www.pulpandpapercanada.com

My name is Dave

www.pulpandpapercanada.com

My name is Dave

is my Story.

I am the TAPPI community. I want to prepare the next generation for success.

My TAPPI story is about passion and wanting to help the industry and sustain it, and help it continually improve.

– David “Dave” Maddux Corrugator Board and Paper Converting Sales Manager of North America for Valmet

There’s more to my story. Scan and view my story

The pulp and paper industry in Canada faces an aging workforce and a diminishing pool of skilled workers. In recent years, companies have been focussing on recruitment and retention best practices to ensure they have the required talent in their facilities.

The industry itself has innumerable opportunities that the new generation of the workforce can take advantage of. However, like any industry, it has its unique challenges. For instance, remote mill locations may be an issue with potential workers seeking jobs only in the bigger or more populous cities. Another potential disadvantage is the lack of awareness of what working in a pulp and paper mill actually is like. The industry is still quite often perceived as a place with dull and dirty operations.

Sukanya Ray Ghosh Editor

Despite the many challenges, Canada’s pulp and paper mills are filled with exemplary leaders who work hard every day to improve processes and efficiencies with best practices and new technologies. In this issue, we celebrate such leaders through our annual Top 10 Under 40 contest. The winners this year have some invaluable inputs on how to encourage more recruitment and retention.

In 2019 and 2021, Pulp & Paper Canada conducted recruitment and retention surveys to feel the pulse of the people employed in Canadian pulp and paper operations. In 2021, responses to the survey reflected the after-effects of COVID-19 on the workforce, such as the challenges they faced due to stringent social distancing rules and different work schedules, among other things. With some distance from the pandemic and all the recent upheavals the industry has been through since then, it will be interesting to see the perspectives of the workforce today. The survey is open until August 30. The results will be published in early October. If you have not yet responded to the survey, please do so. Your opinions are highly valuable in creating positive change. Keep an eye out for the detailed survey report to understand where your peers, colleagues and competitors stand.

If we talk about competing for competent talent, we have to factor in the aspect of safety. Among other things, employees today look for facilities and workplaces that prioritize safety and follow a proactive approach rather than a reactive approach. In this area, pulp and paper mills are actually quite vigilant and have maintained the focus on safety for years now.

In this issue, we highlight two broad themes – workforce and safety. Inside, you will find the results of our annual Safest Mills in Canada contest. Every year, the safety data from the mills show how they are striving to create the safest workplaces.

READER SERVICE

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Administrator

Tel: (416) 510-5113 Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor

SUKANYA RAY GHOSH

647-203-7031

srayghosh@annexbusinessmedia.com

Brand Sales Manager

SONYA HESSON

416-510-5224

shesson@annexbusinessmedia.com

EDITORIAL/SALES OFFICES

CEO SCOTT JAMIESON

519-429-5180

sjamieson@annexbusinessmedia.com

Group Publisher

ANNE BESWICK

416-510-5248

abeswick@annexbusinessmedia.com

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Phone: 416-442-5600

Audience Development Manager Serina Dingeldein 416-510-5124 sdingeldein@annexbusinessmedia.com

Media Designer Alison Keba

Print in Canada ISSN 0316-4004 (Print) ISSN 1923-3515 (Digital)

Account Coordinator SHANNON DRUMM sdrumm@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Canada $58.65- 1 year; $94.35 - 2 year; $19.50 - Single copy

USA $141.78 CDN per year Overseas - $153.00 CDN per year

Occasionally, Pulp and Paper Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

The editors have made every reasonable effort to provide accurate and authoritative information but they assume no liability for the accuracy or completeness of the text or its fitness for any particular purpose. All rights reserved. The contents of this publication may not be reproduced in part or in full without the publisher’s written permission © Annex Publishing & Printing Inc.

Sustaining member, Pulp and Paper Technical Association of Canada; Member, Alliance for Audited Media.

On that note, I would like to bid all of you goodbye. It has been an absolute pleasure learning and writing about this industry. I am passing the reins to my colleague Sarah Sobanski, who will bring in fresh perspectives on relevant content for all our beloved readers.

PPC

Irving Pulp & Paper plans for generational upgrade of Saint John pulp mill

Irving Pulp & Paper has submitted a preliminary application to undertake a major upgrade to Saint John’s westside pulp mill. This reportedly represents a new long-term capital improvement plan and a potential $1.1 billion investment.

Known as NextGen, the project will increase the mill’s capacity while also increasing the green energy it generates, reportedly making it one of the top-producing kraft pulp mills in the world. An Environmental Impact Assessment (EIA) related to the project has been submitted to New Brunswick’s Department of Environment.

The company intends to construct a new recovery boiler to replace the 1970sera boiler. This project will increase production by approximately 66 percent and facilitate several new environmental upgrades to the historic mill including a new turbine and green energy generator which will help decarbonize New Brunswick’s electrical grid; technological improvements to re-use water and reduce the mill’s water consumption; and decommissioning an oil-fired boiler which will reduce the CO2 emitted from the mill.

During the four-year construction phase, the $1.1 billion capital investment project will reportedly generate over $172 million in tax revenue for provincial and

local governments; generate $539 million in employment income and create more than 2,200 person years of employment; boost provincial GDP by $711 million; and generate $409 million in household spending and generate opportunities for hundreds of local contractors.

next president and CEO

Cascades has appointed Hugues Simon as its new president and CEO. Previously president of the Wood Products business at Resolute Forest Products, Simon took over his new role on July 1, 2024.

“It is with great humility that I am joining the team at Cascades, a company with both a rich history and deeply ingrained values. I am proud to join a company that is recognized as a pioneer in recycling and the circular economy committed to innovation and a client-centric approach, all of which is reflected in the quality of its products and its people,” said Simon.

The appointment follows an extensive succession planning and recruitment process, supported by an international firm, in anticipation of Mario Plourde’s planned retirement. After more than 11 years at the helm of the company, Plourde will support the new president and CEO during a transition period lasting until December 2024, after which he will act as a special advisor.

“It is with great emotion that I am

Innofibre

Quebec industrial innovation centre Innofibre recently conducted a research project that has demonstrated that used food and beverage cartons, which are mostly made from paperboard, show great potential for the manufacturers of moulded pulp packaging. Carton Council of Canada shares in a press statement that at present, no manufacturer of such packaging in North America uses pulp made wholly or partly from fibres derived from recycled cartons.

For this research, Innofibre produced pulp from post-consumer cartons obtained from a Quebec material recovery facility (MRF), which it then reportedly transformed into moulded products using two commonly used techniques: transfer moulding and thermoforming.

“Our tests confirmed that recycled carton fibre pulp has similar mechanical and physical properties to virgin kraft pulp,” explains principal researcher Eric Desnoes. “This means that we can manufacture high-quality moulded products with it.”

According to the researcher, the strength of carton pulp is, therefore, significantly higher than that of mechanical pulp, such as that obtained from old newspaper, which is the pulp most frequently used for moulded products made from recycled fibres. In addition, the research concludes that carton pulp would be particularly suitable for industrial manufacturing, given the relatively short production time of items and a shrinkage rate that does not interfere with nesting.

announcing my retirement after nearly 40 years at Cascades. It has been a great privilege to work with the Lemaire family and the entire Cascades team,” stated Plourde, current president and CEO of Cascades. “The time has come for me to pass the torch, and I am confident that Hugues’ expertise and experience will enable him to successfully lead Cascades.”

A graduate in administration from the Université de Sherbrooke, Simon has over 30 years of experience in key positions in the manufacturing sector, including as president, of the Wood Products business at Resolute Forest Products. Previously, Simon was president of BarretteWood, where he worked from 2012 to 2020.

“We are very pleased to announce the appointment of Hugues as president and CEO,” said Patrick Lemaire, chairman of Cascades’ board of directors. “His extensive experience in leadership positions in the industrial products sector will be a great asset to the company and to our customers.”

