claude Paradis, who worked directly with Sylvain for lean energy initiatives at the mill, says he was the best energy mill leader he’s ever had the opportunity to work with.

“We worked on various energy-related topics together, such as: water usage reduction, thermal energy savings, fibre loss reduction, and power optimization. I have to say, I’ve worked with over 20 different mills in North America with the goal to implement the Lean Energy approach and management. Never did I meet someone like Sylvain, as rigorous and skilled. His leadership is based on science and human relationship. He stays focussed on the main objective and deliver great long-term sustainable results. The 90-per-cent GHG emission reduction was a real, concrete achievement that has been sustained over time,” Paradis says.

Sylvain is constantly on the lookout for ways to improve the mill through the latest technologies.

“Sylvain is never okay with the status quo. He’s always ready to challenge existing practices in order to identify ways to optimize processes and integrate more efficient and sustainable solutions,” Renee says. “He played a key role in implementing advanced technologies such as the Heat Recovery Unit (HRU) and energy projects aimed at reducing the mill’s carbon footprint. Furthermore, the ISS (Inter-Stage Screening) project which he helped develop, resulted in a 15- to 16-per-cent reduction in electricity consumption, leading to significant savings for the company.”

In addition to his work at S.E.C. Papier Masson WB, Sylvain has contributed to moving the industry forward on various initiatives.

“He has contributed to numerous research projects in collaboration with renowned research centers such as PAPRICAN. He was one of the lead engineers behind the world’s largest and most unique PTM line, capable of producing 740 tons per day of thermo-mechanical pulp,” Renee says. “He has actively participated in raising awareness and training young people, particularly at the secondary school level, taking time to introduced them to the science and pulp and paper industry.”

Adil Zerhouni, who formerly had the pleasure of Sylvain as his supervisor and is a currently colleague, says Sylvain deserves to be recognized for his ability to transform bold ideas into concrete successes, while making significant contributions to improving industrial processes and the sustainability of the company.

“A significant example of Sylvain’s work is the development of the TMP project, which revolutionized production at the mill. When launched in 1999, Sylvain’s idea was seen as bold and unconventional. However, he successfully convinced the industry that this unique technology was the key to the future. The project not only optimized production but also integrated solutions like the HRU, contributing to more efficient energy management,” he says.

Adil adds that through Sylvain’s mentoring and hands-on involvement, he has strengthened employees’ skills and promoted the importance of the industry to the local and national economy, while encouraging the integration of more sustainable and innovative practices.

“His commitment to the sector is reflected in his continuous efforts to improve standards and enhance the competitiveness of the pulp and paper industry,” he says.

Sylvain is sometimes asked why he has spent his entire career at a single mill. Knowing his level of commitment to the company and the environment, his answer comes as no surprise.

“I’ve spent 36 years at the mill, and a lot of people say, ‘That doesn’t make sense. Why didn’t you take the opportunity to change?’” Sylvain says. “I stayed here because I was able to see the impact of the projects on the sustainability of the plant and then go even further.

“I stayed long enough to be able to see things like 90-per-cent greenhouse gas reduction. It’s nice to see that I can bring all my projects to the end and evaluate

the efficiency. I’m still passionate about the process controls and environment. I’m able to look at the back and say, ‘Okay, we did a great job.’”

Mark Mosher Vice-president, Pulp & Paper, J.D. Irving

After graduating from University of New Brunswick with a bachelor’s degree in chemical engineering in 1986, Mark Mosher ventured out into the workforce to look for the start to his career. He recalls it was a challenging time to be new graduate.

“The whole pulp and paper and energy sectors, the job prospects for engineers coming out of school was very bleak,” he says. “So, I went back to school to do a master’s – like almost everybody else in my class – waiting for the jobs to materialize. I decided to pursue a master’s degree in pulp and paper because it was a new program being offered, and I knew there were a number of pulp and paper mills at that time around Atlantic Canada.”

While studying for his degree in pulp and paper and process controls, Mark found himself wandering the halls of the

chemical engineering building and overheard the Dean speaking with a colleague about Irving Pulp & Paper being interested in hiring a contract student to do some process and controls work. Mark jumped on the opportunity immediately.

“I jumped in my car and drove to the pulp mill, showed up the gatehouse and said, ‘I’m here to apply for your job,’” he recalls. “I started with a six-month contract and then got offered a full-time job.”

