NOVEMBER/DECEMBER 2023

This year’s crop of Under 40 Top 10s simply shines p. 12

INSIDE

What is Leading 3D Modelling? p. 20

Five Easy Ways to Enhance Performance p. 22

BY DON HORNE

NOVEMBER/DECEMBER 2023

This year’s crop of Under 40 Top 10s simply shines p. 12

What is Leading 3D Modelling? p. 20

Five Easy Ways to Enhance Performance p. 22

BY DON HORNE

This is my second year gathering your Top 10 Under 40 entries, and it always amazes me just how talented all of you are. Here are a few of the entries we received:

Olivia Brown, Preconstruction Manager, Special Projects, EllisDon:

“She goes above and beyond to ensure that all work executed on-site adheres to relevant codes, regulations, and quality standards. Her meticulous approach to risk management and her proactive identification of opportunities to mitigate risks make her a true asset to the industry.”

Cory Robinson, Operations Manager, Energy Crane Service:

“His passion with all facets of the company and the crane business supersede what any normal person would consider a passion. He is obsessed with anything crane and takes the time to know every crane in our fleet and rental fleet inside and out.”

Kelsey Patrick, Marketing Manager, Falcon Equipment:

“She is collaborating with crane operator influencers on Instagram, creating content and keeping up with the market trends. She is promoting our cranes in a trendy and fun way on our social media platforms, directly impacting our crane sales. Kelsey is our shining star and deserves recognition for her contribution to the crane industry.”

Yannick Santerre, Chief Mechanic of the conventional crawler cranes, GUAY:

“Yannick initially joined GUAY in October 2016 as a crane mechanic at our TroisRivières branch and then, transferred to lend a hand at our Anjou branch in April 2018. From his very beginnings with GUAY, we were able to observe his passion for cranes and his dedication to his work.”

Julien Raby, Engineering Manager, Irving Equipment Ltd.:

“With an unwavering attention to detail, regardless of the magnitude of the job, Julien aspires to engage and inspire the highest level of teamwork throughout our organization.”

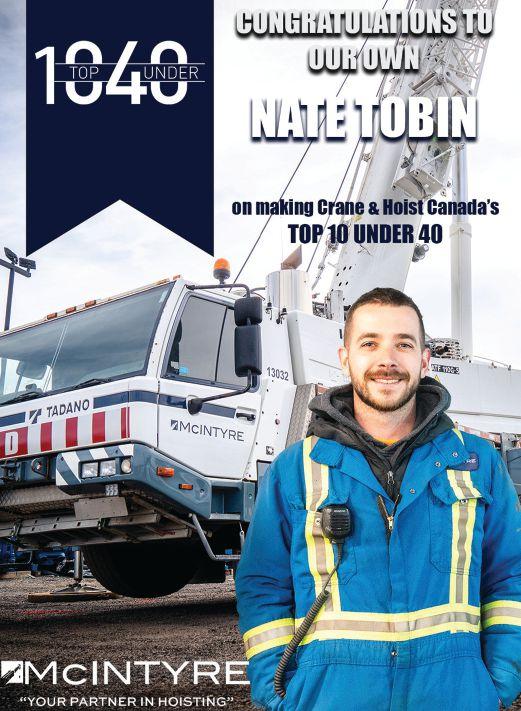

Nathan Tobin, Operations Manager, McIntyre Crane & Rigging:

“Recognized by many within his team as being one of their favourite co-workers,

Nate is also revered by clients, contractors, service providers, and competitors for his positive energy, friendly attitude, impressive knowledge base and operational skill, professional conduct, and managing capabilities.”

Cameron Spencer, Parts Specialist, MLTruck Equipment:

“Cameron has become one of the key go-to people within our organization, with a can-do attitude and a passion to go the extra mile.”

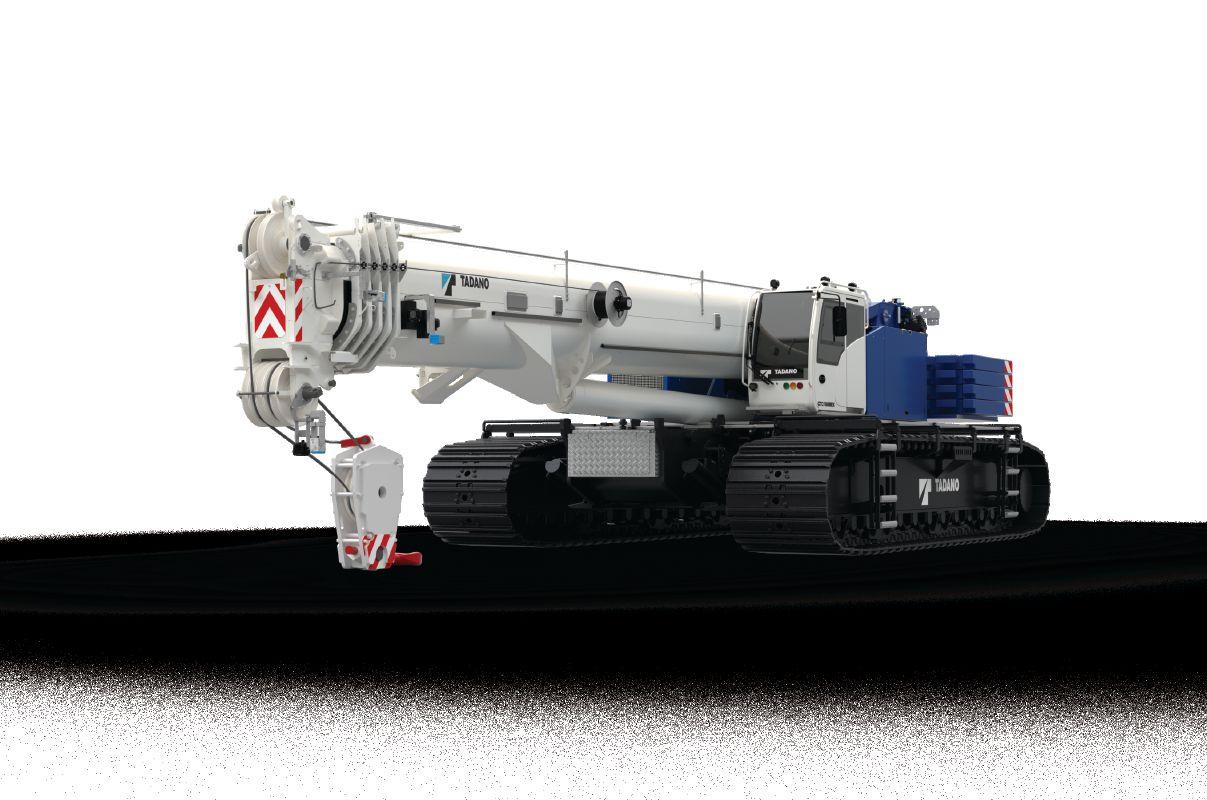

Louis Francescutti, Secton Manager, Canada, Tadano America Corp.:

“Louis started off with Tadano as a technician and has proven to show not only that he has the knowledge and expertise to be our top technician but, has proven that he can lead a team and grow the company in the service and support department for all of Canada.”

