Pulp & Paper Canada invites you to advise us of any changes in your mill listing.

Please forward all information to directory09@pulpandpapercanada.com

The Pulp & Paper Canada Annual Mill Directory provides details of operating (and temporarily closed) pulp, paper and board mills in Canada.

Editor

CINDY MACDONALD

Assistant Editor, Mill Directory

MARY ELLEN LAMKEY

Market Production Manager

KIM COLLINS

Publisher JIM BUSSIERE

Executive Publisher, Manufacturing

TIM DIMOPOULOS

Vice-President, Publishing

ALEX PAPANOU

President, Business Information Group

BRUCE CREIGHTON

EDITORIAL OFFICE

80 Valleybrook Dr., Toronto, ON M3B 2S9

Phone: 416-442-5600

Fax: 416-510-5140

800-268-7742 (from Canada)

800-387-0273 (from U.S.)

CUSTOMER SERVICE

E-mail: customerservice@bizinfogroup.ca

Phone: 416-442-2122, 800-668-2374

Pulp & Paper Canada Annual Mill Directory is published by BIG Magazines LP, a division of Glacier BIG Holdings Co. Ltd.

All rights reserved. The contents of this publication may not be reproduced in part or in whole without the consent of the copyright owner.

B

CA

Boxboard – East Angus .............. 20

Boxboard – Jonquière 20

Boxboard – Toronto .................... 21

Fine Papers – Breakey Fibres (Ste-Helene) .............................. 21

Fine Papers – Saint-Jerome 21 Fine Papers – Div. Rolland (Saint-Jerome) 22

Forma-Pak (Kingsey Falls) .......... 22

Tissue – Candiac 22

Tissue – Kingsey Falls ................. 23

Tissue – Lachute 23

Tissue – Laval .............................. 23

Tissue - Toronto Converting 23

Tissue - Toronto Paper Machines (Scarborough) 23

Tissue - Toronto Paper Machines (Scarborough) 23

Tissue - Toronto Paper Machines (Whitby) 23

l AKE u TOPIA PAPE r

Utopia 45

l O u ISEVI ll E

SPECIA l TY P r OD u CTS

Louiseville .................................... 45

MACKENZIE P ul PMI ll CO r PO r ATION

Mackenzie .................................... 45

M A rl BO r O P APE r/P APIE r S

M A rl BO r O

Drummondville 46

MEADOW l AKE

MEC h ANICA l P ul P

Meadow Lake 46

MI ll A r WESTE r N FO r EST P r OD u CTS

Whitecourt 47

MINAS BASIN

P ul P & POWE r CO. l TD.

Hantsport ..................................... 47

NANAIMO FO r EST P r OD u CTS

Harmac Pacific (Nanaimo) .......... 48

NE u CE l SPECIA l TY CE llul OSE

Port Alice (F) 48

NO r AMPAC INC.

Cabano (F).................................... 50

Kingsey Falls ............................... 50

Mississauga ................................ 50

Trenton (F) 52

NO r T h E r N P ul P

NOVA SCOTIA

Abercrombie Point (F) 53

P O r T hAWKESB ur Y P APE r

Port Hawkesbury ......................... 53

Q u ESNE l r IVE r P ul P COMPANY

Quesnel 53

rESO lu TE F O r EST

Pr OD u CTS I NC .

(F) ................................... 60

............................... 61

Kenogami ..................................... 62

Laurentide (Grand-Mére) (F)........ 62

St. Felicien (F) 64

Thorold (F) 64 Thunder Bay ................................ 64

rOCK T ENN La Tuque 67 Containerboard (Burlington) 67 Montreal Extrusion

AdityA BirlA Group

Head office

Address: Aditya Birla Centre, 1st Floor C

Wing, S.K. Ahire Marg. Worli Mumbai, India 400 030

Tel: +91 22 6652 5000, Fax: +91 22 6652 5741 Website: www.adityabirla.com

History:

A US $24 billion corporation with a market cap of US $31.5 billion, the Abitya Birla Group operates in 20 countries: India, Thailand, Laos, Indonesia, Philippines, Egypt, China, Canada, Australia, USA, UK, Germany, Hungary, Brazil, Italy, France, Luxembourg, Switzerland, Malaysia and Korea. Products: aluminum, copper, cement, carbon black, textiles, fertilizers, chemicals, sponge iron, mining, fatty alcohol, fatty acids insulators, software, BPO, finance and insurance, telecom, retail.

AV Cell

Head office

Address: 175 Mill Rd Atholville NB E3N 4S7

Tel: 506 789-4319, Fax: 506 789-4137 Website: www.av-group.ca

personnel

Hum Res Mgr: Elizabeth O’Keefe

Tech Mgr: S Pai

VP/COO: Ashley Irvine

Pulp Machine Supt: Denis Lanteigne

Hum Res Coord: L Bernard

Process Eng: Tanya Irvine

Asst Prod Mgr: Luke Caissy

Prod Mgr: Kevin Parker

Mtce/Engrg Mgr: Jamie Reinsborough

Parent Company: The Aditya Birla Group. Transportation: Railroad (CN); Highway

Production Capacity

Pulp: Bleached dissolving pulp, 360 t/d

Equipment

Wood Plant

Chip Unloader: 1 Rader 50’ truck dumper

Chip Handling: Rader Pneumatic, 180 t/h

Chip Screening: Acrowood system

Bi-Sulphite Pulping Plant

Digesters: 7 batch, 8640 ft3 each (5); 10,000 ft3 (2)

Knotters: 2 Ingersoll-Rand HiQ knotters

Washers: 2 Beloit two-stage pressure

Primary Screens: 4 centrisorters

Secondary Screens: 1 centrisorter Tertiary Screen: 1 centrisorter

Bleachery Process Stages: E-D-Ep-H

First Extraction Stage: 12’ I.D. x 110’ H - 120

min retention time

Washer: 1 Ingersoll-Rand Coru-Dek 11’6” x 14’

Dioxide: Pre-retention tube 5’ I.D. x 48’ H. 3 min. retention. Tower 14’I.D x 57’ H., carbon steel (C.S.) tiled lined - 27 min. retention time.

Washer: 1 Ingersoll-Rand Coru-Dek 11’6” x 14’

2nd Stage: Extraction tower 15’ I.D x 62’ HC.S. tiled lined, 120 min. retention time. Washer: 1 Ingersoll-Rand Coru-Dek 11’6” x 14’

3rd Stage: Hypochlorite: pre retention tube - 7’ I.D. x 70’ , 31 min. retention time, tower 19’ I.D. x 65’ H - C.S. tiled lined - 180 min. retention time.

Washer: 1 Ingersoll-Rand Coru-Dek 11’6” x 14’

Bleached Stock Cleaning

Cleaners: 192 Celleco Cleanpac 350 - 4-stage system plus reject control unit; 160 Celleco Cleanpac 270 - 4 stage system

Thickeners: 2 vacuum filters - 9’6” x 18’

Bleached Pulp Storage: 1 - 350-t tank - 24’ I.D x 87’ H

Production & Finishing Plant

Fourdriniers: 2 Dominion, each with 133” wires, suction couch, 3 plain presses and 4860” x 130” face dryers

Cutter Layboys: 2 Lamb-Grays Harbor Baling Press: 1 Baldwin, 835-t

Wire Tying Machines: Oval strapping Scale: Toledo

Steam Plant

Recovery: Mg0& SO 2

Evaporators: Aqua Chem - vapour compression spray film type - 8 effects. Four-body system with each body split longitudinally to make eight effects

Recovery Boiler: B & W Boiler, 2-drum water-cooled recovery units with refractory line primary furnace. Designed to burn with 652 t/d of dry solids from spent magnesium base liquor at 57% solids content and produce 2,586 t/d of steam at 8600 KPA and 510°C

Precipitator: 1 Flakt electrostatic precipitator

Absorption Tower: Flakt with cooling stage & 4 absorption stages, plus fortification tower

Sulphur Burner: Celleco pressurized furnace type - 30 t/d capacity

MgO Washer: Sala - vacuum filter type

Effluent: 150’ dia. reactivator type, activated sludge secondary reactor, two secondary 120’ dia. clarifiers

Hog Fuel Boiler: 1

Foster Wheeler: 1 2 drum unit designed to burn 15.5 bone dry tons/hr. of hog fuel at 56% moisture content and produce 1,635 t/d of steam at 8600 kPa and 515°C

Source of Power

Turbine Generator

Asea: ASEA radial flow type - single extrac-

tion back pressure unit with capacity of 20,000 kVA

Head office

Address: 103 Pinder Rd Nackawic NB E6G 1W4 Tel: 506 575-3314, Fax: 506 575-3300

History:

The company was formed in January, 1967 and was owned by Parsons and Whittemore, Inc. The mill started production in May 1970. September 2004, the mill declared bankruptcy and closed. April 2005, the mill was acquired by Tembec and Aditya Birla. The official reopening took place June 15, 2006.

personnel

Mtce/Eng Mgr: John Bartlett

Procurement Mgr: Stephane Laflamme

Exec Asst: Pat Bourgoin

Purch/Logistics Dir: Ravi Ghate

VP/COO: Frank Slater

Fin Controller: Krishna Khaitan

Mtce Eng: Fred Allen

Sr Process Eng: Carolyn Drost

Energy Mgr: Rajeev Goel

Corp Purch Mgr: Bill Graham

Sr Engr Technol: Peter Hinton

Process Mgr: John Howell

Buyer: Gary Jones

Sys Eng: Doug Phipps

Supt Wood Room: Brian Thornton

Mgr Qual Cont/Rsch Dev: Jarislav Stavik

Pres/CEO: Shankar Ray

Act Fibre Mgr: Jason Scott

Hum Res Mgr: Ginette Archambault

Process Eng: Jay Balanrishnam

Chem Plant Mgr: Brian Elliott

Env/Sfty Mgr: Hercules Georgiadis

Parent Company: 75% Aditya Birla Group; 25% Tembec

Sales Agents/Brokers: Tembec International Sales Corp., 70 York Street, Suite 1120, Toronto, ON, M5J 1S9, Tel: 416-864 0217, Fax: 416-864 1979, E-mail: joey.ducharme@ tembec.com; Tembec International B.V., Suite 2008, Capital Mansion No. 6, Xin Yuan Nan Road, Chao Yang District, Beijing 100004, China. Tel: 86 10 8486 3711. Fax: 86 10 8486 5008. E-mail: tiean.huang@tembecbj. com. Tembec International B.V., CP268/ OLS, 1274 Signy, Switzerland. Tel: 41 22 994 8822. Fax: 41 22 994 8828.

Production Capacity: 800 t/d

Equipment

Wood Handling

Chip Storage Capacity: 100,000 - blower/belt/ flinger

Chip Consumption: 850,000 t

Roundwood Consumption: 1,000,000 - hardwood

Log Deck: 2 32t Cardinal Drag chain

Chip Unloaders: 1 65ft. B.I.D. Portable

Chip Handling: 1 333yd. Cat Loader 988G

Debarkers: 2 60ft. Savico Rotary

Chippers: 1 200 t/hr. Gulghum 112’’ 8 knife

Chip Screens: 1 160 t/hr. K.M.W. Rotary

Kraft

Digesters: 6 batch 950 t

Washers: 1 CBF/3 C.I.R. 1,000 t/800 Ingersoll Rand, Press drum Filter/Corv-Deck

Knotters: 2 Primary/1 Secondary 800 Ingersoll Rand (2)/Noss, B3L Hi-Q/Raditrim 630.

Primary Screens: 2 800 Bird 800 Model

Secondary Screens: 1 Sec. / 1 Tertiary 800 Bird 800/200

Thickeners: 1 800 Canron Drum

Centricleaners: 2 LD/8 Twin/1 Cyclean Bird/ Ahlstrom Andritz

Bleach Plant

Bleaching Stages: 5 (1 up flow; 4 down flow)

Bleaching Sequence: D~o/E~op/D~1/E~2/ D~2

Washers: 5 900 t Canron Drum

Towers: 5 900 t Canadian Erectors

Mixers: 4 Chemical 900 t; 2 Static/2 IR 600, Canadian Single Shaft

Chlorine Dioxide Plant: 1 22 t OLIN

Mathieson, Omni Proc.

