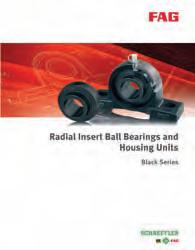

Rugged bearing offers misalignment capabilities

Baldor’s Dodge Type EXL tapered roller bearing provides both misalignment and expan sion capability, while maintaining industry-standard Type E mounting dimensions. The split ductile iron housing allows the cartridge-style inner unit to swivel freely in the housing, allowing up to plus or minus 4 degrees of static misalignment. Mounting dimensions are equivalent to any standard Dodge or competitor’s Type E dimensioned product. The totally sealed inner unit incorporates the Dodge XTS triple-lip seal for increased protection in harsh environments. Offering a 13% to 14% increase in load ratings over the previous design, the bearing is available in both two- and four-bolt pillow blocks and uses the same inner unit for both expansion and non-

expansion housings. Bore sizes range from 1-3/16 in. to 5 in.

Baldor Electric

Online Reader Inquiry No. 543

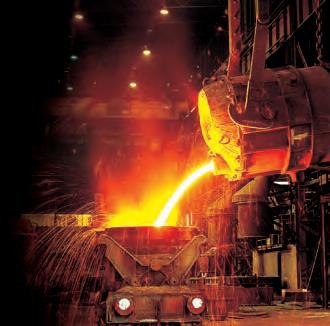

Welded seal technology is for large-diameter seals

SKF Canada offers welded seal technology service in the field. Using this technology reduces maintenance time and offers higher performance than using a standard split seal. This service is dedicated to the company’s large-diameter seal range. Typical applications are hydraulic presses (automotive industry), hydraulic hammers (steel industry), hydropower turbines and main propeller rotary shafts in the marine industry. Welding is done on site with a portable welding unit and SKF technology and materials.

SKF Canada

Online Reader Inquiry No. 542

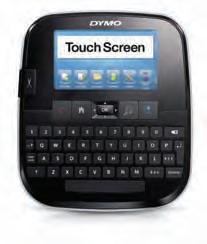

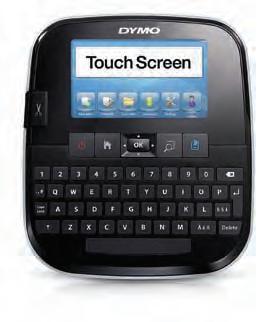

Stand-alone touch screen label maker prints labels fast

The Dymo LabelManager 500 TS is a stand-alone label maker that features a full-co lour touch-screen. Simply tapping on the large screen allows the user to edit, format and customize labels, while the fast print speed makes it efficient for creating high volumes of labels. Using a computer-style keyboard for fast text entry, the device prints labels when connected to a PC or Mac, and can also be used independently of a computer for convenient portability. Other features include 300 dpi resolution for clear graphics, barcodes and logos, automatic label cutter, and customization tools, including a wide selection of fonts, font sizes, text styles and boxes, and hundreds of built-in symbols and clip art. Also included are a wide variety of Dymo D1 labels in 1/4-in., 3/8-in., 1/2-in., 3/4-in. and

While other manufacturers have chosen to leave the DC motor market, ABB and Baldor continue to invest in product development and U.S. manufacturing in order to offer the widest variety of permanent magnet and wound field industrial DC motors in the world.

DC motors continue to provide the right solutions to many application requirements. We now can supply IEC or NEMA frame motors, stock motors from 1/50 to 500 Hp or custom-designed motors to 3000 Hp to meet your specific application. If you need a DC motor anywhere in the world, call Baldor! baldor.com 479-646-4711

The Most DC Choices

Unmatched Quality

Superior Reliability

Quickest Delivery Available

American Made Since 1920

1-in. widths for applications from file folders to binders, and a rechargeable battery pack.

Dymo

Online Reader Inquiry No. 548

Rapid assembly hose system reduces setup time

Parker Hannifin, Parflex Division, has developed a compact, anti-corrosive and quick-to-connect hose and fitting system for low-pressure hydraulic and pneumatic sys tems. The Rapid As sembly Hose system consists of Parflex 515H hose and brass RA quick-connecting hose fittings and adapters. The lightweight, fibrereinforced, low-pressure thermoplastic hose has good kink resistance. The connector design is very simple, durable and easy to install, eliminating the need for wrenches or other tools. Sealing is achieved through the use of petroleum and synthetic hydraulic oil-resistant elastomeric O-rings. The hose is particularly suited for routing through tight spaces while maintaining flexibility. Sizes range from 3/16 in. I.D. to 1/2 in. I.D. in a single or multi-line assembly.

Parker Hannifin

Online Reader Inquiry No. 544

Clamp-style shaft collar line is versatile

Ruland offers one-piece, twopiece and quick-clamp-style shaft collars. Clamp-style shaft collars are easy to re move and infinitely adjust able, and will not mar the shaft. One-piece collars dis tribute compressive forces even ly around the shaft for a tight fit and improved holding power. With an additional screw, the two-piece collar has superior holding power and can be installed without removing other components. Quick-clamping shaft collars feature a low-profile clamping lever which is operated by hand without the need for tools.

RotoPrecision

Online Reader Inquiry No. 551

Linear systems come in a wide variety of configurations

Lee Linear offers pre-engineered, readyto-mount linear systems that can be easily incorporated in almost all drive control applications. Aluminum shaft support rails in standard lengths of 24 in. and 48 in. are used in shaft rail assemblies as economical methods for mounting casehardened and precision ground 60 Plus or 440C shafting. The as semblies conform to industry speci fications and pro vide stable and efficient linear motion guidance for continuous or intermittent load operations. Shaft and rail systems are available in six standard configurations, which incorporate a single, double or twin pillow block. Either two cast steel support blocks or an aluminum rail can support the carriage plate. Systems are available with either roller bearing pillow blocks or with Precision Plus self-aligning linear ball bearing pillow blocks.

Lee Linear

Online Reader Inquiry No. 549

MRO

Obtain free additional information about any of these items by using our online reader reply card at www.mromagazine.com/rsc.

When you have to replace your chain, Timken Drives can deliver “Cut-to-Length” chain and save you up to 20% in scrap and inventory costs. Drives also offers new material technology, so your chain lasts longer too. Up to 3x’s. To discuss your specific chain application, contact your authorized Timken Drives distributor, or call our technical service department and we’ll help you out.

Drives for food processing / 11

Equipment cleanliness in food plants is getting more scrutiny than ever. Here is advice on washing down your drives without washing away your profits.

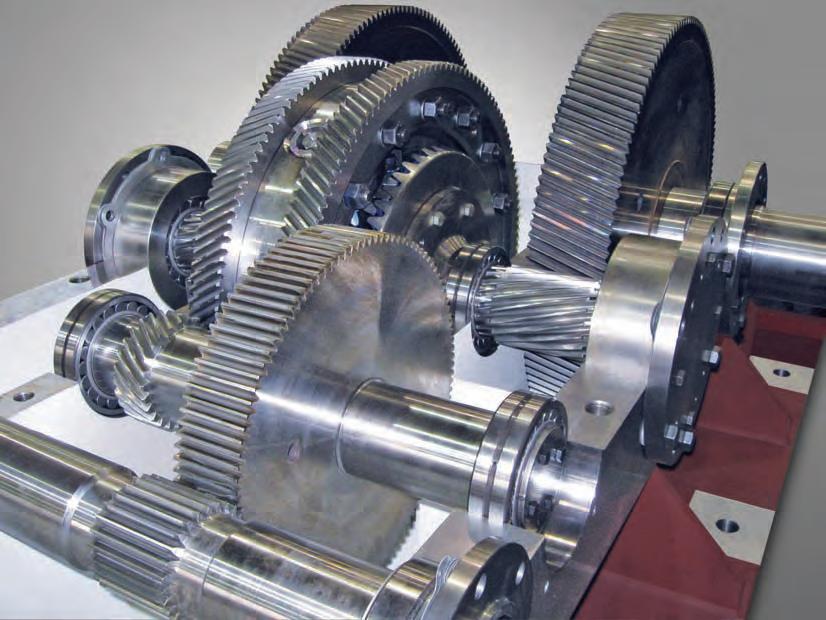

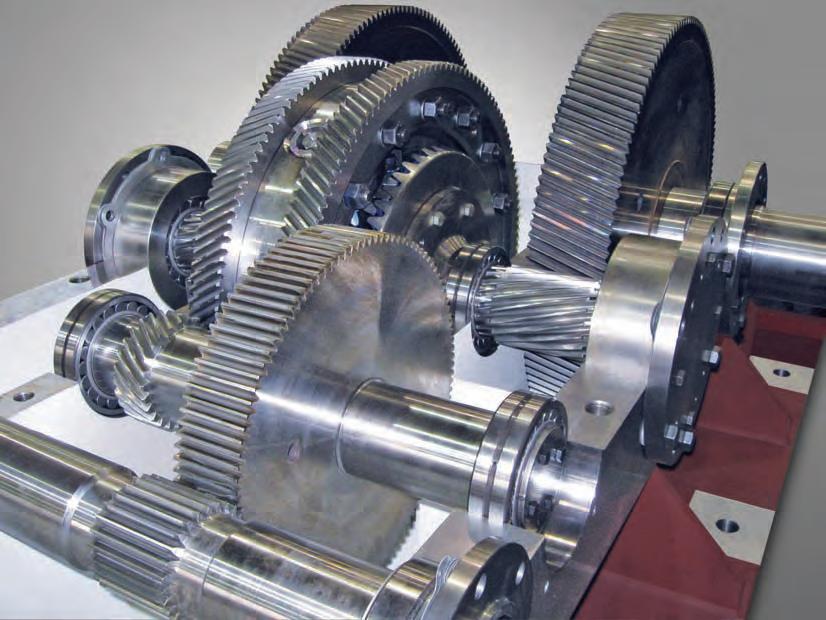

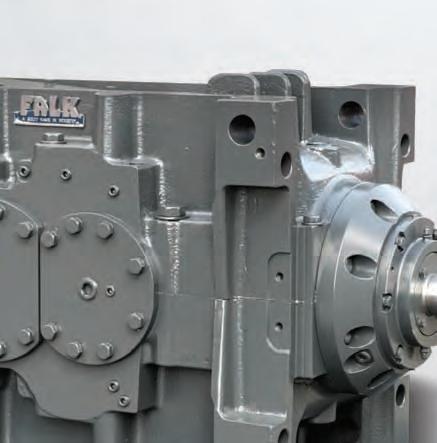

Maintaining large gearboxes / 12

How operating conditions and the performance requirements of driven equipment affect gearbox design and maintenance, especially lubrication.

p12

Torque monitoring techniques for steam turbines / 16

Precise torque monitoring at the coupling can maximize steam turbine/compressor performance, as this retrofit at the Quenos Olefins plant shows.

