MACHINERY AND EQUIPMENT

25th Anniversary Issue!

Laser alignment reduces turbine vibration

Fixing CMMS annoyances

Field evaluating electrical products

Slashing lube and bearing costs

Report from PTDA’s Industry Summit

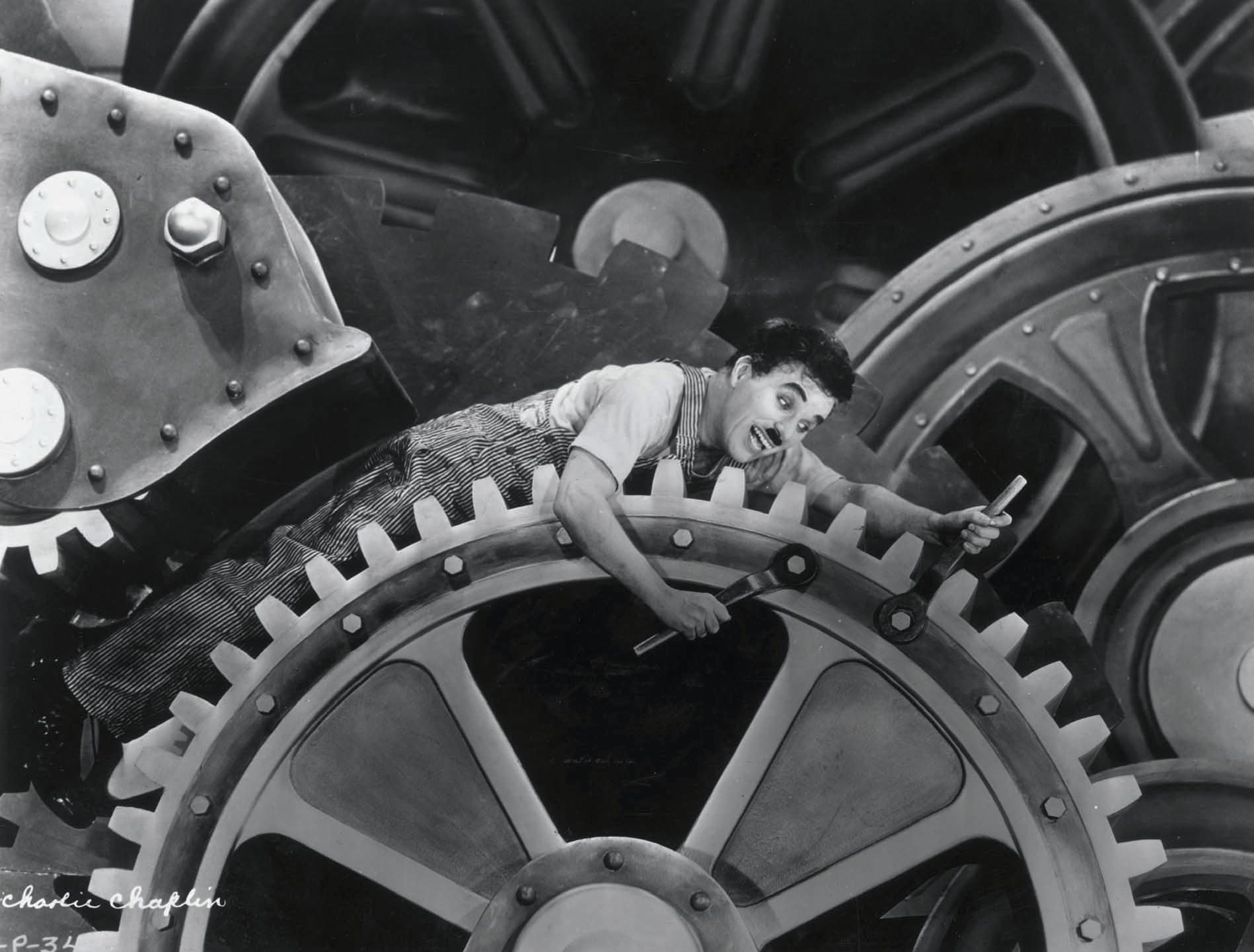

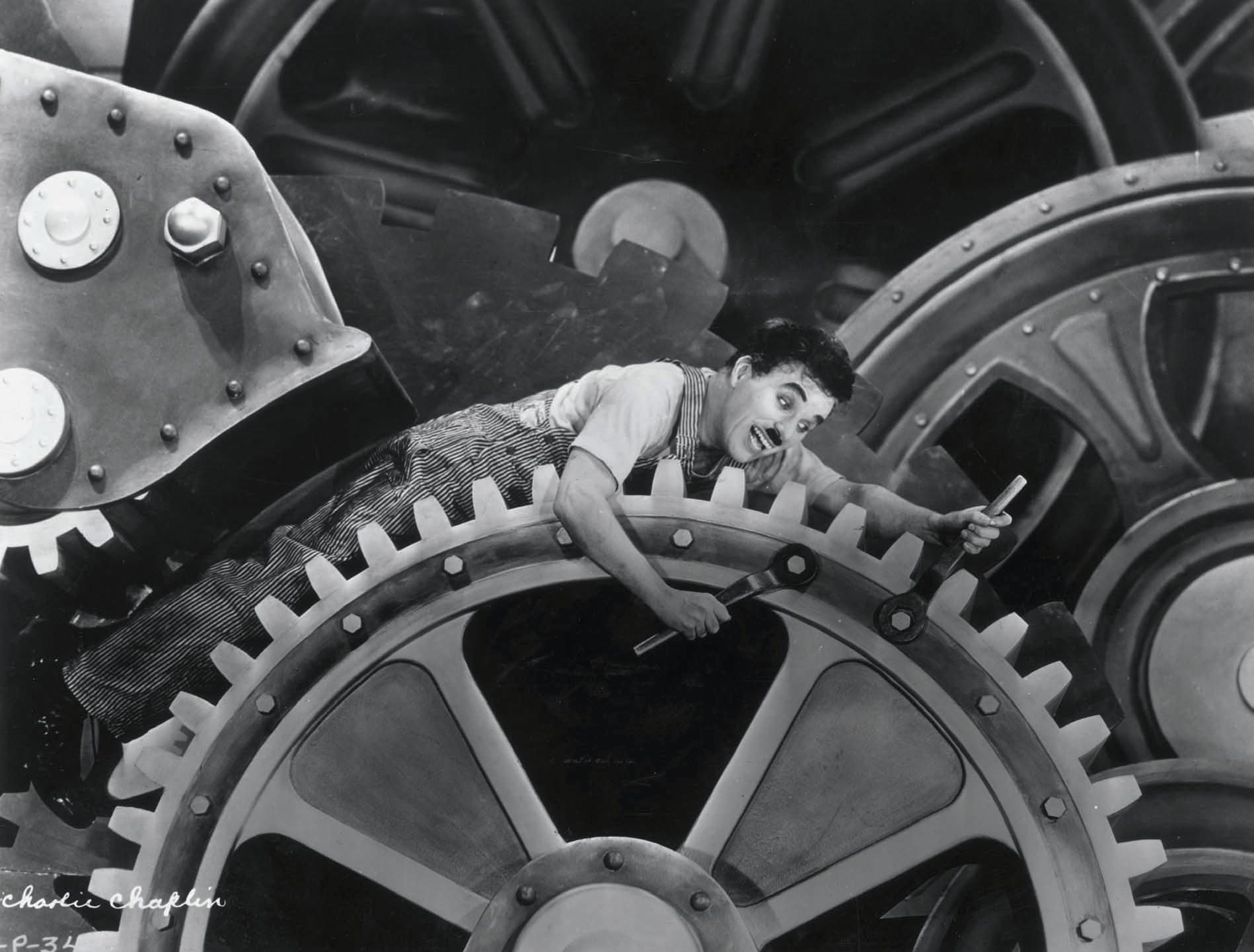

MODERN TIMES?

Oldham couplings can act as a mechanical fuse

Oldham electrically isolating couplings from Ruland Manu facturing are three-piece coup lings manufactured with two hubs and one centre disk in acet al for high torsional stiffness, or nylon for vibration and shock absorption. Torque transmission is accomplished by mating the slots in the centre disk and the drive tenons on the hubs with a slight press fit for zero backlash. The disk slides on the tenon to allow for a relatively large amount of parallel misalignment. Oldham couplings are electrically isolating and can act as a mechanical fuse. If the plastic insert fails, it breaks cleanly and does not allow any transmission of power, thus preventing damage to more expensive components.

RotoPrecision Inc.

Current probes offer measurement flexibility

The Fluke iFlex flexible current probes expand the measurement range of certain Fluke meters to 2,500 AAC. The large coil allows users to reach around large or awkward-shaped conductors up to 6 in. in diameter, while the small, 0.3-in. profile allows the coil to reach between the tightly packed cables. Supplied with a 6-ft cord, the probes are available in 10-in. and 18-in. sizes. The model i2500-18 probe is in cluded with the Fluke 381 and 376 clamp meters. Both this model and the i2500-10 are com patible with Fluke 374 and 375 clamp meters. They are rated for safe use in hazardous locations.

Fluke Electronics Canada Reader Service Card No. 304

Leak diverter kit protects equipment from overhead leaks

Spill Busters leak diverter kits from Can-Ross come in a 5-gal pail and allow process industries to divert water leaks from leaky roofs and ceilings and also to process liquid leaks from overhead equipment such as valves and gaskets. The components are compatible with most chemicals. These handy kits allow maintenance staff to control and divert process liquids to a containment area, where they can remain without causing health and safety risks and damage to equipment until repair work can be scheduled.

Grinding disc flaps wrap right around periphery

Polifan-Curve is a new Pferd flap disc designed to quickly achieve a smooth, consistent surface finish on fillet welds. The radial construction shape offers a superior solution for this common task. The tough material removes scale and bead from all metals. It works faster than grinding wheels with out the risk of undercutting the workpiece. It offers excellent tool life, including the radius edge of the disc.

Pferd Canada Inc.

