Get control over costly compressed air

Use wireless testing to increase safety

Take charge of equipment history records

EASA Ontario garners international attention

Get control over costly compressed air

Use wireless testing to increase safety

Take charge of equipment history records

EASA Ontario garners international attention

Bearing isolator is designed to protect the environment

An environmentally friendly bearing isolator designed for flooded and oil mist applications has been introduced by Garlock. The EnDuro design core features a bi-concave surface incorporated within a fluorocarbon stator, providing long life and reliable bearing protection. The seal prevents the loss of potentially environmentally harmful bearing lubrication, while also preventing contamination ingress in flooded or oil mist environments. Featuring three different sealing technologies in one compact, selfcontained unit, the bearing isolator is designed to quickly and easily replace contact lip seals and traditional bearing isolators. It is available in shaft sizes ranging from 0.875 in. to over 6 in., with flanged, flangeless and custom configurations offered.

Garlock Sealing Technologies

Online Reader Enquiry No. 306

Curved-jaw locking pliers have extra-strong grip

Irwin Vise-Grip curved-jaw locking pliers feature a self-energizing lower jaw, offering a powerful grip with no slipping or stripping. There is no need for heavy input pressure, as the jaws tighten for maximum grip as torque is applied to the tool. Two core models are available, the Fast Release, featuring a one-handed, triggerless release and anti-pinch, non-slip ProTouch grips, and the Original, with a classic trigger release. Constructed of high-grade, heattreated alloy steel, the pliers establish multiple contact points with the work piece, which contributes to the tight grip. They are available in lengths of 5 in., 7 in. and 10 in.

Irwin Tools

Online Reader Enquiry No. 308

Washdown motor line resists contamination

Baldor offers a broad range of washdown and paint-free motors and controls, all-stainless motors and speed reduc ers, linear motors and controls, and servo motors and controls. Washdown motors include AC, DC, JM pump motors, inverter duty, vector duty, SmartMotors, AC servo and a choice of finishes. Super-E premium-efficient designs are available in every configuration. The motors suit applications requiring high-pressure cleaning with caustic solutions. Easy to clean and sanitize, the all-stainless speed reducers come with solid or hollow bore outputs in three frame sizes through 5 hp.

Baldor

Electric Online Reader Enquiry No. 319

Lift lineup upgrades improve user comfort

Southworth Products has redesigned its Dandy Lift line of lifter/transporters for increased convenience and comfort. The Multi-Grip position handle allows users to select the most comfortable hand position for the job at hand, while the Qwik-Grip lowering handle has an oversized, open-triangle design that makes it accessible from almost any position. The large, open-loop design of the 180-degree access foot

pedal allows the pedal to be pumped from different angles, while providing solid contact regardless of footwear. In addition, the company offers two redesigned models of its portable auto-levelling platforms, the Dandy Levelers.

Southworth Products

Online Reader Enquiry No. 320

Absorbent promotes protection of the environment

Enviro-Dri absorbent from Can-Ross com prises highly absor bent, wood-fibre granules coated with a fire-resistant material to comply with regulations related to the transportation of dangerous goods and landfill leachate requirements. Completely crystalline silica free, the product can be used for the quick, efficient clean-up of oil, grease, water and other non-aggressive liquids. It consists of 40% cellulose fibres that are made of wood waste that otherwise likely would end up in a landfill. Packaging is available in paper or plastic. Can-Ross Environmental Services Online Reader Enquiry No. 321

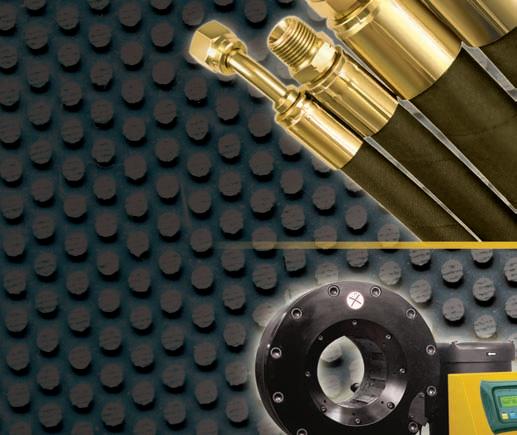

Digital hydraulic tester is compact

Omega’s digital HFP-110/120 hydraulic tester is a compact, lightweight, self-con tained, portable tester with lab oratory accura cy. Designed for fast diagnostic troubleshooting of all types of mobile or sta tionary hydrau lic systems and components, the device makes all flow pressure and temperature measurements simultaneously from one point. The large, 3-1/2-digit LCD display makes for easy measurement reading. This CE compliant tester has additional features that include pressure relief disc protection and low-battery/overrange indicators. Applications include hydraulic system testing, and hydraulics testing in automotive and manufacturing industries.

Omega Online Reader Enquiry No. 322 MRO

Our printed reader reply cards have been phased out. Please use our Online Reader Reply Card at www.mromagazine. com/rsc to request additional details directly from suppliers.

Sky-high challenge:

Servicing the wind / 13

The installation of wind power facilities is booming, yet Canada’s wind turbine maintenance infrastructure is in its infancy.

Using wireless testing to increase MRO safety / 15

A wireless datalogging multimeter allows a user to set up a laptop at a centralized location and then sequentially obtain readings throughout a site without relocating the computer, and without getting his or her hands into a dangerous situation.

Compressed air isn’t free? / 16

There is an attitude that since it’s just air and because it’s used every day, it’s free, even if there are obvious system leaks. Unfortunately, compressed air is an extremely expensive utility. Here’s how to get control over your compressed air systems to reduce energy costs and your facility’s carbon footprint.

MRO and safety show in Toronto attracts 2,000 delegates / 25 Acklands-Grainger hosts The Works, billed as Canada’s largest maintenance repair and operations (MRO) and safety show.

EASA’s Ontario Chapter maintains international spotlight / 26 p8

The electrical menace / 19 How to properly handle safety issues with electrical equipment in hazardous areas.

Big change means a major leap of faith / 20 Follow along with Step 37 in a journey to World-Class Maintenance at the Plentya Paper Company as the maintenance team takes a major leap towards transforming the organization.

Achieving success with maintenance records / 21

Here’s how to get maintenance staff to accurately record work order information so equipment history records will be of value.

Editor’s Notebook / 6 Industry Newswatch / 8

Business Briefs / 12

Mr. O, The Problem Solver / 12

The Safety File /19

Maintenance Management / 20

CMMS Solutions / 21

MRO on the Road / 25-26

Product News

Product Spotlight / 2

MRO Components / 22

Focus on Safety / 24

‘An offshore wind industry in Ontario would create permanent green jobs in the operations phase.’ Len Coad / 8

‘It is really hard to find a Canadian company to come in and competently work on wind turbines.’

Trevor Smith / 13

‘With Bluetooth, MRO professionals can monitor readings at a safe distance from hazardous locations.’

André Rebelo / 15

‘Of the energy required to produce compressed air, less than 20% of input energy is left for use. That means 80% of what is paid for is used up before it’s put in the distribution system.’

Doug Waetjen / 16

We all know the need for maintenance will never go away. And it seems that every maintenance department in the country needs more money to meet its targets. But what if you could tell management that if it let you have the budget you really want, the maintenance department could end up saving the company a lot of money, putting more profit on the bottom line? That would get their attention. And it should give you all the assets you need for a successful and smooth-running maintenance operation.

First of all, the concept behind this scenario is based on the fact that a small amount of money saved generally puts a large amount of money on the bottom

line of a corporate spreadsheet.

Ralph W. “Pete” Peters of the Maintenance Excellence Institute puts it into perspective, as follows. Based on an assumption that an organization’s net profit ratio is 4%, that means it needs $25 of sales for each $1 of net profit generated.

That also means if you could save $40,000 in the maintenance department, for your company that would be the same as having an extra $1 million in sales revenue. The bean counters would certainly like those numbers.

But how?

There are several avenues to explore to enhance a maintenance budget: Improving craft productivity, increasing equip-

ment uptime, reducing maintenance storeroom inventory, getting better pricing from suppliers, or improving equipment life are just some plausible examples.

For example, by using a computerized maintenance management system (CMMS) to improve craft utilization – having the right skills and carrying the right tools to the right job at the right time – could result in a net gain of craft productivity of 20%. If your shop has 40 craftsmen averaging a wage of $35,000 a year, that 20% increase could save $280,000 a year. Or you may instead forgo the labour savings and get the backlog of work orders cleared and have more time for predictive/preventive maintenance, versus breakdown work.

Clearing all those outstanding work orders would likely result in increased equipment uptime. Say downtime was reduced 25% (from 8% to 6%). In an operation where the value of downtime was estimated to be $800,000 annually, a 25% increase in uptime would put

machine tools x foundries x metalworking machinery x lawn & garden x speed reducers medical x instruments x transmissions x kilns x mining x pharmaceutical x HVAC x hoist transportation x agriculture x washdown x construction x gear box x pumps x steel mills railway x band saws x aggregates x pulp & paper x spindles x grinders x textiles x vibrating screen x hand tools x electric motors x power generation x compressors x automation x idlers

Just some of the places you’ll find Koyo bearings.

wind turbines x automotive x conveyors x aerospace x stamping x recreation vehicles blowers x food & beverage x winches x cranes x excavator x fans x robotics x sander x mixer back-up roll x paver x printing press x debarker x head pulley x dryer x track roller x planer oil & gas x clean room x extreme environments x forestry x return rolls x traction motors x tunnel boring x rock crushers x rolling mills x work rolls x smelting x sawmills

$200,000 of value on the bottom line. Being better organized also can reap large financial benefits. If the inventory of spares in the maintenance storeroom could be cut by 25% — for example, from $1 million to $800,000 — the carrying costs for all those extra items would be eliminated. Assuming carrying costs of 30%, that $200,000 savings would put $60,000 on the bottom line.

Of course, you may want to use these savings to invest in a CMMS, training, or test and measurement equipment that will give you the improved troubleshooting capabilities and productivity gains you need. In this case, the cash on the bottom line can come later, but meanwhile, you’ll be well on your way to a smooth-running operation and to achieving a world-class standard in maintenance – without begging the boss for a bigger budget each year.

It’s certainly worth a try.

