The next level of strength in recycled board production

Deteriorating recycled fiber quality, closed water loops at paper machines, and increased starch cost challenge paper and board producers’ ability to build strength into their products. In the increasingly competitive environment, the efficiency of the strength program can be crucial for your productivity.

Based on decades of manufacturing and innovation in GPAM chemistry, Kemira has developed a nextgeneration dry strength technology to help board manufacturers overcome these challenges and stay competitive.

Kemira FennoBond™ 5400 delivers a significant strength boost cost-efficiently. The product can be manufactured onsite or delivered as a finished product.

PULP PAPER &

Getting political

Whenthe federal government introduced several new Clean Economy Investment Tax Credits (ITCs) in the 2022 Fall Economic Statement, those active in the clean energy sector had reason to get excited. These credits ranged between 15 to 30 per cent for capital invested in eligible assets.

Things got even more interesting during the 2023 Fall Economic Statement, when a proposal was brought forward to include equipment that utilized waste biomass. This proposal was then reiterated in Budget 2024 with draft legislation released in August 2024 that would expand eligibility to include equipment that produces electricity, heat, or both from waste biomass. Unfortunately, the final implementation was indefinitely delayed after prorogation of Parliament in January 2025 and continues to be delayed to this day.

Andrew

Snook Editor

While this frustrating news might cause some players in the biomass space to be repeatedly banging their heads against their sustainably produced desks, one company has had enough of the delays and has taken action.

In May 2025, Domtar submitted an e-petition to call on the Government of Canada to support a biomass investment tax credit in the 2025 Fall Economic Statement.

As Domtar’s senior director of public affairs Chris Stoicheff eloquently stated, “It is imperative that government act to pass the draft legislation for biomass ITCs in the 2025 Fall Economic Statement to realize the full and complementary benefits for Canada of economic growth in the forestry sector, including decarbonization, rural economic development, and wildfire risk reduction.”

Kudos to Domtar for standing up for this important initiative! I’ve personally signed the e-petition, and hope that enough signatures are collected to make government take notice and act to help support those active in the biomass sector.

As Stoicheff mentioned in our correspondence, including biomass energy ITCs in this year’s fall federal budget will help the Government of Canada:

• Encourage growth in Canada’s forestry sector by incentivizing capital investment in an innovative and sustainable energy source;

• Advance Canada’s climate commitments towards net-zero;

• Reduce forest fire risk by utilizing forest residues and waste as fuel;

• Support rural and remote communities by creating jobs and economic opportunities;

• Displace emissions-intensive energy sources with a low carbon form of energy; and more.

To locate and sign the petition, go to: www.ourcommons. ca/petitions/en/Petition/Search and enter “e-6530” into the search engine.

The petition will be closed on August 27, 2025. Help let our governments know how important the biomass sector is for the future of forestry jobs in Canada! PPC

READER SERVICE

Print and digital subscription inquires or changes, please contact

Angelita Potal, Customer Service Administrator

Tel: (416) 510-5113 Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor ANDREW SNOOK

416-510-6801

asnook@annexbusinessmedia.com

Brand Sales Manager

SONYA HESSON

416-510-5224

shesson@annexbusinessmedia.com

EDITORIAL/SALES OFFICES

CEO SCOTT JAMIESON

519-429-5180

sjamieson@annexbusinessmedia.com

Group Publisher

ANNE BESWICK

416-510-5248

abeswick@annexbusinessmedia.com

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Phone: 416-442-5600

Audience Development Manager Shawn Arul

416-510-5181

sarul@annexbusinessmedia.com

Media Designer Emily Sun

Print in Canada

ISSN 0316-4004 (Print)

ISSN 1923-3515 (Digital)

Account Coordinator

SHANNON DRUMM

sdrumm@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Canada $58.65- 1 year; $94.35 - 2 year; $19.50 - Single copy

USA $141.78 CDN per year

Overseas - $153.00 CDN per year

Occasionally, Pulp and Paper Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

The editors have made every reasonable effort to provide accurate and authoritative information but they assume no liability for the accuracy or completeness of the text or its fitness for any particular purpose. All rights reserved. The contents of this publication may not be reproduced in part or in full without the publisher’s written permission © Annex Publishing & Printing Inc.

Sustaining member, Pulp and Paper Technical Association of Canada; Member, Alliance for Audited Media.

Nova Scotia making wood products a priority

The province of Nova Scotia recently stated that it has directed all departments to search for opportunities to use mass timber, wood pellets, biomass, biofuels and other wood products made from residuals related to sustainable harvesting and sawmilling.

“Now more than ever, we want to use local products for build ing and heating in Nova Scotia,” said Public Works Minister Fred Tilley. “That’s why government is leading by example and using more wood products in our own buildings. It’s one of many steps our government is taking to make Nova Scotia more self-reliant and energy secure and to grow our economy and create jobs through innovation in our forestry sector.”

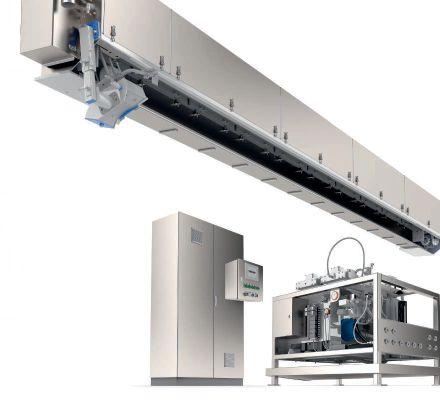

Planning a paper or board machine rebuild?

Success starts with trusted expertise

The Province added that all departments are to prioritize wood products in new construction, renovations and conversions from oil heat, including projects partially or fully government funded where applicable.

“This will produce economic benefit for Nova Scotian families while we increase the use of local, sustainable products. Building and heating with wood will produce jobs and reduce our carbon footprint. It’s a great way to support our forestry sector and take charge of our low-carbon future,” stated Tory Rushton, Minister of Natural Resources.

