Innovative PONSSE BTS for bio transportation

Ponsse North America

4400 International Lane

Rhinelander, WI

Office: 715-369-4833

A.L.P.A. Equipment Ltd.

Balmoral, N.B.

CANADA

office: 506-826-2717

www.alpaequipment.com

ReadyQuip Equipment Sales Ltd.

Timmins, Ontario

CANADA

Office: 705-268-7600

www.readyquip.com

Hydromec Inc.

Dolbeau-Mistassini, Quebec

CANADA

Office: 418-276-5831 (Dolbeau)

Office: 418-543-1115 (Chicoutimi)

www.hydromec.ca

Woodland Equipment Inc.

Kamloops, BC

CANADA

Office: 250-372-2855

www.woodlandequip.com

www.ponsse.com

The new PONSSE BTS System increases standard fixed bunk loads by more than fifty per cent when compressing forest residues. Loads do not exceed the outer diameter of the forwarder bunks, saplings are saved enabling future growth.

Field tests have shown results in the 10-12-ton load capacity range allowing a semi trailer to be filled in about three loads – over 30 tons of biomass in total! The new PONSSE BTS bunk also handles round wood loads in a locked position.

PONSSE BTS specifications:

• 10 tons of hydraulic compression

• 53 degree travel out-ward

• 58 degree travel in-ward

• User friendly foot pedal operation

• Tubular heavy duty construction

• Fixed heal for better loading control

• Brush grapple

• Optional PONSSE LoadOptimizer scale

CANADIAN BIOMASS

Blazing Trails in Biomass Use

Tembec taps a number of biomass sources in the BC Kootenay region, from roadside slash to yard waste and more. We drop in to talk gear and future markets and supplies.

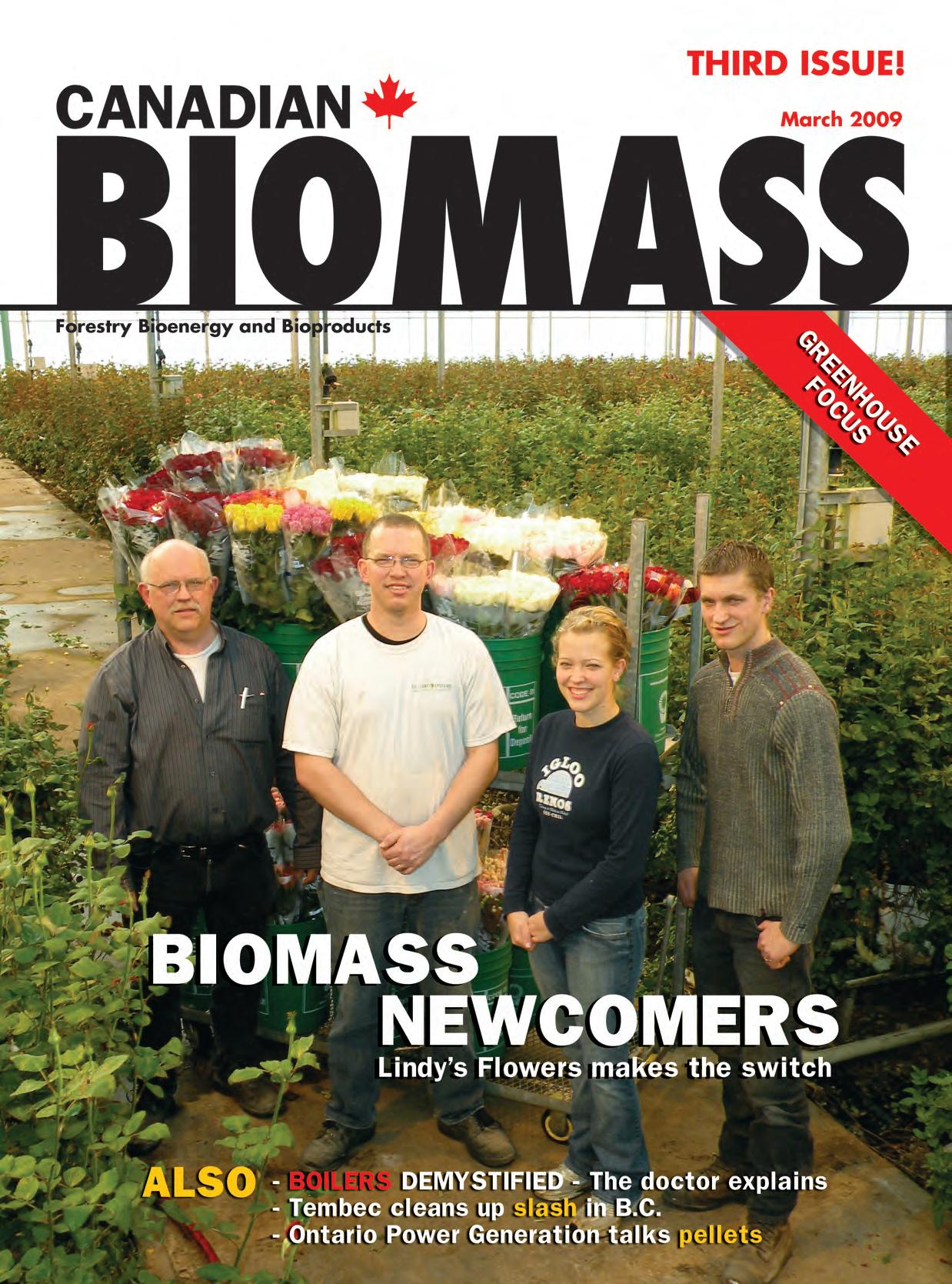

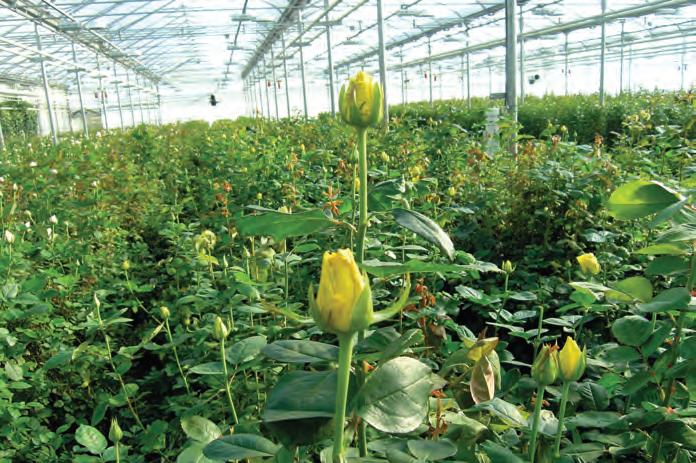

10 Greenhouse FOCUS

We look at a sector that is both biomass processor and potential customer. Includes a report on Lindy’s Flowers’ conversion to pellets, a BC greenhouse’s move to capture carbon credits, and advice from CANBIO on moving to bioenergy.

15 The Combustion Doctor

Fernando Preto talks about options for biomass combustion, combined heat and power, gasification, bio-oils and much more. A must-read for anyone thinking of getting in the game.

22 Generating Business

Plans to convert Ontario Power Generation’s coal-fired stations to biomass create opportunities for an Ontario biomass industry, and pellet producers everywhere.

33 Grinder Guide

An update on stationary grinders for mills or fixed facilities.

“As boiler systems move into greenhouses, sawmills or other industrial clients, we’re seeing more issues with insufficient training. Suppliers in some cases deliver the system, show the clients how to turn it on or give basic mechanical instructions, and then leave.”

Our Cover: Biomass-warmed, greenhouse-grown flowers are the family business for John, Scott, Monique, and Ben Lindeboom of Lindy’s Flowers. Story on page 10. Photo: Dave Harrison/GHC.

IBrand Building

Finding customer-driven solutions is the first step to a biomass economy.

f forest biomass for energy is a brand, we’d best start taking more care in building it.

As recent events show, there are factors outside our direct control that may conspire to damage the image of forest biomass as a reliable, consistent alternative to fossil fuels.

Most damaging is recent news that would-be biomass brokers New England Pellet will not be able to meet supply obligations made to hundreds of residential customers in the Northeast US relying on them to keep their homes, and families, warm. The company had taken around $200 a ton from consumers in return for what was to be a sure supply of wood pellets this winter. Now the company is being sued by the attorney general of Connecticut for continuing to pre-sell pellets long after it knew it could not deliver. Many of these pellet consumers are new to the game, having recently given the pellet sector their trust in the face of escalating oil prices. Uncertain when, or if, they will see their pellet supply, these homeowners are not likely to be strong advocates for our industry moving forward. This is all the more unfortunate given what looked like a growing surge of pellet users in the massive Northeast US residential market.

