SCAB SOLUTIONS

Looking beyond management strategies for common scab

GET PROTECTION FROM DAMAGING SOIL-BORNE DISEASES AND NEMATODES WITH VELUM RISE.

Protect your potato crop with an in-furrow application of Velum® Rise fungicide/nematicide. Velum Rise delivers excellent control of soil-borne black scurf, stem and stolon canker caused by Rhizoctonia solani. It also offers suppression of black dot and nematodes which are some of the causal agents of the potato early dying (PED) disease complex.

Rise to the challenge and get the performance you need with Velum Rise.

10 | What makes a potato processing powerhouse?

What unique challenges and opportunities lie in Alberta’s thriving landscape?

By Jim Timlick

14 | Beating the heat Developing practical strategies for Western producers to help reduce the impact of heat stress on potatoes.

By Carolyn King

18 | Rotations to boost yields and profits A look at alternative crop rotations in P.E.I.

By Carolyn King

BREE RODY EDITOR

UNCERTAINTY, RESILIENCE... ELEPHANTS?

This morning, I sat down to rewrite (yes, rewrite – more on that in a moment) this editorial, when I found myself unable to free myself from a certain distraction: there was an elephant in the room (well, cubicle). He kept poking me on the shoulder, saying, “Hey, you’re going to write about that thing, right?” (For the purpose of this story, let’s say elephants can speak English). If only the elephant knew I’d been trying to write about that thing for two weeks – but I keep having to rewrite it.

If you haven’t figured it out, the elephant in the room was insisting I discuss the 25 per cent tariffs U.S. president Donald Trump had been promising to impose on Canadian imports since November. The move affectsthe entire Canadian economy, and potatoes are no exception. Canada is a net exporter of potatoes, and most exports go to the U.S. In total, we had more than $3.1 billion in net exports for 2024, according to Stats Canada.

That’s not due to a lack of appetite, either. We are simply a big country that grows great potatoes – too many for all 41 million of us to eat (I can check with the elephant to see if he can help).

By now, you know the tariffs were paused for 30 days on Feb. 3, before taking effect. For reference, I am writing this on Feb. 5, meaning by the time you read this, things could look different. That underscores the recurring theme of uncertainty, which has been present for months.

Does this sound familiar? Think back to five years ago, when the term “unprecedented times” was repeated so often, it almost became a meme. “May you live in precedented times” became a dark joke. Now, in 2025, “uncertain” has become the new “unprecedented.” Like its predecessor, it’s not actually funny. Uncertainty makes things difficult to plan and is hard on markets.

So, is “may you live in certain times” a reasonable wish? Probably not. Of course, the Canadian potato industry has lived with uncertainty before, from the flat demand and too-high Canadian dollar of the early aughts to the COVID-induced plummet in demand of 2020 – and even the recent potato wart saga that kept P.E.I. in a state of uncertainty.

This isn’t an attempt to find silver linings in uncertainty. But, in these uncertain times (sorry), we do press on with innovation. The beauty of science is the pursuit of certainty. As such, the research covered in this issue, which includes innovations against environmental stressors (heat stress – see Page 14), fertility (crop rotations – see Page 18) and disease (common scab – see Page 22) are as relevant in 2025 as they were in 2024. However, you will find mentions in some features, like in our focus on the growth of Alberta’s processing sector (Page 12) or our summary of the Canadian Potato Summit (Page 6), where tariffs came up in one presentation.

The fact is, the topic fundamentally changes the context in which we view Canadian potatoes – and all agricultural commodities. On one hand, the general public has begun to more acutely understand what it means to be a net exporter of a good.

On the other hand, it’s because of our innovations that we produce such high-quality potatoes –and so many of them!

So read on as you prep for the growing season, whatever it might look like.

LOTS OF OPTIONS. ONE DESTINATION.

Our products help you on your way to higher yield and superior quality.

Aim® EC herbicide – Tank-mix with Reglone® Desiccant for more complete vine kill, leading to better tuber quality.

Beleaf® 50SG insecticide – Reliable aphid control, unique anti-feeding action and low impact on many important beneficials , with a short 7-day PHI.

Coragen® MaX insecticide – Residual control of ECB and CPB with a short 1-day PHI, in a new, highly concentrated formulation that covers more acres with less.

Cygon® 400EC insecticide – Improved formulation! Consistent, locally systemic control of leafhoppers, with a short 7-day PHI.

Exirel® insecticide – Systemic, residual control of sucking and chewing pests, including CPB, ECB, armyworms, flea beetles and aphids, with a short 7-day PHI.

Verimark® insecticide – Fast uptake for in-furrow control of CPB and potato flea beetle.

CHECKING THE POTATO PULSE

Canadian Potato Summit taps into industry and agronomic trends.

by Bree Rody

Growers can rarely rest on their laurels. Being proactive is better than being reactive. And good things take time to see.

These were insights from the fifth annual Canadian Potato Summit, which was held virtually Jan. 16.

The main purpose of the Summit, hosted by Potatoes in Canada, has always been to bring growers and other industry stakeholders together and keep them updated on the latest agronomic research, findings and trends.

Continuing to do so in a virtual format allows the information to be delivered efficiently, with speakers hailing from Atlantic Canada, Manitoba and everywhere in between.

Putting potatoes in context: business matters

Although the Summit mainly focused on agronomic updates concerning pests, diseases, fertility and other issues affecting potatoes, the event kicked off with a session that covered numerous aspects of the business from a grower’s perspective – since nothing underscores the importance of the Canadian Potato Summit quite

like quantifying the important role potatoes play in Canada’s agriculture industry and overall economy.

United Potato Growers of Canada GM Victoria Stamper delivered a business update on behalf of UPGC, which covered the status of the growing seasons across the country – planted acreage, yields and broader trends affected by weather and the like.

Utilizing current and historical data, Stamper and UPGC’s data showed that Canada remains a potato production powerhouse.

“Although our planted acreage haven’t reached the peak – back in 2003, over 457,000 acres – we can see that production has surpassed [previous levels] with the assistance of steadily increasing yields.”

For the 2024 growing season, estimates put the season at just over 391,000 planted acres, nearly 384,000 harvested acres, 330.9 overall yield, and production of nearly 127,000,000 hundredweight, a modest increase (0.3 per cent) from 2023. That slight increase came after some recent revisions to StatsCan’s 2023 numbers –

TOP: AAFC’s Judith Nyiraneza, a specialist in regenerative soil practices, has studied a number of field plots that were subject to different combinations of regenerative practices.

initially, the production amount was expected to be lower this year than last year’s. The result? It was a record 2024.

That doesn’t mean every region shared similar spoils. It wasn’t all sunshine in the east, for example, although in this case, the rainy days were welcome. “We had a lot of consistent rain in New Brunswick, P.E.I., Quebec, even into Ontario,” said Stamper, noting this was almost the opposite of the 2023 season.

Harvest – not simply what is pulled out of the ground, but what is suitable for storage – increased in most eastern regions, while most western regions saw modest decreases in harvest. Stamper said in her work, most of the growers with whom she’s spoken have been pleased with the harvest.

Processing powerhouses Alberta and Manitoba also saw slight decreases in planted acreage thanks to some decrease in processing sector acreage. “We are slightly down overall, [with] most of that in the west.”

But some demands indicate that Canadian potato consumers are seeing red – which in this case would be a good thing. “We’re seeing a bit of a tighter inventory on reds,” she said, indicating that demand outpaces supply slightly when it comes to red potatoes.

Stamper’s outlook also pointed to trends and changes at home, and what the development of Canada’s economy means for the potato sector. Quick-service restaurants such as Tim Hortons, McDonald’s, Starbucks and A&W (the top purchasers of potatoes) have mostly seen small increases in their footprints, with the exception of Tim Hortons, which had a small (0.8 per cent) decrease.

More than 85 per cent of Canadian households purchase potatoes, and that trend continues to be the driving force between high-demand items such as frozen French fries.

Stamper’s talk also discussed trends and developments in the U.S. and Europe with some insight into what this means for Canada.

Naturally, this resulted in the biggest question on everyone’s minds (both on Jan. 16 and today): tariffs.