Resolving fan vibration problems / 20

A modern balancing instrument, data collector and analyzer unit helps reduce vibrations from five exhaust and circulation fans.

My MRO: A Nova Scotia Breakdown / 22

Here is the first of a new series in which you, the reader, can share your stories about your personal off-the-job maintenance and repair challenges. We start with Carroll McCormick’s tractor troubles.

p22

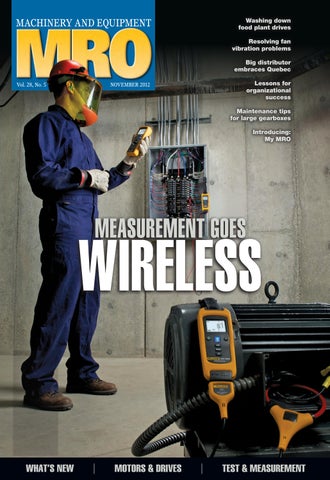

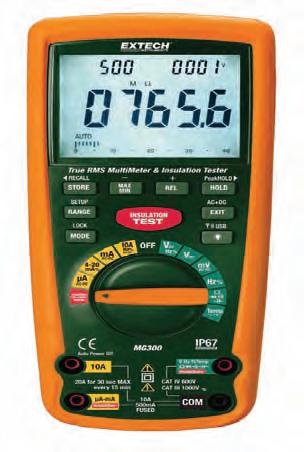

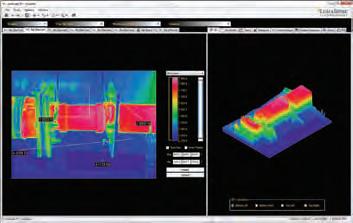

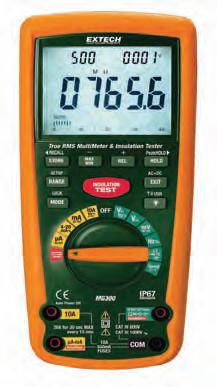

Cover story: Measurement goes wireless / 30 Wireless tools like Fluke’s CNX system, Extech’s MG 300 and Onset’s Hobo data logger are part of the trend toward safer monitoring and troubleshooting.

p2

MRO on the Road / 34 Applied Industrial Technology’s Quebec trade show attracts 400 delegates.

Mr. O, the Practical Problem Solver / 10 Seven steps to help protect gearboxes from moisture.

Maintenance 101:

Building a maintenance cost-management system / 24 Stage 6 in an eight-part program towards achieving world-class maintenance.

Supervisory Suggestions: Essential steps for organizational success / 25 Here are six lessons your organization should master.

The Safety File: The end of industrial exemptions / 26 Professional engineers aim for a co-ordinated process that puts the public interest first.

p30

Editor’s Notebook / 6

Industry Newswatch / 8

Business Briefs / 10

Mr. O, The Problem Solver / 10

Maintenance 101 / 24

Supervisory Suggestions / 25

The Safety File / 26

MRO on the Road / 34

Product News

Product Spotlight / 2

Focus on MRO Components / 27

Focus on Motors & Drives / 29

Focus on Test & Measurement / 30

‘Food manufacturers are under relentless pressure to ensure that their environments meet or exceed ever-stricter standards for cleanliness and hygiene.’

Gates / 11

p31

p32

‘At gearbox operating temperatures of between 180°F and 200°F, the recommended time between oil changes is reduced by 75%.’

John Proven / 12

‘The next time I know that it’s PM time, or when condition monitoring signals a condition red, I will schedule the downtime. Honest!’

Carroll McCormick / 22

‘The attitude of the person making MRO purchases is very important.’

Peter Phillips / 24

Gas driven single point automatic lubricators

This new generation has been designed around the needs of real users. The unit is now even easier to set up and recycle, while keeping their best feature inside:

The SKF high performance lubricants

When Carroll McCormick, MRO Magazine’s Montreal-based, multiple-award-winning senior contributing editor, told me about a recent personal machinery maintenance experience, it led to an idea for a new column in the magazine based on your own off-thejob challenges and successes.

We’re calling it ‘My MRO’, and Carroll’s story about the breakdown of his tractor at his property in Nova Scotia is the lead-off to what we hope will become a popular new section.

I’m sure you all have plenty of stories like this one. As you know, our trademark character, Mr. O, the Problem Solver, is the messenger for your practi-

cal tips and advice for onthe-job maintenance work. Now we have an opportunity for you to share your misadventures, troubles and successes from your own garage or workshop.

We sure hope you’ll play along. To encourage you, we’ll reward your submission with a gift card worth $25, plus a coveted Mr. O Problem Solver t-shirt. We’re getting a new batch made up just for the occasion. Simply send us a photo of you and your project, and up to 600 words. You can submit them by e-mail to broebuck@mromagazine.com or write to Bill Roebuck, Editor, Machinery & Equipment MRO, 80 Valleybrook Dr., Toronto, ON M3B 2S9.

By the way, the same deal goes for any new Mr. O Problem Solver tips that apply to the workplace. Send us your solution to an industrial machinery or equipment maintenance problem (it helps to include a photo or sketch) and we’ll share your advice with the rest of our readers.

Talking about our readers makes me think of some other news you might find of interest. Our most recent readership survey, done in June, told us 100% of readers surveyed rated MRO magazine from Excellent to Good overall. We also learned 98.9% think MRO meets the needs of their industry. We were somewhat surprised at how much you like to share your copies with others; according to the survey, the average total readership of each edition, including passedalong copies, is 63,449. That’s impressive reach for a magazine like this.

Separate studies showed that we continue to see growth in readership of our

website. In September 2012, the number of unique visitors increased to 34,393 and page views reached 54,408. As well, subscribers to our weekly e-newsletter now total 13,443. If you’re not getting our newsletter every Tuesday morning, you can sign up on our website – it’s a great way to catch up with the past week’s news if you don’t have time to log on to our site every day.

We also saw growth in the number of subscribers to our digital editions – now totalling 4,465. If you are a tablet user, it’s an easy way to read MRO magazine anytime, anywhere. And if you want to refer to an article you saw in print, just go online to our website, mromagazine.com, and look it up. Everything from the year 2000 and on is there.

To close, we thank you sincerely for your feedback and your support. And we really hope to see your stories for our new My MRO column.

Bill Roebuck, Editor & Associate Publisher

NOVEMBER 2012

Volume 28, No. 5

Established 1985 www.mromagazine.com www.twitter.com/mromagazine

EDITORIAL

Bill Roebuck, Editor & Associate Publisher 416-510-6749 broebuck@mromagazine.com

Ellie Robinson, Art Director

Contributing Editors

Simon Fridlyand, Steve Gahbauer, Carroll McCormick, Peter Phillips, Robert Robertson, Angela Webb BUSINESS

Nick Naunheimer, Publisher 416-510-6868 nnaunheimer@mromagazine.com

Eric Achilles Cousineau, Adv. Sales Manager 416-510-6803 eachilles@mromagazine.com

Kimberly Collins, Advertising Production 416-510-6779

Melinda Marasigan, Subscription Enquiries 416-442-5600 x3548

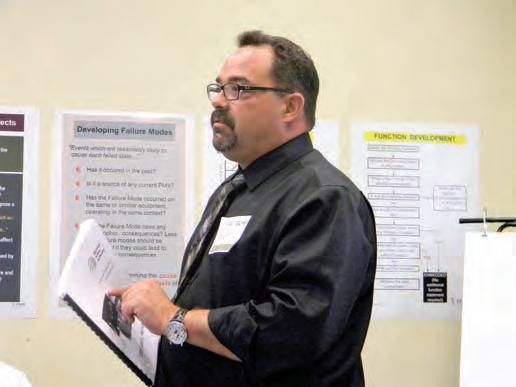

Burlington, ON — The topics of boosting uptime performance and keeping people in the workplace safe from electrical harm were highlights of the recent annual meeting in Burlington, ON, of the Hamilton Chapter of the Society of Maintenance & Reliability Professionals (SMRP).

Mark Jorgensen of the Electrical Safety Authority (ESA) and James ReyesPicknell, co-author of Uptime, were the keynote speakers at the event, which also featured the election of new chapter officers for 2012-13.

“The ESA’s vision is to have a prov ince free of electrical fatali ties and serious injury, dam age or loss,” said Jorgensen, who has been part of the ESA’s Harm Prevention Group for more than 15 years. “The ESA has been ac tively involved in developing an electrical safety program that meets all the require ments of CSA Z462-12.”

Reyes-Picknell of Con

portant to focus on factors, such as critical assets, teams, processes, strategies, leadership and people,” he said. “Creating a new maintenance culture requires you to change behaviour on the shop floor, as well as obtain top management support and slaughter any corporate sacred cows that may exist in the organization.”

The SMRP Hamilton Chapter’s goal is to create opportunities for those in maintenance to network and learn from each other, as well as promote worldwide maintenance excellence, said Liane Harris of ECS2 Group, the association’s past chair.

“We’re excited about the SMRP’s Certified Maintenance and Reliability Technician (CMRT) program. CMRT is suited for maintenance mechanics, as this professional certification offers an opportunity to stand out from the crowd and be recognized.

“With the CMRT program, the four domains of knowledge that are covered include

the book, Uptime: Strategies for Excellence in Maintenance Management, said uptime alone isn’t enough to achieve excellence, nor is it a stand-alone maintenance initiative.