Going forward we’ll likely need a large supplier or coalition of suppliers with the brand power and proven reliability of a Shell Oil or Esso. When you sign a heating oil contract with such players, you may gripe about the price, but the thought of shortages never crosses your mind. If we want to win over the American and Canadian consumer, we’ll need the same clout.

Then there are more technical issues such

as the trials and tribulations of some industrial users in matching biomass fuel with combustion technology. In our greenhouse focus, you’ll read Heather Hager’s article about Lindy’s Flowers’ switch to biomass and its difficulties in getting its boiler to feed and burn well using a variety of agricultural feedstocks. The good news is they seem to have found success with hardwood pellets. Yet they suffered more aggravation than necessary getting there.

In some ways this isn’t a forest biomass issue – the early trials were with nonwoodbased biomass. Still, to the greenhouse sector at large, it all becomes a problem with using biomass. By default the problem becomes ours.

The issue is education. Biomass pioneers need accurate information to choose the right combustion technology to match the intended fuel source (or sources) and to design a transport, storage, and feeding system to make it all work as simply and painlessly as possible. It behoves our industry to help this education process with such key markets as the greenhouse sector. For that reason, we have invited Dr. Fernando Preto of Natural Resources Canada’s CanmetENERGY to explain the finer points of commercially available combustion systems and have arranged to have this issue reach over 4000 greenhouse contacts through our partners at Greenhouse Canada Magazine. I welcome these readers and encourage them to consider Dr. Preto’s suggestions carefully. Regardless of the product, it’s all about providing solutions, not new problems.• Scott Jamieson, Editor/Group Publisher sjamieson@annexweb.com

Volume 3

Editor/Group Publisher - Scott Jamieson (514) 457-2211 ext 24 sjamieson@annexweb.com

Field Editor - Heather Hager (519) 429-3966 ext 261 hhager@annexweb.com

Western Editor - Bill Tice

Market Production Manager

Josée Crevier (514) 457-2211 ext 21 jcrevier@forestcommunications.com

National Sales Managers Tim Tolton - ttolton@forestcommunications.com 450-458-4341

Guy Fortin - gfortin@forestcommunications.com 90 Morgan Rd, Unit 14 Baie d’Urfé, Que H9X 3A8 Ph: (514) 457-2211 Fax: (514) 457-2558

Western Sales Manager Tim Shaddick - tootall1@shaw.ca 1660 West 75th Ave Vancouver, B.C. V6P 6G2 Ph: (604) 264-1158 Fax: (604) 264-1367

Production Artist - Brooke Shaw

Canadian Biomass is published five times a year; March, June, August, October, and December. Published and printed by Annex Publishing & Printing Inc., and distributed as a supplement to Canadian Forest Industries and Canadian Wood Products magazines.

Printed in Canada ISSN 0318-4277

Circulation e-mail: cnixon@annexweb.com Tel: (514) 457-2211 Fax: (514) 457-2558

Mail: 90 Morgan Rd, Unit 14 Baie d’Urfé, Que H9X 3A8

Subscription Rates:

Canada - 1 Yr $48; 2 Yr $85; 3 Yr $115 Single Copy - $6.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $44 US; 2 Yr $75 US Foreign – 1 Yr $75 US

From time to time, we at Canadian Biomass make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2009 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianforestindustries.ca

BURNING issues

First NatioNs to supply bioreFiNery

Paramus, NJ – In November 2008, Raven Biofuels International Corporation entered into a Memorandum of Understanding (MOU) with the Kamloops Indian Band (KIB) of Kamloops, BC, to further the development and construction of a proposed cellulosic ethanol biorefinery and cogeneration power plant in conjunction with the KIB. The nonbinding MOU outlines a mutual interest towards pursuing an alli-

ance leading to the construction of a cogeneration power facility and biorefinery using technology and expertise provided by Raven, plus a site, feedstock, and other resources provided by KIB. KIB brings significant access to feedstock resources secured through a multiyear provincial forestry agreement in which KIB has rights to 124,000 cubic metres of beetlekilled wood within the Kamloops Timber Supply Area.

Raven, through its Canadian subsidiary, and KIB plan to move ahead quickly and develop a course of action for the lease of a 30-acre site with direct rail and road access located near Kamloops, BC, for the construction of a facility. Current plans identify an initial annual output of 7 million gallons of fuel-grade ethanol and 4 million gallons of furfural and related chemicals and lignin cake; future capacity could be increased

eNerkem Fires up commercial bioFuel plaNt

Montreal, QC – Enerkem Inc.’s first commercial-scale biofuels and biochemicals plant is entering the start-up phase with the production of clean, conditioned synthesis gas. Construction on the plant, located in Westbury, QC, began in October 2007 and the facility was mechanically complete in December 2008. The conditioned synthesis gas (syngas) platform has been finalized and is in an advanced commissioning stage in preparation for its upcoming start-up.

The syngas platform serves as the chemical production platform to which methanol and ethanol production modules will be added over the next months. Once these gas-to-liquid modules are bolted to the syngas platform, Enerkem will become the first commercial producer of liquid fuels and biochemicals using renewable, nonfood, negative-cost feedstock.

The Westbury plant will be the world’s first ethanol plant to use negative-cost and unconven-

tional materials—treated wood from used electricity poles. It is operated by a team of 13 people and will produce 5 million litres (1.3 million gallons) of secondgeneration ethanol annually. The Enerkem thermo-chemical process uses one tonne of waste to produce 360 litres (95 gallons) of ethanol.

Enerkem is one step closer to becoming the first commercial producer of biofuels and biochemicals using waste biomass feedstock.

New plaNs For co-geNeratioN iN bc

Vancouver, BC – Biomass Secure Power is obtaining the necessary approvals to build a 10-megawatt co-generation plant in Abbotsford, BC. The plant will be constructed on property owned by a greenhouse

Forestry

operator who has signed a 20-year lease to allow co-generation operations on the site. The greenhouse has also agreed to purchase hot water heat and CO2 on a fixed contract price. A second greenhouse

located nearby is also interested in purchasing hot water heat.

The electricity produced at this site will be sold to BC Hydro under its Standing Offer Program. The fuel will be whole trees that have

to double this proposed production.

Planning for a definitive agreement includes a feasibility study to develop arrangements with KIB for a continuous supply of approximately 500 dry tons per day of organic cellulosic waste. This feedstock would primarily be wood chips from regionally sourced, mountain pine beetle-killed wood, as well as other appropriate wood waste sources from the area.

been destroyed by the mountain pine beetle; these trees must be removed to reduce the danger of forest fire. The plant is expected to commence operations in late 2010.

St. John’s, NL – In December 2008, the Newfoundland and Labrador government released its consultant’s report on the comprehensive review of the forest industry in Newfoundland. Many of the recommendations in the report have already been implemented and several biomassrelated initiatives have been undertaken. In April 2008, the provincial

government announced a $14 million Forest Industry Diversification Program to assist the industry to identify and develop specific new products and market opportunities.

A residential wood pellet rebate program provides a 25 percent rebate for the purchase of residential wood pellet appliances to create a local market for wood pellets. One

wood pellet production facility is already in operation and a second facility is under development. The provincial government has also contributed $1 million for a cost-shared economic study with Corner Brook Pulp and Paper to convert wood to an alternate fuel source to reduce the mill’s requirement for bunker C oil.

BURNING issues

Forestry For reNewable eNergy

Toronto, ON – A report released by the Atlantica BioEnergy Task Force in December 2008 says that actions must be taken to implement renewable energy technologies in the forest products industry of the Atlantica Region (New Brunswick, Nova Scotia, Maine). The study, compiled by PricewaterhouseCoopers (PwC), recommends 15 distinct actions to be taken to drive the Atlantica Region to the forefront of the renewable energy economy. The report puts forth recommendations in areas of sustainable forest management, transportation infrastructure, transmission and distribution systems,

technology, greenhouse gas strategy, market development, financial support, and regional collaboration in research and education.

“The Atlantica Region is rich in forests and has historically depended on the forest industry to drive its economy,” says Bruce McIntyre, leader of PwC’s Forest, Paper, and Packaging practice in Canada and a partner in the firm’s Sustainable Business Solutions practice. “But the Region is now struggling to attract new investment and is facing the added challenges of high log and wage costs, weak markets, and energy costs that are above average.

Without new investment, the business prospects for the Region’s forest products sector are bleak, with little room to improve energy efficiency, develop emerging technologies, or generate new sources of revenue.”

