Top

Trouble shooting for

motors and drives

Digital soft starter virtually eliminates pump water hammer

Baldor’s MST digital soft starter with six-SCR three-phase voltage control offers protection for the motor, the soft starter and the load, ensuring trouble-free operation. Available from 7.5 hp to 1,000 hp at 208 VAC to 575 VAC, this product is suitable for a wide variety of applications, including pumps, compressors, fans, conveyors, mixers and stirrers. It features programmable torque control, providing a more linear acceleration during start that reduces wear and tear, and during stop, virtually eliminates pump water hammer. Two styles are available, an open starter or an enclosed combination starter. The open starter has a small footprint for easy mounting and is loaded with performance-improving and energy-saving features. The enclosed combination starter combines over-current

SP TLIGHT

protection and overload protection in a single package.

Baldor Electric

Online Reader Inquiry No. 345

Metric retaining ring is designed for thin-walled mechanical components

The Smalley Steel Ring Company has introduced a line of metric Hoopster retaining rings. These rings are designed to retain mechanical components when space is a problem. Suitable for light to heavy loads and particularly for thinwalled tubes, the easy-to-install and -remove ring features a low profile, precision circularity and small radial size, allowing it to be an unobtrusive com ponent in an assembly. An additional feature is its potential for high thrust capacity. Also, the low radial profile will not twist or deform under load. Over

150 new rings are available from 10 mm to 76 mm in carbon and 302 stainless steel.

RotoPrecision

Online Reader Inquiry No. 346

Redesigned parallel shaft gearmotor adds power, performance

Bodine Electric has introduced a new generation of its type E and F gearmotors. The 42A5-FX is a completely rede signed permanent magnet DC parallel shaft gearmotor that provides up to 40% more torque than previous E/F models. Forty stock models are of fered with either 12/24VDC- or 90/130-VDC-rated motor windings. New syn thetic lubricant allows the FX gearhead to operate at a wider temperature range while at the same time im proving overall gearhead

Increase your operations efficiency and profitability by reducing installation errors, maintenance costs and downtime. The Rexnord® ZAF6000 series bearings and new ZLF6000 large bore bearings are direct drop-in replacements to industry standard SAF bearings. Pre-lubricated and shaft-ready, these bearings decrease installation and removal time by as much as four times versus SAF models.

And, you can find Rexnord bearings at your local Motion Canada location. Our local sales and service specialists are experts in application and technical support, providing the parts and the know-how you need to stay up and running.

The brands you count on from the people you trust…that’s Rexnord and Motion Canada.

include overload protection circuitry, which safeguards both the pump and the operator from excessive amp draw or temperatures, and a trigger lock-off mechanism that protects against unintended operation during transport. The pumps are designed for a wide range of industries, such as mining, construction, industrial, power generation and more, and suit applications such as servicing machinery, moving paper rolls, lifting rail cars and rail alignment, mobilizing heavy equipment and gear pulling.

Top troubleshooting tips for motors and drives / 14

Learn insider advice from five hands-on maintenance experts.

What’s the best way to boost uptime? / 18 Four experts offer suggestions on how to put the brakes on reactive maintenance and increase asset uptime and reliability.

MRO on the Road / 25 Baldor reveals the inner workings of its motor plants; Tenaquip holds customer appreciation days.

MRO on the Road / 26 Big Acklands-Grainger MRO and safety

columns

Mr. O, the Practical Problem Solver / Quelling problems with electric motors.

departments

Editor’s Notebook / 6

Industry Newswatch / 8

The Safety File: How machine safety boosts productivity / 19 The major goal behind an Overall Equipment Effectiveness program is to minimize or reduce the causes of inefficiency in the manufacturing environment. Here’s how to do it.

Maintenance 101:

Implementing CMMS software / 20

Here are the important issues to consider and questions to ask before selecting a new computerized maintenance management system. This is Stage 8 in an eight-part program towards achieving world-class maintenance.

Business Briefs / 10

Mr. O, The Problem Solver / 12

The Safety File / 19

Maintenance 101 / 20

MRO on the Road / 25, 26

Product News

Product Spotlight / 2

Focus on Motors and Drives / 22

Focus on Condition Monitoring / 23

editor’s selections

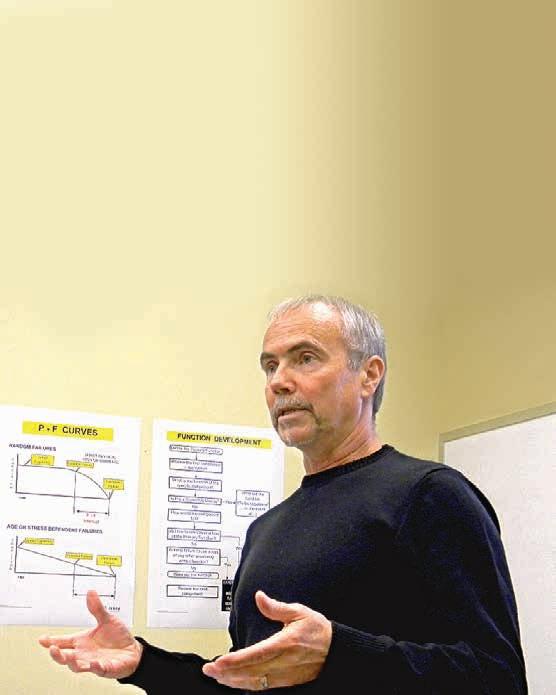

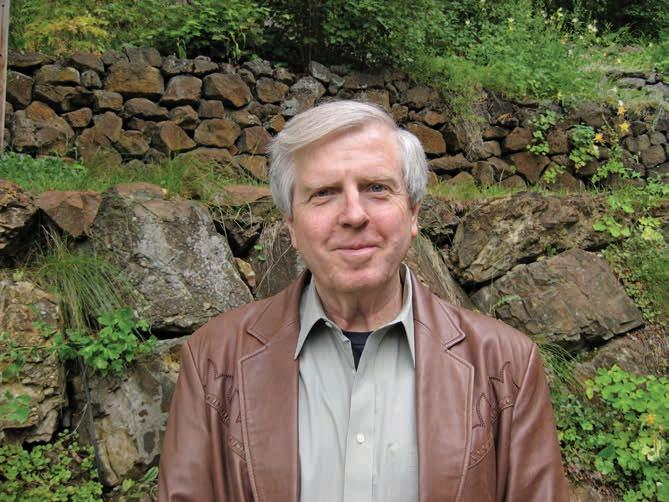

Terry Wireman of Vesta / 18 p2 p22 p22

‘Use clean dry air to blow the dust out of the drives. It cannot be compressor air.’

Bill at BJ Electric Motor & Control Ltd. / 14

‘In the worst cases, vibration can knock equipment out of service and halt plant production.’

Colin Plastow of Fluke Canada / 16

‘Now, new ways of applying NDT are expanding, and doing so at a critical time when an aging NDT workforce will be retiring in the next five to 10 years.’

Larry Cote of CINDE / 17

‘Most equipment failures can be traced to the neglect of basics, such as proper inspections, lubrication and fastening.’

More than we appear to be

s we launch the first issue of another year (our 28th), we thought it would be a good time to chat about the close relationship between the print magazine you are holding and our website at mromagazine.com.

First of all, it might be useful to know that any time you want to look up something you remember reading in MRO Magazine, you can always find a complete digital version of it on our website. On our home page, you’ll see the cover of the current issue and a link to the Digital Edition. Want to look up a previous issue? Just click on Print Archives, and you’ll find digital

editions from 2009 to the present, as well as text versions of our issues back to the year 2000.

The same section of our home page also lets you renew your subscription. By renewing annually, it helps keep our list up-to-date and current, which is important because of the twice-yearly auditing done on our circulation by a third-party organization. That audit proves to advertisers that we send the print magazines and digital editions to everybody we say we do.

If you’re a frequent computer or tablet user, you may want to receive MRO Magazine in its digital-only version –

or get both it and the print edition. That’s an option you can choose using the online Subscription Form.

It’s also a good idea to sign up for our weekly eNewsletter. It summarizes the news, feature stories and events that were posted on our website in the previous week. One click on a headline or link will take you to the full story on our website. It’s an easy way to keep up-to-date on what’s happening in the MRO field without having to visit the website every day. To sign up, use the Subscribe heading on our home page and select Free Newsletter Signup.

By the way, you can always opt out of receiving additional content from our industry partners, though the fact is, we really don’t send out very much of such material, and we ensure what we do distribute is timely, relevant and useful for you.

