Not sure which protection is right for your team or have challenging hand safety or product questions? Ask our experts!

Submit your questions

Send us your hand safety and product questions through our online form

Get quick expert advice from a real person

Receive answers from your hand safety expert, usually within 1 business day

Ask for more help when you need it

Continue the conversation online, by phone, or at your worksite if you need more guidance

Visit superiorglove.com/ask-an-expert or scan the QR code.

BRANDI COWEN

JAMES CARELESS

TREENA HEIN

NICLAS MANSON

By Brandi Cowen, Editor

Do you have a plan to communicate with your employees and support them in the wake of a tragedy?

The question has been on my mind lately as I draft reports on workplace injuries and deaths, and their consequences.

I ’m very fortunate – I’ve never had a colleague seriously injured or killed on the job. However, I have experienced the sudden loss of a valued mentor. Though she was off the clock when she died, my employer at the time took care to promptly share the news company-wide, grant everyone the time and space they needed to process and grieve her loss, and support her department personally and professionally in the weeks that followed.

I don’t know what was happening behind the scenes, but from my perspective, the senior leadership team remained open, respectful and grounded in our shared humanity through a very challenging time. There was such grace in every communication and decision that I wondered if there was a policy outlining, step by step, who should do what, when, and how. Surely, I thought, they can’t be

making this up on the fly.

Would the leadership team have done things differently if this employee had died on the job? Of course. For one thing, the province’s Ministry of Labour, Immigration, Training and Skills Development would have been involved. The resulting investigation may have changed what information was communicated to employees and when.

Getting your response right can impact your employees, and your organization, for many years to come.

B ut I think much of the response would have remained the same because it was driven by the organization’s values: Transparency. Connection. Community.

Maya Angelou famously said, “People will forget what you said, people will forget what you did, but people will never forget how you made them feel.” That’s especially true in moments of trauma, which can affect memory formation.

When I think back on the day I learned of my mentor’s passing (a rare day off just because), I

Paula Campkin: chief safety officer, Energy Safety Canada

Marty Dol: president and founder, HASCO Health & Safety Canada

Uyen Vu: director of communications, Institute of Work & Health

Natalie Oree: prevention consultant, SAFE Work Manitoba

David Powers: EHS director (Atlantic), Sysco Canada

recall picking up my cell and seeing several missed calls from my manager. I remember being flooded with dread, as she wasn’t the type to interrupt anyone’s vacation time. I know I called her back right away, but I forget how our conversation went. I remember it ended with a moment of shared sadness and tears on both ends of the line.

The following days play out the same way in my memory. I’m left with feelings and impressions, more than concrete memories of events, announcements, or policies. What I remember most is feeling genuinely cared for by my employer. Years later, that feeling is still with me.

How much might that sense of genuine care mean to an employee who witnessed a co-worker seriously injured or even killed on the job?

This brings me back to my original question: Do you have a plan to communicate with your employees and support them in the wake of a tragedy? Perhaps more importantly, does that plan align with your organization’s values?

Getting your response right can impact your employees, and your organization, for many years to come.

Richard Quenneville: senior director of corporate services, T. Harris Environmental Management

Maureen Shaw: lecturer and presenter

Dylan Short: managing director, The Redlands Group

Suite 400, Toronto, ON M2H 3R1

EDITOR

Brandi Cowen 437-770-4370 bcowen@annexbusinessmedia.com

MEDIA DESIGNER Graham Jeffrey

ACCOUNT CO-ORDINATOR Cheryl Fisher 416-510-5194 cfisher@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Barbara Adelt 416-510-5184 badelt@annexbusinessmedia.com

BRAND SALES MANAGER Silvana Maiolo smaiolo@annexbusinessmedia.com

GROUP PUBLISHER Anne Beswick abeswick@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

ISSN 0827-4576 (Print) ISSN 1923-4279 (Digital)

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published four times per year –Winter, Spring, Summer, Fall Canada $70/yr plus tax

USA $98/yr CDN Foreign $162/yr CDN Single copy $19 CDN

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2025 Annex Business Media All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Threads of Life’s board of directors appointed Eugene Gutierrez as the organization’s new executive director, effective Jan. 15. “As a member and volunteer for Threads of Life, Eugene brings a deep understanding and great passion for our mission,” said board chair Peter Deines. “His leadership will allow us to position ourselves for the future and further grow the reach and impact of our organization.”

Threads of Life – the Association for Workplace Tragedy Support is a national Canadian charity that provides peer support programs to individuals and families affected by work-related fatalities, serious injuries and occupational disease. Threads of Life is passionate about working to prevent future tragedies.

The search for a new executive director had been underway since the previous executive director and founder Shirley Hickman announced her intention to retire back in August 2024.

Along with other families personally affected by workplace tragedy, Hickman established Threads of Life in 2003. Hickman’s 21-year-old son, Tim, died after an explosion at the arena where he worked part-time.

Gutierrez has also been personally affected by workplace tragedy, having lost his father, Bot, to a workplace fatality.

“Threads of Life has played a major role in the healing journey for myself and my family after my dad’s death,” Gutierrez said. “I am deeply honoured to step into this new role and continue the vital work of this organization. I am committed to helping Threads of Life grow and expand its reach to serve all who need this support.”

Study reveals we’re at a turning point for head protection

54 per cent of safety managers who reported training workers on how to maintain their head protection.

J. J. Keller & Associates, Inc., a provider of safety and compliance solutions, and the International Safety Equipment Association (ISEA) recently joined forces to conduct a comprehensive study on head protection practices and challenges – and there are some big ones.

Key findings from the study include:

• Head protection terminology is unclear in the market today. While most safety professionals responding to the study expressed confidence that they understood various head protection terms, research revealed significant confusion and over-simplification in the differences (and similarities) between hard hats and helmets.

• Safety managers experience multiple pain points when it comes to managing head protection. With more options for head protection than ever before, safety managers find themselves navigating a more complicated decision-making process. They are challenged to get employees to consistently wear head protection. They’re also challenged to find head

protection that is comfortable for all workers.

• Care and maintenance of head protection needs improvement. Only 54 per cent of responding safety managers reported training workers on how to maintain their head protection.

• Standards organizations, manufacturers and other experts have an opportunity to educate the industry. These groups can provide safety managers with clarity, guidance and education to address the evolving landscape of head protection.

“Head protection has been a cornerstone of workplace safety for decades,” said Cam Mackey, president and CEO of ISEA.

“While the growing variety of head protection options provides greater choice, it has also introduced some confusion for safety professionals and workers. Addressing these challenges head-on and clarifying the most effective solutions and standards will ensure better protection and safety for all.”

The results of the study, titled “A Turning Point for Head Protection,” can be downloaded from www.jjkellersafegear.com.

The Canadian Centre for Occupational Health and Safety (CCOHS) has launched a new online portal to help small- and medium-sized businesses across Canada meet their health and safety responsibilities.

The Business Safety Portal offers an accessible, scalable, low-cost solution to help owners and employers understand their legal obligations for protecting workers from injuries and illnesses and keep up to date with their health and safety policies, training, and other regulatory requirements.

