Precision decisions

The difference precision manure management makes. | 8

Know thy manure

A Minnesota project comes to fruition. | 11

Let them cook The latest on biochar. | 18

May/June 2024

Precision decisions

The difference precision manure management makes. | 8

Know thy manure

A Minnesota project comes to fruition. | 11

Let them cook The latest on biochar. | 18

May/June 2024

Storage needs, sampling and other techniques may differ on smaller farms, but they’re equally important.

BY JAMES CARELESS

JAMES CARELESS

RONDA PAYNE

The nice thing about trade publications – like Manure Manager – is that we write about niches (I’ve heard there’s riches in those)! Only a small percentage of people in North America are this personally interested in the application, storage and management of livestock manure, but those who are, are very interested. That’s why the North American Manure Expo is simultaneously: a) the only farm show completely dedicated to manure management; and b) always well attended by some of the most enthusiastic individuals you’ll ever meet.

But that doesn’t mean all Expos are the same. Because we change locations every year, we will meet people with different needs – different regions mean the predominant livestock industries vary, as do the size of farms, local regulations around manure, etc. This means storage needs, processing priorities, application timing and even road rules are all different!

This year, the North American Manure Expo will take place in Auburn, NY, in the beautiful Finger Lakes region

busier spring and summer seasons for applicators. Some states will have a tougher time than others retaining talent. In some states, there is a natural inclination toward the idea of your children taking over business operations when you retire, whereas some areas are trending away from that tendency.

This is also why intelligence and insights into our market are not a niceto-have, but a must-have. This summer, we are launching an industry survey about business operations in the for-hire manure applicator industry. We want to hear from applicators on how the economy and environment are affecting the way they do business – how they attract, hire and re-hire talent, how they train and what they feel they do and do not have time for. We might see some broader industry trends, but some issues might be more pronounced in different parts of the country.

The industry is niche, but that doesn’t mean everyone has the same goals, challenges or benchmarks. For example, national-level targets on greenhouse gas emissions are going

“Intelligence and insights into our market are a must-have.”

– which looks quite different from Wisconsin, where we were in 2023. Or look at our 2022 show in Pennsylvania, where hogs are a bigger part of the conversation – according to data from the USDA obtained between December 2023 and January 2024, hogs represent 12.6 percent of the state’s livestock heads, compared to a much smaller percentage in Wisconsin or New York.

This also means that the labor needs and concerns will vary from region to region. Some states will boast

to be easier for some states to meet than others depending on resources, geography and other factors that have been in place for decades.

That’s why I am excited to head to another new state for the Expo this year to learn about the challenges and triumphs of the ag industry in New York State – and something I’m also looking forward to in Ohio in 2025.

Have a great summer, and remember to savor the few free moments you have, appreciating all your progress.

For more info visit huskyfarm.ca or call 1-800-349-1122

Trailing shoe booms from 6m to 30m in width. BlackBird trailing shoe booms in stock Summer 2024. Various incorporation options available. Contact us for more info on tank sizing options.

The USDA has detected highly pathogenic avian influenza (HPAI) in dairy cows in some areas of the U.S. According to the USDA’s Animal and Plant Health Inspection Services, HPAI has been detected in dairy milking cattle in: Idaho, Michigan, Texas, Kansas, New Mexico, South Dakota and Ohio. All data is current

as of April 24. There have been no detections in Canadian dairy cows. Risk of human transmission remains low and pasteurized milk remains safe to consume. Clinical signs of an infection in cattle include a decrease in milk production and/ or feed consumption and a thicker consistency of milk. The animals

appear to recover within one to three weeks, and the disease does not spread as quickly between cattle as it does between birds. No cows have died from the virus so far, and the World Organisation of Animal Health (WOAH) does not recommend restrictions on the movement of healthy cattle and their products.

In response to HPAI being detected in U.S. dairy cows including in the state of Michigan, Michigan State University Extension has published an article on manure management practices in dairy herds specifically for disease control. It is known that infected cattle shed the virus in milk, and other secretions including feces are considered “plausible sources” of infection, although this is not yet proven. Nevertheless

it remains imperative that livestock farmers and manure applicators practice safe biosecurity as a line of defense against the spreading of HPAI and other diseases. Important steps recommended by MSU include:

• Practice open communication about the application of manure, whether infected or not. This includes informing the owners of neighboring farms

BY THE NUMBERS: MANUREDB

5

Number of laboratories recruited for the preliminary study.

100,000 500,000

Manure samples shared from the five labs between 2012 and 2021.

Estimated number of samples currently in the database, from 14 participating laboratories.

and anyone who might be using the same routes as you to transport manure.

• If spreading infected manure, avoid roadways commonly used by anyone else who might be hauling manure, and use fields away from main roadways and livestock areas.

• Create designated footpaths and vehicle routes on the premises in order to dimmish crossover between applicators and farm employees and/or visitors.

• Keep detailed records.

• Properly, thoroughly disinfect and sanitize equipment between uses.

• Have dedicated equipment, including footwear and clothing, for manure transfer and application. Or, utilize disposable coveralls and booties.

65

Different animal types included in the database.

states represented in the database.

%

2004

Year the Midwest Plan Service published book values of manure.

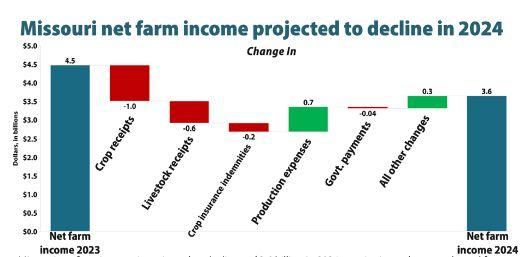

University of Missouri’s Rural and Farm Finance Policy Analysis Center (RAFF) has predicted a decline in net farm income in its latest Missouri Farm Income Outlook.

The report offers a statelevel glimpse at financial trends and indicators in the state’s farming sector based on receipts, production expenses and other components. The report estimates a $0.8 billion decrease in net farm income for 2024, based on declining market receipts and lower crop prices. The decrease indicates a drop of 18 percent.

Scott Brown, RAFF interim

director said in a statement that the report indicates “some relief” because of decreased production expenses. However, “Reduced livestock inventories and lower crop prices are impacting Missouri producers.”

It is important to note that Missouri’s net income decrease under-indexes against the general U.S. trends; the report estimates a 25.5 percent decrease in U.S. net farm income. Missouri’s projected decrease in net farm income is driven more by crop receipts (which are estimated to decline by 11 percent) than livestock (projected to decrease by nine

The National Pork Producers Council will return to Des Moines on June 5 and 6 for the 2024 World Pork Expo.

The World Pork Expo, which has been ongoing since 1988, attracts approximately 10,000 pork producers and industry professionals every year. Exhibition space exceeds 300,000 square feet, and the 2023 edition saw nearly 400 North American companies on-site as exhibitors and sponsors.

The goals of the Expo include spreading education and business insights, connecting producers and professionals with new technology and providing opportunities for networking and camaraderie. “Producers come to Expo to reconnect with their peers, to share and exchange ideas,” said Scott Hays, National Pork Producers Council president and Missouri pork producer, in a statement.

percent). Cattle and hog cash receipts could also see recovery in the next calendar year, along with Missouri farm income in general. Production expenses are forecast to decrease by five

percent in 2024, driven by lower costs for fertilizer, feed and fuel. However, expenses for purchased livestock, seed, labor, taxes and capital consumption continue to increase.

The Ontario government is investing up to $836,250 over three years to increase the capacity of rural volunteers and organizations across the province. The Ontario Association of Agricultural Societies is partnering with the Rural Ontario Institute to provide training and workshops that will enhance leadership and governance skills, as well as management practices.