Reader Service Card No. 316

Can-Ross Environmental Services Reader Service Card No. 303

The Industrial Choice

When it comes to industrial electric motors, power transmission products and drives, no other manufacturer offers more than Baldor...that is why Baldor is The Industrial Choice! Whether your application requires a fractional or 15,000 Hp motor, a variable frequency drive, mounted bearings or gearing, a pulley or sheave or even a standby generator, Baldor is the choice most preferred by industry.

When your next project demands the most reliable and energy efficient products available, look to Baldor as your one source for more industrial solutions.

• Superior Reliability

• Unmatched Quality

• Local Sales and Support

•

Anti-stick coating speeds gasket removal

Garlock has developed an anti-stick agent that facilitates removal of gaskets from flanged joints. Flange Free is a high-temperature, inorganic coating that the company is applying to its line of compressed-sheet gasketing, including extreme-grade gaskets for critical-service applications. The coating is fused to the surface of the gasket material and does not contain chemicals that could cause the gaskets to degrade. In most cases, gaskets treated with the product

can be removed in a fraction of the time and force required to remove untreated gaskets without damaging equipment or injuring workers. Because they can be removed intact, they are easy to dispose of properly.

Garlock Sealing Technologies Reader Service Card No. 305

Cutting wheel receives performance enhancements

An ultra-thin cutting wheel for portable angle grinders, the Zipcut from Walter is made of abrasives with an improved engineered formulation for more durability and better cohesion. The integrated-rib design enables an operator to cut fast and comfortably, while using less pressure than other thin cut-off wheels. Heat is kept lower, resulting in less discoloration and minimal burr. The wheel is

heavily reinforced for extra safety, yet is flexible and resistant to twisting and bending. The improvements result in less surface damage, longer disc life and straighter cuts. Walter

in this issue

features

MRO magazine celebrates its 25th anniversary / 8

A brief history of our first quarter century is bolstered by comments from contributors across the country.

Reducing lube and bearing costs for western firms / 15 SKF opens a Solution Factory in Edmonton

Understanding field evaluation for electrical products / 16

Electrical product certification and field evaluation processes in Canada, under the direction of the Electrical Safety Authority, help reduce the risk of injury or fire for people or property.

Reducing vibration with laser alignment / 17

Wind turbine drive trains can exhibit highly variable alignment between flexibly mounted generators and gearboxes.

Mohawk College honours first ICP grads / 29

The Industrial Careers Pathway’s first Canadian graduates are from the Mohawk College Industrial Distribution Leadership Certificate Program.

Industry Summit celebrates PTDA’s 50th anniversary / 30

More than 680 people attend the association’s annual meeting, including decision makers from distribution and manufacturing firms in seven countries.

editor’s selections

‘Criticality analysis helped us clarify where we needed to focus.’

Norm Kowalchuck / 15

‘With MRO, it was No-Frills publishing.’

Michael Gulas / 10

‘ALS takes the grease gun out of your hand and replaces it with a wrench.’

Gabriel Lopez / 20

‘Got program bugs? The good news is there is RAID to help you.’

Peter Phillips / 22

‘This was the eureka moment: Procedures!’

Cliff Williams / 23

Modern times require safer workplaces

mages from Charlie Chaplin’s memorable Modern Times movie – like the one on this issue’s cover – give us an insight into industry in the hard times of the 1930’s. All those unprotected workers and that unguarded machinery meant a lot of danger in the workplace back then.

Modern Times, one of the last great silent films, is a story about industry that focused on individual enterprise and the pursuit of happiness. The movie opens with an overhead shot of a flock of sheep jostling in their pen, then rushing through a chute. Instantly, the sheep dissolve into a similar overhead shot of industrial workers pushing out of a subway station at rush hour on their way to work

in a factory. Issued in 1936, Modern Times is about the classic battle of man and the toil and dehumanization of factory life, yet it concludes optimistically.

Although we’ve come a long way from that era of industrialization, it’s taken years of inventions, regulations and advancements in safety to get us where we are today in the workplace. Regarding safety, it seems like these are the real ‘modern times’. But even so, industrial accidents still happen with alarming frequency – sometimes leading to deaths of workers on the job.

Why? We’ve learned that it’s not just guards on machinery and safety training and personal protective equipment

and safe procedures that are needed to keep workers safe. It’s also an attitude of having a safety culture in an organization (the focus on profits over safety has caused many industrial disasters). Yet that’s still not enough to keep us safe.

As our Safety File column (page 21) so aptly points out, work environments can really be made safer by applying new engineering safety solutions. The technology to safeguard plant equipment and machinery exists today and continues to evolve. We just need to see it put into place more frequently.

We hope that’s a project you’ll embrace as we enter a new year – one that happens to be the start of our second quarter-century of publishing. We’re looking forward to bigger and better things in 2011 as the $140-billion North American MRO marketplace gets back on its feet.

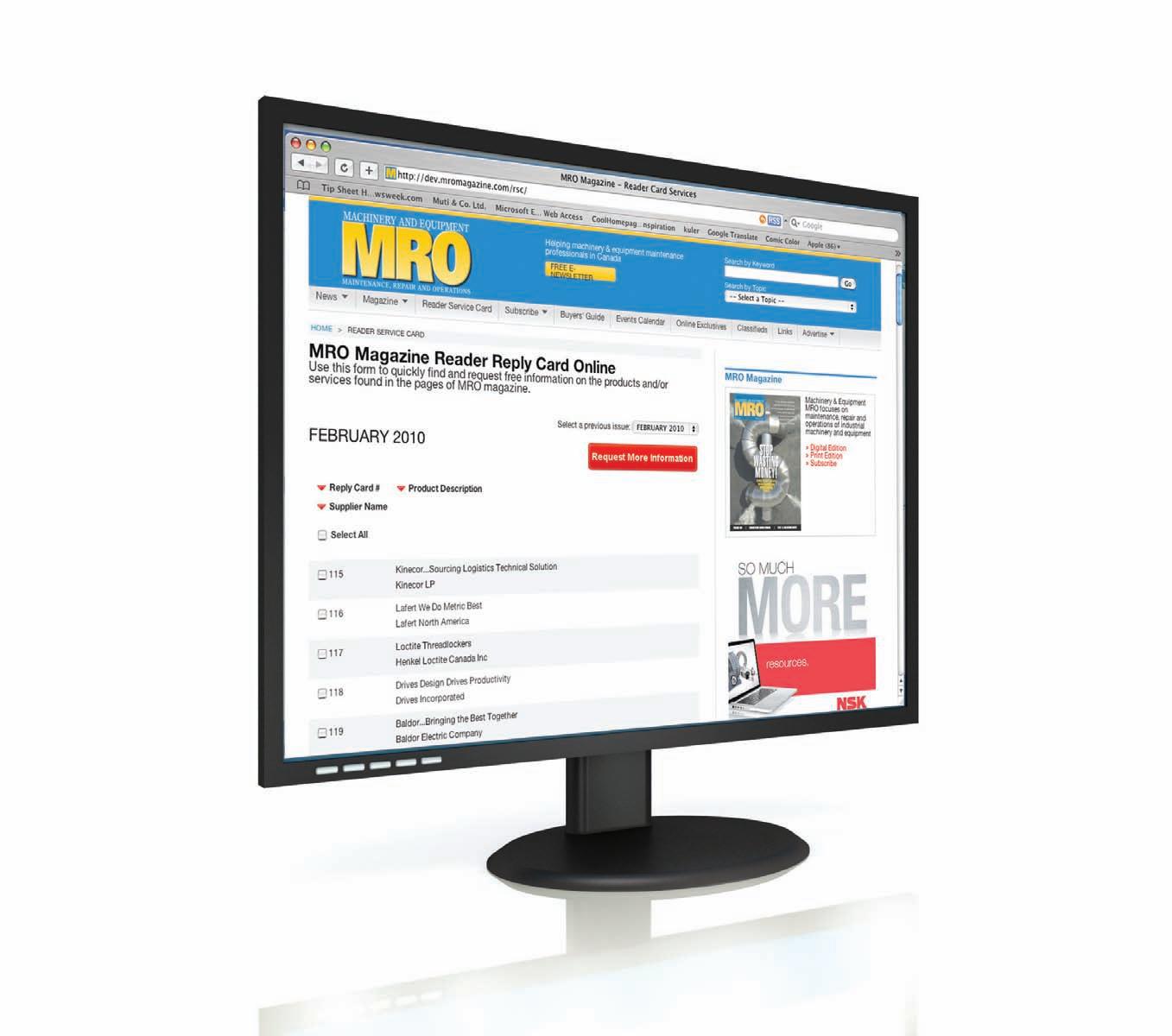

Finally, we want to point out that this will be the last edition in which we’ll in-

Did you know?

Koyo Seiko was formed in 1921. Today we are part of the JTEKT Corporation with consolidated sales of $10.3 billion and employing more than 33,000 around the world.

In January 2010 JTEKT acquired the Torrington® needle roller bearing business from the Timken Company and these products are now available from authorized Koyo distributors worldwide.

The Koyo brand supports an extensive array of applications, forming part of the original equipment for many world-class names and is a trusted supplier to industry for the ongoing repair and maintenance wherever anti-friction bearings are required.

Going green starts with a commitment to the future.

It’s about creating a vision for the future and then communicating that until it becomes a part of your culture. It’s about new approaches to break through old barriers. And it’s about holding true to your commitment when challenges arise.

Koyo continues to research, develop and deliver products that consume less energy, last longer and lighten their load on the environment. Since 2005 we’ve reduced the CO2 output per unit in manufacturing by 30% and since 2008 reduced our CO2 footprint in logistics by 31%.

In 2009 alone we reduced energy consumption in manufacturing by 14%, raw materials by 20% and CO2 emissions in logistics by 16%; all this while maintaining production levels.

Here are some of the many targets we are working towards achieving this year: Zero landfill waste; 90% reduction of 2001 levels of incineration waste; 30% reduction from 2003 levels of overall waste per unit; 5% increase in manufacturing efficiency per unit and 5% reduction in weight per unit.