Randa Fernandes, Director, Operations and Customer Experience, WrightPlan Inc.:

“Since joining WrightPlan Inc. in January 2023, she has immersed herself in understanding the digital transformation needs of the crane and rigging industry from a planning and execution perspective, and even presented her findings as a panelist during this year’s SC&RA Crane & Rigging Workshop.”

These are the highlights of praise offered by coworkers and work colleagues of our Top 10 Under 40 for 2023.

There is a common theme among them all: a drive for excellence and a dedication to ensure customer satisfaction – never settling for “just enough” but always striving to go above and beyond.

Don Horne

Send us your favourite memories

Crane & Hoist Canada magazine will be celebrating 15 years as a publication next year, and we’d love to share your stories once again from over the years.

If you have a copy of the magazine, an article we’ve done on you or a favourite story you would like to see again, drop me a line at dhorne@annexbusinessmedia.com.

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | DON HORNE dhorne@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | SVETLANA AVRUTIN savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR | FARWA SIDDIQUI fsiddiqui@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER | URSZULA GRZYB ugrzyb@annexbusinessmedia.com • 416-510-5180

CONTRIBUTORS | Matt Jones; Emily Newton

GROUP PUBLISHER | DANIELLE LABRIE dlabrie@annexbusinessmedia.com

PRESIDENT/COO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues) Canada: $37.00 + tax per year • USA: $37.00 USD Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

PRINTED IN CANADA ISSN 1923-788X

Publications Mail Agreement #PM40065710

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Crane & Hoist Canada are copyright ©2023 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Advertising Deadline: January 2, 2024 Don’t miss the opportunity to be part of this exciting industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: January 5, 2024. For writers’ guidelines and submission requirements get in touch with the editor, Don Horne, at dhorne@annexbusinessmedia.com

MEMBER OF:

Given the recent heavy rains, Valentine Underground Services sought Sarens’ help to complete the installation of storm drain tank modules within three days.

Sarens participated in the installation of an important storm trap on the North Service Road in Burlington, Ont., where it has been able to provide its crane to the construction team for the lifting and placement of each of the modules for a storm water storage gallery.

The Province of Ontario is carrying out stricter control over the level of water falling during storms, which will prevent occasional flooding in some important sections and areas of the city.

Storm traps are stormwater infiltration and detention systems, and these huge subway tanks also have an extremely important function: storing the first rainwater, which is the most polluting because it carries all the dirt accumulated on the streets and asphalt and regulate its flow to the treatment plants. In this way, the tanks prevent the treatment plants from exceeding their maximum flow and having to discharge the excess, untreated, into the receiving watercourses.

Given the difficult weather conditions in the country and taking as a precedent the rains of last August with rainfall of up to 50 mm, Valentine Underground Services sought Sarens’ help to complete the project in the shortest possible time. The installation of the modules that make up the tank was completed in a period of three days, so that the rainwater that fell could be filtered through the culverts and properly stored in the tanks until the rainfall ended.

As Neil Docherty, Sarens Key Account Manager, points out, “The idea is that before reaching the tanks, the water passes through a series of filters to retain solid contaminants such as plastic bottles among other objects. Once in the tanks, the water is gradually conveyed to the purification stations, avoiding not only contamination of the rivers, but also preventing possible flooding and environmental damage. This is why this project is also an important milestone for Sarens in its commitment to sustainability.”

The work was carried out by a team specially selected by Sarens for the occasion, with an LTM 1070 crane and one operator. Since the system had significant new features that necessitated its installation whenever there were groundwater problems, the contractor wanted to rely on Sarens’ expertise to perform the task as efficiently as

possible. In this way, the Sarens team was able to place approximately 30 pieces weighing 7,000 pounds each, a heavy lifting manoeuvre without transport.

“On this occasion, despite being a novel system, our team did not experience any operational setbacks. In fact, beyond that, we highlight the speed with which our team unloaded and placed the material, something that was of great relief to the community by not having to worry about the possible flooding that could be caused by the next storm,” says Docherty.

Sarens has extensive experience in the Canadian construction industry with similar complex projects, recently doing work on the renovation of Union Station in downtown Toronto, where its engineering team worked on the lifting and subsequent installation of several iron girders, weighing approximately 9.4 tons, for the flying garden that connects the station’s north and south towers. In addition, other projects, such as the refurbishment of the Lafarge cement factory in Bath, Ont.

The Residential Construction Council of Ontario (RESCON) is pleased that leaders at both the federal and provincial government levels are planning urgent actions to tackle the housing crisis.

“The stark and deeply troubling fact is that we are in a housing crisis and face an acute shortage of supply, so it is critical that government leaders come up with steps to spur construction of more housing and purpose-built rentals,” says RESCON president Richard Lyall. “We need millions more units and must pull out all the stops to make that happen. The moves proposed today are a good start.”

The federal Liberals announced the GST will be removed on construction of new rental apartment buildings, which will lead to a five-per-cent reduction on the cost of goods and services. The Ontario government, meanwhile, has indicated that it plans to follow suit with the HST.

“We haven’t built enough purpose-built rentals to accommodate our growing population, yet projects were still being saddled with whopping sales taxes on the fair market value of a building upon completion,” says Lyall. “When encumbered with such formidable financial hurdles, developers often find it difficult to proceed with apartment building projects. These adjustments are clearly a step in the right direction as it will shave costs from constructing apartments and lead to more building.”