While the status of the 25 per cent tariffs was still in question at the Jan. 16 event, the executive order was signed Feb. 1. A pause on the implementation of tariffs for 30 days was implemented on Feb. 3, before the tariffs came into effect, prompting a sigh of relief among producers, but one that is – for now – strictly temporary.

Editor’s note: Press time is Feb. 5, 2025, two days after the 30-day pause on the implementation was announced.

Stamper says the Canadian potato industry, the facts are indisputable: Canada is a net exporter of many goods, including potatoes. Just how much does Canada export? According to StatsCanada’s 2024 summary of the country’s growing season, the country’s potato exports represent a value of more than $3.6 billion across all potatoes (fresh, seed, processing, frozen, etc.), versus imports valued at $534,000.

The U.S. is the recipient of more than 90 per cent of those exports. Alberta is the largest-exporting province, representing just shy of 26 per cent of exports.

At the time of Stamper’s presentation, the status of the promised tariffs remained unclear, but she emphasized the industry’s need from an association level to communicate – with both policymakers and the public – on the importance of potatoes in Canada’s part on the global stage.

“Our government and our associations in Canada are definitely lobbying and are making sure people are aware that tariffs are not

good for anyone on either side of the border,” said Stamper.

Other pressing matters include a potential rail strike, port strikes, the low exchange rate, erratic weather and more.

The problem with pests

Two of the sessions included information on key pests. First, because Manitoba is such a crucial growing province, Manitoba Agriculture’s Vikram Bisht delivered an update on the province’s 2024 growing season and conditions, with a focus on pests and diseases, and a look toward 2025. Later, AAFC’s Christine Noronha delivered a special presentation focused on Colorado potato beetle (CPB) and management strategies for the pest.

Left uncontrolled, CPB populations can cause yield loss of anywhere from 40 to 80 per cent. Currently, with CPB’s adaptability and history of developing resistance to major insecticides, prevention is less of a realistic option than management.

Biological control is one common method – including the method of releasing insect predators and natural enemies of the CPB, such as like the pathogen beauveria bassiana or two-spotted stink bug. Regardless of release methods, Noronha described this method as a strong biocontrol agent.

Besides biological control, physical or mechanical control methods should also be considered. A plastic-lined trench in a field could serve as an effective trap for walking beetles – provided the slope is right. In the right conditions, Nornha said studies show a marked improvement from this control. Other approaches looked at using mechanical technology to literally remove or erradicate the beetles. For example, a prototype of a pneumatic vacuum machine captured an estimated 50 to 70 per cent of L3 larvae in a field trial. A propane flamer similarly overwintered 70 to 80 per cent. “These plans are good, but the size… could be an issue,” said Noronha.

Ultimately, variety is the spice of life, said Noronha, whose key messages included a resistance management plan that involved different methods for the most efficacy. Similarly, for those still using insecticide, said Nornha, rotating insecticides is important, as it will help delay resistance development.

CPB is among the top pests of major concern in Manitoba, according to Bisht, as well as aphids and European corn borer (ECB).

Colorado potato beetle egg mass. CPB has a long reputation of developing resistance against common insecticides.

For aphid tracking, 2022 represented a peak for aphids trapped at eight sites. However, 2023 and 2024 saw a lowering from the peak –with a “peachy” twist, said Bisht.

“In 2023, when our [total aphids trapped] numbers were medium – not too high – our numbers of green peach aphid and potato aphid trapped were very, very high,” he explained.

While 2024 saw fewer both aphids and green peach aphids, Bisht pointed to the “late surge” observed as a pain point, even if the 2024 surge was much lower than 2023. That year, green peach aphids trapped hit a staggering high, with a cumulative 228 caught. By comparison, the 2024 total was 27, but that was still more than souble the 2022 figure of 12. Some Manitoba seed potato fields had an estimated 15 per cent of plants infected by virus from green peach aphid in 2024.

For diseases, Bisht covered the major concerns among Manitoba growers – late blight, powdery scab, black dot and others.

One item of note was an increase in spraing incidence and intensity for potato mop top virus (PMTV) in storage tubers, over the storage period. Research work to better understand the virus will continue in the province, said Bisht.

Breeding trial highlights

AAFC’s Erica Fava and University of Guelph’s Vanessa Currie delivered highlights from the 2024 National Potato Variety Trials conducted by AAFC.

The breeding project’s objectives are to come up with a “superhero-type” potato with desirable traits – early maturity, pest and disease resistant, heat tolerant and more.

It goes without saying: “That’s an awful lot to ask,” said Fava.

With nine trial locations throughout the country, each in markets that were key for various types of potato products (French fries, fresh market potatoes and chips), a total of 39 selections were made. Selections spanned French fry, fresh market (divided into white and red) and chip.

Fava and Currie both noted that even with all those traits in mind, trials showed that size matters beyond aesthetics – size was found to impact yield, marketability and more.

For example, for fresh market potatoes, Fava noted positive feedback on varieties VF170089-26 and F170045-06, “However, it was mentioned that the size profile [for both] was a concern.” And, although total yields for both were comparable to Norland, the marketable yields were comparably low partially due to the size profile.

Following the national trials, the selections can be taken up by industry members to test on their own farms, or through coordinated trials. “If there’s still interest in the lines, they may then be registered as a commercial variety and then marketed.”

Currently, this is done through two main mechanisms: in the first mechanism, the consortium or “club” model, French fry producers pay a “club fee” to the breeding program, which gives them non-exclusive access to the French fry lines.

“This model has been great for our program, because we’ve had a lot of direct communication with members, which has helped our selection decisions... and has also given us some stable programming.”

If a French fry line isn’t suitable for processing, that can then

go through the other mechanism. For fresh market and chip selections within the current cluster (2023 to 2028), they will be offered non-exclusively to those who have contributed to the program. Fava emphasized the need for funding for 2029 and beyond, especially one that encourages feedback into breeding activities.

It starts with soil

What’s good for the soil is good for the environment – and maybe good for potatoes, too.

Judith Nyiraneza, an AAFC scientist and a specialist in regenerative soil practices, discussed how such practices related to potato yield.

Soil with high organic matter, said Nyiraneza, has better structure, water retention (ensuring better defense against drought), improved biological productivity and better nutrient recycling. It’s important for growers to commit to practice that increase soil organic matter, said Nyiraneza.

“Combining several practices might be the key,” she said, which is why the research team explored combinations of crop residue and organic amendments, such as manure at different stages of composition.

Using 2022 modelling from the Quebec Living Lab that looked at estimated soil organic matter over the next 100 years, Nyiraneza highlighted the various practices that, even on their own, raise soil organic matter.

The modeling was based on a clay loam, with about four per cent soil organic matter, and a corn-soybean rotation.

“If you don’t do anything [in terms of practices]… as you can see, it’s business as usual,” said Nyiraneza, pointing to the trendline over time that indicated that the soil organic matter stayed at just above four per cent over the next 100 years.

However, other management practices such as no-till, manure, intercropping, winter wheat plus cover crop and others saw significant increases in soil organic matter over the next century.

To support this thesis, Nyiraneza highlighted two studies from the Atlantic Living Lab that looked at the effects of such practices on potatoes.

The first study, which began in 2017, looked at cover cropping both with and without manure.

Cover crops resulted in higher potato yield, with the top contributing cover crop being pearl millet. Manure showed a clear trend of improved soil health metrics.

The second study, established in 2019, compared primary, noninversion shallow tillage (ST) and moldboard plowing (MP). The two tillage regimes resulted in comparable total yield, marketable yield and specific gravity.

Like her AAFC contemporary Christine Noronha, Nyiraneza told the crowd it is always best to take a multifaceted approach. Combining practices is a good strategy, she said, and it should be considered whenever possible.

But she also emphasized although such practices will result in soil health improvements, such improvements may take a while to be seen. But, like many other management practices that benefit potatoes and the land on which they’re grown, that does not mean they’re not worth it.

Brought to you by DOES THE FUTURE OF AGRICULTURE SEEM GREY TO YOU?

Agriculture in the Classroom is cultivating curiosity by providing hands- on, immersive learning experiences to educate and engage students. The next generation of farmers, policy-makers, and innovators is in the classroom today. Together, we can inspire young people to drive our industry forward.