“Small to medium-sized businesses represent one of the largest employer groups in the country, and many do not have the tools they need to keep their workers safe,” said Anne Tennier, president and chief executive officer of CCOHS. “We wanted to address their specific needs with the Business Safety Portal to make it easier for them to build a safe and healthy workplace culture.”

The portal provides businesses with health and safety guidance specific to their industry and location, and templates and checklists to guide them through identifying health and safety hazards and concerns, assessing the risks to their workers, and developing policies and programs to help protect them. Annual subscriptions to the portal start at $100.

More information about the Business Safety Portal is available at www.ccohs.ca/product/business-portal.

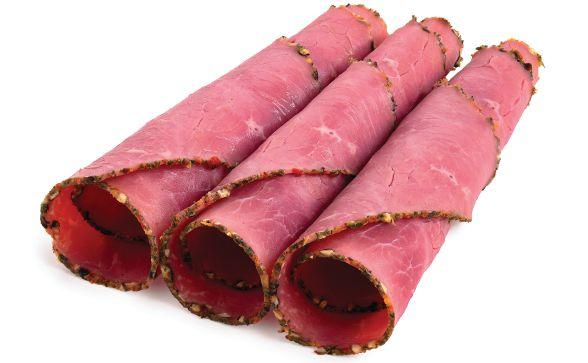

A commercial food processing company is facing 26 charges after an Edmonton worker became trapped in a smokehouse and died. Ontario-based Sofina Foods Inc. is charged with offences under Alberta health and safety laws.

charges a food processing company is facing after a worker’s death

The province says the facility supervisor had gone to check the temperature of the smokehouse in March 2023 and was trapped inside.

The employee was found by a co-worker and later died due to heat exposure.

It’s alleged the company failed to ensure the smokehouse was well maintained and not a risk for staff.

Sofina Foods said in a statement it has co-operated fully with the

provincial investigation and called the death a “deeply saddening accident.”

“Our people are the heart of our business, and our plant superintendent, Samir, was an important part of our Sofina family,” the statement said.

“His passing profoundly affected his family, our team, and our community. We continue to be concerned for them and their well-being.”

Smokehouses are used to process and preserve meat.

The company said that because the matter is before the courts, it would not be commenting further at this time.

-The Canadian Press

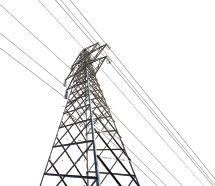

Five workplace safety charges have been laid against New Brunswick Power in the death of power line technician Colin Hume.

The 47-year-old man died while doing restoration work after a snow storm two years ago, when a power pole broke while he was working on the line.

WorkSafe NB alleges that N.B. Power failed to provide necessary instruction to ensure employee safety while removing ice from power lines, failed to provide training on clearing ice from power lines and failed to take every reasonable precaution to keep workers safe.

Charges filed in Moncton provincial court also allege the utility failed to prepare a written transportation process for injured or ill workers, and did not provide a first aid kit at the place of employment.

Nominations are now open for the 2025 OHS Canada Honours, celebrating excellence in workplace safety. The prestigious awards program recognizes individuals and teams for their outstanding contributions to occupational health and safety and their commitment to creating safer workplaces.

“The health and safety community is tasked with a daunting job: helping every worker return home at the end of the day,” said Anne Beswick, group publisher for OHS Canada. “We’re inspired by the dedication, innovation and creativity demonstrated by the OHS Canada Honours nominees year after year, and I’m confident 2025 will be no different.”

This year’s awards program will feature five new team awards:

• Best Eye Protection Program

• Best Head Protection Program

• Best Hearing Protection Program

• Best Heat Protection Program

• Best Cold Protection Program

Nominations are open to anyone in Canada who meets the criteria for individual awards, as well as companies and teams demonstrating OHS success for team awards. Detailed eligibility information is available at ohscanada.com/ohs-canada-honours.

All nominations must be received by 11:59 p.m. EST on Sunday, June 8.

The winners will be recognized during a gala celebration at Palais Royale in Toronto on Sept. 25. Details about the gala will be released later this year.

Study shows injured workers have higher rates of opioid poisonings than the general public

5new categories added to the OHS Canada Honours awards program for 2025

People who previously experienced a work-related injury are more likely to experience opioid poisonings and other opioid-related harms than the general population, according to new research from the Institute for Work & Health (IWH) and the Occupational Cancer Research Centre (OCRC).

The study used data from 1.7 million Ontario workers who had an accepted lost-time workers’ compensation claim between 1983 and 2019.

It found higher rates of opioidrelated harms in this group of formerly injured workers than in the general population. Opioidrelated harms refer to poisonings and mental and behavioural disorders, such as those related to withdrawal and dependence.

Compared to the general working-age Ontario population, emergency department visits for opioid poisonings were 2.4 times higher among formerly injured workers in the Occupational Disease Surveillance System (ODSS); hospitalization rates were 1.5 times higher.

Within the sample of injured workers, several occupational groups had greater risks of opioidrelated poisonings. These included construction (57 per cent higher),

forestry and logging (45 per cent higher), and materials handling (32 per cent higher).

In some groups, higher risks were found only in specific occupations, including nursing aides, janitors and cleaners, and security guards.

“Our results suggest that workrelated injuries are associated with increased future risk of opioid harms,” said Dr. Jeavana Sritharan, OCRC scientist and co-author of a pair of peer-reviewed journal articles on the study. The first paper was published in April 2024, in the Canadian Journal of Public Health ; the second was published in October 2024 in Occupational and Environmental Medicine.

“Part of the reason may be that workers in physically demanding jobs make up a disproportionate share of injured workers,” said Dr. Nancy Carnide, IWH scientist and study co-author. “But part of the reason may also be related to the experience of being injured and recovering from a work injury.”

The study drew on the ODSS, which links records from the Workplace Safety and Insurance Board with healthcare data to identify hospitalizations and emergency department visits for opioid-related harms that occurred from 2006 to 2020.

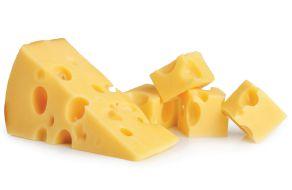

Saputo Produits Laitiers Canada

S.E.N.C. / Saputo Dairy Products Canada

GP has been fined $79,500 after a worker was injured while attempting to clean equipment at its facility in Woodbridge, Ont.

On June 4, 2023, the worker was cleaning and sanitizing equipment used to process and package various cheese products.

The fixed-in-place guards, designed to prevent worker access to in-running nip hazards, were removed from a conveyor to allow the worker access to all parts of the machine for cleaning.

While attempting to clean waste cheese particles that were stuck in the groove of a conveyor drive roller, the worker was critically injured. The conveyor had been running while the worker was cleaning it.

A Ministry of Labour, Immigration, Training and Skills Development investigation found that the worker would not have been injured had the conveyor been equipped with a guard to protect the worker from accessing the in-running nip hazard.