Main Process Control System: Foxboro I/A

Stock Preparation Plant

Pulpers: 1 1,000, Sydrapulper

Consistency Regulators: 7 BTG/Kajaani

Screens: 3 1,000, Black Clawson P24

Cleaners: 1,100 Celleco Cavister

Deckers: 1 680 Canron Vacuum

Main Process Control System: Foxboro I/A

Pulp Finishing Plant

Dryers: 66 Cans/Flakt 1,000t Dominion/ Flakt, Cans/Flakt

Cutter Layboys: 1,000 t, Lambs Gray/ Harbour

Baling Presses: 1,000 t, Dominion

Wire Tying Machines: 1,000 t, Ovalstrapping

Scales: 1,000 t, Lambs Gray

Unitizers: 1,000 t, Ovalstrapping

Paperboard Mill

Screens: 1,000 Trash Screen

Fourdriniers: 1 1,000 Black Clawson, HydroFlyte 250

Main Process Control System: 1 1,000 Foxboro I/A

Bale Handling

Cranes: 1 40 t

Trucks: 4 9,000 Clark clamp truck

Wrapping Machines: 1 1,000 t

Recovery Plant

Recausticizers: 5 600 g/m

Lime Mud Washers: 1 EIMCO Pressure Filter

Evaporators: 7 bodies 1,500 g/m Goslin Birmingham, L.T.V.

Slakers: 1 Size 15 EIMCO

Recovery Boilers: 1 350,000 lbs/hr., B&W, Bi drum

Precipitators: 1 Environmental Elements

Kiln: 1 F.L. Schmidt

Gas Scrubbers: 1 Teller

Lime Dust Scrubbers: 1 Peabody

Dissolving Tank Stack: 1

Power Plant

Power Boilers: 1 400,000 lbs./hr., B&W Bi drum

Steam Generated: 400,000

Type of Fuel Used: #6 + hog Bark: 2 10,000 t/y

Electricity: 304,000,000 kwh purchased Oil: 1 515,000 g/y

Source of Power: NB Power

Water Consumption: 23 526,000 m3

Water Source: Saint John River

Main Process Control System: Foxboro I/A

Effluent/Pollution Control

Dregs Filter: 1 EIMCO precoat

Sludge Disposal: Annual dredging, dewatering by contract Aerators: 19

Process Control

Distributed Control System: Foxboro I/A (Steam Plant, Recaust, Pulp Mill, Machine Room)

AV terrACe BAy

Mill

Address: 21 Mill Rd Terrace Bay ON P0T 2W0

History:

The Terrace Bay mill was purchased by Aditya Birla Group in August 2012. The company announced plans to convert production to dissolving pulp.

Wood source: Crown timber limits Transportation: Railroad, highway

Production Capacity

Bleached sulphate pulp: 455,600 adt/y: 1,352 adt/d; bleached softwood kraft, bleached hardwood kraft

Equipment

Wood Handling

Chip Storage Capacity: 50,000 cds, pneumatic blowing

Chip Consumption: 235,000 cds/y delivered; 230,000 hardwood; 615,000 softwood

Roundwood Consumption: 610,000 cds/y delivered; 530,000 softwood; 76,000 hardwood

Log Deck: 3 de-icing decks

Chip Unloaders: 2 1 - Rader portable, 1Peerless

Chip Handling: 2 reclaims pneumatic

Debarkers: 3 Ingersoll-Rand 90’ x 14’ Chippers: 3 Carthage 96”

Chip Screens: 2 Rader screens (hardwood); 1 Rader V-screen + Rader wave 140 units/h. (softwood)

Pulping Plant

Digesters: 18 capacity 6 @ 3,800; 12 @ 5,000 Washers: 11 capacity 5 @ 1,200; 6 @ 250; 6 Sherbrooke, 5 Ingersoll-Rand, 1 DOL Knotters: 4 capacity 1 @ 1,000; 3 Hooper, 1

Ingersoll-Rand @ 500

Primary Screens: 5 capacity 4 @ 250; 1 Cowan, 4 Hooper

Secondary Screens: 4 capacity 4 @ 50, 2 Ingersoll-Rand, 2 Hooper

Thickeners: 3 capacity 1 @ 500; 1 @ 1,200, 2 Sherbrooke, 1 Ingersoll-Rand

Pulp Dryers: 3 capacity 2 @ 250; 1 @ 1,200, 2-Flakt, 1-Ross

Evaporators: 2 550/2,200 USgalpm Swenson,

Unitech

Slakers: 2 320/900 USgalpm DOL

Lime Kilns: 2 80/200 t/d Allis Chalmers/ Fuller

Clarifiers: 5 DOL

Mud Washers: 2 82,000 ft3/DOL

Bleach Plant

Bleaching Stages: 5/6, 500 adt, 1,150 adt

Bleach Sequence: DcEDED, D1PcEoD1EpD

Washers: 5/6, 500 adt, 1,150 adt. IngersollRand, Sherbrooke, Precision Engineering & Dominion Bridge

Towers: 5/6, 500 adt, 1,150 adt. Toronto Ironworks, Canadian Stebbins

Mixers: 6/4 Cameron & Mid Canada

Welding, Ingersoll-Rand

Chlorine Dioxide Plant: 1 50 t, Sterling R-8 with Honeywell DCS

Main Process Control System: Moore, Bailey, Honeywell & Kajani brightness & residual sensors

Pulp Finishing Plant

Cutter Layboys: 3 capacity 250, 250, 1,200

Lambs Gray

Baling Presses: 4 capacity 2 @ 250, 2 @ 700

Hepburn

Wire Tying Machines: 12 250 each Tennant Scales: 7 3 @ 3,000; 4 @ 1,000 Toledo

Recovery Plant

Recausticizers: 6 16,200 ft3/DOL

Lime Mud Washers: 2 82,000 ft3/ DOL

Lime Kilns: 2 80/200 t/d Allis Chalmers, Fuller

Evaporators: 2 550/2,200 Swenson, Unitech

Recovery Boilers: 2 2.5 Mlbs black liquor solids each, C-E

Precipitators: 2 SF Products; Electrostatic 3

Gas Scrubbers: 1 SF Products

Lime Dust Scrubbers: 2 38,000/95,000 alfm, Air Pollution Ind., Joy Manufacturing

Dissolving Tank Stack: 1 Joy Manufacturing

Power Plant

Power Boilers: 2 425,000 lb/h. B&W total Steam Generated: 1.1 Mlb/h

Fuel Used Per Year: Bark 120,000 odt/y; Electricity 367,000 MWh; Oil 12.0 mig

Power Purchased: 26 MW/h

Water Consumption: 28 M USgal/d

Water Source: Lake Superior

Source of Power

Ontario Hydro + 20 MW Dresser/Rand generator

Effluent/Pollution Control

Primary Clarifiers: 2 Eimco, 150’

Dreg Filters: 1

Sludge Disposal: Hog fuel to PoBo

Sludge Presses: 1

A.S.B.: 64 Acre Multi-Celled Aerators: 38 Aquajet, 2,670 hp

AlBertA NewspriNt CoMpANy

Head office

Address: 2900-650 West Georgia St

Vancouver BC V6B 4N8

Tel: 604 681-8817, Fax: 604 681-8861

Website: www.albertanewsprint.com

personnel

Chairman: Henry H Ketcham III

Pres/CEO: Ronald Stern

Mktg Asst: Linda Huneson Ford

Pres/Alberta Newsprint Sls: Dale A Band

Controller: Lindsay Moyle

Mill

Mailing Address: PO Box 9000 Stn Main

Whitecourt AB T7S 1P9

Tel: 780 778-7000, Fax: 780 778-7070

personnel

Dir: Ronald N Stern

Dir: Henry H Ketcham III

Dir: Wayne Nystrom

Tech Dir: Gary Smith

Elec Supt/Instrument Supt: Stephen Tapp

Envirn Coord: D Moore

Mech Supt: Rodney Wilde

Gen Mgr: Mike Putzke

Prod Coord: Keith Best

Paper Mill Supt: Steve Keefe

Pulping/Utilities Supt: Surendra Singh

Woodlands Supt: Ian Daisley

Engrg Mgr: Bill Newcombe

Fibre Supply Mgr: Rod Brooks

Energy Mgr: Jan Luppens

Materials Mgmt Supv: Audrey Droesse

Parent Company: Joint venture between West Fraser Mills Ltd. and Whitecourt

Newsprint Limited Partnership Sales Offices: Idaho Falls: 208-528-7580. Minneapolis: 651-686-0688. Naperville: 630848-9198 Vancouver: 604-848-9193.

Transportation: Railroad and highway. Production Capacity: 270,000 t/y newsprint

Equipment

Pulping

Mainline Primary Screens: 4 Ingersoll-Rand pressure

Mainline Secondary Screens: 1 IngersollRand pressure

Thickeners: 5 Dorr Oliver sidehill screens

Reject Screens: 2 Ingersoll-Rand pressure Presses: 3 Thune

Chip Washers: 1 Sunds

Bleaching Stages: sodium hydrosulphite 1%

Impregnator: 1 Prex

Refiners: 6 Sunds CD70, 3 Conflo

Reject Refiner: Sunds CD70

Process Control Systems: 1 Bailey Network 90/Wonderware

Disc Filters: 3 Dorr Oliver reverse rotation

Stock Preparation Plant

Consistency Regulators: Metso

Broke Pulpers: Voith/Metso Broke Thickeners: 1 Hedemora Screens: 3 Voith

Cleaners: Celleco - 5 stages

Savealls: 2 Dorr Oliver

Paper Mill Data

Capacity: 750 t/d (average)

Products: Newsprint, Roto News Pulpers: 1 60 t/d Voith

Formers: 1 1,500 m/min Voith - Gap

Dryers: 39 Voith

Winders: 1 2,750 m/min Voith - 2 drum

Process Control System: 1 Bailey Network 90

CD Control Systems: AccuRay, Voith

Calenders: 1 Voith

Roll Handling Equipment

Wrap Line: 1 Lambs

Steam Plant

Steam Boilers - Gas: 2 80,000 kg/h each

Nebraska, package

Steam Generated: 160,000 kg/h

Reboilers: 2 (70,000 kg/h); (30,000 kg/h)

Water Consumption: 25 m3/t

Water Source: Athabasca River

Process Control Systems: Bailey Network 90 DCS

Effluent/Pollution Control

Clarifiers Primary, Secondary: 2 30.5m dia., 45.7m dia

Dump Ponds: 1 7,500 m3 concrete lined

Sludge Press: 2 30 t/d each Phoenix twin wire belted presses, 1 Andritz screw press

Aerators: 2 800 hp Hoffman centrifugal blowers - submerged jet

Activated Sludge Basin: 1 45,000 m3 clay lined

Polishing Basin: 1 38,000 m3 clay lined

Process Control System: 1 Bailey Network 90 DCS

Head office

Mailing Address: PO Box 8000 Boyle AB

T0A 0M0

Tel: 780 525-8000, Fax: 780 525-8423

Website: www.alpac.ca

History:

Construction of the $1.3 billion facility began in May, 1991. In September, 1993, what is now the largest single-line kraft pulp mill in North America began operations.

personnel

Dir Govt Relations: Mike Voisin

Steam Chief/Chem Rec/Utlities Bus Unit

Ldr: Dave Fehr

H&S Bus Unit Ldr: Barry Greenfield

Woodroom Bus Unit Ldr: Tim Whiteley

Pres/COO: Al Ward

VP-Fin/Controller/CFO: Dale Bencharsky

VP Pulp: Daryl Nichol

VP-Woodlands: Bob Nichol

CEO: Sam Terao

Fibreline/Finishing Bus Unit Ldr: Randy Reimer

IT Bus Unit Ldr: Troy Sachko

Fibreline Specialist: Ron Herchuk

Bus Unit Leader-Mtce: Rob Sullivan

Cust Serv Specialist: Terry Smith

Dir-Mtce/Eng: David D’Juric

VP-Hum Res: Derek Getty

CRU Specialist: Wayne Minkus

Chief Inspector/Integrity Mgmt: Arden Delisie

E/I Specialist: Russ Strathdee

Env/Science Bus Unit Ldr: Elston Dzus

Reliability Central Mtce Facilitator: Gord Bertin

Dir-Enviro Resources: Shawn Wasel

Chief Forester - Forest Res Bus Unit Ldr: Kim Rymer

Corp Planning/Fin Bus Unit Ldr: Brent Rabik

Woodland Ops Bus Unit Ldr: Greg Safar

Hum Res Bus Unit Ldr: Mike Pelletier

Integrated Land Serv Bus Unit Ldr: Keith Windeler

ISO Quality Registration: 9001; 14001; 17025

Ownership: 70% Mitsubishi Corporation, 30% Oji Paper Co., Ltd.