Bill Roebuck, Editor & Associate Publisher

EDITORIAL

Bill Roebuck, Editor & Associate Publisher 416-510-6749 broebuck@mromagazine.com

Ellie Robinson, Art Director Contributing Editors

Richard G. Ensman Jr., Simon Fridlyand, Carroll McCormick, Peter Phillips, Angela Webb, Cliff Williams BUSINESS

Nick Naunheimer, Publisher 416-510-6868 nnaunheimer@mromagazine.com

Eric Achilles Cousineau, Adv. Sales Manager 416-510-6803 eachilles@mromagazine.com

Kimberly Collins, Advertising Production 416-510-6779

Melinda Marasigan, Subscription Enquiries 416-442-5600 x3548

Making bearings since 1921.

Tel: 1.800.263.5163••••••Fax: 1.877.326.5696••••••Email: info@koyo.ca••••••www.koyo.ca

Ottawa, ON — The development and operation of offshore wind energy in Ontario could, between 2013 and 2026, create an average of 3,900 to 4,400 jobs per year during the construction phase. It would also produce peak employment of 600 permanent positions in the operations and maintenance of offshore wind turbines.

These outcomes are based on reaching 2,000 megawatts (MW) of new generation capacity over 15 years, a conservative estimate of the market potential for an Ontario offshore wind industry.

The emergence of such an industry would add between $4.8 billion and $5.5 billion to Ontario’s economy during the 2013-2026 period, according to a Conference Board of Canada report assessing the potential contribution of offshore wind generation to the province’s electricity supply, employment and economic activity.

Ontario has made a long-term commitment to renewable electricity, in part to eliminate generation from coal-fired plants. The government’s Feed-in-Tariff (FIT) program has attracted the interest of the global wind power industry. Offshore wind is one of the renewable generation sources permitted in the FIT program, which offers long-term contracts at guaranteed prices for qualifying projects.

“An offshore wind industry in Ontario — one that develops enough projects to be sustainable in the longer term — would create both short-term construction employment and permanent green jobs in the operations phase,” said Len Coad, director, Environment, Energy and Technology Policy, The Conference Board of Canada. “Should development progress as anticipated, it is likely that new industries will develop in the province to service the needs of the growing sector.”

The study, which was financed by Vestas Offshore A/S, quantifies the combined direct, indirect, and induced economic effects on economic indicators, such as real gross domestic product (GDP), employment, income and government revenues.

The analysis finds that, over the 2013 to 2026 period, the development of Ontario’s offshore wind industry would lead to a cumulative total of $10.044 billion in real capital investment and operations spending.

Wind Power Industry, is publicly avail able at www.e-library.ca.

UBC STUDY

Vancouver, BC — With shift work on the rise, so too may be the risk of workplace injury. A recent study by researchers from the University of British Columbia (UBC) concluded that Canadians who work night and rotating shifts are almost twice as likely to be injured on the job as those working regular day shifts.

The study examined data on 30,000 Canadians collected as part of Statistics Canada’s Survey of Labour and Income Dynamics. Trends in work injury were compared among workers involved in different types of shift work from 19962006. The findings showed that even

mal sleep patterns and cause drowsi ness or fatigue, which can lead to workplace injuries.

In the past few decades, the number of Canadians working shift work has risen substantially. The number of women working shifts increased by 95% during the study period, mainly in the health care sector — almost double the 50% increase of men, occurring mostly in manufacturing and trades.

Injuries related to shift work come with a hefty price tag. In 2006, 307,000 work-related injury claims associated with shift work represented more than $50.5 million in costs to Canada’s workers’ compensation system. The study authors recommended that governments and employers consider policies and programs to help reduce the risk of injuries among shift workers.

Although an obvious solution to the risks of shift work would be to eliminate it altogether, this may not be a practical option for many workplaces.

According to the Canadian Centre for Occupational Health and Safety (CCOHS), there are two basic levels where improvements can be made to help reduce the effects of shift work:

1) The organizational level: primarily through the design of shift schedules, education and better facilities, including conducting a risk assessment for every task to be performed during a specific shift

2) The individual level: helping workers to get better sleep, eat a healthier diet, and reduce stress.

More information and comprehensive advice on how to cope with shift work and prevent related injuries can be found on the CCOHS website at www.ccohs.ca/ oshanswers/ergonomics/shiftwrk.html.

Edmonton, AB — More than 280 Alberta high-school students have been recognized with a scholarship to continue their apprenticeship training after high school and become certified journeypersons.

The Registered Apprenticeship Program (RAP) scholarships are designed to recognize student achievement on the job and in the classroom. The scholarships provide $1,000 to each recipient.

“RAP helps high-school students make the link between the classroom and future careers,” said Andy Neigel, president and CEO of CAREERS: The Next Generation, an industry-driven private/public partnership dedicated to the career development of Alberta’s youth. “As a result of these scholarships, more students are entering the post-secondary world and the workforce poised and motivated for success.”

As part of the program, high school students obtain hours of on-the-job training and work experience as credit toward both an apprenticeship program and a high school diploma while earning an income. This year, more than 1,800 Alberta high school students are participating

“A strong workforce of skilled tradespeople will shape Alberta’s future,” said Ray Massey, chairman of the Alberta Apprenticeship and Industry Training Board.

The Government of Alberta, along with industry partners, funds the scholarships awarded to Alberta high school graduates who participated in the Registered Apprenticeship Program and are pursuing careers in the trades. The program also includes Top Employer, Top Instructor and Top Apprentice awards. For more information, visit www.tradesecrets.gov.ab.ca.

Ottawa, ON — Corporate profitability is expected to improve over the course of 2011, based on a strong increase in The Conference Board of Canada’s monthly Leading Indicator of Industry Profitability. The index increased by 0.6% in December 2010, its biggest one-month gain dating back to 2001 (the earliest that data is available).

Following six months of decline, the leading indicator has risen for three consecutive months. Still, the overall index has some catching up to do. Between March and September, it declined by 2.4% and it finished 2010 about 1% lower than in December 2009.

“The recent improvement of the index is thanks to stronger non-residential investment, a rising stock market and increasing raw material prices,” said economist Maxim Armstrong. “Thirty-eight of the 49 industries covered by this indicator recorded increases in December, which is the most since July 2010. Having positive profit indicators in four out of every five industries is another welcome sign, as it corresponds with periods of strong economic growth.”

Firms in the primary sector are poised for a profitable year. Demand for several raw materials has boosted both sales and prices. The agriculture and forestry industry and the mining industry posted the biggest increases of their index in December compared to a year earlier — 12.3% and 10.6% respectively.

The strong Canadian dollar has a significant effect on profitability in most of the industries covered by the leading in-

dicator — the impact is positive for some industries and negative for others. In 2010, the exchange rate was much less volatile than in previous years, but the Canadian dollar remained very high by historical standards and is expected to remain at or near parity with the US dollar in 2011.

The Conference Board’s Leading Indicator of Industry Profitability is constructed from high-frequency data series. The indicators are designed to be predictive of movements in corporate profitability six months hence. An industry leading index is created for the economy as a whole, as well as for 49 individual sectors within the economy, thus providing coverage for most of the private business activity that takes place in Canada.

Glen Ellyn, IL — The Educational Services Committee of the Bearing Specialists Association (BSA) has released the second in a new series of industryspecific educational publications, referred to as Industry Briefs. It’s titled Cement Process.

The Industry Briefs are intended to enhance the association’s existing Bearing Briefs by identifying bearing selection specifics used by individual industries. The Cement Process brief details the use of bearings in cement processing and is available for downloading from the BSA website, www.bsahome.org, under Tools You Can Use.

Specifically, the Industry Brief maps

continued on page 10

When you think “Innovation”, you think about a

bearings. This innovative product not only

relubrication. When it comes to

continued from page 9

the cement manufacturing process and identifies particular requirements for bearings. For example, in the clinker cooler, the brief points out: “Pillow block and flange-mounted spherical and tapered roller bearings are typically found on screw conveyors, belt conveyors and bucket elevators. Large fans may utilize Babbitt-lined, oil-lubricated sleeve bearings. Smaller fans utilize pillow block spherical bearings.”

Additional processes included in this brief — such as crushing, homogenization and fuel handling — are given comparable consideration.

The Educational Services Committee hopes to address bearing selection specifics in various additional industries in subsequent Industry Briefs.

BSA is an international service and educational organization of distributors representing a total of almost 100 companies distributing factory-warranted ball,

roller-, and anti-friction bearings, and invited manufacturers of bearings and related products. For more information, visit www.bsahome.org.

Toronto, ON — PEMAC (the Plant Engineering & Maintenance Association of Canada) has presented its 2010 Sergio Guy Memorial Award to Michel Rioux, a professor and director of the Operations and Logistics Engineering program and Maintenance Management Professional (MMP) certification program at Ecole de Technologie Supérieure (ETS) in Montreal.

As an association, PEMAC strives to personify the highest degree of professional excellence and integrity through its membership and executive. In the early years of PEMAC, many visionary people laid the foundation for this commitment to excellence. One such member

was Sergio Guy. Prior to his early and untimely passing, Guy was highly regarded both personally and profes sionally for his values, ethics and commitment. His devo tion to his family, to his work, and to volunteerism was an inspiration, and he dedicated countless hours to establishing PEMAC as one of Canada’s leading profes sional associations.

In recognition of Guy’s principles, his commitment to PEMAC, and his exem plary contributions to the maintenance profession, PEMAC annu ally honours a worthy recipient with the Sergio Guy Memorial Award.

The award recognizes the efforts of an individual who has made significant contributions to both the profession and the association.

The most recent recipient, Michel Rioux, established PEMAC’s MMP program in the French language domestically and internationally. He has over 10 years of industry experience in both the private and para-governmental sector, and has worked in the field of production and maintenance engineering as an en-

Rioux’ fields of interest, within the framework of his research, courses, seminars and collaborations with the industry, include operations optimization, logistics, reliability analysis, physical asset management and project management. His focus is on the development, improvement and technology transfer of various diagnostic, analysis and decision-making tools with a view to improving company performance.

“His personal and professional attributes of leadership, dedication and visionary contributions set him apart from his peers,” says Norm Clegg, PEMAC’s executive director.

PEMAC is a national not-for-profit association providing leadership, education and certification in maintenance, reliability and physical asset management practices. Its MMP education and certification program is now delivered through the continuing education or contract training departments selected colleges, institutes and universities in Canada using in-class, on-site or live on-line formats in both official languages. For more information, visit www.pemac.org.

