MACHINERY AND EQUIPMENT

How to improve pump reliability

The best tools for working with bearings

Getting ahead of breakdowns

Storing flammable liquids

Ultrasonic cleaning Q&A

IDI sees big success

How to improve pump reliability

The best tools for working with bearings

Getting ahead of breakdowns

Storing flammable liquids

Ultrasonic cleaning Q&A

IDI sees big success

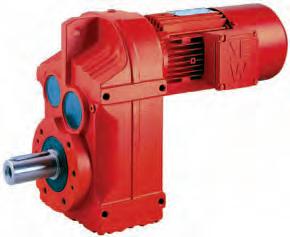

Helical gear unit line gets addition of lower-torque units

SEW-Eurodrive has expanded the lower power range of the robust helical and bevelhelical gear units that are part of the

X Series of industrial gear units by offering units for the torque range of 6.8 kNm to 45 kNm (5,000 ft-lb to 33,000 ft-lb). This expands the torque range to cover 6.8 kNm to 475 kNm (5,000 ft-lb to 350,000 ft-lb). The intelligent, comprehensive gear unit line features finely graduated sizes, variable installation and a wide variety of modular options. Gear ratios range from 6.3 to 450.

SEW-Eurodrive Co. of Canada

Online Reader Inquiry No. 365

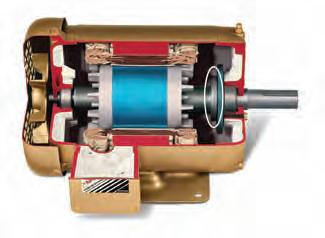

Line of motors with internal bearing protection ring is expanded

Baldor has added 98 ratings to the Baldor Reliance Super-E motors with an internal Aegis bearing protection ring. The addition expands the existing four-pole line of TEFC and ODP designs through 100 hp and also includes two- and six-pole models. In addition, 575-V TEFC motors have been added, 1 to 50 hp, as well as TEFC and ODP close-coupled pump motors. The motors have the grounding ring factoryinstalled internally on the motor, which keeps it from being damaged by external forces. Applications include heating, ventilation and air conditioning blower and fan motors, pump motors, and other general purpose applications using an adjustable speed drive.

Baldor Electric

Online Reader Inquiry No. 366

Wireless shaft alignment system is designed for entrylevel applications

The Stealth S-660 entrylevel, three-axis shaft alignment system, man ufactured by Hamar Laser Instruments, fea tures Bluetooth wireless communication, smart phone data display and high-resolution colour graphics. With Dual Arc technology, spans of 3.05 m (10 ft) are easily achieved with the use of a fan-type laser. Featuring such additional features as long battery life, print software for colour reports and Auto-Clock, the system can be easily operated by the most inexperienced user.

Hyatt Industries Limited Online Reader Inquiry No. 419

Thermal camera detects faults on objects at far distances

Developed for use by technicians and thermographers, the SKF TKTI 30 thermal camera offers a high, 76,800-pixel (320 by 240) infrared resolution and the ability to display thermal and visual images, or a fusion of both, on the bright, sharp 3.5-in. screen. Features include four moveable cursors, cursor temperature difference display, automatic hot and cold spot display and laser sighting. Ther mal analysis tools such as isotherms, temperature gradients and area analy ses are available. The compact, ergonomic and rugged design enables the camera to be used in most industrial environ ments, and the rechargeable power pack allows for five hours or more of use. It comes in a sturdy carrying case.

SKF Canada Online Reader Inquiry No. 368

Rust removal liquid is safe for workers and the environment

Walter Surface Technologies has announced the availability of Bio-Rust, a non-corrosive solution that eradicates rust on iron and mild steel. The product does not use highly corrosive and toxic acids, and is VOC-free, solvent-free and phosphate-free. Also, it does not damage the parent material. Parts requiring treatment are immersed in the liquid and left to soak, leaving workers free to attend to other tasks. The product can remove 1.0 kg (2.2 lb) of iron oxide per 20 l. Applications include in fabrication shops to clean steel prior to painting or coating operations, and for maintenance workers in the transportation and military sectors.

Walter Surface Technologies

Online Reader Inquiry No. 369

Rugged thermal camera takes sharply focused images

Fluke has introduced five thermal imagers, the Ti110 and Ti125 for industrial and commercial applications, the TiR110 and TiR125 for building diagnostics applications, and the Ti100 for general use. Capabilities include automatic focus, with a manual focus option for close-ups, IR-Fusion technology, which blends digital and infrared images into a single image to pre cisely document problem areas, and one-handed operation. This rugged point-and-shoot device, weighing just 1.63 lb, is built to survive drops up to 6.5 ft. It comes with an AC power adapter, lithium ion smart battery (Ti125 and TiR125 in clude two each; others one each), USB cable, SD memory card, hard carrying case, soft transport bag, adjustable hand strap and a manual.

Fluke

Online Reader Inquiry No. 370 MRO

Case studies: Solving old problems / 11

We revisit four companies we’ve previously written about for updates about their most recent maintenance activities and learn of some interesting solutions to their earlier problems.

Tools for working with bearings / 16

Proper mounting and removal techniques, using the best tools for the job, can ensure maximum bearing performance.

How to improve pump reliability / 18

For most common pump applications, coating upgrades are among the best ways to improve performance and increase the mean time between failure.

Maintenance Management: Adding up the successes / 24

Follow along with Step 44 in a journey to world-class maintenance at the Plentya Paper Company. This is the penultimate step in this series, which will conclude in our June 2012 issue.

Maintenance 101: Getting ahead of breakdowns / 26

Here is the fourth set of activities in our eight-stage program on achieving world-class maintenance. Every company needs to work on its maintenance culture and to recognize that the vicious cycle of breakdown maintenance must be broken.

Cover story: Is that a screwdriver in your ear? / 21

Ultrasound technology is no longer just for leak testing. It is a complementary companion for vibration analysis, infrared imaging, motor circuit testing, oil analysis, and in particular, reciprocating compressor valve testing.

Is your ultrasonic cleaning system living up to its potential? / 22

Need to clean or degrease parts? Here are some common questions and answers about ultrasonic cleaning equipment and its performance.

MRO on the Road / 34

IDI Independent Distributors Inc. sees big success at its Supplier Summit and IDImart trade show in Montreal.

The Safety File: Storing flammable liquids / 27

How to properly use storage cabinets for flammable and combustible liquids in industrial facilities.

Editor’s Notebook / 6

Industry Newswatch / 8

Business Briefs / 10

Mr. O, The Problem Solver / 10

Maintenance

Management / 24

Maintenance 101 / 26

The Safety File / 27

MRO on the Road / 34

Product News

Product Spotlight / 2

Focus on

MRO Components / 28

Focus on Bearings / 30

Focus on Pumping / 31

Focus on Safety and PPE / 32

‘Our guys are becoming specialized in replacing and maintaining some of the bearings we are using for special applications. They are better able now to analyze the causes of bearing wear, like contamination by water or dust, overheating or overloading.’

Denis Lanciault / 11

‘In lean times, it may be difficult to allocate scarce funding to upgrading rather than just repairing a pump. But with upgrades, the payback can be very quick.’

Eugene Vogel / 18

‘We’ve known for more than 20 years that ultrasound provides the earliest warning signals for mechanical failure.’

Allan Rienstra / 21

hile each issue of this magazine tends to highlight the topics of our main feature articles and columns – both on the cover and on our contents page – there are, in fact, many interesting technical and engineering innovations and solutions to read about in our Product News pages in each edition. So for a change, I’d like to point you to just a few that I found particularly interesting in this issue.

An innovative co-extruded gasket from Sweco is described in item 409 on page 28. It combines both white and black silicone. The black is conductive and the white is not, allowing the gasket to dissipate static electricity in high-static processes while only the food-grade,

non-conducting portion is exposed to the product being processed.

On page 29, item 412 from Meltric is an electrical receptacle box designed for wet environments that includes built-in circuit protection for safety. It also offers a dead-front safety shutter for protection from live parts and arc flash, a practical and safe combination in a unique design.

On page 30, What’s New in Bearings highlights bearings that fight corrosion, not just by using stainless steel, but also by applying thermoplastics (Kilian, item 372), or special plating, such as cadmium (Accurate Bearing, item 371). Timken, in item 376, notes an average increase of 10% in the load ratings for its tapered roller bearings, while Kaydon

offers tips on spotting the warning signs of bearing failure.

What’s New in Pumping on page 31 targets products for harsh operating conditions, such as item 383 from KSB that pumps corrosive, gaseous or temperature-sensitive liquids, or even solids-bearing liquids – all this in a single, modular design. And a Goulds pump from ITT – item 380 – is designed to be maintained even while it is running –now that’s innovative!