The funding will help the Ontario Association of Agricultural Societies partner with the Rural Ontario Institute to provide educational supports focused on leadership, governance and community engagement to more than 200 agricultural societies across the province.

It will also aid the development of other resources that will help

agricultural societies hold fairs and events promoting agriculture and the agrifood industry.

“Ontario’s agricultural societies play an important role in leading amazing, annual rural community activities. This educational initiative will enhance the leadership, governance skills and best management practices in important rural organizations, and by extension our agriculture and food industry across the province,” said Lisa Thompson, Minister of Agriculture, Food and Rural Affairs in a statement.

“By investing in people who give so much to maintain our rural traditions and communities, we are showing our appreciation for their commitment and leadership.”

University of Saskatchewan’s Jeff Schoenau shares lessons learned from research on precision manure management.

BY JAMES CARELESS

Science has proven it: Taking a ‘one size fits all’ approach to manure application is not the best way to stabilize crop yields and reduce nutrient runoff from manure applied to fields. Instead, a precision approach to manure application that takes a field’s unique characteristics into account and uses this data to regulate the dosage delivers the best results.

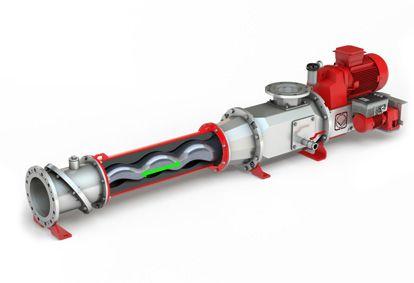

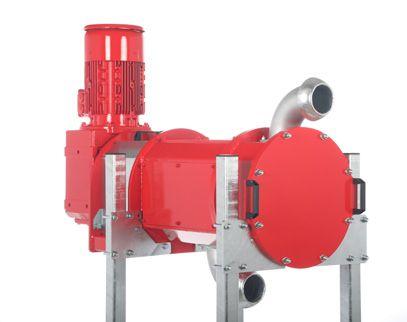

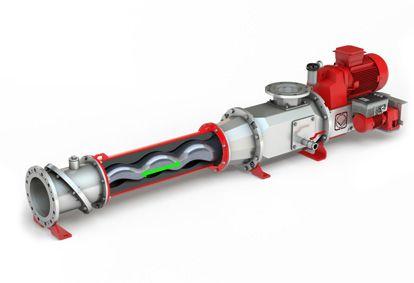

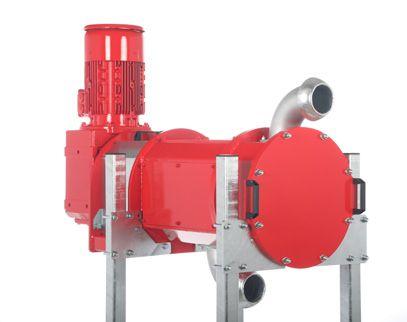

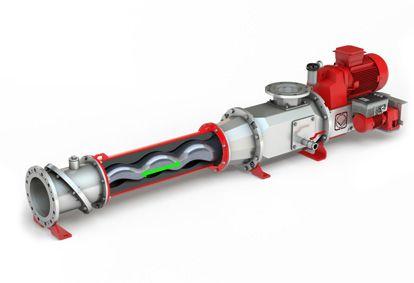

This truth was clearly demonstrated in a multi-year ‘Precision Cattle Manure Management’ study conducted at the University of Saskatchewan Livestock Forage Center of Excellence near Clavet, Saskatchewan. The field research was from 2018 to 2022, with the aid of numerous research partners across

university and government.

“Our goal was to evaluate the agronomic and environmental performance of precision variable rate application of cattle manure with setback from water bodies, compared to traditional constant rate application,” says study co-lead Jeff Schoenau, professor of soil fertility and at the University of Saskatchewan.

“I’ve done quite a bit of work in the past with liquid manure and ways of using it more effectively, including injection into the soil. And with the opening of the Livestock Forage Centre of Excellence with the Beef Cattle Research and Teaching Unit at the U of S here around 2018, we had the

ABOVE Manure used as part of the Beef Cattle Research and Teaching Unit study.

opportunity to obtain a manure applicator that had variable rate capabilities. So that led to the development of a proposal and the onset of the project.”

The reason Saskatchewan is so interested in precision manure application is the variability in this province’s soils. Factors that cause this variability include landscape and parent material variations that cause fluctuations in available nutrient and organic matter content in the province’s farm fields. Since cattle manure adds both organic matter and nutrients to these fields, “we theorized that there would be a benefit in applying more cattle manure to those areas of the test field that were lower in organic matter and low in nutrients, while cutting back or eliminating application in those parts of the field that already had plenty of organic matter and high levels of available nutrients,” says Shoenau, who is also the Saskatchewan Ministry of Agriculture soil nutrient management chair in USask’s department of soil science, College of Agriculture and Bioresources. “So that was the strategy that we took – comparing a traditional manure application where you just apply a constant rate across the field to a precision approach where manure application is varied across the landscape. Another part of our precision cattle manure application treatment was that we employed setbacks from areas in the field where water would accumulate from spring snowmelt runoff or heavy rains. Those were areas of the field that we did not apply any manure at all.”

According to the Saskatchewan Soil Information System (2019), the field chosen for the precision manure application study is primarily composed of Bradwell Orthic Dark Brown chernozemic soil with Bradwell Eluviated Dark Brown chernozems on its lower slopes. It was split into three zones of approximately 40 acres to provide comparative data, with each zone having three replicate micro-watersheds. One zone underwent only commercial fertilizer applications to serve as the study’s control. The second zone experienced conventional constant rate manure application across the entire landscape, and the third underwent variable rate precision manure application with setback from watershed basin centers.

The manure applications for the constant and variably treated fields were done in spring 2019 and spring 2021, after the snow had melted but before the fields were seeded with silage barley. Water samples were collected from the watersheds prior to treatment in 2018 and 2019, and afterwards in 2020, 2021 and 2022.

According to the final report on the project filed with the province’s Ministry of Agriculture (‘ADF 20170025 Precision Cattle Manure Management For Agronomic and Environmental Benefit at the U of S Beef Cattle Research Unit’), the functional goal of the cattle ABOVE

A barley field that was used as part of the study.

When the going gets tough, turn to the toughest pumps in the field. Vaughan has unique configurations for: • Barn Finish Pits • Separator Feeds • Lagoons • Digester Mixing • Scraped Manure • And More! 888-249-CHOP | CHOPPERPUMPS.COM

ABOVE

An example of solid, variable rate manure application.

manure application rate used in the study was “to meet the anticipated phosphorus requirements of silage barley grown on the field over the study period”.

To achieve this goal, “We used 40 acre zones for each of our treatments,” says Schoenau. “Our dosage prescription was pretty simple: Where we had areas of low long term productivity identified by Echelon NDVI imagery of the field, we applied higher rates of manure, and where we had areas of high productivity like in the depressional areas, we cut back. So we were putting generally more manure on the knolls, cutting back in the depressions and eliminating manure application in the watershed basin centers in our precision variable rate treatment.”

The subsequent measurements that were taken to compile data and support conclusions included silage barley yield and nutrient uptake, soil nutrients, phosphorus, nitrogen and coliforms in run-off water, greenhouse gas production, soil carbon and nitrogen amount and cycling, and any hormones found in the soil, water and manure.

According to the precision manure application study’s final report, “The

total silage barley yield, nitrogen and phosphorus uptake over the five years was similar among the three treatments, but with variable rate manure treatment resulting in more uniform production across the landscape.” In other words, tailoring the manure dosage to the ‘lay of the land’ ensured that all areas delivered consistent barley yields.