Saputo pleaded guilty to failing, as an employer, to ensure the measures and procedures prescribed by section 25 of the Regulation for Industrial Establishments were carried out in the workplace, contrary to section 25(1)(c) of the Occupational Health and Safety Act.

In addition to the $79,500 fine, the court imposed a 25 per cent victim fine surcharge as required by the Provincial Offences Act The surcharge is credited to a special provincial government fund to assist victims of crime.

$100,000

fine imposed on Rite Way Mfg. Co. Ltd. after a worker was seriously injured by a suspended piece of metal

On Dec. 11, 2024, Saskatchewan Health Authority pleaded guilty in Rose Valley Provincial Court to one violation of The Occupational Health and Safety Regulations, 2020. The company was fined for contravening subsection 16-5 (1) of the regulations (being an employer fail to ensure that every ladder is designed, constructed, used and maintained to perform its function safely, resulting in the serious injury of a worker).

As a result, the court imposed a fine of $53,571.43 with a surcharge of $21,428.57, for a total amount of $75,000.

One other charge was withdrawn.

The charges stemmed from an incident that occurred on May 11, 2023, in Kelvington, Sask., when a worker was seriously injured when they fell from a stepladder.

On Nov. 12, 2024, Rite Way Mfg. Co. Ltd. pleaded guilty in Regina Provincial Court to one violation of The Occupational Health and Safety Regulations, 2020

The company was fined for contravening subsection 13-3 (1) of the regulations (being an employer fail to ensure that every lifting device, including all rigging, used at a place of employment is designed, constructed, installed, maintained and operated to perform safely any task for which the lifting device or rigging is used, resulting in a serious injury to a worker). As a result, the court imposed a fine of $71,428.57 with a surcharge of $28,571.43, for a total amount of $100,000.

Three other charges were withdrawn.

The charges stemmed from an incident that occurred on Jan. 2, 2023, in Regina; a worker was seriously injured when they were struck by a suspended piece of metal.

General Coach Canada has been fined $60,000 after a worker was critically injured by an unshielded saw blade.

The company, which is based in Hensall, Ont., and manufactures and assembles park model and house trailers, pleaded guilty to failing to ensure the saw was equipped with its shield and a riving knife as required by section 24 of Ontario Regulation 851/90. As such, the company breached its duties as an employer under section 25(1)(c) of the Occupational Health and Safety Act

On April 20, 2023, a worker was cutting a piece of melamine using a table saw. The protective shield that goes over the saw blade, preventing inadvertent contact with the blade, was missing when the worker was critically injured.

Following the incident, and an investigation by the Ministry of Labour, Immigration, Training and Skills Development, General Coach Canada installed the protective shield on the saw, as well as a riving knife.

In addition to the $60,000 fine, the court imposed a 25 per cent victim fine surcharge as required by the Provincial Offences Act. The surcharge is credited to a special provincial government fund to assist victims of crime.

On Oct. 31, Saskatchewan Power Corporation was sentenced in Prince Albert Provincial Court regarding one violation of the province’s The Occupational Health and Safety Regulations, 2020.

The corporation was charged with contravening subsection 30-16 (4) of the regulations (fail to ensure that no worker works and no equipment is used or operated within the minimum distance from any exposed energized electrical conductor set out in column 1 of table 19 of the appendix, resulting in the serious injury of a worker).

One additional charge was withdrawn.

The Court imposed a fine of $500,000 with a surcharge of $200,000, for a total amount of $700,000.

The charges stemmed from a worksite incident that occurred on May 9, 2022, near Sandy Bay, Sask., where a worker was seriously injured when exposed to a high voltage of electricity.

The fine comes shortly after Saskatchewan Power Corporation was fined $840,000 following the deaths of two workers in Weyburn, Sask., on Oct. 8, 2020. The workers were fatally injured when they fell to the ground from the bucket of a bucket truck.

24_014609_OHS_Canada_Winter_CN Mod: December 27, 2024 2:01 PM Print: 01/06/25 page 1 v2.5

The Canadian Centre for

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well-being – physical, psychosocial, and mental health – of

in Canada by providing information, advice, education, and management systems and solutions that support the prevention of injury and illness. Visit www.ccohs.ca for more safety tips.

Is your workplace setting the standard for civility? A lack of civility and respect often lies at the root of workplace issues such as violence, harassment, and bullying. Without proactive steps, even a seemingly healthy workplace can develop a toxic culture filled with resentment, rudeness, and hostility. The good news? With the right approach, you can foster a culture of respect and civility that benefits everyone – and directly contributes to workplace safety.

In a respectful workplace, everyone interacts with courtesy, care, and consideration. This behaviour extends to customers, clients, and the public. For workers, a civil environment enhances job satisfaction, perceptions of fairness, and overall morale. Organizations benefit too, with improved teamwork, stronger supervisor-staff relationships, and reduced absenteeism and turnover. Respect and civility reduce the likelihood of conflicts escalating into unsafe situations.

B uilding this kind of workplace requires intention, commitment, and daily practice. Civility is not just a moral responsibility but also necessary to ensure a safe and thriving organization. So, how can you make respect and civility the standard? Here are twelve actionable tips to help.

What exactly does civility mean in your workplace? Workers need to be able to reference a clear definition, which can also provide the basis for a policy or code of conduct that outlines the employer’s expectations for respectful and civil behaviour. Include examples of both positive

and negative behaviours to ensure clarity. For instance, speaking politely, listening actively, and avoiding gossip or sarcasm. If your workplace works with clients or members of the public, also include expectations for their behaviour when interacting with your organization.

Encourage workers to participate in creating the code of conduct so that it reflects the team’s shared values. Regularly revisit this commitment during meetings or performance reviews to reinforce its importance. A well-developed code serves as a constant reminder of the organization’s dedication to a civil and respectful work environment. Host team discussions or workshops to explore what respectful behaviour

looks like in everyday interactions. A shared understanding sets the foundation for accountability and growth while reducing potential safety concerns that could result from misunderstandings or interpersonal conflicts.

3. Train and develop

Provide training and resources that emphasize respectful workplace behaviours. Topics might include active listening, constructive feedback, conflict resolution, anger management, recognizing unconscious bias, and strategies for dealing with difficult customers. Equip everyone to recognize and address uncivil behaviour effectively, with the confidence that your workplace policy or code of conduct supports them. Leadership training should

also focus on modelling respect, creating an inclusive environment, and conflict management strategies that maintain the dignity of everyone involved. These efforts help everyone de-escalate potential conflicts before they become an issue.

4. Incorporate respect and civility in your communications

Adopt non-discriminatory language in all forms of communication. Respect workers’ privacy by maintaining the confidentiality of personal information. To ensure accessibility, make communications easily available through handbooks, bulletin boards, or online platforms. A respectful tone in communication helps set the standard for interactions and reduces potential for misunderstandings that could lead to unsafe situations.