Change the future at aitc- canada.ca

WHAT MAKES A POTATO PROCESSING POWERHOUSE?

For Alberta, physical, geogrpahic, economic and even cultural qualities come into play.

byline Jim Timlick

With a focus on Canada’s role in the North American and global economy sharper than ever before, those outside of Canada’s borders have begun to take notice – if they haven’t already – of Alberta as oil country. It’s well-known to Canadians, and beyond, that it is home to one of the largest oil reserves in the world.

But it could just as easily be referred to as Canada’s potato capital.

In 2024, Alberta produced about 30 million hundredweight (cwt) of spuds, according to a Statistics Canada report released in December. That topped every other potato producing province including P.E.I. (25.9 million cwt) and Manitoba (27.4 million cwt). In fact, Alberta’s 30 million cwt accounted for 23.7 per cent of the potatoes produced in the country this past year.

Alberta’s booming potato sector is big business, according to a recent report produced by Alberta-based agricultural consulting firm Serecon Inc. on behalf of the Potato Growers of Alberta (PGA). The Alberta Potato Industry: Growing Success in 2022 says the province’s

potato industry contributed $2.87 billion to the Canadian economy and $2.31 billion to the Alberta economy in 2022. That included $662 million in labour income and 9,390 jobs in Canada with some 7,380 jobs in Alberta. Those numbers have continued to climb since.

One of the key factors driving this boom is the province’s potato processing sector. That should come as no surprise considering 73 per cent of the potato acres in Alberta are grown for the processing of frozen potato products and potato chips, according to the PGA report.

And that boom is expected to continue. Cavendish Farms opened a new frozen potato processing plant in Lethbridge in 2019 that tripled the company’s production capacity and requires more than 735 million pounds of potatoes annually. Meanwhile, McCain Foods is putting the finishing touches to a $600 million expansion of its processing facility near Coaldale. It is the company’s largest ever capital investment. It is expected to be completed by June 2025 and will require another

ABOVE: With more than 2,200 acres, Taber’s Nakamura Farms is one of Alberta’s largest producers.

significant boost in potato production in the province.

Potatoes in Canada recently spoke with a group of industry experts and analysts about the boom in the potato processing sector, the reasons for it and what it has meant for producers. Here’s what they had to say:

What’s behind the boom?

What has been driving the boom in Alberta’s processing sector?

Darren Haarsma, a principal with Serecon Inc., says one of the primary factors has been the growth in the frozen potato product market in Asia. That has increased export opportunities for potato producers in the U.S., particularly for those in the Pacific northwest. As a result, U.S. domestic availability has decreased which has increased export opportunities for Alberta producers to the States.

“U.S. domestic availability, production minus exports, has been decreasing even though the U.S. population has been increasing. As a result, you’re seeing that Alberta’s and Canada’s production has been backfilling (that supply),” he says.

Good for growers

The growth in the processing sector is reflected in the fact that the number of planted acres of potatoes in Alberta has been steadily increasing over the past decade. In 2014, the number of potato acres in the province was at 56,000. By 2019 that figured jumped to 62,000 acres when the Cavendish Farms plant expansion came online. In 2023, the number of planted acres sat at 80,000, which produced the province’s largest potato crop ever.

One of the biggest beneficiaries of this growth has been potato growers. Not only has it allowed many existing producers to expand their operations, but it has also enticed some farmers who never grew potatoes before to give it a shot.

“We’ve added some new growers over the last couple of years and we’re going to add some more with this (McCains) expansion, so it’s been good that way,” says PGA executive producer Terence Hochstein.

“People that have been wanting to get into the industry and have done their homework and got their financing in order, now with the expansion, it’s allowed them to come online. It’s not been that all the growth is from within. It’s a good opportunity because of the boom.”

All of this increased demand for potatoes and potato products has also been good for Alberta’s seed potato industry, Haarsma says. About 60 per cent of the seed potato that comes out of Canada is exported out of Alberta and into the U.S., meaning there are greater export opportunities for Alberta seed producers due to the increased demand.

Why Alberta?

There are more than a few reasons why Alberta producers have been well positioned to take advantage of the increased demand for processed potatoes.

The availability of water, or access to irrigation, has been one of the primary factors. Approximately 87 per cent of Alberta’s potatoes are irrigated, primarily in the southern region of the province.

Another key reason is the entrepreneurial spirit of producers. The PGA report states that the “strong entrepreneurial drive of

Everything you need for washing, processing and packaging potatoes

Wyma are experts in designing end-to-end line solutions, project management, and automation. We provide fully flexible design and expert implementation, supported by the highest quality service for the life of our products.

Get the best from every harvest!

Talk to us today Leighton +64 21 220 6535 leighton.h@wymasolutions.com

Jason +1 715 627 3718 jason.storch@volmcompanies.com

farmers” has been a major factor in the growth of potato production in the province. Equally important has been their willingness to work together for the good of the industry, Hochstein says.

“You’ve heard the saying in the U.S. military of leave no man behind? Well, it’s no different here,” he says.

“Everybody is in this together. It’s the communication amongst the growers. There are no secrets in this industry, even though it wasn’t always that way. Everybody wants the industry to succeed so therefore everybody helps each other out.”

Haarsma points out that the study he helped author indicated that the average yield in Alberta is 30 per cent higher than in the rest of the country. He says that higher yield makes Alberta attractive to processors because it means they have fewer farmers and less acres to deal with.

Jonathan Neilson is a research scientist with Agriculture and Agri-Food Canada based in Lethbridge who specializes in potato health. He says favourable weather conditions make Alberta an ideal location for growing potatoes. It gets plenty of warm days followed by cool nights which is important, especially later in the growing season, in helping tubers to bulk up.

Neilson says Alberta is also unique from other potato producing provinces in that it has longer and more diverse rotations. In New Brunswick and Manitoba, potatoes are commonly part of one-intwo-year or one-in-three-year rotations whereas in Alberta they are typically part of a one-in-four-year or longer rotation.

“That (longer rotation) is going to help with your disease pressure. There’s also some soil health building that happens,” he says.

“Plus, we tend to have really diverse cropping systems. I think there are something like 20 different crops that are growing routinely in this part of the country that are sold for either food or processing markets. When you have these longer rotations, and more diversity in the system, that’s going to promote higher soil health and that translates into increased yields.”

Staying the course

Hochstein sees substantial room for the continued growth of

Alberta’s processing sector. He’s not alone in that regard. The PGA report states, “there is significant, suitable land … for potato production expansion.”

However, he stresses that in order for that to happen the industry must continue with the methodical approach to expansion that has worked so well for it to date.

“Expansion is great, growing is great. You want to become the biggest or the best or whatever. But with that you’ve got to do it in a calculated way. You can’t jump in half-hearted; you’ve got to be calculated. We’ve very methodically gone about how we’re doing this,” he explains.

“One of the conversations that we’ve had all along with our processors … is we’re willing to engage and be part of this, but we’re not going to compromise our rotations. We’re not going to take shortcuts. We’re not going to jeopardize the economic practices that we’ve worked so hard on to maintain that quality. It’s been very calculated, very deliberate and will remain so.”

Neilson also sees room for growth in Alberta’s processing sector.

He says one of the limiting factors could be future water availability. Although the province has yet to get into a situation where it hasn’t been able to hit its irrigation targets, he says that could happen at some point if the province were to continue to experience prolonged droughts.

The good news is the Alberta government along with the Canada Infrastructure Bank and eight irrigation districts recently embarked on a $815 million plan to modernize irrigation district infrastructure and increase water storage capacity in southern Alberta.

“That means there could be some opportunity for some additional growth, but it’s not going to be a boom like it has been for the last five or 10 years. You just can’t bring on that much capacity and continue to do that. There’s a limit to everything,” cautions Hochstein.

Ideal qualities

Russet Burbank continues to be one of the most popular varieties of potatoes with processors, according to Neilson, because its well suited for producing French fries.

Coaldale’s 845 Spud Farms primarily sells its potatoes to local Cavendish and McCain plants for processing.

Coaldale’s Boston Farms has previously been recognized as a top potato grower from McCain.