The GTA alone needs more than 300,000 new rental homes in the next decade, according to an earlier report released by the Building Industry and Land Development

Association, the Federation of Rental-housing Providers of Ontario (FRPO), Urbanation Inc. and Finnegan Marshall Inc. The rental housing deficit in the GTA is expected to double in the next 10 years to 177,000 units. Meantime, the supply of purpose-built rentals will need to rise from a projected 47,000 units to a minimum of 124,000 units in the next decade to keep up with demand, according to the report.

Conservative Party leader Pierre Poilievre also announced that he will be tabling a Building Homes, Not Bureaucracy Act next week that will give more money to municipalities that are building and meeting housing targets and take funds away from cities and gatekeepers that aren’t hitting goals. Cities will be required to increase the number of homes built by 15 per cent each year or a percentage of their funding would be withheld. Cities that exceed that figure would get a bonus.

He has also proposed removing the GST on the building of any new homes with rental prices below market value and is addressing municipal level barriers.

“We need quick and bold action on the

housing front to bring us back from the dark abyss,” adds Lyall. “Mr. Poilievre’s proposal would encourage cities to reach their housing targets, speed up the construction of much-needed new condos and homes, and make it easier for developers and builders to get shovels in the ground as soon as possible. Such a situation is a win-win for everyone.”

RESCON is also advocating for tax incentive programs that eliminate the collection of taxes on profits emanating from residential construction projects where the funds are re-invested into advancing similar projects. Programs like this resulted in tens of thousands of housing units in the 1960s and 1970s.

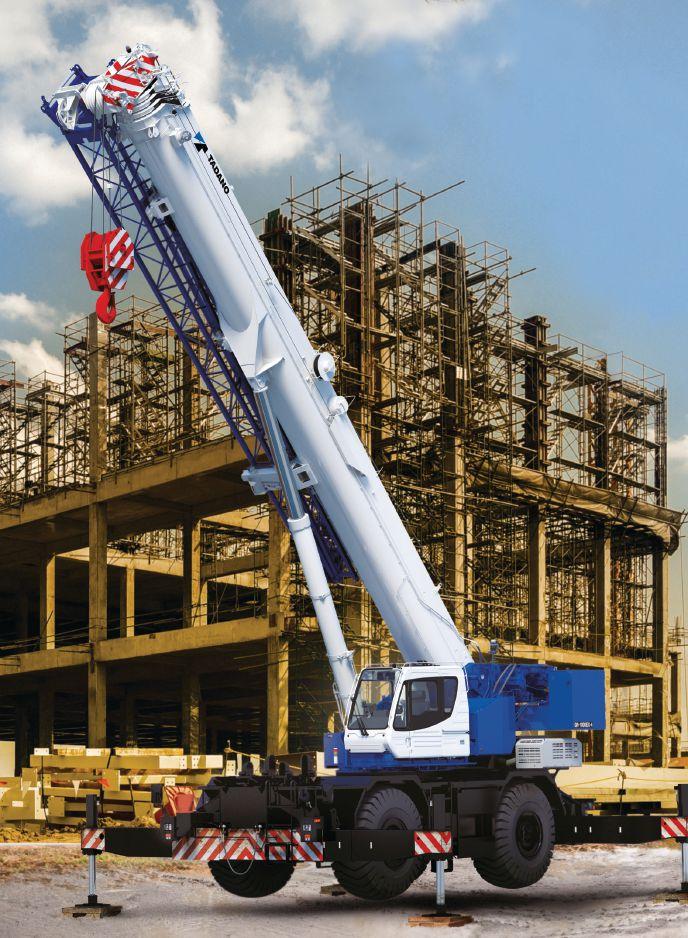

The all-terrain crane market size is expected to grow by (US) $4.46 billion between 2022 and 2027. However, the growth momentum of the market will be progressing at a compound annual growth rate (CAGR) of 5.2 per cent during the forecast period.

The market is segmented by capacity (less than 200 tons, 200-500 tons, and more than

500 tons), application (construction, industrial, and utilities) and geography (APAC, Europe, North America, South America, and Middle East and Africa).

The growing construction industry is the key factor driving the growth of the all-terrain crane market. The global construction industry accounts for a large part of the building sector, including companies, homes, and manufacturing facilities. The construction sector is playing a key role in the development of countries’ economies, and global economic sustainability.

The development of infrastructure in the world will result in an increased use of manufacturing and construction machinery, like all-terrain cranes, which will drive the growth of the market during the forecast period.

The report analyzes the market size and growth and provides accurate predictions on the growth of the market.

• The report recognizes the following as some of the key players in the all-terrain crane market: Action Construction

Equipment Ltd., Bocker Maschinenwerke GmbH, Broderson Manufacturing Corp., Elliott Equipment Inc., FURUKAWA Co. Ltd., Guangxi LiuGong Machinery Co. Ltd., KATO WORKS CO. LTD., Kobe Steel Ltd., Liebherr International Deutschland GmbH, Manitex Inc., SANY Group, Sumitomo Heavy Industries Ltd., Tadano Ltd., Terex Corp., The Manitowoc Co. Inc., TIL Ltd., Xuzhou Construction Machinery Group Co. Ltd., Zoomlion Heavy Industry Science and Technology Co. Ltd., and Altec Inc.

• All-terrain Crane Market is fragmented in nature.

• Market to observe 3.71 per cent YOY growth in 2023.

Market Dynamics:

Leading Trends

• The increasing popularity of telematics in all-terrain cranes is a primary trend in market growth.

• On construction sites with limited space, all-terrain cranes are used. Most all-terrain crane users have difficulty navigating in such tight spaces. In such a situation, it would be very helpful to apply telematics to these cranes.

• Incorporating such technologies into all-terrain cranes will improve the efficiency and safety of construction projects.

• All-terrain cranes are equipped with external telematics and Internet of Things solutions from third-party market players, allowing operators to access technical information about the collision avoidance system in real-time.

• Such advancements in the field of all-terrain cranes are expected to fuel the growth of the all-terrain cranes market during the forecast period.

Significant Challenges:

• The lack of skilled and qualified crane operators is a major challenge to the growth of the global mobile crane market.

• The cause of the skills shortage is attributed to the inadequacy of the education system and the poor awareness of the profession among young people.