The Province added that focusing on using wood products aligns with the Nova Scotia Loyal program, reduces reliance on imports, enhances export markets, supports the province’s forestry sector, reduces greenhouse gas emissions and assists with the province with its transition to a low-carbon economy.

“The Province’s commitment to prioritize using wood in public buildings is an important step that aligns economic prosperity with environmental stewardship. It creates a powerful circular economy supporting sustainable forestry practices and Nova Scotia’s softwood lumber industry by stimulating demand for highvalue local wood products. That includes using high-performing, low-carbon mass timber to build the essential infrastructure Nova Scotians rely on. At a time when supply chain security is paramount, this is a clear commitment to investing in our own resources and communities,” stated Patrick Crabbe, president and CEO, Mass Timber Company.

Rebuilding a paper or board machine can boost performance and competitiveness, and there are many important things to consider before getting started.

With decades of experience across all types of rebuilds, Valmet has compiled expert advice, tips, and industry insights to support your decision-making and ensure a successful project.

Download our FREE guidebook to learn:

• How to develop a winning rebuild strategy

• Ways to minimize costly risks

• Tips for a faster, smoother ramp-up to full production

Scan the QR code or visit https://bit.ly/4eYCGh4 to download your copy today!

THE SHIFT TO NET PRICING

Why pulp buyers and sellers are abandoning traditional list pricing: benefits for individual companies and also industry-wide

By Treena Hein

It’s now been nine years since a new global ‘net’ pricing index for pulp was launched by Trade Tree Online (TTO), a company based in Quebec and South Carolina. Since then, Risi Fastmarkets has made its net pulp pricing index more prominent in its offerings.

While many pulp deals still employ list pricing, buyers and sellers increasingly favour the new system. List pricing, which came into being decades ago, involves deals where published ‘list prices’ are offered along with a discount. Negotiations are private and no one knows what discount anyone else is getting. The discounts have continually escalated over time.

TTO managing director Fraser Hart (based in Charlotte, N.C.) minces no words about this way of hammering out pulp deals. “It’s a silly waste of time,” he says. “I used to be a seller and I know what it’s like to spend so much time and energy going back and forth on list prices and discounts. The discounts get larger every year to make it look like sellers are getting a deal, but the prices also increase every year. It’s pointless and a new system was badly needed. Our net pricing index is a direct transaction-based index that reliably tracks the market, making contract deals much more straightforward.”

Carter Antal echoes these comments, describing list pricing as disjointed and unclear. “The discounts are up to/and in some cases over 50 per cent now,” explains Antal, global director of sales for ALPAC and based in St. Albert, Alta. “It’s a weird system that’s difficult to manage and very time-consuming. Net pricing, on the other

hand, moves with the market and is very transparent. It’s much more reflective of true market value.” There is always going to be some negotiation about other factors in the deal, such as service level and payment terms, he says, but net pricing makes deals clear and very fast compared to the past.

Guilherme Melhado Miranda, managing director at Suzano, Americas (the world’s largest market pulp producer) also views net pricing as a positive development. “The discounts are so crazy now, you’re going to have to reset the list prices,” he says. “It’s much better for a commodity product like pulp to have more transparency with how the prices are set. It makes retailers more comfortable, it makes all parties more comfortable. It’s best for everyone.”

Wider industry benefits

Because in list pricing both the list price and discounts increase each year, locking into two- or three-year deals with a fixed discount is a risky business move. Net pricing, however, enables multi-year contracts, which Hart says brings more stability to the industry compared to

annual contracts. Deals over several years can enable better strategic planning.

Hart also believes that having transparency in setting prices avoids conflict between buyers and sellers. “The efficient pricing environment provided by net pricing also promotes efficient supply allocation,” he says.

Uptake at Suzano and ALPAC

At Suzano North America, net pricing as a single index is already part of some deals but list pricing remains the basis for most agreements. However, a combination of list and net pricing is increasingly common across the company’s contracts.

“In conversations with customers, it’s usually a combination of several factors of what we’ll use to make them most competitive,” says Melhado. “It’s always a good discussion with them, finding the common ground, but not always an easy conversation. The normal way to negotiate up until now has been for the buyer to ask for a discount, so there’s a process for buyers as a group to understand that it doesn’t make sense to ask for a discount with the net price. I think that with this or

with anything similar, where a new system comes into play, the most comfortable path is to use both for a little while, so I think there will be more movement towards using a hybrid model for deals for some companies in the near future with some exposure to list indexes and some net pricing.”

ALPAC had already started using net pricing six years ago when Antal took his present role, and Antal says it’s the basis for most of their deals at this point. “It has depended on customer preference,” he reports, “and it’s taken a few years to gain momentum, but the use of net pricing has really accelerated for us over the last three years. Some producers and suppliers still prefer to use list pricing but I believe it could drop to zero over the next few years, partly due to customer preference and partly due to ours. There is also some mixing of list and net prices to make a sort of hybrid pricing. Sometimes the list and net prices do move differently, so suppliers and producers want to hedge their bets, but I think that this will disappear in the next few years as well. List pricing is increasingly insignificant.”

System basis

With TTO, buyers and sellers willingly submit monthly spot pricing data directly or indirectly from their sales platforms. TTO confidentially standardizes and aggregates this data to generate a volume weighted-average net price index. “Anyone buying or selling can submit,” says Hart. “We are getting a highly-representative data set that we believe includes the substantial majority of spot transactions. We also get data from our transaction platform. To ensure our price is accurate, we also have an auditing system that flags anything that is too low or too high and we look into that.”

Risi Fastmarkets did not respond to inquiries about how it collects data.

Antal says “it’s good to have two systems, because their prices can be compared. In fact, over the last five years, I’ve analyzed them and they are both accurate within a dollar over the long term. They might differ on a monthly basis, and the timing can be different but they are very similar.”

Hart reports that at this point, more than half the North American buyers have shifted to using either the TTO or Risi net

price index. He expects that all contracts will be net price only within three to five years. In his view, some buyers or sellers may never use anything else but list pricing, but use of net pricing is definitely accelerating.