For a copy of Koyo’s Corporate Social Responsibility report please visit www.koyo.ca

Making bearings since 1921.

clude printed Reader Reply Cards in each copy. We’ve found that more and more readers are using the Internet to find advertisers’ information and the sources for items mentioned in our feature articles and Product News sections, so we’re following the trend and are saving some paper to boot (a good thing for the environment). We expect you’ll find it’s faster, easier and more effective to request the information you want though our Online Reader Service Card at www. mromagazine.com/rsc. It’s available 24/7 from any computer connected to the Web. (And if your one of the few who don’t want to use this service, don’t hesitate to call, fax or write to us with your request). Now, let’s look ahead to our 26th year of Machinery & Equipment MRO. Read more about my thoughts on this milestone, and those of several other readers, in the special anniversary section starting on page 8. Bill Roebuck, Editor & Associate Publisher

Carroll McCormick, Peter Phillips, Angela Webb, Cliff Williams

BUSINESS

Nick Naunheimer, Publisher 416-510-6868 nnaunheimer@mromagazine.com

Eric Achilles Cousineau, Adv. Sales Manager 416-510-6803 eachilles@mromagazine.com

It’s our 25th anniversary

elcome to the 25th anniversary issue of Machinery & Equipment MRO Our publishing organization was founded as an independent small business in September 1985, and the first issue was published in December of that year.

Over the years, we’ve had a few different owners; first, the founding partners, Peter Helston and Victor Zellermeyer. Then, in 1990, the company was sold to Southam Business Communications. In 1998, Southam’s magazine group was acquired by Hollinger International. And four years ago, the operation was sold again, this time to Vancouver-based Glacier Media.

However, despite these ownership changes, MRO magazine has had only one editor (such editorial longevity a rarity in the publishing business). I started planning the editorial content for our first issue based on the insights of Peter and Victor, and honestly never anticipated still being in charge of its content a quarter of a century later. But as many of you know, it’s a great market involving exciting industries, and it kind of sticks to you like glue.

We’ve evolved significantly from our early days — and expanded our operations too — adding supplements for the lubrication and electrical markets, an innovative website featuring daily industry news, and other products and services for readers

BY BILL ROEBUCK

ers to reach Canada’s maintenance decisionmakers, and to provide useful, practical information to those working in maintenance, repair and operations in the country’s mines, mills, manufacturing plants, utilities and distributor branches.

provides readers with informative and timely content that is geared to their day-to-day professional needs. The magazine was designed to be an effective way for suppli-

Interestingly, we’ve just done a poll that shows almost a quarter (24%) of our readers have been reading the magazine over the past 15 to 25 years. Another 35% have been subscribers for between five and 15 years. And 40% are from over the past four years. We think that’s a pretty good breakdown – lots of loyal, long-term readers, and lots of new blood too.

BY PETER HELSTON

Please consider adding your own comments or reflections on the past 25 years. We’d love to read them, so don’t hesitate to get in touch by sending an e-mail to broebuck@mromagazine.com.

the past 25 years

It is probably fair to say that the idea for Machinery & Equipment MRO magazine was conceived as a result of a recession. This world was a very different place back in the early 1980’s. As publisher of Canadian Machinery & Metalworking, a Maclean Hunter magazine, I could look out at the worldwide machinery and equipment business and see trends taking shape. But after the awful recession of ’81-’82, which in some ways was worse than the recent ‘Great Recession’, nothing was the same as it had been. Canada’s metalworking machinery manufacturing industry virtually disappeared in the space of 18 months — the OEM business had never experienced such tough markets!

Often, though, good enterprise can spring from bad times. Some companies like Canadian Timken had been regular advertisers in CM&M for 75 years. But in January of 1981, at the start of that awful economic period, I had a call from Denny Arnold, marketing manager for Timken in Canton, OH. He wanted to break the bad news to me that after 75 years of advertising in the

magazine, Timken was not renewing its contract for 1981 due to the economic times. Timken was “shifting its advertising focus from the OEM market to the MRO market.” I asked Mr. Arnold what the “MRO” market was.

Over the next year, Denny educated me on exactly how this market worked, the importance of distribution, and the fact that no magazine in North America served this market directly at the time. Needless to say, it is a magazine publisher’s dream — and a fairly rare one at that — to find a market that has no magazine occupying that space, especially a sector as large and vibrant as the machinery aftermarket.

After a year of research into the MRO market, it was evident this was a sector crying out to be served by a business magazine. Why there were no magazines in Canada and the US serving it simply came down to the fact that ‘maintenance’, either machinery or facilities, just didn’t sound that sexy. Little did our publishing industry know then about how important a business it was.

The rest of the story is this: I worked up a plan for Maclean Hunter to launch a magazine to serve the machinery MRO market. Unfortunately, the executives at the company saw this idea as a threat to

We’d like to thank every one of our readers for their loyalty over the years, and also thank our many advertisers — without their support this magazine would not have been possible.

As we enter our second quarter-century, we’re encouraged to have just come out of yet another recession (our third). A growing economy means we’ll be able to continue investing in relevant content – some traditional and some new and innovative. We certainly hope you’ll be along for the ride.

Bill Roebuck is the editor and associate publisher of Machinery & Equipment MRO and mromagazine.com.

many existing company magazines that had bearing, drive, lubricant, motor, etc. advertising (they were right in this assumption, as it turned out). So they turned it down.

That is why Machinery & Equipment MRO became an independent magazine, when we launched it in the fall of 1985, with Bill Roebuck at the helm of the editorial, as he is today. Congratulations to Bill and Machinery & Equipment MRO magazine for nurturing that original idea for a quarter century.

Peter Helston was one of the two founding publishers of MRO magazine.

Retaining its focus

BY VICTOR ZELLERMEYER

The notion for a magazine focusing exclusively on the general upkeep and maintenance of machinery and equipment came to us in the early 1980’s, a difficult time for the general economy. It’s fair to say, all of us involved with the launch of this magazine had a huge personal and financial stake in the success of MRO.

After five years of tremendous growth and financial success, as NAFTA was taking shape and one-by-one, manufacturing plants were moving south of the border, the magazine was sold to Southam — and that pretty well ended my personal involvement with Machinery & Equipment MRO

It certainly gratifying to see not only that MRO remained the focused magazine it always was, but that the founding editor Bill Roebuck is still at the helm.

Congratulations to the entire team and here’s wishing you continued success.

Victor Zellermeyer was one of the two founding publishers of MRO magazine.

A contact point

BY CLIFF WILLIAMS

Twenty-five years ago, I had been in Canada just four years. The steel industry was booming, Oshawa was GM north, and there were 10-12 pulp and paper companies operating in Canada, employing thousands of people. Interest rates were just coming off historical highs of a recession, but companies were still investing.

Work planning was carried out on micro-fiche systems. Multi-skilling had not been heard of, and if you wanted a spare part, it involved a lot of telephone calls.

We had just hired a contractor to do some line-shaft alignments using a newfangled device — a laser aligner. At the time, vibration analysis was done through both ends of a screwdriver.

This was the world that saw the birth of MRO, a magazine designed to bring everyone the news of the changes that were taking place in the world of maintenance and to allow a contact point for those who wished to get a better understanding of the tremendous shift towards the technical age that was happening.

Quickly switch to today, where Canadian industry has gone through enormous change and is still evolving. Interest rates are at historical lows but no-one seems to be investing. The market is global — and so is the competition.

Almost everyone has a CMMS system, but for many the planning is no better than before. Most alignments are done with a laser, while a screwdriver is only used for driving screws. We can talk in real-time, order parts, get involved in forums and receive training from anywhere in the world, while just sitting at our desks.

And MRO magazine is still bringing us the news we need, and it allows us to

understand the current environment though informed articles and topics — and now it’s immediately available when we want through the use of the Internet.

As the saying goes, ‘The more things change, the more they stay the same.’

Cliff Williams is the corporate maintenance manager at Erco Worldwide.

A significant milestone

BY MARY SUE LYON

Let me begin by extending a hearty congratulations to Machinery & Equipment MRO upon reaching this significant milestone of 25 years in publication. MRO has been a tremendous ally and source of news support for the Power Transmission Distributors Association throughout the magazine’s entire history.

The magazine has been a resource to PTDA for communication with its Canadian membership and prospective membership throughout the years. Your coverage of our annual Industry Summit has always been thorough and always provides the ‘Canadian’ angle for the event.

In addition, the support of the publisher and editor of Machinery & Equipment MRO was instrumental in PTDA’s initiation and growth of its annual Canadian Conference. Now in planning for its 10th annual Canadian Conference, the editorial and advertising support of your magazine has been an invaluable asset to building and sustaining interest in this event to serve the significant power transmission/motion control dis-

tribution industry across Canada.

On behalf of the entire PTDA organization, we wish you much continued success.

Mary Sue Lyon is the executive vice-president of the Power Transmission Distributors Association.

Documenting the changing MRO world

BY DON LATHAM

For the past 25 years, the MRO magazine has reported on the changes that have occurred in Canadian industry. We have seen manufacturers consolidate their MRO supplier base under the concept of integrated supply. They have also reduced their engineering and maintenance departments and created business opportunities for new service companies.

Growing with MRO

BY JOHN LAMBERT

Twenty-five years ago, I was a recently promoted foreman, moving from ‘the tools’, as we say, into management. It was not an easy move because it was on-the-job learning. Moving away from my skills as a tradesman, where I was comfortable, to take on a position that is more about people management, was a challenge.

We have also seen the consolidation of industrial distributors into large companies, while at the same time start-up, value-added distributors discover new niches in the marketplace. And emerging new MRO communities in recycling and renewable energy have arrived on the scene.

MRO magazine, in print and on-line, continues to document our changing MRO world.

Don Latham is the president of Belterra Corp.

They say that you learn by your mistakes so I can also say I learned a lot. Good information on maintenance was not readily available, unless you were receiving the MRO magazine, which was the only magazine that came into our plant. It was the link for us on what was going on in the outside world of maintenance. It was how we learned about new technologies.

There was always a copy on my desk and I also got a copy for the shop so it could be passed around — and it was. Yes, there were trade shows, but in the early 1980’s, we were running very lean and mean and we could not afford the time to send any of the foremen or supervisors.