• The aging populations in many advanced economies are exacerbating skills shortages as many young people prefer non-technical jobs.

• Most operators in non-developed areas have no formal training or education, resulting in poor equipment handling.

• Thus, such factors will hinder the growth of the market during the forecast period.

• The less than 200 tons will account for a major share of the market’s growth during the forecast period. All-terrain cranes with a lift capacity of less than 200 tons are mainly utilized in smaller-scale constructions, most notably within confined spaces. These cranes have been designed to meet the demands of clients who require simple, all-terrain mobile cranes that are able to operate under limited conditions in urban areas.

• The demand is expected to increase in the coming years by increasing numbers of eco-friendly and energy-efficient buildings in urban areas. Thus, such factors will drive the growth of the segment during the forecast period.

The ProLift Rigging Company is launching a new operation in Brampton, Ont. to serve the greater Toronto–Hamilton area.

“Today marks a significant chapter in The Pro-Lift Story,” says Jesse Taylor, President and Chief Executive Officer of ProLift Rigging. “We are now an international company, uniquely positioned to provide our clients with industrial construction services in yet another important market — further increasing the value we bring as a supplier and a partner.”

Toronto is the 12th full-service branch for ProLift and the first located outside of the United States.

Pro-Lift Toronto “is staffed by a team of experienced riggers and machine operators” managed by crane and rigging industry veteran Matt Rix, says Taylor. Rix joined The ProLift Rigging Company earlier this year specifically to oversee the development of international markets.

“While the launch of our Toronto branch is certainly an exciting event, it is just the beginning,” said Matt Rix, Branch Manager & Head of International Development for the ProLift Rigging Company,

Randa Fernandes has been promoted to Vice President, Operations & Customer Experience at WrightPlan Inc., a developer of operations management software for crane, rigging, machinery moving and millwright businesses.

“In this position, Randa will have a greater focus on WrightPlan’s business strategy, product direction, internal processes and overall company growth, all while continuing to lead its customer experience and solutions

Randa Fernandes

delivery,” says Adam Gall, manager of sales and marketing.

Since joining the company in 2023 as Director, Operations & Customer Experience, “Fernandes has already proven herself an industry thought leader, sharing her expertise and knowledge as part of the panel on Utilizing New Crane & Rigging Technologies during this year’s SC&RA Crane & Rigging Workshop,” adds Gall.

There were more cranes over construction sites in Toronto than the other 13 key markets combined, according to the latest crane count report from international property and construction consultancy firm Rider Levett Bucknall (RLB).

Overall, the company found a net decrease in cranes in North America since the first quarter, which aligned with a high project completion rate.

“The current economic situation has many feeling like they are playing a chess match with no endgame,” says Julian Anderson, FRICS, president of RLB North America.

“Despite these challenges, the construction industry has been remarkably resilient. The pieces on the economic board may still be shifting, but we are continuing to make well-considered moves and are positioning us for a stronger, more secure financial future.”

Boston and Toronto were the only cities in the report with increased crane counts in Q3, with Toronto’s 240 cranes leading all 14 centres by a wide margin. Calgary, Honolulu, New York, Phoenix, Portland and Seattle all held steady in their crane counts, and Chicago, Denver, Las Vegas, Los Angeles, San Francisco, and Washington, DC, each had their crane count figures drop more than 20 per cent.

In addition to crane count data, RLB also released its Quarterly Cost Report. Together, the two documents provide an eye-opening perspective on the North American construction industry.

With data current to mid-Q3 2023, the latest RLB quarterly cost report shows that the national average cost of construction in the U.S. rose 1.55 per cent over the previous quarter. Much like their American counterparts, prices were considerable higher in the two Canadian markets included in the report.

Cropac Equipment Inc.

Cropac carries a wide range of equipment:

• Boom Trucks

• Tower Cranes

• Forklifts & Telescopic Handlers

• Crawler Cranes

• Rough Terrain Cranes and much more!

SINCE 1977, CROPAC EQUIPMENT HAS BEEN COMMITTED TO PROVIDING QUALITY EQUIPMENT, PARTS, AND CUSTOMER SERVICE ACROSS CANADA. Cropac has branches in: ONTARIO - QUEBEC - ALBERTA - B.C.

2024 annual general meeting will be in southwestern tip of Ontario

The Canadian Crane Rental Association (CCRA) annual general meeting is headed to Windsor, Ont., June 11-13, 2024.

Prior to that, the Winter Board Meeting will be held in Nashville, Ten., February 8-9, 2024.

The Association welcomes all crane companies, manufacturers and suppliers to the industry. Members are from across Canada and the United States; crane rental operations, manufacturers and suppliers of cranes and equipment, suppliers of services used in the specialty crane rental business in Canada.

Once a year, the CCRA holds a conference and general meeting, a unique annual event that provides the opportunity to meet with the leaders of the Canadian crane industry.

To learn more, go to this site: https:// ccra-aclg.ca/welcome/

Coming on the heels of a very successful SC&RA Workshop in Oklahoma City, Okla., the Specialized Carriers & Rigging Foundation (SC&RF) is conducting its second annual Industry Workforce Survey to de-

termine the state of the industry and is requesting all SC&RA member companies’ participation.

According to a statement from the SC&RF, “This survey will provide necessary data to compare against the 2021 data collected as a workforce development benchmark.”

The 2023 research report, State of the Workforce in the Crane, Rigging and Specialized Transport Industry, provided analysis of the data on specific occupations and their average education level, wages, and turnover. The report in 2024 “will be used to assist members and the SC&RF as they build a case to support careers in the industry for educators, schools, and parents.”

“The efforts to re-establish skilled trades as valuable, worthy career options are gaining traction – and this data supports all the claims,” states the SC&RF. “The data is collected anonymously and will be analyzed and published to benefit advocacy efforts, recruiting programs and to enhance and grow the SC&RF’s ongoing workforce development initiatives.”

Respondents will receive a thank you gift.

The SC&RF Workforce Ambassador Program welcomed several new members at the Crane & Rigging Workshop last month.

The following companies have committed to engaging with their community to help raise industry awareness: Buchanan Hauling & Rigging, Inc.; Crane Tech Solutions LLC; Gallagher; GMVykon; Liebherr Mobile and Crawler Cranes; Link-Belt Cranes; Marsh McLennan; Mazella; Mr. Crane, Inc.; Phoenix Crane Rental; PSC Crane & Rigging; and Wilkerson Crane Rental, Inc.