Item 395 describes upgraded Kimberley-Clark work gloves that provide better grip when used with oil or industrial grease. Items 393 and 394 both outline safety headgear that is lighter than previous designs for better worker comfort. And with more women in the workplace, somebody has finally developed personal protective equipment in smaller women’s sizes – see Gateway’s products in item 392. These, and more, are found in What’s New in Safety and Personal

machine tools x foundries x metalworking machinery x lawn & garden x speed reducers medical x instruments x transmissions x kilns x mining x pharmaceutical x HVAC x hoist transportation x agriculture x washdown x construction x gear box x pumps x steel mills railway x band saws x aggregates x pulp & paper x spindles x grinders x textiles x vibrating screen x hand tools x electric motors x power generation x compressors x automation x idlers

wind turbines x automotive x conveyors x aerospace x stamping x recreation vehicles blowers x food & beverage x winches x cranes x excavator x fans x robotics x sander x mixer back-up roll x paver x printing press x debarker x head pulley x dryer x track roller x planer oil & gas x clean room x extreme environments x forestry x return rolls x traction motors x tunnel boring x rock crushers x rolling mills x work rolls x smelting x sawmills

Protective Equipment on page 32. And we can’t leave out the items in Product Spotlight on page 2. There you’ll read that SEW has expanded the lower power range of its ‘intelligent’ industrial gear units (item 365), and about a new wireless shaft alignment system – item 419 – that can be operated easily by inexperienced users. We’ve also included a write-up on a non-corrosive solution from Walter that safely removes rust on iron and mild steel without damaging the parent material. There’s also two point-andshoot thermal cameras that feature the latest user-friendly features to enhance productivity – see items 368 from SKF and 370 from Fluke.

Keep in mind that additional information on any of the products described briefly in this issue – there are more than three dozen – can be obtained from the suppliers by using our online reader reply card at www.mromagazine/rsc.

Bill Roebuck,

Editor & Associate Publisher

2012 Volume 28, No. 2

Bill Roebuck, Editor & Associate Publisher 416-510-6749 broebuck@mromagazine.com

Ellie Robinson, Art Director Contributing Editors

Richard G. Ensman Jr., Simon Fridlyand, Carroll McCormick, Peter Phillips, Angela Webb, Cliff Williams BUSINESS Nick Naunheimer, Publisher 416-510-6868 nnaunheimer@mromagazine.com Eric Achilles Cousineau, Adv. Sales Manager 416-510-6803 eachilles@mromagazine.com

Collins, Advertising Production 416-510-6779

Marasigan, Subscription Enquiries 416-442-5600 x3548

Tel: 1.800.263.5163••••••Fax: 1.877.326.5696••••••Email: info@koyo.ca••••••www.koyo.ca

Ottawa, ON – The demographic and economic clout of the Western Canadian provinces is expected to continue to grow, according to the Conference Board of Canada’s Provincial Outlook-Winter 2012. The recently-released 2011 Census revealed that the western provinces are a magnet for new arrivals, and strong commodity prices are expected to boost the western economies over the next two years.

“The recent economic slowdown is now barely noticeable in Western Canada,” said Marie-Christine Bernard, associate director, provincial outlook. “Despite concerns over global growth and the lasting fiscal problems in Europe, growth in the Western Canadian provinces is expected to be a full percentage point stronger than in the rest of the country this year and next.”

The Canadian economy is forecast to post real growth in gross domestic product (GDP) of 2.1% in 2012. All four western provinces can expect growth at or above that level this year, while none of the other six provinces will grow by more than 1.9%.

Alberta is expected to lead all provinces both in 2012 and 2013, with economic growth forecast to be 3.3% this year and 4% next year. Global oil prices are expected to remain high, boosting construction and expansion of oil sands projects. By 2013, Alberta’s unemployment rate is expected to be down to 4.5%.

Saskatchewan is already experiencing tight labour markets and its unemployment rate in 2013 is forecast to match that of Alberta. After a gain of 5.2% last year, Saskatchewan’s real GDP growth will ease to 2.6% in 2012 and accelerate to 3.5% next year. Mining and manufacturing are among the province’s strongest sectors this year.

Manitoba’s agriculture, manufacturing and utilities sectors are expected to perform well in 2012. In particular, agriculture is expected to bounce back following the 2011 floods. Solid population growth is bolstering demand for housing and retail sales. Overall, the provincial economy is expected to grow by 2.7% in 2012 and by 2.6% in 2013.

British Columbia is being held back by external factors, such as moderating growth in China and a modest improvement in the US housing market. Restrained public sector spending will dampen construction. All in all, British Columbia’s economy will grow by 2.1% this year, and real GDP growth will accelerate to 3.6% in 2013.

Ontario’s economy will feel the pinch of deficit-reduction efforts at both the federal and provincial levels. Ontarians’ real after-tax incomes will post only a

small gain in 2012 as both employment and wages advance at a moderate pace. As a result, Ontario’s economy will grow by just 1.9% in 2012, although stronger growth of 2.8% is expected in 2013.

Quebec has a few bright spots in its outlook, notably strong business investment in Northern Quebec’s mining sector. But lower public infrastructure investment, a decline in housing starts, a weak labour market, and declining real disposable income will limit real GDP growth to 1.4% in 2012.

The Maritime provinces face modest growth prospects. Nova Scotia’s economy will grow by 1.5% in 2012, but 2013 offers a brighter outlook thanks to new natural gas production and stronger manufacturing. New Brunswick can also expect growth of 1.5% this year, following a long-awaited rebound in the job market. The end of fiscal stimulus in Prince Edward Island will limit the Island’s real GDP growth to 1.4% in 2012.

Newfoundland and Labrador’s economy is in transition. The oil and natural gas industry has reached peak production, but iron ore mining in Labrador is on the upswing. The province’s economy is forecast to grow by just 0.7% in 2012, before accelerating to 2.1% in 2013. Strong employment and wage gains mean that the province is attracting workers rather than losing them.

CANADIAN-OWNED SWISS MANUFACTURER CELEBRATES

50 YEARS OF BEARING PRODUCTION

Bulle, Switzerland – Wälzager Industriewerke Bulle AG (WIB), a specialty manufacturer of miniature precision ball bearings located in Bulle, Switzerland, is celebrating its 50th anniversary of bearing production. Originally a private company, WIB was acquired by NSK in 1990 and subsequently by RotoPrecision (Canada) Inc., Mississauga, ON, in February 2003.

Founded in 1961, WIB produces a full range of precision ball bearings made ac cording to international specifications in metric and inch dimensions, including single- and double-row radial ball bear ings; self-aligning ball bearings; cylin drical, spherical and gothic-grooved track rollers; special drawing bearings; and precision rolls and sleeves.

With a broad industrial customer base of original equipment manufactur ers and distributors in over 30 countries around the world, WIB currently employs over 100 production, sales and administrative staff.

gone a tremendous restructuring, including very substantial investment in equipment, processes and capacity,” says Gregg Robinson, president of RotoPrecision (Canada).

RotoPrecision is a privately held group of distribution and manufacturing companies that was founded in 1958. It operates branch offices and stocking locations in Toronto, Montreal and Vancouver; manufacturing facilities in the UK and Switzerland; and a specialty lubricants provider in Mississauga

Halle, Germany – At the end of March 2012, KSB Aktiengesellschaft started production of its high-efficiency SuPremE electric motor series its factory in Halle on the river Saale, Germany. In contrast to conventional synchronous motors, the German pump manufacturer’s motor does not contain any magnetic materials, such as rare earths, which are regarded critical raw materials and which cannot be mined without considerable environmental impact in the countries of origin. Since the new drives no longer need failure-prone rotor position sensors, they are said to be as reliable as speed-con-

trolled asynchronous motors. Because of the low temperatures within the rotor, the life of the new motors’ bearings is even longer than before.

The motor, which was first presented as a prototype at the Hannover trade fair in 2009, is equipped with a four-pole rotor that only consists of a laminated core without a cage. The rotor laminations are specially shaped to guide the lines of flux.

The new synchronous reluctance motors provide users with a technology that is ideally suited to also fulfil the future requirements that energy-efficient drives of pumps will have to meet. They have at least 15% less power dissipation than that prescribed by Regulation EC 640/2009 for efficiency class IE3 from 2015 or 2017, depending on the motor rating. This means that the motors reach efficiency level IE4 as per IEC/CD 6003430 Ed. 2 already.

In contrast to asynchronous motors, synchronous reluctance motors still have a good efficiency when they are not run at full load. But this is exactly what is very often the case in day-to-day operation practice, where many motors operated in speed-controlled applications mainly run at reduced speed.