However, some processors are starting to look at new or different varieties that have a better environmental footprint. Many of those varieties tend to require less water and use less nitrogen, and also possess better processing traits.

While Neilson was reluctant to name specific varieties being considered, he says processors are investigating varieties from several different growing regions including Europe. Some have even started their own internal breeding programs, he adds.

AAFC is currently conducting a study into several new varieties to determine their ability to withstand heat stress. Another study it is conducting is looking at their capability to recover from severe weather conditions including hail. (For more on heat and hail stress in Alberta potatoes, see Page 14).

As for what processors are looking for in a potato, yield remains the number one priority followed by important traits such as size, says Neilson. Size profile is important because French fries generally must be a certain length which requires the potato to be a certain size.

Neilson says shape is another important consideration because processors don’t want any kind of deformities such as knobs, also called heat runners, which could make a portion of the potato unusable. Storability is becoming an increasingly important consideration so that potatoes don’t rot due to disease while in storage or become discoloured when fried.

Future threats

One possible risk to the prosperity Alberta’s potato industry is

enjoying is the danger posed by changing climate trends which could lead to new disease threats.

Neilson points to blackleg as an example. While the overall pressure of blackleg remains fairly consistent, the dominant species of it appears to be changing, one of which appears to be better adapted to surviving overwinter. This combined with changing weather patterns might lead to higher disease pressure over time

Another possible threat Alberta producers may have to deal with is new U.S. president Donald Trump. On Feb. 1, Trump signed an executive order to apply a 25 per cent tariff on all Canadianproduced goods entering its neighbour to the south, following through on a promise made in November. That executive order has since been put on hold. (Editor’s note: As of press time, Feb. 5, the 30day pause is in effect).

Hochstein says whilemeasures such as tariffs would be a concern for his organization and its members, the issue would not have the same effects across Alberta’s entire potato industry due to the diversity of operations.

“The processors are multinationals. They operate on both sides of the border. That’s more at their level of discussions, not ours. We provide a raw product. How they market their product and where it goes, that’s for the next level up of production to decide.

“However, there is concern in our seed industry about remaining competitive with the U.S. market when it comes to selling our seed south of the border. A 25 per cent tariff would wreak havoc on our seed industry and our ability to maintain the relationship that we have established with our U.S. customers.”

BEATING THE HEAT

Developing practical strategies to reduce heat stress impacts in Alberta potato crops.

by Carolyn King

You can’t stop an extreme heat wave as it slams into your region, but you might be able to reduce the harm to your potato crop.

That’s the idea behind an Agriculture and Agri-Food Canada (AAFC) project to develop tools to help Alberta potato growers minimize heat stress impacts on tuber yields and quality.

Heat stress is a concern among global potato growers, and although it is not a constant source of pain for growers in Alberta, that doesn’t mean growers should not be aware of strategies, especially if warming trends persist.

Temperature has been cited by some as the single-most crucial uncontrollable factor when it comes to both the growth and yield of potatoes. Temperature plays a critical role in all stages of potato

development, but the most critical stages for temperature have been identified as tuber initiation and bulking. The growth stage at which heat stress occurs can have implications not only on the potato’s overall development but also on the cultivar’s response to high temperatures.

For example, some research shows effects are more pronounced early stages of tuber formation (which can prompt drastic tuber yield reductions, according to 2013 research from Serock, Poland) than in later stages, which can lead to quality deterioration (as found

TOP: The research group installed drip lines to apply products being tested.

INSET: AAFC’s Jonathan Nielson is leading a project looking at practical strategies to reduce the impacts of heat stress.

in 2017 research from South Korea).

While developing heat-resistant varieties is also a major focus for researchers and breeders around the world, helping all potatoes stand up to the heat through management strategies is the key goal of this new AAFC project.

Jonathan Neilson, a research scientist with AAFC-Lethbridge, says although heat stress is not an annual issue for Alberta potato production, it is a recurring problem.

“Some years, we have really stressful heat conditions, and then other years we go into a cooler, wetter cycle. There have been a few heat dome events in recent years, with prolonged periods of around 35°C and sometimes even reaching 40°C,” says Nielson, who is leading the project.

So, while heat stress is not a constant source of problems on an annual basis, from a sustainability perspective, it’s something Alberta potato growers nevertheless must deal with.

Growers must learn to address the impacts on yields and quality – especially crucial if such head events become more frequent in the future, which many argue

“If the tubers are immature or stressed, the sugar dynamics can change.”

is a distinct possibility. The good news is, there appear to be strategies.

Heat stress basics

The impacts of heat events on potato crops depend on such factors as the potato variety, the crop growth stage when the event occurs, and the event’s duration and intensity.

Neilson notes that the optimal temperature for tuber production depends on a few factors like the potato variety, but it is usually somewhere in the range of 15 to 20°C.

Above 20°C, the tuber growth rate tends to decline. Once the temperature climbs even higher, results can be even more stark.

“Once the temperature gets over about 30°C, overall growth stops. And when temperatures oscillate between going over

and then under that maximum temperature, you have photosynthesis and plant growth stopping and starting.”

How heat stress manifests in tubers

That stopping-and-starting can affect overall tuber yields – the tonnage, the average tuber size, and so on. It can also affect tuber quality, causing various types of deformities and other problems.

“For example, you can get heat runners after a pause in tuber development. That’s where [instead of resuming an increase in tuber size when growth restarts], the tuber starts producing knobs because the eyes break dormancy and start growing out,” he says.

“Another possibility is secondary tuber sets. The plant sets the first set of tubers and then gets stressed out. But when growth

Gold standard in potato protection.

Potato growers demand excellence. Win big this season by protecting your potatoes from insects, weeds, and plant-parasitic nematodes. From start to finish, Corteva Agriscience™ offers a suite of high performing products to elevate the performance of your potato crop. Talk to your local retailer to learn more.

restarts, instead of continuing to grow the first set, it will start producing a second set.

“As a result, you get tubers of different physiological age going into storage, so you get differences in the size profile.”

This means, for instance, you might get a mix of a lot of big tubers with a lot of small tubers.

“That is obviously not ideal because you want all your tubers to be within a certain size range that meets your contract.”

Another key impact of heat stress is the effect on fry colour. “If the tubers are immature or physiologically stressed, the sugar dynamics can change,” says Neilson.

That can result in a dark colour when the potatoes are fried, for a lower quality end-product – especially bad news for Alberta’s wildly successful processing sector.

“You can get overall dark French fries or dark chips. But you can also get different patterns; a more common one is sugar end, where the french fry is very dark at one end and light at the other.”

A suite of stress-related studies

Neilson’s heat stress project is one of a collection of weather-stressrelated potato projects in his research program.

“Our goal is to develop the tools and methodologies to find stress-related problems, recommend a solution, and verify that the solution is actually working,” he continues. “Then once we’ve got all of those pieces in place, we want to give that to growers and have them use it,” he says.

So, one overall program objective is to develop methods to rapidly assess large amounts of field data to identify weather-stress problems in crops.

The idea is to be able to get the relevant stress information to growers in a timely enough manner so growers have an opportunity to deal with the stress problem in their fields before it becomes irreversible.

And the other key program objective is to work with methods shown to reduce stress impacts in a greenhouse, a laboratory, a different growing region or a different agricultural system, and adapt those methods for real-world potato production under Alberta conditions.

Neilson’s heat stress project is funded by the Potato Growers of Alberta (PGA).

He is also leading a nearly completed hail stress project, which received funding from Results Driven Agriculture Research and inkind support from the PGA.

Additionally, Nielson has some AAFC-funded projects looking at how field operations can be managed to reduce general weather/ climate stress in potatoes.

His program is designed to have these individual projects build on each other, with tools, methods, equipment and learnings from one project being applied to the other projects.

Addressing heat stress

The heat stress project’s first full field season was in 2024, and it will run for two more years. The field work is taking place at AAFC’s Vauxhall Research Farm.

The experimental setup includes methods to ensure high temperatures in the plots. For instance, Neilson and his research group are using greenhouse tunnels to simulate short-term heat stress.