Later, when I made supervisor, I was still hungry to learn. I was taking night school classes for subjects like motivation and management (I learned later that these words do not always go together).

But most of the technical information came to me from the articles I read in MRO magazine.

Little did I think that one day I would be writing such articles for the same magazine. This happened after I started my own business in 1994. I had started by offering training for tradesmen in topics such as shaft alignment using dial indicators. A friend of mine knew one of the publishers of MRO magazine, Victor Zellermeyer, and set up a meeting between us. The idea was that he could give me some insight into starting my business, how to market it, and so on. What he did was introduce me to one of his clients, who sold vibration instruments. So without going over all the details, we added instrument sales to our company’s offerings.

Many of you will know how successful we have become and I owe a lot of it to my relationship with this great magazine — not only for my early education in maintenance but also for providing the link into instrumentation. MRO magazine also has published articles that I have written for machinery installation and condition monitoring, which I appreciate. So my hat’s off for this great magazine. I would always support them, given the opportunity. They have been a tremendous provider of good-quality information for our industry over these years and I look forward to continue reading it for many years to come.

Three cheers for MRO!

John Lambert is president of Benchmark Maintenance Services Inc.

Consistency, without the fluff

BY MICHAEL GULAS

I had been working in the bearing and power transmission business for 10 years when MRO magazine first came out. I remember the first edition. The publication has been true to its mandate, which was to present an unbiased and informative representation of the MRO industry in Canada.

I also remember visiting Peter (Helston) just after the first year of the magazine’s life and Peter summed up MRO as “no-frills publishing.” Solid reporting without the fluff.

In reflection, I can think of two impressive features of the magazine that have kept my interest over the years. One is consistency. I enjoy the articles and reporting on ‘What’s New’, and items like covering the industry conventions and changes that occur in its many com-

panies and organizations.

The other interesting aspect of MRO is the diverse but focused reporting on technological advancements and trendy changes that occur in the Canadian industry.

The magazine has remained Canadian and I like that. I hope to be able to enjoy MRO for another 25 years.

Michael Gulas is business development manager – industrial at Oiles America Corp.

Steadfast and true

BY KEN BANNISTER

Thinking back to 1985, two major transitions were occurring in the maintenance shop that would have major ramifications for the future of asset management: 1) disco was no longer being played on the radio, and 2) the PC computer — along with its accompanying first-generation CMMS software — created a major

transformation in how we performed maintenance work.

Since then, the maintenance department has absorbed many revolutionary changes in its quest for asset reliability and availability, undertaking to overcome the negative aspects of downsizing and attrition, while mastering the complex requirements of new technologies.

Throughout this turbulent period, Machinery & Equipment MRO has remained steadfast and true to its maintenance audience for 25 years, providing a mirror to the changing times through a format that delivers easy-to-understand explanations of often complex subjects, easing the pain of change for its readers. In today’s throwaway society, in which corporate takeovers regularly destroy legacies, achieving a quarter of a century’s sustainability is a truly marked event. Much of the maga-

zine’s success must be attributed to its only editor, Mr. Bill Roebuck, a person I respect very much and am pleased to call my friend.

Congratulations, Machinery & Equipment MRO magazine! I am pleased to have been a subscriber, avid reader, and contributor to your magazine for much of your past 25 years, and hope to continue for many years to come!

Ken Bannister is the president of Engtech Industries Inc.

Maintenance getting the attention it deserves

BY PETER PHILLIPS

Here’s what I have seen over the past 25 years. For many years, maintenance departments have been seen as a necessary cost to keep the equipment operating and in good enough condition to serve its purpose, whether it was producing product in a manufacturing facility or ventilating a room in a university.

Over the past 25 years, there has been a monumental shift in the way companies look at maintenance. Just-in-time manufacturing, lean manufacturing, reliability-centred maintenance and many other initiatives have brought maintenance to the forefront.

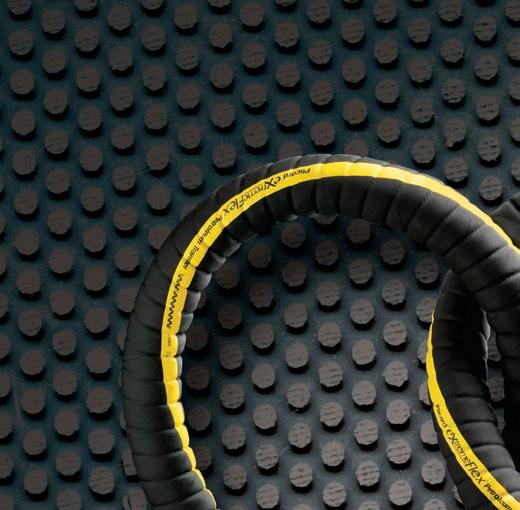

of petroleum transfer hose

Organizations have realized that effective maintenance practices that include detailed preventive and predictive maintenance procedures, proper parts, tools and technical training are key factors in the reliability of equipment, thus improving overall availability.

After many years of struggling to maintain the equipment with limited resources, the maintenance department is now enjoying the attention it deserves.

Peter Phillips is president of the CMMS consulting firm Trailwalk Holdings.

A unique Canadian presence

BY STEVE O’BRIEN

Some pithy observations: The MRO market has changed dramatically over the past 20-plus years. The independent distributors have continued to shrink, while the large US-based chains have grown.

The OEM market has gone from base manufacturing into specialized niche markets in order to adapt to both currency fluctuations and shrinking demand at home (markets such as solar and turbine power, and oilfield equipment like coil tubing injectors).

Through all this, MRO magazine has managed to create, develop and maintain a unique Canadian presence in the marketplace. Technical articles, editorial commentaries and industry news all have a distinct Canadian perspective. MRO magazine never fails to emphasize that we know our own products and services better than anyone else.

MRO magazine also realizes that the flow of information is changing. The enduser today is most concerned with obtaining all his product information at the speed of light, with readily available, cost-saving materials at his fingertips. Service has gone from having reliable ontime deliveries to the fastest delivery. The price mantra has turned into the performance mantra (e.g. ‘I’ll pay a little more but it has to last longer’).

MRO magazine understands this in a

Fault sensors allow remote shutdown of wind turbine

Perth, Scotland — The wind farm at Drumderg hill in Perth and Kinross, Scotland, consists of 16 turbines that can generate 37 megawatts, enough to power 25,540 homes for a year. Working atop a 330-ft-tall wind turbine is a dizzying task — not least because the platforms continue to rotate in search of wind during maintenance checks.

Bad weather poses no serious risk to the machinery, but in strong gales, sensors housed in the nacelle can automatically slow down or halt the blades. Failing that, the owner of the site, Scottish and Southern Energy, can shut down the turbines remotely from its head office in Perth if any fault is detected.

Engineers work in a buddy system, each relying on their partner to stick to safety rules. Access to the top of each turbine is via a two-man lift inside the shaft, which brings them out just below the nacelle.

BEARING ASSOCIATION LAUNCHES AWARENESS CAMPAIGN AGAINST COUNTERFEITING

Canton, OH – According to the World Bearing Association (WBA), in the past two decades, counterfeiting in general has grown by 10,000% globally. While there has been much reporting about consumers being taken advantage of by counterfeits in music, film, home electronics and designer clothing, a far greater risk lies in industrial counterfeiting of items such as tires, seals and bearings. All these products are safety-critical and fake versions pose a real threat.

As a result, the WBA has launched an awareness campaign to inform about safety hazards arising from counterfeit bearings. “Our initiative is aimed at sensitizing the public on the dangers associated with counterfeits,” says James W. Griffith, WBA president, and president and chief executive officer of The Timken Company.

“The WBA is thus intensifying its anti-counterfeiting initiatives — that means information for customers on the one hand and consistent prosecution of offenders through the competent authorities on the other.”

The WBA anti-counterfeiting information campaign will reach out to various audiences over the next three years through e-mails, Website banner ads, social media and the campaign site, www.stopfakebearings.com. On the website, consumers can learn more about counterfeiting and what branded-bearing manufacturers are doing to stop it.

“Everyone who buys, sells, mounts and uses bearings can be adversely affected by counterfeits, so it is in their best interest to be on the lookout for them,” says Griffith. “Manufacturers of products containing industrial bearings may be held responsible for damages. We want purchasers to realize that counterfeiting is a widespread and serious problem.”

Counterfeiting also violates intellectual property, such as patents and trademarks. Because counterfeits look like and are marketed like genuine, premium-brand products, it usually takes a trained expert to identify them.

Premium manufacturers invest continuously to develop their technology and

improve the quality and value of their products. “When counterfeiters copy the look of industrial bearings — and apply respected brand names that aren’t theirs — they are infringing upon the rights of the manufacturer,” concludes Griffith.

The WBA is a non-profit and unincorporated industrial association. It was founded in 2006 by three regional bearing associations: the American Bearing Manufacturers’ Association (ABMA), the Federation of European Bearing Manufacturers’ Association (FEBMA), and the Japan Bearing Industrial Association (JBIA).

continued on page 12

Having the right tools for critical maintenance and repair work can make a big difference in your production efficiency. Kinecor carries a comprehensive line of mill supplies from the world’s most reputable manufacturers.

Kinecor – a single and complete source of industrial components and services for all of your MRO needs.

Engineer Ross Kennedy balances on top of a wind turbine as he carries out a check of the rear aileron.

Photo: Toby Smith, Daily Mail

DISTRIBUTOR BRINGS TOGETHER EMPLOYEES AND SUPPLIERS

Mississauga, ON — Canadian Bearings Ltd. held a sales and service meeting for both suppliers and employees across Canada at the Hotel Novotel Toronto in Mississauga, ON, on Oct. 2, 2010. “A sales and service meeting of this size hasn’t been held in more than a decade,” said CB busi-

� Cleans

�

�

ness manger Ali Moghadam. The theme of the event was ‘Ready to Deliver More’.

“We’re the industrial supplier of choice for many of Canada’s large and small manufacturers,” said CB president Farrokh Khalili. “Today, CB is a lot more than bearings. We offer one of the most comprehensive lines of products in the industry, with nine categories of product solutions. During the event, we got common understanding of our expanded offerings, our service innovations, our future plans, and the Ready to Deliver More campaign.”