KSB plans to also supply the motors to other manufacturers of rotating equipment.

This motor, first presented as a prototype at the Hanover trade fair in 2009, does not contain any magnetic materials.

Chicago, IL – The Bearing Specialists Association (BSA) and the Power Transmission Distributors Association (PTDA) recently approved a revision to the widely used Product & Price Information Format (PPIF).

“Since RotoPrecision’s acquisition of WIB in 2003, the company has under-

Based on research and recommendations by a joint task force led by Rex Davis, vice-president, supply chain, IBT Inc., PPIF version 2.3 adds optional fields for providing product information on green designations and certifications. The effective date of PPIF Version 2.3 was March 31, 2012.

To meet the needs of customers who require a product with a green designation, the latest version of PPIF includes four optional fields for manufacturers to use in providing green information to distributors. These new optional fields in PPIF v. 2.3 enable manufacturers to indicate whether a product is ‘green’ or environmentally friendly, the classifications of eco-friendly products, the independent organization or agency providing the rating or certification, and the green validation of the product.

Since 1999, the Product & Price Information Format has simplified the transmission of price and product information from suppliers to distributors by elimi-

nating the patchwork of proprietary manufacturer pricing formats. This universally accepted format has streamlined the cumbersome, time-consuming process of updating database records to reflect current information.

In addition to IBT, companies represented on the PPIF Revision Task Force include Applied Industrial Technologies; BDI; Kaman Industrial Technologies Corp.; Loctite Industrial Group, Henkel Corp.; Motion Industries Inc. and The Timken Company.

For more information about PPIF v. 2.3, visit www.bsahome.org/tools/ppif or www.ptda.org/PPIF.

BSA is an international service and educational organization of distributors representing almost 100 companies distributing factory-warranted ball-, roller-, and anti-friction bearings and invited manufacturers of bearings, and related products. PTDA is a US-based trade association representing 178 power transmission/motion control distribution firms. Its members also include 180 manufacturers that supply the PT/MC industry.

Chicago, IL – The PTDA Business Index indicated the fourth quarter of 2011 (4Q2011) was the seventh consecutive quarter for business growth among PTDA members, with a reading of 67.3.

Both distributors and manufacturers saw growth in 4Q2011. Distributors outpaced manufacturers for the first quarter in the survey’s history.

Compared with a reading of 68.1 for 3Q2011, the recently re leased fourth-quarter results in dicate the power transmission/ motion control industry is ex panding at a slightly slower pace than before.

The index reading indicates the rate of change compared with the previous period. For example, a reading of 50 indicates no change from the prior period, while readings above 50 indicate growth and below 50 indicate con traction. The further the index is above or below 50 suggests a fast er or slower rate of change.

PTDA members participating in the Business Index expect 2012 to be another year of growth with an average forecast of 9%, up from 8% in the 3Q2011 survey.

For more information, call 312-516-2100 or visit www.ptda.org.

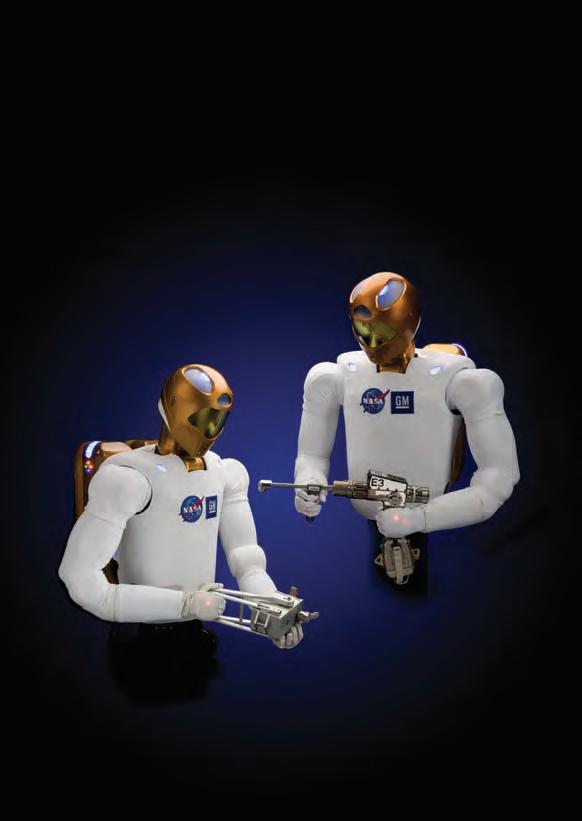

Cape Canaveral, FL – Astronauts and robots have united in space with a healthy handshake. The commander of the International Space Station, Daniel Burbank, shook hands in February with Robonaut. It’s the first handshake ever between a human and a humanoid in space.

NASA’s Robonaut was launched aboard space shuttle Discovery last February. Crews have been testing it to see how it one day might help astronauts perform space station chores. The maintenance applications of the R2 Robonaut – a

collaborative robot or cobot – were dis cussed in the ‘I, Cobot’ feature in Machinery & Equipment MRO’s September 2010 issue; the story and photographs of the cobot can be found by searching for the term ‘robonaut’ in the Search box on the home page at www.mromagazine.com.

Glen Ellyn, IL – The Bearing Specialists Association (BSA) 2012 Annual Convention takes place April 29 to May 1 at the Hyatt Regency Coconut Point Resort and Spa in Bonita Springs, FL. The bearing industry event is for authorized distributors of bearing products and services and the manufacturers of those products.

The conference theme of ‘Technology

Drives Productivity’ is expected to challenge the industry to consider how to best leverage the latest business tools.

To learn more about the convention, go to www.bsaconventions.org or call the association at 630-858-3838.

Toronto, ON – Two MainTrain maintenance conferences – one in the west and one in the east – are scheduled to take place in 2012. The events are organized by the Plant Engineering and Maintenance Association of Canada (PEMAC).

MainTrain Fort McMurrary is planned for Oct. 1-3, 2012, at the Sawridge Inn and Conference Centre in Fort McMurray, AB. MainTrain Toronto is scheduled to take place at the Novotel Toronto Centre in downtown Toronto, Nov. 19-22, 2012. The Toronto conference will be produced in conjunction with the annual International Maintenance Excellence Conference (IMEC) organized by the University of Toronto and the Centre for Maintenance Optimization and Reliability Engineering (C-MORE).

The 2012 theme for MainTrain, an annual peer-developed maintenance, reliability and asset management conference for knowledge transfer, technical training and networking, is Creating & Measuring Success.

For more details, visit the website at www.maintrain.ca or call 1-877-523-7255.

ROLLING

NSK supports its customers with a full range of rolling bearing and linear motion products engineered to perform better – and last longer. Our unrivalled technical knowledge allows us to understand their operational challenges and provide industry-specific solutions that improve bearing life and increase operating performance. For maximum productivity through advanced innovation, reliability and performance, Think NSK.

News and views about companies, people,

• International power transmission group, Renold, has launched a version of its website suitable for access by smart phones. The mobile-optimized version has been designed to work perfectly with small screens and redirects users automatically whenever a mobile device visits www.renold. com.

“This will be particularly useful for engineers working on large sites needing quick information on a Renold product while away from a computer, and for engineers on the go,” says David Turner, Renold Chain’s marketing communications manager.

• In February 2012, three new appointments were made at Timken Canada, St. Thomas, ON. Louis Cormier was named regional sales manager – west, Bruno Mylchreest was named regional sales manager – east, and Andrew Platt was named customer service manager for Canada. Cromier is responsible for sales in British Columbia, Alberta, Saskatchewan and Manitoba, and also continues in his previous role as the product specialist for the Timken Housed Unit product line across Canada. Mylchreest is responsible for sales in Quebec, New Brunswick, Nova Scotia, Prince Edward Island, and Newfoundland and Labrador. All three appointees report to Frank

G. Mascia, general manager of sales in Canada. Mascia took over this position in November 2011, at the same time Evan Boere was named business development manager for Canada.

• The Timken Company, Canton, OH, has been recognized as one of the World’s Most Ethical Companies for 2012 by the Ethisphere Institute, an international organization focused on the advancement of best practices in business ethics.

Timken markets friction management and power transmission products and services. Timken was named among the 145 most ethical companies globally through consistent demonstration of integrity in business practices and initiatives. For more information on Ethisphere’s list of the World’s Most Ethical Companies, visit www.ethisphere.com/wme.