In Europe, where TTO is the only net pricing index available, adoption is also starting to pick up. Hart pegs it at about 10 per cent of current deals. "This is the way people in Europe are moving towards only using net pricing. They’re using a few ways to experiment with hybrid models, to dip a toe into the water. For example, you can have a contract where the net price is examined once or twice a year. Or you might try one small contract linked to TTO and nothing else,” he says.

The TTO team also believes that the independent and reliable price indices of net pricing will finally provide the basis for a viable financial futures market for pulp. This, says Hart, will enable sellers and buyers to better de-risk through more reliable hedging programs and will give participants throughout the value chain more mature risk management tools.

TOP 10 UNDER 40

Winners of Pulp & Paper Canada’s 2025 Top 10 Under 40 contest discuss staying motivated, inspirations and more

Nolita Grübel

Senior Sustainability Analyst, Mercer International, Vancouver, B.C.

What inspired you to work in the industry?

My lifelong passion for the outdoors and nature naturally led me to pursue education in natural resource management and sustainable business. What truly excites me about the industry is the direct opportunity to apply my education, contribute to the responsible use of forest resources, and support the critical role that sustainable forestry plays in advancing towards a more sustainable future.

What keeps you motivated?

What keeps me motivated in my current role is the unique opportunity to contribute to projects that positively impact both our business and the environment. I love that my daily work has wider implications for society, and it’s incredibly rewarding to be part of the sustainability transformation taking place across the industry, working alongside such an amazing team and passionate community.

What do you consider your best achievements in the pulp and paper sector?

One of my most fulfilling achievements has been playing a key role in our sustainability communications, particularly with our annual sustainability reporting. This work is important in helping stakeholders understand how the industry is evolving through innovation, diversification and circular economy approaches. My goal is to help a wider audience grasp just how crucial a vibrant, sustainable forestry sector is within Canada and globally.

How do you plan to advance the industry? I hope to advance the industry into a better future by directly supporting its sustainability transformation. This means helping our company and the broader sector meet ambitious sustainability goals and grow more diversified in the sustainable solutions we offer society. A big part of this is leveraging compelling storytelling, robust data sharing, and transparency to effectively communicate our progress and build trust with all stakeholders.

How can recruitment and retention be improved?

I think the industry needs to embrace bold storytelling. We should proudly showcase our accomplishments – from investing in local communities to leading emissions reduction projects – sharing these wins actively with prospective employees. Being more visible on social media, highlighting the sheer diversity of roles within forestry, and clearly communicating our values will resonate deeply with both current and future talent.

Stephanie Blier

Human Resources Manager, Supervisor Kruger, Kamloops, B.C.

What inspired you to work in the industry?

I got into the pulp and paper industry by chance right after I graduated university. Growing up in downtown Montreal, I never imagined I would be working for a pulp mill. This industry wasn’t on my radar. Now, after 13 years in this industry, I would find it hard to leave. I love how it’s fast paced, full of challenges, and has lots of opportunities to grow and learn.

What keeps you motivated?

I enjoy feeling that I can make a difference and I have an influence on the culture at the mill. The mill always gave me autonomy to look for opportunities, grow projects and implement changes. I never felt like I needed to hold back on my ideas. I was always supported to see them through.

What do you consider your best achievements in the pulp and paper sector?

I am very proud of the relationship we have grown and sustain with our union executives at the mill. We are able to continuously work collaboratively. We work together when we face roadblocks, we listen to each other’s needs and limitations and we try to find win-win solutions. This allows us to spend more time on constructive conversations and projects and also implement changes that are more aligned with everyone’s needs.

How do you plan to advance the industry? I want to continue working on making the industry more accessible and inviting to diversity. A lot of work is currently

being done and changes are happening, but there is still a lot more that we can do.

How can recruitment and retention be improved?

I think it is always a good idea to connect with the youth. We need to show them early on in their career and even before they chose a career path how rewarding and exciting a career in the pulp and paper industry can be. We also should continue offering internships, co-ops and apprenticeships to give them a taste of the industry. Subsequently, I feel that the success to retention right now is to provide flexibility and allow for a healthy work/life balance while also generating discussions with our employees about their career paths, opportunities, dreams and goals, training and development and growth.

Olivier Proulx Operations and Maintenance Technician

Kruger Products, Crabtree, Que.

What inspired you to work in the industry?

Got an internship right after college and never left. While looking for this internship, Kruger had a good reputation and gave me an opportunity as soon as I came knocking.

What keeps you motivated?

There is always a new technology or solution to help operations and maintenance to achieve their goals. So many operators, supervisors and directors have ideas that just need some time to evaluate and explore.

What do you consider your biggest achievements in the pulp and paper sector?

I developed, with the help of my cowork-

ers, a PBI report that extracted data from multiple sources. At the end of the day, we try saving clerical time for the supervisors so that they can have more productive time with the operators and challenge what need to be challenge.

How do you plan to advance the industry? By obtaining valuable data from the sensors and controls we have and eventually having AI assist the maintenance or operation teams with managing this data to solve issues, help with training, increase OEE, etc.

How can recruitment and retention be improved?

They should use social media tools and be present in schools for recruitment. Most of the mills have a long history that just needs to be heard. Retention is a mix of work relationships, conditioning, environment, and region. You might want to come take a look at our mill, you’ll find the answer.

Hammam Thabit Process Engineer, AV Nackawic Inc., Nackawic, N.B.

What inspired you to work in the industry?

My interest in the industry began during university, when I shared an apartment with a roommate who worked at a local mill. That exposure sparked my curiosity and led me to explore the industry’s critical role in New Brunswick and the broader Canadian economy. I was fascinated by the scale and complexity of its operations and saw strong potential for long-term career growth and the opportunity to apply engineering to drive improvements that support sustainability and ensure the industry’s long-term success.

What keeps you motivated?