The study indicates that there are opportunities to revitalize the forest industry and its competitiveness by making use of available wood feedstock for the production of bioenergy, biofuels, biochemicals, and other bioproducts in an environmentally conscious manner. However, it remains unclear how much wood feedstock is available for use in bioproducts and at what cost this

possible pellet plaNt For the rock

Roddickton, NL – A local forestry entrepreneur has plans to build a pellet plant in Roddickton, NL, according to Aaron Beswick of The Northern Pen newspaper. Ted Lewis, who owns a local logging operation and sawmill, is considering creating a pellet plant that would use sawmill residue and wood that is unsuitable for sawlogs. The peninsula’s

pulpwood and sawdust market has dropped off since Corner Brook Pulp and Paper shut down one of its paper mills last year. The plant would produce about 50,000 tonnes of pellets

Bruce McIntyre, leader of PricewaterhouseCoopers’ Forest, Paper, and Packaging practice in Canada.

can be brought to market. “These issues and opportunities could apply to the forest industry right across North America,” says McIntyre. The report and recommendations can be found at www.atlanticabioenergy. com.

annually, which could be shipped to mainland Canada and across the island. The plan has received support from the Northern Peninsula Forest Resources Association.

www.raycomfg.com : 800.392.2686

Dispose of waste wood without breaking the bank! RAYCO’s new line of compact, horizontal grinders creates an affordable solution to your waste-wood needs. The highly productive RH1754 introduces a new class of compact horizontal grinders that are truly mobile, compact machines designed to grind pallets, green-waste, lumber scraps, construction debris, and sawmill waste while minimizing the expense and hassle of large units. At only 14,500 lbs, the RH1754 can be easily moved with lighter trucking equipment and operated on smaller job sites, inaccessible to larger machines. Its low fuel consumption keeps operating costs at a minimum yet its high productivity rate will match that of machines costing nearly twice as much. Finally… there is a horizontal grinder within reach of the small contractor.

Contact your authorized RAYCO dealer for more information or call 800.392.2686 for a dealer near you.

Biomass forecast

According to the Strategic Assessment for European Biomass Energy Markets by Frost & Sullivan, biomass will play a significant role in the European energy market in meeting the target for 20 percent renewable energy by 2020. Biomass currently accounts for about 5 percent of total energy consumption in Europe (15–20 percent in Finland, Sweden, and Austria) and is used mainly for heat and power cogeneration and municipal district heating.

J.D. Irving Ltd. gets loans

The New Brunswick government is providing J.D. Irving Ltd. with a $15-million term loan to upgrade the Grand Lake Timber operation and a $4.5-million term loan to upgrade the Deersdale sawmill. The loans are intended to help J.D. Irving Ltd. install a new biomass boiler at each site to dry wood products prior to shipment, reducing production costs and making the facilities more energy efficient.

BC mill chips beetle-killed trees

RiverCity Fibre’s new whole-log chipping mill in Kamloops, BC, opened in November 2008. The mill processes mountain pine beetle-killed trees to supply chips for Domtar’s Kamloops pulp mill, as well as fine material for the pellet industry and waste material for Domtar’s bioenergy plant.

Waste not, want not

Buchanan Lumber, a family-owned and -operated sawmill located in High Prairie, AB, is making use of its sawdust by compacting it into 5-lb wood-

only densified firelogs. Compaction of the sawdust into logs reduces the shipping volume and thus transportation costs. Benefits of the firelogs include no bugs, little smoke, and high BTUs.

Guide to biomass policies

State Woody Biomass Utilization Policies, compiled by Dennis Becker and Christine Lee of the University of Minnesota’s Department of Forest Resources, is available online at www.forestry.umn.edu/publications/ staffpapers/index.html. This database provides a comprehensive, up-to-date guide to woody biomass legislation for each U.S. state.

Ontario funds bioproducts research

The Northern Ontario Heritage Fund Corporation is investing $333,000 to establish an Industrial Research Chair at Nipissing University in North Bay, ON. The Chair will work on economically and ecologically sound proposals and conduct a forest resource inventory to support current and emerging demand for forest products such as biofuels and biopharmaceuticals.

Northern Ontario looks to pellets

Both Westwind Forest Stewardship, which manages the publicly owned French-Severn Forest near Parry Sound, and Algoma-area Clergue Forest Management have received funding from the Northern Ontario Heritage Fund Corporation to study the potential for a wood pellet industry. The studies will address the logistics, fibre availability, and costs associated with starting wood pellet mills.

BURNING issues

Forest iNdustry’s priorities For Federal budget

Ottawa, ON – In December 2008, the Forest Products Association of Canada (FPAC) laid out five urgent priorities that the federal government must address in its upcoming budget if it wants to secure the forest products industry as a cornerstone of the Canadian economy. “What we need is smart spend-

ing and bolder economic policies to make sure our industry not only perseveres, but is able to capitalize on the investments it has already made modernizing its mills, diversifying its markets, and greening its product,” says Avrim Lazar, president and CEO of FPAC. Three of the priorities are related to biomass and

bioenergy: help spur the transformation to bioenergy; provide tax incentives for investment and innovation; and invest in research and development, market development, and product promotion.

Avrim Lazar, president and CEO of the Forest Products Association of Canada.

eNsyN aNd uop to develop greeN gas

Des Plaines, IL – Ottawa-based Ensyn and Honeywell’s UOP company have formed a joint venture to combine Ensyn’s thermal combustion and UOP’s refining technologies. The plan is to offer the technology and equipment to convert waste biomass such as residuals from the agricultural and forestry sector and woody construction and demolition materials into pyrolysis oil.

Pyrolysis oil can be combusted in industrial burners and furnaces for power and heating or further refined into transportation fuels such as gasoline, diesel, and jet fuel. However, the oil is corrosive and unstable, making it difficult to store and transport. UOP has been awarded a $1.5 million grant from the U.S. Department of Energy to develop economically viable technology to modify the

composition of biomass pyrolysis oil to solve these issues.

“The development of secondgeneration biofeedstock conversion technology is critical for biofuels to support our growing energy needs,” said Jennifer Holmgren, general manager for UOP’s Renewable Energy and Chemicals business. “Finding a cost-effective solution will ensure that pyrolysis oil is a viable

renewable source for power and transportation fuels.”

“We believe this alliance will generate multiple commercial breakthroughs in the biomassto-energy world,” says Dr. Robert Graham, chairman and CEO of Ensyn. The joint venture aims to develop and commercialize technology to convert biomass to drop-in transportation fuels by the end of 2010.

syNgas to power tissue plaNt

New Westminster, BC – Kruger Products Ltd. has selected Nexterra Energy Corp. to supply a biomass gasification system for its tissue mill in New Westminster, BC. The gasification system will convert locally sourced wood residue into synthesis gas (syngas) that will be fired directly in a boiler in place of natural gas. The Kruger installation will produce 40,000 lbs/h of process steam and displace about 445,000 gigajoules of natural gas annually, which is equivalent to the amount of natural gas used to heat 3500 homes in Canada for one year. It will also reduce greenhouse gas emissions from the plant by more than 22,000 tonnes per year, the equivalent of removing nearly 5500 cars from Canadian roads.

slash harvest demo a success

Payette National Forest, ID – In August 2008, the U.S. Forest Service provided a well-attended demonstration of woody biomass chipping and hauling using newly developed equipment. Their aim is to collect forest residues and thinned trees from hazardous fuel reductions for alternative uses. In the past, most slash has been piled and burned at the site, creating environmental concerns. Now, once collected, this material will be burned in highly efficient biomass burners to generate heat and electricity, and in the future may be used in cellulosic ethanol production. Some of the harvested biomass

Biomass is collected using the roll-off trucking system.

will be used in the Fuels for Schools program to heat public schools in the area.

The demo showcased a hook-and-lift roll-off trucking system developed by Craig Thomas and the Montana Community Development Corporation, as well as a stinger-steered chip van hauler developed by the U.S. Forest Service San Dimas Technology and Development Center. This new equipment facilitates the removal of previously unused biomass. Standard chip vans are unable to negotiate the rough logging roads. The new systems can move both slash and chipped material and can operate on narrow forest roads.

Kruger, Nexterra, and FPInnovations have formed a consortium to build the new system, which will be the first commercial demonstration of Nexterra’s direct-fired gasification solution. The project has received support from Natural Resources Canada, Western Economic Diversification Canada, the British Columbia Innovative Clean Energy Fund, and Ethanol BC. The plant should be completed in late 2009.

Komptech USA Inc.

1724 Majestic Drive #104 Lafayette, Colorado 80026

Phone: 720 - 890 - 9090 info@komptechusa.com

Nexterra’s biomass gasification system at the Kruger mill will be the first of its kind in the pulp and paper industry.