Marketing: Alpac Pulp Sales Inc., Suite 300, 1199 West Hastings Street., Vancouver, BC, Canada, V6E 3T5. Tel.: 604-669-4111. Fax: 604-682-7441. Regional sales office in Tokyo, Japan.

Other Certification: Forest Stewardship Council (FSC), Gold Level Progressive Aboriginal Relations (PAR)

Production Capacity: 560,000 ADMt t/y hardwood; 90,000 ADMt t/y softwood.

Mill

Address: PO Box 8000, Boyle, AB, T0A 0M0, Tel.: 780-525-8000, Fax: 780-525-8423. Website: www.alpac.ca

Transportation: CN Rail

Production Capacity: 2,100 ADM t/d hardwood; 1,650 ADM t/d softwood

Equipment

Wood Plant

Chip Storage Cap.: 4 hardwood piles, 1 softwood pile; 84,000 m3/pile

Chip Production:: 2.6 million m3sub/y

Roundwood Consumption: 2.9 million m3sub/y

Slasher: 1 Nicholson Maxi

Debarkers: 1 Drum Ingersoll-Rand, 1 Drum Tree Length Mets

Chippers: 1 Carthage, 328 m3/h, 1 Camura GS Chipper, 421 m3/h

Chip Screens: 2 Acrowood Disc CTS, 2 Liwell Secondary

Pulping Equipment

Digester: 1 Kamyr, 2,125 t/d

Washers (Pre O2): 2 Sunds PW40120 (in parallel), 1 Kamyr ADW

Knotters: 2 Ingersoll-Rand Hi-Q

Screens: Hooper, 4 primary, 1 secondary, 1 tertiary, 1 quartenary, 1 swing

Oxygen Delignification: 1 Stage Sunds - 60 min

Presses (Post O2): 2 Sunds DPA 1572

Bleach Plant

Bleaching Stages: Open wash followed by 3 Sunds stages, total - 6hrs.

Bleaching Sequence: Open Wash D100 Eop D100

Washers: 4 Sunds CCB 40160

Towers: 4 Sunds

Mixers: 4 Sunds

Chlorine Dioxide Plant: 1 R8-Sterling, 38 t/d

Oxygen Plant: Praxair, 38 t/d

Pulp Finishing Plant

Pulp Machine: Valmet 8.13m (320”) trim

Pulp Dryer: ABB Flakt

Cutter Layboy: Lamb-Grays Harbor

Baling Presses: 2 Hepburn, 1,100 t/load

Chemical Recovery Plant

Recausticizers: 4 GL & V causticizers

Pressure Filters: 2 GL&V (1 white liquor, 1 weak wash)

Lime Mud Washer: 1 GL & V

Lime Kiln: 370 t/d C a O Allis Minerals

Evaporator: 5 effects/6 body Ahlstrom, 675 t/h

Recovery Boiler: B & W, 3,200 t/d BLS

Precipitators: 2 Research-Cottrell (in parallel)

Main Process Control System: Honeywell TDC-3000

Utilities/Power Plant

Power Boiler: 1 B & W, 260 t/h steam

Type of Fuel Used: Bark, 315,000 t/y

Precipitators: 2 Research-Cottrell (in parallel)

Steam Generators: 2 40 MW Mitsubishi

Turbines

Water Consumption: 85,000 m3/d

Centrifuges: 2 Alpha-Laval Aerators: 32 100 hp

Effluent/Pollution Control

Clarifiers: 4 Ecodyne (2 primary, 2 secondary)

Bioreactors: 2 activated sludge, 55,000 m3/ reactor

Centrifuges: 2 Alpha-Laval Aerators: 32 100 hp

AtlANtiC pACkAGiNG produCts ltd.

Head office

Address: 111 Progress Ave Scarborough ON M1P 2Y9

Tel: 416 298-8101, Fax: 416 297-2218

Website: www.atlantic.ca

History:

Atlantic Packaging Company was formed in 1946. All outstanding shares are owned by I. Granovsky (Chairman). The company, which began as a paper bag manufacturer, began extruding polyethylene film in 1958, in 1959 began manufacturing corrugated cartons and in 1960 entered the field of gummed tape. In 1968 it started production of paper following installation of a paper mill; 1983: installed tissue mill; 1990: installed 2nd tissue mill and newsprint mill.

personnel

Pres: Dave Boles

VP-Mfg: Peter Connelly

Chairman: I Granovsky

VP-Fin: P Doyle

Sr VP-Sls: Bob Hagan

Dir-Logistics: Todd Kostal

VP-Mills: Gerry Murray

Converting Operations: Brampton, Ingersoll, Mississauga & Scarborough, Ont.; Montréal, QC

Subsidiaries: Mitchel-Lincoln Paper Co. Ltd.

New forest pAper Mill

Mill

Address: 333 Progress Ave Scarborough ON M1P 2Y9

Website: www.atlantic.ca

History:

Opened 2006. Joint venture of Atlantic Packaging and Mitchell Lincoln.

personnel

VP-Mills: Gerry Murray

Production capacity: Mid to high-grade corrugated medium.

Mill

Address: 111 Progress Ave Scarborough ON M1P 2Y9

Tel: 416 298-8101, Fax: 416 297-2218

personnel

Dir-Ops: G Murray

Mill Mgr: L Easton

Linerbd Mill Supt: R Aldridge

Tissue Mill Supt: S Wayland

Linerbd Sls Mgr: J Pepper

Production capacity Paper: 600 t/d linerboard & corrugating medium

Equipment

Stock Preparation Plant (Linerboard Mill)

Pulpers: 3 continuous 2 250 t/d; 1 500 t/d

Broke Pulper: 1 continuous Cleaners: 9 Voith high-density Turbo Separator: 2 300 t/d

Linerboard Machine

Fourdrinier: 1 with top former, 172” trim Dryers: 67 5’ dia., 50 psi - 100 psi

Winder: 1 Pope reel

Rewinder: 1 2-drum, 172” trim

Tissue Machine

Twin Wire: 104” trim

wHitBy MAll

Mill

Address: 1900 Thickson Rd S Whitby ON L1N 9E1

History:

Former newsprint mill converted in 2013 to produce liner and medium, including lightweight grades.

Production Capacity Paper: 100% recycled liner and mediums

BowAter Mersey pAper CoMpANy liMited

Head office

Mailing Address: PO Box 1150 Liverpool NS

B0T 1K0

Address: 3691 Hwy 3 Brooklyn (Queens) NS B0J 1H0

Status

Permanently closed June 2012.

History:

During August 1928, Mersey Paper Company Limited was incorporated and construction of a newsprint mill commenced. Commercial production began on November 27, 1929. In May 1956, the Bowater Corp. of North America Ltd. incorporated Scotian Paper Co. Ltd. to acquire the assets of the old Mersey Paper Co. Ltd. In June 1956, the name was changed back to Mersey Paper Co. Ltd. and in 1959 it was changed to Bowater Mersey Paper Co. Ltd. Application was

made in September to Provincial Secretary to change the name to Bowater Mersey Paper Company Ltd. with effect on October 16, 1975 (application granted). In 1963, The Washington Post Company, Washington, D.C., purchased 49% of the common stock from Bowater Corp. of North America, now called AbitibiBowater Incorporated. Bowater Mersey amalgamated with Newsprint Shipping Services Ltd. on January 1, 1994. AbitibiBowater changed its name to Resolute Forest Products in Oct 2011.

Mailing Address: PO Box 1150 Liverpool NS B0T 1K0

Address: 3691 Hwy 3 Brooklyn (Queens) NS B0J 1H0

Status

Permanently closed June 2012

ISO Quality Registration: 9001-2008

Head office

Address: 7979 Vantage Way Delta BC V4G 1A6

Website: www.bkitech.com

Status:

Permanently closed Dec 2012

History:

In 1986, Merfin commenced converting tissue and toweling for the commercial market. In September 1989, the first air-laid machine commenced production. In October, 1994 the converting subsidiary was moved to North Carolina, USA. In May, 1995 the second airlaid line commenced production. In April, 1996 construction began on the third air-laid line in Cork, Ireland. In 1997, the company was purchased by Buckeye Technologies of Memphis, TN.

Plant Mgr: Laurence Li

BuildiNG produCts of CANAdA Corp. (lA Cie MAtériAux de CoNstruCtioN Bp CANAdA)

Head office

Address: 9510 rue Saint-Patrick LaSalle QC H8R 1R9

Tel: 514 364-7406, Fax: 514 364-9029

Website: www.bpcan.com

Status: The LaSalle Paper Mill was closed at the end of 2007. The plant is still operational

History:

The company originally incorporated as Building Products Limited on December 5, 1925, manufactured only roofing products and was formed by the amalgamation of two companies, one of which was in existence since 1905. Since 2003, Building Products of Canada Corp. is a privately held company.

personnel

Pres/CEO: Y Gosselin

VP-Admn/Fin: M Serre

Mech Spec: Mario Gagnon

Total Employees: 300

Parent Company: Emco Building Products Corp.

Mills: Pont Rouge, QC; Edmonton, AB Sales: Dartmouth, NS: 90 Wright Ave., B3B 1P2. Tel.: 902-468-5128. Fax: 902-468-5667; LaSalle, QC: 2850 Dollard. H8N 2V2. Tel.: 514-364-0671. Fax: 514-367-5274; Toronto, ON: 63 Huxley Road, M9M 3B4. Tel.: 416747-1103. Fax: 416-747-1109; Edmonton, AB: 3703 - 101 Avenue NE, T5J 2K8. Tel.: 780466-1133. Fax: 780-465-1181.

Products: Asphalt shingles, roll roofing, asphalt felts and sheating, chipboards, coatings & cements, wood fibre boards, decorative tiles, building paper.

edMoNtoN plANt

Mill

Mailing Address: PO Box 576 Stn Main Address: 3703 101 Ave NE Edmonton AB T5J 2K8

Tel: 780 466-1135, Fax: 780 465-1181 Website: www.bpcan.com

personnel

Plant Mgr: R Tintinaglia

Paper Mtce/Tech Mgr: J Dhatt

Hum Res Mgr: Herb DeJong

Total Employees: 172

Transportation: Edmonton, C.P.R

Paper Sales Center: PO Box 576m 3703 - 101 Avenue, Edmonton, AB T5J 2K8. 780-4661135. Fax: 780-465-1181

Output For Sale: 30,000 t/y paper (not converted)

Production Capacity

Paper: 130 t/d roofing felts, chipboard

poNt rouGe plANt

Mill

Address: 420 rue Dupont Pont-Rouge QC G3H 1S2

Tel: 418 873-2521, Fax: 418 873-2340

personnel

VP-Mfg: Simon Pierre Fortin

Mtce Mgr: A Savard

Project Mgr: A Huard

Qual Cont/Rsch/Dev Mgr: A Proulx

Distrib Supvr: Stephane Boilard

Mtce Buyer: Claude Bussieres

Admv Dir: Jean-Robert Mathieu

Total Employees: 150

Transportation: Road access only

Output for Sale: 67,000 t/y of woodfibre products

Production Capacity Paper: 28 999 t/y of roofing felt, 50% of which is made from recycled paper plus 67,000 t/y of woodfibre boards and tiles

CANAdiAN forest produCts ltd.

tAylor pulp

Mailing Address: PO Box 330

Address: 8300 Cherry Ave E Taylor BC V0C 2K0

Tel: 250 789-9300, Fax: 250 789-3089

History:

Started by consortium of British Columbia sawmill owners - Fibreco Export in 1988. 1999 purchased by shareholders Slocan Forest Products. Slocan was acquired by Canfor in November 2003.