GreenFirst Forest Products has announced that Kap Paper, a wholly owned subsidiary of GreenFirst, has entered into a loan agreement with a third party establishing a non-revolving term loan facility of up to $24 million to support its paper mill operations in the town of Kapuskasing. The loan is to be used for general working capital purposes.

“The financing will afford us the opportunity to move forward our long-term strategy for Kap Paper, ensuring its competitiveness,” said Terry Skiffington, Kap Paper’s CEO.

GreenFirst shares in a press statement that Kap Paper remains focused on mill operations and has made considerable improvement on the operational challenges faced in the last two reported quarters, some of which were caused by external events. Kap Paper looks to build on this momentum to further improve operational efficiencies in what has been a tough pricing environment for paper products.

“The company’s sawmills in Kapuskasing, Hearst and Cochrane utilize Kap Paper’s operations as an outlet for their chips. The financial support is integral to the company’s long-term strategy,” said Joel Fournier, GreenFirst’s CEO.

How a process safety approach can be applied to black liquor recovery and other high-risk work activities

By Alexandra Skinner

Process safety is a critical part of overall workplace health and safety – especially in industries like pulp and paper manufacturing, where hazardous materials and complex equipment are commonplace.

While many occupational health and safety programs focus on individual work tasks, process safety looks at an entire process, from end to end. It examines things that can go wrong with a process and how the safety of workers or others may be impacted.

Trevor Williams, Occupational Hygiene Officer with WorkSafeBC, says, “There are many process hazards and associated risks in complex industrial facilities like kraft pulp mills. It is important that workplaces minimize the likelihood and potential consequences of serious incidents such as fires, explosions, chemical releases and structural failures.”

While major process safety incidents are infrequent, their consequences can be catastrophic, requiring a vigilant and structured approach to managing the risks.

Process hazards and risks common to kraft pulp mills include:

• Chemical hazards: Toxic, flammable, corrosive, reactive and explosive substances are typically present, and there are many risks from the unintended reaction of incompatible substances.

• Steam and pressure systems: Potential for steam releases or explosions from high-pressure systems.

• Combustible dust: Explosion of wood dust or other combustible dust inside process equipment or inside occupied work areas due to hazardous accumulations.

• Confined spaces: Risks of asphyxiation, toxic exposures or other incidents in con-

It is essential to regularly question and challenge the

events to inform safety improvements.

fined spaces during maintenance.

• Electrical hazards: Dangers of electric shock, arc flashes or fires from electrical systems.

• Equipment failures: Malfunctions in critical machinery leading to leaks, spills or explosions.

• Environmental risks: Release of pollutants into the environment, risking regulatory penalties.

• Human factors: Unforeseen risks from the interactions between people, equipment and their work environment (i.e., human error).

Managing risk in your workplace involves determining what might cause harm to your workers and ensuring you take reasonable steps to prevent that harm from happening. At the most basic level, this typically includes the following steps:

1. Identify hazards: Begin by identifying hazards in your workplace, with input from workers. In a complex, hazardous workplace, this usually requires a formal process to identify hazards and potential emergency incidents that can occur. This exercise is commonly referred to as a “HAZID.”

2. Assess risks: After you determine what hazards exist in your workplace, assess the risks these hazards pose to ensure you and your workers adequately understand them. Common elements that might be addressed in risk assessments include causation of incidents, consequence of incidents, probability of incidents, the efficacy of existing control measures and potential additional or alternate control measures to further reduce the risk. When assessing risks, you must consider all parts of the system and how the various components may interact. It’s not just physical things but also the actions

that people take and how they move or navigate through the workplace. There are many methodologies used in process safety for risk assessments depending on the application, including HAZOP, WhatIf, Bow-Tie, LOPA, FMEA, Fault Tree, Human Factors Assessment, and others.

3. Implement control measures: The next step is to control the risks. The greatest risks should be addressed first. If you cannot eliminate a risk, you will need to implement control measures to minimize it. This could involve process/ design changes, engineering modifications, administrative procedures or personal protective equipment. Engage your workers in these discussions.

For major hazards, a layered approach to controlling risk is often needed to provide independent layers of protection or redundancy in case of the failure of a control measure.

Following the hierarchy of controls can help you select and implement more effective and reliable control measures to mitigate risks.

status quo – employers can’t wait for major accident events to inform needed improvements. Regularly monitoring, reviewing and updating your hazards, risks and control measures is critical to ensure control measures remain effective. Monitoring activities include preventive maintenance, inspections, audits, function tests and calibrations, to name a few. Control measures need to be updated periodically over time as new risks are found or more effective control measures become available.

There are various process safety management programs that offer further guidance to ensure an effective risk management system for major, complex process hazards.

Black liquor recovery serves as a prime example of where a focus on process safety can significantly enhance workplace safety.

Recently, WorkSafeBC issued a risk advisory focusing on the hazards associated with black liquor recovery boilers

avoided due to workers quickly evacuating the area and sheltering in place in the protected control room. Similarly, in March 2023, a worker suffered severe burns when they were struck by molten smelt ejected from the furnace.

“These incidents underscore the need for robust process safety planning to mitigate the potentially catastrophic risks associated with this complex, hazardous equipment,” says Williams.

WorkSafeBC’s risk advisory emphasizes the importance of staying aware of evolving knowledge of hazards, risks, and available control measures – especially for workers assigned to power and recovery operations and routine inspection and maintenance activities.

Addressing these risks requires a proactive process safety planning approach involving a multidisciplinary team of managers, engineers, operations and maintenance personnel familiar with the process, work activities and incident risks. By integrating tailored process safety measures, employers can effectively minimize

4. Communicate: Your risk management program will not be effective if no one knows about it. Document and share your safe work procedures and policies with workers. Provide managers, supervisors and workers with orientation and training on how to identify hazards and what to do to control the risks. Consult with workers regularly on concerns, risks and the efficacy of current control measures.

5. Monitor, review and update: One of the key principles of process safety is to regularly question and challenge the

in kraft pulp mills. The dangers linked to black liquor recovery boilers include steam and hot water releases, furnace explosions, molten smelt runoff and dissolving tank explosions.

Despite the industry’s awareness of many of the major risks, Williams says that recent incidents show smelt ejections, heavy smelt runoffs and dissolving tank explosions have been identified as a significant and potentially under-appreciated risk to workers. For example, in December 2022, there was a serious dissolving tank explosion in B.C., with serious injuries or fatalities

the likelihood of an incident, mitigate the potential consequences of such incidents, protect workers, and foster a safer workplace environment.

For more information, see these resources on worksafebc.com:

• Process safety: Managing risk in highhazard sectors

• Risk advisory: Dangers of black liquor recovery boilers in kraft pulp mills | PPC

Alexandra Skinner is the manager of government and media relations at WorkSafeBC.

Winners of Pulp & Paper Canada’s 2024 Top 10 Under 40 contest discuss what keeps them motivated to excel.

By Sukanya Ray Ghosh

Anew generation of leaders is making waves in Canada’s pulp and paper industry. The winners of the 2024 Top 10 Under 40 program stand out due to their passion, expertise and relentless pursuit of excellence.

Pulp & Paper Canada’s annual Top 10 Under 40 program highlights how young leaders are shaping the trajectory of the industry and charting the path for continued success. Their innovative solutions and leadership inspire their peers and colleagues to rethink what is possible.

Here, we celebrate the accomplishments of these talented individuals in the pulp and paper industry, recognizing their achievements and the promise they hold for a sustainable tomorrow. This year, the winners have shared their thoughts on what inspired them to work in the pulp and paper industry, what keeps them motivated, their best achievements and more.

Want to recognize a future leader? Nominations for the 2025 contest open at the beginning of next year. Congratulations to our 2024 winners!

Process engineer, Irving Pulp & Paper, Saint John, N.B.

Pulp & Paper Canada: What inspired you to work in the pulp and paper industry

Ashley Bland: I was first exposed to the pulp and paper industry during a practice school course in University. I

was interested in the process and the importance of this industry in New Brunswick. I wanted to be involved with the opportunities for improvements to support sustainability for long term success of the industry.