5. Be a role model

Leaders set the tone for workplace behaviour. Managers and supervisors should receive training on respectful leadership practices and commit to being present and engaged with their teams. Leaders who actively promote respect, practice fairness, and address issues promptly are better equipped to de-escalate conflicts and maintain a psychologically safe environment.

6. Be considerate when you speak

Humour in the workplace can take many forms. Not all of them are appropriate, nor are they appreciated by everyone. Before making a joke, pause to consider your audience. Is the joke at someone else’s expense? Could it be embarrassing or demeaning? If the answer is yes to any of these questions, don’t share the joke! Also consider how unconscious bias might affect the way you talk about a person or a group of people. Are you perpetuating stereotypes? There are plenty of ways to keep things light without potentially dehumanizing others. Incorporating unconscious bias education into your training program can help everyone recognize jokes or statements that might be at the expense of others.

7. Be inclusive

Be courteous and friendly – these actions

A respectful tone in communication helps set the standard for interactions and reduces the potential for misunderstandings that could lead to unsafe situations.

foster a positive working culture. Find out how co-workers would like to be addressed. Learn and use preferred names or pronouns and avoid nicknames or labels that could come across as patronizing. Everyone wants to be recognized and have a sense of belonging, so look for opportunities to include others that you may not generally socialize with by asking for their input, inviting them to lunch, or acknowledging their birthday. Bridging social barriers and discovering common ground with your colleagues can be rewarding and improve job satisfaction. Make a conscious effort to include everyone, particularly those who may feel isolated. Inclusivity also reduces feelings of alienation, which can contribute to workplace tensions.

8. Give your full attention

Respect begins with active listening and undivided attention. In meetings or conversations, avoid distractions like checking your phone or multitasking. Notify others if you’ll be late for a meeting to show consideration for their time. By being present, you demonstrate that everyone’s contributions are valued. Attentive communication can also reduce the risk of misinterpretation, which can lead to unnecessary tension or conflict.

9. Use respectful language

Please. Thank you. Excuse me. I’m sorry. Use these words regularly to establish civility. Express appreciation to co-workers for their help, avoid interrupting others when they are speaking, and apologize sincerely if you have mistakenly offended someone. These seemingly small gestures all help to contribute to a culture of respect.

10. Say hello

It costs nothing to offer a simple acknowledgement of co -workers. Next time you’re passing a colleague in the hallway or see them in the lunchroom, acknowledge them by saying hello. Courtesy is infectious and can help boost morale. Positive daily interactions can also reduce the emotional tension that sometimes leads to a psychologically unsafe environment.

11. Celebrate successes

G ive others credit when they do a good job. By recognizing the achievements of others, you can contribute to building a culture of generosity and trust, while allowing others to share in the satisfaction of a job well done. Recognizing successes in the workplace helps everyone feel valued and appreciated, which strengthens team cohesion. A cohesive team is more likely to communicate effectively and resolve issues peacefully.

12.

I gnoring inappropriate behaviour can erode workplace culture and compromise safety. Establish clear policies that outline expectations and consequences for violations. Encourage open, constructive problem-solving and address conflicts promptly. Follow up with all parties involved to ensure resolution and prevent any recurrences. For example, implementing a formal complaint process with defined timelines for resolution can reassure workers that their concerns are taken seriously, reducing the likelihood of any retaliatory or unsafe actions.

C reating a culture of respect and civility doesn’t happen overnight, but small, consistent actions can have a profound impact. More than a nicety, civility is a critical factor in maintaining a safe and harmonious workplace. Simple gestures like active listening, thoughtful communication, and inclusive practices go a long way toward making everyone feel safe, valued, and respected. By prioritizing civility, you can help foster a healthier, more productive workplace where everyone thrives

As Canada’s standardization needs evolve, CSA Group is helping shape solutions that address critical gaps across industries. With a commitment to enhancing the lives of Canadians, CSA Group continues to advance standards in both public and private sectors. Looking ahead to 2025, the organization is set to expand into emerging industries and take on new challenges while strengthening its leadership in occupational health and safety.

In this forward-looking Q&A, CSA Group’s Inga Hipsz shares her vision for the year ahead, offering insights into the organization’s strategies for identifying opportunities, fostering collaboration, and delivering impactful results that will shape the future of standards in Canada.

I am the vice-president of standards, strategic development at CSA Group. Our team plays a key role in identifying standardization gaps where CSA Group can help address sector challenges for the benefit of Canadian society. These sectors either lack their own standards or have been relying on international standards to guide their work. Oftentimes, homegrown standards or Canadianspecific content is required to better address national needs. Expanding into new sectors involves extensive research, active engagement, and attentive listening to various groups within the sector, each of whom may hold differing perspectives. It also requires securing industry support and forming new technical committees of external subject matter experts.

How does CSA Group identify and prioritize the topics that need new or updated standards?

We must first determine whether a potential sector aligns with CSA Group’s mission and assess whether there is a need for our support across jurisdictions in Canada. There also must be an urgency from the industry and the appropriate levels of government to confirm the readiness for them to develop and adopt these solutions.

As part of CSA Group’s standards development and public policy efforts, we regularly collaborate with external subject matter experts to create research reports and papers that explore the needs and applications of standards, focusing on how they can positively impact Canadians. These documents often serve as catalysts for discussions in workshops. We also prioritize gathering input not only from experts but also from various interest groups that may be affected by a new or updated standard.

What are some emerging trends or risk areas that CSA Group is currently focused on for 2025?

We remain deeply committed to occupational health and safety (OHS) for our employees, members, and Canadians from coast to coast to coast. In every new sector we have explored, addressing OHS – whether through existing standards or new developments – has been essential. While our current OHS standards have made a significant impact, there is room to do more, including providing specific guidance on emerging topics like psychological health, workplace violence, cybersecurity, personal protective equipment, and

CSA Group is a global organization dedicated to safety, social good and sustainability. It is a leader in standards development and testing, inspection, and certification around the world, including in Canada, the U.S., Europe and Asia. CSA Group’s mandate is to hold the future to a higher standard.

CSA Group is currently developing a suite of transit and passenger railway operational safety standards, including a national framework for key safety indicators.

extreme working conditions.

In 2025, we will focus on expanding our newest sectors: transit and passenger rail, and agriculture and agrifood. While these sectors are not obviously OHS-related, several key projects will contribute to future OHS advancements. Notably, we are developing a suite of transit and passenger railway operational safety standards, including a national framework for key safety indicators. We are also addressing the issue of violence on transit systems by collaborating with partners from the transit sector to define critical safety and security indicators, with the hope of establishing consistent data collection methods to better understand and address this growing concern.

What is CSA Group’s vision for the future of occupational health and safety standards?

The increased harmonization of federal, provincial, and territorial regulatory references to Canadian OHS standards is essential to help promote labour and equipment mobility, and to ultimately set a consistent, standardized level of worker safety across Canada. Currently, only 13 of CSA Group’s 244 expert-approved and published OHS standards are harmonized by all Canadian jurisdictions, which means that different regions can set and apply different rules. This can be inefficient, confusing, and risky to workers and organizations alike. To address national OHS issues in a

uniform way, it is important to get all regions to agree to use the same OHS standards. To support this, CSA Group liaises regularly with the Canadian Association of Administrators of Labour Legislators –Occupational Safety and Health (CAALL-OSH), which is leading the effort to increase regulatory harmonization of standards.