Crambo

Universal shredder for green waste and wood

• High throughputs up to 110 tons/hour

• Aggressive feed with 9 feet, 3 inch long, counter-rotating shredding shafts

• Low speed shredding produces less fines

• Very consistent particle size output

3 fraction star screen

• High throughput with precise selectivity regardless of material moisture

• Simple speed control for fast particle size change

• Even the 500 yd3/hour XXL model is still fully mobile

Photo: Craig

Warming up to Biomass

The successful conversion to biomass heating has presented some challenges for this 80,000 square foot greenhouse. In the end, hardwood pellets provided an answer.

By Heather Hager

Not

everything worthwhile is easy. Take the switch to biomass. Although often beneficial over the long term, it’s not always the easiest process and may require a lot of experimenting and fine-tuning. Brothers Scott and Ben Lindeboom of Lindy’s Flowers in Dunnville, ON, should know. They installed a Decker Brand multifuel boiler rated for 3.5 million BTUs into their family-run greenhouse in the spring of 2006. Since firing the boiler, they’ve tried several fuels and learned quite a bit about boiler mechanics.

“The motivation behind the move to biomass was the rising energy prices,” explains Scott Lindeboom. “We went with the Decker boiler because of the automatic feed and automatic ash removal. A place our size could not afford to have someone standing around full time to keep the boiler going. We just don’t

have the square footage to justify that.”

The system is automated via a touch-pad control panel, and the facility and controls are set up to allow the convenient installation of a second boiler. The system combines a gravityfed fuel supply with a boiler, an economizer, and a heat storage tank. “The economizer takes a lot of dust out of the air and brings the stack temperature of the boiler down from about 500ºF (260ºC) to about 250ºF (120ºC),” says Lindeboom. The economizer uses the extra heat to warm the cold water before it enters the boiler, making the boiler more efficient. During the warmer months, the heat storage tank stores the heated water during the day when the greenhouse is warmed by the sun. The

stored heat is used at night to keep warm air circulating and to vent the humidity, reducing mildew problems in the greenhouse and keeping the plants healthier.

The Lindebooms first started burning oat hulls in their Decker system “with pretty good success for the first couple of months.” However, changes to the manufacturer’s pellet recipe caused the fuel to plug the boiler. They then burned anthracite coal from Pennsylvania for about a year and a half. It flowed through the bin and into the auger quite well, burned clean with low sulphur and emissions, and kept the boiler fairly clean. The main drawback, however, was the amount of ash. “Because we had so much ash, we thought maybe there’s a better way,” explains Lindeboom.

Wood chips were not an option because they will not flow through the gravity-style grain bin without plugging. But the brothers

The Decker Brand multifuel boiler features automatic infeed through the back and automatic ash removal from the bottom right. Photo: Heather Hager.

The red grain auger is used to fill the grain bin (foreground) with wood pellets. The wood pellets are fed directly into the boiler via a gravity-fed auger system. Heat is stored in the heat storage tank behind the boiler building and used at night. Photos: Dave Harrison/GHC.

found a mulch and pellet manufacturer located about 150 km away in Putnam, ON, so they made the switch to hardwood pellets. They have been burning wood pellets since May 2008. They are finding that each 40-tonne truckload produces about five wheelbarrows of wood ash. “We’ve been burning pellets since May and just pulled our first wagonload of ash out,” says Lindeboom. “We’re very happy with the wood pellets. Every different fuel requires different attention in certain areas, but so far with the wood pellets, it seems to be working quite well.”

The brothers estimate that they will burn 120 to 150 tonnes/month of wood pellets during the peak heating season. Their storage capacity provides enough pellets for about one and a half to two weeks during the peak season. During off-peak heating, the storage capacity provides three to four weeks of supply. There is the potential to build another storage bin to

have extra pellets on site, says Lindeboom, but the need is not a pressing one because the supply seems to be reliable.

costs aNd maiNteNaNce

Lindeboom estimates the investment as close to a quarter of a million dollars, factoring in all of the equipment, including the purchase of an auger to fill the storage bin, plus the building, concrete, engineering, and welders and electricians. “It was a costly endeavour to put up the boiler room. It pays off because you save money on gas of course, but it’s not like building greenhouses where it brings in more income. It’s a capital investment you make in order to maintain a certain energy cost instead of letting it go up.” He’s expecting about a five-year payback in energy savings.

Then there are the unexpected costs. “The first boiler that we put in was defective,” says Lindeboom. “They replaced the boiler for free, but you have to get the welders and electricians in again. And we had to open the roof to the boiler room in order to get the crane to pull the old boiler out and put the new boiler in.” Although the daily maintenance only involves about 10 minutes of cleaning and checking for obstructions, Lindeboom says that he has been a bit frustrated with the amount of upkeep in terms of replacement parts, cleaners, and refractory.

When asked about the learning curve to run the system, Lindeboom says that it was quite steep. He likens it to buying a new car: When you hear a strange noise, at first you’re not sure whether it’s normal operating proce-

dure or a reason to visit a mechanic. “In the background, you hear a bit of a bang—those are the cleaners inside the boiler cleaning the tubes out. We heard it on the first day and thought ‘okay, that’s the noise it makes,’ but when we hear them now, we can hear whether it’s working properly or not.”

“If you’re going to go into biomass, you almost have to become a bit of a boiler mechanic yourself or have someone around who wants to become a bit of a boiler engineer,” he says. “The only way you can learn is by being there when it breaks down to learn how to fix it or how to prevent a problem.” For example, when they switched to wood pellets, the auger began to clog and overload the motor. They figured out that they could prevent this problem by making the input hopper smaller. “When you become your own boiler mechanic, you learn how to tweak things to make it work properly.”

gas vs. biomass

With the current infrastructure, the Lindebooms could install a second biomass boiler fairly easily. Still, they are waiting to see how the first winter goes with the wood pellets. “We’d love to put a second boiler in, but we want to get through a winter where it will actually run the entire winter without having to rely on gas heavily before we would even think of putting in a second one.”

And despite the 3.5 million BTU rating, the Lindebooms have yet to get more than about 2.8 million BTUs out of their system. “We have a 3.5 million BTU gas boiler up front, and it can easily heat this whole place and shut off during

Scott Lindeboom with the hardwood pellets the growers settled on after trying other fuels.

the day. If we do the calculations and compare apples to apples, we’re not getting the heat out of this boiler like we should be.”

Comparing natural gas to wood biomass, Lindeboom says that he likes the wood pellets because they have reduced costs below those for natural gas. He also mentions that they’re consistent, environmentally friendly, and carbon neutral. And he’s very interested in opportunities to earn carbon credits for burning biomass rather than fossil fuels to help offset some of the infrastructure costs. But he also likes the convenience of his old system. “Still, I

Wood

Pelleting Plants

Equipment, Mr. Rick B. MacArthur 309 Primrose Lane, Newmarket, Ont L3Y 5Z1

Phone:001-905-836 5643

Fax:001-905-836 6037

rbmacarthur@sympatico.ca www.akahl.de

think natural gas has got to be the nicest fuel to burn,” he says. “You turn it on, you turn it off, you walk away. Biomass, let’s face it, it is more labour intensive.”

“So, are we totally happy with the system? Well, today we are because it’s running. It has helped us to keep our costs down. But some days you just think, throw that thing in the scrap bin and turn the gas back on and just live with the extra costs.”•

The Lindebooms use biomass heating to keep 80,000 square feet of roses warm year-round. AMANDUS KAHL GmbH & Co. KG

Burning for Credits

the conversion to biomass technologies can generate multiple payoffs. Take SunSelect Produce Inc. of Aldergrove, BC, for example. It has reduced its fuel costs, obtained carbon credits, and generated an environmentally friendly company image by converting its greenhouses from natural gas to biomass heating and installing energy-saving heat curtains to reduce greenhouse gas emissions. The biomass boilers are fuelled by wood waste obtained from a local sawmill. The transition from business as usual to biomass was made with the help of Offsetters of Vancouver, BC, an offset project developer.

Offsetters’ aim is not just to broker carbon offsets to offset direct greenhouse gas emissions, but also to invest in renewable energy and energy efficiency projects that would not have otherwise occurred. “What we do is identify projects that aren’t happening for some reason,” explains Morgan McDonald, director of sourcing for Offsetters. “Either there’s a technical barrier whereby the company has heard of the technology but they’re not quite convinced about it, or they’ve heard about it but think it’s going to be too expensive, or in fact they’ve done the number crunching and it is too expensive. If they could trim the cost a little bit, then they’re willing to go for it. That’s where we step in and provide that extra bit of funding that makes it affordable to them.”