P&PC: What keeps you motivated in your current role?

AB: In my current role there are always new projects and problems to solve. I am able to see the impact of my contributions to improving processes that benefit the team and the organization. We have a very supportive and collaborative work environment which allows me to continue to learn

continue to improve efficiency and sustainability for the future.

P&PC: How do you plan to advance the industry into a better future?

AB: Promoting continuous improvement to ensure our industry remains efficient and environmentally responsible. Coaching and mentoring others on these practices will help drive the culture for the industry to succeed long term.

P&PC: What should the industry do to encourage better recruitment and retention?

AB: The industry should continue to modernize through new technology and innovation. This will help to stay competitive and attract new employees. Training and development opportunities should also be prioritized to allow employees to progress and learn skills to continue to grow the industry.

from others and contribute to the success of the organization as a team.

P&PC: What do you consider your best achievements throughout your time working in the pulp and paper segment?

AB: Obtaining my Six Sigma Green Belt has given me the tools to drive improvement and work with others to lead change in the organization. I am also involved in a research consortium which helps to understand and address issues that many mills in the industry are facing. This program drives innovation to ensure pulp and paper organizations

FARHAD JALILIAN Operations specialist,Canfor

Pulp, Prince George, B.C.

P&PC: What inspired you to work in the pulp and paper industry?

Farhad Jalilian: I have a passion for increasing efficiency, reducing waste and optimizing yield in manufacturing processes. The fact that pulp mills have been striving to become more sustainable over the recent

decades inspired me to become a part of the journey. Manufacturing pulp and paper is an intricate process of converting wood chips to free-flowing fibres that are used for a vast variety of fibre-based products, consumed daily by billions of people around the globe. This, for me as a pulp mill worker, presents an incredible opportunity to create value for the country and the society, including my own family.

P&PC: What keeps you motivated in your current role?

FJ: The opportunity of driving impactful improvements keeps me motivated in my current role as an operations specialist in the digester-brown stock areas at Northwood Pulp mill. I closely work and collaborate with operators, shift supervisors, managers, engineers, maintenance planners and skilled trades workers to implement solutions to issues and limitations. I am a strong believer in the ability of teams where individuals’ skillsets are combined into a powerful and effective group.

P&PC: What do you consider your best achievements throughout your time working in the pulp and paper segment?

FJ: Over the past five years, I have been able to be a major contributor to the reduction of chemical usage in the mill, most specifically by minimizing soda losses in the mill. This has translated to a magnitude of tons of less caustic chemical consumption every day, and cost savings of millions of dollars every year. I have also allocated a specific focus on reducing fibre rejects in the mill from wood chip screening to reducing the volume

of rejected fibre in the brown stock screening. I have been assisting the operations and maintenance teams to increase the reliability of the mill as well as optimizing operational strategies. I look at each unit operation, from kraft digesters, atmospheric and pressure diffusers to brown stock knotters, washers, pressure screens, wash presses and try to develop solutions in keeping them within the target operating windows through production dynamics. As a result of these continuous improvements, Northwood pulp mill has been running reliably and efficiently, meeting and exceeding production targets in the past couple of quarters after a few challenging years.

P&PC: How do you plan to advance the industry into a better future?

FJ: I would like to gain experience in various aspects of the forest industry, the lifecycle of forest products, and contributing to optimization of processes from logging and harvesting to log milling and making fibrebased products. Deploying economical and innovative ideas with minimal cost and higher rates of return is something that I am passionate to pursue in my career.

P&PC: What should the industry do to encourage better recruitment and retention?

FJ: Among various ways of enhancing recruitment, I believe creating a true sense of pride and reward in manufacturing jobs is key to attract new talents and encourage employee retention. For retention, creating a safe, positive and friendly work environment where employees enjoy working as a team, not just

coming to work for the hours is important.

Plant manager, Cascades Papier, Kingsey Falls, Que.

P&PC: What inspired you to work in the pulp and paper industry?

Jason Perreault-Gelinas: Being a native of Kingsey Falls, the town where Cascades’ head office is located, it was instinctive from an early age to enter the industry. What inspires me most about the pulp and paper industry is the value it adds to raw materials and the environmental awareness it brings, giving a second life to materials while producing a value-added product.

P&PC: What keeps you motivated in your current role?

JP-G: First of all, the operational challenges of the pulp and paper industry motivate me on a daily basis. Recovery is evolving rapidly, and the nature of recycled fibres is changing. So we have to be constantly on the lookout to integrate new technologies to ensure the sustainability of operations, while continuing to develop products. I’m very passionate about this! I’m also driven by people management, surrounding myself with motivated, engaged people to create a winning culture. My vision of team cohesion is that everyone is working towards the same goals.

P&PC: What do you consider as your best achievements throughout your time working in the pulp and paper segment?

JP-G: In February 2024, I was recognized as the Cascades Specialty Products Group winner for the value “Stronger Together.” Cascades annually presents The Source Awards to recognize employees whose journey, commitment and achievements embody one of its corporate values. The “Stronger Together” value unites our strengths and brings us together – persevering, moving forward, bringing people together and winning together are some of the qualities this award recognizes. Finally, my team and I were able to review our processes, optimize production, and maintain a positive work environment so that in just two years under my leadership, the plant’s productivity increased by more than 15 percent.

P&PC: How do you plan to advance the industry into a better future?

JP-G: For me, it’s vital to ensure greater eco-awareness in the industry to secure a better future. Social and environmental awareness certainly means reducing water consumption and greenhouse gases, but it’s just as important to ensure the diversity of our raw materials. These days, there are plenty of interesting alternative fibres!

P&PC: What should the industry do to encourage better recruitment and retention?

JP-G: First of all, to encourage better recruitment and improve retention, it’s in the industry’s best interest to focus as much as possible on people’s well-being, and to listen to them in order to create a stimulating and

rewarding work environment. What’s more, it’s important to ensure that we have the right individual profile, in terms of both pulp and paper skills and personality. This is the key to building team cohesion and a culture of excellence.

Health and safety manager, Cascades Tissue Group, Candiac, Que.

P&PC: What inspired you to work in the pulp and paper industry?

Jessica Carbonneau: My last two internships were with Cascades. Right from my first internship, I knew that my career would be in manufacturing. The pulp and paper sector is an environment where you can continually learn new ideas and apply these principles to improve processes. The other concept that inspired me was the self-help aspect, where everyone helps each other and wants to make things work as a team. The pulp and paper industry is more like a community, where everyone seems to know each other from one company to the next.

P&PC: What keeps you motivated in your current role?

JC: Navigating through challenges and obstacles has always served to be a catalyst that motivates me in my work. I was a production manager

for several years and sought to take on new opportunities that would bring me out of my comfort zone. I love learning and helping the people around me. I enjoy taking on new challenges and developing my team. We have experienced many issues in terms of health and safety due to current staff turnover. I stay motivated by keeping in mind the vision I want to achieve with OHS over the next few years at Cascades.

P&PC: What do you consider as your best achievements throughout your time working in the pulp and paper segment?

JC: This is a difficult question for me to answer. I am a person who doesn’t like to brag about my achievements. All of the things I’ve done that I am proud of have been built with the support of a team. Probably one of the things that I am most proud of is having led my team to exceed planned targets by setting production records. On a personal level, I’m proud to have convinced management to invest in the replacement of a major part of the machine I was supervising at the time. This project made me realize that I could positively impact and influence my work.

P&PC: How do you plan to advance the industry into a better future?

JC: My future vision of OHS applies to all sectors of the industry. It is a vision where OHS becomes a core value for everyone, and where our employees go home not just as they were before – but as a better version of themselves. My goal is to create an environment where people are motivated to come to work because

they feel positive after their role, they feel listened to and valued for their involvement, and that everyone cares about each other.

P&PC: What should the industry do to encourage better recruitment and retention?