We are also continuously strengthening and updating the existing CSA Group OHS standards portfolio by considering leading practices, technological advancements, material science developments, lessons learned from industry experiences, and new research results. Additionally, we are enhancing our standards to address the needs

of workers in various contexts. These include a changing climate, increasing preparedness and resilience, workplaces undergoing energy transitions, the growing digital and AI space, an aging workforce, new and developing sectors, accessibility, mental health, and a country with a growing diversity of population, including in the areas of gender, ethnicity, and cultural and religious beliefs.

OHS professionals will continue to be integral to the development and evolution of OHS standards. They actively participate in standard drafting committees, provide valuable feedback during public reviews and after publication, and contribute to research that informs standards updates. Their expertise helps standards remain relevant and effective, addressing emerging safety challenges and incorporating new technological advancements. This collaborative effort helps shape a safer future for all workers.

How does CSA Group measure the impact of its standards?

C SA standards help make workplaces and communities safer. Hundreds of CSA OHS safety standards are referenced by industry and government in business practices, regulations, and legislation. This contributes to an overall decrease in workplace accidents and injury claims. In fact, injuries and lost time claims decreased by 33 per cent between 2000 and 2020. This decrease translates into the prevention of some 393,000 workplace incidents every year, according to the Association of Workers’ Compensation Boards of Canada. OHS legislation that uses updated, evidenceinformed and relevant standards does more than promote safer workplaces, it creates greater efficiencies, increasing overall productivity across the economy.

By Era Poddar, PhD, CCPE

Human factors, also known as ergonomics, is an integral part of any design, be it a system or a single product. When applied effectively, this unique discipline can significantly reduce human error and prevent injuries, while increasing productivity and quality. However, since its inception during WWII, only a few associated professionals outside the human factors and ergonomics (HFE) community have been aware of the discipline’s breadth of application.

We constantly interact with products and systems with built-in HFE concepts, often without realizing it. For example, smartphones are designed to fit comfortably in the average user’s hand and offer touchscreen interfaces that minimize the need for precise physical effort. The position of buttons, display size and colour, and weight of these devices all account for how people interact with them for extended periods, with the aim of avoiding repetitive strain injuries and excessive hand fatigue, and reducing errors. Similarly, car seats and the various controls we regularly interact with account for HFE concepts. The seats are designed with adjustable positions, recline options, and lumbar support to ensure comfort for drivers and passengers of various sizes. The placement of controls like the steering wheel, dashboard, and pedals is optimized for easy access without overextending or straining. The design accounts for differences in body size and driving posture, as well as how people use controls to drive safely and efficiently.

seeks to understand how humans interact with other elements of a system, such as a workplace.

The fact is, HFE is all around us, but awareness of the concepts outside the professional community remains low, despite being critical to human well-being and performance.

E rgonomics, often defined as the science of designing the workplace (i.e., system) and its components to fit the workers’ or users’ needs, plays a crucial role in almost every setting. The acronym HFE reflects both human factors and ergonomics, which are used interchangeably as they have the same aims.

According to the International

Ergonomics Association (IEA), “Human factors and ergonomics (HFE) is concerned with the understanding of interactions among humans and other elements of a system. It is the profession that applies theory, principles, data, and methods to design and optimize human well-being and overall system performance. Practitioners contribute to the design and evaluation of tasks, jobs, products, environments and systems to make them compatible with the needs, abilities and limitations of people.”

In any setting, HFE directly influences worker safety, productivity, and the quality of the product.

Where are we now?

Recent rapid changes in technologies (i.e., Industry 4.0, robotics and artificial intelligence) and workplaces, including the shift to hybrid work, emphasize the importance of a collective, proactive understanding of HFE to maintain human wellbeing and performance.

There are numerous regulations across the globe ensuring employees get support on workplace ergonomics issues when they need it. However, most of the time, the approach is reactive rather than proactive. That means an HFE professional is called in when a problem has already occurred. But as a 2015 study published in the Journal of Construction Engineering and Management established, including HFE in the early design phase reduces overall costs and improves operational safety and operator well-being. Hence, controlling the problem at the root level becomes challenging when attempted retroactively. This shows there is still much to do to enhance the understanding of HFE and its proactive application.

In Canada, the Association of Canadian Ergonomists – Association canadienne d’ergonomie (ACE) is dedicated to advancing HFE through a multidisciplinary, collaborative approach.

What are other countries doing?

The IEA is an international federation of HFE societies and networks. It encourages building networks where member societies work together to achieve mutual aims. ACE is an IEA member society.

Recently, at an IEA conference held on Jeju Island in South Korea, HFE professionals from all over the world met over five days to discuss progress in the field, share scientific excellence around HFE research, and learn from each other. The

Spreading the concept of ergonomics beyond the dedicated HFE community requires strategic communication, effective outreach, and practical engagement with various audiences.

triennial congress showcased technological brilliance, and also presented several sessions to strategize the future development and direction of the field.

In a special panel called “Bringing ergonomics and human factors beyond the ergo-community,” the discussion explored strategies for extending the HFE concept beyond HFE professionals. National federated societies from countries including Canada, Australia, the U.K., the U.S., Sweden and Chile shared their strategies on this topic. All the member societies recognized a tangible gap between what we know about HFE and the practical application of this knowledge at the government, industrial, and operational levels.

Interesting ideas and strategies emerged from this session, and one key factor repeatedly emphasized was effective communication! Think diverse communication channels like podcasts, articles, public seminars, and videos directly addressing HFE and its use in business. Integrating HFE courses into the curriculum of associated disciplines (i.e., design, allied health) and offering consultations as subject matter experts in various fields like aviation, healthcare, remote work, AI and transportation, were also discussed. Another key strategy mentioned was active communication with policy makers, stakeholders, and business leaders. This may require training HFE professionals in public policy

for effective communication with lawmakers and policymakers.

What’s next?

Spreading the concept of ergonomics beyond the dedicated HFE community requires strategic communication, effective outreach, and practical engagement with various audiences.

M ultiprong education and advocacy strategies should be adopted through various channels like education, industry networks, expert knowledge exchanges, etc. Collaborating with member societies internationally and exchanging ideas, strategies, and best practices will be the key.

Teaming up with professional agencies from associated fields beyond the HFE community (e.g., engineering, design, architecture, quality, allied health) to host joint events like webinars, networking, symposiums, townhalls, etc. could be another effective channel for improving awareness, and encouraging collaboration, knowledge exchange, and inclusion in education and training in the associated domains. Understanding the lingo of these other professions is key to effectively communicating and promoting HFE concepts.