At the same time, “Post-harvest surface soil nitrate and phosphate levels were lower in low slopes and depressions of the variable rate treatment zone,” said the report. “This was consistent with the observed slightly lower amounts of soluble P [phosphorus] and N [nitrogen] in runoff water observed in the variable rate treatment compared to constant rate. Soil nitrate levels at 30-60cm and 6090cm depth were greater in the constant rate treatment zone than the variable rate and commercial fertilizer zones, which may reflect the observed additional mineralization of manure organic N to nitrate in depressions without set-back followed by leaching by spring snowmelt run-off. No phosphorus or nitrogen loading was evident from the manure applications after five years.”

Worth noting: Both constant and variable manure applications “did not

have a large effect on nutrients and coliform bacteria in snowmelt runoff when compared to the inorganically fertilized control,” the report said. “The E-coli in snowmelt was not affected by manure application but rainfall-generated runoff in 2019 and 2021 following manure application had elevated counts of the pathogen.”

As well, there were lower nitrous oxide emissions “observed in the basin centers of the large catchment area watersheds in the variable rate treatment compared to traditional constant rate [treatment],” said the report. “The variable rate manured watersheds were also a stronger CH4 [methane] sink than the constant rate manure watersheds.” Not surprisingly, total soil nitrogen mass was boosted in both manured zones compared to the control zone, while neither showed any “measurable hormonal concentration [that] could be detected in soils or snowmelt water in any treatments.”

The bottom line: “Overall, the variable rate precision manure application strategy appears to provide agronomic and environmental benefits compared to traditional constant rate manure application,” the report said. In plain language, adjusting manure application rates to reflect field characteristics is good for crop yield and for the environment.

With hard data like this at hand, it seems obvious that farmers who adopt the precision manure application approach can expect more consistent crop yields and reduced environmental impacts on their fields.

These results came as no surprise to Schoenau. “Low lying areas of fields on the prairies often have quite high organic matter and fertility to begin with,” he says. “So they generally don’t need too much more organic matter and nutrients added, whether it’s manure or fertilizer. Meanwhile, that smoothing out of production across the field area can offer some benefits in improved harvestability of crops. Then there’s the environmental benefits that we see from this as well.”

The overall conclusion is that precision manure application delivers the results that one would hope for, on all fronts. This is why farmers who apply manure to their fields will want to consider adopting this approach themselves. •

BY JAMES CARELESS

Which nutrients can be found in manure these days, and in what proportions? And how can this information be used to aid farmers in applying the right kinds and amounts of manure as fertilizer?

Answers to these and other manure-related questions can be found online at ManureDB (http://manuredb.umn.edu). Short for ‘Manure Database’, ManureDB collects nutrient data garnered from standardized manure laboratory analyses and then creates updated ‘book values’.

The website then organizes this data by year, manure source, and nutrient composition by percentage (total solids, nitrogen, phosphorus, potassium, sulfur, and ammonium-N), so that users can make informed fertilizer decisions.

Melissa Wilson is one of the driving forces behind ManureDB. She is an associate professor at the University of Minnesota who works in extension and research, with a focus on manure management.

Nancy Bohl Bormann is a PhD candidate at the University of Minnesota whose main project during graduate school was working on ManureDB.

Manure Manager magazine spoke with them both about the genesis, structure, and usefulness of ManureDB. Here is what they told us.

ABOVE

Manure Manager: What is the story behind ManureDB?

Melissa Wilson: When I first got to Minnesota, one of the things that I really started thinking about is how we don’t really have good book values of what manure nutrients look like that are recent. All of the book values that we have are from the early 1990s-2000s, and things have significantly changed since then — whether it’s diets, we’re raising bigger animals, all of those sorts of things. And all of those will influence the nutrients that are in manure.

Nancy Bohl Bormann: My thesis advisors Dr. Melissa Wilson and Dr. Erin Cortus at the University of Minnesota proposed this project and received grant funding for a U.S. manure test database in 2020. As manure management experts they get questions about what are expected nutrient values for different manure types, and they have noticed some differences in current manure samples and published book values. Many of the published book values or approximate nutrient concentrations were gathered over twenty years ago, usually from just a few states.

Animal feeding, housing, genetics, manure storage and handling, and nutrition continue to evolve, influencing the nutrient concentrations in manure.

So ManureDB was created to aggregate manure analyses from across the country into a dynamic database in partnership with the Minnesota Supercomputing Institute. The accompanying ManureDB website was publicly launched in summer of 2023, with the data download feature released in January 2024.

MM: What values are covered in the ManureDB charts, and why?

Wilson:A lot of times when people call me and ask for typical nutrient content of manure, they’re often looking for nitrogen, phosphorus, potassium, and sometimes other nutrients. I get questions about sulfur. Sometimes we get questions about how much carbon might be in manure, some of the micronutrients, some of the secondary nutrients like calcium and magnesium as well. So we included all of that information in the database.

There’s also characteristics, like solids content, and some of the other information that we included would be animal species. If we know where the samples came from, what kind of storage system they came from, that information might be included. So it’s basically anything that would be included

when a submitter takes a manure sample and sends it to a lab, whatever information they include for that manure sample will potentially come to us. The only thing we don’t get is any personally identifying information. So at most we will know the state that the manure came from, maybe the first three digits of the zip code, if that’s shared with us, but not the full zip code. We don’t have addresses, we don’t have customer names or anything like that.

Bohl Bormann: Currently on the homepage you can review some summary statistics for beef, dairy, swine, poultry, sheep, and horse for the analytes of total solids, total nitrogen (N), phosphorus as P2O5, potassium as K2O, sulfur, and ammonium-N. All of these are shown with units as percent and on a wet (as-received) basis. We encourage use of the median values, as outliers have less influence on them compared to means (averages).

MM: How is the data compiled?

Bohl Bormann:First, a data use agreement is signed between the laboratory/data partner and the University of Minnesota as data privacy is an utmost concern.

The data arrives in spreadsheets from the laboratories, and we ensure it fits our standardized data template. It then passes through two validation steps prior to uploading to the database where the data is stored in common units for all analytes.

MM: How is the data being used, and who is using it?

Wilson: There is actually a wide range of the manure user community, people that would use this information. And we see it kind of helping farmers who might be planning new manure storages because they want to know how much nutrients they might have in that storage in a given year. So that helps them plan.

We have agricultural consultants who might be writing manure management plans, and if they don’t have a good idea of what the nutrient content is of the manure that they’re planning for, they can look up these book values. And it’s also really good for farmers and ag consultants to compare their manure samples to regional values, to see if there is something off. Are they running in the normal ranges? Is there something they need to tweak?

So, we see the agricultural community

be operated in unison or independently.

• Available in 30’ and 40’

• Full galvanized frame

• WER Distributer

• Rear hitch (max towing 5000 lbs)

• Available in 30’/40’/60’

• Full galvanized frame

• WER Distributer

• C/W ball blow-out

• Rear hitch (max towing 5000 lbs)

TPH COILER

Use as a stand alone unit, or as an addition to a developing drag line system. (3 models available).

HOSE MOVER

The telescopic hyd width adjustment provides a large surface radius when moving hose.

INLINE CHOPPER

Improve productivity by reducing blockages in the drag line system and reduce pump repairs. DISTRIBUTOR

The high grade chopping system, and auto-reverse function, ensure an obstruction free distribution.

SPREAD BOOM

Maximize Efficiency with better spread. Heavy duty construction & galvanized frame.

using it that way, but we’ve actually had a lot of interest as well for researchers who are doing modeling or other exercises, looking at nutrient content of manure, they can actually get real numbers instead of using these old numbers from the 2000s. And that helps improve the models or whatever they’re trying to do for their research.