JC: We need to continue to do things differently in order to motivate employees who want to come and work for us for more than just a salary. Accept that humans make mistakes. I also think that if we work to improve the orientation process for new employees, they will be more inclined to stay – and will have a more successful experience. To encourage better recruitment and retention of our employees, we need to provide them a pleasant, healthy and safe working environment, one in which they can flourish and contribute to the company’s success.

Power & recovery technical assistant, Kruger Kamloops Pulp, Kamloops, B.C.

P&PC: What inspired you to work in the pulp and paper industry?

Joseph Chambers: I grew up in the interior and a good portion of my family and friends were employed by the forest industry. During university, I was fortunate enough to have a summer student position at the Kamloops Pulp mill and I was

able see how diverse the process is and how much opportunity there is for learning.

P&PC: What keeps you motivated in your current role?

Joe C: The people I work with. I want to do my part to make sure the process is safe for everybody to work in. I want to do my part to make sure we operate within our environmental policy and make our productivity goals to help ensure we all have a place to keep working at.

P&PC: What do you consider your best achievements throughout your time working in the pulp and paper segment?

Joe C: I would say that it’s the working relationships that I have established with the people at the mill. This mill is filled with awesome people who are very good at what they do. I get to work with teams that consist of people from every department in the mill, a few examples being: operators on the production floor, maintenance groups, process technicians in our lab, our engineering team, people in our finance department and admin areas, they are all awesome.

P&PC: How do you plan to advance the industry into a better future?

Joe C: At my level I plan to keep doing my part to make sure our mill runs in a safe and productive way. This will prove that this industry and this mill is worth investing in and prove to future employees that this industry is a good one to work in. With that investment and with people we will be able to access the technology necessary to advance.

P&PC: What should the industry do to encourage better recruitment and retention?

Joe C: This is closely related to the previous question. The industry needs to prove that it is worth people investing their future and their careers in. They need to see that the industry will be able to support them and their families. People need to see that there is opportunity for growth where they work and that if they want to become a leader within their organization, they will be supported in that.

KASRA RAYANI

Millwright apprentice level 1, Kruger Products, New Westminster, B.C.

P&PC: What inspired you to work in the pulp and paper industry?

Kasra Rayani: I have always been drawn to the production setting and the mechanical aspects of manufacturing where there is room for continuous improvement. I have a natural drive to make things better and the pulp and paper industry offered an opportunity for me to make a difference.

P&PC: What keeps you motivated in your current role?

KR: As a millwright apprentice in the converting maintenance department, I am faced with challenges everyday which help me to learn and grow. I am excited about going back to school and learning a new set of skills.

P&PC: What do you consider your best achievements throughout your time working in the pulp and paper segment?

KR: Safety has always been a top priority for me. My contributions to the Joint Health and Safety committee and my progression of roles have been a source of pride especially since I have earned the trust of my colleagues who appointed me as the Mill Safety Representative since 2023.

P&PC: How do you plan to advance the industry into a better future?

KR: Continuous improvement, optimization of equipment and process efficiencies are essential to remaining competitive within the industry so that we can continue to offer our consumers high quality tissue paper products.

P&PC: What should the industry do to encourage better recruitment and retention?

KR: The pulp and paper industry is very unique and requires a specialized skillset that allows people to grow in their careers. Communicating the opportunities and raising the industry’s profile are key to encouraging people to join the industry.

KOOWAR SINGH Continuous Improvement Engineer, Mercer Celgar, Castlegar, B.C.

P&PC: What inspired you to work in the pulp and paper industry?

Koowar Singh: My inspiration to enter the pulp and paper industry traces back to a field trip to the Celgar mill during my undergrad at UBC. As a starry-eyed chemical engineering student, I was captivated by the scale of equipment and intricacies of the processes. However, what left a lasting impression were the people I encountered –engineers and operators who genuinely enjoyed their work. So, when a job position opened up at Celgar after I graduated, I was eager to join the team. Since then, my appreciation for the industry has only deepened.

P&PC: What keeps you motivated in your current role?

KS: Being relatively new to my current role, the steep learning curve and the challenges that come with it are signifi cant motivators for me. The excitement of building my skills and contributing to some truly impactful initiatives keeps me energized. It’s invigorating to be part of teams that work collaboratively, pushing each other to achieve more. I’ve been fortunate to have mentors who placed immense trust in me, allowing me to lead initiatives and take risks with unconventional ideas.

P&PC: What do you consider your best achievements throughout your time working in the pulp and paper segment?

KS: Over the past seven years, my most significant achievement has been the professional relationships and connections I’ve formed. These bonds extend beyond

my coworkers and mentors at Celgar to include consultants, vendors and industry peers. I feel part of a community within the industry that I can rely on for both technical problem-solving and navigating the nuanced, non-technical challenges we all face. These relationships have been instrumental in my growth, making me appreciate the collaborative and supportive nature of the pulp and paper sector.

P&PC: How do you plan to advance the industry into a better future?

KS: In my experience, the success of any initiative – whether large or small, complex or straightforward – hinges on the engagement of our end users, be they operators, clients or customers. With the rapid advancement of technology, we need to embrace and integrate it into our business practices. The ability to analyze large amounts of data and use it to enhance transparency and garner buy-in is crucial. By leveraging these technological advancements, we can move information faster and more clearly than ever before, ensuring the industry continues to evolve and improve.

Pulp and paper facilities, often nestled in smaller towns, enjoy a unique advantage in their close ties to the local community. This relationship allows us to strengthen our positive impact on surrounding communities. By fostering these connections, we can create initiatives that not only benefit the industry but also contribute to the well-being and growth of the communities we operate in. This dual focus on technological innovation and community engagement

is key to driving the industry forward into a better, more sustainable future.

P&PC: What should the industry do to encourage better recruitment and retention?

KS: To attract and retain top talent, the pulp and paper industry needs to focus on enhancing the overall experience of working in the sector. With its commitment to a sustainable circular economy and strong community ties, the industry has a lot to offer. By broadening job opportunities to include non-traditional roles like data scientists and software developers, we can tap into a wider talent pool as our business needs rapidly evolve.

THARMAKULASEKARAM Plant manager in succession, Cascades Containerboard Packaging, Vaughan, Ont.

P&PC: What inspired you to work in the pulp and paper industry?

Kugenthini Tharmakulasekaram: I have always wanted to work in manufacturing as it gives me an opportunity to have boots on the ground. It is rewarding be a part of an industry where they are driving change towards sustainability and innovation.

P&PC: What keeps you motivated in your current role?

KT: Being able to build relation-

ships and interact with all the employees is the best part of my job. Every day is a different day and I love to work in a fast-paced environment where there are continuous challenges. Through interacting with various departments whether it be operations, maintenance or logistics, I am always learning. The culture and the environment make coming into work enjoyable.

P&PC: What do you consider your best achievements throughout your time working in the pulp and paper segment?

KT: Being able to implement lean six sigma methodology and the continuous improvement mindset within the plant has to be one of my best achievements. Being able to improve efficiency of machines and reducing waste. It was through a collaborative and facilitative approach as it was needed to be able to drive change management through the employees.

P&PC: How do you plan to advance the industry into a better future?

KT: Focusing on creating a culture of innovation and learning excellence. Being able to be proactive and adapt to the tools and technology that is at the forefront is crucial as well. We need to be able to look at the changing supply and demand dynamics in our industry. We need to strive to always look at developing ourselves and others around us through leadership development. As the world is shifting towards artificial intelligence, we need to see how we can best utilize that in our industry to help us advance towards the future.

P&PC: What should the industry do to encourage better recruitment and retention?

KT: We need to focus on succession planning with younger individuals and it is very crucial to focus on it as we have a larger retiring workforce. Having mentors within the business is critical to one’s development and being able to show an individual there are different career paths you can go through.

Manufacturing manager, Kruger Products, Mississauga, Ont.

P&PC: What inspired you to work in the pulp and paper industry?

Mathieu Bilodeau: As an engineer, the pulp and paper industry is a very deep field where you can learn and challenge yourself everyday day. I was exposed very early in my career to various types of experiences (engineering, problem solving, trials, projects, etc.) and my passion for pulp and paper evolved from there.