GUNS ‘N SMURFS GOLF CLASSIC ATTENDED BY PTDA MEMBERS

Mesquite, NV — Since 1991, a group from the power transmission industry has been heading to a golf course following the annual Industry Summit of the Power Transmission Distributors Association (PTDA) for a three-day Invitational Golf Classic. This year’s event took place in Mesquite, NV, following the 2010 Industry

tall and short players, plays homage to former members Dan Thrussel, Ken Fee and Ron Starr, industry stalwarts who have since passed away. This year’s winner of

POSITIVE OUTLOOK FOR 2011 SEEN IN LATEST PTDA BUSINESS INDEX

Chicago, IL — According to the third quarter results of the Quarterly Business Index released by the Power Transmission Distributors Association (PTDA), PTDA members are projecting 10% growth on top of the 14% average growth expectation for 2010.

In the third quarter, respondents experienced expansion, albeit at a slightly reduced rate than the second quarter. The overall reading for the third quarter was 74.6, compared to 77.0 in the second quarter. A reading above 50 indicates expansion.

A comparative review of distributor and manufacturer results show that manufacturing expanded at a faster pace than distribution, with a reading of 76.6 for manufacturers vs. 71.2 for distributors.

A US-based trade association, PTDA represents 185 power transmission/ motion control distribution firms that generate more than $10 billion in sales and span 3,500 locations in North America and 11 other countries. PTDA members also include 181 manufacturers that supply the PT/MC industry.

SOME SYNTHETIC LUBE MARKETS ON A GROWTH CURVE

Cleveland, OH — US demand for synthetic lubricants and functional fluids will expand more than 3% per year to $4.8 billion in 2013, with growth rising at an even faster pace in volume terms to reach 520 million gallons, according to a new study by The Freedonia Group.

Engine oils and hydraulic and transmission fluids will experience the fastest gains as synthetics finally begin to penetrate the conservative medium- and heavy-duty truck markets.

While engine oils and hydraulic and transmission fluids will achieve relatively strong growth going forward, other types of synthetic lubricants and fluids are expected to realize a slow decline in demand through 2013, largely as a result of falling average fluid prices. From a product standpoint, the greatest declines will be in heat transfer and metalworking fluids. Synthetic metalworking fluid demand will suffer from increasing substitution of bio-based fluids for synthetics.

These and other trends are presented in Synthetic Lubricants & Functional Fluids, a $4,700 (US) study. For more information, visit www.freedoniagroup.com. MRO

More detailed versions of these stories, along with many additional news items, can be found online at www.mromagazine.com.

At Canadian Bearings’ Ready to Deliver More meeting, suppliers hosted display booths for their products.

The 2010 Guns ‘n Smurfs’ golf classic was won by Pierre Bouchard (standing, third from left).

Company Briefs

News and views about companies, staff, product lines and more.

• The Power Transmission Dis tributors Association (PTDA) Board of Directors has unanimous ly selected Ann Arnott, currently PTDA’s vice-president of programs and services, to succeed Mary Sue Lyon as the next executive vicepresident of PTDA, effective Janu ary 1, 2011. Lyon is retiring after 16 years in this position.

• V.J. Pamensky Canada Inc., Toronto, the exclusive Canadian importer for WEG products, which are manufactured in Brazil, has launched a new website at www.pamensky.com, reports marketing coordinator AJ Zellermeyer.

• The ABB power and automation technology group, Zurich, Switzerland, will acquire Baldor Electric Company, Fort Smith, AK, a North American supplier of industrial motors, in an all-cash transaction valued at approximately $4.2 billion. The deal is expected to close in the first quarter of 2011.

• The Manufacturer Council of the EPTDA (European Power Transmission Distributors Association) is inviting all manufacturer member companies to bring along two of their distributor companies, who are not yet a member of the association, to join the EPTDA’s 2011

Annual Convention in Budapest, Hungary, on September 28-30, 2011, on a complimentary basis. “This initiative signals our firm commitment to take EPTDA membership to new heights,” said Jos Benneker, chair of the EPTDA Manufacturer Council and sales manager, Europe, David Brown Benzlers. For more information, visit www.eptda.org.

• Endress+Hauser Canada Ltd., Burlington, ON, a supplier of industrial measuring technology and automation equipment, is celebrating its 20th anniversary in Canada. The Swiss parent of the company launched its Canadian operation in 1990. The company employs over 100 people at offices in Montreal, Calgary and Edmonton, as well as Burlington. In addition, the company recently expanded into Saskatoon.

• Under the hot Utah sun at the Bonneville Salt Flats Sept. 20-24, 2010, four racing teams shattered standing world land speed records, using streamlined cars and motorcycles that traveled at speeds of 280

mph to over 400 mph. Broken were the land speed records for a naturally aspirated race car, streamlined motorcycle, turbocharged streamliner and streamlined racecar. Virtually every car in the competition relied upon Loctite products to enhance performance. According to Mike Shannahan, Henkel’s director of marketing for the North American general industry business, “Loctite products, especially our threadlockers, are critical to racing performance, and the teams really appreciated our help and support throughout the Shoot-out.”

• The Cooper Bearings and Kaydon Bearings divisions of Kaydon Corp., Phoenix, AZ, have announced a joint sales initiative by their North American sales teams aimed to improve coverage and give customers more bearing choices from a single source. Kaydon and Cooper will continue to develop and manufacture their own product lines in their own facilities, but will now offer them through a single sales and distribution network. The joint sales initiative is being managed by Brian Short, director of distribution sales for Kaydon Bearings.

• Ian Parkhill, president of Wera Tools North America, Burlington, ON, reports the company has now completed the transition of its logistic support centre to Tucker, GA. “We have also relocated our North American Sales and Marketing Support Center,” he says. The company’s Canadian office is now located 4129 Harvester Rd., Unit H, Burlington, ON L7L 5M3.

• Emerson Bearing, a Boston-based bearing company catering to OEM and MRO markets internationally, has recently announced a new Machine Tools division. Customer care representatives in the new division are trained to accommodate the unique needs of machine tool clients. The division was created to meet increased demand and significant growth in this market over the past couple of years. Marketing specialist Bob Piracini leads the new division.

• As part of its customer care program, Emerson Bearing provides a bearing failure analysis service that helps clients determine the cause of bearing failure so that they may prevent future failure and predict reliability. Clients also can use the Bearing Failure Analysis program within the Technical Toolbox on the Emerson Bearing website located at www.emersonbearing.com.

• Two industrial companies play a supporting role with astronauts performing a spacewalk repair in the movie Hubble 3D. In May 2009, when the future of the Hubble space telescope was hinging on delicate repairs performed by NASA astronauts using ATK’s Mini Power Tool, ATK needed precision components required for the job. Now ATK and Timken are featured in the movie. ATK’s Mini Power Tool, equipped with Timken custom thinsection precision ball bearings engineered especially for the application’s unique requirements, helped to enable the crucial repairs to return the Hubble Space Telescope to active duty.

Land speed record-breaking racer Charles Nearburg, flanked by Loctite Land Speed Shoot-out producers Mike Cook Sr. (right) and Mike Cook, Jr., poses in front of the Spirit of Rett.

PTDA’s Ann Arnott.

Reducing lube and bearing costs

Bearing supplier opens a Solution Factory in Edmonton that includes its first bearing

refurbishing facility in Canada.

BY CARROLL MCCORMICK

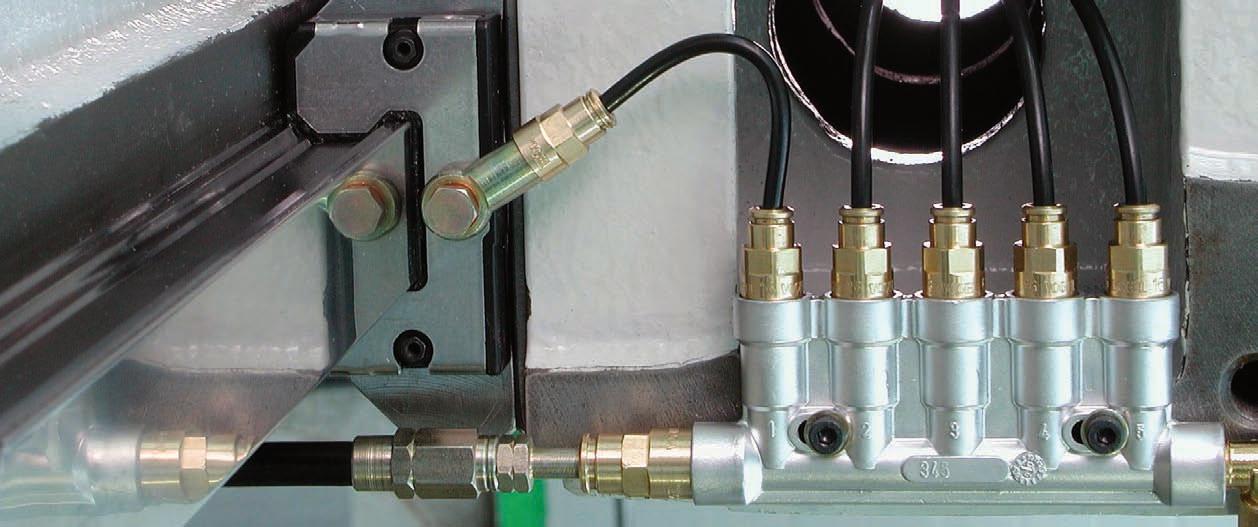

In Edmonton in October 2010, bear ing, seals and maintenance solutions provider SKF Canada celebrated the opening of the global company’s 15th Solution Factory. The 18,000 sq ft (1,672 sq m) facility houses new and ex isting capabilities under one roof.

The largest room in the Solution Fac tory is a 14,000 sq ft (1,300 sq m) repair area, divided into three bays. The first bay is for fabricating seals, assembling lu brication skids and other miscellaneous repair and servicing activities. The sec ond bay, equipped with a five-tonne crane, is for bearing remanufacturing. The third bay is for repairs and future expansion.