Knowing that my work makes a real difference. I’m not just solving technical problems, I’m actively helping reduce the mill’s carbon footprint and improve overall efficiency in ways that deliver tangible impact. Each day brings new challenges that push me to keep learning, adapting, and growing. Being able to see the direct impact of my efforts is incredibly rewarding. I also find it especially rewarding to collaborate with people across the mill, learning from operators, engineers, and leadership, and turning shared challenges into long-term improvements that strengthen both operational performance and sustainability. It is also revealing to see the impact that my facility has on the local community.

What do you consider your best achievements in the pulp and paper sector?

One of my most impactful achievements has been my involvement in the Strategic Energy Management program, where I supported major energy efficiency initiatives that resulted in significant reductions in fossil fuel use and emissions. This included implementing energy-saving measures, leading cross-functional audits, and identifying opportunities to optimize heat and recovery system performance across the mill.

How do you plan to advance the industry?

I plan to support the pulp and paper industry’s future by promoting energy efficiency, sustainability, and innovation across all levels of operation. This includes using datadriven decision-making to identify inefficiencies, optimize processes, and reduce emissions. I believe the industry can benefit greatly from sharing best practices, adopting emerging technologies, and fostering a culture of continuous improvement. By staying engaged in collaborative programs like Strategic Energy Management (SEM) and supporting cross-sector knowledge exchange, I hope to contribute to a more resilient, competitive, and environmentally responsible pulp and paper industry

How can recruitment and retention be improved?

The pulp and paper industry needs to do a

better job showing people what it really offers. It’s not just one job, it’s an entire process, from raw material to finished product, involving a wide range of roles in operations, engineering, quality, maintenance, process and beyond. When we take the time to explain how things work, answer questions, and show genuine interest in people’s growth, it sparks curiosity and connection. Also, strong outreach to schools and co-op programs can bring in new talent. That’s where recruitment starts. For retention, it’s about creating a supportive environment, recognizing effort, and building strong team connections.

Andrew McHugh

Capital

Project Manager,

Irving Pulp and Paper Ltd. Saint John, N.B.

What inspired you to work in the industry?

I was fortunate to have the opportunity to complete a co-op work term at Irving Paper while completing my degree in mechanical engineering. While there, I saw a drive for excellence and a culture of collaboration within the sector that I hadn’t seen in other industries. As a mechanical engineer I was also fascinated by the full range of equipment used in pulp and paper mills so I knew even before graduating that the culture and technical scope in the pulp and paper

industry would be a great fit for me.

What keeps you motivated?

As a project manager I’m motivated by the satisfaction I get from working with our project teams to develop improvements and solutions within the mill and then getting to see the work progress through design, construction and commissioning. Seeing a project that we’ve been working on for years be put into service and start improving the safety, reliability, efficiency and production capacity of the mill makes all the work worth it!

What do you consider your best achievements in the pulp and paper sector?

One of my proudest accomplishments was executing an emergency project to install a system to divert DNCGs to the mill’s backup power boiler to allow for maintenance on the primary power boiler. We were able to complete boiler modifications and purchase, install and commission rotating equipment, piping and valves in just 12 weeks to meet the maintenance timeline.

How do you plan to advance the industry?

To do my part in advancing the industry into a better future I plan to continue working with our project teams to execute innovative projects that will ensure the long-term sustainability of the mill by increasing energy efficiency, reducing

material input costs and maximizing reliability and production. A strong pulp mill allows for a strong forestry sector in our region and preservation of the industry in general.

How can recruitment and retention be improved?

The industry should focus on ensuring that professionals and the public have a good understanding of everything the industry does to protect and manage the environment we operate and live in, and also focus on promoting the sustainability of the industry. We should ensure that employees are matched with suitable positions for their interests and strengths and that they’re given opportunities for continuing education, training and career advancement.

Valois Parisien Senior Technical Lead Enero Solutions, Montreal, Que.

What inspired you to work in the industry?

What drew me to the pulp and paper industry is how fascinating and complex the processes are—there’s always something new to learn or improve. But what truly inspired me is the people. From day one, I saw the leadership, ingenuity, and teamwork that define this industry, which made it feel like the right place to grow and contribute.

What keeps you motivated?

What keeps me going is knowing that even small process improvements can create real, lasting value—whether it’s boosting a mill’s efficiency, reducing environmental impact, or making someone’s day a little easier. The ability to make a meaningful impact through continuous optimization and technical problem-solving makes the work impactful and rewarding.

What do you consider your best achievements in the pulp and paper sector?

One of my most meaningful achievements has been building strong working relationships with colleagues and clients at various mills. Those connections have led to great collaboration, knowledge-sharing, and a lot of professional growth.

How do you plan to advance the industry?

I believe the future of the industry lies in its digital transformation—and not just from a technical standpoint by implementing new tools, but also by making sure people feel confident and supported using them. My goal is to help drive innovation while fostering engagement and trust, so that change is not only effective, but sustainable.

How can recruitment and retention be improved?

To improve recruitment and retention, the industry should highlight its wide range of opportunities it offers and the meaningful impact each individual in this industry can have on sustainability, innovation, and operational performance. It’s important to emphasize that the pulp and paper industry is here to stay—with deep roots in both small towns and large communities—and plays a vital role in everyday life. Showcasing the industry’s dynamic nature, from technological advancements to its evolving environmental practices, can help attract those looking for a challenging and longterm career.

Leslie Ruggeri

Plant Manager, Succession Team

Cascades, St. Marys, Ont.

What inspired you to work in the industry?

The people are what has inspired me to continue to work in this industry. When I started my career in human resources

at Cascades, I had the opportunity to work with people across different levels of the organization—from the plant floor to senior leadership. I was amazed by how smart, hardworking, and kind the people are. Over time, and especially as I have transitioned into operations, I have learned that some of the most creative, strategic, and brilliant minds work in this industry in all roles and at all levels. What has inspired me most is how these people show up every day with humility and an inspiring work ethic.

What keeps you motivated?

What keeps me motivated in my current role is the constant opportunity to grow, and the great people I have the pleasure of working with. Manufacturing is an incredibly dynamic environment with new challenges daily that allow me to think creatively, adapt quickly and work with a team to come up with a solution, together. There is something so special about watching a team collaborate and successfully overcome challenges through perseverance and teamwork.