P&PC: What keeps you motivated in your current role?

MB: Everyday I learn something new with my job. It is very stimulating ! Exchanging knowledge and experiences with my team is something very important. It is truly rewarding to be able to support people’s development.

P&PC: What do you consider your best achievements throughout your time working

in the pulp and paper segment?

MB: I had the chance to be part of a strong team to manage the start-up of our new TAD tissue machine in Sherbrooke in 2021. The project itself was a big challenge and I was very proud to contribute directly to such a great success story. Our learning curve was quick and we now have the opportunity to operate one of the fastest TAD machine in the world and push its boundaries!

P&PC: How do you plan to advance the industry into a better future?

MB: The tissue industry is very dynamic and competitive. I see our industry moving towards new products, new technologies and new processes that are more and more environmentally friendly to fit our customers’ needs and the public’s expectations with respect to waste reduction, water reduction, energy reduction, etc.

P&PC: What should the industry do to encourage better recruitment and retention?

MB: I think that one of the main points in answering this question is to keep our people stimulated. It could be through new roles and responsibilities, special projects, new positions, promotions, etc. Creating opportunities is key!

SYLVAIN FILLION

Senior financial director, FP&A and commercial manager, Cascades Containerboard Packaging, St. Bruno, Que.

P&PC: What inspired you to work in the pulp and paper industry?

Sylvain Fillion: Being raised in Quebec, Cascades was a wellknown company with a great

notoriety. When I finished my degree, I saw an opening at Cascades, which was undergoing a technological transformation. It was interesting to blend my curiosity for new technologies and my sustainabilityoriented values.

P&PC: What keeps you motivated in your current role?

SF: Bringing value by proving relevant business and financial insights to grow the business, while developing and coaching driven individuals towards their goals.

P&PC: What do you consider your best achievements throughout your time working in the pulp and paper segment?

SF: I’ve had the opportunity to evolve in two pulp and paper sub-segments: Tissue and containerboard/packaging, while contributing on different aspects of the business (new business, supply chain efficiency, innovation, etc.). Being able to comprehend and contribute in such different settings is something I’m proud of.

P&PC: How do you plan to advance the industry into a better future?

SF: I plan on making sure that the industry is equipped with state-of-the-art finance tools, processes and people so that it better navigates its macro environment.

P&PC : What should the industry do to encourage better recruitment and retention?

SF: The industry should make sure to use and promote new technologies as part of new skill sets required, while simultaneously be close to the school system as part of building the future generation of workers. From there, retention can be enhanced with good set of core values, respect and opportunity for growth. PPC

From steam system design to PT2X™ steam joint installation, we help dry paper faster and more reliably.

The latest on how Canada’s leading firms are successfully recruiting youth and keeping them in the sector

By Treena Hein

For some years now, all major companies in Canada’s pulp and paper industry have been working hard on recruitment and retention. They’ve long been participating in career fairs, maintaining good relations with local educational institutions and more, learning what’s most effective and honing programs accordingly. They’ve also introduced fresh initiatives to make accepting a position and staying over the long haul more attractive in various ways. Overall, these programs focus on providing more support for future career growth and ensuring a good fit to achieve long-term satisfaction.

Let’s start with some updates from Kruger, which has just implemented a new leadership mentoring program. Within this framework, senior executives share expertise with new employees, encouraging their career growth based on common interests. However, “the program also includes extensive workshops, training and conferences related to developing leadership abilities,” explains Marie-Claude Tremblay, Kruger director of communications.

Kruger has also optimized its career websites to facilitate smoother application processing and recently began offering the new Joseph Kruger II Scholarship Program for employees’ children. A total of 40 scholarships will be given annually.

For its part, Cascades has been hard at work honing both its intern program and its creation of positions for new graduates, with specialized programs tailored to various professions.

“Over the years, we have significantly enhanced these initiatives to offer even greater opportunities for growth and devel-

opment,” says director of communications Christine Beaulieu. “Being a large company with over 10,000 employees and 70 units across North America allows us to have interns in multiple fields of study. Every year, we welcome students in engineering, finance, accounting, human resources, law and many other fields. So many possibilities are available internally, with career opportunities in both factory settings and at the corporate headquarters.”

Internships are offered three times a year, but there is some flexibility for timing and for specific positions, depending on the area of operations and current intern study level. Cascades encourages these interns to come back for additional internships, trying different areas to better decide what career path is best. “We talk about the opportunities available after their studies

and internships,” says Beaulieu. “We often get questions on those subjects, and it is important to note that we have possibilities and special advantages if you receive an offer after an internship.” Also, if interns receive an offer of employment, Cascades will provide financial aid for their last year of studies.

In addition, current Cascades interns are given the opportunity to build a professional network through various activities – first and foremost Internship Day, a tradition that “has become an integral part of the intern experience.” There are also virtual activities, escape room fun and various conferences that enable these students from various North American units to get to know each other and collaborate.

While Cascades already has partnerships with school institutions (with com-

petitions, school committees, etc.), the company has now extended its reach to vocational training centres. For example, in September 2023 Cascades established a vocational diploma program, allowing 12 new employees to learn skills onsite within one of its plants in Drummondville, Québec.

In fall 2023, Irving Pulp & Paper launched a new seven-month technical training program that’s already showing success. All 24 graduates now work at the company after graduating in April. The program is expected to repeat every two years.

In addition, this year Irving Pulp & Paper offered jobs to 18 new employees before graduation from post-secondary institutions in a wide variety of disciplines, from engineering to the skilled trades to business management.

Communication specialist Lauren McKinley adds also that “each year, we hire dozens of co-op and summer students from local post-secondary institutions, allowing them to develop their careers here at home.” From 2019-2024, their number totalled 373.

Irving Pulp & Paper also has a ‘Development Program’ scholarship for first-year students at New Brunswick Community College in various pertinent technical programs. Eight children of employees are also chosen from across Canada each year for scholarships.

Next, let’s look at an update to the Engineer-in-Training (EIT) Program at Paper Excellence (PE). Now in its third year, it’s described by Liz Lange (senior manager, talent acquisition) as “one of the most important and impactful talent programs in our history.” PE is currently exploring the potential to include Domtar and Resolute mills in the program.

Over 18 months, EITs learn from the company’s senior engineers, participating in projects and learning how to lead initiatives and support mill operations teams with day-to-day operations and troubleshooting. Of course, these young professionals can also provide fresh perspectives that re-energize their experienced peers. “The EIT program creates a bond across generations of engineers,” says Lange, “and

gives us a chance to pass down the valuable knowledge to the young minds. We believe the impact we make is not only good for PE but also good for the industry…We are incredibly excited and proud to see this program being the most effective program contributing talents in the age group of 21-27. And we are actively exploring the possibility of expanding this program enterprise-wide, with the vision to tackle the aging workforce problem at a wider scale.”

The program is proving very popular. Many candidates re-apply if they don’t get in the first year, and successful applicants also provide referrals of suitable candidates. “PE has a well-established reputation within Canadian universities that have engineering programs,” says Avneet Hayer, a human resources generalist at PE. “We also get great feedback from current EITs that they are learning a lot, with good support and mentorship available.”

Regarding which program aspects have proven to really work well, participants like the $1,000 relocation bonus and also the way they are able to work under an engineer to accumulate hours towards their own engineering degree. The EITs also find connecting with other EITs valuable.

To ensure employees feel valued and important, among other initiatives across the industry, Kruger has put a ‘Recognition Program’ in place. Using a third-party app, all employees in the company’s industrial sectors can offer recognition to their colleagues. It’s also a platform for recognizing work anniversaries, with employees able to

select a gift from a list.

“Kruger also offers a referral program to reward employees who refer qualified candidates eligible to fill open positions, with a bonus if the candidate is hired,” says Tremblay. She adds that most office positions are offered in a hybrid home office-come to work model. All employees are able to access initiatives allowing career growth and personal development, including conferences, social activities and training programs like LinkedIn Learning.”