Bohl Bormann: Since manure is so variable in nutrient concentrations, having an actual manure test for your farm is always the best for calculating application rates. However, when creating nutrient management plans for new farms with no manure history, comparing regional nutrient values for an animal type, wanting to benchmark your farm’s manure, or use in agricultural research, this could be a helpful resource.

MM: What overall value does this data provide to your users?

Bohl Bormann: This is the largest project of its kind that we are aware of, and it is planned to continue collecting manure sample data on an annual basis to keep the database growing and current. Caution must be used with the data however, as not all samples have great detailed metadata, such as manure storage type or animal life stage. Some parts of the country have greater lab participation, and therefore have more samples to influence the database. We plan to archive the data annually in USDA’s Ag Data Commons.

MM: Beyond helping with application rates, what else is this information useful for? Could it inform decisions such as storage, or even decisions made at an animal level; such as diet?

Bohl Bormann:The project accepts whatever analyses a laboratory runs on samples, so besides macronutrients, we record micronutrients and metals, along with other ratios and measurements. A researcher was interested in the carbon content of manure, and while that is not a routine measurement, we did have some samples with carbon measured. Other less often measured analytes such as chloride are available for review. A laboratory had some detailed information on poultry litter treatments and bedding types that could be of interest for comparisons. Having increased metadata included with sample results will add more utility for other uses.

MM: What response have you been

getting to ManureDB, and what impact is it having in the industry?

Bohl Bormann: We have received interest and excitement for the project from parties working in all sorts of aspects of manure management and our website analytics show people from 20 different countries have visited the website. Again, this is a very new resource that is continuing to evolve, and we are still working to add collaborators and more data while improving the website.

Wilson: We’ve actually had a lot of positive responses even from areas of the industry that we hadn’t even considered. For instance, the American Biogas Council is really interested in knowing what kind of gas production they could get out of manure. So they’ve been really interested in trying to help us find data to put into the database so that they can use it for modelling those sorts of things. So it was kind of an interesting factor that we hadn’t really even considered.

But even with our farmers, I can pull data from the database that’s recent and relevant from Minnesota, the upper Midwest — wherever it may be — and show them what the trends are looking like over time, and what the trends are currently. They’ve

been really interested to see this data because they might know their barn or the barns that they work with, but they’ve been really intrigued to see how that compares to what we see kind of in the regional averages. So overall, it’s been pretty positive.

MM: What are your future plans for ManureDB?

Wilson: Our plans are to get continued funding so that we can have updates annually. Right now, all the data that we’ve pulled from different labs around the country, they’ve given us data as far back as they can. So we have some data back into the 2000s up through current. Sometimes labs are more recent where they can only give us five years, 10 years, and so forth. So just kind of filling out the database more, getting more lab partners from different areas of the country will definitely be helpful. Right now, we have manure samples from almost every state except for Alaska. Having that regionality will be really important moving forward, because right now all the book values that we have in the country are national and they typically are not necessarily representative of all the different regions. •

Manure management is beneficial to farms of all shapes and sizes, but small farms require specific care when it comes to storage, sampling and more.

BY JACK KAZMIERSKI

While larger farms see manure management as an essential and integral part of their overall operations strategy, sometimes smaller farms have trouble with the idea that manure has to be managed, and that it’s simply not going to disappear on its own.

Mary Keena, extension specialist at North Dakota State University (NDSU) says in her experience, some owners of smaller farms simply didn’t think about the need for manure management before acquiring animals.

She says people are almost surprised when they realize that they’re going to have to contend with manure on a regular basis. “I often hear things like, ‘What are we supposed to do with this stuff,’

or ‘I didn’t know they would make so much. Nobody told us,’” Keena laughs. “I hear that quite a bit. I think that manure is a bit of an afterthought for some people and it tends to kind of sneak up on them. They suddenly find themselves with two feet of manure in their corrals, and they don’t know what to do with it.”

In North Dakota, Keena explains, a lot of farmers have between two to five horses, and often manure management isn’t part of the planning process. It’s not something they think about before purchasing their horses. “They’re great animals,” she says, “And they’re a lot of fun, but then they poop. And nobody thinks ahead about what they’re supposed to do with all that manure.”

The problem can be exacerbated in situations where these smaller farms are located close to city limits. “The neighbors will complain about the piles of manure,” adds Keena. “Not only are they unsightly, but they smell bad too.”

The first step in a successful manure management strategy is planning. According to Keena, this means figuring out where the manure will be stored. “If you have a smaller farm,” she explains, “and you have your animals in a barn, during the winter, then you might be removing the manure and putting it right outside the barn door. But in the spring, you’re going to need to move that manure, because right outside your barn door is not a good storage area.”

Rather than handle the same manure twice, Keena recommends using a more permanent manure storage facility. “You only want to move it once,” she adds. “You want to take it out of the barn to a more permanent area where you can let it sit to burn down so you get a volume reduction, or you’re going to compost it in the spring and summer, and then use it.”

One of the key considerations when choosing a location for manure storage is safety. “We want a place where we’re not going to pollute groundwater or surface water,” explains Keena. She recommends a non-porous surface, like a concrete slab or clay, and a place where there’s no risk that floodwaters can wash out the manure pile in the spring or summer.

Sarah Fronczak, Michigan State University Extension environmental management educator agrees. “Safe storage would be in a manure storage

facility,” she says, “and that means a three-sided manure storage facility with an impermeable base of some sort. It’s even better if it has a roof.”

Neither Keena nor Fronczak recommend temporarily stacking or storing solid manure directly on the ground. As far as liquid manure is concerned, Fronczak says there are a number of options. “It could be an above-ground storage facility that is engineered to hold liquid manure, or it could be an in-ground pit of some sort,” she explains. “However, I don’t see a

lot of these kinds of facilities on very small farms, because they don’t tend to produce a lot of liquid manure on smaller farms.”

Another key consideration is access. In other words, is the area that has been selected for manure storage easily accessible? You’ll need to get equipment in there in order to turn the pile of manure when it’s composting, so think about whether you’ll be able to get that equipment in and out with ease?

“If you can’t get into the area and turn that pile, then composting is going to be very hard to do, because turning is a huge part of composting,” explains Keena.

Depending on the size of the farm, you might be able to turn the manure with something as small as a pitchfork, or you may need something as large as a tractor. Either way, you’ll want to make sure you can access the area where the manure is stored in order to turn the pile regularly.

Easier said than done – composting is a science that requires the right amount of heat and moisture, explains Keena. The carbon-to-nitrogen ratio is another key consideration, and it varies dramatically, depending on the source of the manure. Keena is the lead author of a guide, published by the NDSU, which offers detailed advice on how to properly compost manure. The guide is available here: https://www.ndsu.edu/agriculture/ extension/publications/compostinganimal-manures-guide-process-andmanagement-animal-manure-compost.

Composting can also be an added source of revenue for smaller farms, explains Fronczak. “Different states have different rules about how you can package and sell compost,” she adds. “So I would recommend that farmers check with whichever agency is in charge of that in their state.”

Compost, or even the manure itself, can be sold to a variety of clients, including farmers and homeowners with a garden of their own. “Gardeners will come in and happily take a pickup truckload,” says Fronczak, “And depending on the price of nutrients, you may or may not want to charge for that.”

Many smaller farms, Fronczak explains, don’t charge for manure because they simply want to get rid of it. “But we’ve seen a spike in the cost

of nitrogen and phosphorus in recent years, and people have been selling a lot of manure,” she says. “So depending on what’s happening with the markets, it may or may not be profitable to do so.”

If you opt to keep the manure and spread it onto your own fields as a fertilizer, you can do the job yourself, or you can hire a third-party to do the job for you. The latter is a common practice with larger farms.