Those companies that have already partnered with school or community members are already an Ambassador.

The Workforce Ambassador Program looks different for every company and every community; like classroom presentations or attending a career fair. For some companies, the annual “construction days” is a great way to see and be seen.

As part of the Workforce Ambassador Program, companies are grouped by size and will earn points based on activities during the year.

✓ 197’ 7-section main boom

✓ 263’ max tip height

✓ 33’ longer than standard 120|HT

✓ Longest truck crane boom on the market

This year’s crop of Under 40 Top 10s simply shines

By Don Horne

The future of the heavy lifting industry looks bright. Armed with a strong work ethic, initiative, curiosity, and a commitment to training and safety, the 2023 Top 10 Under 40 selections are setting the bar for young professionals across the industry.

Whether they work in leadership, operations, maintenance, sales or support, these crane and hoist employees are highly regarded by their colleagues, clients and peers.

Congratulations to our 2023 winners!

Manager, Test Right Rigging Ltd.

Vancouver Island, B.C.

“Garrett Margetts is the most well-rounded person I know in the lifting industry,” says his father and his boss, Wayne Margetts. “From great people skills to executing major lifts, from manufacturing slings to testing overhead lifting devices, Garrett is ahead of his peers.”

His ability to run a 125-ton conventional friction crane, implement jack and roll jobs, estimating, problem solving and always looking out for his fellow workers, he adds.

“Garrett gets complex jobs done on time within budget and with safety at the forefront,” he says.

Preconstruction Manager, Special Projects, EllisDon. Calgary, Alta.

“She goes above and beyond to ensure that all work executed on-site adheres to relevant codes, regulations, and quality standards. Her meticulous approach to risk management and her proactive identification of opportunities to mitigate risks make her a true asset to the industry,” he says.

As a Preconstruction Manager, Olivia’s talents shine even brighter.

“Her involvement in developing technical content for proposals and RFPs showcases her ability to craft winning solutions. Collaborating with architects, engineers, and other stakeholders, she consistently delivers design solutions that meet clients’ needs and budgets,” says Davoli. “Olivia’s skills in evaluating alternative design and construction methods have optimized project costs and schedules, demonstrating her ingenuity and foresight.”

Olivia’s impact extends beyond her daily responsibilities. She has actively contributed to the professional development of her team, developing financial training content and training materials for knowledge-sharing platforms. Her role as a member of

Alex Davoli’s coworker Olivia Brown is deserving of a Top 10 nomination because of her dedication and dedication to detail.

“Olivia’s day-to-day job duties include project management. She consistently delivers on key responsibilities, including developing and maintaining project schedules, expertly managing project budgets, and overseeing all aspects of procurement, from subcontracts to material ordering,” says Davoli. “Her ability to seamlessly coordinate and communicate with subcontractors, consultants, owners, and stakeholders ensures that projects run smoothly and efficiently.”

But what truly sets Olivia apart is her unwavering dedication to safety and compliance.

SAIT BSc Construction Project Management Advisory Committee further underscores her commitment to industry growth and education, he points out.

Additionally, Olivia’s membership in the Calgary CCA Young Construction Leaders and her role as a content advisor for “Project Coordination 101” for EllisDon Corporate’s “Knowledge Hub” demonstrate her passion for fostering leadership and sharing knowledge within the construction community.

“Olivia’s remarkable achievements in project management, preconstruction, and her contributions to industry knowledge and education make her an outstanding candidate for Crane & Hoist Canada’s Top 10 Under 40 list,” says Davoli. “Her dedication to excellence, safety, and innovation is truly exemplary and deserving of recognition.”

CORY ROBINSON

Operations manager, Energy Crane Service.

Stony Plain, Alta.

Cory Robinson’s employer Jesse Myshak has only the highest praise for his Top 10 nomination.

“Cory in my opinion is a huge driving force in our company’s success and growth over the years,” says Myshak. “His passion with all facets of the company and the crane business supersede what any normal person would consider a passion. He is obsessed with anything crane and takes the

time to know every crane in our fleet and rental fleet inside and out.”

It is his knowledge of the cranes that the company operates and the functionality of each unit that allows Robinson to give customers an honest approach to their projects.

Energy Crane Service would like to congratulate Cory Robinson on his designation. Cory along with the many employees of Energy Crane Service are an integral part of our growth. They provide a great culture and poses a profound ability to perform their tasks safely and efficiently making Energy Crane a true leader in the industry. Thanks to Cory for his hard work and dedication to our group and paving way for the future ahead. We appreciate your commitment to the raising the standard.

“Cory first started with our group in August of 2017 as a crawler hand and has proven himself time and time again, working himself into an operations managers position within Energy Crane,” says Myshak. “His commitment to the personnel and the customers ensure our growth and making Energy Crane a well-known crane company within our and other provinces.

To sum it up: Cory is a crane nut: he lives and breathes the crane industry and to honour this individual with this recognition would speak volumes to his passion in this industry.”

KELSEY PATRICK

Marketing Manager, Falcon Equipment Ltd.

Surrey, B.C.

Kelsey Patrick started her career at Falcon Equipment as a Marketing Coordinator in 2017, where she was brand new to the crane industry. It was her passion, drive and motivation that were evident from the beginning, and she would be a leader in the

crane world, earning her promotion to Marketing Manager in 2021.

“Kelsey has countless achievements; some of her outstanding work includes hosting Canada’s first-ever Truck-Mounted Crane Rodeo from inception to execution,

held in our head office in Surrey,” says Blair Norberg, Vice President at Falcon Equipment. “In this event, Falcon’s Annual Crane Rodeo, the local crane operators from the industry competed with one another; there were games and prizes and an overall successful, fun-filled event.”

Building on this success, “Kelsey plans to host the Crane Rodeo in our other branches to include local crane operators in those areas to participate in this event,” says Norberg.

Kelsey has excelled in creating brand awareness and maintaining our social media presence.

“She is collaborating with crane operator influencers on Instagram, creating content and keeping up with the market trends. She is promoting our cranes in a trendy and fun way on our social media platforms, directly impacting our crane sales,” says Norberg. “Kelsey is our shining star and deserves recognition for her contribution to the crane industry; we look forward to her continued growth and success at Falcon Equipment.”