Another option on our site is to choose Topic Alerts (under the Magazine tab)

for various subjects you’re specifically interested in – bearings, for example. Then, as soon as there is breaking news on that keyword, we’ll send you an alert about it by e-mail. It’s a pretty nifty way to keep up-to-speed on a wide variety of industrial topics.

As well, say you need to research a new product to solve a production line problem. Well, our website also offers access to a handy Buyers’ Guide. Click on the link for it on our home page and you’ll be able to search for keywords by product or service, company name or brand. The database, part of our company’s eSource Network, contains more than 34,000 products from 550,000 companies, so you’re sure to find what you need.

As you can see, MRO Magazine is doing its best to give you all the information you need, whenever you need it, wherever you are.

Bill Roebuck, Editor & Associate Publisher

FEBRUARY 2013 Volume 29, No. 1

Established 1985 www.mromagazine.com www.twitter.com/mromagazine www.twitter.com/mroontheroad

EDITORIAL

Bill Roebuck, Editor & Associate Publisher 416-510-6749 broebuck@mromagazine.com

Ellie Robinson, Art Director Contributing Editors Simon Fridlyand, Steve Gahbauer, Carroll McCormick, Peter Phillips, Robert Robertson, Angela Webb BUSINESS Nick Naunheimer, Publisher 416-510-6868 nnaunheimer@mromagazine.com

Eric Achilles Cousineau, Adv. Sales Manager 416-510-6803 eachilles@mromagazine.com

Kimberly Collins, Advertising Production 416-510-6779

Melinda Marasigan, Subscription Enquiries 416-442-5600 x3548

Increased workplace safety expected with repeal of engineering’s industrial exception

Toronto – Effective March 1, 2013, those in Ontario responsible for professional engineering work in relation to production machinery or equipment must be licensed by Professional Engineers Ontario (PEO). The Government of Ontario has approved a change to the Professional Engineers Act that will remove the so-called industrial exception on March 1, 2013.

In addition, Ontario has also approved a regulatory provision to help employers make the transition to the new requirement. Under this regulation, employers who file a transition plan with PEO by March 1 will have up to one year to meet the requirement.

With the repeal of section 12(3)(a) of the Professional Engineers Act, individuals must now be licensed by PEO if they do any act within the practice of professional engineering on machinery or equipment used to produce products for their employer in their employer’s facility.

In 1984, when the exception was enacted, requirements existed for Ontario’s Ministry of Labour engineers to approve predevelopment reviews of proposed industrial processes and associated equipment. This requirement was replaced by Regulation 851 under the Occupational Health and Safety Act, which introduced the current requirement for industry to have professional engineers approve Pre-Start Health and Safety Reviews (PSRs) prior to the start-up of newly installed or altered production equipment or machinery. If a PSR finds deficiencies in the setup of equipment or machinery, the equipment or machinery cannot be used until the necessary changes are made and a PSR approved.

“Repealing the industrial exception brings professional engineering in again at the beginning of the production process development cycle, so that the requirements under the Professional Engineers Act support and complement the requirements and intent of the PSR process,” said

“Engineering is regulated to serve and protect the public interest, and professional engineers are accountable to PEO for doing just that by maintaining a high quality in their work and also by considering its overall implications. Bringing this mindset into the design of the production process should be costeffective for industry by lessening workplace illness or injury and associated workplace insurance claims, and minimizing retrofitting, downtime and equipment replacement.”

Instructional webinars and information about the new requirement are available on the PEO website at peo.on.ca.

Reader responses

• Stan G. comments, “I’m fine with the ‘engineered’ approach. However, at what point does competency come into question? How are the credentials of a ‘licensed’ individual factored into the safety equation? It seems to me that competency is a thorny issue that we don’t like to discuss in the engineering world.”

• “More red tape and non-required costs,” says Andy in response to this story.

• “Will the PEO require that a Canadian P.Eng. review and approve machines designed and built in other countries and subsequently imported into Canada? If not, then why not?” asks C. Stout.

• Finally, a reader who titled his response ‘Money Grab’ said: “Perhaps this is reasonable for those that make a living providing engineering services on a contract basis that do indeed involve the public well-being. But for those in industry that are already following strict ‘code of ethics’ and ‘compliance’ plans regulated directly by their employer and through government regulations, this ‘tax’ appears only to be there to help fill the very empty coffers of the PEO. And the provincial government will soon be filling their respective coffers for many of those in the skilled trades.”

Add your response by calling up this

REMEMBERING

WENDY MCDONALD

Vancouver – Wendy Burdon McDonald, CM, OBC, LL.D. (Hon.), D.Tech. (Hon.), passed away December 30, 2012, at the age of 90. McDonald served more than 60 years as a leader in her family-owned international industrial distribution company, BC Bearing Engineers Ltd. of Burnaby, BC, and later on BCB Corporate Services Ltd. for Norcan Fluid Power Ltd. and BC Bearing Chile SA.

Under her leadership, BC Bearing was recognized with a number of awards, including the Power Transmission Distributor of the Year presented by Machinery & Equipment MRO magazine, and twice as one of the Top 50 Best-Managed Private Companies in Canada. In 2001, the Bearing Specialists Association awarded its first Lifetime Achievement Award to McDonald. The Golden and Diamond Jubilee Medals were presented to her in commemoration of Her Majesty’s accession to the throne and in recognition of McDonald’s contributions to Canada.

She also was appointed a member of the Order of Canada and a member of the Order of British Columbia. She received the Veuve Cliquot Award of Distinction as Canadian Business Woman of the Year, a YWCA Women of Distinction award, the RBC Canadian Woman Entrepreneur Award, and was inducted into Sales and Marketing Executives International’s Academy of Achievement Hall of Fame.

A detailed tribute can be found on our website via http.bit.ly/12fQHPe.

SAFETY BLITZES TARGET WORKPLACE HAZARDS IN ONTARIO

Toronto – Ontario is conducting three heightened enforcement blitzes at workplaces across the province. Inspectors from the Ministry of Labour are visiting underground mines to check on diesel emissions and other hazards that could affect air quality in January and February, industrial and construction workplaces to check for slip, trip and fall hazards in February and March, and health care workplaces to check on workplace

practices, and check that workplaces are complying with the law.

During the blitzes, inspectors check on the condition and maintenance of safety equipment, worker training, the use of safety equipment, and other potential health and safety hazards to help prevent workplace injuries.

Since 2008, ministry inspectors have conducted more than 345,000 field visits, 47 inspection blitzes and issued more than 560,000 compliance orders in Ontario workplaces.

BSA CONVENTION REGISTRATION OPENS

Glen Ellyn, IL – Registration is open for the Bearing Specialists Association (BSA) 2013 Annual Convention, taking place May 4-7 at the Westin Hilton Head Island Resort and Spa in Hilton Head, SC.

With the theme of ‘We’re All in This to Win’, the conference will offer a lineup of speakers selected to help attendees move their companies to the winners circle in the recovering economy, said conference chairman Andy Nations of Bearings and Drives Inc.

“The BSA Annual Convention is the only industry event that brings together the top leadership of authorized bearing distributors and manufacturers,” he added. “As such, it offers networking opportunities along with a business program tailored for the industry leadership who attend.”

The 2013 business program will address winning strategies that meet customer needs. Speakers include Dr. Bruce Yandle, Professor of Economics Emeritus, Clemson University, and Dean Emeritus of Clemson’s College of Business & Behavioral Science. He will talk about the expectations in the recovering economy and the road ahead.

Lt. Col. Rob ‘Waldo’ Waldman, founder and president of The Patriot Group, a

Photo: Bill Roebuck

Wendy McDonald chats with Dermot Strong of BC Bearing Engineers at a BSA conference in 2008.

graduate of the Air Force Academy, and a highly decorated F-16 fighter pilot with more than 65 combat missions in Iraq and Serbia, will talk about Top Gun Leadership. Eric Chester, author, speaker and founder of the Center for Work Ethic Development and an expert on Generation Y, will be heard on the topic of finding the right personnel.

Delegates will also hear from motivational speaker Terry Bowden, a former National Coach of the Year and a television and radio personality.

Also on the schedule are industry updates and BSA’s Conference Table Session, which encourages distributors and manufacturers to build problem-solving relationships.

Complete convention details are available at bsaconventions.org.

MANUFACTURING SHOW RETURNS TO TORONTO SEPT. 30-OCT. 3

Toronto – The newly-improved International Centre in Mississauga, ON, will be the venue this fall for the 2013 Canadian Manufacturing Technology Show (CMTS). The show is returning to the facility after 14 years in downtown Toronto.

CMTS 2013 will take place Sept. 30Oct. 3. Billed as Canada’s largest manufacturing event, an audience of about 10,000 manufacturing professionals from across the country and around the world is anticipated. About 500 exhibits will feature technologies and solutions in the machine tool, tooling, metal forming and fabricating, automation, design engineering, and plant management segments.