TO

6.5% ANNUALLY Cleveland, OH — World fluid handling pump demand is forecast to rise 6.5% annually through 2014 to $69 billion (US). In most developing countries, pump market growth in real (inflationadjusted) items will decelerate relative to the 2004-2009 period. However, this rate of increase will still exceed the average global pace.

Industrialized nations will see pump sales growth rebound in real terms from depressed 2009 levels. Overall advances in the pump market will be restrained by decelerating price hikes, as raw material costs moderate.

These and other trends are presented in World Pumps, a new study from The Freedonia Group, an industry market research firm.

Although growth in developed parts of the world — the US, Canada, Japan, Western Europe and Australia — will not be as strong as in most industrialized areas, it will still be quite healthy by historical standards, according to Freedonia. Process manufacturing will be the fastest growing pump market between 2009 and 2014.

In addition, more stringent environmental regulations will help generate demand for more efficient and betterperforming fluid handling pumps, such as seal-less centrifugal models. The utilities market is also expected to record impressive growth, as spending on water and energy transportation network construction expands rapidly in many industrializing nations.

World Pumps (published 11/2010, 454 pages) is available for $6,100 (US). For more information, visit www.freedoniagroup.com. MRO

News and views about companies, people, product lines and more.

• Gordon A. Duncan, former presi dent of industrial distributor Kine cor LP, has established a new management consulting company, SPAR Consulting Inc., Toronto. Areas of expertise for the company are strategy, acquisitions, manufac turer-distributor relations, pricing and management team develop ment. “I believe that if you develop an effective Strategy, hire the right People, and empower them to take Action, you will get the right Results,” explains Duncan. He can be reached at gordduncan1@gmail.com.

• Almost 20 years ago, Connie Sonsogno left Lafert North America, Mississauga, ON. And now she’s back. During her time away, she continued to work in the power transmission industry, specializing in met-

ric motors. Now, with more than 30 years experience in all aspects of the electric motor industry, Sonsogno has returned to the Lafert NA sales team. Lafert NA distributes metric motors, pumps and gearboxes. For more information, visit www.lafertna.com.

Acklands-Grainger Inc., Richmond Hill, ON, Canada’s largest distributor of industrial, safety and fastener supplies, has entered into an asset purchase agreement to acquire the Nova Scotia and New Brunswick business of Wolseley Industrial Products (Amalgamated) Inc., Mississauga, ON, a distributor of industrial, construction, MRO and safety products. Acklands-Grainger expects an incremental sales contribution

of approximately $14 million from this acquisition over the next 12 months.

• Stoney Creek, ON-based Mueller Flow Control changed its name to Flocor Inc. on Jan. 20, 2011. “Our name may be new,” says Kevin Fullan, vice-president and general manager, “but our management team and employees remain firmly in place. Our warehouse and office locations, phone numbers and contact people also stay the same. Our new tagline, ‘The Piping Products People’, says everything about us.” Its products include commercial, industrial, waterworks, fire-protection and specialty piping.

• Kaydon Corporation Bearings Division has unveiled a new website, www.kaydonbearings.com, and a new brand message. “The new site ... provides more information and a clean, easy-to-navigate design,” said Brian Walters, Kaydon Bearings marketing manager. “It features an improved search function, more product and market information, and additional drawings, specifications and downloads.” It also

introduces Kaydon Bearings’ new brand message: Kaydon infinite bearing solutions. “Research showed that our customers value our exceptional engineering expertise and willingness to create virtually infinite solutions for complex bearing challenges,” said Jeff Manzagol, president. “Our new brand conveys that, while also underscoring our position as inventor and leader in thin-section bearings and as North America’s leader in slewing ring bearings.” • The Bearing Specialists Association (BSA) welcomed 14% more attendees from a record number of companies to its 2011 Winter Meeting, held Jan. 16-18, 2011, at the Hyatt Regency Grand Cypress in Orlando, FL. John Dunlop, senior project engineer with the American Wind Energy Association, shared information about the role of bearing products in wind energy. BSA’s 2011 Annual Convention, ‘Growing Together: 45 Years Strong,’ takes place April 29-May 2, 2011, at the Hyatt Lost Pines near Austin, TX. MRO