In a nutshell, to spread the concept of HFE beyond the dedicated community, we must frame it in terms relevant to the targeted audience. Whether that is businesses, healthcare providers, students, or the public, it is important to present HFE as a niche concern and a broad, accessible, and valuable concept that can improve everyday life, workplace efficiency and return on investment. Through inclusion and collaboration, we can build a sustainable future for the HFE profession and apply the full potential of the discipline, touching human lives, well-being, safety, and productivity.

By James Careless

Workplace violence is a growing problem in Canada, and one that employers need to deal with directly and effectively.

“ Workplace violence is on the rise, and it is becoming more of a problem for many sectors, specifically those that work directly with the public,” says Kristy Cork, specialized consultant in healthy workplaces at Workplace Safety & Prevention Services (WSPS). “I think there are many reasons for this increase in frequency and severity of workplace violence, but it likely comes down to the fact that many people are not coping well with their stressors and unfortunately, workers are on the receiving end. This has been steadily increasing since the COVID-19 pandemic.”

Ontario’s Occupational Health and Safety Act (OHSA) defines workplace violence as “the exercise of physical force by a person against a worker, in a workplace, that causes or could cause physical injury to the worker,” says Henrietta Van hulle, vice-president health, safety and wellbeing with the Public Services Health & Safety Association (PSHSA). “This definition includes the offender’s attempt to exercise physical force against a worker, and/or a statement or behaviour that it is reasonable for a worker to interpret as a threat to exercise physical force against the worker, in a workplace, that could cause physical injury to the worker.”

It can be difficult to know when a person is going to be physically violent at work. However, there are warning signs that can alert managers of this potential before violence occurs.

“ While not everyone will show these warning signs, these behaviours and physical signs may indicate a person’s state of mind,” says Lin Yu, occupational health and safety specialist with the Canadian Centre for Occupational Health and Safety (CCOHS). “Context also matters: Is the person just having a bad day or is this a pattern of behaviour? This is why you need to look for multiple warning signs and evidence of escalation when making an assessment.”

Warning signs associated with someone who could become violent at work include:

• Pushing the limits of acceptable conduct.

• Disregarding the safety of co-workers and others.

• Holding grudges and communicating hope that something negative will happen to the person against whom they have the grudge.

• Refusing to acknowledge job performance issues.

• Being disgruntled more than usual about work and fixating on perceived unfair personal treatment.

• Demonstrating violence toward inanimate objects.

• Evidence of violent behaviours in the past.

• Insisting that they are always right.

Not all workplace violence can be proactively deterred, but some can through preventative management actions.

“For example, you can create natural surveillance by removing large items that obstruct the view from glass walls, windows, and doors,” says Yu. “Natural surveillance allows other employees or members of the public to naturally observe interactions within a work area and deter violent behaviours. Eliminating hidden corners in the workplace is another example. Wider tables and counters and physical barriers can also be used to minimize the opportunity for physical contact in workplaces where employees are interacting with clients or customers.”

Of course, design can only do so much. Human interactions also matter. “Make sure workplace leaders have the time to be present and in contact with their team so they can recognize and resolve issues before they escalate,” Yu says. “Promoting a culture of support, civility, and respect is one way to help prevent workplace violence. To help facilitate this, adopt an attitude of curiosity, and ask questions when you start to notice a change in behaviour or notice that someone is struggling.”

It’s essential for employers to create and enforce workplace violence policies that are clear, detailed, and consistently supported by management.

“A clear workplace violence and harassment prevention policy and program that outlines the expectations in the workplace, provides training on these expectations,

and the measures the employer will take to control and deal with workplace violence is critical,” says Van hulle. “There should be a proactive reporting practice that employees are encouraged to use before events become critical. Investigation policies that include how an employer will deal with an employee who is the perpetrator of workplace violence are also required.”

Cork adds that to win and maintain employee trust in these policies, “there should not be certain individuals in the workplace that get a pass because they are highly valuable, have been around for a long time or hold a position of power.”

As well, Yu notes, “An emergency response plan is essential to indicate how the workplace will respond to a serious incident that is in progress. The plan should be comprehensive, easy to understand and remember, and include three major topics: what will be done, who will be involved, and how necessary communication will be managed.”

After an incident of workplace violence has occurred, the perpetrator should be separated from the victim and placed under control (as defined by the company’s policies). “The first step is ensuring that medical attention

It can be difficult to know when a person is going to be physically violent at work. However, there are warning signs that can alert managers of this potential before violence occurs.

Demonstrating violence toward inanimate objects is one warning sign that a person could become violent at work.

is provided to an injured worker, while controlling the risk of injury to other persons in the workplace,” Van hulle says. “Each event should be investigated and the privacy of both parties protected. In Ontario, the employer must not disclose any more information than is reasonably necessary to protect a worker from physical injury. If there is a risk of violence, the employer must provide workers who can be expected to encounter the person posing the risk of violence and likely to be exposed to physical injury with information, including personal information, related to the risk.”

That’s not all. “Any incident of workplace violence can leave people shaken and can result in a psychological injury,” says Cork. “A debrief is an important tool to support workers and find out what happened so it can be prevented in the future. The first part of any debrief is checking in on the well-being of all those involved. People will want to cope with a traumatic incident in a way that works for them.”

No matter what their rank or level of influence in a company, perpetrators must face the consequences of their actions as laid out in the employer’s workplace violence policies. “Each workplace should have a progressive discipline process that should be followed for any incident of workplace violence or harassment,” Cork says. “This certainly could include termination. And anyone who is physically assaulted or threatened

has the right to press charges. The employer should support this process.”

The decision to fire a perpetrator would likely require an investigation by human resources or an independent third party and is generally based on the severity and/or recurrent nature of events. For safety’s sake, the offender should be suspended from work until the investigation is completed. (Under the legal concept of ‘innocent until proven guilty,’ it may be prudent to keep paying the offender until a decision has been rendered.)

“Charging a person depends on whether the event meets the definition of assault under the criminal code,” says Van hulle. “The police would need to be summoned to make the distinction.”

Workplace violence is a growing problem. It’s up to employers to address this problem proactively, courageously, and consistently.

“No worker should go into work each day worried that they are going to be assaulted,” Cork says. “This is an incredibly stressful way to work and live.”

“Prevention is critical,” adds Van hulle. “Employers cannot wait for events to happen.”

“Ultimately, the goal is to create safe and healthy work environments that protect workers from injuries and harm,” Yu says. “Everyone at work needs to understand what workplace violence is, that it’s a serious matter, and who they can go to for help.”

By Treena Hein

Over the last four years, the landscape of workplace ergonomics has changed substantially. So many people have started working from home, and there has also been an explosion in the development of softwarebased tools that can aid in diagnosis, training, equipment optimization, and more.

As we move further into this new era, here are reflections and insights from:

• Dan Robinson, owner of the consulting firm Robinson Ergonomics in Coquitlam, B.C. Robinson has a doctorate in ergonomics and has been practicing since 1990.

• Alex Smith, director of program and service development at U.S.-based DORN Companies in Colorado.

• A aron Miller, provincial healthcare director in Kelowna, B.C. who has been working in ergonomics for two decades.