The show is being presented by the Society of Manufacturing Engineers. With Canadian headquarters in Toronto, SME promotes an increased awareness of the value of manufacturing among industry professionals and the public, while supporting educational initiatives and introducing career options for those entering the industry.

Event partners include the Canadian Machine Tools Distributors’ Association (CMTDA), Canadian Tooling and Machining Association (CTMA), Canadian Manufacturers & Exporters (CME), Automotive Parts Manufacturer’s Association (APMA), Canadian Wind Energy Association (CanWEA) and the Business Information Group, publisher of Machinery & Equipment MRO magazine and mromagazine.com.

For more information, visit cmts.ca or call 1-888-322-7333.

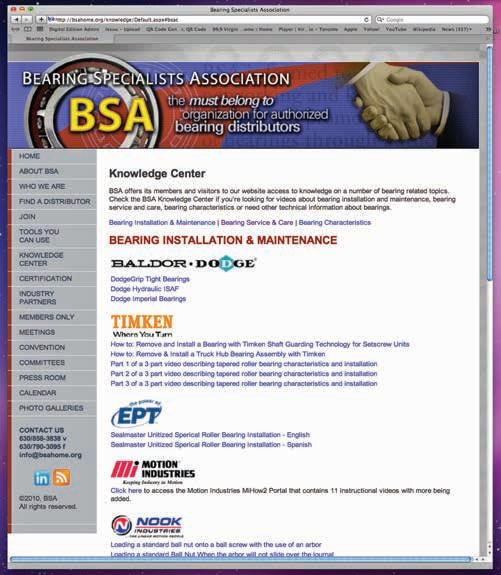

BEARING VIDEOS AVAILABLE NOW ON BSA WEBSITE

Glen Ellyn, IL – Inviting industry leaders and participants to ‘get the picture’ about bearings, the Bearing Specialists Association (BSA) has launched a new online Knowledge Centre featuring how-to videos on Bearing Installation and Maintenance, Bearing Service and Care, and Bearing Characteristics. The videos were produced by a number of BSA’s participating manufacturers and can be found online at bsahome.org.

BSA believes the videos offer both a

resource for problem-solving and a training opportunity for distributors and end users. The Knowledge Center was jointly developed by BSA’s Social Media Task Force chairman Kevin Haffey of NSK Americas, and Educational Services Committee chairman Jim Neill of Motion Industries Inc.

BEARING GROUP’S EDUCATION PROGRAM EXPANDS FOR 2013

Chicago, IL – The American Bearing Manufacturers Association (ABMA) has opened registration for its 2013 education program. In addition to the usual course locations, the association has also added a west coast offering for its Essentials Course, which will take place

April 9-11 in Phoenix, AZ.

ABMA education courses offer participants a blend of valuable bearing theory and reference material, along with the ability to use this knowledge in real-world scenarios. In addition, ABMA says no other courses in bearing technology offer access to industry experts with the knowledge and experience of its course faculty.

For more details and to download the brochure, visit the website at http://bit.ly/YuXn7r.

MAINTRAIN CONFERENCE TO MOVE TO CALGARY IN 2013

Toronto – The Plant Engineering and Maintenance Association of Canada (PEMAC) reports that its next MainTrain conference will be held in Calgary, AB, at the Sheraton Cavalier hotel, Nov. 18-21, 2013.

To make MainTrain better, changes are planned, says Cindy Sneddon, PEMAC executive director. “Firstly, PEMAC has made the decision to focus MainTrain as an annual, cross-sector conference on sharing excellence in the theory and practice of maintenance, reliability and asset management. Secondly, we will be hosting meetings of the Global Forum on Maintenance and Asset Management in conjunction with MainTrain 2013. This will bring international speakers in the field of maintenance and asset management to the event.”

For more information, visit the website at www.maintrain.ca. MRO

Business Briefs

News and views about companies, people, product lines and more

• C&U Americas, Plymouth, MI, the North American subsidiary of The C&U Group, China’s largest bearing producer, and the 11th largest bearing maker in the world, has named Bill Childers as its new president. The announcement was made by XianLiang (Peter) Zhou, chairman of C&U Americas, who noted that Childers brings a wealth of management experience and bearing market expertise to the C&U Americas team. Prior to C&U, he served as president of Rexnord North American Sales for four years. He was also president of the Superior Electric divison of Danaher, president of NSK Canada, and a senior vice-president at NSK Americas Industrial Childers started in the business with

Emerson Power Transmission and capped off a 25-year career with the company as its vice-president of sales.

• Brooks Instrument LLC, Hatfield, PA, a provider of flow, pressure, vacuum and level solutions, has appointed Scott Amsbaugh as general manager. He is now responsible for overseeing Brooks’ global business operations. “Brooks is a stable company with strong growth plans,” said Yahya Gharagozlou, group president of parent firm ITW.

• The SKF Group, Gothenburg, Sweden, has been awarded a contract by the American Bridge Co. to supply advanced technological solutions for the main hub for Caesars Entertainment’s Las Vegas High Roller observation wheel. The 550-ft-tall

wheel will be equipped with two SKF spherical roller bearings that are the largest ever produced at the SKF manufacturing facility in Gothenburg, along with related technologies within SKF’s platforms of seals, lubrication, and consulting services. The two custom-designed SKF spherical roller bearings (one within each side) weigh approximately 8,800 kg, and have a 2,3000-mm outer diameter, 1,600-mm inner diameter and a width of 630 mm.

• Konecranes, Burlington, ON, has appointed Roger Morin as training manager for Canada. He will work in close cooperation with the company’s service branches as an additional sales and support resource in the promotion, sale and delivery of regional seminars, on-site customer specialized training, operator training and Konecranes Training Institute courses. The Konecranes Training Institute provides training in over 40 North American cities each year. In 2013, the following seminars are scheduled for Canada: Calgary April 22-26; Toronto May 6-10; Edmonton Sept. 9-13; Vancouver Sept. 23-27; and Sudbury Nov. 11-15. For details, visit cranetrainingu.com/regional-seminars.

• Bearing manufacturer NSK Corp., Ann Arbor, MI, plans to set up a $70-million manufacturing subsidiary in Mexico in order to better deal with the expansion of automobile production in Mexico, and in order to keep up with expected growth in the automotive segment among the North American Free Trade Agreement (NAFTA) countries of the United States, Canada and Mexico. Through the establishment of the subsidiary, NSK will be better positioned to provide products such as automotive bearings in a timely manner. The new company will be called NSK Bearings Manufacturing Mexico S.A. de C.V., and will be located in Guanajuato, Mexico. It will be represented by Steven Beckman, senior vice-president of NSK Corp. The size of the plant site area is about 100,000 square metres. Commencement of operations is planned for spring 2014. NSK currently has eight manufacturing sites and 20 sales offices in the Americas. The company’s Canadian operation, NSK Canada, is based in Mississauga, ON.

• NTN Bearing Corp., Mount Prospect, IL, has launched a new website to serve customers in North America and South America. Combining its business territories in Canada, the United States, Mexico, and Central America and South America, NTNAmericas.com allows visitors from all regions access to product information, distributor searches and

SKF workers assemble a bearing for the Las Vegas High Roller observation wheel.

Photo: SKF Group

training programs. “The new website … is an important component of One NTN, our internal campaign to provide a unified approach to serving our customers in the Americas, and make doing business with NTN even easier,” said Pete Eich, executive officer and deputy general director of the Americas Region. The site allows visitors from all regions access to NTN’s training programs, such as its three-day Product Training School, E-Knowledge Web Training and On-site Mobile Classrooms that come to the customer. E-Commerce sites such as Distributor On-Line and Customer Portal for US and Canadian customers remain accessible from the new site, which replaces the separate websites previously operated by NTN Canada, US, Mexico and Panama. Founded in 1918, NTN operates more than 60 plants worldwide and is the third largest bearing manufacturer in the world.

• Vale, the Brazilian-based parent of Toronto-based mining exploration company Vale Canada Ltd., has signed a major contract with Metso to deliver 110 heavyduty slurry pumps to its Moatize coal mine in Mozambique. The order is part of Vale’s plan to increase the mine’s capacity to 11 million tonnes. The value of the order is EUR 3.3 million. The pumps are specially designed for the demanding conditions associated with mining and for easy maintenance. The Moatize delivery consists of heavy- and extra-heavy-duty horizontal and vertical spindle spillage pumps specifically designed for the given applications, most of which are considered as arduous. High-chrome iron alloy is the material best suited for coal applications, providing excellent abrasion resistance with good corrosion resistance. At Moatize, the most aggressive-duty pumps are the cyclone feed pumps, where the Metso XM400 pump was selected. This extra-heavy-duty design was specifically chosen because of

its large-diameter impeller, which enables the pump to operate at minimum rpm, reducing impeller tip speed and hence the rate of wear. The inlet diameter allows the minimum inlet velocity, reducing both abrasion and impact wear. Wet end life is therefore considerably extended. All pumps chosen for this project are designed for ease of maintenance during normal and routine inspection or repair. Bearing frames and rotating elements can be removed as a unit, enabling efficient impeller and gland seal component renewal.