With all these initiatives and new ones to come, Canada’s future pulp and paper workforce is sure to remain strong, despite fierce competition from other industries, an aging population and more. Paper companies are having success because they’re listening more closely than ever before.

A good example of this is Cascades new Graduates program, described as “a head start for young professionals in finance, human resources, supply chain management and engineering.”

With this program, graduates gain a permanent position at the company but rotate in different areas over two to three years. “This enables new graduates to explore new opportunities, engage in diverse projects, discover their preferences, secure permanent positions and experience rapid career advancement,” says Beaulieu. “Based on our intern survey and feedback, it has been shown that those criteria are the main ones that younger people look at when searching for their first professional opportunities.” PPC

For nearly 100 years now, Pulp & Paper Canada’s Safest Mills in Canada contest has been benchmarking safety performance of mills. The contest recognizes the outstanding safety records of participating mills by ranking mill frequency from lowest to highest. In the event of ties, mills are ordered by the most to least worker hours. Mills are increasingly focussing on risk prevention strategies

to enhance safety. For example, Irving Tissue in Saint John, N.B., introduced a risk team to focus on critical task areas for improvement. Cascades Specialty Products Group’s Forma Pak facility purchased a Reach pallet truck and installed a beam in the adjuster’s workshop to prevent him from repeatedly bending over and lifting a heavy load. Congratulations to all participating mills for achieving their safety goals!

“We will mark 500 days without a recordable accident in July 2024. We carry out the follow-ups required by our processes and we ensure everyone is rigorous in these follow-ups. In 2024 we have placed significant emphasis on mental health.” – Cascades Containerboard Packaging – Cabano

By taking a collaborative approach to HSE, the pulp and paper industry can improve mill safety from the woodyard to the finishing section

By Kyle Wismer, hse manager, na field services & automation and nick lising, senior manager, hse at valmet

The pulp and paper industry has begun to take a renewed, collaborative approach to health, safety and environment (HSE) on the worksite. Organizations are promoting an open dialogue between mills, original equipment manufacturers (OEMs) and contractors. Together, they are focusing on developing positive safety attitudes, skills and behaviours that go beyond occupational safety compliance and move toward a goal of zero harm. This goal demonstrates a deeper acknowledgment and understanding of situational risk, as well as meaningful adjustments to reduce it.

The organizations leading this initiative are making progress toward a positive safety culture by implementing new processes and behaviour-based programs, as well as supporting others as they begin to renew their focus on site safety. With effective planning, commitment to common goals and rules, clear responsibilities, good coordination and open communication, partners across the pulp and paper industry can help ensure everyone on a worksite goes home healthy and safe.

When beginning a new project, it’s easy to think about what needs to be done to complete the work. It takes a little more care and awareness to think about what needs to be done to complete the work safely. Mills can hold HSE meetings and safety kickoffs for

Some mills host safety summits with OEMs and contractors, where participants discuss safety and how to improve it together.

new projects and planned shutdowns. Such meetings can include employees, OEMs, contractors and other partners.

HSE meetings are examples of behaviourbased safety programs. Behaviour-based safety is a deliberate method of minimizing hazards and safety risks by predicting outcomes of behaviours, then proactively adjusting those behaviours to achieve a safer outcome. It is practiced by watching how people engage with or within a space, process or practice and making appropriate changes that improve safety. By taking the time to evaluate safety risks and hazards, teams are better prepared to work toward safer outcomes.

For instance, there is a concern around mechanical lifting and workers standing under a suspended load due to the size of rolls and equipment at a mill. Valmet, for example, has taken a hard stance on this issue, prohibiting standing under a suspended load as one of the company’s Life Saving Rules. Field service technicians can speak

about such Life Saving Rules to customers and contractors to implement safer practices.

In addition to a kickoff, mills can hold daily HSE meetings throughout a project or shutdown’s duration. These discussions with OEMs and the contractors can help determine evolving hazards and develop ongoing risk-prevention strategies. This level of pre-work understanding can get everyone in a safety mindset each day and minimize risks through repetition. Even if some conversations start to feel redundant over time, it’s valuable to have them just in case anything has changed.

What makes HSE meetings so effective is communicating what’s personally at stake: Why do you work safely? Some folks think of their families, activities they enjoy doing outside of work or future goals. By personalizing the message, these meetings make the understanding more impactful and people on the worksite more intentional.

If all parties participate in planning, commitment and responsibilities, there is a greater chance that procedures will go smoothly. Making these assessments and changes while establishing expectations can help improve the safety of the shutdown, future site safety and continued HSE conversations long after.

Some mills are already working toward establishing positive safety cultures and seeking support from industry partners. These mills have hosted safety summits or conferences that include OEMs or contractors. During the summits, participants have necessary conversations about safety and how to improve it together. This allows everyone

to provide their perspective, offer solutions, get buy-in and gain an equal understanding that they can take to the worksite. These summits can be a huge step toward improving the safety conditions and culture at mill sites. Summits help mills develop and implement safety training and help everyone that enters a site better understand safety expectations. This level of awareness can remind personnel to keep safety top of mind and hold all parties accountable for the safety of one another. Summits also improve collaboration by starting the safety conversation in a neutral way. It’s important that mills remain open when visiting contractors or OEMs express a safety concern, as they can help mills identify and mitigate hazards. Fixing these hazards can prevent accidents and help staff and visitors alike to feel safe on-site.

There are some areas and processes in a mill that have more obvious safety risks and hazards than others. While these areas and procedures may be made safer through behaviour-based safety, some -

times automating manual tasks is the best accident prevention.

One example is smelt spout maintenance for recovery boilers. When manually cleaning deposits from smelt spouts, operators often come in close contact with hazards such as molten smelt, liquor and hot gases. Smelt spout robots put distance between operators and physical hazards, reducing safety risk.

For example, Valmet installed its first smelt spout robot in a North American mill in 2023. The robot performs the physical cleaning cycles, while operators program the cleaning sequence and maintain remote control. The robot is also equipped with an onboard camera so operators can evaluate performance and troubleshoot issues. Automated technology such as smelt robots can also improve efficiency and productivity, and free operators to focus on other priorities.

In the past, mill safety was driven by compliance. Today, mills are taking a step beyond meeting standards and updating processes, integrating technology, providing training and implementing behaviour-

The transformation of your waste by grinding adds value to the process and reduces production costs in addition to eliminating your waste.

Our hammer hog is designed according to your needs, and manufactured for use in applications requiring robustness and reliability. Its design allows for easy and quick maintenance. Available with vertical or horizontal inlet, residue extraction is done by suction.

Applications: Hardwood / Softwood / Particle board, OSB, MDF

Selection criteria Capacity (lbs/hr) Desired particle size Type

Humidity

based safety programs. The people in organizations want to make sure everyone is safe because they genuinely care.

While operational safety is invaluable and employee well-being is reason enough on its own to practice a positive safety culture, safety can also affect the overall success of a mill. Mills with a positive safety culture can benefit from greater productivity, reduced costs and better morale and staff retention. By preventing accidents, employees may miss fewer days of work, and companies can minimize incident-related costs. Companies that tend to have a stronger safety culture may also have less turnover and be more attractive to potential hires.

It’s important to remember that implementing new processes for cultivating this kind of behavioural change takes time. Mills can benefit from the positive safety culture of their OEMs and work with them to develop, implement and measure progress toward their own safety goals and create their own HSE policies. Together, members of the pulp and paper industry can make continual progress and help ensure everyone works – and goes home – safe. PPC

By Joanne Palma, P.Eng., M.Eng., consultant, pulp solutions

When comparing different chemicals used in paper production, many factors need to be reviewed to determine which product adds the most value. The use of the Return-On-Investment (ROI) method, like the process for a capital project, will result in a more complete evaluation than just comparing dollar costs per tonne of product ($/t). When manufacturing paper that is sold by area (for example, linerboard), the savings in lower basis weight to achieve target strength as well as energy consumption, will affect the ROI. Knowing the process bottlenecks will determine if the chemical application allows for an increase in production rate.