What is being really well addressed today?

Robinson: The profession is now recognized as something that has value in the workplace and sometimes within the design of products. Now, ergonomics is part of provincial OHS regulations and is used as a buzzword in marketing to describe something that is well-designed.

Another aspect that I think is well addressed is the need to engage and involve people in the process of ergonomics. [In the past], clients would ask for an assessment and solutions but ask that I don’t speak with employees and don’t tell them what I am doing. That isn’t ergonomics and I never accepted those parameters in taking on a project. I don’t see the same challenges now going into workplaces and asking to speak with and involve workers in the process of understanding their work, their challenges and possible solutions. It’s seen as a normal approach.

Miller: The focus on safety in the healthcare environment, including providing employees

with the equipment they need to do their jobs…This includes both those working in hospitals and other healthcare settings, along with administrative and corporate staff, many who switched to remote work during the pandemic. Health and safety, and especially ergonomics, is coming much more to the forefront as healthcare staff are proactively looking to reduce risk of injury.

Smith: There has been a significant increase in demand for ergonomic support in 2023 and 2024. This includes risk assessment, training and creating strategies to eliminate injuries, how to best work with automation, etc. There is now a solid recognition of ergonomics as being important to injury prevention and safety. Ergonomics is now part of the training and education of company/organization safety officers.

Miller: The focus on the built environment and how it is being used as a tool to improve health. This includes more access to natural light and materials which promote health and healthcare designers are looking to how the built environment is improving care through the use of spaces for technology to support care, along with flexible designs that can be easily modified based on the care team working in the spaces. A great

example includes the design of new medical equipment with height adjustability to the extent not seen previously for both the patient and the staff. These new designs are reducing the risk factors for musculoskeletal injury/disorder (MSI/D).

I am also very excited about the use of data analytics and being able to use data to better understand where and why injuries are occurring. Previously, so much information was kept on paper-based charts, but with the increased use of databases for tracking information, there is a new opportunity not previously possible to easily examine workplace injury trends to create proactive approaches to reducing risk factors for injury.

Robinson: Developing assessment and analytical tools that involve sensors to collect workplace data and analytics to assess posture, repetition rates, force, thermal load, vibration, etc. could be game changers. As computing power and the ability to handle large data sets has progressed, we are able to gather real-time full-shift data and rapidly distill that into quantified measurements of work or of risk factors at work. This will change ergonomics in future, I believe, but will not eliminate the need for skilled humans to interpret the output of these systems and to provide that

participatory, human-centred approach to developing solutions. It may allow ergonomists to spend more time on solution-focused aspects of ergonomics and less time on quantifying and understanding the background problem.

Smith: We are using a system that combines AI with motion capture and it’s very useful to enhance what we already do. I didn’t see a lot of value in it initially, but there are many benefits. Its calculations speed up the workflow and it can also calculate metrics that are quite difficult to obtain manually, for example low back compression, where the worker’s height and weight, the weight of the item, etc., must be factored in. It’s also a huge benefit in demonstrating risk. Without an ergonomics and anatomy background, it can be difficult for people to see things as an ergonomist sees them. With motion capture, it’s easy for workers to see where the risk of injury is being introduced, and to see with a screen overlay how to mitigate risk. It accelerates the process from assessment to correction and education.

Smith: Technology advances so quickly that sometimes the human interaction with that technology is overlooked a bit. Engineers are very good at what they do, the equipment they design works so well, but the position and posture you have to assume to do maintenance or even operation will create strain over time. The marriage between ergonomists and engineers is the best way forward, as they each have expertise to contribute, and this way we can produce equipment that works well and also supports movement that will cause minimal or no strain on joints etc.

Miller: In health care, we need to make sure teams have the tools that they need to ensure those they supervise are avoiding injury and long-term issues. The healthcare industry is continuing to grow and many healthcare roles and tasks continue to be manual in nature, based on the medical needs of patients. My concerns continue to be how to design the healthcare environment to continue to remove risk factors for

injury. This includes continuing to use robotics, mechanical height adjustable equipment and other types of technology to continue to remove manual high-injury tasks.

Robinson: I am concerned that some are moving towards excessive trust in [artificial intelligence (AI)] as a replacement for skilled, experienced human consultation. AI is being used in some contexts to feed in questions and use the answers that are provided to make decisions without adequate assessment of the accuracy of the AI response and without engaging in the kind of interactive analysis that happens during a worksite visit or interview. Smart use of AI to assist and inform an ergonomics process can be an advantage but I also have concern that the primary focus of ergonomics has become MSI/D prevention due to OHS regulations when there are many other benefits that are not always recognized.

L astly, product, workstation or facility design is where an ergonomist can have the greatest impact on success, yet most requests [for input] are made after a design is complete and in use.

In your view, what tools or research are most needed in ergonomics today?

Miller: We need preventative measures in injury management. Everything is virtual now and with those new tools, we can pinpoint where injuries happen in the healthcare system. Health care is one of the highest occupational categories for injury risk due to the unpredictability (different patients in different environments) and potential violence. Even so, with digital tools, we can look at trends within the healthcare environment and discern how we could do

things differently and change training and tools to ensure better safety.

Robinson: The major issue that I see is weak or conflicting evidence regarding some workplace risk factors and specific injury outcomes. We know that the generic risk factors of awkward posture, forceful exertion, repetitive or sustained postures or force, vibration, contact pressure, etc. increase risk of MSI/D. Most of these risk factors do not have clearly defined doseresponse relationships that can predict specific injuries, and it is even more complicated with combined exposures to multiple risk factors. For example, how much force, how many repetitions and for how many years are needed to result in work-related lateral epicondylitis (tennis elbow)? We know that those combined exposures increase risk but there is still dispute over how much is required to be confident that an injury is likely to occur, or on the flip side, that an injury occurred at work due to the risk factors.

Smith: We need research demonstrating to the industry that safety officers need to become businesspeople. Yes, all safety leaders and executives want to reduce injuries and protect safety, but we need to tie this to higher productivity and profitability. We know anecdotally that almost 95 per cent of the individuals we work with report they are more productive at their job after we have implemented a strategy, and their supervisors also almost all report higher productivity across the department. This is because people aren’t worried about getting injured, they feel more comfortable and cared for, and they’re therefore more engaged. It would be good to have a published study on this, as it would further justify investment in ergonomics.

308 Circle Dr. E Saskatoon SK S7K 0T6

Tel: 888-653-5028

Web: https://aedadvantage.ca

Since 2003, AED Advantage has been providing lifesaving automated external defibrillators (AEDs) throughout Canada in our mission to protect communities across the country from sudden cardiac arrest (SCA). When you choose to shop with us, you’re not just purchasing a life-saving-device, you’re taking a proactive step to safeguard your employees, customers, loved ones, and community from the devastating effects of SCA. You’re not alone in this journey! We’re here to support you in keeping your AED rescue-ready and ensuring peace of mind. When you purchase from AED Advantage, you are automatically enrolled in our AED Management Program which includes: Unlimited access to our AED specialists AED Health Assessments

Monthly inspection reminder

Expiration date reminders

Easy trade-in program

That’s the AED Advantage

99 Crompton Dr. Barrie ON L4M 6P1

Tel: 647-699-7702

Web: www.aed.ca

AED.ca is Canada’s AED company. We are automated external defibrillator (AED) specialists. We sell and service AEDs and offer AED inspections and training. Do you have questions on which AED is best for your location? We offer expert advice and can help create an AED program for your location(s). We truly care and are here to help you protect the people at your location.