• KSB Pumps Inc., Mississauga, ON, the Canadian arm of the German-based KSB Group, has upgraded its pump maintenance and overhaul service offerings. The expansion includes a high-bay workshop connected to the company’s new headquarters building. “With the new space, which is equipped with a 16tonne crane and expanded machine-shop facilities, we can handle almost any size of pump from all pump manufacturers,”

says Gary Zeidler, national service manager for Canada. He says the KSB Pumps service team has demonstrated their skills in projects that have ranged from routine maintenance and overhauls (including field service) to extensive rebuilds for severely damaged pumps or pumps that must be re-configured to meet new operating conditions.

• Heather Dollman has been appointed Ontario district sales manager for Montreal-based Renold Canada. Reporting to Rick Hamilton, president, she covers the GTA and East, Southwest, Central and Northern Ontario. (The eastern areas of Ontario nearest the Quebec border, including Ottawa, will continue to be covered by Patrick Gregoire.) Dollman is well-versed in all Renold products, having sold for the company previously. Also, the company has refreshed its logo, adding Canada in red and creating consistency with the company’s US logo, which has a similar design.

Quebec City and Beauce markets. The current management team of Steve Harvey and Carl Harvey will continue with the organization. Solutions Industrielles Chicoutimi provides bearings, power transmission products and repair services through one location in Chicoutimi. Yves Gauthier, former owner, will continue with the organization. Both businesses will continue to run under their current operating names, and both now report to Mike Allen, vice-president for the Eastern Canadian operations of Applied.

• Twiflex Ltd., a supplier of advanced braking technology for industrial applications, has launched a new website that provides information about its lines of industrial disc brakes, centrifugal clutch couplings and flexible couplings and shafts. The website, www.twiflex.com, contains selection guides and braking calculations.

Aligning a pump with the driver shaft

Problem: Working with a client recently, I had cause to revisit a couple of the basics of shaft alignment as it relates to mounting the driver. Obviously this doesn’t even get close to the detail required to accurately align shafts for a high level of equipment reliability, but it’s worth remembering.

• Sean O’Brien, president, AcklandsGrainger Inc., Chicago-based Grainger Inc.’s Canadian subsidiary based in Richmond Hill, ON, has resigned from the company, effective March 23, 2012. O’Brien joined Acklands-Grainger as vice-president, sales, in November 2007, taking on additional responsibilities for e-business and marketing in early 2009. He was named president in September 2009. Mike Pulick, president, Grainger International, will serve as interim president of Acklands-Grainger. He had become head of Grainger’s international businesses on January 1, 2012. “We respect Sean’s decision to pursue opportunities outside the company and wish him well in his future endeavours,” said Pulick.

• Motion Industries Inc., Birmingham, AL, a distributor of industrial maintenance, repair and operation (MRO) replacement parts, recently recognized 62 of its key suppliers as participants in its Operational Excellence Supplier Partnership program at its North American 2011 Meeting in Atlanta, GA. Suppliers were recognized for making significant contributions in the area of supply chain integration and process improvement. This program has spanned seven years and has resulted in over 1,000 individual implementations to improve supply chain efficiency. Suppliers achieving the highest level of improvement for 2011 are Climax Metal, ITW Devcon, General Bearings and RBC Bearings. Motion Industries is a wholly owned subsidiary of Genuine Parts Company

• Applied Industrial Technologies, Cleveland, OH, has acquired two Quebec industrial distribution firms, Spécialités Industrielles Harvey, Quebec City, QC, and Solutions Industrielles Chicoutimi, Chicoutimi, QC. Terms of the sales were not disclosed. Spécialités Industrielles Harvey distributes bearings and power transmission products, plus hydraulic, pneumatic and electrical components, from two locations serving the

Solution: First of all, always perform the vertical alignment before the horizontal alignment. This is simply because the vertical movements will usually affect the horizontal position, while the horizontal movements won’t affect the vertical position.

If you are still using a 16-lb. sledgehammer or other blunt instrument to move the driver, it’s about time it was replaced with jacking bolts. When you need to move the driver from right to left, try backing off the horizontal jacking bolts on the left side and inserting the precise amount of shims in between the driver and the bolts, as required. Then reposition the bolts against the shims. The shims may reflect different corrections at the front and at the rear of the driver.

Remove the shims, loosen the holddown bolts, and tighten the jacking bolts on the right side, thus moving the driver towards the jacking bolts positioned on the left side. When the driver is held firmly between the jacking bolts on both sides, then tighten down the hold-down bolts, thus positioning the driver in its corrected location. Loosen off the jacking bolts.

Accurate alignment of the pump and driver shaft will always improve the reliability of the pump

Mr. O’s thanks for this tip go to Ross Mackay of Aurora, ON, author

Do you have a solution for a maintenance problem? Send it in and if it’s published, we’ll send you a Mr. O Problem Solver T-shirt. Include your address, telephone number, print complete details and, if possible, add a sketch to help explain your tip. Send your tips to Mr. O, Machinery & Equipment MRO, 12 Concorde Place, Suite 800, Toronto, ON M3C 4J2.

WE REVISIT FOUR COMPANIES FOR UPDATES ABOUT THEIR MOST RECENT MAINTENANCE ACTIVITIES AND LEARN OF SOME INTERESTING SOLUTIONS TO THEIR EARLIER PROBLEMS

BY CARROLL MCCORMICK

Preventive maintenance system not working? High-maintenance components wearing you down? Training needed on critical bearings? Machine wear taking its toll? Need to do better system monitoring? Require an easier way to monitor equipment health? Well, you’re not alone. These are the same problems experienced by companies profiled in previous case studies published in Machinery & Equipment MRO. So we sent writer Carroll McCormick back to talk to some of those same companies again and learn how they have dealt with their problems. Each has found innovative and effective solutions.

When Machinery & Equipment MRO profiled Lasalle, Quebec-based shingle manufacturer Building Products of Canada Corp., the maintenance department was well into a program to regain control of maintenance from a preventive maintenance system that was not working (Bringing Maintenance Back to Reality, November 2009). Additional training has been part of the cure.

In the past three years, the maintenance team, which includes mechanics, pipefitters, welders and machinists, has received training on bearings, power transmissions (belt pulleys, sprockets, chains and couplings) and laser alignment for couplings.

Denis Lanciault, vice-president of operations, BP Canada, focuses in on the bearing training, which the entire 30-member team has received from Montreal-based Proaxion. “They received training adapted for critical bearings we have on our equipment. They received information about different kinds of bearings we have, learned how to assemble them on the shafts, learned how to analyze and measure wear, and how to choose adequate bearings for different applications.”

Nimble skills with bearings are

awfully handy in this plant, as aggressive conditions such as sand, asphalt, gravel, limestone, hot and cold water and tar can kill them in less than a month.

Staff received training on site in groups of seven or eight. It was a refresher course for some and completely new information for others. They spent about eight hours working with bearings on workbenches, and then they went directly to machines in the production line to finish their training.

“Our guys are becoming specialized in replacing and maintaining some of the bearings we are using for special applications. They are better able now to analyze the causes of bearing wear, like contamination by water or dust, overheating, overloading or just normal wear,” Lanciault says.

The maintenance shop was already well-outfitted for most bearing interventions. The company only had to purchase filler gauges for gapping bearings before and during installation. As for the program’s benefits, Lanciault explains, “It increases the lifetime of bearings because they are well-installed and tightened, it reduces downtime due to unplanned breaks and leaves us more time during planned shutdowns. Proaxion is also analyzing and monitoring critical bearings for us. Then they send us a summary of their data analyses that guides us for preventive bearing replacements.”

After 14 months and 175,000 tonnes of garbage, it is time to change out the shredder at the Otter Lake Solid Waste Management Facility just outside of Halifax, NS ( High-Motivation Maintenance, September 2010 ). With the big machine, designed to reduce garbage to pieces five centimetres in diameter or less, all that tonnage has taken its toll. The sizes of the pieces have been creeping up to 15 centimetres in diame-

continued from page 11

ter, a sure sign that the shredder is ready for a rebuild.

Otter Lake processes between 550 and 600 tonnes of garbage daily. After removing as much recyclable material as possible, the rest goes through the 14tonne shredder, to the Waste Stabilization Facility (WSF) for partial decomposition, and then onward to landfill cells.

Otter Lake has two shredders. In April 2012, the one that has been munching garbage non-stop for over a year will be removed using a 90-tonne crane and a rebuilt spare put in its place – a four to six-hour operation.

“I’ve been doing this for 14 years. We have it pretty much down to a science now,” explains Terry Barkhouse, head of maintenance for Mirror Nova Scotia, Bedford, NS. The private company runs the facility for its owner, the Halifax Regional Municipality.

As the shredder wears and the shredded pieces get bigger, they interfere with the functioning of the agitator units in the WSF. Too, Barkhouse notes, “As the teeth get worn, the jamming increases.” This is a bad thing, as the system has to be shut down and the offending object, say a lawnmower blade, cut out with welding torches.