Introduction

When installing capital equipment, an ROI method is often used to compare different options with many parameters examined to determine the best option. However, the cost of equipment is only one of the parameters in the assessment. The ROI should be the total annual savings divided by the capital cost. There are times when the lowest-cost equipment ends up being a more expensive solution overall.

Historically, buyers have been attracted by the cost per kg of product. For commodity products, this works well. As more specialty chemicals have been developed, there has been a slow change in looking at the chemical cost/t of paper and the impact on one parameter or the quality of the product. Even though this

is better, it is still not the best way of evaluating the true value of a chemical additive used in the production process.

Linerboard sold in North America must meet a specific sheet-strength requirement and there are basis weight guidelines for each grade. The salable tonnes are calculated by correcting the actual tonnes to the standard basis weight since the selling price is based on surface area. If the target strength can be achieved at a lower basis weight, this is usually beneficial for the paper machine and the end user and will affect the whole value chain.

Many things affect the strength of the product with the basis weight being only one of the factors. Other factors that affect strength are refiner energy, fibre orientation, formation/retention, fibre morphology and the wet and/or dry strength chemicals that are added. The overall goal is to produce the required strength for the minimum cost. The challenge is to adjust all the variables that affect strength

and find the combination that results in the lowest cost. The effect of the different chemistries on the production rate is an important part of the evaluation since increases in production rate will increase mill profits. This evaluation approach is ROI analysis. For chemical addition, the ROI is the net savings divided by the cost of chemical addition.

Raw material purchase and processing are examples of costs. If less fibre is needed to meet strength requirements, this will lower the raw material cost of the final product. If the bottleneck of the mill is in stock preparation, this may allow for an increase in m2 produced per day, adding further value.

The energy for refining is another variable in linerboard mills. Generally, increasing the amount of pulp refining will increase the strength of the pulp due to fibre development. Refining also cuts fibres, creating fines. Increasing pulp fines decreases the drainage of the pulp in the forming sections, resulting

in the need for more drying energy and potentially slower speeds if drying is limited. Since the increase in strength from increased refining allows for lower basis weight, the change in machine speed will depend on the relationship between increased strength and decreased drainage. Over-refining lowers the strength since refining cuts fibres indiscriminately.

For high-performance recycled linerboard, the key strength parameters are in the cross direction (CD) instead of the machine direction (MD). The strength depends on fibre development and fibre orientation. If the drainage of the pulp increases, machine adjustments can be made to make a more square sheet. This results in higher CD strength properties since some of the MD strength is transferred to CD where it is needed for this grade. Ring Crush is one of the tests used. The Ring Crush Index is the Ring Crush / Basis Weight of the sheet. Comparing Ring Crush Index of different operating conditions will allow for basis weight savings to be easily calculated for the ROI analysis.

The paper mill production rate can be limited for various reasons. Three different conditions will be examined in this paper. If pulping or machine feed equipment is one of the mill bottlenecks, then the machine speed is limited by the basis weight of the paper for grades sold by area. If the machine is dryer limited, the amount of steam needed to dry the paper determines the highest machine speed. Sometimes, the machine is already running at its maximum speed, so no increase in production is available. The market is another consideration. When the market is saturated, you may not be able to sell increased production. On paper machines that make more than one grade, the production rate may be different for different grades. For example, a low basis weight grade may be machine speed limited while a high basis grade may be steam limited. The ROI of chemicals is affected by what parameters limit the production rate.

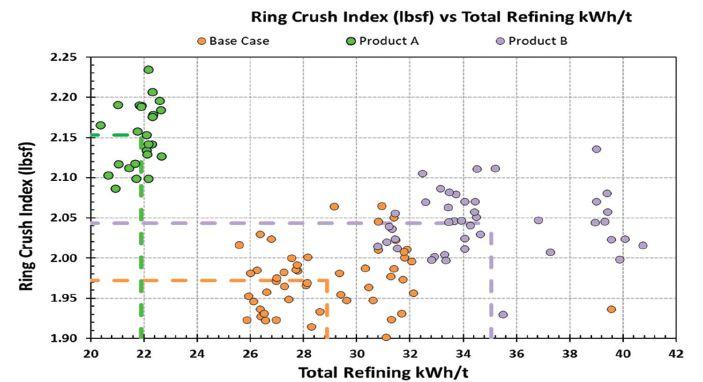

For illustrative purposes, the effects of two products (A and B) used to increase the strength of linerboard fibre were tested and compared with results without the products – the base case. The goal of the trials was to meet the Ring Crush strength requirements at a lower basis weight. Since the goal is to produce the same quality of paper, the Ring Crush index was used to calculate the basis weight for the three conditions.

OEMs like Valmet can ease this transition and modernize these relationships in the industry— whether they include the equipment owner, trade organizations, employees, students, or new hires.

Unlock a world of knowledge by downloading our new OEM Guidebook today! Learn more at valmet.com/legacy-of-trust

When comparing different conditions for linerboard, looking at the Ring Crush Index versus refining energy gives a good indication of potential value of various products. Higher Ring Crush Index means that the target Ring Crush can be achieved at a lower basis weight. Lower refiner energy means savings in refiner energy costs. How changes in basis weight and refining energy affect the production rate needs to be determined for each mill and potentially each grade.

Figure 1 compares the data from linerboard trials for the base case (orange), product A (green) and product B (purple). Both chemicals resulted in a higher average Ring Crush Index than the base case. Product A clearly results in a higher Ring Crush Index at lower refiner energy compared to both product B and the base case. Product B has a slightly higher average Ring Crush index compared to base case, but it requires a higher average refining energy to achieve this strength increase.

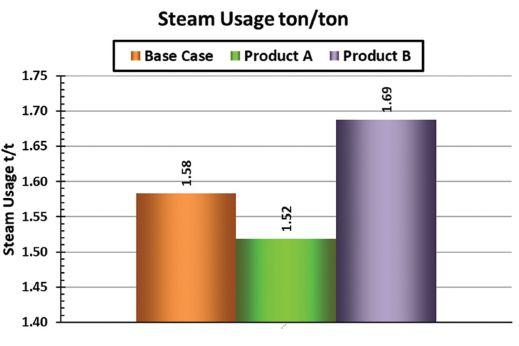

Increases in refining energy often result in a slower drainage due to an increase in fines. Figure 2 shows that the average steam consumption is lowest for product A which also has the lowest refining energy. The chemicals themselves may also affect the drainage.

In an examination of a strength trial for linerboard, the following information is required for evaluation:

1. Cost of fibre/m2

• Basis weight needed to meet strength specifications,

• Cost of fibre ($/t).

2. Production rate

• Incremental tonnes have higher value since fixed costs are covered in the base production. [1]

• Production rate for linerboard is by area, not tonnes,

• Understand the bottlenecks and impacts for each grade.

3. Cost/m2 of all strength developments

• Refiner energy kwh/t (converted to m2),

• Cost of chemicals added ($/m2).

4. Cost of drying energy /m2

5. Percentage of first quality rolls

• Downgrading or repulping of lower

than specification rolls lower net profit.

• When the mill is running close to the lower limit, this may be significant.

To calculate the ROI for the two products examined, the following assumptions are used:

• Normal basis weight of the grade is 254 g/m2,

• The paper basis weight is adjusted to keep the same Ring Crush,

• Fibre costs $65/t for OCC [4],

• Value of incremental salable tonnes is $250,

• Look at 3 different production rate bottlenecks,

• Electricity costs $0.033/kwh, ([5], average October 2022 to September 2023),

• The addition of other chemicals does not change,

• Cost of steam is $20/t of steam,

• Percentage of first quality rolls in not

affected,

• All other costs /m2 are constant.

The first step was to calculate the basis weight and energy consumption for the base case and each product. These results are listed in Table 1. This data was used to calculate costs (Table 2). The costs listed in Table 2 are the same for all production conditions.