Irving Equipment is proud to congratulate on making Crane & Hoist Canada’s Top 10 Under 40 as a leading innovator in the Canadian crane industry.

As one of the most innovative minds in the industry, Julien’s expertise has consistently determined the successful completion of countless projects.

YANNICK SANTERRE

Chief Mechanic of the conventional crawler cranes, GUAY. Montréal, Qué.

Yannick Santerre has a passion for cranes, says work colleague Olivier Giguere.

“Yannick initially joined GUAY in October 2016 as a crane mechanic at our TroisRivières branch and then, transferred to lend a hand at our Anjou branch in April

2018,” says Giguere. “From his very beginnings with GUAY, we were able to observe his passion for cranes and his dedication to his work.”

Always looking to gain more knowledge, Yannick was quickly recognized by his colleagues for his involvement in the garage, as he does not hesitate to assist anyone who needs his help.

After having continued to develop his expertise over the years, combined with his pleasure of sharing his knowledge, Yannick was nominated to the position of foreman of the East-Montreal in May 2021.

“Everything indicated that he was the ideal candidate to support his colleagues in the maintenance of the branch’s fleet,” says Giguere. “In June 2023, Yannick was again promoted to Chief Mechanic of the conventional crawler cranes, where he will take on new challenges with the project team regarding the maintenance and repair of our crawler cranes fleet at the provincial level. For GUAY, Yannick is a reference because of his work ethic and the work quality that he delivers every day.”

JULIEN RABY

Engineering Manager, Irving Equipment Ltd.

Saint John, N.B.

Thane Tapley, a work colleague of Julien Raby, has only the highest praise and respect for his Top 10 nomination.

TOP UNDER

We’re proud to have you on our team.

Congratulations, Garrett Margetts, for earning a well-deserved spot among the Top Ten Under Forty.

Your dedication, boundless enthusiasm, and steadfast commitment to delivering exceptional results continue to elevate our entire organization. We take immense pride in having you as a valued member of the Test Right Rigging Team.

“As Engineering Manager at Irving Equipment, Julien Raby, P.Eng, demonstrates the highest level of leadership and professional conduct, excelling in the many aspects of the heavy lift and transport industry,” says Tapley. “Julien’s passion for safety and innovation have been demonstrated repeatedly throughout his 18.5 years at Irving Equipment, while managing wind, shipbuilding, petrochemical and countless other heavy industry projects.”

Raby’s involvement with the Canadian Crane Rental Association, the CSA-Z150, further demonstrates his passion to innovate and improve safety throughout the crane and heavy transport sector.

“With an unwavering attention to detail, regardless of the magnitude of the job, Julien aspires to engage and inspire the highest level of teamwork throughout our organization,” says Tapley.

Operations Manager, McIntyre Crane & Rigging Ltd. Calgary, Alta.

Nathan ‘Nate’ Tobin is becoming a highly respected rising star in Southern Alberta’s crane and hoisting landscape. A native of Newfoundland and Labrador, Nate had craning in his blood with renowned family members already well-established in the trade, says coworker and HR manager David Monteith. “Nate entered the trade at an early age and never looked back, earning his Red Seal in Mobile Crane Operation in 2018 at just 23 years of age. Nate’s peers quickly recognized him as a standout operator, worker, and person.”

Despite having well-established connections through his family in craning, Nate would endeavour to blaze his own trail, relocating to Alberta in the summer of 2019, and would go on to join McIntyre Crane & Rigging Ltd. in Calgary, Alta., in April of 2021 as a Crane Operator and Media Manager.

“Here, Nate could merge his two passions of cranes and videography,” says Monteith. “As the company took on more projects, Nate started accepting more responsibilities and quickly became the go-to person for quotes, lift planning, dispatch, and fleet service. Nate also plays a key role in employee development, training, and career planning.”

In March 2023, less than two years into his tenure with McIntyre Crane & Rigging Ltd., Nate would be appointed to the role of Operations Manager.

“Responsible for day-to-day operations and managing a team of 17 employees, eight mobile cranes and boom trucks, and a fleet of 26 other vehicles and equipment,” says Monteith, “Nate would also go as far as to put his money where his mouth was, further demonstrating his commitment to the company and his passion for Craning by investing in an ownership stake in McIntyre Crane & Rigging Ltd., where he continues to be a driving force in the expansion of the company, not just in terms of immediate market share growth but also in establishing long-term sustainable business planning.”

No matter how challenging your needs, AIROMAX AM 27 is your best ally for mobile cranes in industrial applications. The tire is particularly suitable for road usage. Thanks to its All Steel casing and the special tread design, AIROMAX AM 27 provides extraordinary traction along with high load capacity.

AIROMAX AM 27 is BKT’s response to withstand the toughest conditions in the construction industry.

For info: Western Canada 604-701-9098 Eastern Canada 514-792-9220

As remarkable as Nate’s career has been so far at just 27 years old, possibly more impressive is how well-liked and respected Nate is.

“Recognized by many within his team as being one of their favourite co-workers, Nate is also revered by clients, contractors, service providers, and competitors for his positive energy, friendly attitude, impressive knowledge base and operational skill, professional conduct, and managing capabilities,” says Monteith. “Nate embodies the epitome of a competent crane operator, a leader, and a friend.”

CAMERON SPENCER

Parts Specialist, ML-Truck Equipment.

Abbotsford, B.C.

Mathew Friesen nominated his coworker Cameron Spencer, recognizing his key contributions to the company.

“Cameron received his Red Seal as a Partsperson five years ago, where he worked in the industrial supply area and then moved into on highway truck parts,” says Friesen. “Cameron wanted a more challenging and specialized focus in his career path.”

on being selected by Crane & Hoist Canada as one of the lifting industry’s Top 10 Under 40!

We at Tadano are proud to have you on the team and thrilled to see your dedication and commitment to the Canadian lifting industry.

ML Truck had an opportunity for Spencer to do so and he made the switch.

“Here we are just over a year later and Cameron has excelled in his overall parts knowledge as well as a true understanding of our crane industry,” says Friesen. “Cameron has become one of the key go-to people within our organization, with a can-do attitude and a passion to go the extra mile, ML Truck is very excited to see Cameron further develop his skills, while keeping our company in the top tier of the crane industry in B.C.”