personnel

Area Supvr: Dick Duncan

Supvr: Dwayne Edwards

Purch Mgr: Dan Hogg

Cust Serv Mgr: Darren Guilov

A-Mill Mgr: Albert Eisler

Div Controller: K Salmon

A-Prod Mgr: Hal Bulmer

Elect Technol: Mike Landucci

Planner/Buyer: Wayne McKale

Crew Supvr: Doug Snyder

Energy Mgr: Craig Thomson

Safety Coord: Randy Martinson

CEO: Don Kayne

Mtce Mgr: Patrick Cochrane

Total Employees: 110

Transportation: Railway 100% with 95% travelling off-shore via coastal ports

Production Capacity

Pulp: 690 t/d BCTMP

Equipment

Wood Plant

Chip Unloaders: 1 Rader

Chip Handling: 1 Rader

Chip Storage Capacity: 7 days

Chip Consumption: 240 000 bdu/y

Rechippers: 1 Carthage 48” 0-2000 ft3/h

Chip Screens: 1 BM&M 1 4/well

Pulping

Primary Screens: 6 I.R. model 2/2 D - slots

Secondary Screens: 1 I.R. model 2/2 D - slots

Thickeners: 2 I.R. 5M0, 1 Hymac 48” 64 adt/d

Centricleaners: 185 - Hymac model RB 200

EH

Presses: 6 Andritz (dewatering), 2 Andritz heavy duty 3.2m

Chip Washers: 1 Sunds Defibrator

Bleaching Stages: 2 lines of 2 stages each

Bleaching Sequence: 2 lines of 2 stages each

Pulp Dryers: 2 330 t/d each, Flakt flash dryers (low temp)

Refiners: 5, 400-t each, Sunds Defibrator CD 76 refiners, complete with 2 - 23,000 primary,

3 19,000 hp CGE drives - secondary and rejects

Process Control Systems: 1 Emerson Delta V DCS; 1 Q.E.S. technology finishing line system

Bleach Plant

Bleaching Stages: 2 stages each of 2 lines

Bleaching Sequence: 1 HC H 2 O/1 HC H 2 O

Washers: 3 per line - 2 lines, Arus Andritz

double wire press 3.2 m

Towers: 2 per line

Mixers: 6 Arus Andritz fluffer/mixer

Pulp Finishing Plant

Baling Presses: 2 - 330 t/d Sunds Defibrator slab presses, 1 Sunds Defibrator bale press

Wire Tying Machines: 3 Ovalstrapping,

Lamb Grays bale line

Scales: 1 Toledo

Unitizers: 1 Ovalstrapping

Stock Preparation Plant

Repulping Systems: 2 Hymac model 14-2B48 Turboflex II

Power Plant

Power Boilers: Heatech

Steam Generated: 70,000 lb/h

Process Control System: Emerson Delta V

Effluent/Pollution Control

Clarifiers: 2

Settling Ponds: 2 - 8 day

Sludge Disposal: 1 Arus Andritz, 1 Phoenix

Aerators: 6

Source of Power

Electricity: Purchased - approximately 80,000

kW from BC Hydro

Head office

Address: 230-1700 75th Ave W Vancouver

BC V6P 6G2

Tel: 604 661-5241, Fax: 604 661-5226

Website: www.canforpulp.com

personnel

VP-Sls/Mktg: Sean Curran

Chairman: Charles Jago

Dir: Peter JG Bentley

VP-Hum Res: Onkar Athwal

Dir: Ronald L Cliff

Dir: Stan Braken-Horrocks

Dir: David M Calabrigo

Dir: Michael J Korenberg

Dir: Conrad Pinette

Dir: William Stinson

Energy Leader: Mike Todd

Gen Mgr Fibre Supply: Rick Cooper

CEO: Don Kayne

Pres: Brett Robinson

CFO: Alan Nicholl

VP-Ops: Martin Pudlas

ISO Quality Registration: 9001

Ownership: Canfor Corporation, 50.2%; Canfor Pulp Products Inc.

Mills: Northwood Pulp, Intercontinental

Pulp, Prince George Pulp and Paper

Sales Offices: Vancouver, BC; Brussels, Belgium; Tokyo, Japan; Taipei; Taiwan;

Seoul,South Korea

Research & Dev. HQ: Vancouver, BC

Production capacity: Market pulp: 1,033,000 t/y; Kraft paper: 135,000 t/y

CANfor pulp iNNoVAtioN

Address: 138-8610 Glenlyon Pkwy Burnaby BC V6J 0B6

Tel: 604 228-6710, Fax: 604 228-6723

Website: www.canforpulp.com

History Canfor Pulp Innovation (formerly Research & Developement Centre)

personnel

Technologist: Ranbir Heer

Eng: Wendy Tsai

Technologist: Patricia McBeath

Technologist I: Alice Obermajer

Dir-Rsch/Dev: Paul Watson

Energy Leader: Mike Todd

Rsch Scientist: Paul Bicho

Total Employees: 6

iNterCoNtiNeNtAl Mill Mill

Mailing Address: PO Box 6000 Stn Terminal

Address: 2533 Pulp Mill Rd Prince George BC V2N 2K3

Tel: 250 563-0161, Fax: 250 561-3921

Website: www.canforpulp.com

personnel

CFO/Sec: T Hodgins

Corp Controller: R Remesch

Prod Mgr-PG/Intercon Pulp Mills: C Walls

Mtce Mgr-PG/Intercon: S Sidsworth

Tech Dir: Sandra Morrison

Chief Eng: Blaine Willick

Energy Leader: Mike Todd

ISO Quality Registration: 9001; 14001

Parent Company: Canfor Pulp Limited Partnership

Pulp: Canfor Pulp Limited Partnership, 2301700 West 75th Avenue, Vancouver, BC

Wood Source: Sawmill residual chips

Transportation: CN Rail, Highway Production Capacity: NBSK market pulp: 315,000 admt/y

Equipment

Wood Plant

Chip Unloading: 1 hydraulic truck unloading dumper

Chip Handling: Belts, trippers and front end loaders

Chip Storage: Outdoor piles

Chip Screens: 2 Rader primary V-screens, 2 Liwell secondary & tertiary screens, 2 Rader slicers, 1 air density separator, 1 Black Clawson disc scalper

Kraft Pulping Plant

Digester: 875 t/d Kamyr continuous Knotters: 2 -- Impco model B, H.Q. pressure knotter (one spare); 1 -- Noss Raditrim model 630 sec., 1 -- Impco vibratory (spare) Washers: 1 Kamyr pressure diffuser; 2 Impco end-valve 4.1 m x 6.7 m

Primary Screens: 4 CIR model 212D pressure screens

Secondary Screens: 1 CIR model 212D pressure screen

Tertiary Screen: 1 -- Ingersoll-Rand

Centrisorter C-110 (unbleached)

Cleaners: Noss Radiclones (5 stages), 1 CIR trash screen

Drainer: 1 Hymac 150 stockdrainer

Deckers: 1 Kamyr 4.3 m x 8.5 m unbleached; 1 CIR end-valve 4.1 m x 7.3 m bleached and 1 Kamyr 2.4 m x 7.3 slusher

High Density Towers: 2 brown and 2 bleached

Oxygen Delignification: 1 CIR pre-O2 washer 4.1m X 8.5m; 1 CIR single shaft steam peg mixer; 1 Sunds SMB-50B high shear oxygen mixer; 1 Sunds O2 reactor 3.6m X 30.5m; 1, O2 reactor blow tank 6.7m x 17m; 2 Sunds DPA-1255 post-O2 wash presses; 2 Ahlstrom MC pumps

Recovery Plant

Lime Mud Washer: 2 Dorr mudwashers, 2360 m3, 2800 m3

Lime Kiln: 1 Eimco lime mud; precoat filter 3.6 X 6.7m

Evaporators: Horton Sextuple Effect; 2 RCC pre-evaporators; 2 RCC concentrators

Recovery Unit: 1, 1450 t/d solids B & W

Precipitator: 1 ENELCO electrostatic

Recausticizing: 1 Eimco No 20 KCS slaker; 2 WLC 1930 m3, 2800 m3; 1 Eimco GLC 3260 m3

Bleach Plant

Process Stages: DEopDEpD

Washers: 1 Impco titanium, Coru-dek I, 13’6” x 22’ (D100); 1 Impco 316SS, 11’6” x 22’ (E2); 1 Impco 317ELCSS, 11’6” x 22’ (D1); 2 Impco 6-7% molySS, Coru-dek III, 11’6” x 22’ (Eop,D2)

Towers: Impco 1-upflow ClO2; 1-upflow/ downflow Eo; 1-downflow E2; 2-upflow

Mixers: 1 Komax static mixer, 4 double shaft Canron steam mixers, 1 Sunds SMA-50B Eo mixer; 1 Sunds titanium high shear mixer; 2 Alstom Ahlmix AM25-20

ClO 2 Plant: 1, 45 t SVP Methanol generator system

Production & Finishing Plant

Fourdrinier: 1 Black Clawson Cantilever

Hydroflyte, 6.0 m wire

Pulp Dryer: SF Flakt type L. 19 decks

Cutter Layboy: Lamb-Grays Harbor

Baling Lines: 1 Lamb-Grays Harbor, 1 Cranston

Baling Presses: 2 Burrard 907 tonne

Wire Tying Machines: Ovalmatic

Wire Tying Unitizer: Ovalmatic

Steam Plant

Boilers: 1 Foster Wheeler hog fuel, oil, or gas, 204,000 kg/h of steam @ 4100 kPa; 1 B & W Recovery, 229,270 kg/h of steam @ 4100 kPa

Source of Power

B.C. Hydro and steam turbines on major drives

Power Plant

Cogeneration System: 1 Mitsubishi backpressure unit, 25mw @4100 kPa inlet

Effluent/Pollution Control

Clarifier: 1 primary clarifier, 180’ dia.meter x 10’-20’ deep

Dregs Filter: 1 Dorr-Oliver dregs pre-coat

filter 6’ dia.meter x 6’ long

Sludge Treatment: 1 Passavant sludge thickener, 55’ dia.meter x 12’-14’ deep; 1 Andritz 8-3 rotary screen thickener; 1 Andritz model 2412 screw press, 29-30 bdt/d capacity

Sludge Disposal: hog fuel

Aerators: 1, 24-hour 5-day aeration basin, design flow 20,000,000 USgal/d; 2 Simcar #9 fixed surface aerators, 100 hp each, 11 Aqua-Later floating surface aerators, 60 hp each; 1 aeration lagoon, common with Prince George mill, 245,000,000 Usgal. capacity, 1080 subsurface helical aerators, air supplied by three 600 kW. Roots air blowers.