What do you consider your best achievements in the pulp and paper sector?

One of my best achievements has been building strong and authentic relationships across many departments in the organization. I’ve had the privilege of working with some of the brightest and most dedicated people that continue to inspire me to this day. People who have challenged me to think critically, pushed me to get better every day, and reminded me to never lose sight of the very important human side of being a leader. These relationships have been key in my development as a young

professional and have helped shape me into the person I am today.

How do you plan to advance the industry? I think the future of the industry depends on us not being afraid to think differently and to strive for continuous improvement in all areas. We need to move past “the way it’s always been done” and allow people to think outside the box, work together across different areas of the organization, and challenge the status quo. There is so much untapped potential all around us; in our people, in our plants, and in our processes. By encouraging open minds and embracing fresh perspectives from different voices, we can continue to grow our industry into a better future.

How can recruitment and retention be improved?

I think one way to improve both recruitment and retention is to invest in developing new leaders early in their careers. Empowering people to explore different roles, take on new challenges, and learn from experiences in different departments. It promotes personal growth and creates a more adaptable workforce that is well equipped to take on tomorrow’s challenges. When people feel like they are contributing to the team and have a sense of purpose, they are more likely to be engaged and committed for the long term.

Benjamin Granger Demand and Supply Planning Manager, Cascades,

Candiac, Que. What inspired you to work in the industry?

I honestly knew very little about the pulp and paper industry before my first internship at Cascades. At first, I didn’t expect

how interesting and complex this industry could be. As I learned more, I realized how amazing it is to see the entire process and how we have an impact on millions of people’s lives every day. What keeps me passionate is the constant challenge to manage complex operations while staying flexible and adapting quickly to fastchanging market conditions.

What keeps you motivated?

Over the past few years, I’ve had the chance to experience multiple opportunities within the supply chain sector. We have been facing many challenges that constantly push me to think outside the box and adapt rapidly. I enjoy tackling complex problems, making sure the plan is clear, and working together with the teams to reach our goals. I find it very rewarding to lead crossfunctional teams and witness how strong collaboration can improve the entire supply chain’s performance. I also appreciate how much the pulp and paper sector is focusing on sustainability and environmental improvements.

What do you consider your best achievements in the pulp and paper sector?

One of my proudest achievements was the implementation of an integrated planning system that significantly improved demand-driven production scheduling. This project boosted our service levels and helped reduce inventory, mainly through better coordination between supply chain, sales, and operations teams. In addition, with the teams, we developed and implemented a strong sales and operations planning process that improved alignment across departments, increased forecast accuracy, and facilitated proactive decision-making. This new approach helped bridge the gap between sales expectations and operational realities.

How do you plan to advance the industry?

I believe there’s huge potential in bringing AI into our supply chain processes. Using AI-powered analytics and predictive tools can help us improve demand forecasting, optimize production scheduling, and manage inventory more effectively. I also aim to promote a culture of continuous improvement and collaboration across departments

to increase operational efficiency and adapt quickly to market changes.

How can recruitment and retention be improved?

I think the industry needs to promote its commitment to sustainability and technological progress. This is key to attract a new generation of professionals who want to work in a purpose-driven and innovative environment. We also need to invest in solid training and development programs that equip employees with both technical and soft skills. Offering clear career paths progression and promoting a healthy worklife balance will also help retain talent.

Louis Chauvette Technical Manager

Cascades, Victoriaville, Que.

What inspired you to work in the industry?

During my engineering study, I got the opportunity to complete an engineering internship at Cascades. I was impressed by the level of expertise and knowledge required to transform recycled raw material into new products. After a few years in a consulting engineering firm, the possibility to be at the heart of circular economy and sustainable initiatives inspired me to head back to the pulp and paper industry. It’s a constantly evolving industry that presents exciting technical challenges.

What keeps you motivated?

My main motivation is to ensure that my team has the right mindset and capabilities to navigate complex projects and operation challenges. “Stronger Together” is a core principle in my leadership approach. I’m proud when people are united towards common goals, that’s when results exceed expectations. Every day, I learn something

new, exchanging knowledge between different teams helps me better understand their reality and gain deeper insights into the pulp and paper industry.

What do you consider your best achievements in the pulp and paper sector?

Over the years, one of my most significant achievements has been building strong, trust-based relationships with plant and sector teams. The Cabano electrical boiler project is a realization that I’m proud of. I was member of the engineering team. This project has a significant environmental impact of reducing ±10,000 tons of GHG emissions every year as well as increasing steam flow stability at the mill. Another project was the shaft and slitting/trim edge automation project on a machine. This project enabled automatic production order changes by selecting the correct shaft and slitting/trim settings without stopping production. It also eliminated the need for employees to manually handle slitting and trim knives, representing a major improvement in health and safety. My team was responsible for electrical, automation and machine safety integration.

How do you plan to advance the industry?

As an automated production engineer, I firmly believe that modern automation and digitalization solutions will improve safety, productivity, quality and efficiency. Additionally, sustainability technologies will shift toward circularity and bio-based product. To support sustainable growth, short and long terms plan must be defined and continuously realigned with business needs. Successful integration of new solutions in mills depends on their operationalization and reliability. Moreover, technological solutions must be supported by internal or external system experts to ensure long-term performance and adaptability.

How can recruitment and retention be improved?

It’s important to be present in colleges and universities to highlight career possibilities, technologies advancement and sustainable initiatives applicated in the pulp and paper industry. Students can visualize their profession and potential achievements in the industry. For retention, it’s

essential to define individual career path, every person wants to grow in their own way, and the industry offers so many possibilities. For those who enjoy new challenges, create opportunities through new roles, special projects and more.

Olivia Carter

Fibre Line Assistant Superintendent, Dryden Fibre Canada, Dryden, Ont.

What inspired you to work in the industry?

Growing up in Dryden, the industry has had a major role in keeping our town vital. Before choosing post-secondary education, I had the opportunity to co-op at the mill with a group of process engineers. This really demonstrated how I could combine my interest in science and engineering with local industry. Getting to come home and work in an industry that drives sustainability has been very rewarding.