Clients entering the Solution Factory by the front door step directly into an exhibition room. Here they can see static and active displays of SKF products such as specialty bearings, seals, mechatronics and power transmissions. Nearby is a training room and remote diagnostics centre (RDC).

The grand opening of the Solution Factory was well-attended by SKF personnel and maintenance specialists from the oil and gas, and pulp and paper industries, in western Canada. SKF Canada president João Ricciarelli summarized the mission of the Solution Factory. “Customers want solutions: reduced time to market, reduced cost of production, improved productivity. The Solution Factory puts all the resources we can give our customers in one place … we want to transfer knowledge from ourselves to our customers.”

To illustrate Ricciarelli’s point, Norm Kowalchuck, maintenance service co-ordinator at Cenovus Energy, Calgary, AB, presented a case study of how SKF devised maintenance strategies for Cenovus; e.g., criticality analysis and preventive maintenance. “The criticality analysis helped us clarify where we needed to focus,” explained Kowalchuck. The work yielded over $6 million in soft savings, with a return

on investment (ROI) of about three months.

Shawn Elliot, senior advisor at Vancouver-based Daishowa-Marubeni International Ltd.’s DMI Peace River pulp mill in Peace River, AB (489 km northwest of Edmonton), presented a case study in which he discussed how the mill integrated SKF solutions into DMI’s reliability strategies. He reported a roughly 25% drop in lube and bearing costs, an increase in equipment availability of 2-3% and operator-driven equipment reliability up about 100%. “Operator-driven reliability has been the biggest change for us in the past five years,” Elliot said.

After more chat and a ribbon cutting ceremony, SKF divided the attendees into groups for a tour and demonstration of seven areas of the Solution Factory. These cover what SKF calls its five platforms: Bearings, Seals, Lubrication, Mechatronics and Reliability Services.

The first stop was in the centre bay where, for the first time in Canada, SKF will have a bearing refurbishing capability. After incoming bearings are inspected, they are cleaned in a Quadra-Jet Model 250 washer (think giant dishwasher) that can accept bearings up to 49 in. (124 cm) in diameter. Afterward, technicians check

bearing clearances, dismantle, repair, reassemble and pack customers’ bearings for shipping. These operations were scheduled to begin by the end of October.

In the second area we saw presentations of different types of SKF solutions; e.g., lubrication system designs, vibration monitoring systems and the company’s work in the hydrocarbon processing industry. SKF provided illustrations of equipment such as pumps, blowers, fans, and maintenance tools such as portable electronic devices and other application-specific solutions.

After a stop and talk in the exhibition room, we passed through to the fourth area: the RDC. This room is equipped for Remote Data Capture and analysis, diagnostics reporting and the general making available of data to customers 24/7. A key advance in the creation of the RDC is that SKF engineers no longer have to physically visit equipment to collect data.

The most physical expression of SKF’s commitment to, as Ricciarelli put it, “equip the world with knowledge,” was parked at the fifth stop beside the refreshment table: After our group came, conquered and left, I stayed behind to learn more about the SKF solutions vehicle — a 26-ft (7.9-m) Kenworth with a walk-in, custom-made show-

room kitted out with demonstration equipment and graphics representing SKF’s five platforms.

This solutions vehicle, which replaces an SKF tool truck that had seen 12 years of service, has been on the road since May 17, 2010. It has already visited 171 endusers and the plan is to have it on the road for 50 weeks of the year.

During each appointment that the solutions vehicle has with middle managers at a company, SKF has two goals: Enlighten end-users about the five platforms and explain how they allow SKF to create solutions, according to Mark Howard, business manager, seals platforms. “As we inform them about what we have and do, we ask probing questions about how their plant is operating. The overall concept is to discuss [how much] they spend a year and how they can reduce maintenance costs. We want to talk about how to increase uptime and reduce costs.”

Hopelessly behind the pack again, I got a private tutorial on a demonstration lubrication system in bay three. The Solution Factory will design and assemble custom lube system skids here, do assessments and perform associated services. Until now a service that Toronto-based SKF provided primarily from eastern Canada, this Edmonton-based capability will improve response time to customers.

Stationed a few feet away in the last section was the sealing solutions area and an Economos NG 040 SealJet. It is capable of quickly fabricating seals, including oneoff orders, up to 18 in. (45.7 cm) in diameter; the Economos has software that translates measurements from a client’s hardware to calculate the correct replacement seal size. While the machine rapidly carved a red seal, we learned that 70% of SKF’s seal business is for the aftermarket. By 2015, SKF plans to have 30 Solution Factories around the world, all connected and following a common standard. As for Canada though, explained Ricciarelli, “We are investing a lot in Canada in engineering capabilities — application engineers who can help customers.” MRO

Montreal-based Carroll McCormick, an award-winning writer, is the senior contributing editor for Machinery & Equipment MRO.

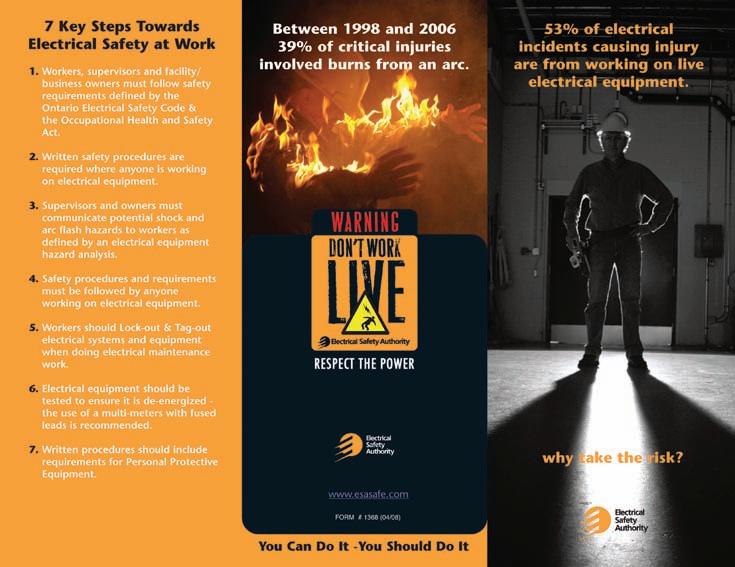

Understanding Field Evaluation

Electrical product certification and field evaluation processes in Canada, under the direction of the Electrical Safety Authority, help reduce the risk of injury or fire for people or property.

BY RICK MARTIN

When you use, maintain or repair machinery and equipment with built-in or add-on electrical components, you likely will assume you don’t need to be concerned about the electrics. But have you wondered what it is that manufacturers or importers of electrical products have to do to make sure they have electrically safe products?

The Canadian Electrical Code (CEC) requires equipment to be ‘approved’. Generally that means a certification organization such as CSA (Canadian Standards Association) or UL (Underwriters Laboratories) makes sure the product meets an acceptable level of safety, as specified in the Canadian standards (for others that handle certification, see www.esasafe.com). But these standards and the certification process are geared up for larger production runs. So the industry has a gap to fill for small quantities of electrical products. This gap can be filled by Field Evaluation (FE).

For a manufacturer to get a product certified, it generally means it needs a production run in excess of 500 units per year. For smaller production runs (1 to 500), the ‘Authorities Having Jurisdiction’ (electrical inspection agencies) in Canada allow equipment to be field-evaluated to a Canadian standard called CSA SPE-1000.

Field Evaluation is only concerned about the electrical safety of a product. It is not a substitution for certification, because sometimes certification will address other safety issues such as electromagnetic radiation, burns from lasers, location of emergency stop switches, etc. CSA SPE-1000, the standard that the FE process follows, has three mandatory non-destructive tests. Basically the electrical safety requirements of the standard and the CEC are followed to ensure the product is electrically safe. A serialized FE label must be put on the equipment personally by an inspector accredited by the Standards Council of Canada. Some people believe this process to be even safer than certification, since every product must be inspected and labelled. The inspectors follow a specified procedure that has been developed by experts in the electrical industry and the process is audited by the Standards Council of Canada.

In the US, the technical requirements are very similar but not quite as well-defined for production runs of small quantities.

FE would be found useful for the following situations:

• The equipment is already manufac-

tured, shipped or installed

• The equipment is manufactured in small quantities

• Cost of certification for the small volume does not make good business sense

• There is not enough time for the manufacturer to organize and to arrange a certification process

• The manufacturer is testing the market with a small quantity

• The manufacturer wants to make sure the design is reasonable before proceeding with the somewhat slower and more expensive process of certification.

How certification and field evaluation got started

The following is a brief history of how certification and field evaluation started in Canada. First, the Electrical Safety Authority (ESA) evolved from Ontario Hydro, which was once the Hydro Electric Power Commission (HEPC).

It is not surprising that few people realize that ESA has affected the safety of electrical equipment for the people of Ontario and Canada. This evolution of equipment approval over the past century has created an environment with so many subtle controls in place that a relatively safe environment exists.

In the 1890’s, steam-driven generators made it possible for the majority of Ontario villages with over 3,000 residents to have access to electric streetlights. It was only a year or two later that the Toronto Incandescent Electric Light Company was established — and then the electrical safety of equipment became an issue in Canada.

This safety initiative came from the Canadian Fire Underwriters Association (CFUA). The CFUA was concerned about the massive financial liabilities its members could face from structural fires caused by electrical equipment. Therefore, in 1892, the CFUA appointed an inspector to ensure that all electric equipment was installed in accordance with CFUA requirements.

The new power source also had caught the fancy of consumers and nowhere was this more evident than in the City of Toronto, where scores of contractors and builders came forward to meet the demand with inferior, often bogus, and clearly dangerous equipment.

To offset growing concerns, significant amendments were made to the Power Commission Act in 1912 and 1914 to ensure that electrical equipment was safe.

In 1918, the HEPC Approval Laboratory was established to test electrical equipment to determine its adherence to

specific and stringent guidelines. The Approval Laboratory department was operated by HEPC and resulted in the establishment of rules and regulations for testing and approving electrical materials, devices and fittings. The initial approval labels that were applied were actually solid bronze metal.