The team is also planting drip lines along with the potatoes so they can circulate water that has been heated to different temperatures, in turn increasing the root zone temperature. After, the team is planning to use these lines to apply the products that they are testing to see if root zone placement boosts product effectiveness.

In the trials, they are measuring yields, temperatures and many other factors.

These data collection activities include flying drones over the plots weekly to take spectral measurements (measurements of different wavelengths of light to assess things like the crop and soil conditions), as well as taking spectral and physical measurements on the ground.

The goal of the project is to evaluate some commercially available products that are shown to help with heat stress impacts in other parts of the world or other agricultural systems.

“We’re trying to work out the technicalities of making them work for Alberta growers, given the differences in our growing systems [from the rest of the world],” says Nielson.

By focusing on addressing some of the technical barriers for growers when it comes to adoptiong a product, their efficacies can be better understood in the context of Alberta.

Key barriers and questions include: “When do you apply it [the product]? How is it applied [spraying versus fertigation]? How much do you apply? Do you apply it once or multiple times?”

And that work also leads back to an important research question for Neilson: How are the products or practices altering the physiology of the potato plant to make the production system more resilient to the stresses it is experiencing?

A drone image shows some of the heat-damaged plots.

Evaluating products and methods

Two products the team is currently testing are glycine betaine and algal extract. Glycine betaine is naturally produced in some plants, but it can also be commercially manufactured; Neilson’s group is testing the commercial, purified form. The algal extract product that they are testing contains glycine betaine as well as some other compounds shown to help with plant stress.

Neilson and his group are also looking at the effects of applying calcium as a soil additive to reduce heat stress impacts in potatoes. “Calcium is a really important chemical for every biological organism. It plays a lot of roles in keeping cells active and dividing,” he notes. “Mostly in controlled settings, calcium applications have been shown to help plants maintain metabolism under stressful conditions, for instance, by allowing the plants to keep growing leaves and keep photosynthesis going.”

Another component of the project’s field trials builds on an earlier project led by Neilson about the use of cover cropping and/or intercropping in potato production for building soil organic carbon.

He explains, “We know soil organic carbon is a big contributor towards soil health, and better soil health tends to improve stress resistance in plants. But exactly how that works is what we’re looking at.”

In that earlier project, Neilson and his group observed a decrease in canopy temperature and soil temperature in the potato plots that had cover crops or intercrops.

Now, in the heat stress project, they are digging a little deeper into the cooling effects of these practices.

“We can’t be in the business of testing every product on the market.”

They hope to answer such questions as:

• Do the specific placements of the potato crop and the other crops matter to the temperature effects?;

• Are the temperature effects significant enough to make the practices worth doing?; and

• Is the cover crop or intercrop competing against or working with the potato crop?

Hail stress: initial findings

A master’s student in Neilson’s group is currently analyzing the data from the aforementioned hail stress project. One of the main outcomes so far from the nearly completed project is that the amount of impact from hail stress depends not only on the hail’s intensity but also on the timing of the hail event.

“When the potato plants are hit by hail in the bulking period, which is late July to August in Alberta, they tend to suffer a more negative impact than if the plants are hit later or earlier in the season,” says Neilson.

“That makes sense because if the hail hits later in the season, then the crop is already grown so there’s not as much yield impact,

although we’re still delving into the quality issues.

“And if the hail hits before tuber set, then the plant has a chance to regenerate; it will be delayed by a couple of weeks, but it will still be able to complete tuber set.”

Another main finding relates to the effects of glycine betaine and algal extract in helping plants to recover from hail stress.

“We found that if we apply glycine betaine or algal extract products, and we have a hailstorm in the early bulk period when the plants are particularly susceptible, then the crop is able to recover back to close to what it would have been without hail damage,” notes Nielson.

“Since these two products promote cell division and cell growth, we suspect that their application is allowing the plant to resume growth more quickly after a stress event.”

Tools for growers

Neilson is also looking into how to deliver timely, relevant, easy-to use, stress-related information to Alberta potato growers.

“Currently, we can really well describe a potato crop, so we can tell you two weeks later what the crop looked like two weeks ago. But we want to be able to say within 24 hours, ‘Here is what we’re seeing,’ and maybe provide a risk assessment that says, ‘You’re at risk of this problem, and here are some potential things that you can try to address the problem.’”

Neilson and his group are already working on a tool for hail stress. They have pulled together published data from past studies by other researchers and used it to build a preliminary model. The model would, for example, allow growers to enter their own data about a recent hail event, such as the event’s timing, amount of hail damage, and so on. Then the model would estimate the expected decline in the marketable yield based on the available data.

Right now, the model is using data from other places and many years ago. However, the idea is that Alberta growers could add their own current and historical data to the model’s dataset, so the model could be trained for an Alberta context.

Neilson has also started talking with the PGA about considerations like what type of information would be most useful to growers and how would growers like to receive that information. He expects this effort will involve talking with many individual growers, processors and others about their information needs and preferences.

Ultimately, Neilson would like to be able to give growers tools to not only identify weather-stress problems in their own potato fields but also tools to evaluate the effects of different products on reducing weather-stress impacts.

That, he says, would allow growers to make timely, cost-effective management decisions based on their own specific situation.

“In my view, my role as a government scientist is not necessarily to tell growers something like ‘This is the best way to grow potatoes’ because every field is different and every potato operation is different, with its own particular production system, equipment, and so on,” he says.

“We can’t be in the business of testing every product on the market because there are many, many products and new ones are coming out every year,” says Nelson.

“Providing growers with the tools to make the evaluations themselves is where I think we’ll have the biggest impact.”

ROTATIONS TO BOOST YIELDS AND PROFITS

A look at alternative crop options for potato rotations in P.E.I.

by Carolyn King

These days, many Prince Edward Island potato growers are combining their own expertise with practical research results to choose alternative crop rotations focused on achieving their goals for productivity, profitability and sustainability.

For years, a rotation of barley (underseeded to red clover)/red clover/potato (B/RedCl/P) has been a mainstay of P.E.I. potato production.

“That rotation was dominant because a lot of our potato farms were mixed farms that also had dairy or beef livestock. Barley was grown to feed the cattle and the straw was used to bed the cattle, and double-cut red clover and grass was fed to the cattle. Even if potato farmers didn’t have their own cattle, they traded land or rented land with someone who had cattle,” explains Ryan Barrett, research and agronomy specialist with the P.E.I. Potato Board (PEIPB).

“But since the early 2000s, the number of beef cattle in P.E.I. has dropped by about half, and the number of dairy cattle has dropped slightly.” So local demand for barley and red clover has really declined.

The traditional B/RedCl/P rotation can also have drawbacks for potato yields. For example, red clover is associated with potato early dying complex (PED), a major yield-limiting potato disease caused by the Verticillium fungus and made worse by root-lesion nematodes. Barrett says, “In some research that I and others worked on, we found that our Verticillium and nematode numbers were generally higher in fields that had red clover in the rotation than in fields that didn’t.”

As well, red clover has traditionally been plowed into the soil in the late fall, and research shows this can increase the risk of soil erosion and nitrate leaching.

So, P.E.I. potato growers are trying a range of rotational alternatives, usually within the framework of a three-year rotation. “Although no one potato rotation has become dominant, there is definitely a more diverse mix of crops, both cash crops and diseasesuppressive crops or soil-building crops,” he says. “Especially when

ABOVE: A field of tillage radish being grown as a fall cover crop in Prince Edward Island.

only about 10 per cent of our acres are irrigated, we’re very focused on having soil that will retain moisture, isn’t compacted and will produce a good crop of potatoes.”

Alfalfa alternative

A very large number of acres are still in barley/forage/potato rotations, but PEIPB surveys show alfalfa is increasingly replacing red clover, with as many or more acres in alfalfa than in red clover. Barrett notes, “Alfalfa is a deeper-rooted crop than red clover, helping with soil compaction. We also see indications that it is less associated with Verticillium and nematodes, and it is usually a higher quality forage and does better in dry weather.”

In these rotations, alfalfa is usually underseeded with a cereal crop and then terminated the following year. “Some people leave the alfalfa until later in the fall, so they can get the majority of the growing year out of it. Then they kill it by plowing it, to have the field ready for potatoes the next year,” he says.