The worn unit will be moved to the shop, where maintenance will tear it down, discard the old shredder disks and install a new cutter stack package from the Oregon, US-based manufacturer, SSI Shredding Systems Inc. The package, which includes new disks, seals, bearings and spacers, costs US$50,000.

“We rebuild it in our spare time. We usually have it done in three to four weeks and it’s tarped, ready to go. We don’t like to leave it for too long,” Barkhouse says.

In June 2011, Montreal-based Cofely Services, began installing monitoring devices on the 10 linear motors on the tilt tray system, part of the baggage handling system (BHS) at the Montreal-Trudeau International Airport that serves domestic and international traffic (Strength in Numbers, September 2009).

The tilt tray system is a racetrackshaped, 230-metre long conveyor that consists of 212 wooden trays. As bags journey through the BHS, conveyors push them onto the trays, which circle endlessly like sushi boats in a high-flying restaurant. When a tray and its bag pass above the chute associated with the right baggage wagon and the right airplane, the tray tips the bag onto the chute. The tilt tray system is the highestmaintenance part of the BHS, requiring 160 hours a month of preventive maintenance.

The new motor monitoring system will track electric current consumption to create a baseline of a healthy motor. It will then compare this to a graphical trend of each motor as it approaches the end of its useful life. With the proper trending and analysis, the maintenance team will be able to tell when a motor is about to fail.

The motors are all driven by a common frequency inverter. It can be difficult to detect a motor failure, since only seven of the 10 motors are required to operate the tilt tray system. Yet a failed motor can eventually affect the frequency inverter and shut down the system. “We want to eliminate the perturbation of [the BHS] caused by a tilt tray failure and we also want to protect the element representing the single point of failure,

which is the frequency inverter,” explains Pierre Loyer, director of airport services for Cofley Services.

“We are integrating the data in our centralized database for our reliability analyst to interpret. Eventually, our computerized maintenance management system, Maximo, will be able to generate automatic work orders and produce an overall equipment efficiency dashboard,” Loyer adds.

The tilt tray motor project is part of a larger picture: the ongoing adoption of the 5S concept, including systematic and condition-based intervention, which Cofley began implementing in September 2011. As more system monitoring equipment is installed, other goals are to extend the expected life of specific parts or equipment, benchmark equipment to identify improvement project opportunities and further train the maintenance personnel.

continued on page 14

Review the original case studies online at www.mromagazine.com, where you’ll find archives of all issues of Machinery & Equipment MRO since 2000 and complete digital copies of editions since 2009. The four stories referenced here include:

1 | Building Products of Canada Corp. (Bringing Maintenance Back to Reality, November 2009, page 13).

2 | Otter Lake Solid Waste Management Facility (High-Motivation Maintenance, September 2010, page 22).

3 | Baggage handling system at the Montreal-Trudeau International Airport (Strength in Numbers, September 2009, page 14).

4 | Canadian National Railway (Workin’ on the Railroad, April 2005, page 24).

Just because different companies’ gearmotors may appear similar from the outside doesn’t mean they’re built the same on the inside. Take apart a Bison gearmotor, compare it to the competition, and you’ll see a difference.

For over 50 years Bison Gear & Engineering Corp. has been designing and manufacturing fractional horsepower electric motors, gearmotors and gear reducers used in industrial and commercial OEM applications worldwide. Bison’s strong engineering tradition, based on Robusticity™ principles, offers products with up to twice as much torque in the same package size as competitors.

In the past three years, the maintenance team, which includes mechanics, pipefitters, welders and machinists, has received training on bearings, power transmissions (belt pulleys, sprockets, chains and couplings) and laser alignment for couplings.

Since November 2011, Canadian National Railway Co. has been using three different systems, each on a different set of some of its locomotives, to remotely monitor their health (Workin’ on the Railroad, April 2005 ). The goal is to collect data that will indentify trends that can be used to prevent failures and help CN rewrite its periodic maintenance

tasks based on actual locomotive needs.

The first system is EMD Intellitrain, made by Electro-Motive Diesel Inc., LaGrange, IL. Intellitrain sends a data pack, which includes five seconds of data prior to a fault becoming active, to a central location whenever a locomotive generates a fault. EMD analyzes the fault and generates an e-mail with a description of the fault and troubleshooting procedures to identify the reason for the fault.

�

�

�

�

Intellitrain also collects data from the locomotive every hour when it is performing under certain defined conditions. EMD can then send out proactive e-mails with maintenance instructions that can prevent a possible failure. The messages include trends like crankcase pressure building up, coolant pressure getting low or cooling fans not performing as intended.

The second system, GE Expert-OnAlert, by GE Transportation, Erie, PA, transmits real-time incident data to a central location, where remote monitoring diagnostics specialists review the data and issue repair recommendations.

There are three codes, depending on the severity of the incident: Red indicates that an immediate action is to be taken to prevent the locomotive from becoming disabled on the main line. Yellow requires that a plan be put in place to insure that either a temporary correction is taken or plans are put in place to continue working with the locomotive at a repair facility. White indicates a recommendation to correct something that is not going to have an impact on the performance of the locomotive, but that needs to be done the next time it is in the shop for repairs or maintenance.

The third system is Wi-Tronix from Wi-Tronix LLC, Bolingbrook, IL. When a fault is logged, Wi-Tronix sends data and a description of the fault to a website where CN personnel can review the data pack and provide additional information to help identify the reason for the fault. The goal is to identify trends so CN can take corrective action when the locomotives are in the shop for maintenance.

CN has a weekly scorecard it uses to evaluate the benefits of all three systems. It is studying the accuracy of the troubleshooting instructions and how well they work to prevent main line failures.

All four companies that were revisited to update their original stories had made progress with their maintenance issues, using technology, training, new systems or improved planning, reflecting the fact that preventive maintenance and problem-solving are continuous processes in most forward-thinking industrial facilities. MRO

Montreal-based Carroll McCormick is the senior contributing editor for Machinery & Equipment MRO.

Bearings are made to exacting tolerances and have very fine surface finishes. In order to maintain the geometrical precision and the surface integrity of ball and roller bearing raceways and rolling elements, it is mandatory that care in storage, handling and installation be observed.

Although the hardened bearing steel used to manufacture bearing components can withstand heavy pressures during operation, bearings are vulnerable to the stresses of metal-to-metal contact that occur when they are mishandled. When a bearing is bumped or dropped, rolling contact damage usually results. Either the raceways are dented (brinelled) or scuffed. Damaged areas become the focal points for premature failure.

The best way to ensure the maximum performance and anticipated life from rolling bearings is taking extreme care during the installation process. Using the proper installation tools is the first step in assuring a successful result.

Preparation is the key to any successful bearing installation. Before a bearing is drawn from its place of storage, an organized work area must be created that ensures cleanliness, safety and easy access to all of the required tools.

The bearing installation tools discussed here are applicable to a variety of sizes and styles of bearing. However, they may not work in all situations, so care must be taken when you make your selection. It’s important to use proper bearing installation tools in order to avoid the misuse of hammers, chisels, screwdrivers, torches and other general tools that could contribute to permanent bearing damage.

Small- and medium-size bearings with interference-fit inner rings are commonly mounted with the aid of a bearing heater. The purpose of the bearing heater is to expand the inner ring enough so that the bearing can be slipped on to the shaft, up to the shoulder, without the use of force.

Bearing heaters have many advantages, but they also can destroy a bearing very quickly. Bearings heaters should be equipped with certain safeguards to prevent permanent bearing damage.

For example, a bearing heater should have a timing cycle. This timer turns the heater on and off every few seconds until the bearing reaches its selected temperature. This will prevent brinelling from rapid heating.

In order to prevent overheating, a bearing heater should be equipped with a temperature probe. If this is not the case, other monitoring procedures must be employed.

Since the bearing becomes magne tized during heating, some heaters fea ture a demagnetizing cycle. It is strong ly recommended that you use a heater with this feature.

When installing tapered bore bearings that utilize an adapter sleeve and locknut, a hook spanner wrench is needed to complete the assembly and set the clearance. The spanner is a specialized wrench with pins or tabs around the circumference. These pins or tabs fit into the notches of a locknut. The 90° spanner is the most common; however the 180° spanner requires less effort, since more of the force applied at the handle is translated to torque on the nut.

When it becomes necessary to remove a bearing from an assembly, care must be taken to avoid damage to raceways and rolling elements. In these instances, use a bearing puller. There are wide variety of sizes, capacities and styles from which to choose.