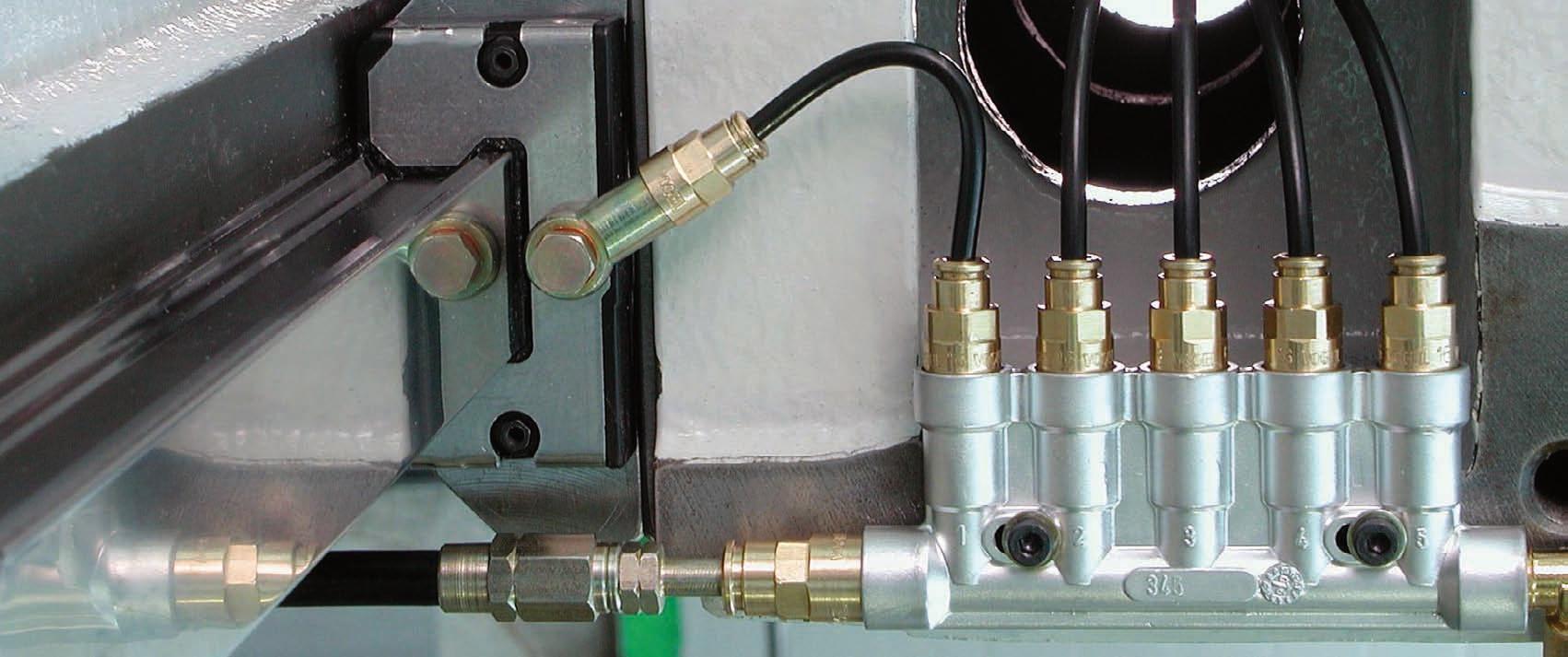

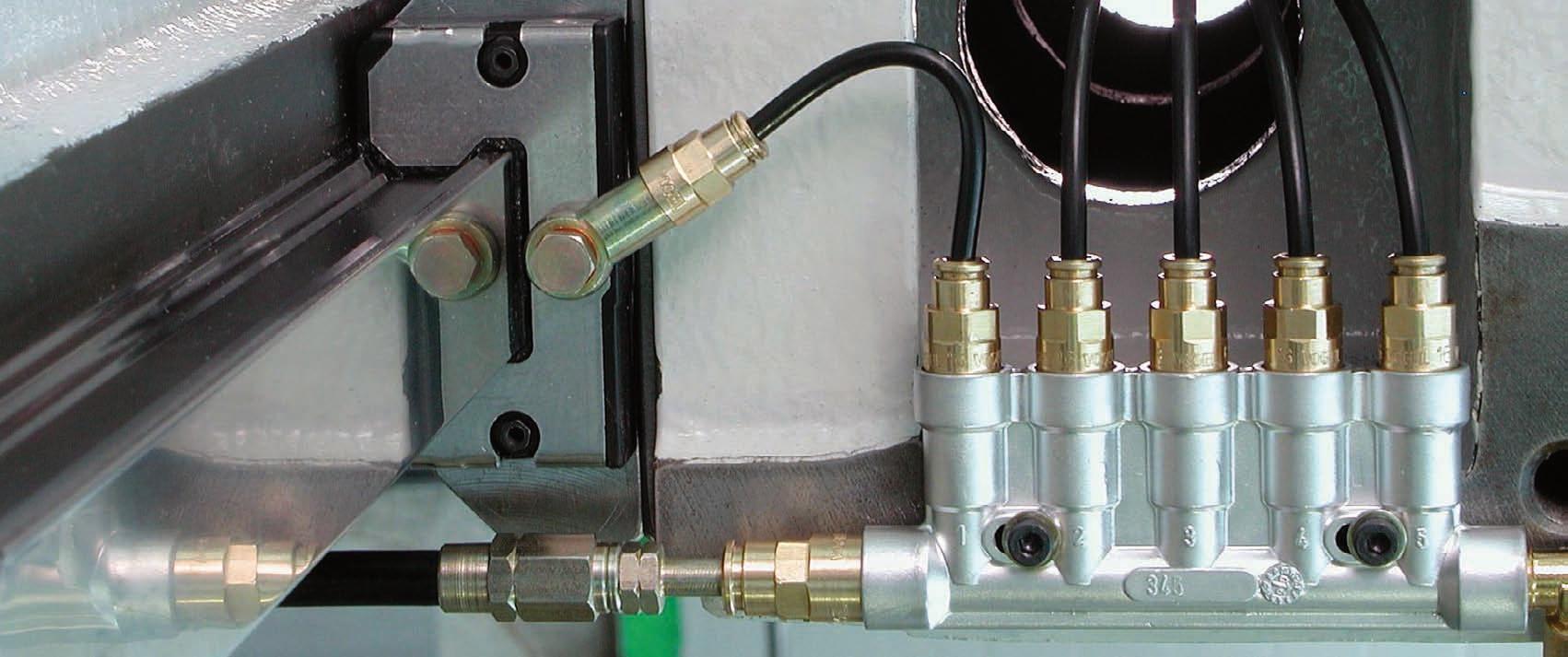

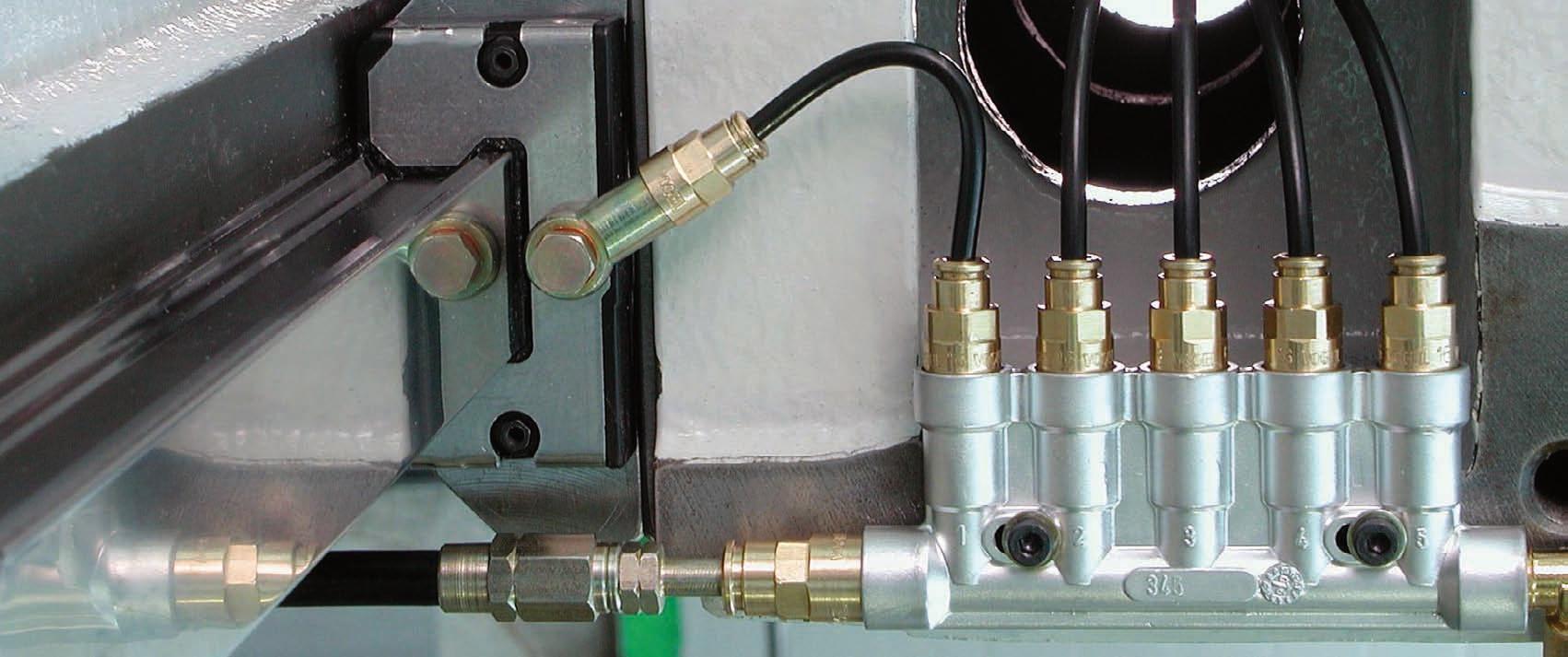

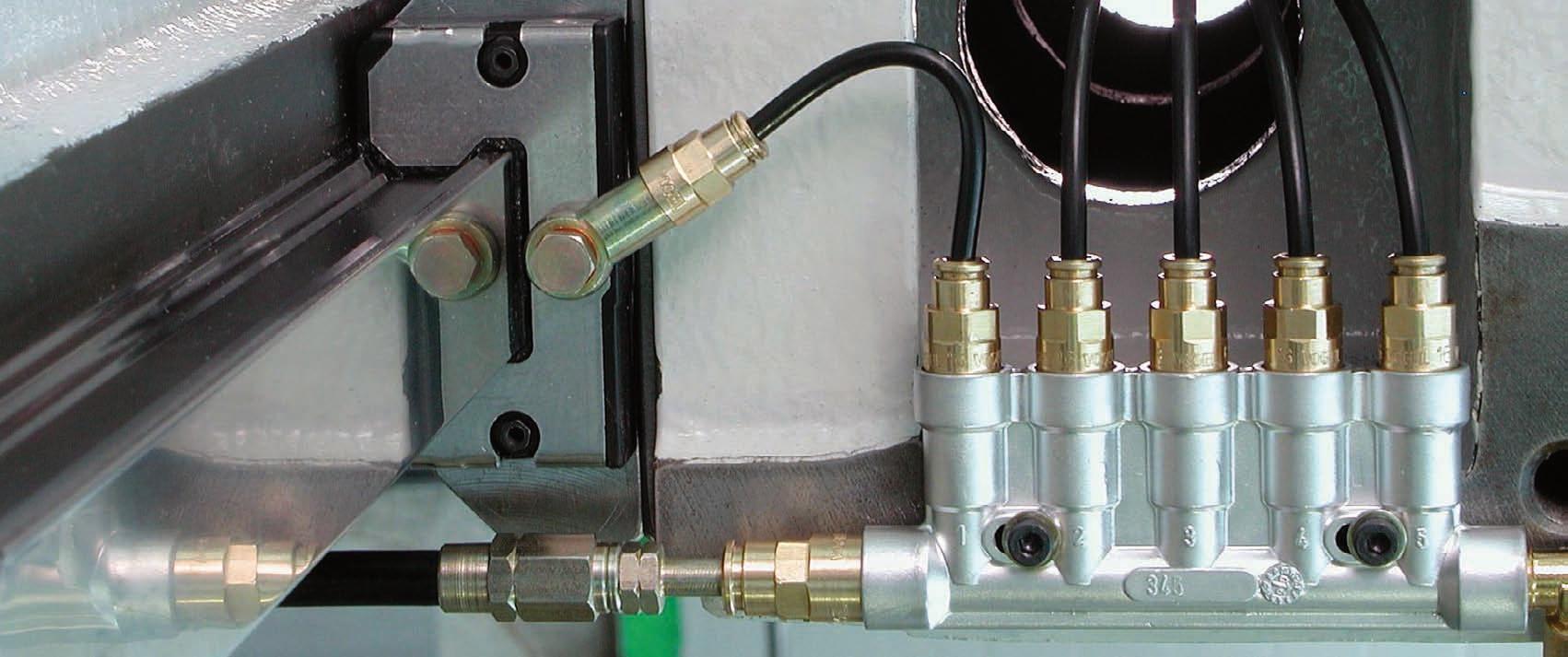

Problem: A large industrial plant located about 300 km east of Thunder Bay, ON, had a new 5,000-psi hydraulic system installed. There were some last minute changes to the pump location and a number of hoses had to be shortened and re-located. There had been a lot of hydraulic hammer noticed before the changeover and the management felt that this anticipated problem should be addressed at the same time. Solution: Hemlo Equipment Ltd. of Marathon, ON, was asked to design and install a system that would solve both problems. The design consisted of a table made with 1-in. pipe and Kee clamps, with a 1/2-in. x 4-ft x 16-ft plywood top. Unistruts were laid on top of the table so that they were free to move. Gates G6K, SAE 100R15, 6,000-psi hydraulic hose and couplings were used. The fittings at both ends were 45º elbows, in order to allow the smoothest possible flow. The anticipated hose failures were avoided by:

1. Using 45º fittings at each end, rather than 90º fittings, in order to allow smoother flow of the hydraulic oil in the system.

• Introducing the first threadlocker in tape form!

• Locks nuts and bolts against vibration loosening

• Seals against corrosion and leakage

• No mess, no waste

• Can be pre-applied

• A must for every toolbox!

QuickTape® - the same reliable performance you’ve come to expect from Loctite® liquids and sticks - neat and easy to apply.

Henkel Canada Corporation 2225 Meadowpine Blvd. Mississauga, Ontario, L5N 7P2 1-800-263-5043

2. Letting the Unistrut metal framing float on top of the table, allowing it to move, rather than trying to fight the hammer and vibration. The system has been in regular use for six years without a hose failure.

Mr. O’s thanks for this tip go out to Harold Paulson, design manager at Hemlo Equipment. For more information, he can be reached at harold@ hemloequipment.com.

Do you have a solution for a maintenance problem? Send it in and if it’s published, we’ll send you a Mr. O Problem Solver T-shirt. Include your address, telephone number, print complete details and, if possible, add a sketch to help explain your tip. Send your tips to Mr. O, Machinery & Equipment MRO, 12 Concorde Place, Suite 800, Toronto, ON M3C 4J2.

BY CARROLL MCCORMICK

Perched on hilltops and other especially windy sites across Canada, wind turbine generators (WTGs) are contributing 4,055 megawatts (MW) to Canada’s power grid — enough to power over one million homes. Output is steadily rising as new projects come on line and as old WTGs are replaced with higher-output models.

The Canadian Wind Energy Association (CanWEA), source of the 4,055 MW figure, lists 111 wind farms and sites, and 2,309 WTGs – located everywhere but New Brunswick, the Northwest Territories and Nunavut. However, assuming a generous average 1.5 MW/turbine, the actual number of turbines could in fact be closer to 2,700.

Despite the amount of hardware out there, it seems that the opportunities for MRO (maintenance, repair and operations) providers have barely begun. Most wind farms are less than a decade old — just seven of the wind farms on the CanWEA list predate the year 2000 — and many machines are just starting to come out of their original equipment manufacturer (OEM) maintenance service warranties.