What keeps you motivated?

Working within the operations group at a pulp mill means no workday is the same. The diversity in the problems we work

through as a team throughout a week is something that keeps me on my toes. The collaboration throughout the mill is also a part of my job that I enjoy. Working with a team that energizes each other makes coming to work everyday fun.

What do you consider your best achievements in the pulp and paper sector?

When I look back on the last 6.5 years, I am most proud of the relationships I have made throughout the mill. I have been very fortunate to work within many multi-disciplinary teams to meet mill-wide

goals together. Whether it is our front-line operators producing our pulp or the maintenance team looking after our equipment I feel like the community we have on-site is something to be proud of.

How do you plan to advance the industry?

I plan to keep doing my part to continuously improve our mill. Working collaboratively as a team to improve process, safety and environmental compliance is essential. Participating in industry-wide committees is also important to continue to move the industry forward.

How can recruitment and retention be improved?

I think it is important for employees to see developmental opportunities within a company. Companies that put emphasis on promoting and developing from within help keep employees engaged and stimulated. It is also important that facilities are investing to be both reliable and innovative to remain viable in years to come as technology advances. PPC

SAFEST MILLS IN CANADA

For 99 years, Pulp & Paper Canada’s Safest Mills in Canada contest has been benchmarking safety performance of mills. The contest recognizes the outstanding safety records of participating mills by ranking mill frequency from lowest to highest. In the event of ties, mills are ordered by the most to least worker hours. Mills are increasingly focusing on risk prevention strategies to enhance safety.

For example, Dryden Fibre Canada’s mill in Dryden, Ont. launched its “Courage to Care” campaign during the company’s health and safety month in October 2024, which generated fantastic results. Kruger’s Corner Brook Pulp & Paper's in Corner Brook, Nfld.

performed auditing of safety programs and rolled out a new Field Level Risk Assessment, and improved incident investigation process.

Domtar’s Alma Paper Mill in Alma, Que. notes that its successful safety program stems from a combination of lots of communication; leadership belief that all incidents are preventable; leadership engagement; weekly on-the-floor audits; two oneon-one meetings with employees and the site manager per year; mandatory pre-job risk assessments; and seven triggers for requiring a new risk assessment.

Congratulations to all participating mills for achieving their safety goals! PPC

“We are thrilled to announce that we have achieved a 0 Rolling Total Recordable Incident Rate (TRIR) at the end of November! This incredible accomplishment is a testament to the dedication and commitment of every single team member to maintain a safe and healthy work environment. Our focus on safety procedures, hazard identification, and looking out for each other has made this milestone possible.”

– Mercer Peace River Mill, Mercer International

SULTS

“This was a top performing Domtar mill due to the site leadership in production and in safety.”

- Alma Paper Mill, Domtar

“This result can be attributed to increases in auditing of safety programs, roll out of a new Field Level Risk Assessment, and improved incident investigation process. For the Incident Investigation Process we have adopted a new Kruger Integrated Operational Excellence program. This program looks at items such as triggers for incident investigation, resiliency, and just culture.”

- Corner Brook Pulp & Paper, Kruger

Category B.

J.D.

Category C.

ELIMINATING EMISSIONS

Mercer International investing in innovative tech to meet future targets

By Andrew Snook

Mercer International is a major player in the global forest products sector. Between its operations in the U.S., Canada, and Germany, the company has a consolidated annual production capacity of 2.1 million tonnes of pulp, 960 million board feet of lumber, and 230,000 tonnes of biofuels.

The company has been hard at work finding ways to reduce its overall emissions. It is targeting a 50-per-cent reduction in Scope 1 emission intensity and a 35-per-cent reduction in Scope 2 emissions by 2030. To do this, Mercer International is focused on reducing emissions and exploring opportunities to sequester carbon throughout its value chains. The

majority of the company’s overall energy production (86 per cent) comes from renewable biomass sources such as black liquor and wood waste from its various forest products operations.

All four of its pulp mills run on selfgenerated green energy. In 2022, the company’s mills had a combined generation capacity of approximately 400 MW of electricity with 60 per cent of the electricity used to power mill operations and the surplus sold to local grids, which generated approximately $100 million in revenue for Mercer International while creating renewable energy for regional utilities.

Juan Carlos Bueno, president and CEO of Mercer International, says meeting the company’s Scope 1 intensity targets is the company’s current focus.

“When you think overall about our greenhouse gas emissions today, it’s around 486,000 tonnes of CO2 on Scope 1,” Bueno says.

Mercer International’s biggest project coming online in the near future to help meet their Scope 1 targets is the conversion of a lime kiln at its Stendal Mill, the company’s largest pulp mill in Germany. Currently fuelled by natural gas, the lime kiln will be converted to a bio-based fuelled lime kiln.

“That would be a significant contributor towards that goal of reducing 50 per cent of Scope 1 GHG emission intensity,” Bueno says.

Converting this lime kiln is no small feat. It requires an investment of about 35 million EUR, which in today’s conversion

is nearly $55 million (50-per-cent incentivized by government grants).

“We’re very eager to get that started by the end of this year. That would mean that in a year-and-a-half or two years that would become a reality, and Stendal would become almost a carbon neutral mill,” Bueno says.

He adds that while meeting emissions targets is a main goal of this project, their customers also demand these targets be met.

“The large tissue companies, some of the large paper companies, those that have a business much more global and sophisticated, they see that demand from their customers themselves, and they themselves have huge drivers around these things,” Bueno says. “They also have the same goals of reducing greenhouse gas emissions on Scope 1 and Scope 3 – we are part of their Scope 3 emissions – meaning our emissions are counted in their supply chain footprint – so they’re putting pressure on us to make sure that we contribute positively to their goals. We’re in a chain where everybody’s looking at the same picture, and that that helps, because

then we’re all we’re all heading in the right direction. We’re all supporting each other as we run through this.”

While no company would want the negative press and public outcry from not meeting their emissions targets, there is more at stake if the company were to fail.