• Commercial Solutions Inc., Edmonton, AB, was advised Jan. 23, 2013 by Industrial Distribution Group Inc. (IDG), that the board of directors of IDG had withdrawn IDG’s proposal to acquire the company. Commercial is an independent industrial distributor with 23 services centres and about 275 employees located primarily in Western Canada. MRO

mromagazine.com.

Quelling problems with electric motors

Problem: In our facility, several electric motors are noisy, show signs of vibration wear, and provide less than ideal service life. What are some useful tools to determine the causes of these problems?

Solution: For condition monitoring and troubleshooting of electric motors, a useful device is the electrical discharge detector. It can identify motors suffering from electrical erosion without dismounting them, providing a valuable gain of time.

Detecting electrical discharges and getting rid of them helps extend equipment life, reduces vibrations and the noise/comfort complaints of users, lowers operating costs, increases the long-term value of the system, and reduces maintenance interventions.

A laser tachometer is also useful everywhere speed is a critical parameter. A simple control can be performed and all the related risks are minimized. It helps in adjusting the equipment properly, helps reduce unnecessary energy costs and improves the efficiency and performance of the whole system.

As well, a sound-pressure meter lets you put figures on the apparent noise of your installation. A meter can satisfy environmental working rules and bring trust and seriousness to your installation. Using a sound pressure meter also will help reduce the noise/comfort complaints of users, and improve the performance perception of the whole system.

Mr. O thanks SKF Canada’s Paul Michalicka, head of maintenance products for North America, for these tips.

Do you have a solution for a maintenance problem? Send it in and if it’s published, we’ll send you $25 and a Mr. O Problem Solver T-shirt. Include your address, telephone number, complete details and, if possible, add a sketch to help explain your tip. Send your tips to Mr. O, Machinery & Equipment MRO, 80 Valleybrook Dr., Toronto, ON M3B 2S9.

Mr.0 The Practical Problem Solver

The delivery to Vale consists of over 110 Metso pumps like these.

Photo: Metso

BY CARROLL MCCORMICK

TIP TALK

TEN HANDS-ON MAINTENANCE TIPS FOR MOTORS

AND DRIVES

Routine care of motors is a familiarsounding and important part of a maintenance routine, for sure. But did you know that rogue electrical currents can blast bearings, that dust can knock drives offline or that a special screwdriver can keep muscle-bound electricians from causing motors to behave unreliably?

Read on to pick up some tips from onthe-job experts.

TIP{1} Perform regular health checks on motors. There are lots of parts in motors that need regular care. “Not unlike having a check up at your doctor’s office, periodic checks and measurements of your motors assist in early detection of any possible issues,” says Mark Gwinnett, head of service division, ABB.

“Tests such as PdMA (which can refer both to predictive maintenance and the PdMA Corporation, which specializes in predictive maintenance and condition monitoring), vibration and oil analysis will provide a complete health check on your motor.

“Critical applications in Canada’s oil sands in Fort McMurray – those that are in harsh conditions, for example – rely on these tests to ensure the motors are in top operating condition. These tests are also done on critical spares that could be required during emergency replacement.”

TIP{2} Tighten motor electrical connectors to the manufacturers’ recommended torque settings. For three months, a part of the domestic and international baggage handling system (BHS) at the Montreal Pierre Elliot Trudeau International Airport had logged faults, saw baggage totes delayed and go missing, and one time, the bag handling system stopped working.

The big trouble was that troubleshooting revealed nothing. That was until maintenance noticed one day that one of the system’s 75 motors was running very slowly.

“We opened the motor junction box, where six bolts hold electrical connectors. They were misshapen and cut, giving a bad elec-

trical connection. They had been tightened down so hard that they broke,” recalls Ghislain Reindeau, interim site manager, Cofely Services, which operates the BHS. Maintenance discovered that 10% of the motors had bad connections. Cofely bought a set of high-end Wera torque screwdrivers and set them to the torque settings recommended by the motor manufacturer. “With the torque screwdrivers, I am 100% certain that the bolts will not be overtightened,” Reindeau declares.

TIP{3} Protect motor bearings from transient voltage damage. “The biggest issue we see with variable speed drives (VSD) and motors is the failure of the purchaser to buy some sort of protection for the bearings. VSDs can send harmful transient voltages down the shaft and wreck the bearings,” says Rob Van Bavel, district manager, Baldor Motors and Drives Ltd. He’s based in Edmonton, AB.

An unprotected motor may last only a few weeks. “You can hear the noise from metres away. The user thinks it is a bad bearing. Users in heavy industry understand the problem, but a lot of users in lighter industries do not,” Van Bavel says.

One solution is to order new motors with grounding bushings or retrofit them into existing motors – a task that maintenance teams should be able to do in-house. The bushings may cost between $200 and $500. For Class I, Division 2 hazard areas, however, which have a potentially explosive atmosphere, ceramic bearings

are the safe solution, he advises.

TIP{4} Remove dust to prevent drives from tripping off. Nuisance trips that down drives may be caused by a dust and static discharge problem. “They may appear as ground faults, temperature faults, over-current faults or communications faults,” says Bill (who only goes by his first name). He works at BJ Electric Motor & Control Ltd. in Stewiacke, NS. “Dust will stick to the boards and cause a trip because of a static charge. Everything on your drives

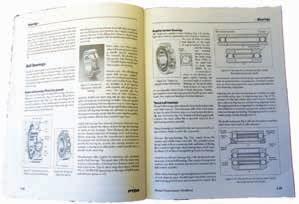

Fig. 1: Transient voltage damage from variable speed drives can destroy bearings. It takes a microscope to see the damage, but it is plainly audible from metres away.

Fig. 2: Dust-covered motors will overheat and die young.

Fig. 3: Check for deteriorating insulation or corroded terminals in motors operating in wet or corrosive environments.

Fig. 1

Fig. 3

Photos: Carroll McCormick

Fig. 2

works on very low voltage. It does not take much to cause a nuisance trip.”

Cleaning dust out of drives should be part of the preventive maintenance program. Bill has two tidbits of advice for what to do come cleaning time: “One, make sure the power of is off for 30 minutes to let the capacitors bleed off before you blow them out. Some people say five minutes is enough, but it is not. Two, use clean, dry air to blow the dust out of the drives. It cannot be compressor air.”

TIP{5} Ventilate and clean motors and drives to prevent overheating. Motors and drives are designed to operate at certain temperatures. Bill offers this rule of thumb. “If a drive or motor is meant to operate at a 30-degree Celsius rise, it should be running at 60 degrees in a room with an ambient temperature of 30 degrees.”

What happens if the operating temperature is higher? “Every 10-degree increase in temperature above normal running temperature shortens the life of the drive or motor by half,” Bill says.

“For your PM, open up your drive and look for dust buildup and contaminates. Check to ensure that drive fans are not only freewheeling, but also are operating. Blow out the drives and motors.”

TIP{6}

Regularly rotate the shafts in spare motors. There are stories out there of a maintenance crew pulling a brand new spare off the shelf, installing it and having it quickly fail or not work at all. A possible reason, especially for heavier motors, is that it sat for a long time without the shaft being rotated, so the weight on the bearings damaged the race.

“The weight of the armature will, over time, cause a bearing to put an indentation in the race. You put the motor in service and it doesn’t last very long,” says Peter Phillips, owner of the maintenance and training consultancy Trailwalk Holdings, in Windsor, NS. Consider incorporating a twice-yearly, 180-degree rotation of the shafts in your CMMS PM routine.

TIP{7} Double-check the amperage setting in your drives before starting up a new system. Phillips tells the story of a Canadian company that installed a packing line that had been built in the United States. The variable-frequency drives in the packaging equipment had been set in the US for 480 V and 3 A, but the Canadian plant was running on 575 V. The installers forgot to change the amperage from 3 amps to 0.3 amps and all 26 motors fried within days of starting up the line.

The moral of the story is that if you have a voltage change, double-check that the amperage is appropriate to the plant voltage; e.g., by removing the motor cover and verifying with a meter that the motor is drawing the right amperage.