“In Canada, manufacturers have a strong hold on warranty service. We do not have any service technicians working for us currently. I work directly with our OEM,” explains Trevor Smith, maintenance supervisor of a large Ontario wind farm (he requested that we withhold the farm’s name). “The WTG maintenance industry is in its infancy,” he emphasized.

“It is really hard to find a Canadian company to come in and competently work on wind turbines,” says Smith. “One problem I see with the industry now is the lack of local repair loops. With large pieces of equipment, there are a lot of components and not a lot of local repair loops. We are trying to get manufacturers to outsource equipment, such as gear-

WIND

WIND

boxes, to more local companies.”

Almost all of the big turbine equipment suppliers, such as Enercon and Vestas, have two- to 10-year warranty maintenance service contracts, or longer, according to Jason Van Geel, president and general manager of Carlsun Energy Solutions, headquartered in Port Elgin, ON. “Every project starts this way.”

Carlsun, along with Cambridge, ONbased Moventas Ltd., are notable exceptions to this OEM lock on MRO work. Moventas, one of the world’s largest manufacturers of wind turbine gears, does gearbox inspection, repairs and rebuilds for Canadian WTG owner-operators. Carlsun, founded in 2005, divides its expertise roughly equally between working as a general contractor for WTG installations and being the provider of non-construction services.

“We are among the very few companies in Canada approved by equipment suppliers to work on their WTGs,” says Van Geel. That said, the company’s expertise is the replacement of major components, not MRO, at least as of yet.

So far, there are a few other small-tomedium Canadian companies equivalent to non-OEM type MRO providers, such as

United States-based Energy Maintenance Service LLC of Gary, SD, or Outland Energy Services of Canby, MN. There are none of the size of, for example, the massive non-OEM independent company, EnXco, based in San Diego, CA, according to Mark Eagle, wind gear and field service manager, Moventas. (EnXco has a Canadian affiliate, EDF EN Canada, based in Toronto.)

Maintenance and servicing

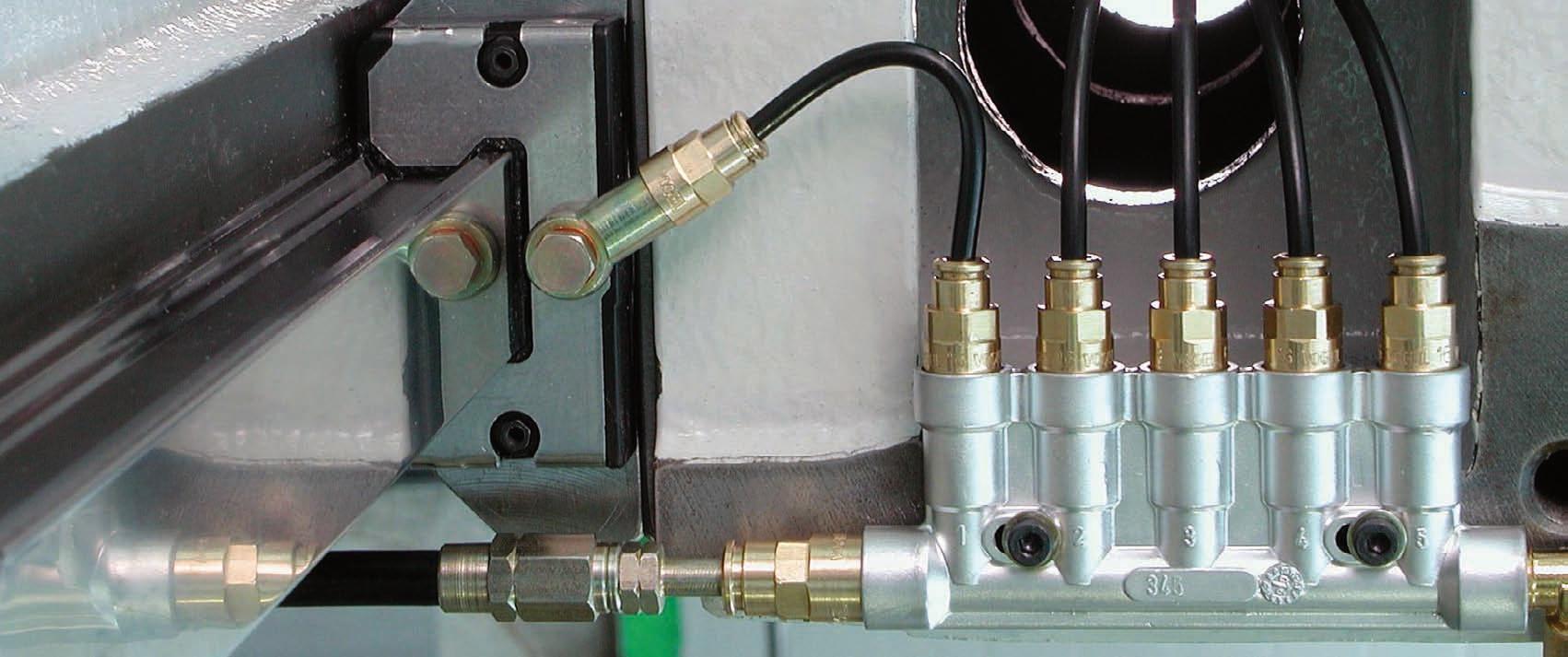

The main equipment in a WTG, for example, the gearbox, generator, pitch and yaw motors and hydraulic systems, are contained in the nacelle — a boxy structure to which the blades are attached — that is perched on top of the tower. For scheduled inspections and lubrication, which take about two days for each turbine, the WTGs must be shut down.

Maintenance schedules are manufacturer-specific. Some recommend a sixmonth service schedule for some components, such as filters and for lubrication, with more extensive inspections on a 12month schedule. The chance of an unscheduled, forced visit for maintenance within any six-month period is about 30%, according to Smith. Scheduled servicing is mainly lubrica-

tion: grease, oil, hydraulic fluids for yaw and pitch systems, and for drive trains. “There are moving parts everywhere. They need lubrication and maintenance,” Van Geel explains.

“When servicing gearboxes, Moventas’ techniques include endoscope inspections and vibration analysis, done every couple of years.

WTGs are special workplaces. Technicians must climb 80 metres or so up the inside of the towers to reach the nacelles. Tools for up-tower repairs are selected for their size and weight. Technicians must carefully plan for each repair to avoid excessive downtime.

Space inside the nacelle is limited and major components are extremely heavy: a 1.65 MW generator, for example, weighs 55 tonnes. Gearboxes weigh up to 30 tonnes. For the record, blades weigh roughly 7,500 kg apiece and might be 49 m long. A nacelle and the hardware it contains typically weighs between 81,600 kg and 82,600 kg and an entire WTG can weigh over 317,500 kg.

A minor overhaul would involve a generator alignment or lubrication pump replacement. Some equipment can be disas-

sembled and lowered from the nacelle with a builtin service crane. “Newer and larger turbines tend to be more serviceable,” says Moventas’ Eagle.

A gearbox replacement would be a major exercise. A specialist company like Carlsun might bring in a 650-tonne hydraulic crane to remove a gearbox and replace it with a spare. Moventas, on the other hand, would remove and repair or overhaul the faulty gearbox in its own shop.

Eagle describes some of the main challenges working on WTGs. “Besides the obvious problems associated with working 90 metres up in the air, the space up-tower is very limited. Moving around the equipment is difficult and takes a toll on the body and sometimes even one’s patience. Good housekeeping is a must and goes a long way to reduce fatigue and speed up the job. When the winds are high, it’s too dangerous to perform some procedures.”

Workplace safety quickly comes out in conversation. “There are very stringent safety qualifications. Safety is tied with technical qualifications in greatest importance and is a very significant department in our company,” says Van Geel. Safety training includes learning how to execute high-angle emergency descents by rappelling from the nacelle.

of their experience, their ability to excel, their attitude and their personalities ... getting along at the top of the towers. Personality is really big.”

A WTG technician has multiple specializations in, for example, mechanics, electrical systems, electronics and hydraulics, Smith explains. “You cannot have someone who is just an electrician. They need a broad understanding of systems.”

Possibly the best-equipped place in the world to receive training on wind turbine systems, if Greg Peterson is right, is in Lethbridge, AB. He is the program administrator for the International Wind Energy Academy, and the industrial and technical training department, at Lethbridge College.

The Lethbridge College International Wind Energy Academy has been offering a 32-week wind turbine technician program since 2004 and has graduated about 150 technicians to date. “It is probably the most comprehensive

Nacelles may only be visited with a buddy and there are stringent safety protocols. Daily inspections are, therefore, impractical. Manufacturers offer at least basic on-line monitoring, generically referred to as SCADA (supervisory control and data acquisition). The OEM SCADA at the wind farm where Smith works does not include vibration analysis of major components, except to prevent abnormal operation of equipment, such as blade overspeed or tower oscillation. “The monitoring system is designed to keep the machine within normal operating parameters,” Smith explains.

More sophisticated condition monitoring systems, however, are slowly gaining acceptance on Canadian wind farms. Moventas offers its Condition Management System (CmaS), which monitors, stores and analyzes data for seven key parameters: temperature, vibration, load, pressure, RPM, oil ageing and oil particle content. The company recently won a contract with GDF Suez (a Belgo-French energy company with North American headquarters in Houston, TX) to install CMaS in 100 Canadian WTGs.

SKF Canada, which already has on-line monitoring systems in more than 1,000 WTGs worldwide, is working to crack the Canadian market. Its WindCon product detects failure modes for equipment on variables such as alignment defects, shaft deflection, clutch and bearing defects, and gear damage and wear. It is currently running a single pilot project, but SKF is ready for much more action: Its remote diagnostics centre in its new Solution Factory in Edmonton is equipped for remote data capture, analysis and diagnostics reporting.

Despite the acceptance of on-line monitoring systems in other industries, Canadian wind farm operators appear not to have wholeheartedly embraced them yet. “In the wind industry, the top priority is to build new capacity. Remote monitoring and predictive maintenance strategies are still being developed, since significant [numbers of WTGs] are still under warranty or just after the end [of them],” says Hugues Martel, division manager, Reliability Systems, SKF Canada. “[But] the earlier that some preventive and corrective maintenance tasks can be scheduled, the more you can save money. For example, some bearings can be changed in the nacelle if you detect the problem early enough. The business case for condition monitoring on wind farms is driving down the cost of doing maintenance.”