Section Manager, Canada, Tadano America Corp. Leduc, Alta.

Justin Andrews is always impressed by the leadership skills of his work colleague, Louis Francescutti.

“Louis started off with Tadano as a technician and has proven to show not only that he has the knowledge and expertise to be our top technician but, has proven that he can lead a team and grow the company in the service and support department for all of Canada,” says Andrews. “Louis at the age of 33 has been promoted to lead the Tadano service and support team in Canada.”

RANDA FERNANDES

Director, Operations and Customer Experience, WrightPlan Inc. Waterloo, Ont.

For the past two decades, Randa has been a technology visionary and digital transformation leader within the software industry, leveraging emerging technologies to help organizations around the globe innovate, grow, and solve complex challenges for customers.

“Since joining WrightPlan Inc. in January 2023, she has immersed herself in understanding the digital transformation needs of the crane and rigging industry from a planning and execution perspective, and even presented her findings as a panelist during this year’s SC&RA Crane & Rigging Workshop,” says Adam Gall, her coworker who nominated her for the Top 10. “Her day-to-day activities see her collaborating with industry leaders and her talented WrightPlan Product and Services teams to develop and implement strategies that streamline processes, reduce downtime, and increase productivity for crane and rigging operations.”

Fernandes is a Women in Tech advocate, a proud mother to two little girls “and a member of mentoring circles that work to inspire, support, elevate and empower more young women to enter careers in tech,” adds Gall.

any

any time with

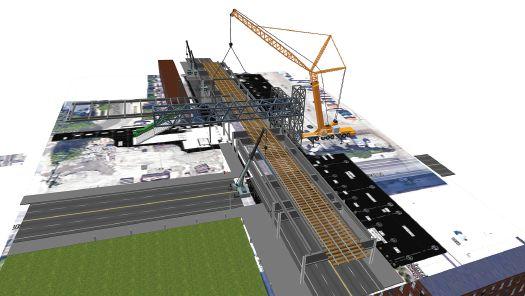

modelling for crane operations planning has come into its own in the last few decades. For many years, Computer-Aided Drafting (CAD) programs were the standard in the crane industry and continue to be used around the world.

But in the mid-2000s 3D modelling started gaining popularity in North America and one of the first products that hit the market in that space was A1A Software’s 3D Lift Plan program. Since then, A1A have become one of the standards in the industry, and Vice-President of Sales and Marketing Bruce Kabalen says that 91 of the top 100 crane companies use their products every day.

Kabalen spoke with Crane & Hoist Canada about the company’s suite of products and how they have evolved alongside the crane industry and technology.

“Technology and time have made our products indispensable in the industry,” says Kabalen. “We have the largest database of crane lift charts in the world with over 2,000 cranes and growing each day. Our products have evolved with changes to internet browsers, and we now offer an app that doesn’t require the browser to function.”

Kabalen says that the A1A Product Suite dissects their core product – the 3DLiftPlan.com website – into role-based programs for users, which offers a variety of applications. SketchPad allows salespeople to plot a jobsite quickly with imagery of the job site so they can begin the lift planning process. Rigging Designer allows users to begin pre-engineered rigging, below the hook, and to customize their specific needs with slings and spreader bars. 3D LiftPlan

gives the user the features and accessibility of the website but optimized for a laptop or tablet without the need for a browser.

“3D LiftVision [the final element of the A1A Product Suite] is a revolutionary program that works only with our new 3D LiftPlan app and allows users to immerse themselves and customers into the cab of any crane and jobsite they have created in 3DLiftPlan,” says Kabalen. “With the use of virtual reality (VR) headsets and joysticks, users can operate the crane in the ‘real’ environment they have created. This is a gamer changer in that customers can see critical lifts before they happen, and operators can practice the lift before they come to the jobsite. All this makes the lift safer and more efficient and provides instant feedback on crane and rigging selection before costly mistakes happen.”

Kabalen says that for A1A’s 20-some employees the biggest part of putting together such software is compiling all the possible information – having the exact dimensions of cranes, all the critical components (carrier, boom, extensions, outriggers, counterweights) and jobsite obstructions such as buildings, fences or other pieces of construction equipment.

“We are in daily contact with our customers and crane manufacturers on changes to their products and adapt accordingly,” says Kabalen on how they stay current. “We also adapt our delivery devices. When browsers no longer allowed for plug-ins that we used we had to change our entire 3DLiftPlan generation engine to comply with the changes. This is the same reason we have developed our A1A Product Suite, ensuring that if browsers

as we know them go away, our products continue to work for our customers.”

Kabalen notes that continuing to meet their customers’ needs with development and updates is the biggest challenge for A1A Software today. Data collection and distribution is always a challenge as they continue to add new cranes and charts as they are released by manufacturers and requested by their customers.

CAD programs are still employed in some areas, most notably in Europe. But Kabalen notes that the advantage that their software brings is that it is much more accessible. Properly operating CAD programs generally involves understanding a large volume of commands and options which can be extremely daunting to users and could require some specific training. A1A’s suite of software is designed to be more user-friendly.

“I think a lot of Canadians and Europeans use a lot of CAD stuff, but they have to have the ability on their staff to do that and that sets us apart from day one,” says Kabalen. “And then the accessibility on the web for us, initially, was a big plus. The simplistic nature of our program lets little crane companies look like the big guys. That’s been a really good thing for the industry, I think.”

A1A are looking to leverage their products to achieve more market penetration into areas like Europe. In particular, Kabalen hopes that 3D LiftVision will open some doors in other markets.

“The crane people will use that from a risk-mitigation standpoint, but also in the training aspect,” says Kabalen. “Yes, there’s training simulators out there, but none of them really put you in an actual real-life setting. And that’s the difference for us. You can say there’s other simulators that teach operation, but that’s not really what we’re after. We’re going to get some of that as a byproduct and a lot of it is going to be where people want real life experience on a job site and that’s a close as physically being there as you can get.”

Looking to the future, Kabalen says that A1A are interested in potential applications for augmented reality (AR) systems – where rather than presenting an entire virtual environment as in VR, AR allows the overlay of graphics and information over the real world. The most common applications of such technology have been on the maintenance side, for example providing guidance to a mechanic as they repair a complicated piece of machinery. A1A Software’s lead developer has previous experience developing AR systems for the U.S. government.