TIP{8}

How to halve the work of recording bearing temperatures and make the data more accessible. When it comes to recording motor temperature readings manually, Phillips says, “People drop the ball all the time. And there is no way to trend the temperatures if they are only on paper.” It can also be time consuming. “One company I know was taking down about 800 readings every day. It took a whole day to key them into the computer,” Phillips says. Phillips suggests the following setup: First, put a barcode sticker on each motor. Read a sticker with a handheld reader (he recommends the Intermec

CS40) and refer to screen shots you have taken and stored in the reader for where to take the readings for the motor that belongs to that bar code.

Use an infrared scanner to take the bearing temperature readings. Key the temperature readings into the reader. Move on to the next motor and repeat. Either by wireless or back in the office with the device in a cradle, transmit the data to your CMMS using software that lets the reader and computer communicate (Phillips uses EAM Mobile software).

This setup not only cuts by half the number of data entries, but the data is now in the computer, where it can be crunched to do temperature trending.

TIP{9}

Consider purchasing drive PM kits. Kits with replacement parts can extend drive life. “Having a pro-active PM program is essential to maximizing the life expectancy of your drives,” ABB’s Gwinnet says. “Many

companies offer PM kits that help keep your drives in top operating condition. They are assembled based on the age of the drive and the life expectancy of key components.

“Customers with a pro-active PM program have seen improved reliability and extended life expectancy of their drives.”

TIP{10}

If a fuse blows in a drive, don’t just replace it. Look for the cause. “I’ve opened up cabinets and found 20 blown fuses sitting in there,” says Bill from BJ Electric. “My biggest beef with electricians is that they just replace the fuses and go home. I don’t like that.

“Don’t just reset the breaker or replace the fuse to keep the motor running. If a fuse blows, there is a reason. That is very dangerous. There is a reason why the protection devices are there.” MRO

Carroll McCormick is MRO Magazine’s award-winning senior contributing editor.

Tracking temperature and vibration

Both of these conditions provide important maintenance signals.

BY COLIN PLASTOW

achines in trouble usually provide telltale evidence that you can read in order to diagnose their problems. Two of the most useful indicators are temperature and vibration. Most mechanical components emit a certain amount of heat and vibration in the normal course of operation. But excessive heat, cold or vibration can tip you off to underlying problems, so you can fix them before they lead to a breakdown and bring production to a halt.

Today’s latest test tools, such thermal imagers and vibration testers, can help measure heat and vibration and even interpret the data. They can tell you what the underlying problem may be and guide you in making repairs.

Monitoring temperatures

An abnormally hot or cold spot — or an unusual thermal pattern — on process equipment often indicates an emerging problem. That makes handheld thermal imagers, which capture two-dimensional images of the apparent surface temperatures of objects, useful tools for regular predictive maintenance of pumps and other equipment.

With thermal imaging, you can discover and diagnose various issues, including high-resistance electrical connections, obstructions that impede airflow, bearing issues on motors, tank levels, and many other mechanical problems.

One way to prioritize infrared scanning is to begin with critical assets whose failure would threaten people, property or product. Then determine what condi-

tions add stress, and monitor those assets more frequently.

For example, the sludge and particulates found in many processes put extra stress on motors, affecting bearings, windings and insulation. That stress can show up as heat detectable by a thermal imager. Such motors should be scanned more frequently than others.

What to look for

A handheld thermal imager such as the Fluke Ti32 Thermal Imager can be used to look for hot spots, cool spots and other anomalies. Be especially aware of similar kinds of equipment operating under similar conditions but at different apparent temperatures. Such deviations might signal problems.

A good approach is to create inspection routes that include all critical assets. Each time you inspect a piece of equipment, save a thermal image of it and the associated data on a computer and track its condition over time. That way, you’ll have a baseline for comparisons that will help you determine whether a hot spot (or cool spot) is unusual.

You’ll also be able to verify when repairs are successful. Whenever you use a thermal imager and find a problem, use the associated software to document your findings in a report that includes a digital photograph as well as a thermal image of the equipment. That’s the best way to communicate the problems you find and to suggest repairs.

When vibration is a problem Vibration can be normal in machine opera-

tion — or it can be both a sign and a source of trouble. Most industrial devices are engineered to operate smoothly and avoid vibration, not produce it. In electric motors, rotary pumps and compressors, fans and blowers, zero vibration is the ideal. In these machines, vibration can indicate problems or deterioration in the equipment. If the underlying causes are not corrected, the unwanted vibration itself can cause additional damage. But how can the plant maintenance professional tell acceptable, normal vibration from the kind of vibration that requires immediate attention to service or replace troubled equipment? The answer requires an understanding of the various causes of vibration.

Common causes of machine vibration

Imbalance – A ‘heavy spot’ in a rotating component will cause vibration when the unbalanced weight rotates around the machine’s axis, creating a centrifugal force. The cause could be a manufacturing defect or a maintenance issue. Imbalance can severely reduce bearing life and cause undue machine vibration and heat.

• Misalignment/shaft runout – Angular misalignment occurs when the axes of a motor and pump are not parallel. When the axes are parallel but not exactly aligned, that’s parallel misalignment. Misalignment may be caused during assembly or develop over time, due to thermal expansion, components shifting, or improper reassembly after maintenance. The resulting vibration may be radial or axial (in line with the axis of the machine) or both. Misalignment can cause coupling wear and failure.

• Wear – As components such as bearings, drive belts or gears wear, they may cause vibration. When a roller bearing race becomes pitted, for instance, the bearing rollers will cause a vibration each time they travel over the damaged area.

• Looseness – Vibration that might otherwise go unnoticed may become obvious and destructive if the component that is vibrating has loose bearings or is loosely attached to its mounts. Looseness can allow any vibration present to cause wear and fatigue in bearings, equipment mounts and other components.

Characteristics of vibration

To understand how vibration shows up, consider a simple rotating machine like an electric motor. The motor and shaft

rotate around the axis of the shaft, which is supported by a bearing at each end.

One key consideration in analyzing vibration is the direction of the vibrating force. An imbalance would most likely cause a radial vibration as the ‘heavy spot’ in the motor rotates. A shaft misalignment could cause vibration in an axial direction (back and forth along the shaft axis), due to misalignment in a shaft coupling device.

Another key factor in vibration is amplitude, or how much force or magnitude the vibration has. The farther out of balance a motor is, the greater its amplitude of vibration. Other factors, such as speed of rotation, can also affect amplitude. As rotation speeds up, the imbalance force increases.

Intelligent monitoring and analysis

The effects of vibration can be severe. Unchecked machine vibration can accelerate rates of wear (e.g., reduce bearing life), damage equipment, create noise, cause safety problems, and degrade plant working conditions. In the worst cases, vibration can knock equipment out of service and halt plant production.

Measured and analyzed correctly, vibration can be used in a preventive maintenance program as an indicator of machine condition, and you can target remedial action before disaster strikes.

For example, the hand-held Fluke 810 Vibration Tester is designed and programmed to diagnose the most common mechanical problems of imbalance, looseness, misalignment and bearing failures in a wide variety of mechanical equipment, including motors, pumps, fans, blowers, and more. It quickly detects vibration along three planes of movement, then provides a plain-text diagnosis with a recommended solution.

The diagnostic technology in the instrument analyzes machine operation and identifies faults by comparing vibration data to an extensive set of rules developed over years of field experience. It’s all done with the intelligence built into the tester, without the long-term monitoring, recording and analysis required for typical long-term vibration monitoring programs. MRO

Colin Plastow is the industrial product manager for Fluke in Canada. He may be contacted by e-mail at colin.plastow@fluke.com. Online Reader Inquiry No. 351

Left: A maintenance technician uses a handheld Fluke 810 Vibration Tester on a belt-driven fan setup. Above: A handheld Fluke Ti32 Thermal Imager can discover and diagnose many equipment issues by monitoring temperature.

with Condition

BY STEVE GAHBAUER

How to NDT

N Save

obtain insurance coverage. Regulatory rules require that inspection personnel be certified, either through a central system such as ISO 9712, or an employer-based system like the one used in the USA.

M ney

ondestructive testing (NDT) has become an important tool for equipment condition monitoring, failure detection and quality control. Evolving technologies and methodologies have raised it to new levels, helping manufacturing and processing plants to save money.

Decades ago, when Canadian organizations were busy learning how to use newly emerging nondestructive testing technologies, the inspection, measurement and quality assurance techniques we are taking for granted today were driving research and creating a new way of looking at these methods.