Occasionally, it becomes necessary to lightly strike a bearing in order to accomplish installation or removal. In this instance, a dead-blow hammer is recommended. This type of hammer is manufactured of a hard plastic with the head filled with a shot material to deaden the blow and prevent bounce-back of the head.

The installation of large-diameter bearings often requires the use of hydraulic equipment for mounting and removal. This makes the job easy and fast and eliminates the huge physical effort needed to do the job. Hydraulics are commonly used for tapered bore bearings and occasionally for cylindrical bore bearings.

Hydraulic fluid is pumped through the shaft to a groove under the bearing, where the hydraulic pressure expands the inner ring. This eliminates the force required to stretch the inner ring as it is being driven up the taper. The inner ring can be mounted using a standard nut or a hydraulic nut.

Hydraulic nuts are made by a number of manufacturers but all employ the same principle: A nut of standard thread is modified so that there is a hydraulic ram sealed in the inboard face. The ram is actuated by hydraulic fluid introduced through the O.D. of the nut. Pressure against the outboard face of the inner ring drives the bearing up the tapered journal. MRO

This is an edited version of the Bearing Mounting Tools Bearing Brief prepared by The Bearing Specialists Association (BSA) for distributors, manufacturers and endusers. Over the past several years, the association’s Educational Services Commit-

FOR MOST COMMON PUMP APPLICATIONS, COATING UPGRADES ARE AMONG THE BEST WAYS TO IMPROVE PERFORMANCE AND INCREASE THE MEAN TIME.

Cost control and efficiency improvement are key to successful plant operations – especially when it comes to volatile energy costs.

Most plant managers are keenly aware that upgrading from standard motors to premium-efficiency designs can save 4% to 6 % on the electric bills for appropriate applications. Yet few realize that simple upgrades can improve pump efficiency 10% to 15% or even more. Often these upgrades yield significant savings on pump maintenance and repair as well – which translates into less downtime and reduced environmental risk.

Available pump upgrades include custom coatings for internal and external parts, shaft and seal modifications, bearing isolators, and bearing housing breathers. Of these, custom surface coatings typically provide the fastest return on investment. When evaluating coating upgrades, however, it is critical to understand pump basics, as well as the pump’s operating environment and system requirements.

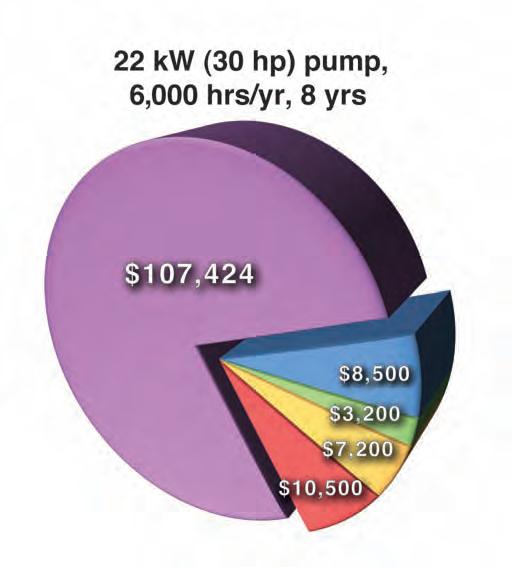

Centrifugal pumps may be less than 50% efficient, but have the potential to improve by 20% to 30% through various upgrades and system changes, according to the US Department of Energy . To create awareness of these facts, the agency is promoting life cycle costing (LCC). As Figure 4 shows (see pg. 19), the acquisition price of a 22 kW (30 hp) pump, that runs 6,000 hrs/yr for eight years, is a fraction of its life cycle cost. Energy is by far the most significant cost, but maintenance and repairs total more than twice the purchase price.

Pump upgrades usually address maintenance and repair issues as well as efficiency, so they can extend pump life and reliability, prevent expensive product from going down the drain, and even help avoid spills that can trigger costly cleanups and fines from regulatory agencies

such as Environment Canada. In many cases, the reduced downtime afforded by the upgrade outweighs all other benefits.

In lean times, it may be difficult to allocate scarce funding to upgrading rather than just repairing a pump. But, as the example illustrates, the payback can be very quick. The resultant savings will then free up funds that otherwise would go for wasted energy and more expensive repairs later. If a pump is already scheduled for service or requires emergency repair, the incremental cost of upgrades may be minimal.

Plant expansions and new installations are also good opportunities to specify pumps with upgraded efficiency and reliability features. Most pump manufacturers can accommodate such specifications, and qualified service centres can usually upgrade off-the-shelf pumps as required.

For most common pump applications, coating upgrades are among the best ways to improve performance and increase the mean time between failure (MTBF). Though they may look like paint, their purpose has little to do with appearance. Instead, they are designed to reduce friction (thus increasing efficiency) or to resist erosion and corrosion (thereby improving reliability and extending pump life). In some applications, they accomplish both objectives.

Typically, coating upgrades are applied to the rough surfaces of the impeller and the volute to improve efficiency while protecting these relatively soft brass or cast iron parts from erosion and corrosion.

Abrasive wear is easy to spot when a pump is disassembled for repair or overhaul, but is often regarded as ‘normal for the application’. In fact, some plant managers think short pump life is so ‘normal’ that they routinely replace pumps at reg-

ular intervals. Most of the time, however, erosion-resistant coatings for the wet end could extend pump life and therefore significantly reduce the operating costs. Often the coating can even be reapplied periodically for much less than it would cost to replace the pump.

Depending on the application, coating upgrades may also be beneficial inside bearing housings or even on external pump surfaces.

Bearing housings: Coating the inside of the pump bearing housing can prolong bearing life by eliminating a destructive contaminant – rust. Even moderate contamination, according to SKF, will shorten the life of oil-lubricated bearings by a factor of four. During the repair process, rust can form on bare cast iron and steel surfaces within a few hours after parts have been cleaned and then exposed to moisture in the atmosphere. Even after assembly, moisture in the air can oxidize inside surfaces. Applying the appropriate paint or industrial coating can prevent

rust from forming and being washed into the bearing by lubricating oil.

External pump, base and related equipment: No one would coat the outside of a submersible sewage pump just so it will look good. But applying a good protective coating now may mean the difference between reasonable reconditioning costs and expensive replacement the next time the pump is pulled up for service.

Choosing the right coating: Any of the coatings designed for pump wet-end applications will provide a smoother surface that reduces friction, even if the primary objective is protection against wear and corrosion. But some, including a number of polymer coatings, are specially designed to cure to a very hard, durable and slick surface that further reduces friction losses. The result is a pump that operates more efficiently and resists corrosion and erosion. Where energy efficiency is important, careful selection of the coating material will pay dividends in reduced operating expense.

Even small efficiency gains can have a big impact on operating costs. For example, consider a cooling water pump that moves 172 cu m/hr at 69 m of head and is 70% efficient (the assumed energy cost is $0.10/kWh).

(kW=cu m/hr x m x s.g.)/(480 x Efficiency)

=(172 cu m/hr x 69 m x 1)/(480 x 0.7)

=35.32 kW x 1.341=47.36 hp

Annual energy costs

=35.32 kW x 5,000 hrs x $0.10=$17,660.

Coating the inside of the pump volute could increase the efficiency to 75% and reduce the energy costs to $16,483, saving $1,177 per year.

Of course, some coating upgrades are worthwhile strictly from the standpoint of improved reliability and extended pump life. For most water and waste-water applications, a good enamel may be adequate, whereas specific epoxies may be required for potable water applications. Epoxies or other polymer coatings may also be necessary for harsher environments involving abrasives, acids, caustics, salt and petroleum byproducts.

Choosing the right pumps to upgrade Not all pumps will benefit from reducedfriction or corrosion-resistant coatings. Appropriate upgrade decisions require both detailed knowledge of the application and a basic understanding of pumps and pump curves. Even experienced plant personnel may find the professional advice of the pump manufacturer or a qualified service centre helpful when considering pump coating upgrades.