Multiple skills needed

Historically, according to Smith, who is is an aircraft mechanic by training, WTG technicians have come from diverse backgrounds. “When I first started, I met linemen, electricians, millwrights, mechanics … one was a farmer with phenomenal skills. The focus was on the breadth

training program that we have seen,” Peterson says. “The key to it is the extensive scope of equipment that we train students on. Our equipment includes 250-kW to 1.8-MW generators and gearboxes, training units for hydraulic systems and sensors, a training tower, a nacelle safety simulator and blades.”

Students come from as far away as South Korea, China and Australia to take the program and graduates can go directly to work in the wind turbine maintenance industry, Peterson says. “The program is 100% driven by service companies [OEMs]. An advisory committee, which includes wind industry OEMs, reviews and makes recommendations on the curriculum.” OEMs will put graduates through additional specific training on their own systems and equipment.

The future for technicians and non-OEM service companies would seem bright. As of last August, according to CanWEA, there were 72 new projects, with a total capacity of 8,695.2 MW, that had signed purchase power agreements and/or that were under construction.

That means there will be roughly another 5,800 WTGs that will need servicing, and the counter keeps on spinning. For example, Alberta alone has an estimated 11,500 MW of proposed wind applications, and environment ministers across the country are plugging wind power as their clean-energy salvation. MRO

Montreal-based Carroll McCormick, an awardwinning writer, is the senior contributing editor for Machinery & Equipment MRO. Reader

BY ANDRÉ REBELO

Testing requirements vary greatly for professionals working in plant maintenance, repair and operations (MRO). Whether you work for a manufacturing facility, a contract MRO company, or are in a specialized industrial setting, one thing remains relatively constant: chances are that when it comes to performing essential electrical testing and monitoring, nine times out of 10, you’re reaching for your digital multimeter (DMM).

Advances in design, functionality, safety and accuracy have improved the usefulness and value of the DMM tre mendously. Increased selection in the marketplace has also led DMM manufac turers to push innovation to increase the versatility of their testers and meters.

Still, take a scenario where you need to monitor or datalog readings over a pe riod of time. You soon discover that sev eral perennial safety problems persist with even the latest test equipment.

In many cases, for example, the prox imity to hazardous voltage or moving components is inevitable. In essence, you’re as close to dangerous connections or components as your test leads permit. Monitoring readings can be hazardous. You can step away to safety if you initiate datalogging, but you’re limited to review ing readings after you’ve retrieved the DMM following the monitoring period.

In some cases, a technician might wish she could clone herself to get the job done right. Consider a situation where a remote task is required, such as opening or closing a breaker, activating equipment to simu late a typical load, or flipping a remote switch. In most of these cases, to monitor or datalog resulting trends on one’s DMM, the help of a second person is needed. At some jobsites, this is a non-issue if there are other workers nearby. But in the MRO world, many technicians are working on their own, often during off-shifts.

and analysis (using included software) on one of two available frequencies (433 MHz or 914 MHz).

With it, MRO professionals can both monitor and datalog readings at a safe distance from hazardous locations. Additionally, it is easier to perform remote tasks such as powering up a device from a control panel that is not nearby. From a time-saving perspective, the EX540 permits a user to set up a laptop at a centralized location and then sequentially datalog

From a convenience and versatility perspective, many technicians add the processing power of a laptop computer to make datalogging more sophisticated and useful. The downside is that if test ing is needed at a number of spots at a jobsite, you now have extra hardware to lug around and set up repeatedly at each measurement point.

Multimeter companies have taken note of these limitations, and DMMs have offi cially entered the world of wireless versa tility. A little over a year ago, a major DMM maker introduced a meter with a detacha ble display for remote, wireless viewing of readings. What you could previously read only on the fixed display of a DMM, you can now take with you and read from a dis tance. It’s a clever step in the right direc tion in terms of remote monitoring.

Another company’s wireless DMM in troduction took the technology a step fur ther with remote streaming of data back to a laptop or PC for real-time monitoring or datalogging. That development came from Extech Instruments, which added the Extech EX540 as a new addition to its EX500 series of industrial multimeters.

The new meter offers wireless connectivity to a laptop or PC using a USB receiver with a range comparable to Bluetooth (10 metres). The EX540 transmits real-time data for monitoring, trending

readings throughout a site without relocating the computer.

The EX540 is a true RMS DMM that, in addition to wireless datalogging, can log up to 10,000 readings internally and also reads voltage, current, resistance, capacitance, frequency, duty cycle (dwell), continuity, diode testing (2.8V), and even temperature. Its accuracy is rated at 0.06% and it has a Category IV overvoltage safety rating, protecting users even on outdoor wiring. Beyond the gee-whiz effect of a heavyduty wireless datalogging multimeter, MRO managers can now expand how they think about testing scenarios and logistics, not to mention how jobs can be performed more quickly and easily. For the invaluable versatility and added safety of remote monitoring and datalogging, the wireless datalogging multimeter has arrived and is here to stay. MRO

André Rebelo is with Extech Instruments, Waltham, MA.

There is an attitude that since it’s just air and because it’s used every day, it’s free, even if there are obvious system leaks. Unfortunately, compressed air is an extremely expensive utility. Here’s how to get control over your compressed air systems to reduce energy costs and your facility’s carbon footprint.

BY DOUG WAETJEN

It is amazing that while there is so much discussion in various media about energy and carbon reduction, most plant personnel fail to realize that there are incredible opportunities for cutting energy waste and carbon gases right under their proverbial noses. These are opportunities that could dramatically improve their company’s competitiveness.

In fact, many management personnel fail to realize that it isn’t always necessary to commit to major capital-intensive programs that produce long-term returns on investment. They often are either not aware of — or just overlook — inexpensive projects with short-term, almost immediate returns that will improve energy efficiencies in their plants.

One project is to look for and repair leaks in utilities such as compressed air and steam. Such projects often provide a very fast and dramatic return on investment. In some cases, they have translated into hundreds of thousands (and as high as millions) of dollars per year with-

out a major capital investment.

Compressed air is one utility that of fers tremendous savings potential. The problem is that there are many plant per sonnel who don’t quite understand that compressed air isn’t free. There is the at titude that since it’s just air and it’s used every day, it’s free and doesn’t require much attention, even if there are obvious leaks. Unfortunately this is far from the truth. Compressed air is an extremely expensive utility.

In fact, back in 1995, the US Depart ment of Energy instituted a Compressed Air Challenge to help industry reduce the use of compressed air by 10% by 2010. It had stated that compressed air is one of the most costly utilities in plants and of all the compressed air produced in the US, 30% was lost to leaks. It estimated the annual cost to be around $3.2 billion! (Results from that program have not yet been released.)

quired to produce compressed air, less than 20% of input energy is left for use. That means 80% of what is paid for is used up before the compressed air is put in the distribution system.

Why is compressed air so costly? It is extremely expensive to produce and it is very inefficient to use. Of the energy re-

Here’s an example of how inefficient compressed air is. If we compare the cost of running a one horsepower electric motor to a one horsepower compressed-air motor,

the former might cost $200 per year while the latter could be $1,500 per year.

One simple approach for those facilities that use compressed air is to schedule routine compressed-air audits and leak surveys. Compressed-air leak surveys often disclose the cost of wasted air affecting the electric bill ranging form tens of thousands to hundreds of thou-

sands of annualized dollars.

Table 1 shows how costly compressed air leaks can be. While the numbers relate to one leak, imagine the cost of hundreds of leaks with sizes ranging from 1/16 of an inch up to 3/4 of an inch.

Leaks and misuse

While design and compressor efficiency are important factors to consider regarding system efficiencies, there are two other contributing factors to excessive energy consumption in a compressed-air system: leaks and misuse.

On the plant level, there are many workers who are under the assumption that air is free and for this reason air is often misused and wasted. Air leaks are ignored. It is not uncommon to walk through a plant where the tell-tale loud hissing sounds associated with gross leaks are heard and taken for granted as background noise. If leaks are too loud to be tolerated, we have seen rags or duct tape wrapped around them to reduce the sound level and make it more acoustically comfortable for the personnel in the area.

Abuses have also been observed. At times personnel have placed air hoses in a position to continually cool their working space. In one instance, an enclosed metal box was set up in a plant with an air hose run through the top, positioned to continually blow air on soda pop cans to keep them cool!

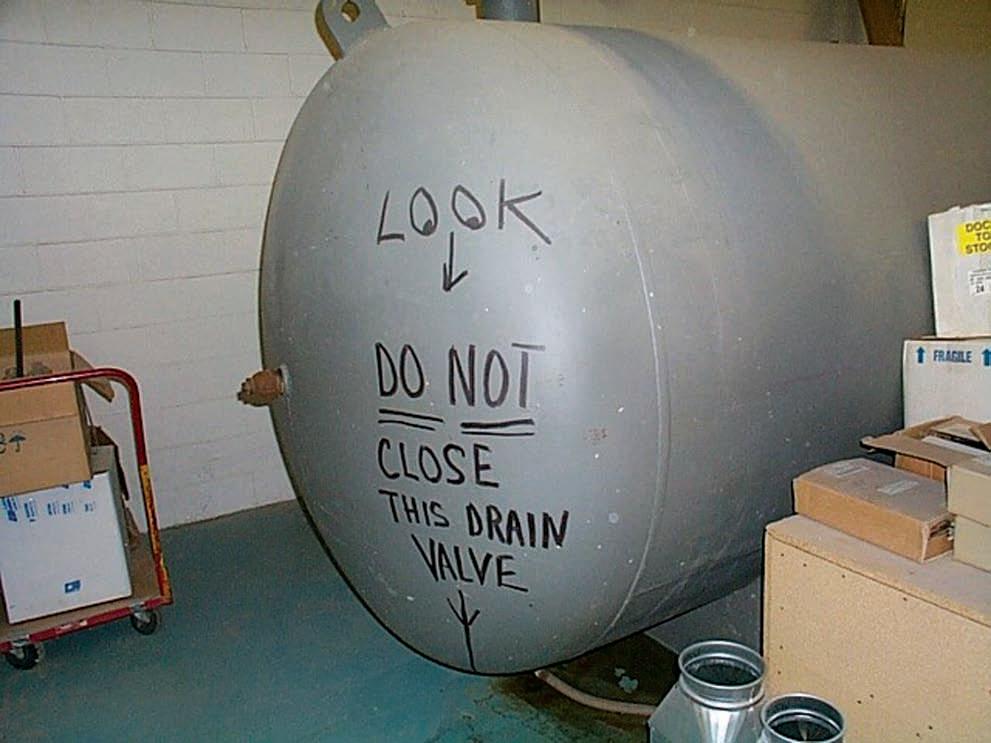

Engineers have also misunderstood the inefficiency and cost associated with compressed air. Some common wasteful and costly practices in plants include using compressed air to blow on and cool bearings, or to continuously blow on conveyors

to clean them. We have seen drain valves left open with warnings placed on the tanks stating: “Do not close this valve, keep it open.”