Products that met the guidelines were declared ‘HEPC Approved’ and later ‘Hydro Approved’. This process was generally accepted by the electrical industry across Canada.

The purpose of this function was to provide standards and testing of electrical equipment to avoid risk of injury or fire to persons or property. This approval process was considered so significant that by 1924 the HEPC was empowered to prohibit the sale of electrical equipment considered to be unsafe for public use.

As a result, the Approvals Section of the HEPC Electrical Inspection Department was established. Soon HEPC was testing products for all of Canada. When other provinces requested the use of the ‘HEPC Approved’ designation and they started to include this approval in their legislation, it quickly became evident that there was a need for a national testing body.

As a result, in 1940, the Canadian Standards Association Testing Laboratory was created by the HEPC, and the CSA certification process began as a self-

contained, self-supporting unit. HEPC continued to approve small quantities of equipment and specialized equipment that could not be done under certification.

And now, in modern times ... Today, in North America, most electrical equipment is submitted to accredited certification organizations (e.g., CSA, UL and others) for approval, but for smaller quantities and specialized equipment, the Field Evaluation process still applies. ESA continues to provide that service as part of its safety heritage.

The best time for manufacturers to get the Field Evaluation process started is at the conceptual design stage. An FE inspector can meet with designers and give tips and suggestions to make the design and the FE process work best. MRO

Rick Martin, P.Eng. MaSc., is the senior research engineer with the Electrical Safety Authority (ESA), an organization created in 1999 by the Ontario government to be responsible for electrical inspection activity and to introduce a broader public electrical safety mandate for the province. ESA tracks electrical incident statistics and works with electrical trades to reduce the number of electrical workplace incidents by encouraging safe work procedures. For more information, visit www.esasafe.com.

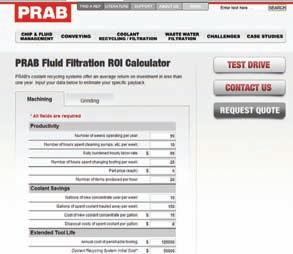

Top: Field evaluation is ideal for electrical products made in small numbers. Above: ESA publishes brochures such as this to help reduce electrical injuries in the workplace.

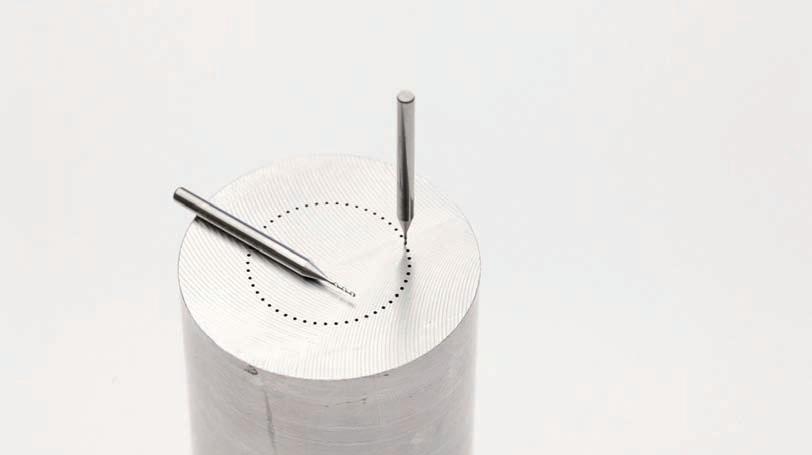

Alignment errors in wind turbine drive trains are among the main causes of vibration in this machinery. They are easy to identify by evaluating the vibration velocity spectra: If the amplitudes at the single and/or double frequency of the generator shaft are too high, the most recent alignment reports should be checked or the shaft alignment should be measured using laser-optical alignment equipment.

Drive trains in a wind turbine exhibit highly variable alignment between the flexibly mounted generators and gearboxes. The generator shaft shifts toward the gear output shaft, depending on load and speed.

To ensure that power can be transmitted during all alignment conditions that arise during operation, system manufacturers usually use couplings with a very large working range (Fig. 1). Here it is important that alignment conditions during operation actually remain within the working range of the coupling in use.

This can be accomplished using couplings as shown in Fig. 2 that are capable of a high degree of displacement. However, even this type of coupling has limitations when it comes to parallel offset, which manifests itself in greater restoring forces, stronger vibrations and premature wear.

Using modern laser measurement methods, a near-perfect shaft alignment can be achieved between the gearbox and the generator with the system at a standstill. In reality, however, it is not desirable to align flexibly mounted drive trains to ‘zero’. Rather, both components must be misaligned while at a standstill so that the ideal shaft alignment is obtained during operation.

FOCUS ON ALIGNMENT

Reducing vibration with laser alignment

Wind turbine drive trains can exhibit highly variable alignment between flexibly mounted generators and gearboxes.

BY DR. EDWIN BECKER AND OLE HOLSTEIN

Here is a glossary of terms for alignment projects.

Erecting: Installation of a machine on-site.

Alignment: Adjustment of the machine into the correct position when it is erected.

Alignment target value: Specification of final condition after alignment (set values).

Alignment report: Description of actual condition achieved after alignment (actual values).

Alignment condition: Condition after alignment with the machine at a standstill and cold. This will change when the machine is in operation and warm.

Displacement: Change in the position of the shaft when changing from one operating state to another, especially from a standstill with a cold machine to a state of continuous operation with a warm machine.

Influences on the alignment condition (in accordance with VDI 2726):

• Heat expansion between the installation and operating temperatures (foundation, housing, shafts)

• Flexible deformation during operation (foundation, housing, shafts)

• Displacements between the installation and operating conditions (due to play, forces and lubrication)

• Skewed position of gearbox shafts due to externally applied masses (brake discs, couplings)

• Radial clearance and wobble of flange

• Radial and axial rigidity of connection coupling.

Angular offset: Measured in degrees, millirad (mrad) or as a relative quantity in millimetres per metre (mm/m).

Example: A coupling with a 100 mm diameter has a gap at the top edge of 1 mm, which causes an angle of 10 mrad (note: 1 mrad = 1 mm per metre; rad is short for radian).

Parallel offset in mm: The distance between the points of intersection of the rotating axes with a certain plane perpendicular to both axes. Usually the parallel offset refers to the distance between the rotating shaft axes in the centre of the coupling.

To achieve this, the direction of the displacements that occur during operation must be known. The data can be entered as so-called target values in all Prüftechnik alignment systems.

Where to obtain alignment target values

The alignment target values can either be taken from the operating manual or obtained from the system manufacturer. However, the wide variety of drive train components and basic frame types makes it difficult to provide general quantitative figures. The actual alignment target values can be determined using a Permalign alignment monitoring system. For this purpose, highly sensitive laser sensors are mounted on the generator and gearbox (Fig. 3) to measure the displacements of the machines in intervals of one second. The measurements can be recorded and further evaluated with any online CMS from Prüftechnik. Thus, customers who already have an online system can simply connect the Permalign components to the system via an RS-232 interface and the measurements can be transmitted to the monitoring centre by remote access.

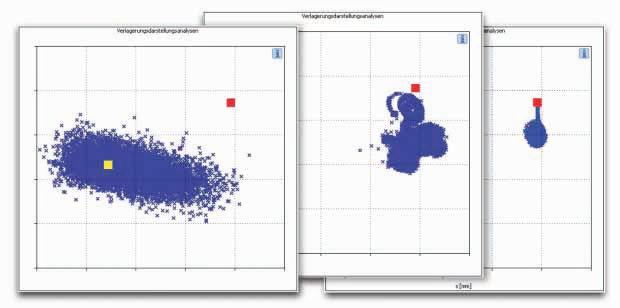

To determine the alignment target values, measurement results are then evaluated under different wind conditions: without wind (system at a standstill), with light wind (system rotating irregularly), with moderate wind and with strong wind. Fig. 4 shows the measurement results in an XY-graph. The resulting alignment target values are then entered into the alignment system and automatically taken into account during the alignment procedure. Typically, the required measurement campaign lasts between one and four weeks — depending on the location and wind conditions.

MRO

Dr. Edwin Becker and Ole Holstein are with Prüftechnik Alignment Systems GmbH, Ismaning, Germany. More on the topic of shaft alignment can be found in the company’s manual for technicians and engineers. Request a free copy by e-mail at info@pruftechnik.com.

Card No. 412

Fig. 1: The four degrees of freedom in alignment. Fig. 2: The shaft of a wind turbine drive train is aligned using a laser system. Fig. 3: A laser system is installed temporarily on a gearbox. Fig. 4: Displacement under various wind conditions – light (A), medium (B), and strong (C).

Fig 2

Fig 4

Fig 3

Selecting High-Temperature Greases

The choice of greases that can withstand extreme temperature conditions poses some challenging lubrication engineering decisions.

extreme conditions they operate under, these extreme temperature conditions poses some

challenging lubrication engineering decisions. In addition to heat resistance, the greases in use often require additional properties like exceptional load-carrying capability, oxidation stability, water washout resistance and good pumpability.

The first step towards selecting the right hightemperature grease is to identify the possible causes of product degradation during operation. Though the primary cause of degradation is thermal stress, contact with air leads to oxidative failure, which also contributes to the degradation.

Once the sources of degradation have been determined, aspects such as viscosity, viscosity index, stability of the composition and the additive package properties also need to be considered.

To a very large extent, the properties of a grease are determined by its three components, the base oil, the thickener and the additive package.

Base oils: Base oils can be subdivided into

mineral and synthetic base oils. Mineral oils are the most widely used base oil components and represent approximately 95% of the grease manufactured. Solvent-refined mineral oils have a high percentage of unstable, unsaturated molecules that tend to promote oxidation. Mineral oils that have undergone extensive processing to remove the reactive molecules or saturate the molecules (with hydrogen) exhibit improved stability (oxidative and thermal).

Combining two or more smaller hydrocarbons to larger molecules produces synthetic hydrocarbon base oils. These base oils provide the best thermal and oxidative stability. Highly refined mineral and synthetic hydrocarbon base oils typically start to degrade at between 110°C and 150°C. For operation at still higher temperatures, ester silicones or fluorosilicones or more highly fluorinated base oils such as PFDF are recommended.