“To boost uptime performance, it’s im

Top: SMRP Hamilton Chapter’s past chair Liane Harris said the new technician certification program offers a career edge to maintenance mechanics. Left: Mark Jorgensen with the ESA’s Harm Prevention Group wants to reduce fatalities and injuries to electrical workers. Above: SMRP

Hamilton Chapter’s 2012-2013 board of directors, from left: Sandra DiMatteo, Hammad Sharif, Jennifer Costello, Carlo Odoardi, Allan Hines, Craig Mock, Pasha Mohammed and Jeff Pottruff. Not pictured: Norm Clegg and Ron Gavrin.

ventive and predictive maintenance, trou bleshooting and analysis, and corrective maintenance,” said Harris. “CMRT bene fits both maintenance mechanics and their employers. For example, mainte nance mechanics are able to further en hance their careers, and employers can have access to mechanics that have wellrounded skills.”

At the meeting, the chapter elected the following board of directors for 20122013: Carlo Odoardi, M.Eng., Conscious Asset (chair); Liane Harris, M.S. Eng., ECS2 Group Inc. (past chair); Sandra Di Matteo, Bentley Systems (vice chair); Jennifer Costello, Bentley Systems (trea surer); and Pasha Mohammed, C. Tech., Kraft Foods Canada (secretary).

In addition, general board members include: Hammad Sharif, B.Eng., EIT, Holcim Canada; Allan Hines, CMRP, Predictive Services Canada; Craig Mock, P.Eng., CMRP, ArcelorMittal Dofasco; Jeff Pottruff, CMRP, ArcelorMittal Tubu lar, Woodstock, ON; Norm Clegg, Plant Engineering and Maintenance Associa tion of Canada (PEMAC); and Ron Gavr in, CMRP, Ontario Power Generation (re tired). (Editor’s note: A CMRP is a Certi fied Maintenance & Reliability Professional as recognized by the SMRP.)

Robert Robertson

On average, people come in contact with 300 surfaces every 30 minutes, exposing them to 840,000 germs.

touching surfaces that are contaminat ed,” said Dr. Allison Aiello, associate professor of epidemiology at the University of Michigan.

Philadelphia, PA — A startling number of Americans may be putting their health at risk by not practicing good hand hygiene, according to a survey conducted in early October 2012.

When asked about their specific handwashing habits, a vast majority of adults (71%) say they regularly wash their hands, but that number may be grossly exaggerated. Nearly six in 10 (58%) admit that they have witnessed others leaving a public restroom without washing their hands. More than a third of Americans (35%) have witnessed coworkers leaving facilities without washing, and one in five consumers surveyed (20%) have witnessed restaurant employees not washing their hands at all. The worst offenders seem to be men by a significant margin.

These survey findings were released by SCA, a global hygiene company and maker of the Tork brand of paper towels and wipers.

Sixty per cent of adults describe handwashing as being critical to their health, and over half (53%) consider washing their hands thoroughly and regularly to be the most beneficial practice for staying healthy. Yet, respondents also admit to skimping on personal hand hygiene after coming into contact with a number of germy environments and objects.

“The average human hand has millions of bacteria, many good, but also sometimes some that can harm health. In

More than a third of men (33%) admit they do not wash their hands thoroughly with soap and water after using the public restroom, compared to just one in five women (20%). Men are less likely than women to typically wash their hands after handling garbage, touching an animal, or sneezing or coughing. Men were more likely than women to describe handwashing as being a necessary hassle.

On average, people come in contact with 300 surfaces every 30 minutes, exposing them to 840,000 germs. For tips on hand hygiene, visit the website at torkgreenhygienecouncil.com.

Mississauga, ON – Independent Distributors Cooperative-USA (IDC-USA), Indianapolis, IN, has signed an agreement with IDI Independent Distributors Inc. (IDI) of Mississauga, ON, granting IDI the exclusive rights to market and sell IDC Select branded products in Canada.

IDI is a Canadian purchasing cooperative of independent industrial distributors who specialize in bearings, power transmission products, fluid power products, as well as industrial, janitorial and safety supplies. IDC-USA is a national purchasing, marketing and selling cooperative representing over 260 independent industrial distributors in the United States.

Both cooperatives have one common goal: to use the combined purchasing power of their members to better serve their customers and compete against large national chains in order to retain distributors’ independence in a rapidly changing and dynamic marketplace.

The new Fluke 805 Vibration Meter is more than a pen. It’s a Fluke meter that gives you results you can trust, time after time.

IDC-USA is assisting IDI with this initiative by allowing it to be the only company authorized to sell IDC Select brand products in the Canadian market.

“Cooperatives working with cooperatives is a hallmark of the cooperative business model, and IDI and IDC-USA have exemplified this over our many years of working closely together,” said Scott Bebenek, president of IDI. “IDI’s members are excited to gain access to a proven, quality line of power transmission and bearing products that they can take ownership of in the Canadian marketplace.”

“We are thrilled to be able to extend the exclusive rights of our IDC Select brand to our sister cooperative in Canada. With IDC Select, we are helping IDI expand the breadth of the product offering available to their independent power transmission distributors,” said Jack Bailey, president and CEO of IDC-USA.

To learn more about IDI, visit www. idiind.com; for more about IDC-USA, visit www.IDC-USA.com.

Ottawa, ON — Of individuals registered in an apprenticeship program between 2002 and 2004, those who completed their program had hourly wages in 2007 that were 21% higher on average than those who did not. The figures are the latest available from Statistics Canada, released in study titled Certification, completion, and the wages of registered apprentices, 2007.

In addition, those who completed their apprenticeship program were more likely to work full time and to be employed in permanent jobs.

Between 1995 and 2007, the number of Canadians enrolled in apprenticeship programs more than doubled, from 163,370 to 358,555. However, over the same period, the number of successful apprenticeship completions increased by about one-third.

Of the registered apprentices who completed their programs, 90% also obtained a Certificate of Qualification, while 10% did not. The Certificate of Qualification conveys the title of journeyperson and the

associated benefits and responsibilities.

Of the registered apprentices who discontinued their program, 90% did not obtain certification, while 10% did.

Average hourly wages were highest ($28.07) among individuals who completed their programs and obtained certification. Wages were lower among those who discontinued their programs but obtained certification nonetheless ($27.25).

Individuals who completed their programs but did not obtain certification had an average hourly wage of $23.92. People who discontinued their programs and were not certified had the lowest average hourly wage ($23.30).

The magnitude of the wage differences varied within detailed trade groups.

Hamilton, ON – Do you have a passion for workplace health and safety or worker rights? Are you a young, creative type, just waiting for your big break? If so, the new, national social media video contest, ‘It’s Your Job!’ could be your chance. Work is an important part of life, but no job is worth getting hurt over. Workplace injuries happen in a heartbeat but the resulting injuries can have a lasting impact on your ability to do the things you like to do. Further, everyone who works has rights under employment standards to be treated fairly in their workplace. As a result, Canada’s ministers of

labour have launched this video contest as part of their commitment to directly engage youth and raise awareness about their workplace safety and rights.

The contest challenges secondary school students and those who are not in secondary school (but are at least 18 years old and less than 25), living in Canada, to use their creativity to develop an original video that can be used in social media to illustrate to younger workers the importance of working safely on the job, or about their rights to being paid fairly for the work they do.

Winners will be chosen from every region of Canada. Entrants could win cash prizes for them and their schools, and maybe even become YouTube sensations. The national entries will be judged by a panel of celebrities that includes Alan Doyle from Great Big Sea and Marc Kielburger of Free the Children. The winning Canadian submissions will be entered into an international video contest.

A selection of top videos will be posted on the ‘You Tube - It’s Your Job’ video contest page from May 4 to May 12, 2013, where they will be viewed and voted on by the public. The videos that receive the most votes in each category will each receive an additional prize of $1,000.

You can submit your videos starting February 1, 2013, until the contest closes on April 5, 2013, at 11:59 p.m., local time.

For more information on the contest and prizes, visit www.hrsdc.gc.ca/eng/labour/health_safety/contest/index.shtml.

More detailed versions of these stories, along with many additional news items, can be found online at www.mromagazine.com.

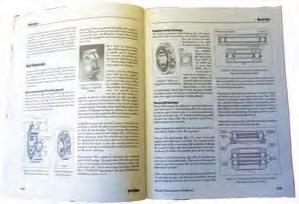

ANGULAR CONTACT BALL BEARINGS.

NSK angular contact ball bearings are designed for the rigorous demands of pump and compressor applications. Our innovative products feature optimized internal geometry to promote increased load ratings and limiting speeds as well as advanced cage design to improve strength and lubricant distribution. High dimensional and running accuracies ensure stable, smooth and energy-efficient operation. For maximum speed, performance and extended bearing life, Think NSK

• VJ Pamensky Canada Inc. of Toronto, one of the largest importers of electric motors in Canada, celebrated its 35th anniversary on Oct. 11, 2012 with a reception and dinner party in its headquarters warehouse. More than 300 guests attended. The company was founded in Toronto

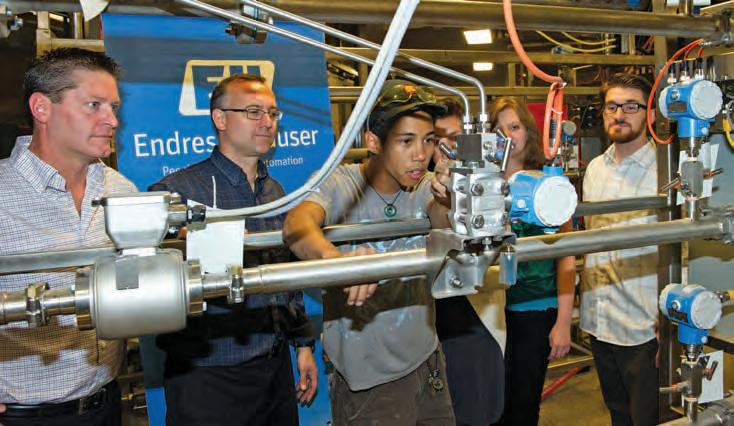

faculty for a $1.4-million high-tech learn ing facility. The new 1,800 sq ft Endress+Hauser Process Lab, located in a new Trades and Technology Complex, will educate approximately 600 students in its inaugural year and features over $1.275 million in top-of-the-line equipment.