“You can hire the folks that spread for larger operations,” adds Keena. “Just keep in mind that their equipment tends to be bigger, so you have to consider whether they’ll be able to access the area where you’re storing the manure, with their larger equipment.”

It may also make sense to work together with a number of your neighbors when hiring a contractor. “Sometimes, it’s easier for applicators to have several smaller farms get together,” Keena says. “So if six of you want manure spread, it may only take them half-an-hour at each locations, but by working with your neighbors, you’ve now made a full day for them.”

If you’re doing it yourself, Keena says you can use smaller spreaders that are able to handle smaller quantities of manure. These can be pulled with something like an ATV of even a lawn tractor.

In a perfect world, smaller farms would be able to convert all the manure they produce into fertilizer or compost for use on their own fields. However, in some cases, animals may produce more manure than a smaller farm could possibly use.

“If you’ve determined that you have more manure or compost than your land needs, you can always partner with a neighbor, if that’s something that’s available to you,” explains Keena. “Does your neighbor have cropland, hay land or pastureland that they’re willing to let you spread the manure on? Or do you have a community supported agriculture program, or a produce grower who needs some product for their greenhouse or their fields?”

In some cases, smaller farms may be tempted to simply put the excess manure into a dumpster and treat is as garbage, but Keena doesn’t recommend doing so because it’s a valuable commodity.

“If you have to let your manure sit in long-term storage for a few years, then that’s what you do,” she says. “It’s not a big deal. But if you’re on the edge of a city limit, then that tends to be an issue, because people don’t want to see your manure pile sitting there.”

Fronczak notes that depending on the size of the farm, and where it’s located, sometimes landfills can be a

smaller farm’s go-to solution. “I see that a lot inside of cities, or near cities, where they might have horse riding facilities, for example, and simply don’t have the land to spread manure on,” she says. “So they’ll have a dumpster and they’ll send the manure to a landfill.”

While sending manure to the local landfill may not be the best practice, for smaller farms that are closer to the city, it may be the only solution, just as long as the local landfill allows it. “It’s going to be less disturbing to your neighbours,” Fronczak adds, “and you won’t get called out for the smell and the bugs.”

If the entire process of managing manure seems overwhelming, Fronczak is co-author of the “Small Farm Manure Management Planning” report, which goes into detail about all aspects of manure management for smaller farms, and can be downloaded here: https:// www.canr.msu.edu/resources/smallfarm-manure-management-planning Like it or not, manure is a fact of life, and a daily part of farming life. It doesn’t matter whether a farm is large or small, manure needs to be managed effectively, or it will get out of hand. Fortunately, there’s a wealth of information and guidance available to help farmers properly store, compost, spread and even profit from a commodity that simply can’t be ignored. •

BY RONDA PAYNE

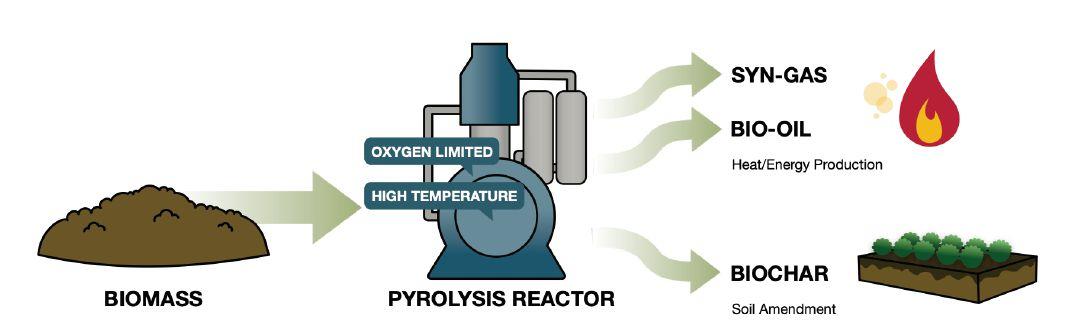

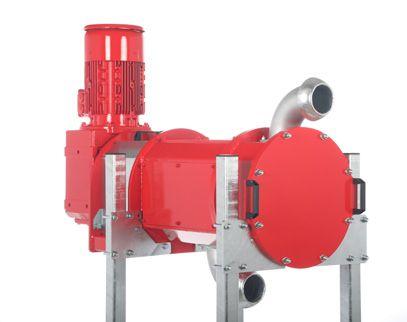

Biochar, the solid resulting from organic biomass material being heated at controlled, high temperatures with limited oxygen (pyrolysis), has long been hailed as a source of carbon and other nutrients for agricultural purposes. With its black, porous, lightweight appearance, it looks similar to charcoal, but without the fiery process to creation.

Although biochar has been used as an agricultural amendment for more than 2,000 years, and has more than a few scientists, advocates, environmentalists, producers and suppliers behind it, it has yet to be incorporated into the modern, commercial-scale agricultural world as a regular treatment to advance soil health.

Researchers in Wisconsin are hoping they can move biochar to take its place in the sun, as well as fields and gardens, by proving the benefits our ancestors seemed to know inherently.

Joseph Sanford, assistant professor in soil and crop sciences with the University of Wisconsin, Platteville has been working with a team to prove the efficacy of biochar in agricultural applications through two studies.

STUDY #1: STUDYING PLANT HEALTH RESULTING FROM THE USE OF BIOCHAR

“There’s not been a ton of biochar field studies,” he explains. “Particularly not in the Midwest. There’s been a lot of lab-based studies. This would be the only study that would look at making biochar from manure and then applying it to field plots and then studying the health of plants.”

This first study, conducted at the Arlington Research Center in Arlington, WI, will explore the benefits to plants of biochar applications to the soil at various rates. All plots (including the control) will have manure applied to them and will look at biochar application of one ton per acre, 2.5 tons per acre and five tons per acre.

This is a large field trial and to Sanford’s knowledge, a similar study has yet to be conducted.

“We will look at ammonia emissions,” he says. “And throughout the year, will look at greenhouse gas emissions. At the end of the year, we’ll look at yield.”

Soil nutrient retention will also be explored.

“We’re going to be looking at the soil throughout the year,” he says. “From the soil health perspective, what impacts are there?”

Biocar, derived from manure, is created through a process known as pylorization.

Fellow researcher, Rebecca Larson, associate professor in biological systems engineering with the University of Wisconsin, Madison, says biochar is one of the more promising developments in terms of carbon sequestration.

“Biochar has more longer-term potential for carbon sequestration that we think. How does that impact it when you apply it to the land?” she inquires. “How it reduces emissions during application.”

By applying manure to all plots, the view of how biochar can be of benefit in manured-systems will be significant to dairy and housed-livestock operations. Granted, these farms would need to invest in the systems to make biochar, but if the results are promising, it may be worthwhile.

While this study is focused on manure-input biochar, the applications are potential opportunities for other industries looking at biochar as an output from their waste materials as well.

“A lot of landscape companies and sawmills are looking into it,” says Sanford. “To manage their waste streams.”

In Platteville, his pilot biochar production system is about the size of a commercial refrigerator and allows the team to produce a greater amount of biochar than previous systems. This allows for the volumes needed for the field study.

“We have been looking at the ability to look at manure as the biomass to put in the pyrolysis system,” says Larson “A lot of people have been looking at using wood chips.”

While biochar produced from wood biomass has been proven to improve soil’s ability to retain water, increase plant-available water content, reduce nitrogen leaching, improve nutrient retention and decrease pollution to groundwater, the same results have yet to be shown from manure-derived biochar.

Previous studies have shown that manure biochar generally increases crop yields.

“You can’t do a yield trial in a lab,” she says. “Is [this study] going to have the same impact that was seen in these smaller scale studies?”