Mark spent the first 20 years of his career assuming growing responsibility within Irving’s Pulp and Paper group during which time he also completed his MBA. In 2006, he was promoted to VicePresident of Pulp and Paper. Over his tenure with the company, Mark has led the company through some of the most ambitious modernization projects in the history of the Canadian pulp and paper industry.

Some of Mark’s accomplishments include:

Irving Paper: Invested $250 million to refurbish the company’s PM1 machine to make supercalendered paper. Commissioned TMP process into the operations.

Lake Utopia Paper: Installed a new environmental treatment plant and new digester. Began producing high-performance medium on the paper machine.

Irving Tissue: Significant upgrades to both tissue machines including Yankee and Winder replacements. Increased mill capacity by 20 per cent.

Since 2012, the mill has completed a series of phases to modernize and futureproof the operation to global scale and standards:

Phase 1 (2012): A new lime kiln and chip unloading system;

Phase 2 (2016): A new continuous cooking plant and new chip screening plant;

Phase 3 (2022): A new pulp drying, baling, wrapping, warehousing, and shipping project;

Phase 4A (construction in progress): A state-of-the-art environmental treatment plant with major upgrades in the wood handling, bleach plant, white liquor plant, chemical off-loading and storage, and other infrastructure upgrades; and

Phase 4B Project NextGen (engineering in progress): Scope includes a new modern high-efficiency recovery boiler, evaporation plant, and a new turbine generator capable of producing up to 145 MW of green power. Other investments include a second new lime kiln and SVP upgrades. Phase 4B represents more than $1 billion of additional investment that will not only double the mill’s production capacity but also position it as Canada’s largest market pulp mill with an annual production capacity of 600,000 metric tons. This will place the mill in the top 10 NBSK pulp mill capacities worldwide.

“The NextGen project will also generate significant environmental benefits,” explains Gary Naves, Director of Human Resources for the Irving Pulp and Paper Division. “By producing 140 MW of green energy and utilizing 70 MW of green energy, the mill will become energy selfsufficient, with the excess green energy available for sale to NB Power.”

The project is expected to support the decarbonization of the New Brunswick power grid by powering upwards of 50,000 homes annually, while recovering waste heat that would otherwise be lost. Furthermore, it will eliminate the mill’s

“Under Mark’s leadership, our mills have become deeply engaged in the local community.”

reliance on heavy oil, marking a significant step toward sustainability and responsible resource use. Through Mark’s leadership, Irving Pulp & Paper has set a new standard for both operational excellence and environmental responsibility, Gary adds.

“His ability to steer the company through difficult economic times, while simultaneously ensuring its long-term growth and success, is a testament to his exceptional leadership and vision,” he says. “As the softwood kraft pulp market continues to grow by 1.7 per cent annually, and with the demands for an additional 450,000 tons of new capacity, Mark’s work is setting the stage for a prosperous and sustainable future for the pulp and paper industry in Canada and beyond.”

A firm believer on promoting from within the company, Mark’s senior leadership

team in the Irving Pulp and Paper Division is 100-per-cent internally filled.

“Mark has built his team with senior employees who have spent most of their careers within our company,” Gary says. “We have rarely had to recruit externally for mill managers, department managers or directors. He has been a strong supporter of internal succession.”

Mark has sponsored over 30 employees to do a master’s level program at universities such as Western, Queens, St. Mary’s University, and University of New Brunswick.

“Under Mark’s leadership, our mills have become deeply engaged in the local community. The Pulp and Paper Division supports four breakfast programs at elementary schools, prepares over 100 holiday family baskets annually, makes various donations to parks and recreational areas, partners with local schools and universities and sponsors key community events such as the Big Brothers Big Sisters of Saint John’s Bowl for Kids’ Sake and Dia de los Muertos, Atlantic Canada,” Gary says.

Mark believes in investing in the latest technologies to keep the Irving Pulp and

Paper Division running as efficiently as possible.

“Under Mark’s leadership, J.D. Irving has undergone some of the most significant capital investments in the country,” Gary says. “Currently we have the most modern pulp dryer in all of North America and will soon embark on installing a billion-dollar recovery boiler. This will make our pulp mill the most modern mill in North America.”

One of Mark’s key mentors that helped teach him about the technical side of the industry was Jim Brewster, who retired several years ago but still teaches at the Technical Association of the Pulp and Paper Industry’s (TAPPI) Recovery Boiler Program.

“He’s one of the most brilliant people I’ve ever met,” Mark says. “He was probably the most technically adept leader that I ever worked with.”

Mark worked under Jim for a few years to learn the heart and soul of a pulp mill. During a time when earnings were high but technical capability wasn’t at a level it needed to be when the downturn started.