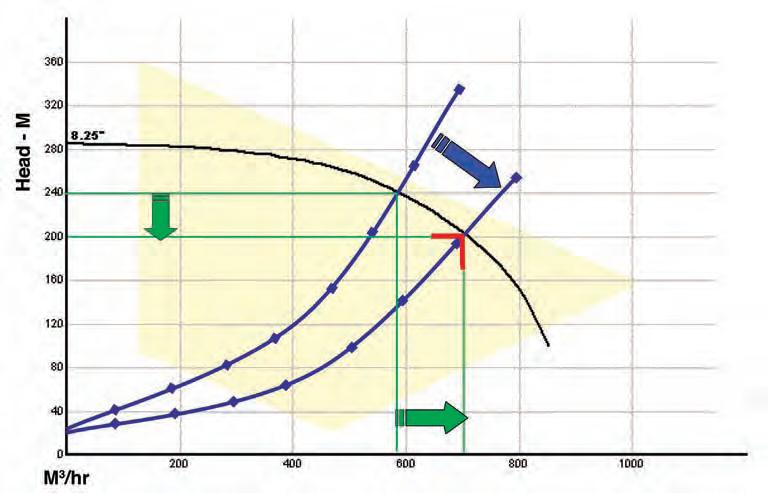

Pump curves: Pump curves relate the head and flow that a centrifugal pump will produce to its efficiency and required input power. As pump head increases, flow decreases – until at maximum head (shutoff head) when flow is zero. If a pump is operating correctly, head and flow will intersect at some point along the curve.

Efficiency dictates the shape and location of the curve, so any improvement in efficiency will tip the curve up, effectively providing more flow for the same head (see Figure 5, pg. 20). This will save energy on pumps that operate at full flow and cycle as needed.

Coatings that reduce friction work on the flow side of the head-flow relationship in centrifugal pumps. Therefore a highflow, low-head pump would benefit significantly from a reduced-friction coating, whereas a pump with very high head and low flow would not.

Reduced-friction coatings can save energy in systems that regulate flow with variable-speed drives. In these cases, more efficient pumps can run slower and still produce the same head and flow, thus saving energy.

However, reduced-friction coatings will provide no energy savings on systems that use a modulating discharge valve to achieve a specific flow (e.g., heating and cooling loads). In such systems, the valve increases (or decreases) friction in the discharge line, which increases (or decreases) head to control flow. If pump efficiency were to improve (providing more flow), the discharge valve would close to compensate, recreating the friction loss that the coating eliminated. (Of course, pumps in these systems may still benefit from coating upgrades that extend pump life and improve reliability by resisting corrosion and erosion.)

Good candidates for reduced-friction coatings include pumps used in municipal water and waste-water industries, refineries and petrochemical plants, and HVAC circulating applications. The coatings are less beneficial in terms of energy savings for pumps that operate intermittently.

22 kW (30

pump - 8-yr life cycle - 6,000 hrs/yr - $0.10/kWh

Industries with high abrasive wear applications that would benefit from corrosion- or erosion-resistant coatings include: waste-water treatment and power generation that typically handle slurries; power generation that uses river or lake water for cooling; and mining operations that have numerous dewatering and production pumps that are subject to sand and gravel. Depending upon the application and type of upgrade being considered, it is often best to first perform a cost-benefit analysis based on known energy costs, the projected efficiency gain, expected pump life, and upgrade costs.

Applying coatings

Surface preparation: Whether the bond is structural (mechanical) or chemical (valence), the coating must adhere to the pump to be beneficial. That means the surface must be prepared properly (see Figures 1, 2 and 3).

A strong mechanical bond requires a microscopically rough finish, which usually is obtained by blasting with sand or a grit like Black Beauty that can achieve an 0.08 mm (3 mils) anchor profile. Chemical bonding depends on sharing of electrons at the molecular level, so

the surface must be free of contamination and blasting residue. In either case, the coating should be applied as soon as possible after the surface has been prepared. Products: Most hard-finish coatings for pump impellers and volutes are pastegrade products that are spread or trowelled on thickly enough to cover surface irregularities and resist abrasion. Many of them are available in thinner grades that can be brushed on. A few spray-on coatings are also available, most of which are epoxy paints.

Polymer coatings are two-part systems that require accurate and thorough mixing. Most of these will cure at room temperature, although moderate heat can accelerate the process. Some polymer coatings contain catalysts that cure at lower temperatures for use on site in cold weather; others are specially designed for application on wet surfaces. Always follow the manufacturer’s recommendations, or have the coatings applied by a qualified service centre.

Price is always a significant factor in pump selection and usually rules out any extras that could extend pump life or improve its efficiency or reliability. When facing the reality of high operating costs for energy and repairs caused by erosion and corrosion, however, it is easy to see the value of properly designed and applied surface coating upgrades. Coatings that reduce friction and thereby improve efficiency can be justified by reduced energy usage when operating conditions meet the criteria discussed above.

The significant costs of maintenance and repairs represent additional opportunities for savings. Pump upgrades that improve reliability provide benefits in reduced downtime and reduced environmental risk. The critical factor in evaluating most upgrade options is to understand the operating environment and the system requirements. When a pump upgrade is a good fit, the investment is easy to justify and will continue to pay dividends for the long run. MRO

Eugene Vogel is a pump and vibration specialist at the Electrical Apparatus Service Association Inc. (EASA), St. Louis, MO. EASA is an international trade association of more than 1,900 firms in 58 countries that sell and service electrical, electronic and mechanical apparatus. For more information, visit www.easa.com, where you can find a list of Canadian chapters and members.

BY ALLAN RIENSTRA

Ultrasound technology is no longer just for leak testing.

rowing up the son of a farm equipment repairman, I learned at an early age to appreciate the versatility of an eight-ounce ball pein hammer, a spanner wrench and a screwdriver. There was practically no fix too difficult for my dad, as long as he had that trusty triumvirate in his travel box. But he also knew there were limitations and he always drew the line where either safety or quality was compromised through the use of the wrong tool. I owe a lot to his practical lessons.

When I started selling ultrasound detectors in the early ‘90s, the technology was little-known and even less understood. Beyond finding compressed air leaks, no one cared about the technology’s other relevant and interesting applications. This frustrated me, as the applications that got me really excited were mechanical in nature, owing to my upbringing diagnosing farm equipment failures. Transferring my enthusiasm to other people in industry proved my biggest challenge. Many roadblocks were put in my way by old-school thinking and outdated practices.

“Testing bearings and steam traps could just as easily be done with a No. 3 Robertson screwdriver strategically placed on one’s delicate cheekbone,” I had been told.

Since then, 20 years have passed and for the most part I don’t see this antiquated thinking any more. Meanwhile I’ve helped pave the way for future generations of ultrasound inspectors the world over. Testimony to the progress made can be found in a book by me and co-author Tom Murphy, Hear More: A Guide to Using Ultrasound for Leak Detection and Condition Monitoring (published by Reliabilityweb.com).

Anyone who has benefited from the advancements made in ultrasound testing will agree that this technology is no longer just for leak testing. It is a complementary companion technology to vibration analysis, infrared imaging, motor circuit testing and oil analysis. Some will assert that the foundation of any predictive maintenance program should be based on ultrasound first –due partly to its versatility, low cost and easy implementation.

Nowadays, meeting reliability professionals who still believe in archaic methods for the detection of machine faults is rare. That made it all the more surprising when I read Dan Wise’s technical article, Knocking Compressor? All you really need is a screwdriver to find the source of the problem (Machinery & Equipment MRO, Nov. 2011, pg. 22). His message compelled me to climb back on my milk box and scream, “You need ultrasound!”

We take safety very seriously. Inspector training is as much about safety as it is about procedure. So it’s hard for me to look past the obvious hazards that could come from sticking a greasy screwdriver on your ear and then placing the other

end against a knocking compressor valve. It is also difficult to ignore the added risk of working in a noisy compressor room without wearing approved safety gear.

Mr. Wise’s article suggests that ultrasound is unnecessary because the technology “takes time to learn.” Instead, he urges inspectors to develop their skills with a screwdriver “by spending time, each day, paying attention to the sounds of compressors.” His advice is conflicting. Are we better to spend time each day learning his old-school screwdriver technique? Or are we better off to spend our time learning how to use an ultrasound instrument that can do so much more?

We’ve known for more than 20 years that ultrasound provides the earliest warning signals for mechanical failure. If you can hear compressor valves knocking with a screwdriver, you are too late. But, there is a fundamental difference in philosophy between what ultrasound inspection proposes to accomplish and what can hoped to be achieved with a screwdriver.

Ultrasound monitors the condition of that compressor valve from the time it is new until the time it is ready to be replaced, all the while providing feedback about subtle changes in its operational condition. The screwdriver method proposed by Mr. Wise’s article is used “to find the source of the problem,” which suggests the knocking is already perceivable to the human ear and it is only a matter of days, hours or minutes before the compressor will fail. I call this firefighting. It is certainly not condition-based monitoring, as it leaves no room for planning the repair.

article by Mr. Wise warns that “Valves can break without warning for a variety of reasons.” It goes on to list some common causes for failure. The real reason machine systems fail “without warning” is because no warning system is in place. Using a predictive technology, such as ultrasound condition-based monitoring to indicate subtle changes in machines over time, allows maintenance to avoid firefighting catastrophes.