• Danaher Corporation and Industries have announced the sale of their joint venture, Apex Tool Group Bain Capital, Boston, MA, for approxi mately US$1.6 billion. Currently, Danaher and Cooper each maintain a 50% joint ven ture ownership interest in Apex. Bain Cap ital is a private equity firm. This transac tion is slated to close in the first half of 2013. Apex will continue to produce and sell brands such as Crescent, GearWrench, Armstrong, Weller, Lufkin, SATA and Wiss, and the company will continue to be headquartered in Sparks, MD.

in September 1977 by Victor J. Pamensky as the exclusive importer of Brazilianmade WEG electric motors, controls and transformers. He and his partners have since grown the company to include branches in Winnipeg, Montreal, Winnipeg, Edmonton, Calgary and Vancouver.

• The well-being of industry in Alberta will be in better hands due to a novel partnership between Endress+Hauser Canada and Calgary’s SAIT Polytechnic. Endress+Hauser Canada, a supplier of measurement instrumentation, services and solutions for industrial process engineering, presented the keys to SAIT

• Bentley Systems Inc. of Exton, PA, a provider of software solutions for sustaining infrastructure, has acquired Burlington, ON-based Ivara Corporation, a provider of asset performance management (APM) software solutions for organizations in asset-intensive industries, including mining and metals, power generation and utilities, oil and gas, and petrochemical. The Ivara EXP solution – a core system for operations and maintenance and the Aladon Network’s reliability practitioners – helps owner-operators to obtain the best performance, reliability and safety from their assets. This marks Bentley’s second acquisition in the operations arena in 2012, the first being InspectTech, Pittsburgh, PA, for transportation asset management.

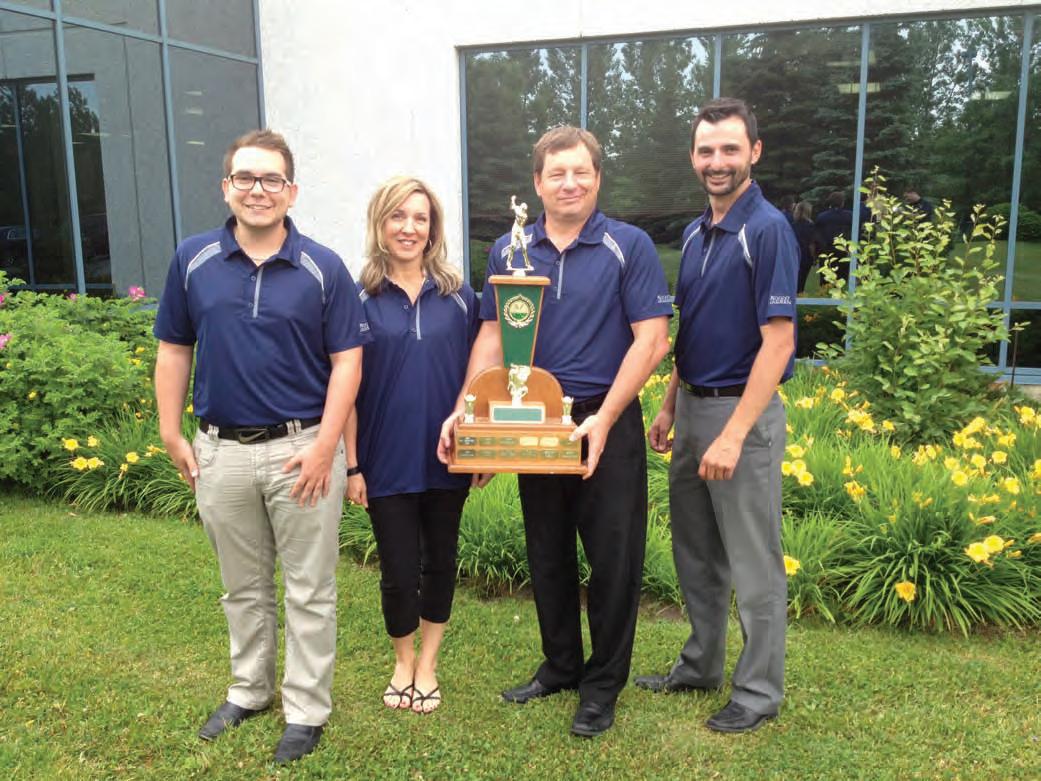

• The 52nd annual Quebec Bearing and Power Transmission Golf Tournament took place June 15-17, 2012, at the Au-

“The Oldest Industry-Specific Sports Tournament in North America,” says Paul Dixon, the Montreal branch manager for Ringball Corp. The event drew 140 attendees, including 104 golfers in 16 company teams. They represented distributors, agents and manufacturers in the bearing and power transmission industry.

• Motion Industries, Birmingham, AL, a distributor of industrial maintenance, repair and operation (MRO) replacement parts, has released the second instalment of its video series via its new MiHOW2 channel, online at www. mihow2.com. A thermal imaging device from FLIR is featured in the latest industrial product/application video release. The segment entitled ‘Troubleshooting and Maintenance Using an Infrared Camera’ can currently be seen online.

• ITM Instruments Inc., Ste-Anne-DeBellevue, QC, and FLIR Canada, Burlington, ON, hosted a free event at the ITM head office on September 5, 2012, with 45 visitors spending the day with the ITM team and participating in many activities. The events included a guided tour that gave attendees the opportunity to see ITM’s facilities, including its calibration and repair laboratories. Seminars, technical sessions and several hands-on activities were available throughout the day. Participants had the choice of selecting two out of four seminar topics: building inspection, security and automation, research and development, or industrial inspection. The event also included a tabletop show featuring products from FLIR, Extech Instruments, Phantom, Retrotec and GMI (Gas Measurement Instruments). Attendees were able to view the newest products as well as see several demonstrations. Both ITM and supplier experts were on hand to answer questions. As well, FLIR

Problem: Our gearboxes operate in a humid environment. Is there any way we can effectively protect them against moisture ingress?

Solution: Common sense is the key to success. The following seven steps should help:

1. Educate maintenance staff to avoid direct jetting of water at ingression points such as shaft seals and breathers.

2. If water spray is inevitable, use passive shields and deflectors to avoid direct water spray on shafts, dipsticks, fill-caps, breathers and so on.

3. Use high-performance seals that suffer less wear and offer better protection against contaminants.

4. Regularly inspect and maintain gaskets on fill-caps, hatches, etc.

5. Replace dipsticks with level indicators.

6. Keep hatches closed tight.

7. Replace a basic vent breather with a desiccant breather, which dehydrates incoming air, or use an expansion chamber, which allows the system to breathe without ingesting external air.

Mr. O’s thanks for these tips go to the experts at Noria Corporation. The company offers public, private and online courses in lubrication. For details, visit www.noria.com.

Do you have a solution for a maintenance problem? Send it in and if it’s published, we’ll send you $25 and a Mr. O Problem Solver T-shirt. Include your address, telephone number, complete details and, if possible, add a sketch to help explain your tip. Send your tips to Mr. O, Machinery & Equipment MRO, 80 Valleybrook Dr., Toronto, ON M3B 2S9.

With widespread E. coli contamination of beef from a major Alberta processing plant in September and October scaring consumers, the importance of equipment cleanliness is being given close attention across North America

When it comes to power transmission equipment used in the food processing industry, some types of drive systems are easier to clean and sanitize than other types. This article examines drive system cleaning and sanitizing challenges facing the food manufacturing industry, so that food manufacturers can make informed choices about how to maintain the highest level of productivity while meeting or exceeding food safety standards.

The food manufacturing industry is subject to food safety regulations designed to control or eliminate microbiological, chemical and physical safety hazards. Microbiological hazards are the most prevalent. They include bacteria, viruses and parasites that can produce disease in humans (pathogens). According to the Centers for Disease Control (CDC), more than 200 known diseases are transmitted through food. In the US alone, an estimated 76 million cases of food-borne disease occur each year, ranging from mild to severe, and resulting in approximately 5,000 deaths annually.

Depending on the type of food manufactured, processors must meet standards imposed by federal agencies, plus

those of provincial and local regulatory bodies. In addition, processors must comply with workplace safety and environmental protection regulations.

In the US, the newest set of Food and Drug Administration-backed standards — the Hazardous Analysis and Critical Control Point (HACCP) regulation — set forth quality guidelines for food manufacturers and requires them to develop a program of good manufacturing practices to keep foods pathogen-free. While HACCP is currently specific to seafood, meat, poultry, fruit and vegetable juice producers, it also affects ingredient manufacturers who supply these industries.

In short, food manufacturers are under relentless pressure to ensure that their manufacturing environments meet or exceed ever-stricter standards for cleanliness and hygiene. The cost of failing to ensure the safety of food can be high, as witnessed by recent, highly publicized product recalls and the ensuing effect on reputations and bottom lines.

Paradoxically, cleaning and sanitation to ensure food safety is vital to a food processing operation, yet it adds no value to the product. This paradox poses a challenge for management. To remain competitive, plants must operate with

maximum efficiency, eliminating downtime whenever and wherever possible. Cleaning and sanitation, however, require downtime. While the frequency and intensity of washdowns vary by the type of food produced, any time spent in this activity reduces production capacity.

It stands to reason that food manufacturers are looking closely at durable, maintenance-free equipment designs that lend themselves to quick, effective cleaning, in order to minimize downtime and maintain higher levels of productivity. Power transmission drive systems are no exception.

According to various industry estimates, the US food and beverage industry accounts for $500 billion in that country’s gross output yearly. If downtime spent in cleaning and sanitizing represented a mere 1% of that gross output, the cost of this activity would amount to $5 billion every year.

To cite an example, one major international meat processor operating 24/7 measures downtime in tenth-of-a-second intervals. Due to the high throughput rate, a few minutes of downtime costs thousands of dollars.