“It’s not on our development plate for next year,” says Kabalen. “But it is on the drawing board.”

By Emily Newton

Construction teams can use condition-based monitoring to lower their maintenance costs, improve site safety, increase efficiency and more. Condition-based monitoring uses sensors and data collection to provide real-time insights into specific performance metrics. Construction teams can apply it in cranes, hauling equipment, vehicles and more.

What are some easy ways site managers and equipment operators can leverage condition-based monitoring to enhance their operational performance and maintenance processes?

1

Proactive repairs are one of the best ways equipment operators can enhance maintenance through condition-based monitoring (CBM). By leveraging monitoring data, equipment operators can significantly reduce maintenance costs and time spent on repairs.

For example, condition-based monitoring gives equipment operators access to data on specific maintenance issues and metrics. This information allows for a highly focused, informed approach to repairs and removes diagnostic guesswork. As a result, maintenance personnel can complete repairs faster and with fewer wasted resources

Additionally, condition-based monitoring allows equipment operators to address performance issues immediately. It can open the door for predictive maintenance, which eliminates an estimated 75% of breakdowns compared to reactive maintenance. As soon as CBM systems detect performance issues, maintenance

personnel can perform small repairs or tune-ups and prevent a major mechanical failure. Businesses can save significant amounts of money spent on new equipment or replacement parts while also minimizing downtime and maximizing the value of their assets.

2

Condition-based monitoring gives construction teams access to a wealth of invaluable real-time data. It results in much broader visibility into daily operations and performance. Site managers and equipment operators can apply that data to actively improve efficiency.

For example, on large construction sites it is notoriously difficult to keep an eye on everything, particularly asset-specific details like operating efficiency. Condition-based monitoring systems can bridge that gap. Site managers can funnel CBM data into one convenient hub or control center where they can view performance data on assets all over their job site.

An increased level of visibility enables a few powerful tactics for enhancing performance. Site managers can easily pinpoint which assets are performing best and worst. Condition-based monitoring specifically is uniquely well-suited for identifying trends in asset performance.

For instance, vehicles in a certain area of a job site might consistently be performing worse due to environmental factors. CBM data might reveal that these vehicles’ engines are consistently overheating, or their drive trains are strained from supplying excessive levels of torque. By investigating these specific metrics, a

The LTM 1110-5.2 with 3 new core features: the crane control system, the driver’s cab and the gearbox. The new LICCON3 crane control system comes with large touch displays and is prepared for fleet management and telematics. The ZF TraXon gearbox with DynamicPerform offers wear-free manoeuvring. Plus a modern crane design –the future of the all-terrain series. www.liebherr.com

site manager may realize part of their site has poor ground traction due to a drainage issue.

Resolving big-picture challenges like this can improve both individual vehicle efficiency and full-site efficiency. With condition-based monitoring, no vehicle or piece of equipment goes unnoticed, ensuring construction teams have the high visibility they need to maximize performance.

3

Data from condition-based monitoring systems is a great resource for developing optimization strategies for vehicles and equipment. The condition-specific metrics offer a detailed look at how a piece of equipment is performing and specific systems where mechanical issues may be occurring.

For instance, a certain motor might be consistently overheating, or an engine component might be causing excessive vibration. This information is important for maintenance processes, but construction teams can also use it to enhance performance by taking a step past repairs.

For instance, an engine component might create high amounts of vibration even if it is in perfect working order. While this isn’t cause for a repair, it does present a great opportunity for optimization. Vibration isolation can improve operational efficiency and safety by preventing vibration from creating issues like loose bolts or impaired precision.

1. CLARITY: They provide clear instructions on what is expected from both parties in a transaction. This helps to prevent misunderstandings and disputes.

2. PROTECTION: They protect both the business and the customer by defining the rights and responsibilities of each party.

3. EFFICIENCY: They save time and resources by providing a standard agreement that doesn’t need to be negotiated for each transaction.

4. LEGAL COMPLIANCE: They ensure that the business is complying with relevant laws and regulations.

5. PROFESSIONALISM: They demonstrate that the business is professional and trustworthy.

With the insights from condition-based monitoring, construction teams can address this type of area for improvement. They can go beyond maintenance to proactively enhance the quality and performance of their vehicles and equipment.

4

Construction teams can utilize condition-based monitoring to ensure everyone on site is working safely. Vehicles and equipment with undetected maintenance issues pose a serious hazard to operators, workers and even civilians.

Real-time data on the mechanical health of equipment is critical for ensuring safety. Sadly, there have been several major crane accidents in recent years, leading to both civilian and worker deaths. Crane accidents are often the result of excess physical strain on the crane itself, whether from its load, mechanical failure or weather-related factors like high winds.

With real-time monitoring, equipment operators can stay ahead of potentially dangerous situations. For instance, CBM data could inform a crane operator immediately when the crane begins showing structural strain due to high winds. Real-time data like this allows for immediate, informed responses to high-risk situations.

5

Condition-based monitoring can help construction teams maximize the value and longevity of their vehicles and equipment. Over time, CBM generates large amounts of data on an asset’s mechanical health and performance. This information is helpful in real-time and over the entire lifespan of an asset.

For example, construction teams can use data from CBM to set and analyze KPIs and goals for aging equipment. Asset health data can reveal trends in performance that may indicate when a piece of equipment is nearing the end of its usable lifespan. That data can also be used to optimize and enhance equipment in order to extend the usable lifespan past estimations.

Other uses for condition-based monitoring support asset longevity, as well. Predictive maintenance based on CBM data minimizes the likelihood of premature equipment failure. Plus, data-driven maintenance can maximize the value of warranties and insurance plans.

Equipment manufacturers and insurance agencies appreciate when businesses take good care of their equipment. They may offer more warranty support or lower premiums to construction companies that are using proactive, data-powered maintenance processes. As a result, equipment can stay in top shape for as long as possible with support from warranties and insurance.

Construction teams can revolutionize their operational performance and maintenance processes using condition-based monitoring. CBM increases visibility, lowers maintenance costs, increases safety, expands visibility, increases efficiency and more. There are countless ways site managers and equipment operators can apply CBM data to maximize the value of their assets and ensure top performance on-site.

Up to $20,000* in help is available right now!

Apply for your grant at