Process Control

Distributed Control Systems: Foxboro I/Aentire mill

Mailing Address: PO Box 9000 Stn A Address: 5353 Northwood Pulp Mill Rd Prince George BC V2L 4W2

Tel: 250 962-3600, Fax: 250 962-3602 Website: www.canforpulp.com

personnel

Corp Controller: R Remesch

Mgr-Gen Mtce: Mike Kelly

Engrg Mgr: Olaf Starck

Mgr-Fibreline: Jason Korolek

Steam/Recov Mgr: D Law

Mfg Mgr: Lance Anderson

Process Eng: Jim Menard

Energy Leader: Mike Todd

Total Employees: 517

ISO Quality Registration: 9001-2008; 140012004

Transportation: B.C.R., C.N.R., highways 97 and 16

Sales Office: Canfor Pulp Limited Partnership, 230 - 1700 West 75th Avenue, Vancouver, BC

Production Capacity

Pulp: NBSK market pulp, 590,000 mt/y

Wood Source: Sawmill residual chips

Equipment

Wood Handling Equipment

Chip Storage Capacity: 180,000 bdt

Chip Consumption: 3 300 bdt/d

Chip Unloaders: 2 + 2, truck & railcar

Chip Handling: Belt conveyors

Sawdust Handling: Belt conveyors

Chip Conditioners: 2 100 t/d

Chip Screens: 4 sets Acrowood, 1,000 t/d each

Pulping Equipment

Digesters: 2 Kamyr continuous, 1,650 t/d total

Knotters: 4 + 1 Hi-Q -Noss, 2,000 t/d

Primary Screens: 4 + 4 Centri Sorter, 1,700 t/d

Secondary Screens: 2 + 1 Centri Sorter, 1,000 t/d

Thickeners: 3 Ingersoll-Rand, 1,800 t/d

Centricleaners: 1 + 1 Celleco-Noss, 2,000 t/d

Press: 1 + 1 Sunds, 2,000 t/d

Pulp Dryers: 2 Flakt, 1,800 t/d

Evaporators: 1 + 1 Horton - Rosenblad

Slakers: 3 Dorr-Oliver

Lime Kilns: 1 + 1 Traylor - Allis Chalmer

Clarifiers: 7 Dorr-OLiver

Mud Washers: 3 Dorr-Oliver

Main Process Control System: DCS Fisher/ Provox

Bleach Plant

Bleaching Stages: 5 + 5, 1,800 t/d

Bleaching Sequence: ODEopDEpD + DEopDEpD

Washers: 5 + 5 I-R, 1,800 t/d, Noss Radiclone

AM80

Towers: 5 + 5, 1 U/D, all others upflow

Mixers: 1 + 6 + 6 Static - Hi-Shear - PEG

Chlorine Dioxide Plant: 1 + 1 R-8 - Solvay, 60 t/d

Main Process Control System: DCS Fisher Provox

Pulp Finishing Plant

Pulp Machines: 2, Beloit (1996), Black Clawson (1982)

Cutter Layboy: 2 Lamb-Grays Harbor, 171 pulp web width

Thune Press: 1 capacity 110 t/d, 35% moisture, Thune

Baling Press: 1 Cranston; 1 Lamb, 1,000 t.

Wire Tying Machines: 46 Cranston

Scalers: 2 Robert Morse bed, Fairbanks electronic head

Wire Tying Machines: 4 + 2 Gerrard Ovalstrapping

Steam Plant

Boilers: 1 Foster Wheeler, using Natural gas, oil with capacity of 350,000 lb/h, 1 Foster Wheeler using hog primarily capacity of 450,000 lb/h

Effluent Treatment

Primary Clarifier: Secondary effluent treatment, UNOX activated sludge oxygen enriched; secondary clarifiers; primarily capacity of 450,000 lb/h

Source of Power

Authority: BC Hydro & Power Authority

Recovery Plant

Recausticizers: 2 x 3 + 2 x 4, Dorr-Oliver, Ahlstrom

White Liquor Pressure Filter: 2 Ahlstrom

Lime Mud Washers: 3 Dorr-Oliver

Lime Kilns: 1 + 1 Traylor - Allis Chalmers

Evaporator: 1 + 1 Horton - Rosenblad

Recovery Boilers: 2 CE

Oxidation Unit: 1 Chemetics

Precipitators: 1 + 1 Joy - Research Cottrell Kiln: 1 Flakt

Gas Scrubbers: 1 + 2 Waterloo - Seallite

Strippers: 1 Lundberg

Dissolving Tank Stack: 1 + 1 DuconMunters

Dregs Precoat Filter: 1 Ahlstrom

Main Process Control System: DCS Fisher/ Provox

Power Plant

Source of Power: 85% self-generated, 20% from B.C. Hydro

Power Boilers: 1 + 1 CE - Foster Wheeler

Steam Generated: Total, 600,000 lb/hr

Water Consumption: 150,000 m3/d

Water Source: Fraser River

Main Process Control System: DCS Fisher/ Provox

Cogeneration System: 2 Stal Laval, 28 MW

Effluent/Pollution Control

Effluent Clarifiers: 1 primary

Settling Pond: 1 secondary

Sludge Disposal: Landfill Aerators: 20

priNCe GeorGe pulp & pAper Mill

Mill

Mailing Address: PO Box 6000 Terminal

Address: 2533 Pulp Mill Rd Prince George

BC V2N 2K3

Tel: 250 563-0161, Fax: 250 561-3627

Website: www.canforpulp.com

personnel

Corp Controller: R Remesch

Prod Mgr-PG/Intercon Mills: C Walls

Mtce Mgr-PG/Intercon Mills: S Sidsworth

Gen Mgr: Martin Pudlas

Energy Leader: Mike Todd

ISO Quality Registration: 9001; 14000

Parent company: Canfor Pulp Limited

Partnership

Pulp: Canfor Pulp Limited Partnership, 230 -1700 West 75th Avenue, Vancouver, BC

Sales Agents

Wood Source: Sawmill residual chips

Paper Sales Agents: Premium 1 Paper, Kelowna, BC

Transportation: C.N.R. via Landtrans, B.C. Railway, Highway

Production Capacity

Pulp: 155,000 mt/y semi-bleached and unbleached softwood kraft pulp

Paper: 140,000 mt/y bleached and unbleached softwood kraft paper

Equipment

Wood Plant

Chip Unloading: Hydraulic rail and truck dumper

Chip Handling: Belts and fingers

Chip Storage: outdoor piles

Chip Screens: 1 Rader primary V-screen; 1 Radar bar screen; 4 model 7 Dillon rotaries; 2 Liwell; 2 Radar slicers; 1 air density separator

Kraft Pulping Plant

Digesters: 1 440 adt/d Kamyr continuous Knotters: 2 Noss Raditrim secondaries, 2

Ingersoll-Rand (pressure) primaries

Washers: 4 (2 lines) Kamyr 3.5m x 4.9m

Primary Screens: 1 1,400 adt/d Metso D15

Secondary Screen: 1 500 adt/d Hooper PSV 2,600

Tertiary Screens: 1 200 adt/d I/R Model 110

Quaternary Screen: 1 50 adt/d Cowan KX

300

Deckers: 1 Sherbrooke 2.7 m x 4.9 m, 1

Canron 3.5 x 4.9 m. vacuum decker

Process Computer: Foxboro (DCS) I/A series

Recovery Plant

Recausticizing: Dorr-Oliver-Long, #15 slaker, 4 causticizers

White Liquor Clarifier: Dorr-Oliver-Long, 4

tray 13.4 m x 8.5 m

Lime Mud Washer: 1 Dorr-Oliver-Long 4

tray, 12.2m x 7.3m

Lime Kiln: 1 F.L. Smidth 3.0 x 83.8 m

Evaporators: Swenson 6-effect, Ecodyne 3-effect, 1-2 effect forced circulation, 22-effect HPD concentrators

Recovery Unit: 1 1550 t solids/d B&W low odour.

Precipitator: 1 PPC, 1 HRC

Spare Clarifier: 1 Dorr-Oliver 4 tray, 13.4m x 8.5m

Bleach Plant

Process Stages: 3 & 2 DEopD & WW

Washers: 5 Kamyr 3.5 m x 4.9 m

Towers: 2 upflow CIO2; 1 downflow caustic, 1 upflow oxidative extraction; 2 wash stages (unbleached) , 2 high density storages

Mixers: 1 Komax inline mixers; 4 Kamyr double-shaft steam mixers, 1 Sunds Eo mixer; 2 Ahlstrom AM25-20 CIO2 mixer

Stock Preparation Plant

Refiners: 4 Sprout-Waldron 1.1 m double disc, 1 Sunds 60” HCR

Broke Pulper: 1 No. 4 Pulpmaster

Saveall: 1 2.4 m x 4.9 m Sherbrooke

Cleaners: Noss Radiclones

Screens: C.I.R. Centriscreens, Jonsson rejects screen

Production & Finishing Plant

Pulp Machine Slusher: 2 Impco, 1 - 2.4 m x 4.9 m; 1 - 2.4 m x 6.7 m

Fourdriniers: 1 Beloit Walmsley with Mitsubishi concept IV headbox 6.4 m, 750 m/ min. (paper); 1 Dominion 4.4 m (pulp)

Paper Dryers: 59 dryer cans, 8 felt sections

Pulp Dryer: SF Flakt Type L, 19 decks

Cutter Layboy: Lamb-Grays Harbor

Winder: Dominion

Baling Press: Dominion 907-tonne

Wire Tying Machines: Ovalstrapping

Steam Plant

Boilers: 1 Foster Wheeler hog fuel and gas. 150,000 kg/h of steam @ 4,100 kPa; 1 Babcock & Wilcox recovery, 210,000 kg/h of steam @ 4,100 kPa, 1 Babcock & Wilcox hog fuel 125,000 kg/h

Source of Power: Self-generated and steam turbines on major drives

Power Plant

Type of Fuel Used: Bark (275,000 odt); Gas (250, 000 GJ); Oil (1,000 m3)

Source of Power: Self-generated and BC

Hydro

Cogeneration System: Mitsubishi condensing, extracting turbine and generator at 60MW

Effluent/Pollution Control

Clarifier: 1 primary clarifier, 180 ’ diameter x 10’-20’ deep

Dregs Filter: 1 Dorr-Oliver dregs pre-coat filter 6’ dia.meter x 6’ long

Sludge Treatment: Common with Intercontinental mill

Sludge Disposal: See Intercontinental mill

Aerators: 1 24-hour aeration basin, design flow 14,000,000 USgal/d; 5 stationary Simcar #8 aerators, 50 hp each; 9 Ashbrooke-I floating surface mechanical aerators, 60 hp each; 1 aeration lagoon, common with Intercontinental mill

Process Control

Control Systems: Foxboro I/A - Kraft mill, bleach plant, paper machine, steam & recovery

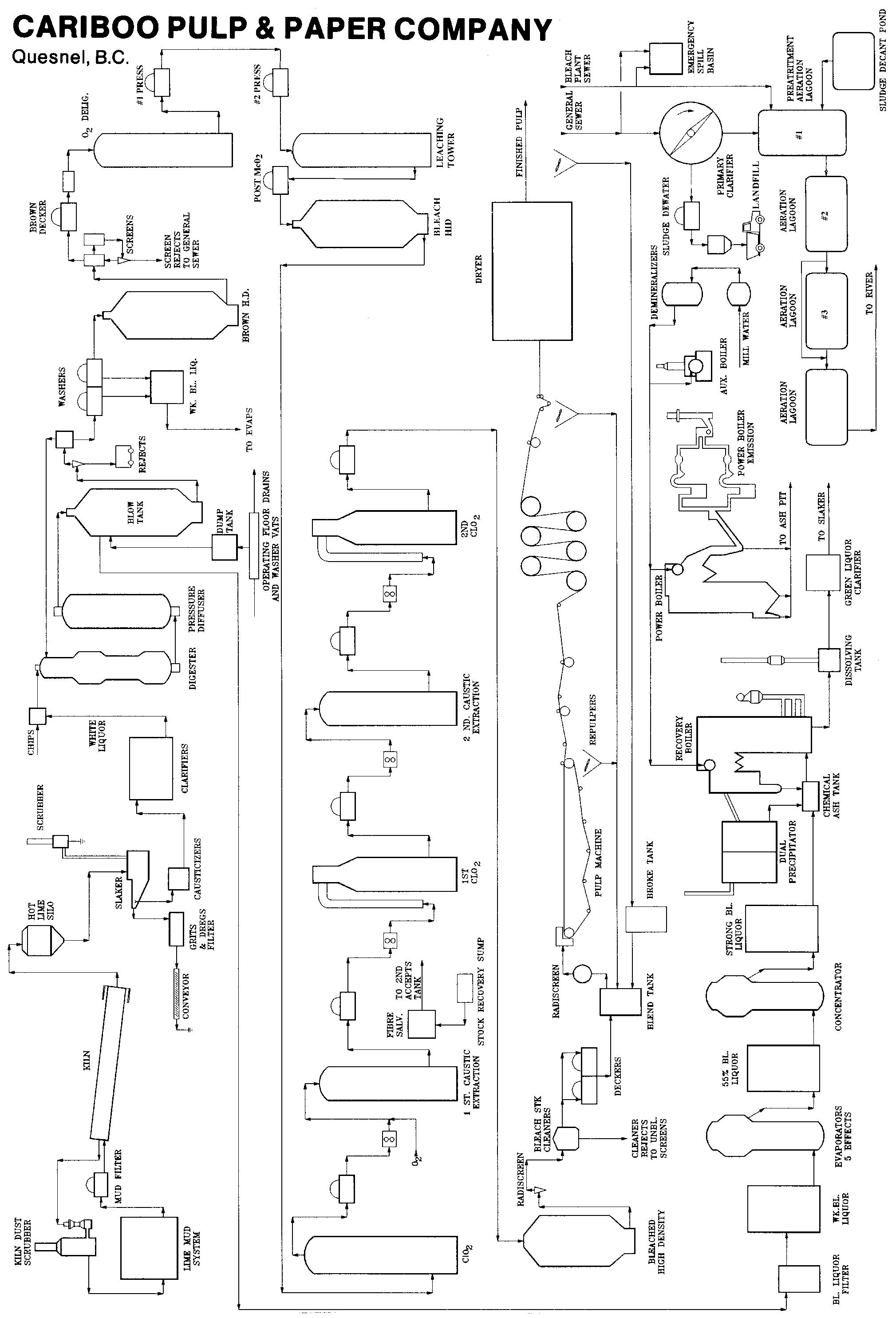

CAriBoo pulp & pAper CoMpANy

Head office

Address: 50 North Star Rd Quesnel BC V2J 3J6

Tel: 250 992-0200

History:

A 50-50 partnership was formed in December 1969 between Weldwood of Canada Limited and Daishowa-Marubeni International Ltd. to build and operate a 934 t/d bleached kraft pulp mill at Quesnel, BC. Weldwood was purchased by West Fraser Mills Ltd. at the end of 2004. www.westfraser.com; www.dmi.ca

personnel

Controller/Fibre Supply Mgr: Mike Pagurut

Prod/Tech Mgr: S Bird

Hum Res Mgr: B Norman

Mtce/Engrg Mgr: D Needham

Mill Mgr: B Eby

Pres: P Rippon

VP: Y Suzuki

Parent Companies: West Fraser Mills Ltd. and Daishowa-Marubeni International Ltd Sales Office: Vancouver, B.C

Mill

Mailing Address: PO Box 7500

Address: 600 North Star Rd Quesnel BC V2J 3J6

Tel: 250 992-0200, Fax: 250 992-2164

personnel

Prod Mgr: Tony Christy

P&R Mgr: D McRae

Mill Mgr: Bruce Eby

Mtce/Reliability Mgr: D Needham

Purch Agt: Norma Morrison

Pulp Mill Supt: John Ayles

Controller/Fibre Supply Mgr: Charlie Ragsdale

ISO Quality Registration: 9001-1993; 14001

Transportation: CN Rail

Products: Bleached kraft pulp

Production Capacity: 340 000 t/y

Equipment

Digester

Kamyr continuous 5.8 x 51.8 m, 1,100 adt/d

Washing

3 Kamyr 4.0 m x 9.1 m, 1 Kamyr pressure diffuser

Screening

5 primary, 2 secondary, 1 tertiary CIR centrisorters; 1 Kamyr decker 4.0 m x 9.1 m

Bleaching

6-stages O-Dc-E/O-D-E-D; 1 Sunds medium consistency O2 delignification system with 2 presses; Kamyr washers; multifibre process chemical plant 2 14 t/d CIO2/ generator (Modified Mathieson)

Stock Preparation

1 Noss Radiscreen, 3 AL80-600 primary radiclones; 2 P100-300 secondary radiclones; 1 P100-300 tertiary radiclone; 1 AM80-75 qua-

ternary radiclone; 1 AM80A-20 quintenary radiclone; 1 RD-2000 Radrideck; 2 Kamyr deckers 2.9 m x 9.1 m

Drying & Finishing

1 Beloit 6 m fourdrinier and press section; Black Clawson double felted 1st and 3rd presses; 1 Ross pulp dryer; 1 Lamb-Grays Harbor overlapping cutter layboy and finishing line; 2 Dominion 907 t bale presses

Recovery

1 Eimco process recausticizing system; 1 cooler equipped Smidth kiln 3.5 m x 91.4 m; 1 Unitech 5 effect evaporator system with concentrator; 1 B & W (Gotaverken Retrofit) recovery furnace; 1 950,000 kg black liquor solids/d

Source of Power

1 Foster Wheeler hog burning power boiler with 218, 000 kg/h steam; 1 Toshiba 101,000 MJ turbo generator; 1 Zurn 114,000 kg/h package boiler; B.C. Hydro 101,000 MJ tie line.

Head office

Mailing Address: PO Box 30

Address: 404 boul Marie-Victorin Kingsey Falls QC J0A 1B0

Tel: 819 363-5100, Fax: 819 363-5155

Website: www.cascades.com

History

Founded in 1964, Cacades produces, converts and markets packaging and tissue products composed mainly of recycled fibres. Cascades employs more than 11,000 men and women in more than 100 modern, versatile operating units in North America and Europe. Cascades’ management philosophy, its more than 45 years of experience in recycling, and its continued efforts in research and development are strengths which enable the company to create new products for its customers. The Cascades shares trade on the Toronto Stock Exchange under the ticker symbol CAS

personnel

VP-Legal Affairs/Corp Sec: Robert F Hall

Pres/CEO-Tissue Grp: Suzanne Blanchet

Pres/CEO-Norampac: Marc-André Dépin

VP-IT: Dominic Doré

VP/CFO: Allan Hogg

VP-Hum Res: Maryse Fernet

VP-Environment: Léon Marineau

Pres/COO-Spec Products Grp: Luc Langevin

VP-Corp Serv: Pascal Aguettaz

Pres/CEO: Mario Plourde

VP-Commun/Public Affairs: Hugo D’Amours

ISO Quality Registration: 9002; 9001; 14001

Sales Office: 772 Sherbrooke St. W, Montréal, QC, H3A 1G1. Tel.: 514-282-2600, Fax: 514-282-2624.

Subsidiaries:

Cascades Canada ULC

Cascades Europe S. A. S.

Cascades S. A. S.

Cascades Holding US Inc.

Cascades USA Inc.

Cascades Recovery Inc.

CAsCAdes eAst ANGus iNC.

Mill

Address: 248 Warner St East Angus QC J0B

1R0

Tel: 819 832-2451, Fax: 819 832-3406

Website: www.cascades.com

Status: Pulp Mill Closed.

personnel

Engrg Supt: S Tremblay

Mtce Mgr: Roch Tessier

Purch Supvr: Richard Ravary

Elec Supvr: Marc Bernier

Asst Paper Machine Supt: Yvon Gagnon

Supvr Steam Plant: Patrice Turcotte

Prod Mgr: Michel Poulin

Controller: Steve Breault

Mill Mgr: Paul Deraiche

Mtce Supvr: Richard Thibodeau

Env Mgr: Richard Lessard

Dir-Hum Res: Alain Daigle

Qual Cont Supvr: Sylvain De Blois

Products: Unbleached softwood, unbleached butcher’s kraft, wrapping, extensible, grocery bag and sack, envelope, gumming, waxing, recycled paper, asphalt laminating and waterproofing and other unbleached converting paper, 275 t/d.

Production Capacity

Paper: 95,000 t/y

OCC: 50,000 t/y

Equipment

Woodhandling & Preparation

Purchased: bark - 2500 t; daily use 150 t/d

purchased

Truck Dumper: 1

Payloaders: 2 Caterpillar

Bark Handling: 1 live bottom bin; 2 belt conveyors; 1 Williams disc screen; 2 Williams hammermills; 1 live bottom bin and 1 chain conveyor (spares)

Paper Mill

Pulpers: 2 Hydrapulpers, 3 Batch

Disc Refiners: 4 Sprout-Waldron, 2 Black Clawson

Centricleaners: Bauer 600 series

Thickeners: 1 Dorr Oliver-Long, 4’ dia.; CIR 1, 6 1/2’ dia.

Pressure Screens: 1 Bird 24, 1 Bird 18, 1 Bird 400, 1 Lamort CH3

Paper Machines: Machine No3: D-E 160” width 150” trim 1,700 ft/min incl. MecFab fourdrinier; Black Clawson presses, 46 - 48” dryers; 1 calender stack.

Machine No 4: Millspaugh 134” width 120” trim 2,400 ft/min incl. GL&V fourdrinier; Beloit Tri-Nip press 46 - 60” dryers, 1 size press, 1 extensible paper unit, 1 calender

Winders: 1 Langston on 160”, 1 Beloit M-24 on 134”

Computer: 1 Measurex 2002 Gemini System on 160” and 1 Valmet Paper IQ-L System c/w Jetmatic actuators on 134”

Rewinders: 1 - 72” CamerON, Wrapping machine: 1 Cyvector, 60 rolls/h

Power Plant/Water & Waste Data

Boilers: Hog fuel-fired: 1 Volcano (3 Welland cells) 60,000 lb/h;1 Babcock & Wilcox dutch oven 45,000 lb/h; Natural gas/ oil fired: 3, 1 Babcock & Wilcox 100,000 lb/h; 1 Babcock & Wilcox 80,000 lb/h (on standby)

Electricity: 297,500 kWh/d, 100% purchased Water: 6.6 million gal/d

Source: River

Air Pollution Systems: Pulp mill: 2 Environair wet scrubbers; 1 Biothermica incinerator (for TRS); 1 Research-Cottrell electrostatic precipitator.

Power Plant: 3 Multi-cyclone dust collectors; 1 Bahco; 1 Joy; 1 AAF (Barron)

Primary Effluent System: Vargo filters on paper machines. Sludge collector at the paper mill

Secondary Effluent System: Joint treatment with municipality, aerated lagoons

OCC Plant (capacity: 240 t/d); 1 screening system (Berd,Vorth); 1 turn wire press (HDS); 1 dispersing unit (Cellwood); 2 screw presses, 1 pre-Reater, 1 disperser

CAsCAdes fjordCell iNC.

Head office

Mailing Address: CP 1970 succ Bureau-Chef Jonquière QC G7S 4R5

Address: 4010 ch St-André Jonquière QC G7S 4X3

Tel: 418 546-4600, Fax: 416 542-5846

History:

The mill was first built in 1962, then shut down in November 1991. Cascades Inc., through its subsidiary Industries Paperboard International, started it up again in 1997 under the name FjordCell Inc.

personnel

Tech Cons: Stéphane Cloutier Plant Mgr: Mario Nepton

Transportation: Highway Production: 82 000 t/y NBSK pulp

Equipment

Pulping

Digester: Kamyr continuous, 1962, 10, 000 ft3

Washer: 3 Sherbrooke drum brown stock, 1962, 8’ x 16’

Decker: 1 Sherbrooke drum brown stock, 1962, 8’ x 12’

Bleach Plant

Bleaching Sequence: D-Eop-D-P Pumps: 4 MC, 2 Impco (1962 & 1977), 2 Ahlstrom (1988 & 1998)

ClO 2 Generator: 1 Sterling Pulp Chemical R8, 1999, 12 t/d

ClO 2 Mixers: 3, 1 Riverside Steel (1962), 1 Kamyr (1984), 1 GL&V-Dorr-Oliver (1998)

Bleaching Towers: 6 3 Riverside Steel (downflow), 1 Riverside Steel (upflow), 1 Riverside Steel (upflow/downflow), 1 AC Plastiques (upflow)

Drum Filters/Washers: 3 1 Impco, 2 GL&VDorr-Oliver

Pulp Finishing Plant

Baling Press: 1 Kamyr, 200 t/d

Recovery Line

Recausticizers: 3

Lime Mud Washer: 1

Lime Kiln: 1 Allis-Chalmer, 105 t/d

Slaker: 1

Boiler: 1 Babcock & Wilcox Low odour, 1998

rebuilt

Type of Fuel Used: 10% natural gas, 90%

black liquor

Precipitator: 1

Kiln: 1

DCS: Valmet 1999 (also in bleaching plant)

pApier kiNGsey fAlls iNC.