Solutions to

One simple, inexpensive approach to reducing compressed air waste in facilities is to embark on an educational campaign. Meetings are often a good start, where the cost of energy waste and its impact on operating costs in particular can be discussed. Personnel can be asked to help identify misuse and be encouraged to inform their co-workers. Motivational signs can be placed around the plant to illustrate wasteful behaviour and suggest changes. Newsletters can be used to promote a campaign. A suggestion box can be set up and rewards or awards given to the most effec-

tive suggestion. In some cases, monetary rewards based on the value of the suggestion have been given to personnel.

As part of the misuse or misapplication of compressed air, a survey can be undertaken to look at alternatives to compressed air. For example, instead of blowing compressed air on a bearing, try a fan. Instead of mixing or agitating with air, try an electric mixer. Keeping in front of the issue and looking around for alternative resources can help reduce the electric bill noticeably.

Since about 30% of all the compressed air produced is lost to leaks, it is imperative for a facility to incorporate a compressedair leak survey program. Not only is this a non-capital intensive, relatively inexpensive approach, the results can be gained

as quickly as the leaks are repaired. Energy consumption, specifically the reduction of electricity usage, also will have an impact on a plant’s carbon footprint.

Compressed air leak detection surveys require planning, personnel, training, equipment, identification, reporting and follow-up.

Without planning, a survey program can be ineffective. Planning includes consultation with plant management and plant personnel, and observation and review of the compressed-air system. A walk-through is recommended for any survey. This is performed to help set up the survey, breaking it down to small workable units. Safety issues can be observed, and route logistics can be planned that include where to begin and where to end in a particular section.

A walk-through can also help plan what equipment will be needed. Are keys needed to open cabinets; flashlights necessary for dimly lit areas; or ladders, lifts or special equipment required to reach piping in ceilings?

Personnel should understand the goals of the program and should understand how to conduct a leak survey.

Training provides personnel with the knowledge and methods needed to effectively perform a survey. Properly trained inspectors learn how to plan for and conduct a compressed air leak survey using inspection techniques that avoid problems such as misidentification or improper labelling, which might lead to costly mistakes and unreliable results. They also learn how to use reporting tools to calculate and demonstrate survey savings.

Using ultrasonic detection of leaks Using the right equipment for the job will add to the effectiveness of the survey. The most common tool for compressed air leak surveys is an ultrasonic detector. These instruments sense the high-frequency components of turbulence produced by air leaks.

Directional in nature, ultrasound is a localized signal that makes it relatively easy to locate the source of the leak. If the instrument is not sensitive enough, some midsized leaks might be missed. If there are accessibility issues, such as leaks in ceilings or in layers of pipes, or behind walls or under ground, special modules that adapt to these situations should be considered.

Identification of leaks is very important. The leak should be tagged and if possible photographed to assist those who are responsible for the repair to locate and perform the repair. A big, brightly coloured tag can help. If possible, a tagging system should be used to correlate with

location, component, pressure, CFM or even the cost of the leak.

Any survey needs reporting. A report can be a form of leak management. A leak report should be useful on many levels. The report helps identify specific leaks and the number of leaks, and provides identifying numbers that can correlate to a work order and the location of the leaks. Some reports will also include a summary of identified and actualized cost avoidance figures, along with identified and actualized carbon footprint reduction numbers. The actualized figures include leaks that have been repaired and represent the real savings of a survey. Unfortunately there have been instances where good intentions resulted in costly mistakes simply because surveys were performed with no allowance for the planning of leak repairs. Some software allows for the summation of surveys over time, demonstrating cumulative annualized cost savings. Other reporting features can include the demonstration of the reduction of the carbon footprint gases that are associated with the energy cost of leaks. Tables 2 and 3 are examples of this type of reporting. It is necessary that all parties responsible for the leak survey be on the same page. Communication is essential. Maintenance managers and planners must understand the necessity of leak repair and a workable schedule must be set.

For example, if 200 leaks are found in a survey and the report is given to those responsible for the repairs without an explanation, there is the possibility that these leaks might be looked on as an additional 200 work orders and left unattended. If discussions of the repairs include the participation of the repair team, a method could be established to break the repairs down into small, workable chunks — starting with the most costly leaks first or pairing leaks that are close together, making leak repair more efficient. Inclusion and communication will lead to cost savings and a successful program.

A follow-up review of the listed repairs will help assure leaks have in fact been repaired and no new leaks have developed due to the repairs. This should also include a review of system pressures that need to be restored to their original settings. Finally, a review of the entire survey will help set up the logistics for all subsequent surveys.

A compressed air leak survey is a truly ‘green’ way to improve profitability. MRO

BY SIMON FRIDLYAND

An area in any industrial facility classified as hazardous is one in which the atmosphere contains, or may contain, flammable or explosive gases, dusts or fibres. In this type of area, a fire or explosion could occur when three basic conditions are fulfilled:

1. Flammable gas, vapour, dust or fibres must be present.

2. The combustible material must be mixed with air in the proportion required to produce a flammable mixture.

3. A source of ignition must act to ignite the mixture. This can be any source that could release sufficient energy to cause ignition. A spark or even a hot surface may release the incendiary energy.

Generally, a potential source of ignition from an electrical system is any spark or hot component that releases energy sufficient to ignite the combustible mixture surrounding it.

The ignition source may occur in any of four mechanisms: a) discharge of capacitive circuits, b) interrupting (opening) of inductive circuits, c) opening or closing of resistive circuits with slow intermittent interruption, increasing the ignition capability (hazard), and d) hightemperature sources.

Ignition mechanisms may occur in relay contacts, switch contacts, fuses, short circuits (from damage or component failure), and arc-over between components or conductors. However, the components or circuits that present a potential ignition source may be designed in a variety of ways in order to prevent the ignition of a hazardous atmosphere.

Three basic approaches are used individually or in combination to prevent the ignition of hazardous atmospheres:

1. I ntrinsically Safe/Non-incentives Equipment: Eliminates the ignition source by designing equipment that cannot cause ignition when in contact with flammable or explosive atmospheres.

2. Gas Purge/Hermetic Sealing: Controls the atmosphere surrounding the potential ignition source so those components are enveloped within a non-hazardous atmosphere.

3. Flame-proof/Explosion-proof Housing: Contains the explosion within the housing, preventing the ignition of the surrounding atmosphere.

Regulations require than an area classified as hazardous be established by an engineer. In Ontario, for example, drawings of a classified area shall be stamped by a professional engineer operating under a Certificate of Authorization issued by the Association of Professional Engineers of Ontario (APEO).

The electrical inspector from an electrical inspection agency (Ontario’s Electrical Safety Authority — ESA — for example) reviews the installation drawings for wiring methods in each classified area of a plant or other industrial facility, and any safety devices such as dust collectors, ventilating equipment, etc., that might have an impact on the installation methods with reference to the stamped drawings. The electrical inspector ensures that the wiring and equipment installed conforms with the requirements of each area.

Any time electrical equipment is destined to go into a classified area, regulations state it shall be reviewed by a professional engineer before it is

built. There are two reasons for this.

First, Ontario Electrical Safety Code Bulletin 18-1-15, as well as Ontario Regulation 851 Section 7, stipulate that a PSR (Pre-start Health and Safety Review) is required when dealing with flammable liquids, potentially explosive processes or dust collectors.

A Pre-Start Health and Safety Review is required if — in a factory other than a logging operation — a provision from the regulation and the circumstances described exist:

(a) When a new apparatus, structure or protective element is to be constructed, added or installed, or a new process is to be used, or

(b) When an existing apparatus, structure, protective element or process is to be modified, and one of the following steps must be taken to obtain compliance with the applicable provision: (i) New or modified engineering controls are used. (ii) Other than new or modified measures are used. (iii) A combination of new, existing or modified engineering controls and other new or modified measures is used. Since a PSR is required, it makes sense to work with the equipment manufacturer at the design stage. It is possible for purchasers to pass on the responsibility for PSRs to their suppliers before the shipment is accepted by using the services of an engineering consulting firm. The firm can work with suppliers and end-users during the manufacture of the equipment, advise the supplier about the local compliance requirements, and co-ordinate any potential issues with the endusers. This approach ensures that when equipment arrives at its final destination,

it is ready to be immediately operational, as the PSR will come with the equipment. The second reason for the review relates to the fact that electrical field evaluation agencies do not do field evaluations of electrical equipment in hazardous areas. Therefore, the design of the equipment has to be reviewed by a professional engineer before it is built, and the client advised as to whether to use approved and certified electrical components acceptable to the ‘Authority Having Jurisdiction in Canada’, or whether it must conduct additional tests by testing laboratories accredited by the Standards Council of Canada. Generally, both of these tasks are combined to reduce and minimize the expenses associated with the compliance process. MRO

Simon Fridlyand, P.Eng., SAFE Engineering Inc., specializes in industrial health and safety issues and PSR compliance. He can be reached at simonf@safeengineering.ca. Online Reader Enquiry No. 403

BY CLIFF WILLIAMS

This article is part of an ongoing series. The introduction appeared in Machinery & Equipment MRO’s February 2005 issue and the series has run in every issue since. Previous instalments are archived online at www.mromagazine.com. In this issue, we pick up where we left off in the December 2010 edition, as maintenance manager Bob Edwards takes a major leap towards transforming the organization.

s Carol, our reliability manager, worked on setting up the new operator routes in our computerized maintenance management system (CMMS), and Fred, our production manager, was ready to roll them out, that was when Pete — one of the millwrights — stopped me in the maintenance shop.

“Bob, I hear that Fred is going to get his guys to record their routes in the CMMS. Is that right?”

“Yes, I think he’s going to do it this week. Why do you ask?”