“But increasingly people are terminating alfalfa in late August with Roundup. Then they do their primary tillage in late August or early September using a vertical tillage machine as opposed to a moldboard plow and at the same time they seed a fall cover crop. For the fall cover, they choose something like radish, barley or oats that will cover the ground and take up any free nitrogen. If you plant that cover in early September, you can usually get a pretty nice green cover to carry into the wintertime. Then the cover is winterkilled so you’re ready for potatoes the next year.

“Another benefit of terminating a legume in August/September is that the majority of the nitrogen from the legume will be available the next year around June/ July when the potato crop needs it. If you plow it in October/November or in the spring just ahead of potatoes, a lot of that mineralization happens in the following September/October when your potato crop doesn’t need the nitrogen.”

He adds, “That has been part of the problem with red clover – people were plowing it later in the fall or the next spring. The nitrogen would mineralize too late for the potato crop, resulting in an oversupply of nitrogen in the system. That is not good for environmental or agronomic reasons.”

To get a better understanding of nitrogen

credits from alfalfa, clover and other legumes, Barrett currently has a ‘Living Labs’ project with Agriculture and AgriFood Canada (AAFC). They aim to quantify the credits and get a deeper understanding of things like the timing of nitrogen release and the effect on the potato crop.

Living Labs is a national initiative of AAFC that brings together farmers, researchers and other stakeholders to co-develop and test beneficial management practices under real-world conditions. Living Lab – Atlantic, which ran from 2019 to 2023, focused on ways to improve soil health and water quality in P.E.I. Barrett and other researchers like Judith Nyiraneza, a research scientist at AAFC-Charlottetown, were involved in Living Lab – Atlantic projects.

The new phase, called Agricultural Climate Solutions – Living Labs, started in 2023. It is continuing with the collaborative approach to innovation development, but it is emphasizing improving sustainability and resiliency in response to climate change and other environmental challenges. Living Lab – P.E.I. includes some practices like cover cropping from Living Lab – Atlantic, but it is looking at the practices from a greenhouse gas emissions perspective.

Other full-season innovations

Growers are making other changes to their potato rotations, like replacing barley with higher-value cash crops such as corn or winter wheat, and replacing red clover with various alternatives.

Barrett has several current projects with producers investigating the agronomic and economic values of different crops in potato rotations, including projects under the Agronomy Initiative for Marketable Yield (AIM). They are comparing B/RedCl/P to alfalfa/alfalfa/potato, potatoes in rotation with soil-building crops like pearl millet, sorghum sudangrass and tillage radish, and rotations with corn instead of barley.

Through another Living Lab project with AAFC, Barrett is evaluating rotational grazing in potato rotations. “We have five or six trials looking at grazing versus the conventional management of forages (mulching or baling) ahead of potatoes, and assessing the effects on things like soil health, nitrogen cycling, and potato yield and quality.”

Barrett’s overall recommendation for full-season non-cash crops before potatoes is to choose options that will help deal with

whatever is the biggest challenge for your potato crop.

He gives a couple of examples. “If my major issue is early dying/ Verticillium, then I’d be looking at crops like sorghum sudangrass or pearl millet or mixtures of those. Both crops seem to be associated with building soil organic matter, and pearl millet is associated with reduced nematode populations.

“If my biggest challenge is wireworm, then I’m likely to choose brown mustard or buckwheat.” Wireworms can cause very costly damage to tubers, and few pesticides are available. These two crops can reduce wireworm populations, and mustard can help with disease suppression.

Nyiraneza agrees that your choice for a full-season non-cash crop will depend on your objectives for that cover. She recommends the chart entitled Rotation Crops Quick Reference Table, compiled by Barrett and available on the P.E.I. Potato Agronomy website.

Interestingly, some P.E.I. growers have turned to growing two years of full-season non-cash crops between their potato crops. Barrett says, “They are trying to feed the soil, keep their costs low, and keep their labour low, and really focusing on maximizing their potato yield.”

Other growers have switched to growing a cash crop in each year of their potato rotation, but with a fall cover crop after every cash crop to benefit their land and their potato crops.

An economic example

Nyiraneza has been the science lead on many potato rotation studies in which she has worked with Mohammad Khakbazan, an agricultural economist at AAFC-Brandon. In one example, reported in their 2023 paper, they compared the B/RedCl/P rotation to a soybean/mustard/potato (Soy/M/P) rotation and a corn/sorghum sudangrass/potato (C/SS/P) rotation. The field experiments took place at Harrington, P.E.I., from 2015 to 2021.

“The goal was to have two cash crops in each rotation and also to consider alternative crops that are increasingly grown in P.E.I. and to include a high biomass rotation (corn and sorghum sudangrass) and a biofumigant crop (mustard),” explains Nyiraneza.

Khakbazan wondered if the potential benefits of such alternative rotations might boost P.E.I. potato productivity and profitability. He notes that P.E.I. potato yield trends were relatively flat from 2009 to 2022. “The average potato yield increase in P.E.I. per hectare per year was 39 kilograms compared to 374 kilograms in New Brunswick and 636 kilograms in Alberta.”

The study’s results showed that potato yields increased by 10.5 per cent under C/SS/P and by 6.7 per cent under S/M/P, compared to B/RedCl/P.

Nyiraneza points out that they have seen similar yield results in other trials. She sees a couple of possible reasons for the lower potato yields with B/RedCl/P. “Even if the soil nitrogen supply is higher under red clover, it is not always translated into increased potato yield. One of the reasons may be that the nitrogen supply from red clover is above the potato requirement, which may extend potato’s vegetative growth under a very short growing season, delaying tuber formation.” The Living Lab project on legume nitrogen credits could help increase understanding of this issue.

“A second reason might be that the alternative crops to red clover may be effective in breaking disease cycles during the potato phase.”

The economic analysis also found that the potato net returns were 32.6 per cent higher under C/SS/P and 20.5 per cent higher under Soy/M/P, than under B/RedCl/P. Despite the higher input costs, the alternative rotations improved profitability.

Cover up in the fall

PEIPB’s most recent surveys show that about 50 to 60 per cent of potato rotation acres now have a fall cover crop before potatoes,

A Living Lab trial field comparing sorghum sudangrass (foreground) with oats in the year before potatoes.

IMAGE COURTESY OF RYAN BARRETT

usually coming after a forage. That number is up from about 25 per cent just five or six years earlier. The adoption of fall-seeded covers after potatoes is also around 50 per cent.

“The number one reason to do a fall cover crop is to keep soil in the field. If you can accomplish that then that is worth the cost of the cover crop. But there is some evidence of other benefits as well,” says Barrett.

In some short-term studies, he has seen trends suggesting that fall covers might also have some soil health benefits. To get a more definitive result, Barrett has a five-year Living Lab project with AAFC, the University of Prince Edward Island and potato growers. This study is comparing the effects of having a fall cover crop every year versus having no fall cover crop, in the same field, year after year.

He also says, “In some of our research, we saw that using a fall cover crop before potatoes was more often than not associated with a potato yield bump of about 5 to 10 per cent.” He thinks the yield increase might be related to improved nitrogen carryover to the potato crop.

Khakbazan investigated the economic advantages of a fall cover crop by evaluating data from two rotations in another PEI study with Nyiraneza. He compared the B/RedCl/P rotation, which had no fall cover before potatoes, and a barley/sorghum sudangrass/winter canola cover crop/potato (B/SS/WC/P) rotation.

Nyiraneza chose winter canola as the overwintering crop for this study because of its potential to help break soil-borne disease cycles during the potato phase, along with providing the other benefits of overwintering crops like reduced soil erosion over the winter and into the spring, increased soil moisture retention, improved nitrogen cycling and higher potato yields.

The SS/WC combo provided a big advantage – B/SS/WC/P resulted in 18.6 per cent higher potato yields and 77 per cent higher

potato net returns than B/RedCl/P.

For fall-seeded crops following short-season potato varieties, Barrett usually recommends winter cereals. He says winter wheat is becoming an increasingly popular choice in the fall after potatoes because it provides an overwinter cover as well as a cash crop in the following year.