It is hoped that this study will bring the positive results anticipated from manure-derived biochar’s application in large crop production systems.

The second study looks at how to take the benefits of manurederived, biochar from manure-heavy regions into other areas where phosphorus is needed in the soil.

“We’re looking at making biochar out of manure itself,” Sanford says. “Instead of composting or doing other treatments on it,

converting it to biochar and getting that phosphorus elsewhere.”

There are a lot of manure applications and additional phosphorus in crop fields in high dairy and livestock operations like those in the Midwest.

Many fields don’t need additional phosphorus making disposal of it a challenge.

“Groups have been looking into this,” he says. “Moving the phosphorus out. When a material goes through pyrolysis, it doesn’t lose any phosphorus. It just becomes a much more concentrated phosphorus.”

The theory is that applying manure-derived biochar at a phosphorus application level should provide plants with the same available phosphorus.

Continued on page 22.

Includes meal voucher and 2-day expo pass

Early bird registration rates end june 15.

7:30 am Tour check-in opens

8:00 am Tour: Water quality

8:00 am Tour: Energy from manure

8:15 am, 9:15 am, 10:15 am Tour: Patterson Farms

8:30 am Tour: Soil health systems

11:00 am Expo grounds open

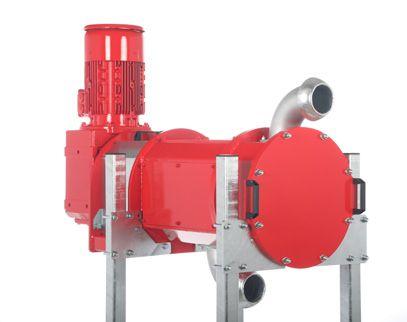

12:00 pm Tent 1: Puck's Pump School

1:00 pm Agitation demonstrations

2:00 pm Separation demonstrations

3:00 pm Safety school

5:30 pm Evening BBQ and networking

7:30 am Expo grounds open

8:00 am - 10:00 am Educational Workshops

10:00 am Explore the expo & Visit vendors

10:30 am Solid manure demonstrations

12:00 pm Enjoy lunch and connect with exhibitors 12:00 pm Tent 2: RNG Production with REV LNG 12:00 pm Tent 3: Slurry management systems with Dairypower Equipment/Troop Equipment

2:00 pm Liquid manure demonstrations

3:30 pm Explore the expo & visit exhibits

4:15 pm Spill response and restoration demonstration

5:00 pm Expo grounds close

• Patterson Farms is a seventh-generation farm milking 1,800 cows planting 2,600 acres, with 1,100 replacements.

• Sunnyside Farms milks 5,000 cows and plants 7,500 cropland acres. They’ll share how they manage nutrients to maximize productivity and protect water quality.

• Aurora Ridge Dairy milks 2,500 cows. See their anaerobic digester that fuels a 600-kW CHP system. Lincoln Dairy, a 6,000-cow dairy tours us through their anaerobic digestionto-RNG system.

• Hear from DuMond Grain Farms and Spruce Haven Dairy Farm about their soil health practices and how, together, they researched and tested applying manure into a standing corn crop as a late-season nutrient source. FOR FULL TOUR DETAILS, VISIT WWW.MANUREEXPO.COM Space is limited. Pre-registration required.

Unprocessed and pelletized manure solids from biochar production.

This makes the phosphorus-rich biochar a benefit to regions outside of the areas that have had heavy manure applications.

“In the field, does that relate to plant uptake and can we use it as a potential phosphorus fertilizer?” he questions. “We know we can densify it. Can we now use that as a fertilizer source. The idea would be to export that to further sources from the farm than you can with manure or compost.”

Larson says part of the problem biochar has had in reaching mass appeal is that the markets aren’t yet created for acceptance of this new (to the modern agricultural world) amendment. The market is not developed enough to support the production of on-farm and mass amounts of commercial-scale production systems.

She says some are moving forward and are taking biomass products to sale, but this isn’t yet common.

“I think the markets are still in development,” she says. “It looks like the USDA is getting some support. There is a possibility for carbon sequestration so there’s the possibility for some funding on that, that may be available. Maybe there’s a potential market here, because there’s some support.”

Just as compost needed to have its market developed, the same goes for biochar.

She feels the data already available shows there is some emission mitigation and improvement to soil health.

“All the collective data show some potential,” she says. “There’s a lot of nuances that we’re trying to build upon and determine.”

So far, pyrolysis reactors have been on an industrial scale and costs are high. Small-scale systems (processing about 2,000 tons per year) start at about $1 million and operating costs vary dramatically based on a significant number of variable factors.

Systems work best with solid biomass that has less than 30 per cent of moisture content so separation prior to starting the pyrolysis process is necessary. Fortunately, as Larson points out, this has an easy, readily available and relatively affordable solution.

“The current way that we’re doing it is separated solid,” she says.

She says that while wet pyrolysis can be done, it takes a lot of energy.

Ultimately, these studies are unlikely to burst biochar onto the scene of agricultural awareness, but they will definitely help bring more data and interest to the topic. There is a lot more ground to cover when it comes to biochar because the variable factors of inputs (wood, plant matter, poultry manure, cow manure, swine manure and more), temperature, speed of process and more make for a variety of potential uses.

Each varied set of inputs can lead to a different application because of the properties of the resulting materials.

“We’ve been looking at ways to get the technology to be more economical,” Larson says.

“There’s a whole bunch of potential ways to use biochar in different systems.”

The team is also looking at how it can prevent nitrate leaching.

“Using it as filter strips. The run off from feed storage,” she says. “That proved very effective in reducing nutrients to leaching in those systems. We ran some other studies and some of those studies were looking at could we put biochar in manure storages, could we reduce ammonia losses. Could biochar maybe absorb that? All those different ways of looking at biochar.”

She says there is significant interest in taking biochar in numerous directions.

Using it as a filter, a fertilizer, field applications, adding it to feed and more.

“We’ve been looking at different ways of using biochar,” she says.

Not bad for a product that was initially seen as a bi-product While biochar is the solid that come from pyrolyzing, other outputs include syn-gas and bio-oil fuels that have been applied to heating and energy uses.

“All biochars are different,” Larson says “You can make them all different. It changes the properties. It would make them useful in different ways.”

Biochar has a promising future in the world of agriculture, but it’s going to take proof, on-farm application and awareness to get there.

“We’re using a screw press. You could use a variety of different things. There’s tons of screw presses out there. That’s one of the most commonly integrated separation technologies. Even some of the smaller organic farms have crew presses.”

With researchers like Sanford and Larson continuing to explore the various uses of biochar, everything from farms and gardeners to environmentalists and agricultural businesses will be learning about the potential applications. • ABOVE

BKT has officially unveiled its new all-steel radial tire, the Powertrailer SR 331. The new model is specifically designed to meet the evolving needs that are typical of trailer and tanker transport applications including road transport operations.

The tire features good flotation properties to reduce soil compaction, and a lower rolling resistance ensures savings in fuel consumption. The tire is also marked by stability, even at high speeds and in challenging situations, such as cornering or traffic circles where significant weight transfer occurs. The tire also ensures excellent transoporation solutions at high load capacities.

“By means of this new tire, we want to ensure a superior level fo the overall end-use experience,” said Piero Torassa, field engineering manager at BKT, in a statement. IN terms of its efficiency for fuel economy, Torassa said, “This is a positive contribution in favor of the environment.”such incredible results.”

Bazooka Farmstar has introduced Wolverine Cloud Monitoring, designed specifically to manage and monitor the performance of Bazooka’s Wolverine agitation boats.