Mill

Mailing Address: PO Box 150

Address: 408 boul Marie-Victorin Kingsey

Falls QC J0A 1B0

Tel: 819 363-5200, Fax: 819 363-5255

Website: www.cascades.com

personnel

Gen Mgr: L Langevin

Sls Mgr: Simon Provencher

Mgr-Qual: Mario Lemieux

Pres/COO: Mario Plourde

Hum Res Mgr: Isabelle Gauvreau

Mtce Mgr: Gaetan Verville

Paper Mill Supt: Alexandre Caron

Tech Supt: Pierre Trahen

Plant Mgr: Sylvain Houle

Controller: Mario Gélinas

Total Employees: 68

ISO Quality Registration: 9001-2008

Raw Material: Waste paper

Production Capacity

Paper: 325 t/d core stock and chipboard, up to 355 t/d recycled pulp

Equipment

Board Mill Data

Pulpers: 1 - 16’ dia. 225 t/d; 1 - 12’ dia. 130 t/d

Refiners: 3 Sprout-Waldron T.F, 2x34”, 1x20”

Cylinder Machine: 6 - 144” width Beloit, 3 Bristol

Cleaning Equipment: HDC, Uniflow, 2 -

Fiberizer Escher-Wyss

Screens: 3 Beloit “S”, 32 J24818; 1 cyclo screen, 2 Bied, 800 and 200

Profilers: 1 Aquatrol

Formers: 3 - Bristol

Production & Finishing Plant

Paper machine: 1, 90,000 t/y

Felt machines: 7 felts, new cantilever press section

Dryers: 110 - 35 and 160 psi

Calenders: 4-roll swimming rolls stack

Winder: 1, Cameron

Main process system controls: Honeywell DCS, TDC-3000, Davinci Experion

Source of Power

Co-generation Plant: 32 MW

Steam: Turbine gas emulsion

CAsCAdes BoxBoArd Group iNC.

eAst ANGus Mill

Mill

Mailing Address: PO Box 2001

Address: 2 rue Angus N East Angus QC J0B 1R0

Tel: 819 832-5300, Fax: 819 832-4756

Website: www.cascades.com

Status: Indefinitely closed

personnel

Dir-Commun: Christine Beaulieu

Mill Mgr: Vincent Goulet

ISO Quality Registration: 9002

Sales offices: Cascades Paperboard Int., 772 Sherbrooke West, Suite 300, Montreal, QC, H3A 1G1. Tel. 514-284-9800, Fax: 514-2891773.

Transportation: Highway, river, port connections

Products: Coated folding boxboard, 160 t/d

Board: Boxboard 190 mt/day, or 69,000 mt/ yr

Equipment

Recycling Plant

Pulpers: 1 Helicopulper

Detrasher: 1 Scavenger

Cleaners (coarse): 4 Black Clawson

Screens (coarse): Bird, Beloit, BC

Deinking: Flotation, 2 Fiberprep

Rotary Cleaners: 1 Gyroclean

Forward Cleaners: 1 Bauer, 1 Beloit

Main Process Control System: 1 Moore

Board Mill

Pulpers: 2 Hydrapulpers, 1 Solvo

Disc Refiners: 6 Sprout-Waldron

Formers: 7

Centricleaners: Bauer 606 series

Consistency Regulators: DeZurik and EurControl

Cylinder Machine: 1 - 110” width 100” trim

500 ft/min incl. 58, 48” and 30, 42” dryers

Dryers: 89

Calender Stacks: 3

On-machine Coater: 2

Winder: 1

Computer: 1 Measurex 2002 system

Power Plant

Power Boilers: 5 Volcano 4 BNW, 325,000 lb/h rated

Type of Fuel Used: bark (75,000 t/y), oil (1.2M gal/y)

Water Consumption: 150 M gal/y

Water Source: river

Main Process Control System: Moore

Effluent/Pollution Control

Clarifier: 1 Graver

Screen: 1 Beloit

Sludge Disposal: 1 Dorr-Oliver & twin-wire press

Mill

Mailing Address: CP 1980 succ PDF Jonquière

Address: 4010 ch St-André Jonquière QC

G7S 5K5

Tel: 418 542-9544, Fax: 418 542-5846

ISO Quality Registration: 9002

Transportation: C.N.R. Jonquière; Port Alfred by water

Production Capacity

Board: 375 t/d paperboard specialties

Output for Sale: 375 t/d paperboard specialties

Wood Source: 130 t/d chips; 250 t/d bark residues from local sawmills

Equipment

TMP

Refiners: 1st stage; 6,705 kW. Defibrator; 2nd stage, 6,705 kW Defibrator Rejects, (2) Sprout Waldron 36/1B

Screens: 2 Bird 110 secondary, 1 Bird 110 primary

Shavings: Washer

Cleaners: 1 stage Celleco 350, 4 stage Bawer 606H

Drainer: Thune Press rejects

Deckers: 1 Sherbrooke 2,44 X 2,44 m, 1

Sherbrooke 2,44 X 3,66 m

Stock Storage: 130 tons

Stock Preparation Plant

Sequencer: Bailey Controls

Pulpers: 1 2,000 ft3 Escher Weiss, 1 - 800 ft3 Emerson, with 50’ dia. vokes rotor, 1 - 446 ft3/pulper with 50” dia. vokes rotor, 1 - 750 ft3 Black Clawson with 56’ dia. vokes rotor

Refiners: 1 Beloit Jones MOD. 3220DD, 5 Sprout-Bauer model R26EM, 2 deflaker Escher Wyss E2K

Proportioners: 16 magnetic flowmeters

Consistency Regulators: 8 E.U.R

Screens: 1 primary Beloit S-32, 1 secondary Beloit S-24, 1 tertiary Lamort CH-5, 1 vibratory Johnson screen 1,22 X 1,83 m

Cleaners: 1 high density Lascorator, 4 stages Bauer 606II with 1 Beloit disk filter. 9 screw presses on brake.

Starch Cooker: 1 Canada Starch, 9 t/d and 1 Stas cooker

Fiber Recovery & Pollution: 1 Poseidon flotator, 4 - DSM Bauer screen, 1 Andritz 1.6 m Mudpress, 1 - Albany gravity filter AES series 4000, 1 - secondary treatment; biological reactor & GL&V clarifier 26.5 m

Production Plant

Machine Control System: Measurex 2000 computer; Bailey Controls Machines: 3 fourdriniers Valmet 155” wide with 1 C Former by GL&V Net Trim 135” Screens: 3 Bird 14LB

Cleaners: Celleco 350, 3-stages on top and bottom plus 2 - RCC Celleco stock savers

Dryers: 82 121.92 cm

Calenders: 1 Mat-on-line Kuster, 1 gloss calender Kuster

Winder: 1 GL&V

Pulpers: 4 broke side pulpers

On-machine Coater: 1 Jagenberg (rod), 2 Jagenberg combi-blade (rod)

Presses: 1 Beloit K. Press, 1 GL&V 2nd press with Kuster roll, 1 GL&V 3rd press with Kuster roll

Paper Finishing Plant

Rewinder: 1 Cameron 152.4 cm

Trimmer: Seybold

Wrapping Line: Signode strapping machine, stretch film roll machine

Steam Plant

Boilers: 1 Volcano refuse bark boiler 120,000 lb/h, 1 package boiler Nebraska 110,000

Source of Power Electricity: 161 KV

toroNto Mill

Mill

Address: 495 Commissioners St Toronto ON M4M 1A5

Status: Indefinitely closed in 2008.

History:

The mill was purchased by Cascades Inc. in 1992.

personnel

Dir-Commun: Christine Beaulieu

ISO Quality Registration: 9002-1996

CAsCAdes fiNe pApers

Head office

Address: 2 rue Rolland Saint-Jérôme QC J7Z 5S1

Tel: 450 569-3951, Fax: 450 569-3933

Website: www.cascades.com

History:

Rolland Inc., whose corporate roots go back to 1882, is one of the most important contributors in the manufacturing and distribution of fine papers in Canada. Member of the Cascades family since 1992, the Fine Papers Group is now a leader in the recycled paper and security markets.

personnel

Chairman: Alain Lemaire

Dir: Bernard Lemaire

Dir: Laurent Lemaire

Pres/CEO: Mario Plourde

Dir-Admn: Mario Ste-Marie

VP-Ops: Daniel Parrot

Gen Sls Mgr: François Belisle

Mktg Coord: Erika Gilbert

Total Employees: 420

ISO Quality Registration: 9002

Parent Company: Cascades Inc.

Mills: Saint Jérôme, QC; Breakeyville, QC

Converting Operations: Cascades Fine Papers Group Inc., Converting Center, 980 Boul. de l’Industrie, Saint Jérôme, QC J7Z 5V9.

R & D Headquarters: Kingsey Falls, QC

Sales Offices: 2 Rolland Avenue, Saint Jérôme, QC J7Z 5S1; 525 Abilene Drive, Mississauga, ON L5T 2H7

Engineering Headquarters: Rolland Division - Saint Jérôme , QC

Products: High-quality uncoated fine papers and security papers from cotton, chemical and recycled pulp grades for commercial printing, business papers, envelopes and spe-

cialty papers

Operating Subsidiaries: Cascades Fine Papers Group Inc.- Rolland Division, Cascades Fine Papers Group - Breakey Fibres Division

Production Capacity

Fine papers: 155,000 st/y (Rolland Div.); 58,000 st/y (Breakey Fibres Div.)

BreAkey fiBres diVisioN

Mill

Address: 739 rue St. Augustin Ste-Hélène-dBreak QC G0S 1E2

Tel: 418 832-6115, Fax: 418 832-5598

Website: www.cascades.com

History:

D’Ésencrage Cascades Inc. was formed in 1984. In June 1984 the company purchased an idle pulp mill from John Breakey Inc. From June 1984 to October 1985 a new warehouse was built and equipment was installed to convert waste newspaper and magazines into de-inked market pulp. In March 1988 additional equipment was installed and completed in July 1988 to produce a wood-free market pulp. Cascades Fine Papers Group Inc., Fibres Breakey Division is the name of the mill since March 2002.

personnel

Mill Mgr: Richard Laramée

Controller: Pascale Painchaud

Waste Procurement: R Roy

Prod Mgr: Pascale Vachon

Tech Supvr: Geniviève Coté

Electronics Techn: Richard Croteau

Total Employees: 50

ISO Quality Registration: 9002-1996; 90012000

Parent Company: Cascades Inc.

Sales agents: Etcan International Inc., 772 Sherbrooke W. Room 200, Montreal, QC H3A 1G1.

Products: Pulp for printing & writing grades Process: chlorine free certified Transportation: Highway

Production Capacity

Deinked recycled kraft pulp: 150 adt/d

Equipment

Recycling Plant

Pulper: 1 Beloit-HC, 4,000 kg

Detrasher: 1 Beloit-Belpurge, 6,000 kg

Rotating Screen: Finck

Fine Screen: 2 Beloit primary fine screens, 1 secondary screen, 1 tertiary screen

Deinking: Flotation 1: 2 Verticel, 250 t/d; Flotation 2: 7 Beloit/Black Clawson, 150 t/d; 200

Primary Cleaners: Beloit Posiflow, Bauer

Secondary Cleaners: Beloit Posiflow

Tertiary Cleaners: Posiflow

Deckers: 4 Hymac, 200 t/d

Fine Screens: 1 Voith, 250 t/d

Dispergers: 1 Frota-pulper, 250 t/d

Consistency Regulators: 2, Kajaani

Cylinder Machine: 136” Kamyr wet machine with 2 presses

Cutter Layboy: Schibbe cutter

Clarifiers: 2 Poseidon, 400 and 800 m3/hr

Clarifiers: 1 Poseidon, 400 m3/h

Screw Presses: 2 Hymac, 1 Poseidon

Main Process Control System: 1 ValmetDamatic XD

Bleach Plant

Bleaching Stages: 2 own, 200 t/d

Power Plant

Power Boiler: 1 Cleaver Brooks, 10,000 lb/h

Water Consumption: 200,000 gal/d

Water Source: River

Effluent Control

Clarifier: 1 Poseidon, 100 m3/h

Bioreactor: 1

Sludge Presses: 2, 40 t/d

Aerators: 3 Aero-2 & 3 Framco TA

Energy Source: Electricity, Hydro Quebec

CAsCAdes Groupe pApiers fiNs - diVisioN rolANd

Mill

Address: 455 rue Rolland Saint-Jérôme QC J7Z 5S2

Tel: 450 569-3900, Fax: 450 569-3988

Website: www.cascades.com

personnel

Mill Dir: P Guay

Purch: Alain DeLisle

Div Controller: Guy Beaudin

Prod Mgr: Daniel Jossart

Prod Planning: Serge Desjardins

Dir Controller: Paul Dubé

Chemist: Michel Hamel

Chief Eng: M Labonté

Tech Dir: Philippe-Serge Tremblay

Ops Supvr: Gilles Morin

Supvr Machinerie: Éric Bérubé

Environ Supvr: Pascal Meunier

Total Employees: 320

Products: 100 different products including printing, business and converting papers. More specifically, the product line consists of recycled papers, security papers used for lottery tickets, bond certificates and bank notes, sulphite and cotton content bonds, writing, text and cover papers, reprographic papers, business and computer form bonds, envelope, greeting cards and specialty papers

Wood Source: All pulp purchased

Production Capacity

Fine papers: 150,000 st/y

Equipment

Pulpers: 10 - 2 Hydrapulper, 1 Jones Hi-Lo, 1 Solvo, 1 Liebeck, 1 IMPCO Multipeller, 4

Voith-Morden

Refiners: 6 Jones DD, 4 Claflin, 1 Jones

Standard

Screens: 3 Black Clawson, 1 Hymac-Hunter Paper Machines: 3 fourdriniers - 190” width, 172” trim, 2240 ft/min; 160” width, 142” trim, 1450 ft/min; 106” width, 90” trim 800 ft/min

Dryers Drums: 155

Size Presses: 3

Calenders: 3

Winders: 3

Rewinder: 1 Jagenberg, 102”

Stock Preparation Plant

Broke Pulpers: 1 272 MTODPD Black Clawson 7.0.