Companies that switch to biomass heating can use carbon credits to finance some of the conversion costs, and can boast about it on their packaging – Locally grown, with no carbon footprint!

as approximately 7500 tonnes/year relative to the conventional natural gas baseline.

installing heat curtains, and some are installing innovative heating technologies that have never been used before, all in an effort to reduce greenhouse gas emissions from what they have been.”

“Working with biomass has been successful for us in the past, and we’re doing more in that area,” says McDonald. And the opportunities are not just restricted to greenhouses. “It could be any institutional building, for example, that is using oil or natural gas or some other fuel for heating and wants to switch to a biomass boiler, but hasn’t done so in the past because there are technical or cost barriers. If our involvement can help switch them over, then that can generate credits that we use for offsets.”

Offsetters is involved in generating offsets from both domestic and international projects. It supports projects like that of SunSelect by providing financial and technical analyses, ongoing biomass supply information, and cash contributions, and arranging for thirdparty verification. “In the case of SunSelect, we identified a project that had some cost involved: the installation of a biomass boiler and the ongoing purchase of biomass in the form of wood chips or shavings. That was different from business as usual, which for them was using natural gas to heat the greenhouse,” says McDonald. Based on actual heating bills and standard energy models, a third-party auditor verified SunSelect’s emissions reductions

In return for its services and contributions, Offsetters gets to buy the rights to the carbon reductions for a negotiated number of years. It then places the offsets for sale through its website or in an international carbon credit registry called the TZ1 registry. Companies and individuals who want to reduce their greenhouse gas emissions footprint to become “carbon neutral” can purchase the offsets, which are then considered retired and cannot be re-sold. Each credit or offset represents the removal of one tonne of carbon dioxide from the atmosphere. Offsetters’ credits currently retail at $20–$30.

expaNdiNg biomass projects

“We’re now doing similar work with a halfdozen other greenhouses,” says McDonald. “Some are switching to biomass, some are

Sawmills, too, might use Offsetters’ services to develop and implement a biomass energy project. “We are working with a sawmill project partner right now in Quebec to bring in some technology so that they can stop burning bunker oil for their drying kiln and start using biomass instead with some very modern and efficient equipment,” says McDonald. “It has a large up-front cost and a lot of unknowns associated with it, which is the reason that it hasn’t happened until now. We are able to help trim those costs and make it more affordable.”

Usually Offsetters seeks out projects and is involved in their development from the outset. In some cases, however, a company may initiate a project such as installing a biomass boiler with the intention of using future carbon credits from the greenhouse gas emissions reductions to help pay for the project. Offsetters might then be involved in brokering subsequent requirements such as obtaining thirdparty verification and registering the offsets. “That would be a special case where we could come in after the fact because they already knew they were going to sell to someone.” Companies that are considering a switch to biomass technologies might consider this type of service in their cost-benefit analysis.•

– Heather Hager

HHothouse of Opportunities

Seek and ye shall find biomass is a good slogan for greenhouse operators in search of a long-term, cost-effective alternative to fossil fuels, according to CANBIO.

By Bruce McCallum

eat has always been a major expense for greenhouses. With the recent steep rise in fossil fuels, many have considered lower cost biomass, but what type of biomass and equipment? With recession comes lower oil and gas prices, but they won’t last. It is sensible to move to lower cost and more stable biomass energy during this brief respite, and there are also environmental benefits from switching to clean, carbonneutral biomass.

As a bioenergy consultant, I have often been asked about the various biofuels and biomass systems to cut energy costs. There are no simple answers. Most greenhouse operations are unique. They vary in size, crops or products grown, season of operation, and heat-load profiles. Daytime heat loads can be significantly lower than those at night. Some have relatively small winter bedding plant operations followed by much larger grow-out acreages. Existing and possible future heat requirements need to be considered.

supply & systems

There is also a variety of biomass available. In most forested regions, mill residues such as sawdust, shavings, and bark make sense. Yet in some regions they are in short supply, especially with so many sawmills down. A thorough search of local mills may still uncover enough fuel to meet your needs, especially if it is stockpiled during summer.

If mill residues are scarce, woodchips may work. They can be bought directly from forestry contractors, or you can buy low-grade roundwood and hire a contractor with a chipper, or buy your own chipper. This approach has been taken by Den Haan’s Greenhouse in Nova Scotia. Woodchips typically cost $45–50 per green tonne delivered.

The moisture content of green woodchips and mill residues is typically 40–50%. Several Canadian companies make fully au-

tomated industrial class (wet fuel) burners, most notably KMW Energy and Wellons FEI Corp. Usually these systems start at about 1 MW (3.4 million BTU/h) capacity. Grovewood Heat builds small-commercial burners that can handle fuels up to 45% moisture content.

Wet fuel burners tend to be larger, more capital intensive, and require more tending than dry fuel systems. It may make sense to pay a premium for drier biofuels that have greater energy content and increase system output. Dry chips can be produced from urban wood waste such as pallets and clean building debris if forestry fuels are unavailable.

Today, many greenhouse owners are turning to a more refined biofuel such as wood pellets. Pellet-burning appliances can offer a high degree of automation and are smaller and cheaper to buy than wet fuel systems of equal capacity. But pellets are generally at least double the cost of green woodchips on a dry matter basis (one tonne of pellets has the energy value equivalent of roughly two tonnes of green woodchips).

Wood pellets are produced in large volumes in BC, Quebec, and the Maritimes. Canadian pellet production surpassed two million tonnes in 2008 and is projected to grow to three million tonnes by 2010. Most are being exported to Europe where demand now exceeds 10 million tonnes. In Nova Scotia, pellets can be purchased in bulk for about $200 per tonne at the plant. One tonne of pellets displaces 450–500 litres of heating oil, depending on system efficiency. In BC, pellets can be purchased for less than $100 per tonne at the plant. Some regions, such as Ontario, currently lack adequate pellet production or distribution, but plants are being planned.

Several Manitoba companies have been building coal stokers that can burn pellets.

Examples include Decker, Pelco, and Blue Flame, all of which are being used to heat Canadian greenhouses. European pellet burners are also starting to be sold in North America, and there will be many more to come. Canadian companies are also beginning to build pellet-burning appliances.

In farming regions, there are other options. Low-quality grains, including those of corn, wheat, rye, and barley, can be burned in multi-fuel burners. For example, more than 50 Danish Tarm Multi-Fuel boilers are burning low-grade grains, mostly in the Prairie provinces. Burning grains typically generates more ash and a lot of solid clinkers, but the savings can justify the extra time spent tending the burners. However, not all pellet or coal burners can burn grains. The Danes have used straw as a fuel for many years. They now have fully automated straw burners in sizes suitable for greenhouse operations.

Greenhouse owners may want to use more than one type of biomass system, depending on the length of the operating season. If you have a large core area that has a long operating season, woodchips or mill residues might be the best option. Pellets may be the best option for greenhouses that are only operated for a few months a year. The lower cost pellet systems are less of a burden if the system is sitting idle for part of the year.

Canada is rich in biomass resources. Biomass fuel prices are stable and competitive with fossil fuels in most regions of the country. Greenhouse owners need to determine which biomass fuels are available in their area and the bioenergy system or systems that best meet their long-term needs.•

Bruce McCallum of Ensight Consulting wrote this article on behalf of CANBIO, specifically for Canadian Biomass. This CANBIO Update will be a regular feature in Canadian Biomass

Burning Solutions

There’s no need to go out on a limb with biomass combustion technology. Very small scale CHP or “biorefinery” technology may be a different matter.

By Dr. Fernando Preto

thegood news for Canadians hoping to use forest biomass for heat is that proven technology is readily available at just about any scale, from wood-burning stoves to the largest commercial plant. The fibre supply and boiler still need to be carefully matched, and supply logistics analyzed in detail, but you shouldn’t have to gamble with your capital investment.

The same can be said for combined heat and power (CHP) or power generation at larger scales, say 10 MW or higher. But once you start looking at the smaller scale projects, and certainly below 3 MW, cost-effective examples of these are the exception rather than the rule in the current Canadian context. Similarly, once we start talking about “biorefineries”, whether to create gas, liquid, or solid fuels, we’re moving even farther into the experimental or prototype realm, where those new to the field or without deeper pockets should be careful. But first, to the relatively simple world of biomass combustion for heat, where industrial options include grate furnaces and fluidized beds.

grate FurNaces

A grate furnace includes a conveyor to feed the biomass on a controlled basis to a combustion chamber where a grate holds the fuel being burned.