“Jim was focused on process improvement and continuous improvement, excellence in really driving the operation to

maximize efficiency, energy production, energy use, quality, and raw material consumption,” Mark recalls, adding that Tony Binotto taught him an equivalent amount about the management side of the business.

Safety has always been top of mind for Mark and he has worked diligently to maintain safe workplaces.

“We have gone from a Recordable Incident Rate of 2.7 in 2010 to an average of 1.2 in the past four years,” Gary says. “Mark was instrumental in introducing technology into safety when Intelex was brought in to enhance our Safety Management Systems.”

The company has participated in the Safest Mill in Canada contest through Pulp and Paper Canada magazine since 2016, and in 2017, Irving Tissue placed first, and in 2022, Irving Pulp & Paper came second place with several top five finishes over the years.

Mark also displayed strong leadership navigating the company through the COVID-19 coronavirus pandemic.

“Mark has shown leadership by ensuring we have an effective training program and leading the division through the

COVID-19 pandemic through open communication and using science from the medical community to ensure the mills remain open and our employees and their families remain safe,” Gary says. “Mark truly embodies our motto of ‘Everyone Goes Home Safe.’”

When it comes to environmental responsibility Mark’s leadership and dedication as vice-president of operations have enabled the division to realize major improvements across the division. Some of these include odour complaint reduction of 86.36 per cent, greenhouse gas emissions reduction of 54 per cent, ongoing plans for water use reduction, effluent quality improvements, and the generation of 140 MW of green energy.

“This kind of progress cannot happen without the kind of leadership that keeps an eye on the prize. Mark has demonstrated a sincere desire for our company to be a good neighbour, going beyond the regulatory call of duty wherever possible,” Gary says.

While many young students view pulp and paper as a “sunset industry,” Mark says their opinions often change quickly the more they learn about the sector.

“When I actually meet with students and show them the opportunities and how technical the business has become, and what the demands are for engineers and people in trades programs, and some of the exciting work that they can get involved with, it’s every bit as exciting as working on electric cars, electrification, or going to work on robotics,” he says.

Mark adds that a lot of attitudes that exist come from how pulp and paper mills were run 30 to 40 years ago when the industry required a lot of manual labour and had very little automation. But today thing has changed dramatically.

“I think pulp and paper for a new grad today can offer every bit as much, and a lot of potential for advancements as many different sectors,” he says. “In my 38 years, I’ve worked in pulp, paper, packaging, tissue. I’ve worked on capital projects. I’ve worked in operations. I’ve worked in maintenance. I’ve worked in finance. The sky’s the limit based on the individuals.” PPC

By Diane Cave

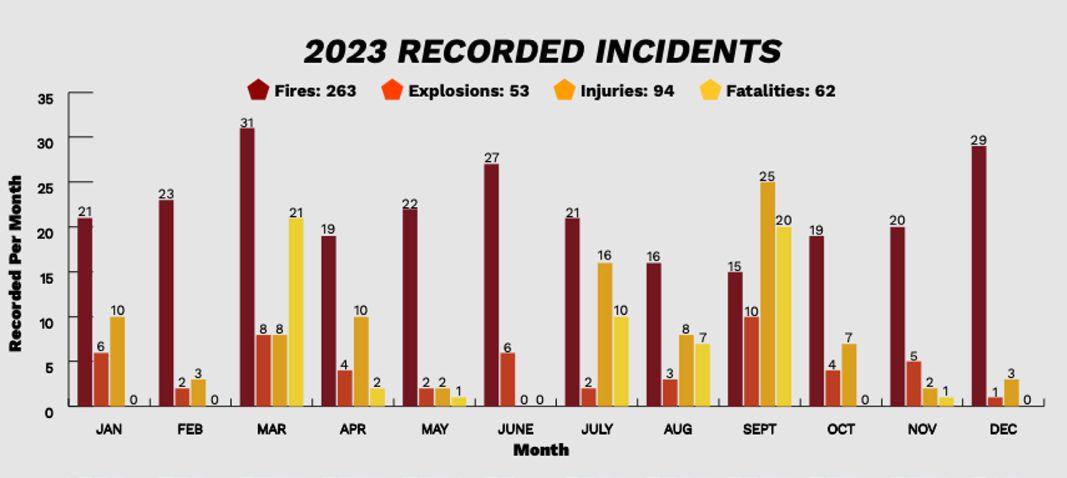

If you’ve ever asked yourself “where did this DHA thing suddenly come from and why is it so important?” or “Why is there such a push for all facilities to have a completed DHA?” Well, you’ve come to the right place. In the world of combustible dust, the DHA has been a hot topic for years.