How much downtime does a typical plant need to incur in cleaning and sanitation? It depends on the operation. Manufacturers have some flexibility in determining cleaning intervals, as indicated in the USDA/Food Safety Inspection Service (FSIS) requirements: “All food and nonfood contact surfaces of facilities, equipment and utensils used in the operation of the establishment must be cleaned and sanitized as frequently as necessary to prevent the creation of unsanitary conditions and the adulteration of product.”

Interpreting this standard, an operator might have to clean processing and packaging equipment at the end of every line change, shift and workday. This could add up to 15 or 20 hours of mandatory cleaning each week. As a minimum, one washdown per shift is a common practice.

Recognizing the need for food processing plants to maximize productivity, the USDA issued a notice in 2006 (FSIS Notice 27-06) providing manufacturers some latitude in scheduling full clean-ups. In part, the notice reads, “To decrease downtime, increase production efficiency and minimize expense, establishments can extend the period between cleanups. However, establishments must … develop, implement and maintain written standard operating procedures (SOPs) for sanitation and … those sanitation SOPs [must] be effective in preventing direct contamination or adulteration of product.”

It goes without saying that food manufacturers can extend the period between cleanups and minimize downtime more easily when their equipment is easy to clean and maintain to begin with.

Drive system washdown considerations

Before examining the relative cleanability and chemical susceptibility of roller chain and belt drive systems, it may be helpful to consider some principles of good sanitary equipment design. A number of standards organizations have developed guidelines for the design and construction of food equipment. While these guidelines may differ somewhat in the details, they all adhere to the same general principles, such as those developed by 3-A Sanitary Standards Inc. for the dairy industry internationally.

3-A standards divide food equipment surfaces into two categories: 1) Food product contact surfaces and 2) Nonproduct contact surfaces.

A food product contact surface is one in “direct contact with food residue, or where food residue can drip, drain, diffuse, or be drawn” (FDA, 2004b). These surfaces must meet rigid sanitary design criteria to prevent food product contamination. Nonproduct contact surfaces are those parts of the equipment (e.g., legs, supports, housings) that do not directly contact food. Because they may indirectly contaminate the food product, however, these surfaces also should follow sanitary design principles.

In terms of sanitary design, all food contact surfaces should be: smooth, impervious, free of cracks and crevices, non-porous, non-absorbent, non-contaminating, nonreactive, corrosion resistant, durable, maintenance free, non-toxic and cleanable. Surfaces coated with metal alloy or nonmetal material (e.g. ceramics, plastic, rubber) must also meet these requirements. Power transmission drive systems, whether belt drives or roller chain drives, would typically fall into the category of a non-product contact surface. Following 3A Standards, non-product surfaces of equipment should be constructed with appropriate materials and fabricated in such a manner as to be reasonably cleanable, corrosion resistant and maintenance free.

Conclusion

In food processing operations, the easier it is to clean and sanitize equipment, the faster it is done. When food manufacturers measure downtime in fractions of a second and tally the cost in thousands of dollars per minute, they will spend every effort to speed the cleaning and sanitizing process along, commensurate with food safety.

MRO

Editor’s note: Due to space considerations, a comparison of the characteristics of chain drive and belt drive systems for food processing operations was not included here. It can be found in the complete online version of this article at www.mromagazine.com. This article has been adapted from a Gates Corporation white paper. Engineering Design Assistance With Belt Drive Systems For Food Processing Applications is available from the Gates Product Application Helpline, 303-744-5800, e-mail ptpasupport@gates. com, or visit www.gates.com/polychain. Online Reader Inquiry No. 500

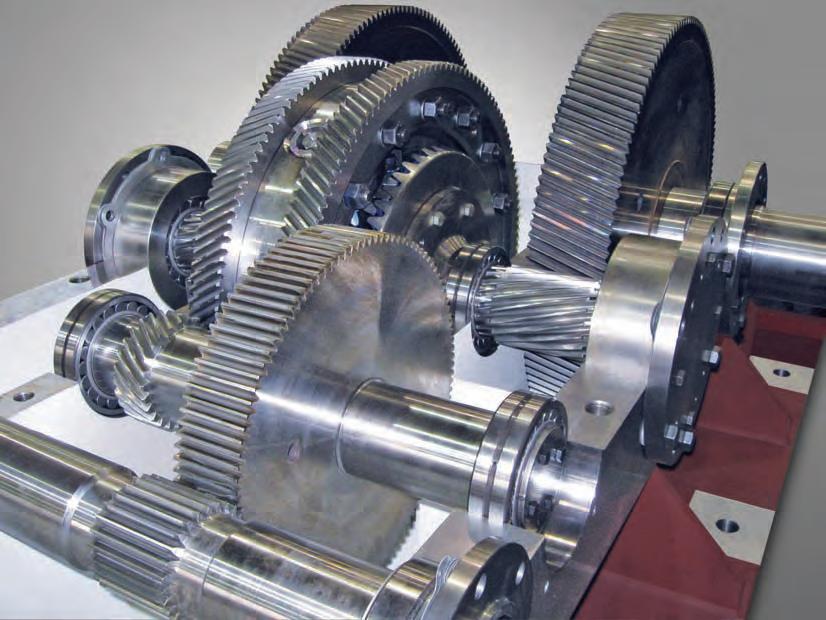

Here is a gearbox manufacturer’s perspective on how the design is affected by the operating conditions and performance requirements of the driven equipment, how this affects maintenance, and especially, lubrication

BY JOHN G. PROVEN

Proper lubrication is the single most important factor in ensuring the continued performance of a gearbox. Gears and bearings require properly specified and maintained lubrication.

Very simply, a gearbox is needed when a process requires normal speeds of equipment to be different than the electric motor, diesel engine, turbine, or other device that is driving the equipment. The large gearboxes discussed in this article can be found in applications including steel processing, mining, paper processing, moveable bridges, petroleum and chemical processing, textile mills, water treatment plants and cement plants, and are used with pumps, fans, compressors and turbines.

The reliability and durability of gearboxes depends on the following factors: the design parameters are properly specified, the unit is properly maintained, and the unit receives the proper lubrication of gearing and bearings.

Gearboxes must be engineered and designed, or properly selected, for the specified operating conditions, which include input speed and power, the required output speed and torque, and the service factor based on the application. Here, the American Gear Manufacturers Association (AGMA) standard recommendations are good, but the user must identify any unique factors.

Other operating conditions to take into consider are the environment, configuration requirements, the duty cycle, the external loading requirement and the desired design life (not necessarily infinite).

Most gearbox manufacturers are experts in engineering, designing and building gearboxes. Yet they are not necessarily experts in all of the processes and industries that they support. In many cases, the process may be confidential and proprietary, and must not be disclosed to anyone outside of the company.

The size of the gearbox is dictated by the amount of power and torque that needs to be transmitted. How much power is required? The gearbox designer/ manufacturer requires the expertise of the bridge engineer/designer, the steel mill OEM/user, the mass transit designer/operator, the ethanol producer, and engineers and designers of a multitude of other industries, to define the operating conditions and performance requirements of the driven equipment.

Gearbox maintenance

All gearboxes must receive periodic maintenance, including an oil change. Oil should be checked regularly for contamination from dirt, debris and other fluids such as water.

The oil should also be changed periodically based on the hours of operation and on the oil temperature. Oil that operates at elevated temperatures (above 150°F) needs to be changed more often than oil that operates at 120°F. As the temperature increases up to 180°F, the oil change frequency increases significantly. Between 180° and 200°F, the recommended time between changes is reduced by 75%.

Elevated temperatures accelerate the breakdown of the oil’s molecular structure, thereby inhibiting its ability to form a protective film. If oil continuously operates above 200°F, a circulating lube oil system should be considered to cool the oil.

AGMA recommends that oil be changed after the first 500 hours or four weeks of operation, whichever comes first. After the initial operation of the unit, AGMA recommends that oil be changed every 2,500 hours of operation or every six months, whichever comes first. AGMA further suggests that these intervals can be adjusted based on the system configuration as recommended by the manufacturer.

Furthermore, it recommends that a condition-monitoring program that identifies changes in the lubricant, such as colour, viscosity, oxidation, water concentration, contaminant concentration, percentage of sludge, and change in oil chemistry (primarily the additives), can be implemented to extend the change intervals. Basically, the rule is to check out the system and make a change to the oil if it makes sense.

In addition to oil, the physical condition of the unit, including the foundation, protective coating, seals, breathers, circulating oil system, couplings and bearings should be inspected periodically. A problem with any of these items, identified in the early stage by plant personnel, can help avoid a catastrophic premature failure of the gearbox.

For example, a worn bearing may cause uneven wear on gear teeth, but prolonged operation in this condition can lead to more severe conditions, resulting in broken gear teeth that can feed to other gears in the train and cause damage to more components that might not otherwise have required replacement.

An adverse condition may not be obvious to the operator but a periodic inspection of the gearing and any changes or acceleration in wear patterns will indicate that something has changed and the cause should be investigated.

Condition-monitoring programs evaluate changes in operating parameters and provide valuable quantitative data that can help forecast when failures might occur. These services can be performed by in-house personnel or contracted out. Oil temperature, level and condition, vibration, noise and the physical condition of seals and breathers are some of the parameters that should be monitored.

selected with the proper viscosity, pour point and chemical make-up based on each application.

All of the design factors listed previously contribute to the selection of the lubricant. Many applications, such as moveable bridge drives, involve relatively slow speeds — 1,800-rpm motors being slowed down to single digit speeds, generally working with high torque requirements.

Relatively slow-speed gears generally operate at pitch line velocities that are less than 2,000 ft per minute. Oil operating at these speeds will not generally be subjected to overheating as a result of churning or internal heat build-up from friction.

Oil shear, the breakdown of the molecular structure of the oil, and air entrainment — both conditions that reduce the effectiveness of the oil — will normally not occur at the lower speeds. There-

continued on page 14

125 years of unmatched chain manufacturing expertise for Canadian industry.

After an initial baseline evaluation of the system is recorded, periodic inspections, photographs and data analysis can be used to identify and evaluate any changes or trends that might signal a problem.