Thickeners: Three different types of thickeners can be used in a grease formulation: Organic (polyurea), inorganic (bentonite, silica) and soap/complex soap (lithium, calcium, sodium, etc.) thickeners. However, the usefulness of the grease over time depends on the stability of the whole formulation package and not just the stability of the thickener.

Polyureas have additional inherent antioxidant and anti-wear properties. Lithium complex thickeners have maximum temperature limits superior to those of simple lithium soap thickened greases. Overall, metal ion soap thickeners have thermal degradation limits that range roughly from 120°C to 200°C.

Additives: The additive must be capable of working synergistically with the thickener and the oil, resulting in a balanced, stable mixture of the three components. The additive package also introduces desirable properties like oxidation resistance, corrosion protection and wear resistance to the grease.

A critical issue that must be addressed prior to the selection and application of greases is the possibility of different greases mixing, and more importantly, their compatibility.

Grease compatibility

Compatibility or incompatibility between hightemperature greases must be addressed prior to their selection and application. Since the total grease formulation is a complex but balanced mixture of its components, any addition of unplanned chemicals can upset this welldefined balance and lead to degradation of performance levels.

Mixing incompatible greases results in an increase or decrease in grease consistency. Therefore it is very important that specially designed high-temperature grease products not be mixed. IL

This article is adapted from Dow Corning’s Molykote Smart Lubrication Series. For more information, send an e-mail to industrial@dowcorning.com, or use the reader service number below. Reader Service Card No. 411

Criteria for selecting a high-temperature grease

1. Is operation of the equipment requiring lubrication continuous or intermittent? If it is continuous, a premium grade product that meets the operational requirements should be selected.

2. What is the real temperature range at which the equipment will operate? Does it exceed 150°C?

3. Does the equipment go through heating and cooling cycles at operating and non-operating intervals?

4. Is the lubricant exposed to moisture during operation? Moisture upsets the thermal stability of the grease formulation.

5. How long are relubrication intervals and how hard is relubrication? If relubrication is difficult, a premium-grade grease product should be chosen to achieve lower maintenance costs (generally, lower maintenance costs more than offset the higher price of the upgraded lubricant).

Lubrication Systems for Fans and Industrial Applications

Veteran industrial equipment operators remember when it was common to flood machinery with as much lubricant as possible to protect it from the heat of high-speed operations. No more. Advances in lubrication technologies have proven that automated lubrication systems deliver a number of important advantages, from faster production times to reduced maintenance costs to a healthier, more environmentally friendly workplace.

Up to 40% of premature bearing failures are caused by lubrication problems — too much, too little, the wrong type or contaminated lubricant. SKF has developed a wide range of automatic lubrication technologies that, while relatively simple to implement, result in significant benefits.

Circulating-oil lubrication systems are used in applications where lubrication points must be cooled and cleaned by the oil. This system can be used extensively in general and heavy industries; typical applications include steel rolling mills, conveyors, paper machine dry end bearings, industrial fans and gearboxes.

The lubrication system must be able to deliver the right amount of high-quality clean oil, with the appropriate temperature, to each lubrication point. The oil then flows back into the lubricant reservoir for re-use after passing through the lubrication points.

The respective system is selected on the basis of:

• the operating conditions

• the accuracy requirements for lubricant quantities

• the geometry of the system

• the monitoring requirements.

Industrial fan units: SKF circulating-oil system

The SKF circulating-oil lubrication unit is ideal for applications where the heat generated by the bearing must be taken away from the bearing, as well as providing lubricity to the bearings or gears, such as rolling bearings on industrial fans, where high speeds and/or high temperatures can preclude the use of grease. These units deliver a continuous flow of cooled and filtered oil directly to the bearings. The pump flow is matched to the bearing and housing size, preventing oil leaks and excessive heat associated with too much oil flow (see Fig. 1).

Controlling and measuring oil flow

SKF Safeflow oil flowmeters are used for controlling and measuring the flow rate of lubricants in oil lubrication systems. This flowmeter has a straight glass flow tube with an internal calibrated cone. Because the oil flows through the float, rather than around it as in ordinary flowmeters, the float is always clearly visible. The oil flow can be remotely and continuously monitored. The alarm system consists of one alarm sensor for each flow tube and one monitoring unit for up to 10 alarm sensors.

The SKF Flowline Monitor flow rate monitoring system introduces a new digital dimension for measuring and controlling oil circulation lubrication system flow rates. The systems operate individually and they can be programmed as well as adjusted separately. With one glance, operators can see the flow rate status of each individual lubrication point from the Flowline monitor (see Fig. 2).

SKF flow limiters are used in large oil-circulating lubrication systems. The task of a flow limiter is to divide up the volumetric flow of

the main line into parallel individual volumetric flow quantities and to ‘limit’ these according to requirements, or to keep them constant.

Additional information on the complete range of SKF Lubrication Solutions is available by visiting www.skf.com/lubrication. SKF Lubrication Engineers are available to assist you in determining the correct lubrication solution to your specific application and needs. Please send your e-mail enquiry to lubrication@skf.ca or call 1-800-207-5823. SKF –The industry’s most complete resource for knowledge engineered lubrication solutions.

Reader Service Card No. 299

Fig. 2: SKF Flowline Monitor.

Fig. 1: SKF SM100 circulating oil lubrication unit.

Holster that Grease Gun!

Eight compelling reasons for using an automatic lubrication system.

Whether you know it as an automatic lubrication system (ALS), an autogreaser or a centralized grease lubrication system, an ALS automatically lubricates multiple points on a piece of equipment from a centralized pump/control unit that is mounted in an easily accessible location.

Such a system dispenses small, measured amounts of lubricant at frequent intervals, while your equipment is operating, thus maintaining the correct amount of grease in the bearing at all times and a consistent lubricant seal to prevent dirt and contaminants from migrating into bearings.

“In talking with people who don’t currently use automatic lubrication systems, we often hear statements like ‘Even if I use an autogreaser, I still have to do a walkaround to inspect the system’,” says Gabriel Lopez, a marketing specialist with Flo Components Ltd., Mississauga, ON. “This is absolutely correct. An automatic lubrication system will not replace your regular equipment maintenance inspection. You still have to check for loose or damaged lines and make sure that everything is operating smoothly.

“What an ALS does is take the grease gun out of your hand and replace it with a wrench. Then, you can use the grease lines

as a guide and have the opportunity to focus on making any necessary adjustments or repairs as you conduct your regular inspection.”

So you might ask, what’s the point of using an ALS? According to Lopez, there are eight reasons why you would use one:

1. Safety: An ALS helps to reduce or eliminate climbing over and under machinery or into difficult-to-reach areas. Whether you’re an owner/ operator of a single piece of equipment, or the maintenance manager for a large operation, the safety of personnel in the workplace is a key consideration.

2. Efficient lubrication: An ALS applies grease while the machine is running, so you don’t have to stop what you’re doing or set aside time to lubricate it — in other words, less downtime. Furthermore, because the bearing is turning when it receives the grease, you get much better grease coverage on the bearing.

3. Better lubrication: Applying grease is often most effective when it is dispensed in small, measured amounts over short, frequent time intervals. Unfortunately, tight deadlines and manpower constraints, harsh environments, severe-service conditions or in some cases the location of the equipment often make this method of lubrication impossible.

Equipment gets greased when it’s available, and when we have the time and somebody available to do it. Clearly, this approach is not optimal for the point that requires lubrication. An ALS makes this problem go away.

Whether you build, produce, manufacture, run or generate, one fact is clear: better lubricants and better lubricant suppliers lead to increased productivity. That’s why Imperial Oil is proud to offer Mobil Industrial Lubricants – recognized worldwide by more than 5000 equipment builders. With the combination of Mobil Industrial Lubricants and Imperial Oil expertise, we don’t just elevate productivity – we help unleash it. Visit www.imperialoil.ca for more information.

4. Better housekeeping: How much grease is too much? According to Lopez, “If you’re oldschool, you keep pumping it in until you see it oozing out of the bearing. This is called overlubrication.” As previously stated, frequent and small, measured amounts will give your bearings the best protection.

In addition to no over/under lubrication, this also means that you get less spillage and leakage. The end results are less wasted lubricant and less mess on your equipment, floor, site, etc. Appearance aside, safety issues (from the danger of slipping) and environmental concerns are even more important problems resolved by using an automated lubrication system.

5. Less downtime and reduced maintenance costs: Time and manpower constraints often make it nearly impossible to keep up with the lubrication requirements of equipment, especially in the harsh Canadian climate. The preventive maintenance provided by an ALS is absolutely key to reducing maintenance costs and minimizing downtime by extending the life of the many pivots, bushings and components on equipment. This also means there will be also fewer replacement parts to stock.

6. Increased overall productivity: Higher productivity results from an increase in machine availability and a reduction in downtime due to breakdowns or general maintenance.

7. Longer equipment life: Because bearing areas are consistently protected and your machinery in general is better maintained, bearings are less likely to fail and need replacement.

8. Helps the environment: For the environment, reduced premature wear of bearings and other components means less landfill. Also, since you’re not over-greasing, you’re depleting fewer resources from the environment and you’re not contaminating the environment with dripping lubricant. IL

Components Ltd. of Mississauga, ON, has been supplying automatic lubrication systems

©iStockphoto.com/ Photoservice

ore than eight out of 10 workers (85%) rate workplace safety first in importance among labour standards, even ahead of family and maternity leave, the minimum wage, paid sick days, overtime pay and the right to join a union, according to a new study from the National Opinion Research Center (NORC) at the University of Chicago.

Despite widespread public concern about workplace safety, the study also found that the media and the public tend to pay closest attention to safety issues when disastrous workplace accidents occur. Even during those tragedies, the fate of workers is often overlooked, such as during the recent oil well disaster in the Gulf of Mexico.

“Workplace safety is too often ignored or accidents taken for granted,” said Tom W. Smith, director of NORC’s General Social Survey (GSS). “It is striking that coverage in the media and public opinion polls have virtually ignored the 11 workers killed by the blowout and destruction of the drilling platform.”