Although there is not a big market for fall rye as a cash crop in PEI, “it is a gold standard at preventing soil erosion,” says Barrett. “Fall rye will establish later than almost anything else. And it will stay green all winter and start regrowing in April before everything else starts to really green up.”

Other producers choose crop options that provide fall cover and then are winterkilled. For example, “growers have had quite a bit of success with radish. You can plant radish in late August or early September, and it will grow fast and make a nice mat. A lot of growers can put a seeder box right on their tillage equipment and do it all in one pass because you’re using low seeding rate of about eight to 10 pounds an acre.”

Part of a bigger picture

P.E.I. potato growers are aiming for rotational options that are financially viable, good for their next potato crop, and work for their farm operation, their land and their goals. Results from studies by Barrett, Nyiraneza, Khakbazan and others are helping to inform those rotational choices.

Rotational alternatives are one component of the overall journey towards more profitable, sustainable, and resilient potato production systems. Nyiraneza emphasizes that there are no magic solutions. “But stacking different management practices is recommended when possible, including things like full-season cover crops, winter cover crops, organic amendment incorporation, returning crop residues, and reduced tillage intensity.”

A rotation trial in Western P.E.I. comparing mustard for biofumigation (left) with barley.

INCHING TOWARD A SOLUTION

Managing common scab is progressing, but a final solution is still in the works.

by Jack Kazmierski

Agriculture and Agri-Food Canada (AAFC) estimates that potato common scab disease costs producers more than $17 million dollars a year in economic losses.

Common scab disease makes potatoes less appealing to consumers, restaurants, as well as chip and fry manufacturers.

AAFC notes that the drier and warmer growing seasons many regions of Canada are experiencing only exacerbates the problem, since these conditions lead to more instances of common scab disease in potatoes.

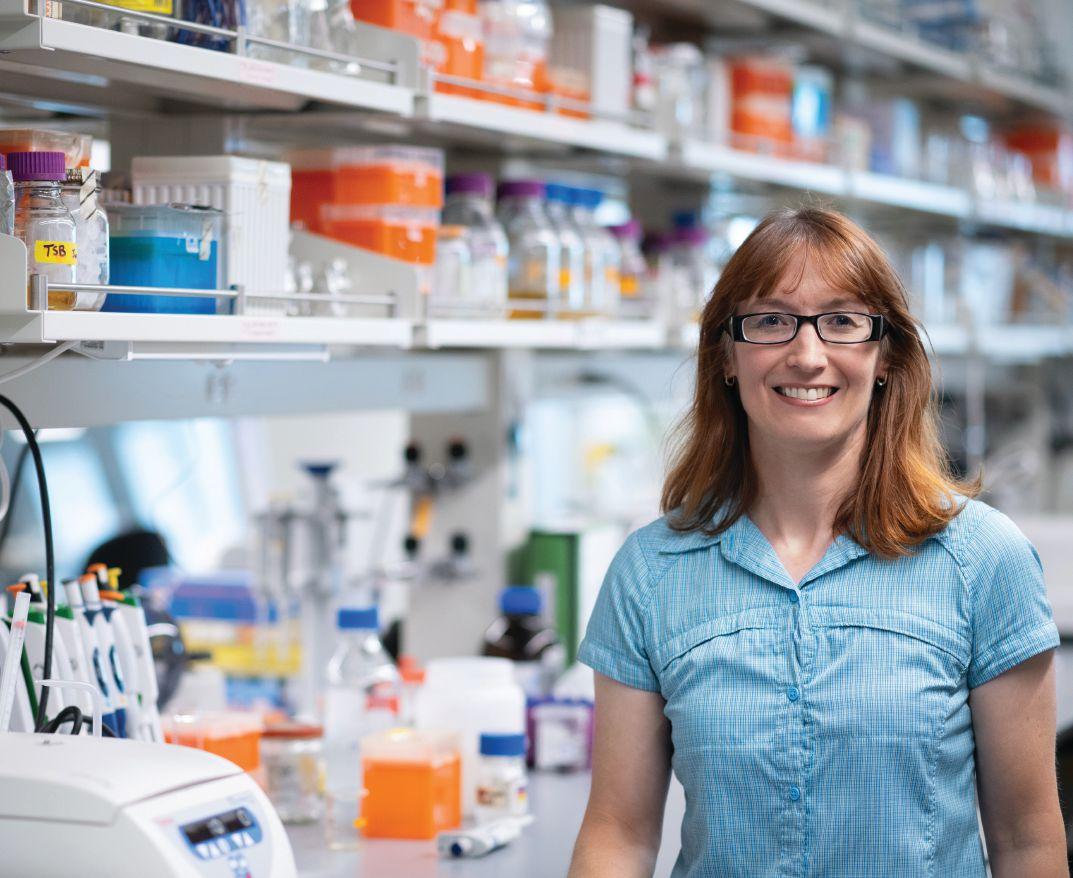

With a number of experts studying the problem, the hope is that we will figure out a way to control the disease sooner rather than later. Although scientists like Dr. Dawn Bignell, professor of microbiology in the department of biology at Memorial University of Newfoundland are looking at the cause of common scab and how to control it, she notes that the solution is part science and part luck.

“It depends on where the research takes us,” says Bignell, “and

unfortunately, there can be a bit of luck when it comes to research and finding solutions.”

A daunting challenge

Common scab has proven to be a tough nut to crack, and Bignell, who is one of many researchers trying to solve the problem, has been working for decades on a solution with the support of the Natural Sciences and Engineering Research Council of Canada.

“I started my own research lab here at Memorial University in 2010, and have been working on the pathogens that cause common scab since then,” she says. “But I actually started working on the problem back in 2006 when I was at Cornell University, so I’ve been working on this for almost 20 years.”

As a microbiologist, Bignell has been studying the characteristics

ABOVE: Symptoms of common scab disease on a potato tuber.

PHOTO

of the Streptomyces bacteria that cause the disease. Although there are many species of this bacteria, the vast majority aren’t a problem. “Since only a small number of species cause the disease, we want to know what makes these particular species pathogenic, and the other species not pathogenic,” she says. “So that’s actually the big question that we’re working on now.”

Streptomyces bacteria are naturally found in all types of soils all over the world, and the bacteria are essential to maintaining the health of the soil. The goal is not to totally eradicate these microbes so that potatoes will never have to contend with common scab, but to learn how to better control the disease, or at least, how to reduce the severity of the disease.

The many years of research have led Bignell and other researchers to a few key conclusions. “The majority of the pathogens make a toxin called Thaxtomin,” she says, “And this plant toxin causes the development of common scab lesions.”

The presence of Thaxtomin has been known for years, Bignell

explains, but more recent research points to the conclusion that this toxin doesn’t work on its own. “There’s evidence from my lab, as well as other researchers, that suggests that it’s not just this toxin,” says Bignell. “There are other factors that pathogens make, and that non pathogens either don’t make, or don’t make the right combination of these factors. So my research is looking at these factors that in addition to Thaxtomin allow these particular species to infect a plant and induce the symptoms that are ultimately associated with the disease.”

These factors, explains Bignell, also may play a part in the type of lesions common scab can cause. “There are upwards of 15 different species of Streptomyces that cause the disease,” she says, “and we know that the lesions can be varied. Sometimes they’re just superficial, sometimes they’re raised and corky, and sometimes they’re deep-pitted and they actually create holes in the potato.

“For the longest time, we didn’t really know why we saw all these differences, but now we think that it’s the particular species of Streptomyces that happens to be in a given field, along with the

Jugs, drums & totes need to be rinsed; bags* need to be empty. Please prepare them properly so they can be accepted.

Year a er year, Canadian farmers are keeping more ag plastics out of landfills.

Bring your empty and rinsed pesticide and fertilizer jugs, drums and totes for recycling; as well as seed, pesticide and inoculant bags for responsible disposal*.

*Bag collection program currently available in AB, SK, MB.

Most Alberta & Manitoba jug collections are now at retail; please use QR code to find out where.

2025 COLLECTION SITES OPEN APRIL 1

info@cleanfarms.ca @cleanfarms

Find a collection loc ation near you at cleanfarms.c a

factors that they’re producing, that might be contributing to the specific symptoms we’re seeing.”