The easy answer to this is compliance with codes and standards, predominately the many NFPA guidelines. Digging into the specifics of NFPA 652, section 7.1.1.2 states that “for existing processes and facility compartments, a DHA shall be completed by September 7, 2020.” Section 7.1.4 goes on to say that the DHA should be review and updated at least every five years. Regulation can differ by jurisdiction. There we have it. Case closed! Codes and standards say it must be done, so it must be done! Not so fast. I’m all for following directives, but I’d like to know why I have to jump on board before I do! So, let’s put the mandated reasons aside and let’s look at the practical side of things.

In my 20-plus years in the industry, I have witnessed a fair amount of jaw dropping things done (or not done) around combustible dust. Often than not productivity, cost, or convenience are prioritized over safety. This pertains to all aspects of combustible dust: electrical area classification, dust collection, interlocks, safeties, design, start ups, the whole gambit. So, who are these malevolent actors, callously putting their people at risk? The unfortunate truth is that it’s not in one area, or one industry, it’s uniform across the board. Due to the complexity of it, combustible dust really is not an area where you want things to be done poorly or by the uninformed. When we look back at the most consequential combustible dust incidents

of the past century the common theme is decisions that were uninformed, cheap or outright reckless. If you don’t believe me, do a YouTube search for “combustible dust explosions.”

Diane Cave

This brings us back to the questions of the importance of a DHA. First, the objective. A DHA is a fact-finding mission to help us understand combustible dust risk. In my opinion the objective of the DHA is not to fix problems but to inform of current hazards and risk witnessed during the DHA. This pertains to process and procedure around combustible dust hazards (both explosion and fire). The objective is to identify the hazards, communicate where the highest risks are, and provide rough ideas on what actions are required to mitigate the risk. The report will not to solve all the combustible dust hazard issues. It will however assist the diligent reader in what the problems are,

where to start, and ultimately how to move the facility towards a safer work environment. If completed and compiled correctly the DHA is a very useful and powerful tool in the hands of a diligent employer.

Combustible dust is in a lot of industries, and the risk is typically handled and protected against poorly. To protect against that risk, we start with a DHA report.

The objective is to outline what the hazards are, what the highest risk is and a general path forward to mitigate those hazards. I think you can start to see how the pieces fit together. Think of it as a (explosion proof) flashlight in a dark, dusty room. Yes, the DHA is something that is mandated to be completed, but it should not be thought of as just checking a box. If done correctly, it can be used to outline where issues in a facility are and how to keep the people (foremost), property and process safe. This knowledge is ultimately the importance of a DHA. PPC

Diane has spent the past 20-plus years working with the design, installation and retrofitting of dust collection systems in industries ranging from sawmills and grain installations to food and beverage and specialty chemicals. Diane’s expertise covers all aspects of dust collection systems from troubleshooting system issues, upgrading systems to meet current codes and standards. Diane has also assessed hundreds of dust collection systems for combustible dust hazards using the latest NFPA codes and standards and completed numerous dust hazard assessments. She can also provide advice and design experience for explosion protection systems, vessel retrofits, Pred verification, and static bonding and grounding. Diane has conducted numerous webinars and training session for clients and industrial publications. She has multiple articles published in various industry magazines.

What’s hot, what’s not, price outlooks, supply situation and more

By Treena Hein

Sustainability, energy concerns and further innovation – these are among key trends surging in the global pulp, paper and cardboard industry as we kick off 2025.

Tomas Anderson, head of key accounts at RISE Research Institutes of Sweden, notes that there’s still a focus on energy reduction in processing where possible and continued R&D into plastics replacement. Both these trends will continue to be driven by consumer demand and regulatory reform.

“The effort to replace plastics with waterproof fibre-based packaging that is relatively easy to recycle or is compostable is really pushing this industry to the brink,” he says. “It’s fairly easy to create water-resistant packaging, but it’s a very difficult thing to create a finished waterproof product that is recyclable or compostable. There are lots of new materials being created that are technically compostable or recyclable, but not easily, and when you look at how to recycle them or what it takes to get them to compost, there are already ten other materials that have been created. We are in a boom for this, and we’ll see what comes out of it.”

Sanna Sosa, senior principal at AFRY Management Consulting, agrees that innovative packaging materials and sustainability are continuing trends.