There are several different types of grates, including fixed or stationary, moving or stepping, and vibrating grates, but the basic premise is the same: The biomass is moved along the combustion “bed” so that by the time it exits the furnace the biomass has all been burnt and nothing but ash remains.

This proven approach generally allows for a 60 to 80% thermal efficiency and has several benefits:

It allows a wide range of project sizes, from below 1 MW (th) to 250 • MW (th). In fact the largest biomass plant in North America is a grate furnace: EPCOR Power’s 66 MWe generating station in Williams Lake, BC. In contrast, the 1.1 MW CHP system at Taylor Lumber featured in the last issue of Canadian Biomass is also a grate furnace. Relatively low capital cost. These are likely the lowest cost among the • industrial or commercial furnaces, and thus will be seen at some of the smaller installations like greenhouses or sawmills, where capital cost is a major factor.

Low dust loading, as they run with a low quantity of air (blowing air • into the system for combustion creates dust).

Widespread availability from commercial suppliers, including several • in Canada.

Still, the design is not without drawbacks. Depending on the application, grate furnaces:

• (i.e. sludge in pulp mills, coal in other applications).

Can result in poor mixing of the fuel, especially when co-firing

Can experience problems with high moisture levels. This tech-

• nology can accept some variation in fuel, but it should generally be 40% MC or less. It should also be over 5% MC, so that some systems do not burn too hot, possibly overheating and damaging the grate material. Ash can also melt if the fuel burns too hot, becoming attached to the grates, jamming them up.

• and jam up the moving grates.

Can have problems with rocks and metal pieces, which drop in

Can have higher emissions at lower loads: When you have a very

• low fire during low demand, the mixing efficiency is lower and you’ll get smoking. Greenhouses can get around this to some extent by using large hot water storage tanks, heating the water in the night, and then using it during the day to heat the greenhouses while the furnace is shut down rather than left idling.

Because of some of the above limitations, the number one message I bring to grate furnace operators, whether greenhouses, sawmills or pulp mills, is that they have to pay careful attention to fuel quality. Some people have to learn the hard way – they buy a furnace for wood chips, and then try to burn another, perhaps cheaper fuel, and find out it doesn’t work. Fuel quality in terms of contaminants and moisture content is key for these systems, a message for everyone from system operator right through to the contractor supplying the fuel.

Operators also need to buy a unit designed for the fuel you’re going

Above: Since moisture content dramatically effects boiler efficiency, as well as haul costs, buying dry biomass, or paying for energy content may be worth looking into.

Page 15: Largely because of Canadian staffing regulations, small-scale co-gen plants like this 4.1 MW system at Vaagen Bros. Lumber in Washington State are the exception here rather than the rule. The norm is for plants of 10 MW and beyond.

to burn – coal burns differently than wood, which burns differently than agricultural residues. If you do want to burn a wide range of fuel types and quality, and have the scale to justify a larger investment, you may consider a fluidized bed.

Fluidized bed

This system’s forte is dealing with two or three different fuel sources at once. Consider the current and future fuel sources carefully when choosing a technology. If your supply may change, if you require mixed supplies to meet your volume demands at times, or if you may be forced to accept varying qualities of fuels in a sellers’ market, consider that fluidized beds are very efficient with mixed fuel supplies.

Fluidized beds are typically cylinders (or square units at the larger scales) that are filled with sand to a small portion of their height (three feet of a 20-ft high cylinder like those used at CanmetENERGY’s Ottawa labs). The bottom is perforated with holes slightly smaller than the sand (so you don’t lose your sand of course), through which air is blown upward at just the right velocity to suspend the sand much like the numbered balls in a lottery draw. When various fuel types are added, they are thus mixed very well during combustion.

typically wet. Biomass also contains less energy by weight than almost any other type of fuel currently used. This in turn creates significant challenges for transport, storage, handling, and more. Even when bone dry, wood typically has half the energy content of coal by weight and one third that of natural gas. On top of that, wood’s fuel density is very low compared to coal (although higher than straw).

You have to buy a combustion unit for the fuel that you are going to burn – A unit designed for coal will not work as well with wood chips, and certainly won’t work as well with agricultural residues.

Aside from the ability to mix fuels, fluidized beds handle wet fuels better. Since the moving sand particles are all pre-heated to about 800 degrees, their motion through the incoming fuel will serve to mix, heat, and effectively combust even wet fuels like sludge. In comparison, wet fuel added to a grate furnace will typically sit there as a lump. That same bucket of sludge in a fluidized bed will be mixed and treated to a much higher heat transfer rate.

The technology also offers good NOx reduction and a very high efficiency, typically between 75 and 85% thermal efficiency. But there are tradeoffs, such as:

• same capacity.

Fluidized beds are very expensive compared to grate furnaces of the

Combine half the energy content with five or six times the bulk and up to 60% MC in fresh biomass, and you’re moving a lot of air and water with your energy. As a result, cost effective haul distances for fresh biomass will likely be well shy of 200 km, limiting the size of plant that can be built in any one location. Storage and handling systems will also need to be larger than those for conventional fuels. Here are some factors to consider:

•

Do what you can to get dry biomass or dry it prior to combustion.

Boiler efficiency falls dramatically as moisture content increases, from say over 80% at bone dry to under 60% at over 55% MC. You’re

They are not widely available at smaller scales, and are not yet cost

• efficient below 10 MW (th). Not coincidently, the largest biomass plant in the world, Alholmens Kraft’s 550 MW (th) plant in Finland, is a fluidized bed burning a mix of biomass, peat and coal. Higher power consumption to keep it running, as you will need a

• compressor to blow the air through the sand.

Some sizing of the fuel is required.

• More training required than a grate furnace.

• This last point is worth a word or two on its own though, since operator training is an issue even with grate furnaces. As these boiler systems move into greenhouses, sawmills or other industrial clients, we’re seeing more issues with insufficient training. Suppliers in some cases deliver the system, show the clients how to turn it on or give basic mechanical instructions, and then leave. Then if there are problems, there is often a lot of trial and error involved in solving them, a lot of frustration, and delays in getting the return from investment. Operator training is an issue, as there is not really a source of training in Canada to shorten that learning curve. CanmetENERGY is discussing this need with several colleges, to encourage the establishment of a renewable energy technologist program.

still challeNges

Yet even though direct combustion technologies like the above are proven, there are still some inherent challenges to using biomass. For starters, biomass other than special cases such as planer mill residues is

more ash. Whitewood is typically less than 0.5% ash by weight, while bark is 2 to 3%, some straws are up in the 5 to 10% ash, and manure can reach 30 to 40% ash. Some of that ash may have a lot of potassium, and so will melt at a much lower temperature, causing clinkering and fouling (plugging) problems. In biomass, as in most things, you usually get what you pay for.

cogeN at what scale?

There is no shortage of cost effective biomass-based power generation options for the Canadian entrepreneur, but how successful you’ll be may well depend on the scale of your operation. At 10 MWe or above, operators have many proven options to choose from.

Yet as a rule, Rankine Cycle (steam turbine) based systems are not economically feasible in Canada much below 10 MWe, largely because of the manpower regulations requiring a stationary engineer on site 24/7 for high-pressure steam applications. There are exceptions where smaller scale systems have proven successful, like sawmills with their own supply and special power needs. But for most of us it comes down to scale – you can’t afford to hire several stationary engineers to create a megawatt of power.

also paying to haul that water, so it may be well worth paying more for drier supplies. Consider sampling loads and paying on a bone dry content, since it’s what you pay per gigajoule that really counts.

Carefully consider the transport, handling, drying, and comminu-

• tion stages during your initial biomass planning stages. Effective logistics are the hallmark of successful bioenergy projects; inefficient transport and handling systems can kill even the best plant designs fed with the cheapest fuels.

There are several prototype systems being tested both here and in Europe for small scale power generation that could get around the high-pressure issue, such as low temperature/ alternate fluid cycles, Organic Rankine Cycle, Brayton Cycle, Stirling engines and more. Yet to date none of these options provides power at an affordable price once capital costs per kW are considered. Research is ongoing.

beyoNd combustioN

Consider densification closer to the biomass source as an option

• if you need larger volumes, and thus a larger draw area for your biomass. Pelletizing is an option, as it will convert raw biomass that is awkward to handle and ranges from 50 to 300 kg/m3 and up to 50% MC into a uniform feed stock at 600 to 650 kg/m3 and less than 10% MC.