Proper lubrication is the single most important factor in ensuring the continued performance of a gearbox. Gears and bearings require properly specified and maintained lubrication. The oil must be

fore, in these applications, the performance of the oil will be very predictable.

Lubrication effectiveness

Lubrication effectiveness is a function of the oil film thickness and the ability of the oil to flow on the gear tooth surface. The viscosity of the oil varies with operating temperature and is the primary means of determining the effectiveness of the selected oil. If the viscosity is low, to the point that the oil does not have time to flow adequately to cover the tooth surface, insufficient lubrication will ultimately cause metal-to-metal contact between the mating gear teeth.

Oil film thickness is not only a function of the oil viscosity, but also the pressure on the gear teeth. Many factors, including the gear tooth design, pressure angle, diametral pitch, crowning and others, determine the forces where two gear teeth mesh. Oil is essentially a non-compressible fluid that

will be squeezed out from between the teeth when force is applied. The film can never be completely eliminated but it will become very thin under extreme operating conditions.

The oil film that remains is important because relative motion exists between the gear teeth — a combination of rolling and sliding. The pitch line of the gear teeth is the only point on the involute profile where the mating teeth experience relative rolling motion. The balance of the contact is a combination. Therefore, with two sliding metal surfaces mating, adequate lubrication film thickness is imperative for long gear life.

The surface finish, or roughness of the face of the gear tooth, also contributes to the recommended oil film thickness. A microscopic cross-sectional view of every surface reveals peaks and valleys defined by the surface finish. The roughness or surface finish of the face of the gear tooth can be measured in microns. As a general

practice, the calculated oil film thickness should be approximately 2.5 to 3 times the surface asperities — the magnitude of the peak and valleys. This amount of oil film ensures that under the specified operating conditions, providing that the oil has been properly maintained, the oil film will be adequate to prevent metal-to-metal contact between gear teeth.

Should metal-to-metal contact occur, scuffing, scoring, pitting and premature wear will be observed. These conditions represent several failure modes of the gearbox related to lubrication.

Oil must also flow properly in order to achieve proper lubrication. As the gear teeth mesh, the viscosity must be such to allow the oil to flow into the mesh. If the oil is too thick – yes, it can be too thick — the oil will not properly flow between the mating teeth. If the oil is too thin, the film thickness will not be adequate. Both conditions will result in metal-to-metal contact between the gear teeth and the initiation of a premature failure of the gearing.

In gear units that require splash lubrication, the gear teeth pick up oil from the bottom of the gear case and deposit the oil on the mating teeth. The gearbox will experience lubrication issues if the oil selected is not viscous enough or if the gear speed — the pitch-line velocity — is too high. In this case, centrifugal force will not allow enough oil to remain on the gear to produce an adequate film thickness. Again, the result will be premature pitting and scuffing, leading to failure.

In applications such as moveable bridges, where gearboxes may be exposed to a variety of temperature and weather conditions, a synthetic grade of oil might be considered, as the viscosity will not change as much as regular oil over a larger temperature range. The use of synthetic oil may not require that the oil be changed out with the changing weather.

If more standard oils are selected, oil heaters, oil coolers or perhaps replacement of oil during different seasons may be required. A factor for operators that must be addressed is that synthetic oils have significantly higher cost than the standard grades. The reduced frequency of replacement could justify the additional expense.

MRO

John G. Proven, P.E., is with Nuttall Gear, Niagara Falls, NY, a division of Altra Industrial Motion. Nuttall specializes in providing packaged helical drive assemblies of both mechanical and electrical components, as well as worm drives, for a wide variety of industrial applications.

BY DANIEL PHILLIPS, TREVOR MAYNE AND MARK ELLUL

All turbo machinery is subject to degradation that, over time, will affect a system’s efficiency and operational performance. Precise monitoring of turbo machinery performance with continuous torque-monitoring systems can be used to identify gradual efficiency loss, allow-

ing a more focused maintenance scope to be developed to return the system to its optimum operation and efficiency.

Torque monitoring based on heat balance, energy balance and other methods uses numerous parameters, such as pressure, temperature, flow rate, gas composition, etc., that require precise instrumentation to properly measure with low uncertainty.* However, phase displacement technology can be used to accurately measure torque directly at the coupling to within 1% of full-scale torque, using a combination of all electrical and mechanical sources of error. This accuracy provides the lowest amount of uncertainty when computing efficiency, compared to alternative methods.

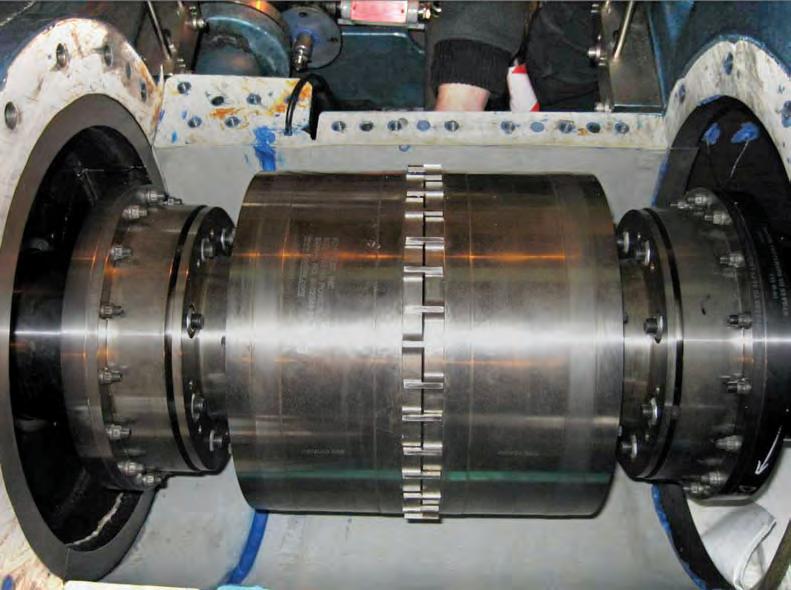

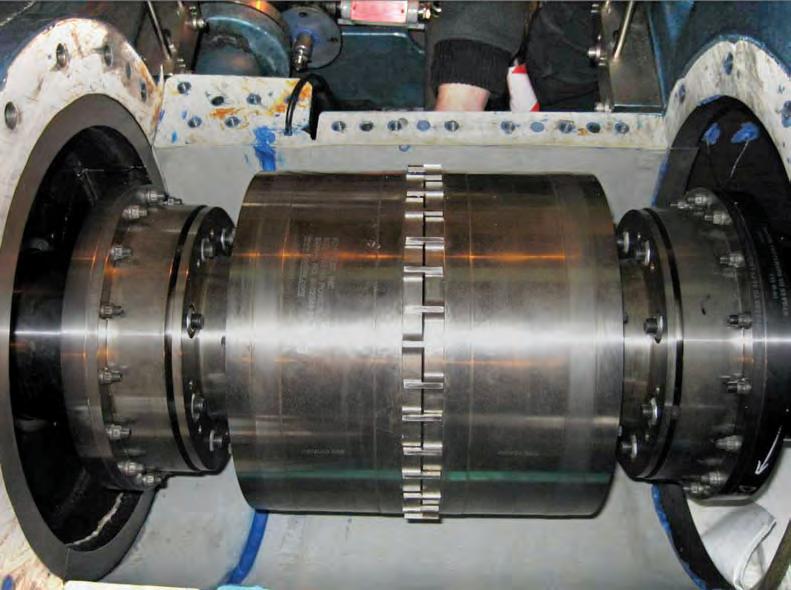

A system of this type was recently installed on a cracked-gas compressor train at Qenos Olefins Pty Ltd. in Sydney, Australia, to determine the causes of a power limitation. The company provides polymer products to Australia’s manufacturing sector. The Kop-Flex Powerlign system uses phase displacement technology for long-term reliability, eliminating the need for recalibration. Two rings with pickup teeth are installed on a torsionally soft spacer, and are intermeshed at a central location. Two monopole sensors 180 degrees apart are mounted on the coupling guard. As the

continued on page 18

* Kurz, R., Brun, K., and Legrand, D., 1999, “Field Performance Testing of Gas Turbine Driven Centrifugal Compressors,” Proceedings of the 28th Turbomachinery Symposium, Turbomachinery Laboratory, Texas A&M University, College Station, Texas, pp. 216-220.

coupling rotates, the ferromagnetic teeth create an AC voltage waveform in the sensor coil, which is digitally processed using known calibration parameters.

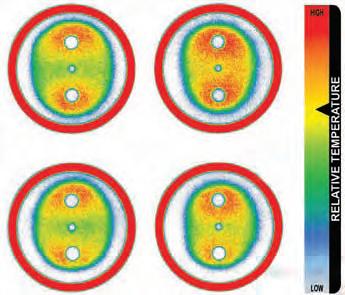

Because of the intermeshed pickup teeth, the system is referred to as a singlechannel phase displacement system, producing two independent torque measurements (see Fig. 3). The Powerlign system will output torque, power, speed and temperature, which can be easily integrated with any DCS system (see Fig. 4).

At the Olefins plant, the operating cycle of the steam-driven, cracked-gas compressor train is seven to eight years. During this cycle, the plant reaches production limitations because the compressor train encounters a power limit. To determine the cause of the power limit as ‘turbine fouling’ or ‘compressor fouling’, or a combination of both, was not confidently possible with the instrumentation that had been installed.

The cause had long been the subject of an engineering debate among the Machinery Group, Process Engineering Group and Operations Department. One option to add more power by upgrading the turbine power rating from 7.5 MW to 9 MW was investigated. This required a capital investment of $2 million. The plant elected to defer this investment and instead installed a torque meter at the major eight-year shutdown.