The system delivers real-time status, diagnostics and analytics for the boats using cloud technology. The system provides:

• Live status, which allows operators to stay informed with

real-time updates on the boat’s location, fault codes, machine status, fuel and DEF levels, engine RPMs and more.

• Electrical troubleshooting, with a green/red light indicator for all electrical components plus detailed voltage and current values on all sensors and solenoids.

• Daily reports, including GPS maps of the entire day’s operations, engine hours, error codes and more.

• Remote connectivity, allowing users to resolve issues quickly.

• Historical analysis, with all reports stored for 12 months, enabling comparison and analysis.

The new system is available for Wolverine boats sold from March 2024 on, and some retrofits are available.

Focus: Safety

8:00AM – Avoiding Road Damage

David Orr, Jeff Griswold

Join us the morning of July 18th for insights and findings from industry experts with CEU credits available.

With more than sixteen educational workshops at the 2024 North American Manure Expo, there is something for everyone!

NEW YORK JULY 17-18

systematic improvements that improve meaningful outcomes. Recently, Cornell and NYCAMH joined forces with dairy farms and industry personnel to apply Lean in dairy. Farm managers practically applied the Lean methods and are using them to improve management systems. This workshop will introduce Lean Six Sigma concepts for use in agricultural operations.

Working together, the local highway and farming communities can protect local roads from damage while still providing access to fields and farms. David will explain how roads fail, what is the effect of different vehicles on the road and shoulder, and ways to reduce the damage. Techniques discussed include: seasonal posting, using alternative wheel and load configurations, and practices for getting in and out of fields.

8:30AM – Road safety

Bernie Kennett, Matt Peck

9:00AM – Johne’s disease management: Findings and farmer perspectives

Whitney Hull

Learn about findings from research conducted on six dairy farms in Vermont that explored targeted culling as a management strategy to reduce Johne’s disease and improve economic viability. This study also looked at farmer perceptions and barriers related to management of Johne’s disease.

9:30AM - Lean Management: Engaging your team for safety and performance

Richard Stup

Lean Six Sigma is a proven approach to analyzing a production system, identifying sources of waste and defects, measuring results, and making

8:00AM – Dairy Soil Water Regeneration Project: Measuring GHG emissions from dairy cropping systems

Victor Green

The DSWR project is a six-year, nationwide research project looking at soil health, ghg emissions and new manure products. The project is an intensive comparison of two different management systems. It compares traditional management practices of using liquid dairy manure, no cover cropping and full tillage to a system that utilizes reduced tillage, cover crops, soil amendments and new manure technology products. The presentation will briefly review the project and present learnings to date.

8:30AM – Biochar to suppress emissions from manure applications

Carol Adair, Heather Darby

Join this session to hear about the impact of biochar on CO2, CH4, and N2O emissions as part of a corn silage experiment at Borderview Farm, Vermont with eight treatments: manure injection, injection * biochar, broadcast manure, broadcast * biochar, fertilizer* biochar, biochar, and control.

9:00AM – Manure practices for greenhouse gas mitigation and climate resiliency

Jason Oliver, Lauren Ray

Reducing greenhouse gas emissions from manure systems and improving the climate resiliency of farms will require various approaches. Here, we review the currently available strategies and technologies with potential to reduce emissions and improve resiliency. The focus will be on practical solutions that can be utilized by farmers and manure handlers today, as well as research highlights from ongoing work of the Cornell PRO-DAIRY, Dairy Environmental Systems program.

9:30AM - Manure tech decision support tool: Applications and optimization for dairy and swine

Jacob Hickman, Teng Lim

Dairy and swine operations are scrutinized due to perceived negative environmental impacts associated with manure handling practices. Many technologies exist to manage manure solids, nutrients and water; however, decision support tools are needed to assist farmers in evaluating the economic and environmental costs and benefits of implementing these systems. The MaNuRe team, a multi-discipline collaborative partnership across universities, is developing a tool that tracks the environmental and economic impacts of many of the current technologies and systems available. In this presentation, we will demonstrate several scenarios to show how the tool can be used to optimize manure management on dairy and swine farms across the U.S.

8:00AM – In-season manure application to growing crops

Glen Arnold, Melissa Wilson

How can producers utilize manure in-season to extend the manure application window, while better utilizing the manure nutrients? With the uptick in rainfall in the past decade in northeastern states, the expansion of the manure application window can help reduce amount of manure needing to be applied in the fall.

8:30AM – Compaction: Avoidance, management, does subsoiling work, CTIS

Kitty O’Neil

9:00AM – Assessing the value of manure: Impacts on soil health and corn yield

Juan Carlos Ramos, Gupreet Kaur

Manure is a tremendously valuable nutrient source. The “Value of Manure” is a statewide project that evaluates the nitrogen value, yield benefits and soil health impacts of various manure sources and application methods.

9:30AM - Whole farm approach to manure application and soil conservation

Brendan Jordan, Jason Burroughs

Livestock manure is a local source of essential nutrients and organic matter for healthy soils and crops. Jason Burroughs, Aurora Ridge Dairy and Brendan Jordan, NYS Department of Agriculture and Markets, will provide on the ground experience with several best management practices used by farmers in New York to build a holistic approach to soil and water conservation and efficient manure nutrient recycling for crop production.

8:00AM – Lessons learned from 10 Years of edge-of-field drainage research in Northern New York

Laura Klaiber, Abby Augarten

Recognizing a need for more locally produced research, in 2013, Miner Institute (Chazy, NY) began conducting year-round edge-of-field drainage studies on the water quality of surface runoff and tile drainage from cropland in the Lake Champlain Watershed. These projects have investigated the environmental and agronomic impacts of systematic tile drainage in corn and grass fields receiving dairy manure. Other projects underway are examining the impacts of a rye cover crop after corn silage and no-till corn silage production.

8:30AM – Rainfall simulation project: How different manure sources impact erosion, P runoff and N percolation

Tibor Horvath

When a water quality impairment event occurs like the Lake Erie toxic algae bloom, the fingers immediately points to farms as the only contributors to water quality problems. Using a five soil pan rainfall simulator we can apply different animal manures in different rates and run a one inch rainfall simulation to demonstrate how manure applications can reduce soil erosion and their relation to nutrient transport off farm fields. These runoff experiments can generate real life data to actually measure how different manure spreading rates (solid and liquid) could affect nutrient transport from farm fields. Here we will share results from experiments conducted in North Carolina, Alabama, New York and Oregon, using the same rainfall simulator approach but different manure sources.

9:00AM – Success stories from the New York Watershed Ag Programs

Mark Burger, Dale Dewing

Both the NYC and Skaneateles Watershed Agriculture Protection Programs are voluntary agreements with farmers to develop and implement wholefarm nutrient management plans. These programs serve as an alternative to installing costly filtration systems required by the Safe Drinking Water Act. The speakers will talk about the history and successes of the programs as well as the challenges faced.

9:30AM - Using risk assessment tools to identify high-risk fields and implement BMPs to avoid N/P losses

Quirine Ketterings

Homegrown feed production is key for dairy farm sustainability. Crops need nutrients to grow and manure is an excellent nutrient source that contains all 17 essential nutrients. However, when applied to risky fields, at a high-risk time, and/or at a rate that exceeds the capacity of the soil to hold on to it and crop to take up the nutrients, manure nutrients can also contribute to nutrient losses to the environment. In this session we will talk about two main tools, the northeast region phosphorus index and the nitrate leaching index to identify high risk fields and implement beneficial management practices to reduce the risk of N and P loss to the environment.

1. Collect 10 quart-sized subsamples from various depths and locations in the manure pile and place them together in a bucket.

2. 2. Mix the subsamples together thoroughly.

3. 3. Place one pint-sized sample into a sampling container.