Now, new ways of applying NDT are

expanding, and doing so at a critical time when an aging NDT workforce will be retiring in the next five to 10 years. And this is happening against a backdrop of mergers and acquisitions, changed economic realities, uncertainties in financial markets, and increasing global competition – all the more reason why you cannot afford to ignore a tool that contributes directly to improving bottom line profits. By definition, nondestructive testing –or nondestructive evaluation (NDE) as some prefer to call it – is the primary means of measuring the structural integrity of industrial pressure boundary components. In many jurisdictions such inspections are now mandatory, either by regulation or to

In Canada, the organization that provides world-class NDT training and certification is CINDE, the Canadian Institute for NDE. It operates a government-approved test centre, conducts Canadian General Standards Board (CGSB) examinations and provides consulting services on a contract basis.

The NDT training certification courses cover CGSB Levels 1, 2 and 3, and the professional development programs cover engineering, materials and components, math preparation, principles and applications of NDT, basic radiation safety, ultrasonic weld inspection and thickness gauging, and weld quality control. CINDE also offers live on-line interactive training through Northern Lakes College.

In addition, CINDE provides on-site training, the most economical, cost-effective and convenient way to train a number of people in a company without paying thousands of dollars for airfares, hotels and meals. Technicians can learn at their own pace and on their own equipment and systems. Courses can be planned around individual department schedules.

So what can NDT do for your enterprise?

That question was answered by CINDE executive Larry Cote and NDT specialist Shane Turcott in a full-day workshop at MainTrain, Canada’s annual maintenance, reliability and asset management conference for knowledge trans-

fer, professional development and networking, convened last November in Toronto by PEMAC, the Plant Engineering and Maintenance Association of Canada.

Cote defines NDT inspection as “a way to monitor the condition of equipment and processes by scanning them for cracks, flaws and other defects at or below the surface.” He says everything from simple visual inspections to advanced technologies and methods can be used for these tests.

Electromagnetism, sound transmission, fluid capillary action, and similar physical and chemical investigation techniques are used to acquire and analyze data. These include surface and volumetric techniques, airborne ultrasound, acoustic emissions, flow monitoring and strain gauging. Tests can include magnetic particle and liquid penetrant inspections, strain and torque measurement, and radiography.

Beyond machine condition monitoring, NDT can also be used to evaluate the structural integrity of buildings, bridges, railbeds, tanks, welds, etc., or to monitor critical process and control equipment. Typical applications include inspections of pipeline integrity and flow, pressure vessels, tubing and barstock, lifting equipment, and roll grinding. “NDT is an essential tool for risk and reliability predictions,” adds Turcott.

For more information about NDT and details about CINDE, visit the website at http://www.cinde.ca. MRO

Steve Gahbauer is an engineer, a Torontobased freelance writer, and a contributor of technical articles to Machinery & Equipment MRO.

Engineering Class Chain

BY ROBERT ROBERTSON

RAISING

U PT I E M

Four experts advise how to put the brakes on reactive maintenance to increase asset uptime and reliability.

To ensure healthy equipment and lessen production shutdowns, it’s vital for maintenance departments to continually refine their asset management practices. According to James Reyes-Picknell, president of Barrie, ON-based Conscious Asset, companies first have to evaluate their uptime scorecard to improve reliability.

Reyes-Picknell also says your assets can obtain a new lease on life with an effective uptime strategy. The reward will be a more robust fiscal bottom line over the long haul.

“Uptime isn’t a standalone mainte nance initiative, nor is it for organiza tions that dabble. Take the jump to achieve cost savings by planning and scheduling work versus doing reactive equipment repairs,” says Reyes-Picknell.

“It’s also important to figure out a business case for uptime. The financial management team and operational exec utives, including the CEO and COO, need to be involved. If not, then you’re not get ting the most out of reliability efficiencies.

“You can’t wait for the budget cycle to come around before taking action. By identifying what’s missing in the business case, you can see where the money will show up. Uptime pays for itself many times over, but don’t treat it like a cost in a budget line or it will be a cost with no return on investment (ROI).

equipment failure, Wireman says management has to adjust its approach in the boardroom right down to the shop floor.

“You have to treat maintenance as a business to optimize expenditures or arrive at the true ROI of an asset. Lots of maintenance budgets are as large as some company’s overall revenue,” says Wireman. “We can be talking millions, if not tens of millions of dollars. Maintenance professionals have to focus on run-

business goals, organizational capabilities and enabling technologies that foster a holistic approach to asset management.

“There remains a culture of reactive maintenance and a reliance on calendarbased maintenance. I would like to say this mindset has changed, but we still run into companies that are 50% to 60% reactive or even higher,” says Lenders.

“These maintenance departments are chasing ‘fires’ to keep ahead. Most people don’t understand what reliability is or the role of uptime. A culture change has

“And don’t assume you’re spending too much today. Processes and possibly even supporting technologies have to be altered, rather than cutting your way to savings.”

What about companies that are saddled with reactive maintenance? ReyesPicknell says one forgotten central element involves the need to further change behaviour, but roadblocks to successful execution can often exist. They include fear-based resistance and suspicion among maintenance staff, as well as “sacred cows” that dwell in the corporate culture and must be removed to give an uptime overhaul a fighting chance.

“We love to change just as long as it’s our idea. Implementing uptime will require the development of new behaviours,” says Reyes-Picknell. “If you don’t have a history of changing them successfully, however, you’re unlikely to succeed with your first attempt. Typically, companies like this have a long history of uptime failures simply because nothing sticks.”

Avoid reactive work

Terry Wireman, CPMM/CMRP, senior vice-president, strategy, with Stamford, CT-based Vesta, says dynamic uptime strategies provide a much-needed ROI shot in the arm for assets. And to hasten a move away from reactive work and the brunt of

centre or profit drain. This negative par adigm will impede uptime performance.

“You want to balance the cost of maintenance versus non-maintenance, but most organizations don’t understand the dollar impact of downtime. They can never properly right size their maintenance organizations. Up to 90% of the maintenance costs for an asset are determined in the design phase of its life cycle. So, a company has to use a team approach with cross-level support to better manage the maintenance costs of an asset.”

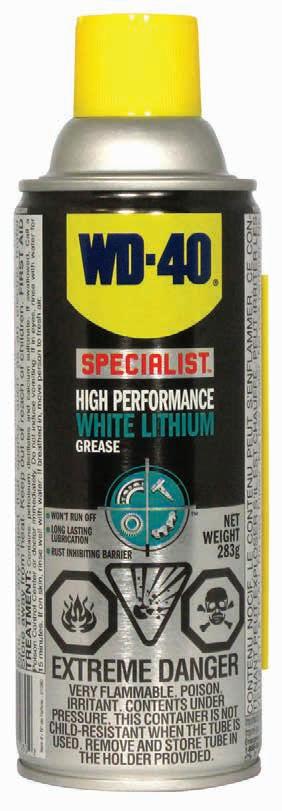

According to Wireman, uptime success all starts with the reliability basics. This includes the use of a preventive maintenance (PM) program and MRO inventory and purchasing procedures. “Most equipment failures can be traced to the neglect of basics, such as proper inspections, lubrication and fastening,” says Wireman. “A survey shows over 50% of all equipment failures have a root cause in one of these areas. Using a good PM program will reduce or eliminate the occurrence of these incidents.”

A new language

Florian Lenders, director of The Aladon Network with Burlington, ON-based Bentley Systems (formerly Ivara Corp.), says improved uptime requires people to understand, speak and apply a new language. He also says companies must consider the big picture, including the alignment of

to occur where proactive maintenance, not reactive, is the new normal.

“Despite the advancement in reliability thinking and technologies over the past 10 years, the change hasn’t occurred in many industries,” says Lenders. “People have tried various single-point tools, but they lack an over-riding business process. In a lot of cases, organizations focus on short-term bottom line results without a clear plan in place.

“Becoming more proactive within a business and organizational framework will help bring operations, maintenance and engineering together as asset stakeholders.”

To gain traction with uptime implementations, Lenders calls for the establishment of a common set of reliabilitybased corporate goals and objectives. “You also want to develop business practices that identify everyone’s roles and responsibilities,” he says.

“Don’t forget to align existing technologies and add new ones to better manage predictive systems. Stay the course with your vision through to completion, as it doesn’t happen overnight. Lastly, enable your people to manage assets with the right incentives to achieve success.”

cites an explosion that destroyed a large storage tank containing a mixture of sulphuric acid and hydrocarbons at a US refinery. The explosion occurred during welding repairs to a catwalk above the sulphuric tank. Welding sparks ignited the flammable hydrocarbon vapour. One contract worked was killed and eight others were injured.

Such situations lead to the question of what role less-reactive maintenance can play to reduce injuries and save lives on the shop floor. According to Levitt, better reliability creates a safer workplace, sustains equipment and strengthens financial numbers. As a result, management has to make uptime and safety a priority across the entire organization.