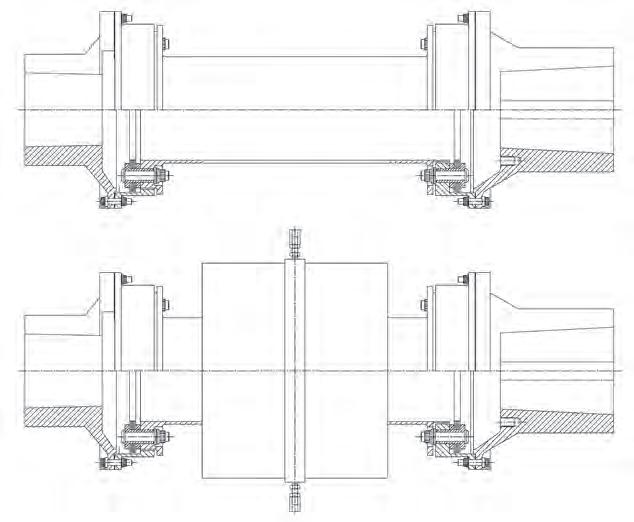

The installation involved replacing the existing coupling spacer and flexible halves with a ‘drop-in’ torque meter and integral flexible elements (see Fig. 1). The torque meter assembly was dynamically balanced to API standards so it was not necessary for the user to return any coupling components for the retrofit. The coupling guard was modified so that the two variable-reluctance sensors could be installed, completing the mechanical installation (see Figs. 2, 5 and 6).

The Powerlign system produces two independent torque signals.

4: Typical output from the Powerlign system. Fig. 5: The completed mechanical installation at the Qenos Olefins plant. Fig. 6: The Smart Spacer as it was retrofited at the Qenos Olefins plant. Fig. 7: Existing coupling arrangement at top, and with retrofitted Smart Spacer, bottom.

On restarting the plant and having completed a number of compressor efficiency improvements, the torque meter clearly showed the 7.5 MW turbine did not require an uprate and that the major power losses were coming from the compressor. The torque meter also allowed online tuning of the seal gas system of the compressor to establish the lowest power draw from the recycles that the seal system introduces. An additional 200 KW of power was reduced from the turbine load with the manual adjustments made on the seal gas system.

The torque meter is now being used to monitor turbine steam fouling issues and process-related compressor fouling so that corrective online washing can be activated as soon as issues arise.

The historical data collected from the torque meter will also provide a baseline of mechanical loading through the drive drain of the cracked-gas compressor over time. This data will be used to determine if increases in the maximum continuous operating speed rating of the compressor and the turbine can be accomplished at minimal costs. This would achieve increases in the operating envelope of the compressor.

The value of the torque meter justified the installation of a second system for the Olefins plant’s second steam cracking plant turbine/compressor train in October 2012. MRO

Daniel Phillips is the manager, field service engineering, at Kop-Flex, Emerson Industrial Automation, Hanover, MD; Trevor Mayne is a machinery engineer with Qenos Olefins Australia; and Mark Ellul is the Qenos I & E specialist at Qenos Olefins Australia.

BY FLORIAN BUDER

Are you experiencing increased vibration levels in your facility? Fan rotor unbalance can be the cause and an up-to-date balancer can be the solution to the problem.

Unbalance is the most common cause of increased levels of vibrations. In one example, in-situ balancing of five exhaust and circulation fans was child’s play with the use of a modern balancing instrument, data collector and analyzer.

For several years, the vibration behaviour of these fans had been neglected at a plant that manufactures cartons. No predictive maintenance program was in place, but eventually a new reliability engineer decided to reduce the vibrations in this equipment by getting it analyzed. After performing several diagnostic tasks, the sources of the vibration could easily be detected.

Accumulation of dust and dirt on all the rotor blades led to a 1x vibration peak in the velocity spectrum. In the analysis, the sine waveform and phase analysis confirmed the results. A static unbalance was the reason for the increased vibration.

The balancing procedure was successfully performed on-site during the next shutdown phase of the plant. The balancing instrument was used for the balancing runs, while the results were archived

in the related PC software.

Static unbalance requires only a one-plane balancing procedure, which was ideal for these fans. The accelerometers were attached to the non-drive end (NDE) bearing in the horizontal direction. The latest monitoring technology offers a second plane control feature, where the second accelerometer controls any negative influence on the NDE bearing during trim runs. This ensures that the vibration on both bearings will be

equally reduced and balanced. The target quality grade of 6.3 (DIN ISO 1940) was easily reached.

The plant went back online a few days later and the operator was extremely satisfied with the result of this service. The manager of the operation later stated: “In the past six years, I have never seen those fans run so smoothly.” MRO

Florian Buder is with Pruftechnik Canada, Laval, QC.

Online Reader Inquiry No. 503

BY CARROLL MCCORMICK

it ain’t broke, don’t fix it” is one old saw. “A stitch in time saves nine” is another. But if I had to explain which saw cuts the mustard and which one is baloney, I’d tell this little story about the sad side of reactive — or breakdown — maintenance.

I live in Montreal and own property in Nova Scotia. In 2010, a freak storm mowed down some of my trees, including 35 valuable pines. Over three visits, I had wriggled my 1967 Cockshutt tractor through the tangle of trees to hook on and drag the pines out into the clearing.

Logs all pulled, this spring I scheduled a sawyer with a portable mill to come in the day after I rolled into town.

On Sunday, day one, the Cockshutt and I happily fed the mill.

I’m hip to the charms of preventive maintenance, if not a card-carrying devotee. I’m good to my tractor, and basic PM tasks like oil, fluid and grease points get my full attention. When a rotten front tire collapsed in 2010 and cramped my style, I saw the future. The next summer my friend Adrian and I repaired the rear rims and I had new skins installed —

$900 and 35 hours of sweat well invested. I was dragging my feet on other growing problems, however. I was too busy. I “had ta git ‘er dunn,” as they say. The doomsday clock was ticking.

Sure enough, when I went to fire up the tractor Monday morning, it rolled over a couple of times and died. It wouldn’t jumpstart or any other kind of start and was deaf to my usual cussing. I called my sawyer. “Ian,” I said, “The damn tractor won’t start. You get to work on your roof today.”

Adrian, who, like me, is self-employed and has nothing better to do than repair ignorant tractors all day, offered to help me troubleshoot the so-and-so.

The batteries, both good batteries, went on the charger and we started on the fuel system. When we found grit in the fuel line, I decided to replace the original glass sediment bowl, which had been leaking anyway, with a shut-off valve and a modern filter. I drained the gas tank and ran into town for parts. Adrian spotted water in the gas. Note to self: buy new gas.

We found no smoking guns in the carburetor, but the throttle shaft was worn. Note to self: buy new throttle shaft. The fuel pump was fine. We put the fuel system back together, hooked up the batteries and primed the pump. I cranked, but had no joy.

We attacked the ignition system. I already knew that the spark plug wires were shot. I just hadn’t had time during my action-packed visits to deal with them. I ran into town for new wires and plugs too, just to be sure. Adrian’s inspection for cracks in the distributor or for

bad points came up negative.

But what about those flat batteries? I knew they were good, because they’d gone flat before (yep) and I’d had them load tested. Wait a sec! Hadn’t I seen a note in the owner’s manual about a dashboard light that was supposed to go out when the engine RPM got above idle, the one that had been glowing such a lovely red for, like, forever? The manual says it indicates a blown fuse in the regulator circuit. We dug into the ratty old fuse holder and found little pieces of fuse. Bingo! I ran into town for fuses.

Mercifully, by late afternoon, we’d resurrected the beast. I called back my sawyer. We hammered down and sawed out 3,700 board feet of lumber that week.

I lost one day of productivity, but had things been worse my sawyer would have waved “Chow, baby,” and caught his Friday flight to Italy. My production plans would have been hash.

The next time I know that it’s PM time, or when condition monitoring signals a condition red, I will schedule the downtime. Honest! After all, it’s what the maintenance guys with their act together have been telling me for years. MRO

Carroll McCormick is MRO Magazine’s senior contributing editor. My MRO is a new column that invites readers to submit personal stories about their off-the-job maintenance challenges and successes. Send us a photo and up to 600 words, and we’ll reward you with $25 and a coveted Mr. O Problem Solver t-shirt. E-mail broebuck@mromagazine.com or write to Bill Roebuck, Editor, Machinery & Equipment MRO, 80 Valleybrook Dr., Toronto, ON M3B 2S9.

This is the sixth segment of an eight-stage program on achieving world-class maintenance. Stage 5 was described in the September 2012 issue of Machinery & Equipment MRO and examined the field of trend management.

ell, here we are at Stage 6 of our world-class maintenance program. Everything we talked about in the past few months has brought us here. Up to now, the stages we have gone through have used precious labour hours and have cost money to implement. However in order to build a Maintenance Cost Management System, we needed to get our house in order.

Let’s look back and see where we spent our time, energy and money, and how that is going to help decrease maintenance expenditures and improve the distribution of maintenance costs. (Editor’s note: Digital editions of previous issues are available online at www.mromagazine.com.)

In Stage 1, we evaluated the equipment condition and put immediate plans into action to eliminate forced deterioration, and we put permanent actions in place to prevent accelerated deterioration. We completed a series of steps that not only evaluated the priority of each piece of equipment, but also how that machine has been performing.

During these evaluations, we had to research equipment history. Breakdowns, mean time between failures (MTBF) and the costs of maintenance and repairs were scrutinized. We also examined our current maintenance practices, including types of maintenance performed, the percentage of preventive or periodic maintenance work orders (PMs) and the backlog of maintenance work that was completed. We created maintenance ledgers that identified equipment subassemblies and prepared detailed spare part lists. We created lubrication maps and schedules and documented safety procedures.

In this first stage, we also set goals based on equipment priority and performance to systematically return equipment to its basic condition and to eliminate forces that would contribute to its deterioration.

So how did this step prepare us to save budgetary dollars? By spending hours prioritizing the equipment, researching performance and documenting equipment data, we in turn invested our money where we would see the most improvement (getting the best bang for our buck). We restored equipment to basic good condition and put basic maintenance plans into action.

We also spent weeks and sometimes months on the organization of the maintenance shop, the lubrication storage areas and the inventory stockroom. Spare parts lists and storerooms were documented and organized so that parts were available when needed and were easy to find.

We analyzed failures and corrective actions were put in place to stop equip-

The first five steps of this world-class maintenance program have decreased expenditures and improved the distribution of costs

BY PETER PHILLIPS

ment deterioration. PMs and backlogged work orders were addressed to provide better equipment servicing and repairs, thereby reducing failures and improving equipment reliability.