4. 4. Place the labeled sample in a cooler and transfer to a freezer if you are not delivering it to the lab on the day it is collected

Manure is highly variable in composition and nutrient availability compared with commercial fertilizer, which has a guaranteed analysis. As reported in the publication Nutrient Characteristics of Solid Beef Manure

in North Dakota , the nitrogen in solid beef manure in North Dakota ranges from four pounds/ton to 32 pounds/ ton. Manure nutrient values depend on many things, including: Manure type; animal source; animal size; animal diet; bedding used; weather conditions; manure handling practices; storage systems.

Accurate sampling and laboratory testing provides actual manure nutrient information. This information allows crop producers to strategize for maximum crop yields and minimal manure nutrient impact to the environment.

Contacting the laboratory you wish to send your sample to, before taking samples, is best. This is because each

lab may have its own preferences for sample size, packaging, and delivery. Some labs will furnish sample containers and mailers free of charge. Your local extension agent can help you find a lab that is right for your needs.

If you have manure storage sites (stockpiles, compost, etc.) from multiple animal sources, take care to collect samples from these sites. Samples should be taken from each manure storage site that represents a different animal source, type, size, age, diet, management practice, and type of storage structure or other factor that could affect nutrient values.

To start the sampling process, collect 10 to 15 quart-sized subsamples using a spade or shovel from various locations and depths in the pile. Avoid sampling the dry top crust or other parts of the stockpile that may not be representative. Mix subsamples thoroughly in a bucket. Collect 1 to 2 pints and place in sealable plastic bag or a plastic bottle with a lid, or use the sampling containers the lab has provided you.

This sampling procedure is consistent with analysis criteria stated in the USDA-NRCS North Dakota 590 Nutrient Management Standard.

Samples must be labeled before sending to the lab for analysis. Labeling with date, species, and location is a good practice (e.g. Fall 2019 beef stockpile). If collected during warm weather, the sample should be placed on ice, in a cooler, and delivered to the lab as soon as possible. If samples are going to be mailed, freeze immediately after collection. Send samples early in the week to avoid weekend layovers. Manure is constantly changing in physical, chemical, and biological characteristics. Keeping samples cool slows down the process of change and

Guliuspe rberte in ponsupe Atrae condacerio utentiem poendam, co ina, ublicure deteris.Erernam lam, etEctiaImi, tempere premque re porepta spidisc illiquias nem unti reheniae sam qui int et

gives you a better snapshot of what is currently happening in the stockpiled manure.

When a manure sample is submitted for analysis you will need to tell the lab what nutrients you want analyzed. You can request almost any nutrient, as well as organic matter, pH, and electrical conductivity (salts). Total nitrogen (N), inorganic N, phosphorus (P) as P2O5, and potassium (K) as K2O are the main nutrients you need to know for nutrient planning. Other nutrients such as sulfur and zinc may also be important for nutrient planning purposes. Total salt analysis may be useful if salts are a concern in the soil to which manure is to be applied.

HOW CAN MANURE ANALYSES BE USED?

Manure nutrient analyses, combined with soil tests, previous crop credits and crop nutrient requirements, can be used to determine the proper application rate for manure. Determine crop nutrient requirements using NDSU Extension publication SF-882, North Dakota Fertilizer Recommendation Tables and Equations

Using the North Dakota Corn N Calculator, it can be determined that for corn grown in Foster County under conventional tillage methods

of medium-texture soils with historic yields > 160 bu/ac with 45 lbs/ac soil test N and soybean as the previous crop, you need 137 lbs N/ac. Knowing there is 20 lbs of N/ton from the manure analysis and that approximately 50 percent of the total N is available for crop production during year one, you

would need to apply the manure at a rate of 13.7 tons/ac. Using NDSU SF882, we know that if our soil test P is in the medium range (8-11 ppm) we need to add 52 lbs P 20 5/ac and if soil test K is in the high range (121-160) then we need to add 60 lbs K2O/ac. We know from our sample above that there are 7.9 lbs/ton P 2O 5 and 8.4 lbs/ton K 2O in the manure. Remember, 80 percent of the P and 90 percent of the K are available the first year for plant growth. So, if you’re spreading 13.7 tons/ac then you are applying 87 pounds of P/ac and 104 pounds of K/ac. Applying the manure from the sample above at a rate of 13.7 tons/ac meets/exceeds the necessary crop requirements. •

Mary Keena is a livestock environmental management extension specialist at the Carrington Research Extension Center. This article was originally published by North Dakota State University. For the full article including sample manure nutrient estimates, visit: https:// www.ndsu.edu/agriculture/extension/ publications/solid-manure-samplingnutrient-management-planning

CHRYSEID MODDERMAN | University of Minnesota Extension

Manure is a first-rate, albeit smelly, treasure trove of nutrients, with all the macro- and micronutrients plants need to grow (though not necessarily in the right concentrations).

While phosphorus often plays second fiddle to nitrogen, it is a vital nutrient for plant growth and worth managing.

Understanding how manure phosphorus behaves after application is important to know how best to manage manure.

A crop farmer piped up from the back row of a meeting, “If phosphorus sticks to soil, why can’t I just bank it up in my soil and have it forever?”

While it’s true that phosphorus is far less mobile in the soil than nitrogen, it can still be lost to the environment through runoff and erosion. In the case of high-phosphorus soils, leaching can also occur.

When excess phosphorus ends up in fresh water, it may cause harmful algal blooms and hypoxic zones where plants and animals can’t survive.

Phosphorus management in manure poses a unique challenge as the ratio of nitrogen to phosphorus cannot be adjusted to precisely meet the needs of the crop.

Inevitably, phosphorus—and other nutrients—will be under- or over-applied when application rate is based on the crop’s nitrogen needs.

by soil microbes, and the speed at which they work is heavily influenced by the environment.

Within the soil, there are three pools of phosphorus that contribute to plant-available phosphorus. Solution phosphorus is inorganic P and readily plant available; the inorganic P supplied by manure contributes to this pool. Active (also known as labile) phosphorus is stuck to soil particles and is released slowly into the solution P pool through desorption.

Fixed phosphorus is composed of mineral phosphorus and is released very slowly over the course of years.

While we tend to focus on the processes that release phosphorus for plant use, keep in mind that these pools are a two-way street and sometimes phosphorus may be tied-up rather than released.

While there are nutrient tables out there for nearly every type of manure, those are just estimates and we recommend sampling your manure for phosphorus as well as other nutrients. Actual nutrient content of manure can vary based on a whole host of management factors including feed, housing type, and storage system. Phosphorus should be reported as P 2 O 5 to align with fertilizer recommendations.

Most forms of manure are notorious for over-applying phosphorus.

Most forms of manure are notorious for overapplying phosphorus, leading to phosphorus build-up in the soil and increasing the likelihood of phosphorus loss to the environment.

Much like nitrogen, manure supplies two forms of phosphorus: inorganic and organic. The inorganic form is immediately plant available, while the organic form is not. Organic phosphorus is tied up and needs to be broken down by a process called mineralization to become plant available. Mineralization is driven

If, for some reason, it is reported as elemental P, convert it to P 2 O 5 by multiplying by 2.29. Also, when applying manure based on the phosphorus needs of the crop, remember that not all the phosphorus is immediately usable by the plant.

In most cases, a simple percentage is used when finding plant-availability for the purpose of application rate calculation.

In Minnesota, we use 80 percent. To calculate application rate, multiply the total phosphorus content – from the manure test – by 0.8 to find the plant-available content.

Availability factors may vary based on state or region, so be sure to use your local recommendations.•

Manure Manager is conducting a comprehensive industry survey to delve into the realm of training, talent and operations within the manure application sector.

We invite your valuable insights to shed light on how the industry is attracting, retaining and training talent.