“Most likely we would lose some of those customers. It has been made explic-

itly clear that this is a condition of doing business in the future. Therefore, you need to show that you care. You need to show that you’re willing to put your wallet where your mouth is and that you are really going to contribute positively to this outcome,” Bueno says.

The Stendal Mill conversion project is of particular importance because it is

Mercer International’s largest pulp mill with the largest lime kiln within the company’s pulp mill assets. The mill produces 740,000 tonnes of softwood pulp (mostly spruce with a diet of spruce, pine and fir).

The company’s other pulp mill in Germany, Mercer Rosenthal, produces 363,000 tonnes of softwood pulp, and could also undergo a similar conversion project sometime in the future.

Given the customer profile for Mercer International’s European pulp mills, these types of projects are a priority for them versus the company’s Canadian mills. This is because most of the customers for its Canadian mills operate within the Asian markets, where the same pressures related to meeting emissions targets are a much lower priority. However, Mercer International is still focused on reducing emissions at its Canadian pulp mill operations.

“We do have another project, a carbon sequestration project, and that would be for the Alberta pulp mill that we have in Canada.”

The Mercer Peace River pulp mill in Peace River, Alta. is a swing mill that produces approximately 475,000 tonnes of hardwood and softwood pulp. The

company is in the process of potentially investing heavily into a new technology for sequestering the CO2 from the flue gases of the pulp mill.

“We’re working with a company in Canada that developed a technology for capturing that CO2. The reason why we’re doing it there is because the mill is located in Alberta, where you have geological formations that are suitable for sequestering CO2,” Bueno explains. “You don’t have to take it long distances. You’re right where you need to be, and that makes the project financially viable.”

The process for removing the CO2 from Mercer Peace River’s pulp mill operations would be a non-intrusive, mechanical process using a proprietary technology developed by Svante, a carbon capture and removal solutions provider based in Burnaby, B.C.

“We’re working with them, going through all the phases that are needed, before we are ready for an investment decision,” Bueno says. “It’s making sure that the technology works, that is the big hurdle. They tested it. They have demos, they have pilot plants, so they’ve done their homework. This would be the first large-scale

pulp mill investment. So, we would be the first of a kind for their technology, and that’s why it takes a bit longer to make sure that we have it all squared through.”

The investment decision will take approximately two years to complete. At an estimated price tag of more than $500 million, there are several hurdles still to overcome. One of the biggest challenges is ensuring that the Province of Alberta and Government of Canada are supportive through grants in offsetting the technology risk. In total, these grants could account for upwards of 75 per cent of the total project costs.

“Alberta is incredibly supportive in both the policy framework and offsetting the technology risks, and that makes a difference,” Bueno says.

If everything aligns for the investment side of the project, the construction will take another two years to complete, meaning the project would come online and begin sequestering carbon from Mercer Peace River sometime in 2029.

Mercer International offered an explanation of Svante’s carbon capture technology works:

Svante’s carbon capture system uses

proprietary solid sorbent filters designed to selectively capture carbon dioxide (CO2) from industrial flue gas. These filters are coated with metal-organic frameworks (MOFs)—engineered nanomaterials that bind CO2 molecules while allowing other gases to pass through. Once saturated, the filters are heated to release the CO2, which can then be compressed for transport and storage. The system operates in a continuous adsorption–desorption cycle and is well-suited for pulp mills like Mercer Peace River, where biogenic CO2 is emitted at scale.

Svante’s technology is compact, modular, and built to handle the challenging particulate environment of industrial flue gas. It also takes advantage of low-grade waste heat from mill operations, reducing energy requirements and increasing cost-effectiveness. With no toxic emissions or liquid solvents, and recyclable materials, the system offers a cleaner, more adaptable alternative to traditional carbon capture methods.

Lignin production

Another interesting project underway is at the Mercer Rosenthal pulp mill in Germany.

The company has invested 10 million EUR into a pilot project where it is producing one ton of lignin per day from

black liquor being produced at the pulp mill. Instead of burning all of the black liquor to produce electricity, Mercer International would rather produce lignin as a potential substitute for fossil-based chemicals in various applications. The plan is to create a commercial lignin production facility within three years.

“We aim to have a commercial site out of Rosenthal that would be a 40,000-ton lignin plant. That means our output of energy would be reduced, because then we would not be burning as much, and we will be extracting this lignin to be able to sell it to the market into products that replace fossil-based fuels and sequester carbon for many years, instead of releasing it when we burn it,” Bueno explains. “We like it because it contributes to our circular economy story in a very significant way. It’s more profitable than energy, and it takes us into a different avenue. It allows the mills to participate in other things and not just be dependent on pulp, and only pulp. Breaking into that paradigm, for us, is very important, making these assets true biorefineries, and being able to do a whole lot more than just pulp.”

While producing byproducts such as lignin has a strong business case, Bueno says it is also the responsible thing to do as a producer, as it provides low carbon solutions throughout the supply chain.

“That’s why we do it. We’re all trying to make our businesses more and more sustainable over time,” he says.

BUILDING BIO-OIL CAPACITY

Arbios Biotech is turning waste wood into renewable fuels

By Andrew Snook

Nestled in the heart of the B.C. Northern Interior is a joint venture ready to turn the locallyproduced residuals of the wood products sector into renewable fuels.

This past November, Arbios Biotech, or “Arbios,” completed the construction and commissioning of its Chuntoh Ghuna biooil production facility located in Prince George. The plant is designed to be able to produce 50,000 barrels of bio-oil annually, which makes it the largest HTL facility in the world. It has received funding support through the Government of British Columbia’s Initiative Agreement Program under the Low Carbon Fuel Standard (LCFS).

The facility also received support during the development stages of the project from Sustainable Development Technology Canada; the BC Innovative Clean Energy Fund; and Natural Resources Canada’s Clean Growth Program.

“Government support has been substantial, and without that, this wouldn’t have happened,” says Rune Gjessing, CEO of Arbios.