Steam & Power

Power Boilers: 4

Fuel: 2 Natural gas/oil, 2 biogaz/natural gaz

Steam Produced: 275,000 lb/h capacity, average 2,670,000 lbs steam/day consumption

Electricity Purchased: 330,000 kWh/d

Water

Daily Usage: 1.5 million gal/d

Source: North River

CAsCAdes forMA-pAk - diV. of CAsCAdes CANAdA iNC.

Mill

Address: 406 boul Marie-Victorin Kingsey Falls QC J0A 1B0

Tel: 819 363-5060, Fax: 819 363-5066

Website: www.cascades.com

History:

Forma-Pak was the second mill in operation for Cascades Inc. The mill celebrated its 35th anniversary in July 2006.

personnel

Pres/CEO-Spec Products: M Plourde

Controller: Chantale Beauchemin

Plant Mgr: Christian Tisiuck

Dir-Ops: Roger Dionne

Total Employees: 30

Parent Company: Cascades Inc.

Mill Location: Kingsey Falls, QC

Research & Development HQ: Cascades

Research & Development, Kingsey Falls, QC

Sales Office: Montreal, QC

Production: Moulded pulp products, 8750 t/y - 25 t/d recycled pulp produced

Equipment

Pulpers: 2

Machines: Filler Flat: 4

CAsCAdes tissue Group - diV. of CAsCAdes CANAdA ulC

Head office

Address: 77 boul Marie-Victorin Candiac QC

J5R 1C3

Tel: 450 444-6400, Fax: 450 444-6455

Website: www.cascades.com

personnel

COO: Jean Jobin

IT Corp Dir: Mario Sylvain

Pres/CEO: Suzanne Blanchet

Commun/Dev: Melanie St-Pierre

Dir-Cust Serv: Johanne Fournier

Dir-Sup Chain: Normand René

Dir-Corp Hum Res: Sylvain Pelletier

Exec VP-Cons Prods: Jean-David Tardif

VP-Mktg/Commun: Thierry Trudel

Exec VP Prods: Stéphane Rousseau

VP-Ops Efficiency: Guillaume Bouvier

Dir Legal Affairs: Catherine Papineau

Total Employees: 2200

Parent company: Cascades Canada ULC

Converting Operations: Laval, QC; Lachute, QC; Pittston, PA; Eau Claire, WI; Kingman, AZ; Candiac, QC; Kingsey Falls, QC; Toronto ON; Waterford, NY, Granby, QC

Mill Locations: Rockingham, NC; Mechanicville, NY; Lachute, QC; Pittston, PA; Eau Claire, WI; Memphis, TN; St. Helens, OR; Candiac, QC; Kingsey Falls, QC; Toronto,ON

R & D Headquarters: Kingsey Falls, QC

Engineering Headquarters: Kingsey Falls, QC

Production Capacity: 531,000 t/y

Mill

Address: 75 boul Marie-Victorin Candiac QC J5R 1C2

Tel: 450 444-6500, Fax: 450 444-0518

Website: www.cascades.com

History:

1963: beginning of operations. Cascades acquisition: 1995.

personnel

Paper Machine Supvr #1: Éric Bilodeau

Paper Machine Project: Benoit Truchon

Receptionist: Louise Beaulieu

Communications and sustainability: Melanie St-Pierre

Controller: Jean-Philippe Lepage

Mtce Mgr: Yannick Faureau

Mill Mgr: Benoît Rouillard

Stockeeper: André St-Laurent

Paper Machine #2 -Team 1/2: Serge Garant

Paper Machine #2-Team 3/4: Jonathan Bouchard

Converting Mgr: Paul-André Gagnon

Transportation/Storing Dept’s: Denis Gétin

Paper Machine Supvr #2: Jonathan Morissette

Total Employees: 180

Total Employees: 202

Transportation: C.N.R

Products: Bathroom tissue, all-purpose paper towels, napkins

Trademarks: Cascades, Décor; North River; New Horizon

Markets: Canada, United States

Industrial Sectors: Retail markets and away from home (AFH)

Environment: Primary treatment and secondary treatment with the city

Production Capacity

Paper: Tissue, 60,000 mt/y

Equipment

Pulpers: 1 Black Clawson & 2 Hymac

Hydrapulper

Paper Machine

Fourdrinier: 1 131” Pamac dry crepe machine, 3800 ft/min

Voith Crescent Former: 6,500 ft/min

Converting Equipment

Bathroom Tissue: 2 PCMC converting lines

Household Towel: 1 PCMC converting line

Source of Power

Electricity: 550 volts, 60 Hz, 3-phase, purchased from Hydro Québec

Mill

Address: 467 boul Marie-Victorin Kingsey Falls QC J0A 1B0

Tel: 819 363-5600, Fax: 819 363-5655

Website: www.cascades.com

personnel

Commun/Dev: Melanie St-Pierre

Controller: Alain Couvrelte

Prod Dir Conv: Yves Simoneau

Supvr: Jean-François Pion

Techn: Marc Fréchette

Dir-Mtce: Sylvain Gosselin

Mill Mgr: Sylvain Hall

Prod Dir PM: Benoit Lacoursière

ISO Quality Registration: 9001-2003; 140012003

Transportation: C.N.R. & Prov. Hwy. No.116

Products: Manufacturing and processing of tissue papers made of recycled fibres.

Bathroom tissue, napkin stock, paper towel stock, specialty tissue paper, facial tissue, recycled pulp

Production Capacity

Towel: 120 t/d

Tissue: 170 t/d

Equipment

Recycling Plant

Pulpers: 2 Black Clawson & Lamort, 12 ft and 16 ft

Yankee: 1 x 10 ft.; 1 x 12 ft.; 1 x 15 ft.

Refiners: 2 Sprout-Waldron, 1 Voith

Paper Machine: 2 Yankee, breast roll former, 1 crescent former, 125” trim

Converting Equipment

Bathroom Tissue: 2 Perini

Facial Tissue: 1 mix suppliers

Source of Power

100% purchased from Hydro Québec

lACHute

Mill

Address: 115 rue de la Princesse Lachute QC

J8H 4M3

Tel: 450 562-8585, Fax: 450 562-1369 Website: www.cascades.com

personnel

Mtce Supvr: Olivier Lassonde

Mill Mgr: Régis Arsenault

Conversion Mgr: Denis Morin

Conversion Supvr: Dave Beaupré

Conversion Supvr: Jean-Sébastien Michaud

Quality Mgr: Julie Lemieux

Project Mgr: Guy Turpin

Project Mgr: Christian Mantha

Sec: Elise De Sève

Paper Machine Mgr: Alain Labelle

Gen Mgr: Serge Leroux

Controller: André Proulx

Environ Supvr: Daniel Caron

Paper Machine Supvr: Charles Beaulne

Mtce Mgr: Nicolas Rosa

Lab Techn: Benoit Graton

Div Controller: François Ratté

Handling/Transport Mgr: Marc Petit

Total Employees: 135

Transportation: C.P.R.

Products: Towels and Tissue

Production Capacity

Paper: Industrial paper towel: 100 t/d

Converting: 36,000 short t/y

Equipment

Pulping & Papermaking

Pulper: Lamort

Refiner: 2 Sprout Waldron disc refiner

Boiler: 3 12,000 lbs, Coil tube, Thermogenic.

ABB Flakt gas system Paper Machine: 1 Paper Machine: 1 Fourdrinier, 3 m. width, 750 m/min

Converting Equipment

Towel Machinery: 3 PCMC, 2 Bretting, 2 Perini

Pallettizer: 2 ABB robot, 1 Electric 80

Source of Power: 100% purchased from Hydro Québec

lAVAl

Mill

Address: 2345 aut des Laurentides Laval QC H7S 1Z7

Tel: 450 688-1152, Fax: 450 688-6245

Website: www.cascades.com

personnel

Plant Mgr: Maté Mrvica

Communications and sustainability: Melanie St-Pierre

Mtce Supvr: Patrick Veilleux

Div Controller: Sylvain Gamache

Handling/Transp: Claude Plante

Dir-Hum Res: Lucie Vaillancourt

Quality Control: Nathalie Lafleur

Admv Asst: Jacynthe Denis

Asst Controller: Mélanie Dufour

Prod Supvr: Marc Leroux

Planification: Olivier Roy

Graphic Services: Joanne Nadon

Total Employees: 80

Products: Napkins

Equipment

Converting Napkin Equipment

toroNto CoNVertiNG

Address: 45 Milliken Blvd Scarborough ON M1V 1V4

Tel: 416 329-5200, Fax: 416 329-5236

Website: www.cascades.com

personnel

Ship Supvr: Rona Evangelista

Controller: Vitaly Bozhkov

Ship Supvr: Rave Harrinarine

Mtce Supvr: Al Kreko

Buyer: Stan Meloff

Hum Res Mgr: Kinnear Carrick

Prod Mgr: Tom Murray

Quality Mgr: Bob Chambers

Commun/Dev: Melanie St-Pierre

Total Employees: 130

Products: Bathroom tissue, paper towel, napkins.

Trade marks: Cascades, April Soft, Optima, Fiesta

Markets: Canada, United States Industrial Sectors: Retail markets and away from home (AFH)

Converting Equipment

Bathroom 2 Perini, 1PCMC

Towel 2 Perini

Napkin 2 Bretting

toroNto pAper MACHiNes

Address: 55 Milliken Blvd Scarborough ON M1V 1V3

Tel: 416 329-5200, Fax: 416 329-5234

Website: www.cascades.com

personnel

Commun Coord: Melanie St-Pierre

Mtce Supvr: Al Kreko

Buyer: Stan Meloff

Prod Mgr: Tom Murray

Controller: Vitaly Bozhkov

Hum Res Mgr: Kinnear Carrick

Ship Supvr: Rave Harrinarine

Qual Mgr: Bob Chambers

Total Employees: 130

Products: Bathroom tissue, paper towel, napkins.

Trade marks: Cascades, April Soft, Optima, Fiesta

Markets: Canada, United States Industrial Sectors: Retail markets and away from home (AFH)

Converting Equipment

Bathroom 2 Perini, 1PCMC

Towel 2 Perini

Napkin 2 Bretting

sCArBorouGH Mill

Address: 111 Progress Ave Scarborough ON M1P 2Y9

Tel: 416 329-5200, Fax: 416 329-5234

Website: www.cascades.com

personnel

Asst Mgr: Jeffrey Hicks

Controller: Ruth-Ann Kuboniwa-Bond

Mtce Mgr: Alfredo Mendez

Prod Mgr: Sylvie Gagné

Mtce Supvr: Eric Piercy