Consider the cost of that “cheaper” fuel. If you opt for demolition

• waste with contaminants such as pieces of drywall or use locally available agricultural residues, realize you will be dealing with

If straight combustion options are commercially available, choices get much more limited as we move to other biomass options like gasification and pyrolysis. These two options vary the amount of air allowed into the system during conversion. Gasification uses partial air exposure (one third the air needed for combustion) to convert biomass to fuel gases (CO + H2, or carbon monoxide and hydrogen) that can be burned in engines for small scale power generation and/or further refined into fuels and chemicals. The technology is available to create this “syngas” efficiently today, but more work needs to be done to further

Continued on page 32

Raw biomass is a non-uniform, often wet material that is hard to store and handle. Pellets offer a possible, more uniform and predictable fuel source.

What Should We Sustain?

FIt’s not easy to define ecologically sustainable levels of forest biomass harvesting.

By Evelyne Thiffault

or the past several years, I’ve been working on defining sustainable levels of forest biomass harvesting that can be used as guidelines for decision making. As a forest soil scientist in a team of mainly soil researchers, I tend to look at sustainability in terms of soil characteristics such as carbon and nutrient content, acidity, and organic matter quality. In my world, we tend to think that if the soils are kept happy, then the whole ecosystem will be happy and function contentedly.

However, if you dig a little deeper (pun intended!) and try to define a ‘happy soil,’ you find that soil scientists have various schools of thought and definitions of sustainability. For example, much Canadian research since the late 1960s regards sustainability as the balance between nutrient inputs and outputs. Nutrient budgets indicate how theoretical net gains or losses of nutrients differ under various harvesting intensities. This kind of model is the basis of biomass harvesting guidelines recently issued by the government of New Brunswick.

Nutrient budgets are also important in defining critical acidity loads; they can predict the cumulative effects of acidic atmospheric deposition and forest harvesting on soils by accounting for acidity inputs and outputs. In Sweden, estimations of critical acidity loads are used to define a site’s suitability for biomass harvesting. In these calculations, the focus of sustainability is on the maintenance of proper soil acidity.

Other soil researchers gauge sustainability by using direct measurements of various factors in the soil over time after harvesting. They compare these with measures done before harvesting or in sites harvested at different intensities, e.g., whole-tree vs. stem-only harvesting. The comparisons are used to understand the effects of a particular type of harvesting on soil processes and to establish how sustainable the practice is.

maNy possible methods—

maNy

diFFereNt results

The difficulty is that the different methods

sometimes disagree on how ‘happy’ a particular soil should be after harvesting. For example, according to nutrient budgets, whole-tree harvesting in jack pine stands on coarse sandy soils is fine, whereas the same practice in balsam fir stands on medium-textured soils is not. However, soil measurements done in field trials 20 years after whole-tree harvesting conclude the opposite. So, sustainability is a moving target, as soil ‘happiness’ can be defined in many ways and at various timescales, all of which are scientifically sensible and logical at a certain level.

And this is just one example from a soil-oriented viewpoint. Last December, I was asked to give a talk on biomass harvesting issues related to soils (about which I knew a little) and biodiversity (about which I knew nothing). I consulted some biodiversity researchers and was startled to learn that what I considered to be adequate amounts of harvest residues left on site to keep the soils ‘happy’ were not nearly enough to keep communities of flies that live on dead wood thriving and well. And I’ll bet that fungus and arthropod specialists would also have something to say about sustainable levels of biomass harvesting.

ing forest management in an era in which ongoing changes push global and regional climates beyond the bounds experienced over the last centuries?

sustaiNable livelihoods

Climate change presents us with an unknowable and uncertain future in which trying to sustain levels of wood production might not be uniformly desirable or feasible—think of the pine beetle outbreaks in BC. As concluded at the International Conference on Climate Change and Adaptation last August in Sweden, it may be time to move away from sustainability based on maintaining past patterns of forest conditions and forest use towards a goal of sustainable livelihoods. This

“ If you dig a little deeper, and try to define a ‘happy soil’, you find that scientists have various definitions of sustainability.”

People may say, “Who cares about soils and flies? Keep the trees growing big and happy: that’s the indicator of sustainability.” But is stable wood volume production the definitive index we’re looking for? One might say “yes!” not only because of the need for a steady wood supply for industry, but also because of the critical role forests play in the fight against climate change. The International Panel on Climate Change states, “Maintaining or increasing forest carbon stocks, while producing an annual yield of timber, fibre, or energy from the forest, will generate the largest mitigation benefit [to reduce greenhouse gas emissions].” Shouldn’t carbon sequestration be the ultimate goal driv-

means that producing forest biomass to meet today’s need for bioenergy could be a transition phase from a fossil-fuel-based society towards a society based on yet-unknown green technologies in which forest bioenergy might not be as important as other forest values such as soils, fungi, and flies! This requires local solutions that not only optimize and combine a multitude of goals and time frames, e.g., sequester carbon, maintain soil quality, preserve biodiversity (justifying fundamental research in all of these sectors!), but that also sustain present and future communities and the people living in them.•

Dr. Evelyne Thiffault of Natural Resources Canada contributes thoughts on biomass harvesting sustainability to Canadian Biomass on behalf of the Canadian Research Group on Ecosystem Sustainability.

Biomass Power

Plans to convert Ontario Power Generation’s coal-fired stations to biomass create opportunities for an Ontario biomass industry.

By Heather Hager

Ontario’s drive to big-time bioenergy is showing both the opportunities and the limitations of this emerging sector. The Ontario government’s plans to phase out coal-fired electricity generation are not new. In August 2007, the Coal Closure Regulation came into force under the province’s Environmental Protection Act. It mandates both a reduction in carbon dioxide emissions from coal firing starting in 2009 and a complete phase-out of coal by the end of 2014. In anticipation of such measures, Ontario Power Generation (OPG), Ontario’s main electricity supplier, has been evaluating the potential for biomass to replace coal in its four coal-fired stations at Atikokan, Lambton, Nanticoke, and Thunder Bay.

“The carbon dioxide limit applies only to coal,” says Bob Osborne, director of public affairs for OPG’s fossil generation division. “We’ve got plants that Ontarians have paid for, and how can we make use of them? Biomass is a good alternative.”

“There were probably two or three different motivations behind the move to biomass,” says Dr. Chris Young, vice-president of projects for OPG’s Fossil division. “Initially, we started looking at what was happening in Europe with biomass: There was significant use of biomass as a cofiring fuel with coal in the electricity industry. And there was an opportunity to be ‘greener’ than we were, which is important in today’s industry, but particularly if you’re operating a coal-fired plant. Subsequently, the province has moved very strongly away from coal, and that creates an impetus to go to biomass, and if possible, 100% biomass.”

Silos have been installed to feed biomass into a generating unit at Nanticoke.

OPG first began by test firing agricultural by-products such as wheat shorts from wheat flour processing and off-grade grain screenings from grain terminals. These are mixed and burned with coal in a cofiring process. “We recognized that wheat shorts would be a cofiring fuel, but if we had to contemplate going to a higher percentage of fuel than about 20%, wood pellets offered the most promise,” explains Young. This is because woody biomass has better chemical characteristics and greater heat content than agricultural by-products. There’s also more of it.

Much of the testing with wood pellets has been performed at the Atikokan generating station in northwestern Ontario because its boiler is better suited for biomass. “Atikokan is a lignite plant, so it’s designed to burn a lower heat-content coal, and the wood pellets are actually a bit better in heat content than lignite,” explains Young. Atikokan’s full electrical output of 211 megawatts has been achieved in short-term trials of burning 100% wood pellets for up to four hours.

In comparison, Nanticoke’s generating capacity is more than 17 times that of Atikokan, at 3640 megawatts, and the boilers are designed to burn higher-grade coal with a higher heat content. This makes it harder to burn 100% biomass. However, OPG has burned 100% wood pellets with natural gas in one of Nanticoke’s eight generating units. “When you start a coal plant, you burn an ignition fuel of oil or natural gas to start the flame. We did a test where the ignition fuel of natural gas was left on and we burned only wood pellets,” says Young. “Our expectation is that we will not be able to achieve the full output at Nanticoke on wood pellets. We believe that the units will be significantly restricted, maybe at about half of normal capability.”

biomass iNdustry required

One of the main limits to the switch to woody biomass is the availability of wood pellets. For the trials, OPG bought wood pellets from British Columbia, Quebec, and Nova Scotia. Young says that these one-time purchases were made with some difficulty. “We’ve seen slowdowns and shutdowns in the forest industry in general, and the pellets from waste sawdust just aren’t available because there’s little waste sawdust. There’s a need for very substantial change in the forest products industry in Ontario to supply our needs if we are to go this way.”