“Well, I was thinking about it and I thought it would be a good idea to give them some tools so that they can give back meaningful information — you know, something like the vibe pen we use.”

“That’s not a bad idea, Pete, but I think we had better crawl before we try and run.”

“Just a suggestion,” he added.

I thought about what Pete had recommended and it did seem like the next logical step to take, but I knew we had to prepare the ground for something as different as this would be. There would be maintenance guys who resented giving over responsibility to the machine operators, and there would be operators who wouldn’t want to take on the responsibility, but I decided I would mention the idea to Fred.

Carol was very excited when she came into my office.

“I’ve set up the delay codes in the CMMS so the guys will be able to record the reasons for delays! You remember how we talked about getting the experienced guys to write procedures so the new guys would have a shorter learning curve? Well, I’ve found a way of linking procedures to the equipment, so that as we build the library, the guys will be able to link to all of the procedures for a piece

Follow along with Step 37 in a journey to World-Class Maintenance at the Plentya Paper Company as the maintenance team comes closer to achieving its goals.

of equipment and choose the one they want. I also took the liberty of setting up a Standing Work Order for Pete, Ted and Ivan, so those millwrights can start developing procedures.”

“That’s progress! We really are on a roll and Pete actually came up with an idea that should be our next goal.”

As I told her about Pete’s suggestion, Fred walked into my office and caught the end of the conversation.

“Wait a minute, Bob, we’ve only talked about recording what we do now — not about doing new things.”

“That’s why they’re called goals, Fred — something to aim for. How can we help you?”

“I just wanted to confirm everything is ready to go, as I want to tell Joe, our plant manger, about it at the Project 600 meeting this afternoon.”

“Yes, everything is set up. I should pull something together for the meeting as well.”

When Fred left, Carol picked up on Pete’s suggestion.

“It’s not as big a step as you and Fred seem to think. What we’re going to do is ask that the operators use their senses on their walk-around. By giving them a vibe pen and maybe our ultrasonic wand, we’re just going to help them quantify their observations.”

“That’s a valid point. I’ll just have to think about it.”

At the Project 600 meeting, Joe explained that we were making progress and the Corporates were impressed, but they wanted to see 600 tonnes per day very soon. “We are victims of our own success, so we need to step up the pace. What have you guys got in the pipeline?”

“We’re going to have the operators record their routes in maintenance’s CMMS,” offered Fred.

I reviewed what we had talked about at the corporate meeting and what Carol had found regarding the newer guys needing guidance to prevent rework.

“One of the things I’ve been thinking about is the topic of authority, which we had talked about with Corporate. It could take

much every one of my calls were that way — so I figured that there was no point in waiting. You think you were surprised? Wait until the guys get to hear about this!” I went straight to Carol’s office to let her know what had taken place and had her schedule a meeting with the guys the very next morning.

At the meeting, I explained what had happened at the Project 600 meeting.

“I’ll sit with a couple of you today and we’ll develop some guidelines about when and who to call in if the need arises. We’ll get a list of telephone numbers for you — won’t we, Carol?”

“The contractors’ phone numbers are in the CMMS and we already have staff home numbers posted in the lunchroom.”

“How are people going to know who to call?” asked Steve, another one of the millwrights.

“Like I said, Steve, we’ll discuss that. Do you want to be involved? I don’t think that it will be that complicated — if the problem is in Stock Prep, you’d call the stock prep guys. We’ll create some criteria for when to call contractors, such as ‘Do we know the exact problem?’ and so on.”

Surprisingly, when I mentioned the operators entering their routes in the CMMS, there was more of a commotion.

us some time before we get a lot of data on the delays in getting jobs done. The procedures will improve knowledge, but we will still have the problems with authority — and I don’t think we’ll make gains quickly enough unless we take a leap of faith.”

“Okay Bob, what do you suggest we do?”

“Let’s copy what they do at the mill we visited in Wisconsin. They allow the tradespeople to call in contractors or other trades and start work without getting permission from the maintenance manager or their own supervisors — especially on the off-shifts.”

“That’s a big move!” Joe exlaimed.

“That’s why it’s called a leap! Wisconsin reviewed every call for the first few months and shared the findings with everyone. They found that pretty much all of the decisions that were made were correct, so they stopped reviewing and reenforced the fact that the only thing that couldn’t happen was to keep the mill down and wait for someone else. It works very well there, so I think we can start with letting them call in contractors or extra help when it’s obvious, and build from there.”

“Okay, as long as you keep your finger on the pulse of what’s happening, Bob,” said Joe. “And Fred, you’re going to have to clearly communicate with your shift people so they understand what’s involved.”

As we were leaving the meeting, Fred walked beside me and he was clearly agitated.

“I just don’t get you, Bob. You talk to me about teams and involvement, and yet when I was in your office this morning and brought up the subject of the Project 600 meeting, you never mentioned anything about giving your guys the right to call in people!”

“That’s because I didn’t even think about it until now! Joe’s speech about speeding things up made me realize that waiting to get the sort of info we need is a waste. Think about the times you’ve been called in the middle of the night just to confirm what the guys at the plant had decided needed to be done. I know pretty

“I’m not too sure about this.” It was Ivan from Stock Prep this time. “Giving them vibe pens and everything?”

I looked at Pete, but he obviously didn’t want to make eye contact.

“I don’t know what Pete said, but we haven’t really talked about that in any detail. What would be the objections? It’s only like taking their senses and quantifying them,” stealing from Carol’s earlier comments to me.

“What do we do with the time that we used to spend doing the vibration routes?”

“Well, some of you can help with the writing of procedures, and who knows, we could buy some equipment and do the detailed vibration work that John, our vibration consultant, did. In fact, you’d be welcome to suggest any other valueadded work.”

This seemed to be good enough, as the grumbling died down and the guys headed off to their jobs.

“Wow, Bob, you really are making decisions on your feet,” commented Carol. “When I mentioned the operators using their senses yesterday, I know you hadn’t thought about taking the work from John. I’ve set up something in the CMMS so that we can capture any downtime from the offshifts as a separate code item, so we can do a review. Also, I’ve created a draft of the operator report that includes vibration readings and ultrasonics, just in case.”

Carol really was turning out to be a great help, and if I was honest, I wasn’t that mad at Pete, even though he’d pushed me further than I had intended to go.

When I got home that evening and talked to my wife, Sandy, about my day, she seemed quite pleased. “I think you are so far into it now, Bob, you may as well take a look at the final picture and just plough straight ahead.

“You’re getting close to your goals and it may take just a few more leaps to get you there. What is obvious is that you’ve built a good foundation for those leaps.”

MRO

Cliff Williams is the corporate maintenance manager at Erco Worldwide, Toronto, ON, and a consultant with TMS - Total Maintenance Solutions Inc., Markham, ON. Your comments on this series are welcomed. He can be reached by e-mail at williamscliff@rogers.com.

Enquiry No. 401

OCMMS systems. Hundreds of maintenance departments are embarking on a quest to record equipment history through work orders created in their maintenance software. Preventive maintenance, breakdowns, repairs and projects are all being entered into their CMMS databases. However, without performing ongoing updates, the equipment history aren’t very useful.

Craftspeople are either recording the work order information on a printed work order or entering it directly into the software. Specific information such as employee labour, parts used and comments are expected to be entered into the appropriate fields in the program.

In the case of preventive maintenance (PM), maintenance people are expected to fill out inspection sheets, record equipment-related data and provide any useful information found during the PM work.

Of course we know the better that this data is captured and documented in the software, the more reliable and usable the equipment information is to the maintenance team.

The question we often get is, how do you get maintenance people to accurately record the work order information, either on the hard copy or in the CMMS? Maintenance managers often ask: how do we know if craftspeople are actually doing the work or just pencil whipping the PM sheets?

Well, I’m going to share with you a few things that have worked at many facilities.

The first decision that needs to be made is whether maintenance people will record the information on paper or enter the data directly into the CMMS. To determine the answer, several considerations need to be discussed. Let’s look at entering work order information directly into the CMMS by the maintenance worker or supervisor.

1. What is the computer skill level of your maintenance team? Can the staff effectively enter information into the software? Or will it be a struggle for them because of their limited typing skills?

2. If you’re going to let them enter data directly into the software, do you have enough software licenses to allow multiple users? If you don’t have enough licences,

• The description of the work

• Parts used

• Tradesmen that performed the work and the work time

• Specific comments from the craftsmen about the job.

PM work orders that are generated by the CMMS also need to be in a format that is easy to read and provides ample space to record the findings of the tradesperson.

When it comes to the actual PM inspection instructions and procedures, there needs to be sufficient space for the maintenance person to verify they have completed everything on the list. There needs to be places for them to record temperatures and other readings. Requiring them to record specific data further encourages the maintenance team to do a thorough job.

For example, instead of numbering the instructions like this: 1. Check motor drive belt condition. 2. Inspect motor coupling. 3. Check motor amperage; you could insert a check box so that the person has to verify with a checkmark that the inspections were completed. l Check motor drive belt condition. l Inspect motor coupling. l Check and record motor amperage: ___ Phase 1 ___ Phase 2 ___ Phase 3.

ty and integrity of the information.

Sharing responsibility

Here’s another option, used in more advanced facilities: the operators of the equipment actually enter repair work orders into the CMMS right from their production/equipment work area.

When a repair is necessary, the operator calls maintenance to the machine using a two-way radio or a PA system. By the time the maintenance technician repairs the machine and goes back to the shop, the operator has already entered the work order into the CMMS. Now all the technicians need to do is add their time, parts used and comments, and close the work order.

This sharing of responsibility to get the repair work into the CMMS works really well. Both parties share the burden of getting valuable equipment work order history into the software.

These PM work orders also can be completed by the technicians in the CMMS or in some cases entered by a clerk and reviewed by the maintenance supervisor. The secret to getting reliable data entered into the software is to make the maintenance people responsible to gather it.

BY PETER PHILLIPS

then the maintenance crew won’t be able

Are you willing to give people time each day to enter their work orders, or is their time better spent out on the shop floor? It will take 30 minutes to an hour each day for them to enter and close their work orders. Can you accept this?

4. If maintenance supervisors are going to enter the data, do they have time to do it or will you need a clerk to enter it? Justifying an extra person to the bean counters so he or she can enter and close work orders is not always an easy task.