AED.ca

3500, rue Saint-Jacques Ouest

Montreal QC H4C 1H2

Tel: 877-746-5653

Web: safecontractor.com

Alcumus SafeContractor takes the pain out of compliance for organizations, helping them protect their people,

their operations, and the planet. We support our network of hiring clients, suppliers, and contractors by keeping them compliant with the standards that matter most, from health and safety and sustainability to ethical behaviour. We deliver an end-to-end contractor management solution that will streamline your internal processes, save you time and resources, and provide your business with unrivalled expert guidance and support.

Key features:

• An easy-to-use digital tool to gain visibility and control of your contractor and worker management

• Access to real-time data about the risk status of your entire business, across sites and departments

• Guidance and support from a team of trained safety assessors

• Collaborate exclusively with reliable and safe contractors who have been approved to a standard of excellence. safecontractor.com

Calgary Place II, 355 4 Ave. SW Calgary AB T2P 0J1

Tel: 587-287-1125

Web: avetta.com

Avetta leads the world in connecting leading global organizations across several industries including oil/gas, telecom, construction materials, facilities management and many others, with qualified and audited suppliers, contractors and vendors. The company brings unmatched access and visibility to its clients’ supply chain risk management process through its innovative and configurable technology, coupled with highly experienced human knowledge and insight. We contribute to the advancement of our clients’ sustainable growth by protecting supply chains from a wide range of potential risks through trusted contractor prequalification, safety training and monitoring, regulatory compliance, insurance/financial stability, and other areas of risk. Avetta currently serves more than 450 enterprise companies and 125,000+ suppliers across 120+ countries. Visit www.avetta.com for more information.

6700 Century Ave. Suite 100 Mississauga ON L5N 6A4

Tel: 905-567-7198

Web: www.bcrsp.ca

The Board of Canadian Registered Safety Professionals (BCRSP) acts in the public interest in granting certification and upholding it as a recognized standard of excellence for competent and ethical safety practitioners. A federally incorporated not-for-profit organization, BCRSP establishes and enforces education, examination, experience, and ethics requirements for CRSP and CRST certified professionals.

710 Cochrane Dr. Markham ON L3R 5N7

Tel: 416-433-9786

Web: www.BradyCanada.ca

Brady is a manufacturer of complete solutions that identify and protect people, products and places. Brady’s products help customers increase safety, security, productivity and performance and include highperformance labels, signs, safety devices, printing systems and software!

604 Industrial Rd. 3 Cranbrook BC V1C 4V2

Tel: 250-426-3400

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical

assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

10121 Barlow Trail NE Calgary AB T0M 0E0

Tel: 403-248-0018

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

10630 176 St. NW Edmonton AB T5S 1M2

Tel: 780-484-6613

Web: brandt.ca/Material-Handling

Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

360 MacKenzie Blvd. #5 Fort McMurray AB T9H 4C4

Tel: 780-791-6635

Web: brandt.ca/Material-Handling

Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

1521 33 St. N Lethbridge AB S7L 0X2

Tel: 403-330-8859

Web: brandt.ca/Material-Handling

Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

101 Burnt Park Dr. Red Deer AB T0M 0E0

Tel: 403-343-7557

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to

students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

Highway #1 East Regina SK S4P 3R8

Tel: 306-791-7777

Web: brandt.ca/Material-Handling

Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

BRANDT TRACTORSASKATOON

800 60 St. W Saskatoon SK S7K 3N2

Tel: 306-664-4141

Web: brandt.ca/Material-Handling

Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

BRANDT TRACTORWINNIPEG

3700 McGillivray Blvd. Winnipeg MB

R3Y 1X2

Tel: 204-231-2333

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of material handling and construction

equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

400 Jamieson Parkway Cambridge ON N3C 4N3

Tel: 519-651-2233

Web: https://bunzlsafety.ca

For over 40 years, Bunzl Safety has been keeping Canada safe at work with the industry’s best safety equipment and supplies. Our experts guide smart decisions to create safer, more productive workplaces and help businesses manage or reduce health and safety costs. No matter what the work, or where, we have the right high-quality safety products to protect your team, backed by expertise and responsive local service, coast-to-coast. With over 8,000 industry-leading safety products, Bunzl Safety provides headto-toe PPE and facility safety products to customers in a wide range of industries including food processing, construction, industrial and manufacturing, retail, healthcare, and more.

2156-12975 84th Ave. Surrey BC V3W 1B3

Tel: 604-763-4558

Web: www.denninghealth.ca

Denning Health Group has been making workplaces safer for 30 years.

We provide true, turnkey, substance use and impairment programs for companies big and small and have done so all across Canada. Our clients include organizations involved in a cross section of industries and government, including some of the world’s well recognized companies. We have also worked with smaller regional and local companies. Denning Health’s founder, Tom Yearwood, LLB, was the lead author of Weyerhaeuser’s policy which withstood a nationwide policy challenge in one of Canada’s biggest arbitrations related to drug and alcohol testing. Tom’s award winning approach ensures that our clients are protected by well written, proven policies and frontline comprehensive training for supervisors. We are based in B.C. but work wherever we are needed.

2425 Skymark Ave., Unit 1 Mississauga ON L4W 4Y6

Tel: 905-212-6600

Fax: 905-212-6602

Web: www.draeger.com

Draeger was established in 1889 as a manufacturer of gas detection and respiratory protection and serves customers worldwide. The current portfolio includes stationary and personal gas detection systems, respiratory protection equipment, fire training systems, thermal imaging cameras and alcohol and drug detection units. “Technology for Life” is the guiding philosophy. Whether in clinical applications, industrial safety applications, oil and gas, mining or fire and emergency services, Dräger products protect, support and save lives.

www.draeger.com

1831 North Park Ave. Burlington NC 27217

Tel: 336-227-6211

Web: glenguard.com

GlenGuard is the ultimate inherent fabric for arc-rated, flame-resistant workwear – delivering the perfect blend of comfort, durability, and versatility. GlenGuard

is lightweight and breathable to keep workers comfortable, and its protective properties are engineered to overcome even the harshest conditions. With the industry’s best weight-to-protection ratio, GlenGuard helps workers reach their peak performance and stay in compliance. Specify GlenGuard and enable your workers to be more compliant with their AR/FR work wear. For more information, visit www.glenguard.com.

1661 Finfar Crt. Mississauga ON L5J 4K1

Tel: 905-823-6150

Fax: 905-823-7608

Web: www.latoplast.com