The first bottleneck condition examined is paper mills that are limited by the amount of pulp they can produce. Under this condition, the production area that the mill can produce per day is controlled by the basis weight of the paper. Since both product A and B have a higher Ring Crush Index than the base case, lower basis weight paper will meet strength requirements. This allows for an increase in machine speed for stock limited mills. Table 3 shows that both products have a good net savings and product A has the higher ROI. Since

product B has higher refining and steam energy per m2, both are cost increases, not savings. The increase in production rate has the largest impact of the ROI.

High basis weight grades are often drying limited. In this case, the amount of steam needed to dry the paper limits the machine speed. Both the basis weight and steam/t to dry the paper is required to determine the machine speed. Due to the higher steam requirements with the addition of product B, a steam limited machine will need to run at a slower speed to dry the paper. Table 4 shows that product A has a good net savings and ROI. The addition of product B will result in a net loss, mainly due to the decrease in production rate.

refining and steam energy than the base case resulting in a net loss of $0.47 per m2 with a ROI of -60 percent. Product B is not an economical choice where there is no increase in production available.

Process changes often have an impact on the environment as well as on the economics. Lower basis weight to meet strength lowers the environmental impact of harvesting trees (virgin) or collecting material (recycle) as well as transportation energy. Lowering refining energy lowers electricity consumption. Lowering drying energy will reduce greenhouse gas emissions.

In this case study, product A has the lowest basis weight, refining and drying energy of the three conditions compared. It is the clear winner from an environmental impact as well as economic issues.

When paper machines are speed limited, an increase in production is not possible. When the market is saturated, there is no value in increasing production rate since increased capacity cannot be sold. See Table 5. Product A has a net savings from fibre and energy of $1.24 per m2 with a ROI of 1100 percent. Product B has higher

If all these factors are not included in the analysis, the true value of the products (A, B) cannot be compared. In the above example, product B has a lower cost per tonne, being $3.00 cost per tonne of chemical used, compared to $5.00 cost per tonne for product A. If only the $/t are considered, Product B would be best choice. However, since product B does not increase the Ring Crush Index as much as product A, it has higher fibre/m2 cost. Product B refining and drying energy are also higher than product A and base case.

Tables 6 summarizes the ROI for the different bottlenecks. Even though Product B is lower chemical cost, it is not the best option in any bottleneck conditions. In fact, it only adds value in a stock limited mill. Product A adds value in all three bottleneck conditions examined.

The environmental benefit can be included in the ROI when there are costs assigned to emissions. For example, the greenhouse gas tax can be included in the calculation. There may also be benefits in the company sustainability plan, resulting in savings.

To accurately determine the total value of paper machine chemicals, it is important to consider not only the cost of chemicals per tonne but also the production rate and overall production costs. This involves identifying and understanding any bottlenecks in the plant’s processes. Not considering all these variables could result in missed opportunities to maximize the ROI of the paper machine. PPC

This paper was presented by author at Paper Week, 2024, Montreal. Please contact Joanne Palma at JPalma@Pulp-Solutions.ca if you have any questions. Table

A review of the past, present and future

By Augusto Quinde

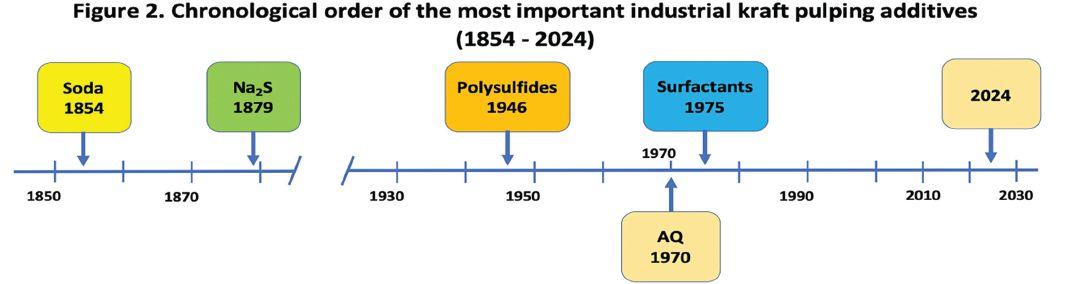

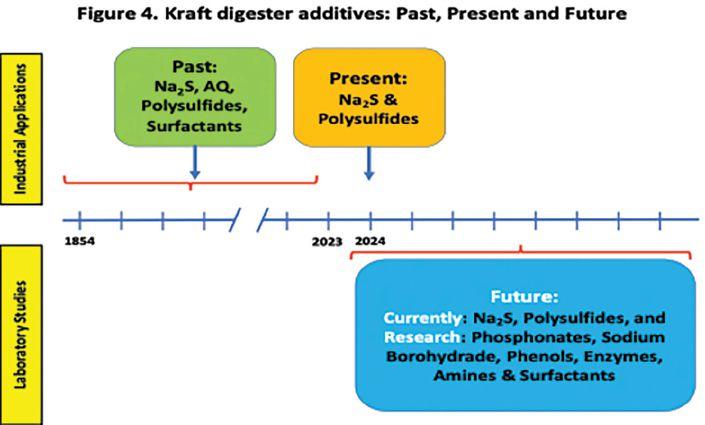

Increasing paper consumption is forcing chemical pulp mills to find new lignocellulosic resources for higher pulp production or to increase pulp yield by using pulping additives. In the last 50 years, we have not seen any new kraft pulping additive in the market. At present, the only additives being used at industrial scale are sodium sulfide (Na2S) and polysulfides (PS).

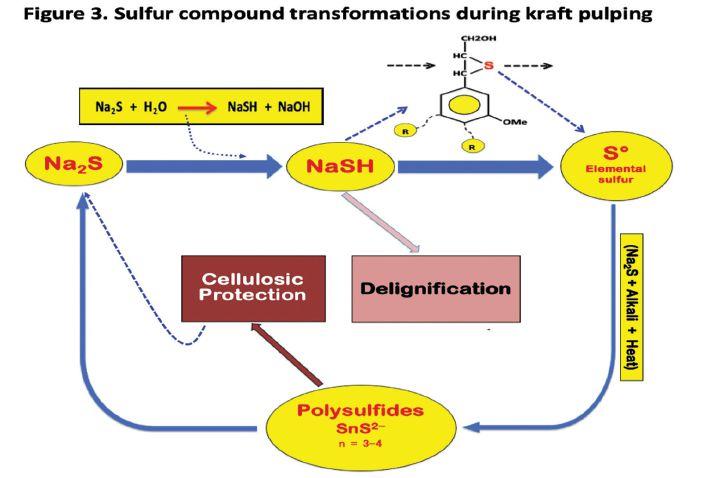

Some kraft pulping additives work in the digester as oxidizing agents or as reducing agents. When using an oxidizing agent or a reducing agent to increase pulp yield, these additives stabilize or protect the carbohydrates against degradation reactions. This cellulosic material protection can be interpreted as less organic material going with the black liquor facilitating the brown stock washing operations and consequently less organic material going to the recovery boilers enabling higher pulp. Polysulfides and sodium borohydride (NaBH4) have been shown to increase pulp yield due to higher retention of glucomannan. Polysulfides oxidize the aldehyde end group to carbonyl end groups and NaBH4 reduces the aldehyde end groups to stable alcohol end groups.

Pulping additives as reducing agents can be used to increase the rate of delignification. Using a normal delignification or an extended delignification process must be dictated by the bleaching requirements at a specified mill. An extended delignification will allow to lower the amount of bleaching chemicals to improve the effluents from the bleach plant.

Additional objectives expected from kraft pulping additives are: improving pulp quality; reducing the refining energy

requirements; optimizing the recovery liquor cycle; and rendering outstanding profits to pulp producers. See Figure 1.

In this paper we will review the most important kraft pulping additives being used in the past (i.e., 1879-2023), the current pulping additives in the market and the potential pulping additives that might be introduced in the future. The emphasis of this review will be on pulp yield and delignification.