Although this first step cost a great deal of money and took a long amount of time to complete, the cost savings were likely staggering. It organized our maintenance department and any maintenance activity that affected equipment performance.

In Stage 2, we focused on breakdown analysis. The goal was to control the reoccurrence of serious failures. We learned investigation methods to analyze breakdowns to discover their root cause. We spent money training our maintenance staff and allowed them time to properly use these skills to eliminate recurring failures.

Using our new investigative skills, savings were realized in the reduction of parts, labour and equipment downtime, as repetitive failures disappeared. We also gained some support from the production department as equipment reliability improved.

In Stage 3, we began to hone our skills in periodic maintenance. Although PM

was performed on equipment before, this step brought it to the next level.

Our work order system and maintenance procedures were revisited. Maintenance instructions and procedures were reviewed and standard maintenance procedures were developed. PM frequencies and their results are now routinely examined to ensure the equipment is being serviced based on performance.

Again, this took dedication to find the hours to gather specific equipment PM instructions and procedures. However, cost savings were realized through more consistent operation of machinery and unscheduled costly repairs began to be eliminated.

Stage 4 developed countermeasures to address weak points in equipment and to lengthen equipment life. Project groups were formed to focus on improvement activities that would develop corrective actions to address weaknesses and to extend the overall life of equipment. These types of studies solve many long-standing equipment problems that companies live with for ages. Solving them takes a team effort from maintenance, production staff, and very often, engineers. It takes time to develop corrective actions

and money to implement the solutions. The outcomes of these project teams include substantial cost savings in labour, materials, product rework and rejects. There’s something for everyone.

Step 5 dealt with trend management using condition-based maintenance (CBM). Advanced methods of equipment monitoring were developed through vibration analysis, thermography, oil analysis and other specialized testing.

A great deal of time and money can be spent here on training and sophisticated technology. However, these new maintenance tools can predict failures well in advance, so that corrective actions can be planned and executed before any breakdown occurs. It deepens the skills of our maintenance team and gives them advanced tools to detect equipment problems.

All this brings us to Stage 6, maintenance cost management of repairs and maintenance (R&M — sometimes called O&M for operations and maintenance). From implementing the first five stages, there has to be a substantial decrease in R&M expenditures. World-class maintenance has been proven to do exactly that — reduce costs and improve reliability. Every step along our journey has prepared us for this stage.

With spare part inventory under control, the money spent on maintenance purchases should now be limited to what is necessary to maintain equipment. PMs and repairs should be organized and be on a predetermined schedule. Overtime should be at a minimum.

The attitude of the person you have making the purchases is very important. I spoke to a maintenance planner the other day and he said something that every manager would like to hear. He said that when he buys anything, he thinks like he is spending his own personal money. World-class maintenance is all about changing attitudes and old cultures. Your budget dollars are never enough, however. Maintaining the momentum you have from the first five stages will be a good place to delegate part of your budget. You’ve seen the savings these stages have generated thus far, so you can imagine the long-term benefits.

You are no longer flying by the seat of your pants, hoping you have what you need, when you need it. You no longer wonder what will be the next disaster that will cause you to spend more money from an already stressed budget and make you answer pointed questions at the morning production meeting.

I don’t know each of your situations, however my advice is to continue what we’ve started in world-class maintenance thus far, budget for it, work it, and enjoy more reliable equipment and a happier maintenance and production staff. MRO

Peter Phillips of Trailwalk Holdings, a CMMS consulting and training company, can be reached at 902-798-3601 or by e-mail at peter@trailwalk.ca.

fore handing them their paycheques. If they wield them skilfully and wisely, managers can use their personal actions to condition and internalize appropriate behaviours in their lower-level staff and managers. Leading by example can become the means with which to pass along organizational wisdom to a firm’s younger, aspiring members. Organizations need to know many things as they march into the future. However, the position this article takes is that before learning any new lessons, it is important to first master the old ones. So beware of the consultant or guru bearing the latest flavour of the month in management wisdom. MRO

Dr. Chris Bart, FCA, is the author of the mission implementation and leadership book, A Tale of Two Employees and the Person who wanted to Lead them, which has been one of the top 10 best selling business books in Canada for nine consecutive years. He can be reached at www. corporatemissionsinc.com.

anaging a plant is challenging for a host of reasons. One of the greatest challenges any manager can face is ‘keeping up’. But, staying abreast of the latest wisdom, information, techniques and opinions of various experts can consume tremendous amounts of time. And the one thing that every hardworking manager lacks is time.

Sometimes — well, most of the time actually — it isn’t about discovering new wisdom. It’s more about knowing what prevails or what is fundamental. The following six items are quick, essential lessons, time-tested and true, that your organization must master to succeed.

This one sounds like a no-brainer, but how many of us actually walk the talk here? In the end, every organization must do everything fairly well, but we can’t excel at everything all at once. We know, intuitively, some things are more important than others. Logically, as well, we are aware we’ve only got so much time and money.

Nevertheless, how many times do we demand our staff members simultaneously provide outstanding customer service, breathtaking cost efficiency, and great creativity, all while managing their day-to-day work with that same excellence? With so many blinking buttons on the console, there’s not enough time to press them all.

Conquering this one step, however, is pretty straightforward. Make a list! Then prioritize the items and tackle them, with focused determination, one at a time. Multi-tasking is incredibly common, and sadly it’s been proven to frequently lead to inefficiency.

People that multi-task are often very busy — and frequently never finish anything. It’s especially important to finish the first before going to the second. Some short-term losses may occur as one priority temporarily takes precedent over another, however one item at a time is the only way to eventually get the whole job done.

This is sort of a variation and follow-up on the first lesson, but it still requires separate treatment. There will always be some new thing that comes along that we can grab and hold as an excuse for abandoning the original plan. Indeed, the urgent always tries to muscle out the important. Resist! Yes, things change. But, it is never a good idea to respond to new information with a knee-jerk reaction.

Often, these distractions happen when (a) unexpected losses hit the organization, (b) elusive yet artificial financial goals are not being realized, and/or (c) senior managers have prematurely convinced themselves they face seemingly insurmountable problems. Before you know it, you’ve lost track of your corporate mission and instead, you’re chasing the latest in an endless stream of new ideas, or battling with a seemingly urgent problem that will distract you and prevent you from keeping your plant operating at peak efficiency.

The best way to work through this? Return to lesson 1.

Managers and staff always seem able to provide a litany of reasons as to why something isn’t happening as planned or anticipated. In fact, often the problems encountered are someone else’s doing. Managers blame subordinates. Subordinates grouse about their bosses. Everyone blames competition, government, the market and anything else that is nameless, faceless or not around. How many times, however, do we blame ourselves for the problem?

As companies look to the future, my advice is to take an unusual perspective. For every problem encountered, each staff member must think: “Somehow, this is (partly/completely) my fault, so what can I do about it?” Blaming others is unacceptable.

The starting point for this new perspective is to take each of the problems that are clearly hindering the ability of your plant to operate in a manner that matches with the goals of the organization and ask staff members what they think they can do personally – or with the help of others – to correct them. Explain why the problem needs to be fixed and help your team to stay focused on finding and implementing the solution through to completion.

I’m not talking about ‘to make profit’. While it’s true that continuous losses signal the end of any organization, focusing only on profit can be a narrow, dysfunctional activity.

The key to knowing why you exist lies in the notion of stakeholders. Many people contribute to the existence of an organization. The big three, though, are customers, employees and society.

Jack Welch, the former CEO of General Electric, and one of the most admired business executives in the world, said that the secret of corporate survival is “to make products of the highest quality and offer them to customers at the lowest price, while acting in an environmentally responsible and sensitive manner.” He was right. So in the immortal words of Nike, “Just do it.”

By the way, those who respond first to the demands of their stakeholders may create such an advantage for themselves that it will make it impossible for their competitors to catch up.

So you’ve got down the setting of priorities, staying on track and satisfying your stakeholders. That’s going well for you, but you’ve still got engagement problems. It should come as no surprise that the individuals who often have problems connecting their employees to the organization are usually the ones who are reluctant when it comes to opening up about the company’s goals, strategies and expectations.

Some managers seem to believe their lower-level staff can’t be trusted with such important information, or worse, that they are mind readers and so there is really no need to explain the firm’s strategy. And still others actually seem to believe that communicating it once, and only once, is enough.

There is no question about it: managers who want the best performance from their teams must perform well themselves.

It is discouraging to realize that there are still leaders of major corporations who don’t understand how negative behaviour affects their organizations. For instance, in an annual survey of America’s toughest bosses, Fortune magazine reports of one company in which the president makes his direct reports ‘bark’ be-

With temperature resistance up to 250°F, you can keep the strength and fixture time you need in higher heat applications.

BY SIMON FRIDLYAND

professional engineer when it related to production machinery or a production process in an employer’s facilities. In other words, an industrial employer did not need to employer or retain a professional engineer for the purpose of designing or evaluating production equipment and processes in its own facility.

On October 25, 2010, the Ontario government passed new legislation known the Open For Business Act, 2010. The act, among many other things, eliminated the industrial exceptions that have existed in Ontario since 1984. However, that section of the act was not to be proclaimed until October 25, 2012, a two-year delay designed to give the Professional Engineers of Ontario (PEO) an opportunity to develop associated regulations.

The Ontario government asked PEO to reach out to industry, explain the narrow scope of this change and help industry with the implementation of the change through a transition plan. PEO had meetings with industry in over 70% of the province and across a broad range of manufacturing sectors.

cess and correcting them can be costly in re-work efforts, downtime and start-up delays – not to mention added administration once the Ontario Ministry of Labour becomes involved. That’s why integrating health and safety at the design stage and before operations begin is a cost-effective way to prevent workplace illness or injury

The elimination of industrial exemptions ensures that legislation exists to coordinate the engineering design phase with the PSR process, creating one integrated and more effective process that puts the public interest first.

In the past, there was a lot of confusion related to fixing the problems identified in the PSR report. Let me give you some typical examples.

worked with industrial machinery and Industrial exemptions have permitted non-licensed persons to do the work of a