“If we can fix some root causes of injuries and deaths, then more maintenance professionals will go home to their families whole and intact,” says Levitt. “Maintenance expediency can contribute to people not following procedures correctly, design flaws and workers not being careful. And when a machine breaks down, it can cause maintenance staff to possibly go into harm’s way.

“You have to look at your plant processes and procedures. To be more specific, equipment running as designed doesn’t require a maintenance person to enter a confined space, repair (and touch) exposed electrical wires, pressure test a generator, sit on top of a tank doing welding, or even be exposed to falling off a ladder. Reliability through successful uptime will remove the risk to people.”

According to Levitt, one company reported its maintenance accidents were five times more likely to happen with breakdown work versus planned and scheduled corrective jobs. He further says that either you plan and schedule your maintenance activity — or your machines will. The answer is to make uptime inroads by no longer applying unsafe reactive maintenance.

“High reliability implies uptime and an effective proactive maintenance program. This catches equipment deterioration before it leads to failure. Since the asset isn’t broken, it’s safer to complete the repair work. It also gives managers more time to effectively deal with unsafe plant hazards.” MRO

Robert Robertson is a Mississauga, ON-based freelance writer and regular contributor to Machinery & Equipment MRO Magazine.

High cost of injuries

Joel Levitt, president of Lafayette Hill, PA-based Springfield Resources,

“You can’t wait for the budget cycle to come around before taking action,” says James Reyes-Picknell of Conscious Asset.

Aladon’s Florian Lenders.

Vesta’s Terry Wireman.

Joel Levitt of Springfield Resources.

Safety and productivity are truly two sides of the same coin.

How machine safety boosts productivity

The major goal behind an Overall Equipment Effectiveness program is to minimize or reduce the causes of inefficiency in the manufacturing environment.

BY SIMON FRIDLYAND

There is a real relationship between equipment safety and machinery output. Occupational health and safety codes and standards mandate that machinery that has exposed moving parts or in-running nip hazards — or anything that may endanger the worker – must have a protective device or guard to prevent access to the danger point.

If people place a box around a machine, although that makes it absolutely safe, it is totally user-unfriendly. Since that is a very impractical solution and it has a big impact on productivity, it would soon be removed. But then the exposure to dangerous moving parts remains.

As you know, there are consequences to non-compliance, and these can include accidents, human tragedies, fines, excessive costs and productivity losses.

However, there is a way of turning liabilities into productivity. It begins with benchmarking and overall equipment effectiveness (OEE). Let me explain how it works.

Overall Equipment Effectiveness (OEE) is a way to monitor and improve the efficiency of your machine using machine guarding arrangements. First of all, we need to measure the parameters of the machine, such as Availability, Per-

formance and Quality.

Overall Equipment Effectiveness (OEE) in numeric terms looks like this: Overall Equipment Effectiveness = Availability x Performance x Quality. Availability is defined as Run Time/ Total Time — the percentage of the actual amount of production time the machine is running compared to the production time the machine is available, or it can be calculated as the total run time of the machine after subtracting all unplanned downtime.

Performance is defined as Total Count/Target Count — the percentage of total parts produced on the machine compared to the production rate of machine, or how well a machine is running when it is running.

Quality is defined as Good Count/ Total Count — the percentage of good parts out of the total parts produced on the machine, or how many good parts versus bad parts a machine has produced.

In a perfect world, reaching a goal of 100% OEE would require 100% availability, 100% performance and 100% quality. Since it is not a perfect world, there are losses in each of these criteria. What are they?

Downtime is a loss to availability. Here are some examples: Unplanned

maintenance, machine changeovers, equipment failure, tooling damage, process warm-up and material shortage.

Speed losses relate to a loss to performance. Some examples include product flow stoppage, tooling wear, components jams, equipment age and material misfeeds.

Quality loss is a loss related to quality. Some examples are damage, rejects, reworks, tolerance adjustments and the warm-up process.

Curbing losses

The major goal behind an Overall Equipment Effectiveness program is to minimize or reduce the causes of inefficiency in the manufacturing environment. For example, by reducing machine adjustments/set-up and machine breakdowns through enhanced maintenance programs, we can reduce the downtime loss.

By reducing the number of machine stops and machine-reduced speeds through enhanced machine guarding design, as well as operator training, we can reduce the speed loss.

By reducing the number of rejects

occurring during initial startup and full production runs through easy and safe access to the adjustment mechanisms of the machine, we can reduce the quality loss.

If you can improve your OEE numbers, you will improve your machine’s productivity.

Table 1 shows an example of real machine production data to help you understand the concept of OEE and the calculation of this data. This example shows the calculation of OEE and the OEE metrics of Availability, Performance and Quality.

Scrutinizing Availability, Performance and Quality, and reducing machine losses through locking in place the most effective methods of running the machine, by using machine guarding arrangements, will enhance Overall Equipment Effectiveness. Safety and productivity are truly two sides of the same coin. MRO

Simon Fridlyand, P.Eng., of SAFE Engineering Inc., specializes in industrial health and safety concerns and PSR compliance. For more information, visit www. safeengineering.ca.

TABLE 1

• The Target Count interval period or Ideal Cycle Time = 1 part every 63

(400 parts should be produced in 420 total minutes of operating the machine).

• If downtime is reduced by 15 minutes (900 seconds), the machine could produce 14 more parts (900 seconds x 1 part/63 seconds = 14 parts)

• Availability improves to (389/420) = 92.62%

• Performance improves to (374/400) = 93.50%

• Quality improves to (369/374) = 98.66%

• OEE improves to (0.9262 x 0.9350 x 0.9866) = 85.44%

• Reducing your downtime by 15 minutes in this example produces a 6% increase in OEE.

©iStockphoto/Thinkstock

how will you use the maintenance software? You can do this through the development of a Business Process Flow for

Issues to consider and questions to ask before selecting a new CMMS system.

Implementing CMMS software

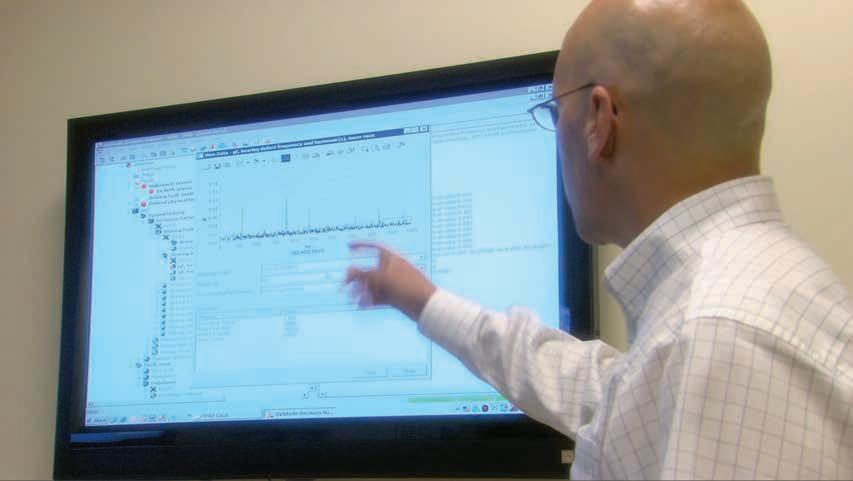

This is the final segment of an eight-stage program on achieving world-class maintenance. Stage 7 was described in the December 2012 issue of Machinery & Equipment MRO and examined the establishment of maintenance systems. This issue offers 10 questions you must ask before selecting a new CMMS system.

This concluding article in our world-class maintenance (WCM) series continues the discussion about establishing maintenance systems described in the previous issue, and specifically deals with the implementation of computerized maintenance management system (CMMS) software.

Although we have talked about CMMS throughout these WCM steps, in this issue, we concentrate solely on how to choose and implement the software.

I have discussed this subject over the years in this column. However, WCM leaves this step to the very end. The reason for this is the number of other steps and stages that need to be developed, documented and implemented on paper first. Only then are we ready to use the software. In WCM we often say, “If you can’t do it manually on paper, you’ll never be able to do it with maintenance software.”

After we have combined all the information in the previous steps, it’s time to bring it all together into open CMMS software. When everything is at your fingertips, your CMMS provides one-stop shopping.

What do I mean about one-stop shopping? Here are a few things you must program into your CMMS:

• All the equipment documents, electronic files, drawings and material lists

• Inventory of vendors, manufacturers, model numbers and cost

• Preventive maintenance checklists, labour costs and replacement parts used during maintenance

• Rebuild schedules, procedures and drawings

• Equipment meter readings, hours, cycles, parts produced

• Predictive maintenance measurements, motor amperage readings, temperatures, vibration readings

• Contractor work orders and contractor costs

• Maintenance employee costs while working on equipment

• Planning and tracking of the progress of projects

• Equipment warranty information.