The facility was originally a joint venture between Canfor Pulp and the plant’s technology provider, Licella, that started back in 2016, where the focus was utilizing residues from pulp mills. By 2020, this concept changed along with the partnership, which is now between Canfor Corporation and Licella. The new purpose of the production facility is to use a variety of forest product residuals to produce biooil that can be further refined for various transportation applications.

While the company was fine-tuning the design of the facility, it was learning more about the production process from Licella’s large-scale pilot plant in Somersby, Australia.

“Improvements were being incorporated into that design concept as we were scoping the facility. At the same time, we were talking to the Lheidli T’enneh First Nation about the project, and said that we wouldn’t proceed without their support,” explains Tessa Gill, external relations lead for Arbios. “We did the feasibility study for the facility while at the same time working with the Lheidli T’enneh to see what the potential

concerns and areas of interest were, before we made the final investment decision.”

“Everything we’re trying to test here, we have tested in Somersby, but that plant is also designed to test other feedstocks,” Gjessing adds. “In Prince George, we are focused on forest residuals or woody biomass.”

Arbios is testing the Chuntoh Ghuna facility using white wood chips and hog fuel, trying to find out the impact each feedstock has on the process downstream. No matter what type of biomass residuals are used, Arbios does not expect to be differentiating its final products based on the feedstock alone.

“As of now, we don’t have any data points that indicate any difference,” Gjessing says, adding that a drop-in renewable marine fuel would be an ideal first product. “That’s simply because it has the widest specs and the engines are the most tolerant.”

Longer-term, the company will produce the best value product, which is still

being decided.

“Obviously, sustainable aviation fuel (SAF) has got a higher price, but it also has a higher cost to make, so we will focus what makes the most economic sense,”

Gjessing says. “Fundamentally, we’re targeting the industries that are the hardest to find a low carbon solution for – long-haul aviation, global marine transportation. It’s going to take longer for these industries to find alternative solutions,” Gill adds.

The Arbios Chuntoh Ghuna facility is targeting the production of renewable fuels that will generate up to an 80-percent reduction rate in carbon intensity (CI) compared to fossil fuel equivalents, which would currently give the company significant flexibility for its products to fall within regulatory requirements around the world.

BIO-OIL PROCESS

The process starts with the biomass which could be sawdust, bark, or other forest residuals, being transported from the storage facility into conveyors where it is screened and sized to prepare it for processing. From there, the biomass is conveyed to a dryer to reduce moisture levels then fed

into a feed bin for processing. The biomass is then transported into a supercritical mixing process where it is mixed with water under high temperature and pressure.

The mix then undergoes a process created by Licella’s proprietary Cat- HTR hydrothermal liquefaction process, which takes approximately 20 minutes to convert the biomass into bio-oil. The bio-oil and water are then separated, where water treatment and recovery takes place. The bio-oil its then ready for refining or upgrading.

The bio-oil is then collected for offsite refining into a renewable drop-in fuel for transportation applications such as marine, trucking or aviation.

EXPANSION PLANS

While the facility is of a commercial scale, further steps will move it towards full commercialization.

“What this plant does is confirm the technology at scale, and we’re already permitted for expansion,” Gill says. “The kind of the expansion we’d be looking at is adding another process line, and there’s plenty of room for expansion on this site.”

Gjessing says successfully scaling up

facilities like this one requires taking several steps or phases that are sometimes overlooked due to lack of capital, impatience, or both.

“Some technologies are easier to scale than others. This one is somewhere in the middle, but there are a lot of learning points even from Licella’s large pilot plant that is much smaller than Chuntoh Ghuna. There’s a lot of learnings between that plant and this one,” he says. “And if you went directly from a pilot plant to a much larger commercial scale, you simply wouldn’t know a lot of things that we already know.”

Scaling up too quickly becomes a major issue when reaching out to investors for the hundreds of millions of dollars required to build a commercial-sized production facility.

“For Arbios, it’s really about de-risking the plant for the next step,” Gjessing says.

FIRST NATIONS RELATIONS

Arbios has been working closely with the Lheidli T’enneh First Nation since the beginning of the project, and it is possible that one of their companies, such as LTN Contracting, could be supplying underutilized forest residuals such as slash, tops and thinnings, to supply the feedstock for the plant. Gill says there is an ongoing study taking place that is looking at the economic feasibility of having such residuals for the plant supplied by a company like LTN Contracting.

“We can’t speak for the Lheidli T’enneh, but the Nation has been very supportive and helpful, and are very engaged with the development of the plant,” Gill says.

In a recent press release published by Arbios Biotech, Lheidli T’enneh First Nation Chief Dolleen Logan stated, “As a Nation, we are focused on working with proponents and projects that focus on long-term environment sustainability. We are proud to see the completion of Chuntoh Ghuna, a facility that reflects our shared values of a sustainable bioeconomy. Further, this project demonstrates what can be achieved when Indigenous communities and industry collaborate in a meaningful way. We look forward to the positive impacts this facility will bring as we transition to a low-carbon future.”

To learn more about this project, visit: www.arbiosbiotech.com. PPC

GIVING BACK

The latest community outreach initiatives from the pulp and paper industry

The Canadian forest products sector is passionate and devoted – not just to the industry itself, but also to its local communities. Here we share the initiatives of pulp and paper companies working to make positive social, environmental and economic impacts across the country.

J.D. Irving, Limited’s Woodlands and Sawmill divisions recently recognized 11 students with the second annual Northern New Brunswick Traes & Engineering Scholarship. The scholarship helps to support students building careers in highdemand fields within their local communities. Applications were open for Grade 12 graduates and mature students interested in skilled trades or engineering who live in rural communities in northern New Brunswick. The scholarship covers the cost of tuition (up to $5,000), ensures paid work terms during their studies and provides opportunities for full-time employment at JDI within the Sawmill or Woodlands divisions after graduation.

Let us help you share your successes. Tag @PulpPaperCanada or use #PPCGivingBack on Facebook or X, or send an email to the editor at srayghosh@annexbusinessmedia.com. We’d love to hear from you!

SEPTEMBER

OCTOBER .25