This important piece of the puzzle will help researchers as they continue to look for solutions. “If we’re seeing a particular symptom in a particular field, then it might be because we have a certain species of Streptomyces, producing certain factors that result in certain lesions,” Bignell says. “Understanding what exactly we’re dealing with will ultimately help us understand how to control the disease, or at least minimize the severity of the disease.”

Mitigating factors

While the Streptomyces bacteria that causes common scab are found in soils all over the globe, they don’t affect all potatoes equally.

“Depending on the variety,” says Bignell, “You will see a variation in the severity of the disease. Certain varieties, like Russet Burbank, are more resistant. However, given the right conditions, and if you have particularly aggressive pathogens present, you will still get the disease, even on resistant varieties.”

In short, there’s no potato variety that is completely resistant to the disease. Bignell says that there’s a lot of research in this area, and that scientists are trying to develop varieties that could be completely resistant to common scab, but even then, that might not be the answer to this problem either.

“We still don’t know whether those varieties would have the desired characteristics that people are looking for in a potato,” she says. “That’s another question altogether.”

Currently, we know that some potato varieties are very susceptible to common scab, while others get the disease, but it’s not as severe. That said, even potato varieties that are known to be resistant to the disease can get a more severe version of it when the weather is particularly warm and particularly dry, Bignell explains.

“The lesions only develop when the tubers themselves are developing,” she says. “So if you have a warm and dry summer, particularly during the stage when the tuber is developing, then that can be a problem. That’s why one of the traditional management strategies for the disease has been to keep the soil moisture above a certain level during that development period.”

Soil pH levels

“Soil pH is another factor that plays a part,” she says. “When the soil is more neutral to basic, that promotes common scab. So, one of the control measures that has been suggested is to drop the pH of the soil, which will suppress scab. However, my understanding is that this can also impact the growth and development of the plant and the tubers themselves, so it’s not a very feasible control strategy.”

Although acidifying the soil sounds like a plausible solution, Bignell warns that it may not always work because some Streptomyces bacteria thrive in a more acidic environment. “We have to keep in mind that we have different species that cause scab,” she says. “In Maine, for example, they were acidifying the soils, and all of a sudden they were seeing more scab developing. As it turns out, they had a different species of Streptomyces that just so happened to be resistant to acidic conditions.”

Microbe warfare and chemical treatment

Another strategy researchers are looking at is biological control, which means using other microbes to suppress the scab-causing

pathogens that are in the soil. “There’s a lot of research in this area,” says Bignell, “but as far as I’m aware, there’s nothing that has been brought to market yet that has been proven to work. It’s one thing to do tests in a lab and in a greenhouse with promising results, and quite another to do them out in the field.”

Spraying the field with chemicals that would kill the bacteria is another avenue that may initially sound like a viable idea, but comes with a myriad of other issues. “The chemicals are not environmentallyfriendly,” says Bignell, “And it doesn’t always work. Most chemicals are fungicides, and these are not fungi—these are bacteria.

“The other issue is that you don’t want to use chemicals that would kill everything that is in your soil, including the non-pathogenic Streptomyces, because these are actually beneficial organisms. So, it’s very hard to find something that would specifically target the pathogens and not kill off everything else.”

Know your microbes

While it isn’t easy to control common scab disease, Bignell notes that it would likely be useful for potato producers to get their soil analyzed so that they know what kind of Streptomyces bacteria

they’re dealing with.

“There is increasing evidence that knowing what’s in a particular field is important,” she says, “So you’d want to work with researchers who can test your soil. The hope is that down the road, we might be able to tell you that your field has this particular species present, and that these control measures have been shown to work better for this particular species versus a different species. So I think really knowing what’s in the field in the first place is very important.”

She offers the example of Streptomyces bacteria that thrive in acidified conditions vs. those that don’t. Knowing which one is present in a field can help potato producers determine whether it’s worthwhile altering the pH of their soil or not.

“Beyond that,” says Bignell, “I don’t think we’re there yet, to be honest. But maybe that’s where biological control can come into play. I mean, down the road, there could be certain biological control agents that work particularly well against one Streptomyces scab pathogen, and another type of agent that works maybe better against another pathogen. There could even be formulations that will control a broader group of pathogens. But we’re not there yet, unfortunately.”

Dawn Bignell is a professor of microbiology who is studying the bacterial pathogens that cause common scab disease.

PHOTO

The rise of smart farming in Canadian potato production. GUEST COLUMN

LUKIE PIETERSE. CONTRIBUTOR

EMBRACING TECHNOLOGY

The global agricultural sector is undergoing a technological revolution, and Canadian potato growers are no exception. Challenges in weather patterns, labour and a rising demand for sustainable practices are prompting growers to turn to smart farming tech to transform their operations.

Canadian potato growers are indeed at the forefront of agricultural innovation, increasingly adopting smart farming technologies to enhance productivity, reduce environmental impact, and address labour shortages. Here are just some of the ways Canadian growers are staying competitive in the global market.

Precision agriculture: Optimizing input usage

Precision agriculture tools are becoming indispensable for Canadian growers looking to maximize efficiency and reduce waste. GPS-guided tractors and variable-rate application (VRA) technology allow farmers to apply fertilizers, pesticides, and water precisely where and when they are needed. This not only reduces input costs but also minimizes environmental impact.

McCain Foods has established a “Farm of the Future” in Florenceville, NB. This farm utilizes precision agriculture techniques, including GPS-guided equipment and variable-rate technology, to optimize input application. By implementing precision soil mapping and monitoring, McCain aims to improve yield efficiency and reduce environmental impact.

Drones: Eyes in the sky for crop health

Drones are becoming increasingly common in Canadian potato fields, offering a bird’s-eye view of crop health. Equipped with multispectral cameras, drones can detect issues like nutrient deficiencies, pest infestations, and water stress before they become visible to the naked eye.

Cavendish Farms in P.E.I. has integrated drone technology into its farming operations. Equipped with multispectral cameras, these drones conduct aerial surveys to assess crop health, identify pest infestations, and monitor nutrient deficiencies. The real-time data collected allows for timely interventions, enhancing crop management and yield outcomes.

IoT sensors: Real-time monitoring

The Internet of Things (IoT) is revolutionizing how growers monitor soil conditions, moisture levels, and weather data. IoT sensors placed throughout fields provide real-time data, which can be accessed remotely via smartphones or computers.

Farmers Edge, a Canadian-based agricultural technology company headquartered in Winnipeg, MB, is a leading example of IoT-

enabled innovation. Their digital platform integrates IoT devices, such as soil moisture sensors and weather stations, to monitor field conditions in real time. These sensors collect data on soil moisture, temperature, and precipitation, allowing growers to optimize irrigation schedules with precision.

Precision tools: Enhancing farm efficiency

Smart farming isn’t just about automation; it’s about using precision tools to enhance efficiency and reduce the strain of labor shortages. By integrating technologies like GPS-guided systems and data-driven mapping, Canadian potato growers are finding innovative ways to maintain productivity.

Kroeker Farms in Manitoba utilizes Real-Time Kinetics (RTK) GPS technology to achieve centimeter-level accuracy in planting, harvesting, and field operations. This precision reduces overlaps, fuel use, and labor hours, enhancing operational efficiency. Additionally, Geographical Information System (GIS) software helps map field boundaries, irrigation systems, and crop performance. These tools allow Kroeker Farms to optimize drainage and resource allocation.

The path forward

While the adoption of smart farming technologies offers immense benefits, it is not without challenges. High initial costs, the need for technical expertise and reliable connectivity in remote rural areas can be significant barriers, particularly for smaller farms.

To address these challenges, federal and provincial governments have introduced funding programs and initiatives to support the adoption of modern agricultural technologies. For instance, the Canadian Agricultural Partnership (CAP) program provides grants for technology adoption, while programs like AgriScience and AgriInnovate promote research collaborations and innovation. Some provinces have also established regional connectivity initiatives to improve internet access in rural areas, ensuring farmers can fully leverage IoT and other datadriven technologies.

By embracing these advancements, Canadian growers are not only securing their livelihoods but also strengthening the nation’s position as a global leader in potato production.