Advanced compressor valve testing

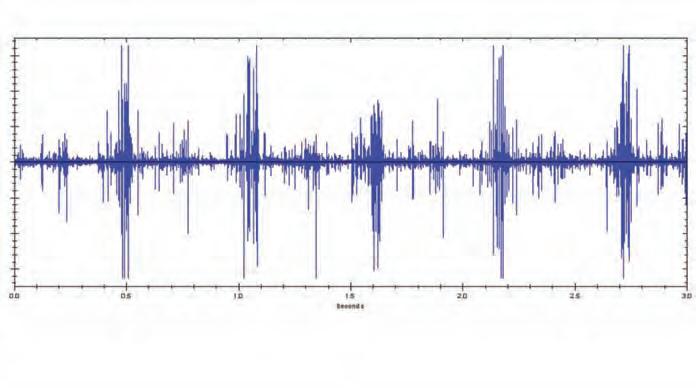

A huge benefit of ultrasound is its ability to record dynamic wave files on reciprocating compressors. Using simple time waveform analysis software, it is easy to expand 1/10th or even 1/100th of a second of data to see a valve open, exhaust and close. During that blink of an eye, we can see if there is complete sealing of the valve seat, and we can even assess the strength of the valve spring.

All of this data can be printed out in a logical report, which serves as a summary for management to decide if further action is yet necessary. Because the document becomes an historical archive, the next action decision will have a basis of comparison.

Reciprocating compressors contain one or more cylinders that compress gases. Pistons travel up and down within the cylinder. On the down stroke, new gas is drawn into the cylinder through an inlet valve. On the up stroke, gas already trapped in the cylinder is compressed and pushed through an outlet valve to a receiver or tank.

In a simple example, vacuum pulls the outlet valve closed and the inlet valve open and pressure does the opposite. In more complex reciprocating compressors, more robust valves operate with springs. Opportunities for failure are many. Seal integrity around the piston cylinder wall reduces the efficiency of compression. Dirty and worn valves do not seat properly due to corrosion and debris build-up around the valve head.

Internal leakage around the piston and the valve head can be detected with ultrasound inspection by recording a dynamic ultrasound signal and analyzing it in the time domain. Early mechanical failures, which can eventually lead to screwdriver-detectable valve knocking, can be seen this way too.

In Figure 1, we can clearly see the impact made by the valve when it is seated and the suction of turbulent air flow when the valve is opened. High-amplitude signals between the valve impacts can reveal mechanical looseness (early knocking) or internal leakage from piston rings or the valve seat. A comparison between similar valves is done easily by scaling the Y-axis of the time signal and presenting it in an overlay or side-by-side mode.

A documented report that can cite the historical evolution of your compressor’s health is an extremely valuable and professional way to present your data. It is a great way to convey to maintenance managers that a problem is escalating and that action is required. It will hold much more credibility than walking into your bosses’ office, grease dripping from your ear lobe, and suggesting that a compressor valve sounds like a “bongo drum” and it should be immediately removed from service. There is no substitution for walking the plant floor and visually taking account of the state of affairs. Much can be learned by talking with operators. Operators have the best pulse on machine conditions, because they work around them every day.

For those who are ready to take the next step (implementation of a conditionbased monitoring program), getting to know the expectations of operations, management and front-line staff is the best approach. From that point, defining the assets that most critically need monitoring is as important a step as figuring out which technologies shall be used to collect the data. Documentation is the final piece of the puzzle and without it, all other initiatives are pointless.

Needless to say, modern techniques for collecting data, which can be trended and reported on, are preferred over archaic methods that rely on individual interpretation and old-school tricks. MRO

Allan Rienstra is the president of SDT Ultrasound Solutions and co-author of Hear More: A Guide to Using Ultrasound for Leak Detection and Condition Monitoring. For more information, visit www.sdthearmore.com. Online Reader Inquiry No. 430

Here are some common questions and answers about ultrasonic cleaning equipment and its performance.

The use of ultrasonic cleaning equipment to clean or degrease parts has gained wide acceptance over the years in all types of industries. And some systems have made significant advancements. Not only does the ultrasonic method provide economic and quality advantages, the superior cleanliness it produces also can mean that items look better, perform better and require less frequent subsequent cleaning.

ing filler valves with a powerful acid. This manual work required him to suit-up and wear heavy gloves to clean the valves with a brush. Because there were so many of these relatively intricate valves to clean, the man put in extensive overtime.

“We brought in an ultrasonic unit and proved that the task could be accomplished better, much quicker and with no exposure to the caustic solvent,” Pedeflous says. “So, it not only made good economic sense, it also removed a safety issue.”

How do I know what size of ultrasonic cleaner is best for my operation? Pedeflous advises those who are thinking of purchasing ultrasonic systems – either for the first time or an additional unit – to talk with suppliers who carry a full range of equipment sizes and models.

Common sources of problems in ultrasonic cleaning include changes in lubricants, manufacturing processes and even raw materials.

In recent years, ultrasonic cleaning has become an indispensable tool for industrial users, including those in automotive, aerospace, food and drug, utilities, electronics and semiconductor cleaning. It works anywhere degreasing or getting the debris and contaminants out of passages and crevices is needed, or where a likenew surface appearance is beneficial.

At the same time, some performance questions frequently are asked by users who have an ultrasonic cleaning system and those who are considering the purchase of one.

“While there are few specific rules for benchmarking the performance of an ultrasonic system, there are some general considerations regarding the overall need for a new system, or evaluating the day-to-day performance of your present system,” says Frank Pedeflous, president of Omegasonics Ultrasonic Clean-

ing Systems, Simi Valley, CA.

How do I know when it’s time to advance to ultrasonic cleaning? If you are evaluating whether to switch to ultrasonic cleaning, you also need to evaluate how you are cleaning the itemsin-question now, and the results you are getting. Results can be measured in terms of the labour, time and cleanliness of the work pieces you are cleaning now. It can also be measured in terms of safety – the risk via exposure to solvents and other harsh chemicals that may be harmful to workers and the environment.

In a majority of instances, ultrasonic cleaning is much more efficient and costeffective than manual cleaning or other methods of degreasing. Pedeflous recounts a recent instance when his firm performed a comparison for a bottler who had an employee working solely on clean-

“In many instances, an operation can do fine with a tabletop model at one or more locations. That gives them production flexibility,” he says. “In other applications, feature-rich models with capabilities such as ‘set-and-forget’ tanks may help boost productivity.

In terms of applications, ultrasonic cleaning systems are used to cleanse or sanitize a wide variety of items that are sometimes intricate, require precision or are delicate. Of course, the technology is also highly effective in cleaning more robust items such as components used in automotive, marine, aerospace and various industrial applications.

Why aren’t my work pieces getting as clean today as they did yesterday? “The usual answer to that question is: Something has changed,” says Pedeflous. The change, however, is not always found at the cleaning station, he adds. Once temperature, chemical concentration and all other cleaning parameters have been ruled out, the search should proceed to consider changes in the manufacturing steps.

Common sources of problems include changes in lubricants, manufacturing processes and even raw materials. Clogged filters, misdirected coolant nozzles and improper machining or finishing practices may also cause ultrasonic cleaning problems. Remember, a change that may be considered inconsequential to the manufacturing process may result in less effective cleaning – until the necessary adjustments are made.

How much ultrasonic power does your cleaning tank require? The right amount of ultrasonic energy (usually ex-

pressed in watts/gallon) depends on the size of the cleaning bath and the difficulty of the cleaning requirement. Tanks in the one- to two-gallon range often provide up to 90 watts per gallon of ultrasonic power, plenty for most jobs, even cleaning out the ultra-fine passages of fuel injector nozzles.

“Achieving the same cleaning effect in larger tanks requires less energy density,” advises Pedeflous. “Excellent cleaning has been demonstrated in tanks having 50 gallons capacity with only 25-30 watts per gallon. The more difficult the application, the greater energy density is required for effective cleaning.”

On the other hand, too much ultrasonic power may result in cavitation erosion occurring on delicate or highly polished parts that are near the transducer-radiating surface. Cavitation is the formation and collapse of low-pressure bubbles that can pit the surface of metals. Aluminum, copper, brass and other soft metals are especially susceptible to cavitation erosion.

What is degassing and why is it important? Degassing is the process of removing small, suspended gas bubbles and dissolved gas from a liquid prior to using it for ultrasonic cleaning.

“Unless you remove the dissolved gas, it can migrate into cavitation bubbles during their formation,” says Pedeflous. “This prevents the bubbles from imploding correctly, which reduces the cleaning effect. Also, the gas bubbles will absorb ultrasonic energy, reducing the ultrasound cleansing intensity inside the tank.”