OPG now buys coal mostly from the U.S., with Thunder Bay and Atikokan using some western Canadian coal. Coal is contracted on intermediate- or long-term contracts, and OPG arranges the transportation to its facilities. Thunder Bay and Atikokan receive shipments by rail, whereas Nanticoke and Lambton receive shipments via lake freighters that are loaded at Great Lakes ports. OPG is considering a similar delivery model for biomass shipments from Ontario sources.

“What we would see happening in Ontario would be the potential for a number of wood pellet mills to be built, and a harvesting industry that supports those pellet mills,” says Young. “What we’d like to do is contract a stable, creditworthy company to supply to us. It will likely be several companies, with the kinds of volumes that we’re contemplating. It’s an opportunity for the forest

industry to enter that supply business with us.”

OPG’s switch to wood pellets would benefit the forest industry by creating a stable market and by promoting the development of infrastructure such as pellet mills, proposes Osborne. In mid-January, OPG requested expressions of interest from potential pellet manufacturers within Ontario to assess potential supply capability, volume, quality assurance, and pricing. The process closed in late February

aNticipated pellet volumes

To get an idea of the potential pellet volume, consider that Nanticoke produced approximately 18 billion kilowatt hours of electricity in 2007. At about 600,000 tonnes of wood pellets to produce one billion kilowatt hours of electricity, roughly 10.8 million tonnes of pellets would be required to produce this same amount of electricity. And that doesn’t take into account the other three coal generation plants. Given that the actual wood pellet production in the whole of Canada in 2007 was roughly 1.5 million tonnes, a mere one-seventh of the potential demand of Nanticoke alone, OPG realizes that it is unrealistic to convert all four plants to 100% biomass and still supply the same output.

“We see a future that involves biomass as the main fuel for some of our coal units, but obviously a different role for the plants and a lower capacity in total available,” says Young. Under the current model of electricity supply, nuclear and hydroelectric plants provide the base load of electricity, and the fossil fuel plants are ramped up to fill in the gaps during peak hours. Converted to 100% biomass, these units would still only be fired to fill in gaps during peak hours, but on a much smaller scale.

“We think that there’s about 2 million tonnes of pellets available

who provides the pellets?

Ontario’s currently unused biomass could become a hot commodity. The Ontario Ministry of Natural Resources (MNR) has estimated that a significant amount of unmerchantable and undersized wood could be harvested annually. In late January, it asked companies to outline their ideas to use this biomass, which could help to support investment and create jobs in Ontario’s forestry sector. Following a review of the submissions, the MNR will determine appropriate next steps, which could include a wood supply competitive process.

Concurrently, Ontario Power Generation (OPG) issued a call to potential suppliers of biomass fuel and transportation services to determine the commercial viability of replacing coal with biomass at existing coal-fired generating stations. OPG will use the information about fuel and costs, costs of required plant modifications, and construction of fuel storage and handling facilities to further develop the business case for safe and efficient commercial-scale biomass electricity generation. •

annually in Ontario. That number reflects the kind of advice that we’ve received from the Ministry of Natural Resources (MNR) and the forest products companies. That translates to a very substantially reduced electricity output,” says Young. “On a rough basis, we think that we could produce about 1/10th of the electricity that the coal plants produced last year, using biomass.”

To meet the demand, biomass would have to be harvested specifically for combustion, and not simply as forest product waste. “It would fit well with the forest strategy of supporting a pulp and paper industry using softwood, with harvesting of low-quality hardwood trees for biomass,” states Young.

OPG is not ruling out a supporting role for agricultural biomass in augmenting the biomass available from the forest sector. “Woody biomass has some attributes that are probably better chemically versus some of the agricultural products, but we would see probably firing a mix of woody biomass and agricultural biomass,” says Young.

chaNges aNd limitatioNs

Dr. Chris Young, vice-president of fossil projects, and Bob Osborne, director of public affairs, feel that OPG’s switch to biomass will benefit Ontarians.

Pellets are the desired form of biomass because they can be burned without major investment or changes to the furnace system. Typically, the coal is ground and blown into the furnace as a fine dust. “With a pellet, you can take the fine dust pelletized and just break up the pellet to blow it into the furnace in the same way. We run it through exactly the same system,” says Young.

Likely the biggest change needed is the construction of covered storage to keep the biomass dry. Modifications to unloading systems may be necessary, and some differences in combustion chemistry require attention. “There’s a different air-to-fuel mix required potentially for biomass versus coal, so we may need to alter the airflow systems into the boiler,” explains Young. Also, an additive in the pellet may be required to manage slagging, the buildup of hard ash, in the boilers. “These are relatively minimal changes in terms of the scale of the generating units,” says Young.

Young expects that it will be three or four years before plans are hammered out and fully implemented. “Pellet mills need to be built, we need to undertake some changes in our facilities to ensure that we can store and handle the fuel safely, and we need to work through all of this on a systematic basis,” he says. In the short term, OPG is undertaking engineering research and more biomass trials, as well as discussions with the province regarding changes in the cost structure of electricity associated with burning biomass.

The differences in fuel chemistry between ‘dirty’ coal and cleaner woody biomass provide benefits in the form of reduced acid gas emissions. Sulphur dioxide monitors on the units show low emissions from the wood pellets, and tests to date indicate that nitrogen oxides emissions from wood pellets are lower than those from coal.

The main limitations with biomass are the sheer volume and cost. “Given that we’re fuel limited, we wouldn’t convert all the units to biomass, so the amount of electricity will be less,” says Young. “At Nanticoke, we do not believe we would be successful in getting a unit

to run at full load, so we would have less capacity in service by that factor as well. And the cost of biomass is substantially higher than that of coal, so it would be a fuel that we would probably use less than we currently use coal.”

If wood pellets alone are burned at Atikokan or Thunder Bay, something close to the full output of those plants could be achieved, says Osborne. The rub is that Nanticoke cannot be removed from the transmission network easily without the insertion of some other major infrastructure to manage the voltage.

“Nanticoke is at a very critical point on the transmission system,” explains Young. “If you took Nanticoke out of that network, it would cause significant problems, and the network couldn’t survive without some major changes. One of the benefits of biomass is the ability to keep Nanticoke in service supporting that transmission network.”

Still, the benefits of biomass are not to be dismissed lightly. “The real advantage is that we’ve got all of this infrastructure that would have to come out of service unless we can find an opportunity to use it. If you look at natural gas-fired generating stations, just the capital cost of those alone is very significant,” says Young. As an example, he cites the new Portlands Energy Centre in Toronto. This natural gas-fired facility was a $730 million (CAD) investment for 550 megawatts of capacity, which is slightly bigger than one unit at Nanticoke. “You’re potentially avoiding that cost by reusing these facilities.” And even if OPG used more natural gas, that’s still a fossil fuel. “You’ll be paying a carbon cost at some point to do that, probably sooner than later,” says Young.

Burning biomass will allow some of the units to continue to function, maintaining a number of the employees. “Then you’ve got the broader implications for the biomass fuels industry developing in Ontario,” says Osborne. “You’ve got all the jobs and economic benefits of that as well.”

“It’s a good opportunity for Ontario,” concludes Young.•

Customer-Driven Process

FThe supply chain starts with the customer, and the entire system will benefit from a flexible plant design.

By Mark Ryans

rom a woodlands perspective, we often perceive the forest as the start of the supply chain. However, in any marketplace, the customer has the last say. For forest-origin biomass, the mill is the customer, so the mill’s requirements play a key role in the design of supply chain logistics.

Most biomass-based combined heat and power (CHP) or power generation plants in service today were designed for sawmill residues as their main source of biomass. The supply chain was simple, and the investment in both the supply system and mill infrastructure was minimal because of the low value of the material. Many delivery sites for biomass across Canada do not even have a tipper for full trucks or trailers. Mills may have an in-line grinder, but the capacity is limited to hogging bark. With forest-origin biomass, the supply chain will be more complex and mill improvements will be necessary.

learN From experieNce

In the Nordic countries, modern boiler technologies are used such as bubbling fluidized beds or circulating fluidized beds that can tolerate high moisture content and foreign material such as grit, leaves, and needles in the biomass. The mill infrastructure is capable of handling deliveries of biomass in various forms from loose residues and bundles to small trees and even stumps. The ability to receive various forms and qualities of biomass puts less strain on the supply system and allows the involvement of contractors who use a range of technologies and methods. This allows each contractor to optimize his/her system to particular operating and stand conditions. A contractor working close to the delivery site may ship small trees from thinnings, whereas a contractor who is far from the mill may consider using bundles to decrease transportation costs. Most biomass is delivered just in time because mill storage capacity is limited and storing commi-

nuted material results in additional dry-matter (energy) losses.