Now let’s discuss how to choose a CMMS to work with your WCM program. Remember, it must coincide with all the strategies developed during our WCM development.

As it is still early in a new year, many maintenance departments will be budgeting for a CMMS acquisition. Here are some issues to think about before selecting a new CMMS system.

What is the purpose of the CMMS?

The purpose of implementing a computerized maintenance management system is to

BY PETER PHILLIPS

improve the efficiency and effectiveness of the maintenance of your company’s assets.

As with any computer system, a CMMS can automate and improve processes that you are already performing. It cannot change your company’s maintenance department from a state of chaos into a place of order — not without a lot of work and careful planning.

A reasonable set of functions for a CMMS includes:

• Managing the inventory of spare and replacement parts used in maintenance

• Tracking the suppliers of those spare parts

• Tracking any external service providers

• Retaining the warranty

• Retaining the maintenance schedule

• Tracking unexpected outages and costs by work order, by machine and by department.

Planning: Current maintenance activities

Before you start shopping for a system, prepare a list of the features that you need. Be sure that you understand what you are currently doing. You may maintain some inventory, but how do you control the re-ordering of spare parts? Do you make plans for preventive maintenance? Do you track unexpected outages by machine? Do you track repair costs against the depreciated value of each machine?

When planning for any computer system, an important question to ask is “What should we do?” In other words,

Planning: Typical functions

Most CMMS systems cover the following

Asset management: Include the type of machine and its serial number, through to cost, depreciation and warranty, to the list of required parts with order quantities, and so on.

Inventory management: Which parts are kept in which bins in which storerooms? Who are the suppliers? What are the minimum and maximum reorder points? What is the order

Personnel management: Which employees are certified to perform what maintenance activities on which machines? What tasks have they been assigned, and for what dates and shifts?

Preventive maintenance: What are the triggers for a machine, calendar days or hours of use? Can multiple machines be included in one maintenance order? Can multiple maintenance plans be made for one machine, depending on the type of maintenance to be performed? Can you set blackout dates so critical productivity periods are exempt from downtime for maintenance? Integrate the machine and personnel schedules to ensure that people with the right skills are available for a particular task.

Procedure management: Maintain a list of tasks for each maintenance assignment, including the skill requirements, parts list, estimated time, and both safety and other associated procedures or notes.

Purchasing: Generate purchase orders when stocks reach the reorder point. Consolidate requirements for one part across several storerooms.

Work order management: Provide a unique W/O number, plus description, date, reason for the maintenance, etc. Record the actual costs, such as downtime and parts used. Accept maintenance requests with different priorities, such as the basic, “My drill press squeaks a bit. Could someone check it tomorrow?” to the more urgent “Pump 3 is running really hot!”

Extra features: Can this system send messages to appropriate personnel by e-mail or text messaging? Does it support bar code readers or RFID (radio frequency identification) to facilitate the recording of stock movement? Are there other systems with which it should integrate, such as the plant’s manufacturing resource planning (MRP) software?

Buying the software: 10 questions to ask

Think about these 10 questions before you select a CMMS system. It will save you a lot of time and frustration.

CMMS packages require work and it is very important to choose the proper system that will do what you need it to do.

1. Is management behind the project?

Most CMMS projects fail as the management is not pushing for it or does not provide enough of a budget for implementation.

2. Are you satisfied with your existing maintenance procedures, work orders, preventive maintenance and continuous improvements? Do you want a system that is built on your established methods or will you try to use the new system to change your habits?

3. What do you want to track with the system?

• Do you want to track asset history and identify problematic assets and protect your investment?

• Do you also want to track maintenance costs? Will you allocate costs for parts, labour and contractors associated with scheduled maintenance and breakdowns?

• Do you want to control your spare parts inventory based on your assets requirements?

• Do you want to track facilities maintenances such as ventilation systems, chillers and building management systems?

• Will you use the system for documentation control, such as blueprints and manuals?

• What about planning and project management? Not all CMMS systems offer that option.

4. Who will use the system?

• Only one person, the maintenance planner or supervisor?

• All technicians?

• Supervisors in production?

• All operators? (This is standard for a WCM-type organization.)

5. What kinds of reports do expect from the system?

6. Are you looking for a scalable solution, where you start small and then develop it over time?

7. Who are the people who will be doing the implementation? What is their background? Do they have maintenance experience to be able to assist you in regard to maintenance management?

8. Do you need integration with other existing business systems?

9. Do you need paperless solutions like handheld devices?

10. Do you need to integrate your condition-based monitoring?

In most cases, it is wise to stick to a standard computerized maintenance management system and keep customizations to a minimum. When choosing a system package, make sure you specify what you want the package to do; there are many expensive solutions with capabilities you may never use. Think of some typical scenarios, and let the salesperson show a group of users (operators, technicians, supervisors and others) the system and how it would handle these scenarios. If you don’t like the usability or if customizations are needed to do the job, consider another system.

CMMS packages require work and it is very important to choose the proper system that will do what you need it to do.

CMMS implementation

While no software package has every desirable feature, the advantage of buying one is that it should already have most everything you need. Insist on visiting one of your software vendor’s customers to see the product in action. Ask them what has been challenging during the implementation process.

Generally, it is best to have the vendor team configure the system and begin entering data in a test environment. Ask about their recommended best practices.

Obviously, a CMMS needs a vast amount of data to support all the features noted above. This is not a trivial task; expect this process to take some time. Often, an implementation will take between six months to a year, with much of that time being spent on data entry.

Use that implementation time to ‘sell’ the new system to its users. Develop a training plan, or have your vendor provide training. Ensure that people are comfortable with the specific tasks they need for their roles. It is helpful if they know what happens outside of their area of focus, such as why a work order needs a priority code, for example.

It is a really good idea to keep a training database for ongoing training for ‘what-if’ scenarios. Some systems are not very forgiving. It’s better to make a mistake in a practice database than in a live environment.

Train both the technical skills and supervisors to work with the new processes.

One of the most important aspects of a system is that the user needs to know what is really happening within the system. Knowing how to navigate through the program is essential; moving around the system easily will take practice. Be sure that people appreciate the need to have complete data entry so that reports display useable data.

Going live

At best, your implementation team will be excited and distracted on the first live day of using your CMMS. Having a solid plan for them to follow is a good way to keep everyone focused.

Have trainers available to answer questions and assist users at their computers. Have clear lines of communication, so people can report problems to the implementation coordinator and be sure that the problems are addressed.

Part of the implementation plan is to log problems and questions. Ensure that

all defects and concerns are addressed promptly, well before the end of the CMMS warranty period.

Conclusion

Without planned maintenance, you get unplanned outages and repairs. To manage a factory-wide maintenance plan without a computer program means relying on a few people to accurately handle a huge number of details. It also means that it will be difficult or impossible to track costs at a level to support decisions about the reliability of each machine. In planning for a CMMS, you will face challenges. However automating maintenance with the most suitable system can make the whole maintenance management process manageable. MRO

Peter Phillips of Trailwalk Holdings, a CMMS consulting and training company, can be reached at 902-798-3601 or by e-mail at peter@trailwalk.ca.

HIGH PERFORMANCE FOR ALL DAY GRINDING

HPTM GRINDING WHEEL

The wheels of choice for a wide range of metal grinding applications

Fast and easy wheel changeover

High performance wheels grind off metal faster

Formulated for safety and high performance in a wide range of metal grinding applications. HP wheels are made from the highest quality abrasive grain which resists wear and quickly takes down welds with ease. Their breakthrough performance sets new standards for general purpose steel grinding.

What’s new in motors and drives

Digital DC drives can be controlled via Ethernet

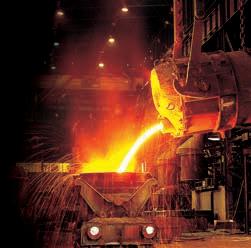

Sprint Electrics’ digital DC drives, ranging from 650 A up to 2,250 A and used for controlling DC motors in heavy industry applications such as metalworking, steel

mills, mining, or the cement, rubber and plastics industries, can be controlled over the Ethernet without the need for a PLC or supervisory computer. Available as twoquadrant or regenerative four-quadrant types, the PLX range is offered with either top-entry or bottom-entry AC busbar position options. This increased drive range is available as high-voltage (690 VAC) or standard-voltage (480 VAC) models, and has an extensive range of software functions and fieldbus communications options such as Profibus, DeviceNet, CC-Link, EtherNet/IP, Modbus and CANopen.

MDA Controls

Online Reader Inquiry No. 300

Drive meets application and system connectivity needs