“Progress to decarbonize packaging, and the pulp, paper and packaging sector overall will continue,” she says. “This has been gaining momentum for several years, and companies across the global pulp and paper industry sectors are working on their decarbonization strategies. The carbon credit markets are developing, carbon capture and sequestration technologies are

developing, and biomass has great potential as a platform for new products and sustainable solutions for reducing carbon emissions in pulp and paper.”

Sosa also notes that new markets and demand for biomass are developing particularly fast – for example, numerous projects to develop sustainable aviation fuels (SAF) such as Simply Blue in Nova Scotia and Pathway Energy in the U.S. working with the U.K.-based pellet manufacturer Drax Group to use biomass pellets in jet fuel production.

Sosa believes that the North American pulp and paper sector could take an even more progressive approach in exploring valorization opportunities within byproduct streams and biomass processing capabilities.

Pulp, paper and packaging sector mergers and acquisitions (M&A) was another big

trend in 2024, and Sosa notes that this may continue into 2025, although on a much-reduced scale. In any case, the 2024 developments will have lasting impacts on the sector.

“We have never seen mergers of the scale we saw last year,” Sosa explains.

In April 2024, International Paper announced a merger with DS Smith, and in July 2024, Smurfit Kappa completed its merger with Westrock, creating two mega-corporations that will compete in the global sustainable packaging solutions market.

In December 2024, Jackson Wijaya, owner of Domtar (acquired by Paper Excellence in 2021), announced that he would take over ownership of Asia Pulp and Paper from his father, but that the companies would remain independent and not merge. Another development in 2024 was the purchase by Brazil-based Suzano (the world’s largest pulp producer)

of Pactiv Evergreen’s pulp integrated cartonboard mill in Arkansas and coating operation in North Carolina. The Pine Bluff mill in Arkansas manufactures liquid packaging board and cupstock, and will add about 420,000 metric tonnes of integrated paperboard to Suzano’s annual production capacity. This will make Suzano a major North American supplier of papers used to produce liquid packaging board.

Sosa explains that the first step after M&A is the chase to deliver the aimed synergies, which often includes keen focus on driving costs savings across the organization and operations.

“In addition, M&A in general may initiate further strategic reviews,” she says. “This may cause further developments in terms of spinning off parts of the merged businesses. It may also spur other mergers and acquisition with expectations of steadier price levels overall, or create positive market structures and dynamics that may attract further activity.”

Returning to Europe, Anderson notes that energy continues to be a large concern for the pulp and paper industry.

“The Ukraine conflict has put a lot of emphasis on energy consumption and securing natural gas and electricity,” he says. “It’s a daily worry. Looking ahead, not only is the energy supply not fixed, the electrification of society itself is stumbling in Europe, specifically. On national levels, the readiness varies significantly as all countries have unique potentials – just look at the difference in available biomaterial supply between the Nordics and the south of Europe creating legislative headaches. Add the new taxes soon to be imposed on CO2 emissions in production processes, and something will need to happen for all players and industries concerned. Fortunately, the boom mentioned, and new accelerative R&D practices coupled with the use of AI will enable a faster development up the technology readiness level ladder, if the public finding and risk capital continues its focus on the greener side.”

Efforts to reduce energy consumption in pulp and paper production in Europe (but also in North America) will continue, in Anderson’s view, in order to control costs but also address ever-stricter regulations.

He also expects to see more innovative community initiatives to use waste heat from pulp and paper plants. One successful venture that has received a lot of recent attention is located in Frövi, a small town in central Sweden, where a new greenhouse the size of 40 football fields is producing tomatoes using heat from warm water piped from the adjacent papermill. The water returns to the mill for re-heating. The greenhouse employs over 100 people and expects to produce 8,000 tonnes of tomatoes per year, 10 per cent of Sweden’s total demand.

Anderson and Sosa predict that global market growth for the pulp and paper industry will remain soft in 2025, and pulp and paper prices will be stable. “We are already in an economic downturn,” says Anderson, “with many political uncertainties ahead and the populations of many countries that are not growing. Inflation

has put a big dent in purchasing power as well.”

Sosa notes that there were high hopes for the market in 2024, and demand did turn slightly positive last year, but not as much as was hoped.

“The de-stocking has continued to be a trend longer than expected,” she says. “Companies want to preserve cash flow and are running lower inventories. Consumer spending in the U.S. has been surprisingly good but the manufacturing activity index has been low all year.”

One area with strong growth in North America is molded fibre products, which can substitute, for example, EPS foam and plastics in food service and take-out packaging, among other applications. Sosa notes that several U.S. states have banned traditional EPS plastics in food service packaging.

“We estimate about one-third of the North American population being covered by EPS foam bans today, and we expect that to grow to 50 per cent by 2030,” she says. “So, there’s a lot of investment activity in molded fiber space, as well as in lightweight paper packaging and bags providing solutions for plastic substitution.”

Anderson also expects the Chinese market to remain strong and robust partially due to their efforts to replace plastics with fibre products and recycling fibre products, but also because China ships so many goods.

“This is despite the fact that China has a looming population crisis,” he says. “But how the tariffs under President Trump will play out is yet to be seen and there are many other levers that could affect the industry in China. But I think it’s safe to say overall that the industry will stay robust and they will continue on their sustainability journey. They are large, and it takes time for them to change, but they are changing.”

Looking at pulp supply, Anderson predicts that the long-term global trend towards using short fibres will continue in 2025, with some big mills in the Nordic countries continuing to use softwood.

There were some mill developments in Canada in 2024, for example, Paper Excellence “indefinitely” shutting down paper production at its Catalyst Crofton mill in B.C. in January, but keeping the pulp side of the mill in operation, supporting 400 workers.

In the first quarter of 2025, Paper Excellence is expected to present a feasibility study of building a new $1.4-billion

mill in Liverpool, N.S., the location of the Bowater Mill that was shuttered in 2012.

In Anderson’s mind, Canada’s pulp and paper industry should focus on the best use of materials.

“You still have trees being destroyed by the Mountain Pine Beetle.”

“You still have trees being destroyed by the Mountain Pine Beetle and we have a similar beetle here that is moving northward,” he says. “We should work together to find value out of this wood. At the same time, your Red Leaf Pulp wheat straw mill project is showing the world that alternative feedstocks can replace wood in areas where there’s an alternative feedstock available. There is also a tissue mill in Germany using wheat straw. I also think it’s very positive that production of lignin for a variety of purposes is growing in both

Canada and Europe, gaining additional value from the paper-making process.”

Sosa notes that replacement of plastics by fibre products in Canada is a little uncertain, as it is globally.

The use of single-use plastics is presently banned in Canada, but that ban could be overturned by a new government after the coming election. She notes that in the U.S., Coca-Cola has made waves recently by scaling back its plastic replacement promises, which may create uncertainty relating to the speed of change in the packaging sector.

“As we’ve mentioned, the challenge is to find the coatings that are recyclable or compostable and come from renewable sources,” she says. “There are now many startups and we do see for example nanocellulose and seaweed coatings that are compostable, but cost is the hurdle for these new materials. The other hurdles are that the new coatings and barriers may require changes in equipment in the manufacturing process, and there is the need to maintain manufacturing speed. We will see if there are any big breakthroughs in 2025.” PPC

To support its strategic growth, Cascades Inc (TSX: CAS) is proud to announce the appointments of two Executive Vice-Presidents.

Mr. Jean-David Tardif has been appointed to the position of Executive Vice-President, Packaging. Mr. Tardif was, until last November, President and Chief Operating Officer of Cascades Tissue Group. Jean-David Tardif holds a bachelor’s degree in mechanical engineering and an MBA. He has worked in each of Cascades’ three groups since joining the Company in 1997. From 2013 to 2017 he was Vice-President, Consumer Products of the Tissue Papers business. He subsequently served as Vice-President, Operations, for the Company’s Containerboard Packaging segment from 2017 to 2019. Mr. Tardif returned to the Tissue Papers business in 2019 and has served as the Group’s President and Chief Operating Officer since then.

Jérôme Porlier will take up the position of Executive Vice-President, Tissue. Mr. Porlier was, until last November, President and Chief Operating Officer of Cascades Specialty Products Group. Jérôme Porlier joined Cascades in 2012 and has held various roles within the Tissue Papers Group, including Plant Manager and General Manager. In 2019, he joined the Specialty Products Group as Vice-President of Operations and subsequently as President and Chief Operating Officer. Mr. Porlier has a bachelor’s degree in mechanical engineering and an MBA and has also completed Six Sigma’s Black Belt Lean Manufacturing continuous improvement training.

“Jean-David and Jérôme are mobilizing and well-organized managers appreciated for their positive leadership. They demonstrated the full extent of their talent for fostering the full potential of high-performance teams and improving

customer service. I am convinced they have what it takes to succeed in these new challenges,” said Cascades President and Chief Executive Officer Hugues Simon.

About Cascades